Patents

Literature

235results about How to "Promote carbonization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and preparation method thereof

The invention discloses a halogen-free flame-retardant polyolefin injection-grade wood-plastic composite and a preparation method thereof. The halogen-free flame-retardant polyolefin injection-grade wood-plastic composite comprises the following components in percentage by mass: 25 to 70 percent of polyolefin resin, 5 to 50 percent of plant fiber, 0.5 to 20 percent of compatilizer, 0 to 30 percent of flexibilizer, 0.5 to 8 percent of dispersant, 5 to 40 percent of fire retardant and synergist and 0 to 1 percent of antioxidant. Compared with the conventional wood-plastic composite, the halogen-free flame-retardant polyolefin injection-grade wood-plastic composite prepared by the invention has the characteristics of simple production flow, less fire retardant dosage, good halogen-free flame-retardant effect, wide molding mode range and the like, and is suitable for various injection-molded products such as shells of electrical appliance products, furniture, materials for automobiles, artworks, building products with complex construction and the like.

Owner:KINGFA SCI & TECH CO LTD +1

Styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and preparation method thereof

ActiveCN101864118AImprove liquidityGive full play to the flame retardant effectBuilding productHalogen

The invention discloses a styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the following components by mass percentage: 25% to 60% of styrene-based resin, 5% to 50% of vegetable fiber, 0.5% to 20% of compatibilizer, 0% to 30% of toughener, 0.5% to 8% of dispersant, 5% to 40% offlame retardant and flame-retardant synergist and 0% to 1% of antioxidant. Compared with the existing wood-plastic composite material, the styrene-based non-halogen flame-retardant injection-grade wood-plastic composite material prepared by the invention has the characteristics of simple production procedure, lower flame-retardant consumption, good non-halogen flame-retardant effect and wide range of forming manners. Therefore, the invention is suitable for various injection-molded parts, such as the housing of electrical products, furnishings, automobile materials, artworks, complex-structured building products and the like.

Owner:KINGFA SCI & TECH CO LTD +2

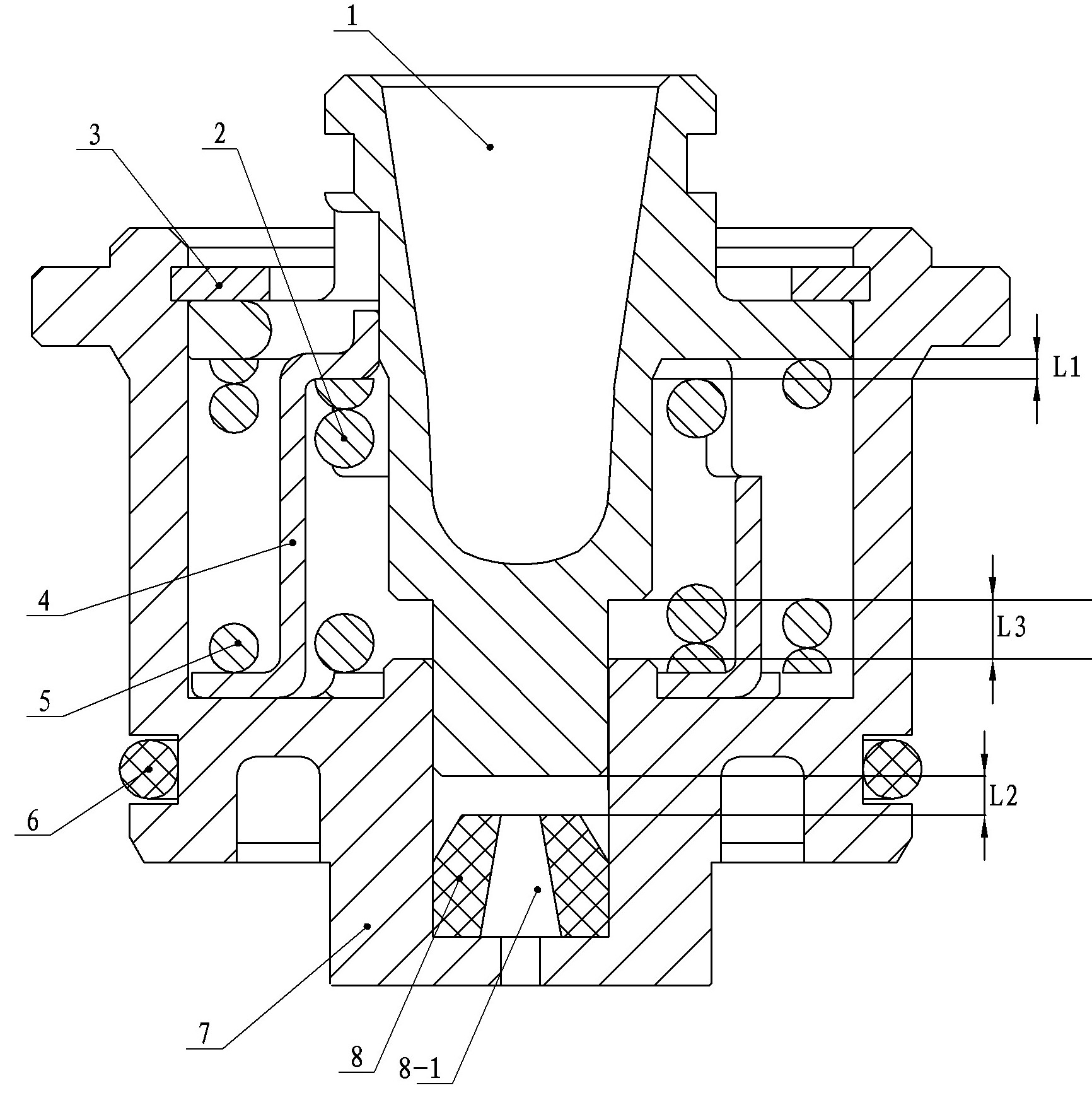

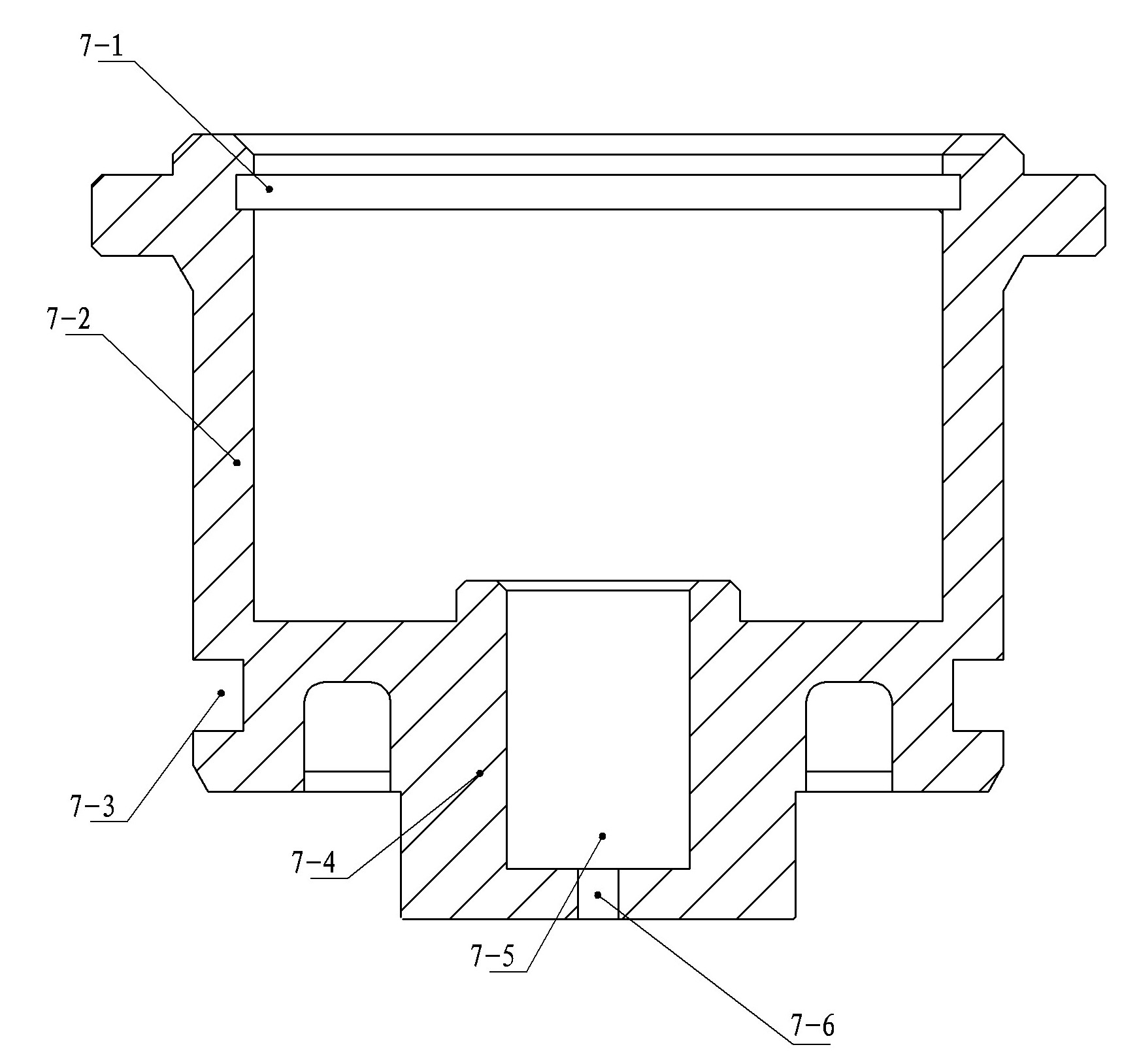

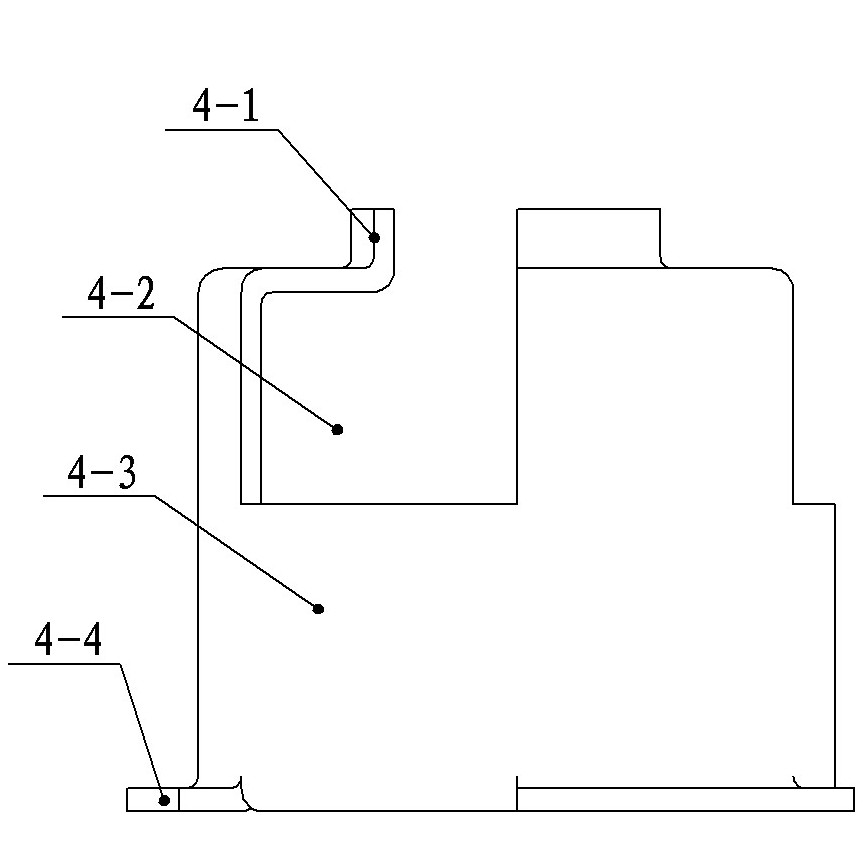

Three-level balance piston assembly

InactiveCN102529939APromote carbonizationAvoid poor brakingApplication and release valvesThree levelCarbonization

The invention relates to a three-level balance piston assembly, which comprises a balance piston, a spring wrapping clamp and a top rod base. The three-level balance piston assembly has the braking output characteristic of a 'three-step' curve, wherein three steps are named as 'three-level cadence braking'. According to the 'cadence braking' principle, compressed air can form pulses in a control pipeline and an air chamber to act on a brake pad, and an effect of acting on the brake pad by the pulses every time is equivalent to an effect of wiping the brake pad once by using a tool. Therefore, by the three-level balance piston assembly, a brake hub can be bonded with the brake pad forcefully, and the carbonization or an enamelum layer of the brake pad is also improved to a maximum degree, so that poor braking is avoided to achieve an excellent braking effect.

Owner:CHANGTONG TECH

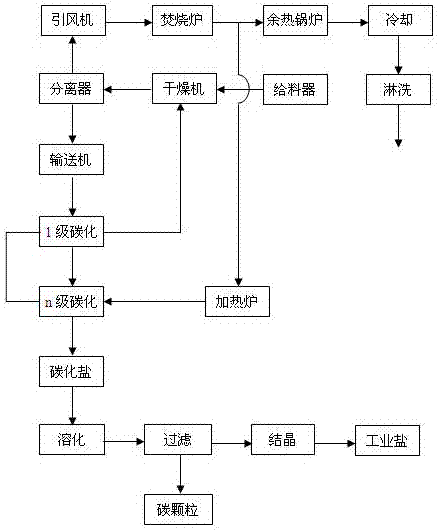

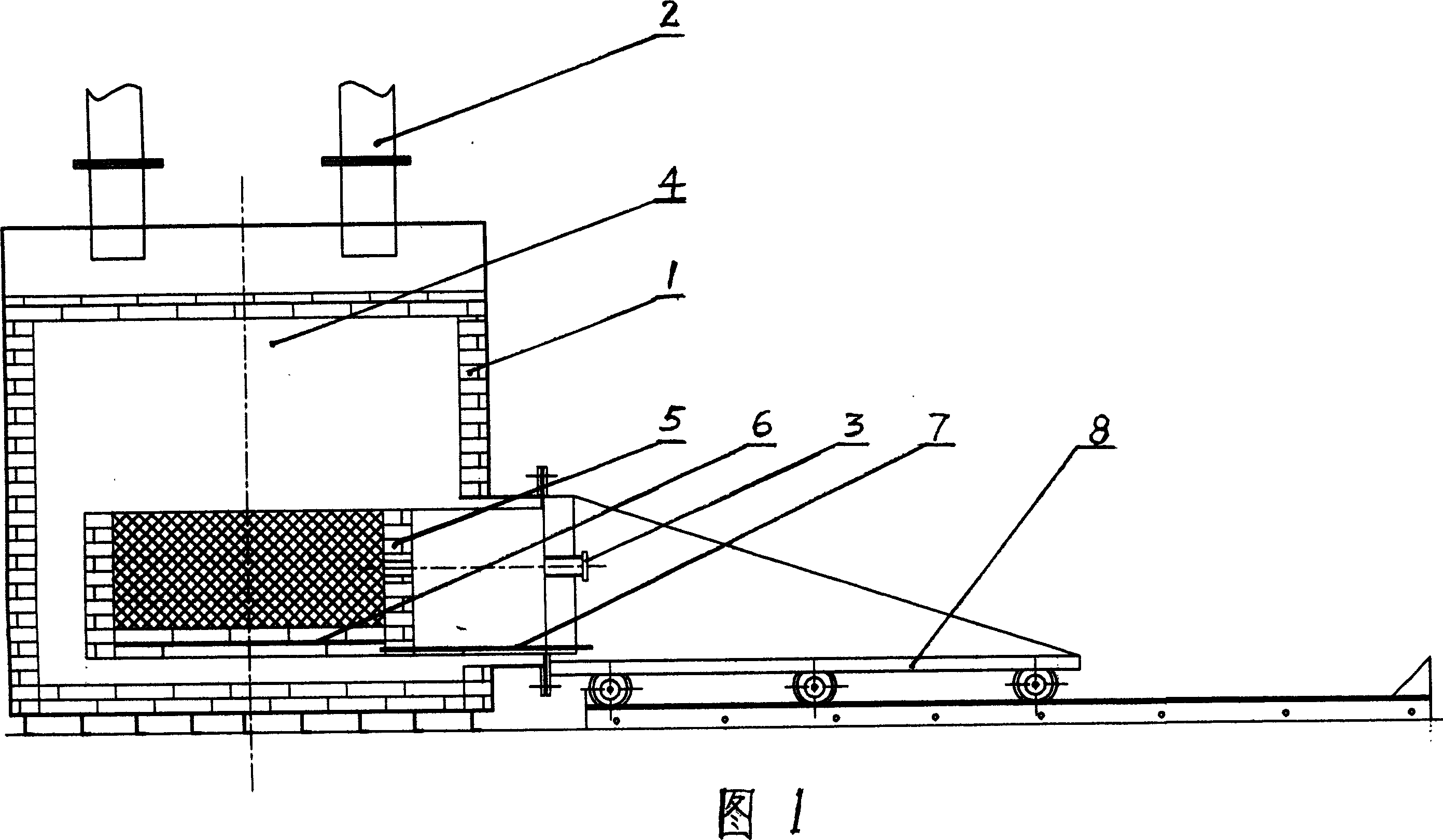

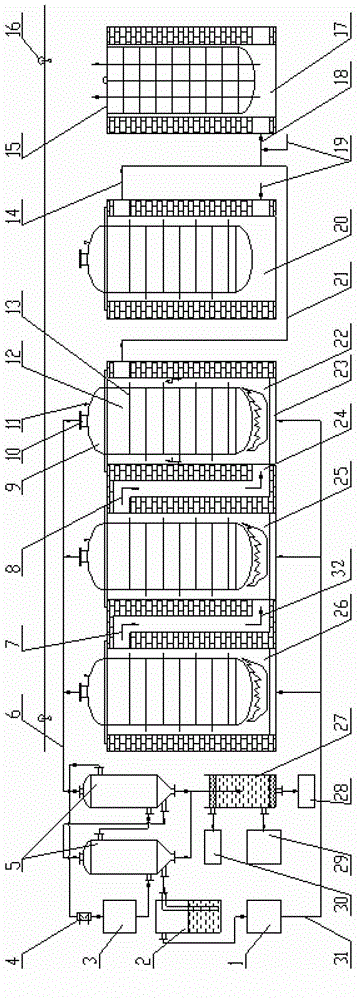

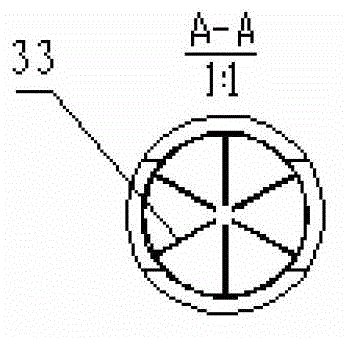

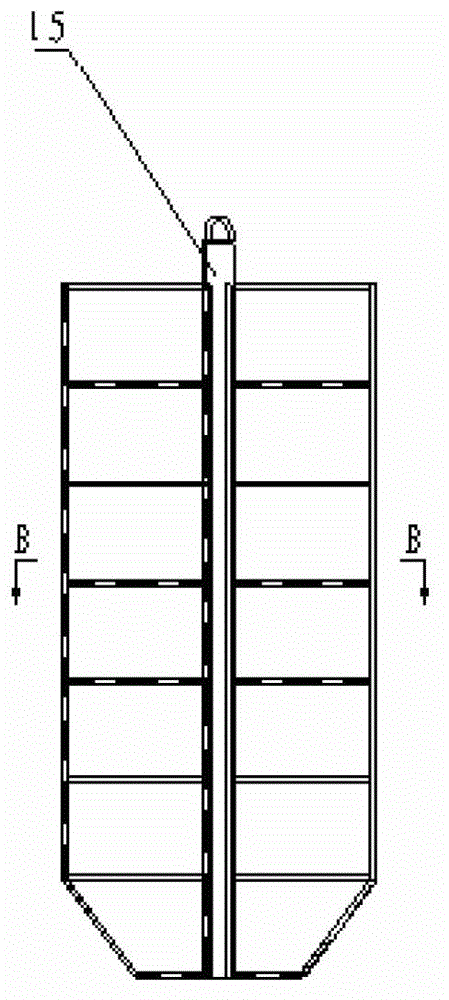

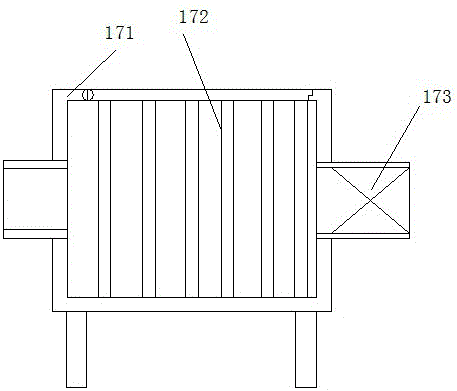

Process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt

ActiveCN106914474AGood dispersionLarge specific surface areaSolid waste disposalTransportation and packagingEnvironmental resistanceDecomposition

The invention belongs to the field of environmental protection, and particularly relates to a process and equipment for graded decomposition and carbonization harmless treatment of industrial waste salt. According to the process and the equipment disclosed by the invention, aiming at the characteristics that each kind of industrial waste salt contains various organic materials and has different physicochemical properties, a plurality of grades of decomposition and carbonization furnaces are arranged to perform graded heating on the industrial waste salt; the heating process is reasonable; the organic materials are decomposed and carbonized within the respective decomposition and carbonization temperature range; the heat-containing exhaust gas generated by decomposition and carbonization is used as a dry heat source; the exhaust gas generated by drying is introduced into an incinerator for incineration; and the hot gas generated by incineration is recycled. According to the process and equipment disclosed by the invention, continuous industrial production is realized, and during the operation of the system, no melting, agglomeration or bonding of the waste salt occurs, no secondary pollutants are generated, no toxic and harmful gas is exhausted, thermal efficiency is high, energy is saved, environmental protection is achieved, and the investment cost is lower than that of other methods; and the process and equipment have the advantages that the process and equipment are high in practicality, are suitable for the removal and harmless treatment of the organic materials of the industrial waste salt in various fields, and are suitable for popularization in industrial production.

Owner:辽宁东大粉体工程技术有限公司

Method for preparing vanadium nitride and device

ActiveCN1562770AImprove thermal efficiencyShort heating timeNitrogen-metal/silicon/boron binary compoundsVanadium compoundsMicrowave ovenVanadium nitride

The invention specially relates to an industrial batch-type vanadium nitride producing method and devices. Grinded vanadium oxide powder and carbonaceous are used as raw materials, which binder is added in, to produce vanadium nitride by heating in microwave oven. The characteristic is mixing vanadium oxide, active carbon and binder according properly ratio, then briqueting and forming, putting the formed material into special microwave heating oven, unceasingly exhausting to keep vacuum, prereducing, carbononizing, nitrating and natural cooling, finally the product is taken out the oven. This product is used as additive agent of various kinds of alloy steel containing vanadium mainly.

Owner:湖南恒星进出口有限责任公司

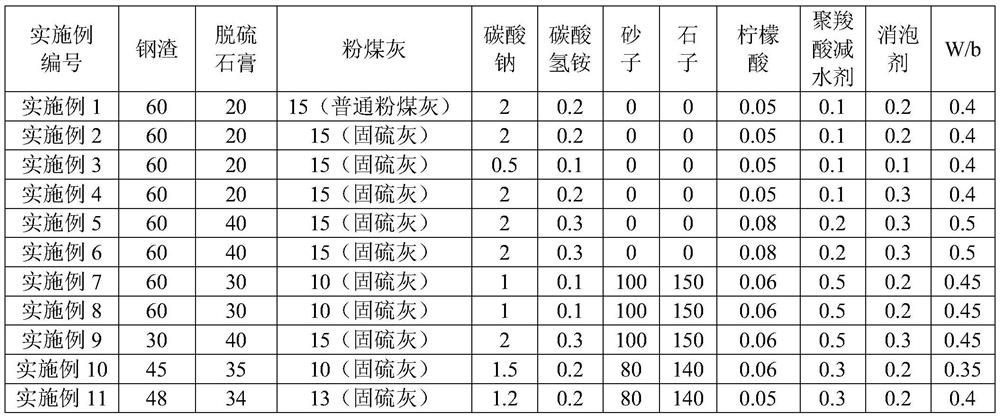

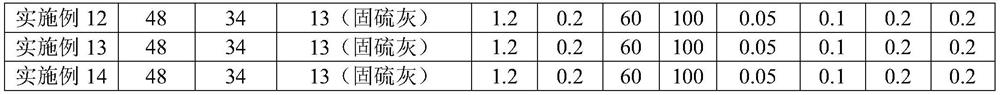

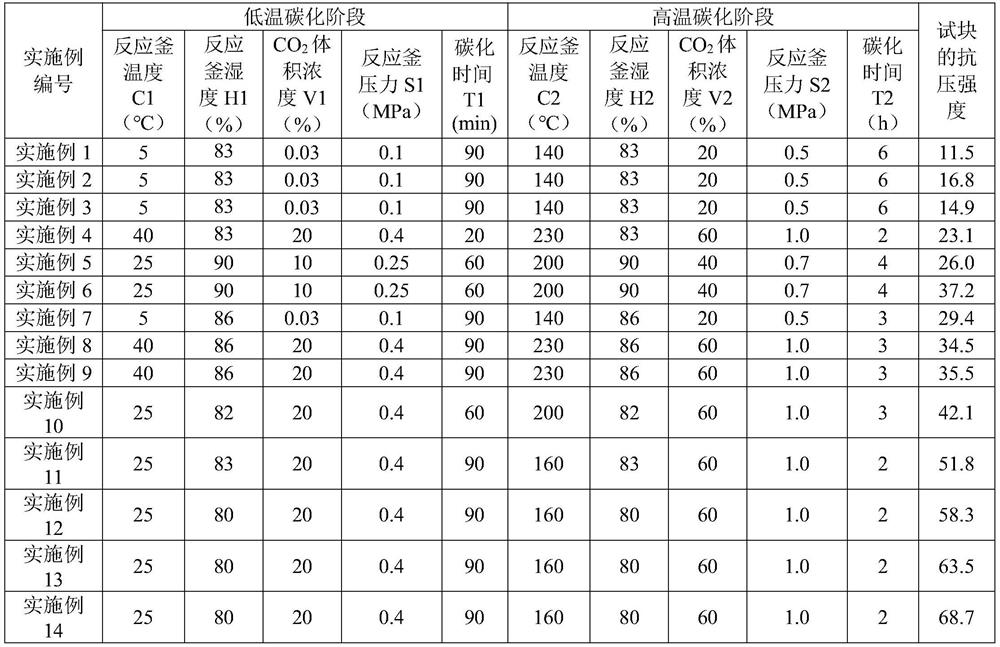

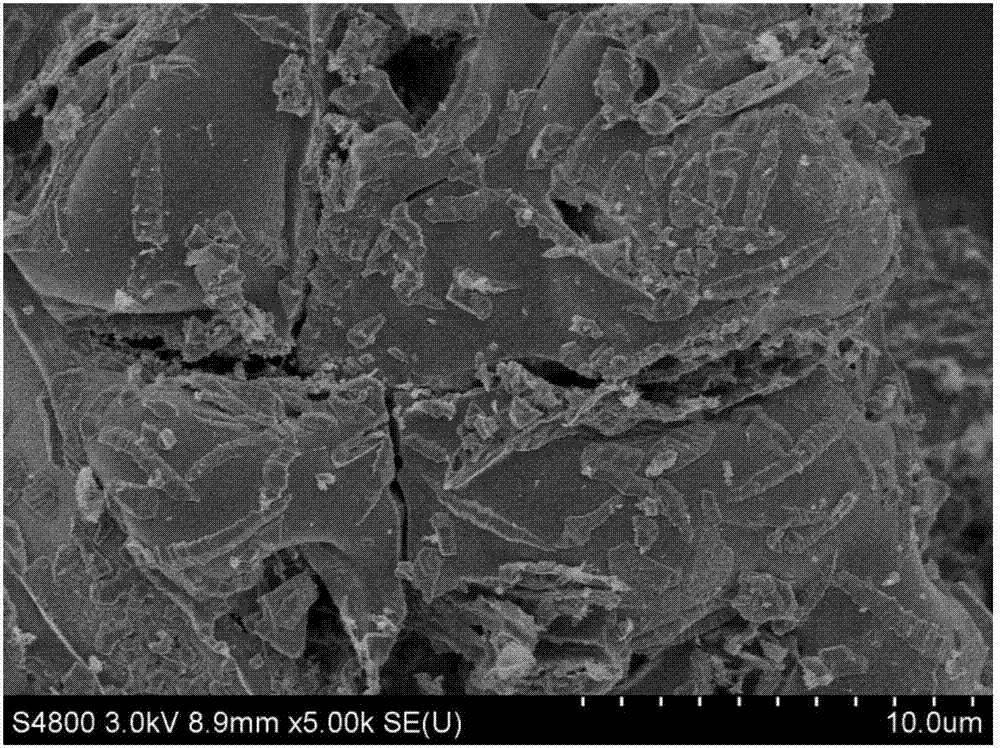

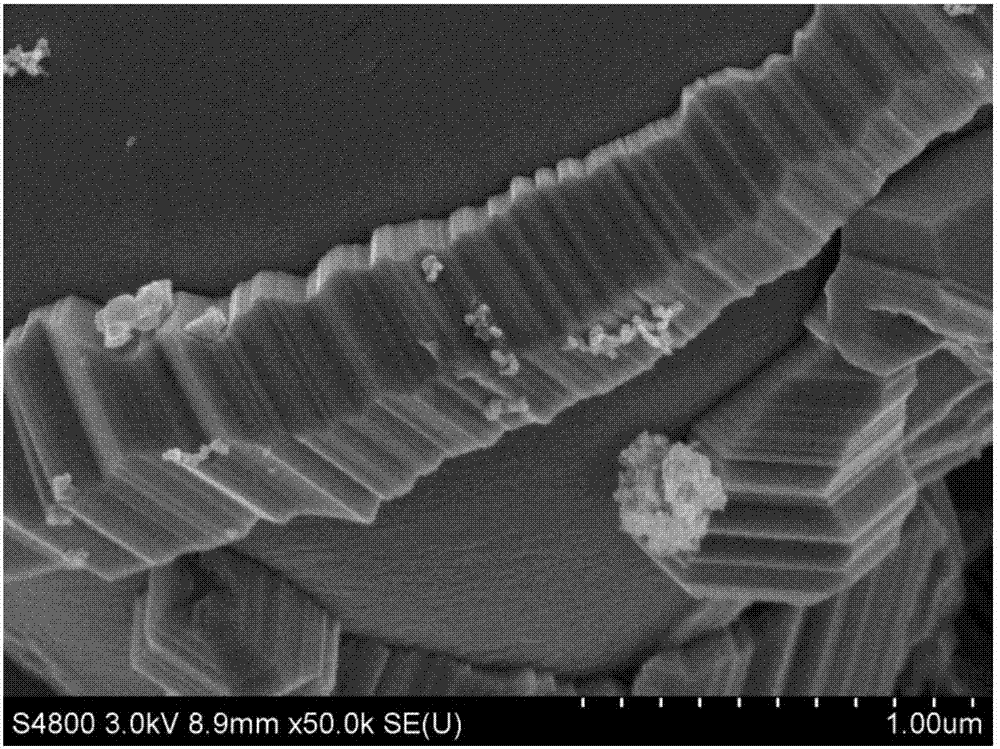

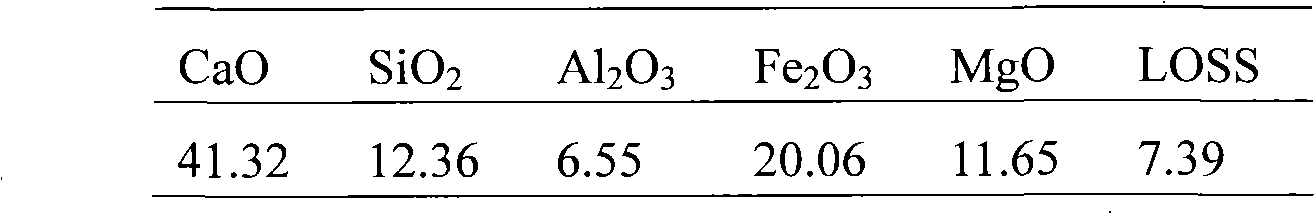

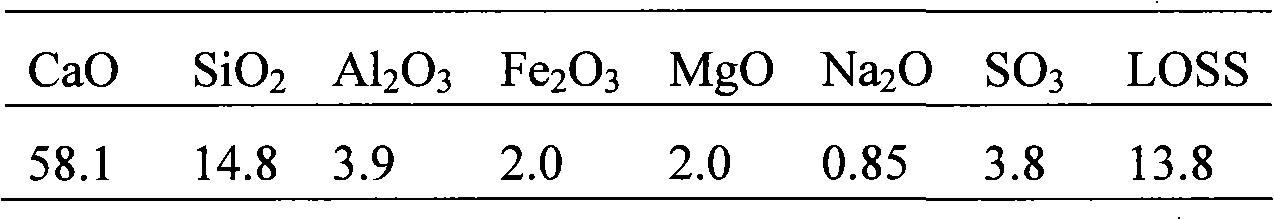

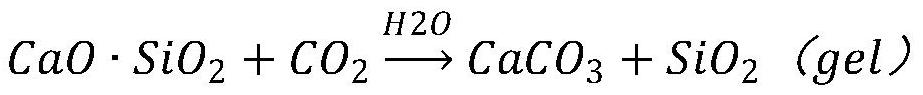

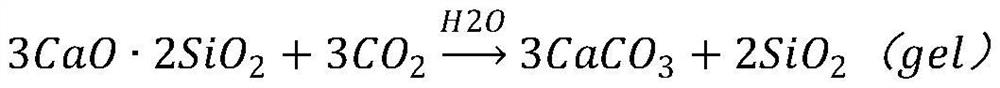

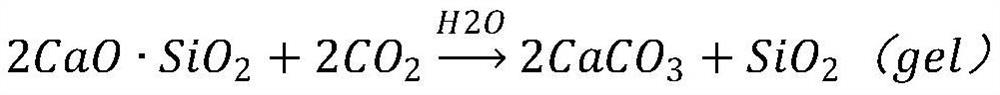

Building material prepared by synergistic carbonization of steel slag, desulfurized gypsum and fly ash and method

The invention belongs to the field of solid waste building materials, and particularly relates to a building material prepared by synergistic carbonization of steel slag, desulfurized gypsum and fly ash and a method. The building material is prepared from the following raw materials of steel slag, desulfurized gypsum, fly ash, sodium carbonate, ammonium bicarbonate, fine aggregate, coarse aggregate, a retarder, a water reducing agent and a defoaming agent and according to the following process: adding water into the raw materials, conducting stirring vibrating or compression molding for 2-4 hours, then conducting demolding, putting a test piece into a reaction kettle, controlling the temperature, humidity, pressure and CO2 volume concentration of the reaction kettle, and carrying out low-temperature and high-temperature two-stage carbonization maintenance to obtain the building material. According to the invention, a carbonization excitant is used for promoting the synergistic carbonization of the steel slag, the desulfurized gypsum and the fly ash, so that the carbonization conversion rate and efficiency are improved, and an effective method is provided for resource utilization ofsolid wastes of the steel slag, the desulfurized gypsum and the fly ash and preparation of the building material by capturing industrial waste gas CO2.

Owner:SHANXI UNIV

Carbonizing system and carbonizing process of wood materials

ActiveCN102911683AQuality improvementIncrease the heat exchange areaBiofuelsEnergy inputCooling chamberAgricultural residue

The invention discloses a carbonizing system of wood materials. The carbonizing system of wood materials comprises a carbonizing device and a by-product recovery device, wherein the carbonizing device comprises a reaction vessel and a reaction chamber for putting the reaction vessel; the reaction vessel comprises a material shelf and a destructive distillation kettle for putting the material shelf; the destructive distillation kettle is composed of a destructive distillation kettle body and a destructive distillation kettle cover; an exhaust hole and a temperature measuring hole are arranged on the destructive distillation kettle cover; the reaction chamber comprises a calcining chamber with a combustion area, a carbonizing chamber, a pre-heating chamber which are sequentially arranged, a drying chamber and a cooling chamber for pre-treatment and post-treatment of wood materials respectively. The pre-heating chamber, the carbonizing chamber and / or the exhaust hole on the destructive distillation kettle cover in the calcining chamber are connected with the by-product recovery device. The system is suitable for carbonizing production of all wood materials such as tree wood, hard weed tree, bamboo material, forestry and agricultural residues (straw, shell, sawdust and on the like). The invention is scientific and rational in process, none in emission and pollution, short in production period and low in cost, thereby being suitable for popularization and application.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Reactive phosphorus triazine flame retardant for dyeing, and preparation method and application thereof

InactiveCN102634974ARaw materials are easy to getEasy to prepareGroup 5/15 element organic compoundsVegetal fibresSolventFire retardant

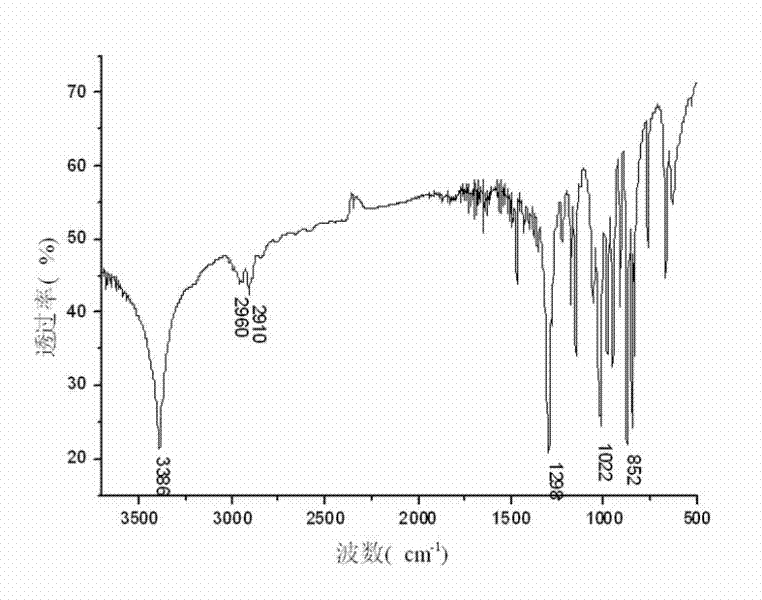

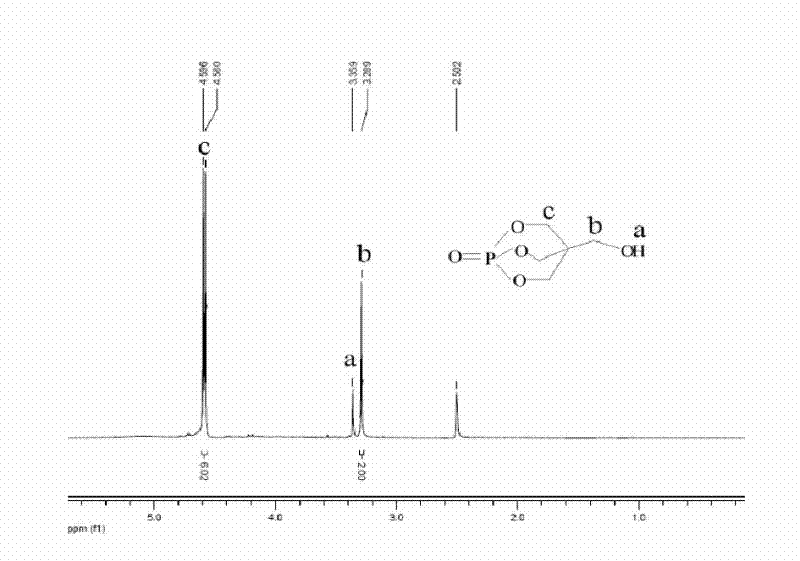

The invention discloses reactive phosphorus triazine flame retardant for dyeing, and a preparation method and application thereof, which belong to the technical field of flame retardants and relate to flame retardant for cotton. A molecular structure of the reactive phosphorus triazine flame retardant for dyeing is OPO3OCLO3OO3PO. The preparation method includes: mixing pentaerythritol with dioxane under protection of inert gases, dropwise adding phosphorus oxychloride at 80 DEG C for two hours, adding two to three drops of triethylamine, allowing for reaction for 4-10 hours, cooling, filtering, vacuum-drying to obtain PEPA after rinsing; and mixing cyanuric chloride with reaction solvent, adjusting the temperature to 10-20DEG C, initially dropwise adding the PEPA and acid-binding agent, allowing for continuous reaction for 6 hours, dropwise adding again the PEPA and the acid-binding agent, allowing for reaction for 6 hours, adding precipitant for precipitation after cooling, filtering, rinsing, and drying to obtain the fished product. The preparation method is simple, the prepared flame retardant has a carbon source, an acid source and a gas source integrated and is higher in thermal stability and better in carbon forming performance, and the PEPA and the triazine structure are complemented while both being given to full play to the advantages.

Owner:ZHONGBEI UNIV

Phosphaphenanthrene polyamide flame retardant and preparation and application thereof

ActiveCN104419003AHigh phosphorus contentEasy to useGroup 5/15 element organic compoundsThermoplasticPolymer science

The invention relates to a phosphaphenanthrene polyamide flame retardant and a preparation and an application thereof. The preparation method comprises the following steps: carrying out graft modification on novel unsaturated polyamide and a phosphorus-containing group; and carrying out additive reaction on 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) to prepare the polyamide flame retardant by using the reactivity of the unsaturated polyamide. The phosphaphenanthrene polyamide flame retardant has the characteristics of being halogen-free, low in smoke, low in toxicity, low in corrosion, good in fire resistance, good in processability and the like; the environmental protection index can meet the regulatory requirements of RoHS, IEC non-halogenation and Reach method of the European union; and compared with the previously known comparable DOPO derivative, the compound has a gas phase flame-retardant effect and a condensed phase flame-retardant effect, is high in efficiency, and can be applied to inflaming retarding of thermoplastic plastics and thermosetting materials.

Owner:GUANGZHOU SHINE POLYMER TECH

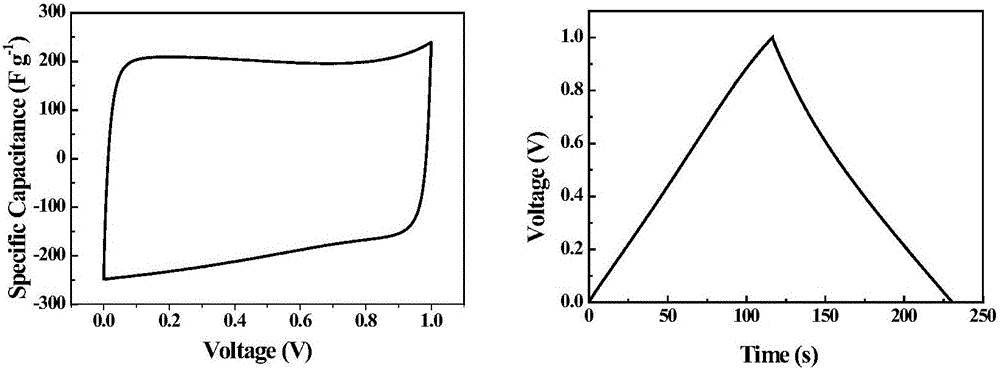

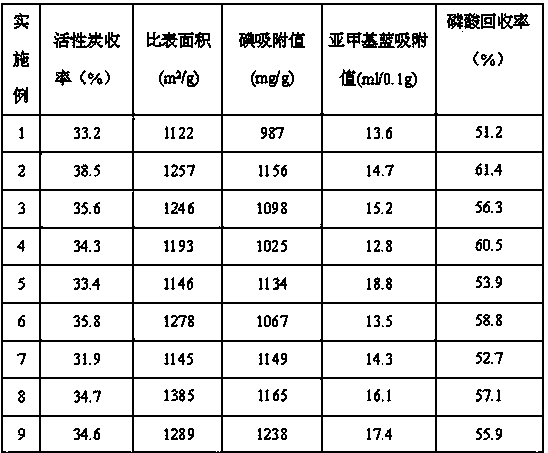

Coconut-shell fiber-based activated carbon for supercapacitor and preparation method of activated carbon

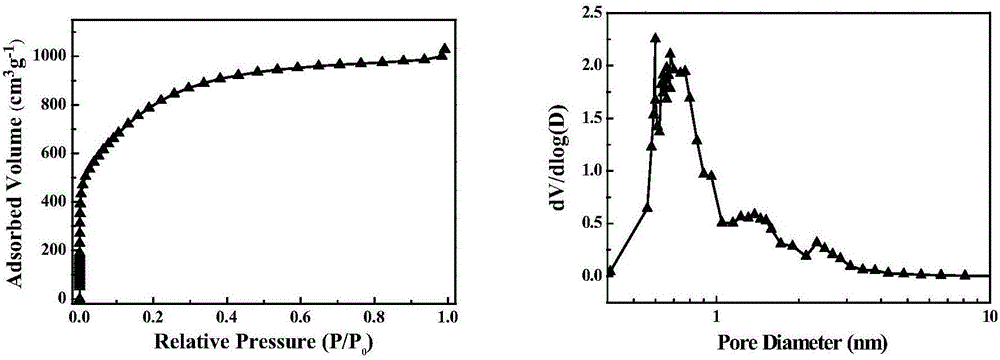

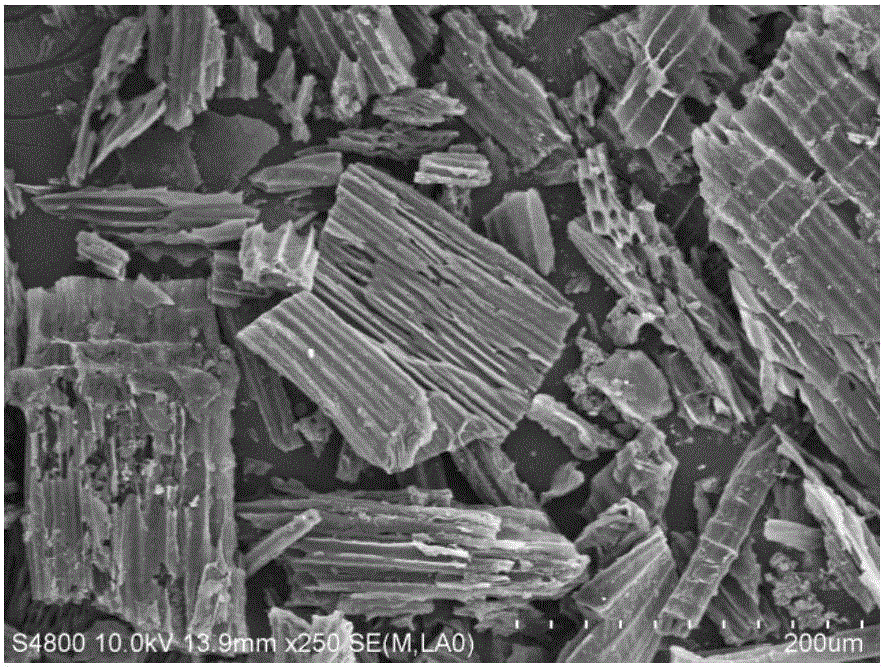

ActiveCN105923634ALarge specific surface areaAbundant specific surface areaHybrid capacitor electrodesFiberActivated carbon

The invention discloses a preparation method of coconut-shell fiber-based activated carbon for a supercapacitor. The method comprises the steps that pretreated coconut shell fibers are crushed and heated up to 700 DEG C to 750 DEG C at the speed of 2 DEG C / min to 5 DEG C / min, heat preservation is conducted for 1 h to 1.5 h, and a carbonized product is obtained; the carbonized product is ground and sieved, and the carbonized product and KOH are mixed to be uniform according to the mass ratio of 1:2 to 1:5; the temperature is increased to 800 DEG C to 850 DEG C at the speed of 3 DEG C / min to 5 DEG C / min, heat preservation is conducted for 1 h to 1.5 h, and an activated product is obtained; the activated product is subjected to water washing and acid washing and water washing till the pH ranges from 6 to 7, drying is conducted, and the activated carbon is obtained. According to the preparation method of the coconut-shell fiber-based activated carbon material for the supercapacitor, the coconut shell fibers serve as the raw material, multi-time activation is not needed, the technology is simple, and the cost is low; the prepared coconut-shell fiber-based activated carbon material for the supercapacitor has a high specific surface area and a high specific capacity.

Owner:HAINAN UNIVERSITY

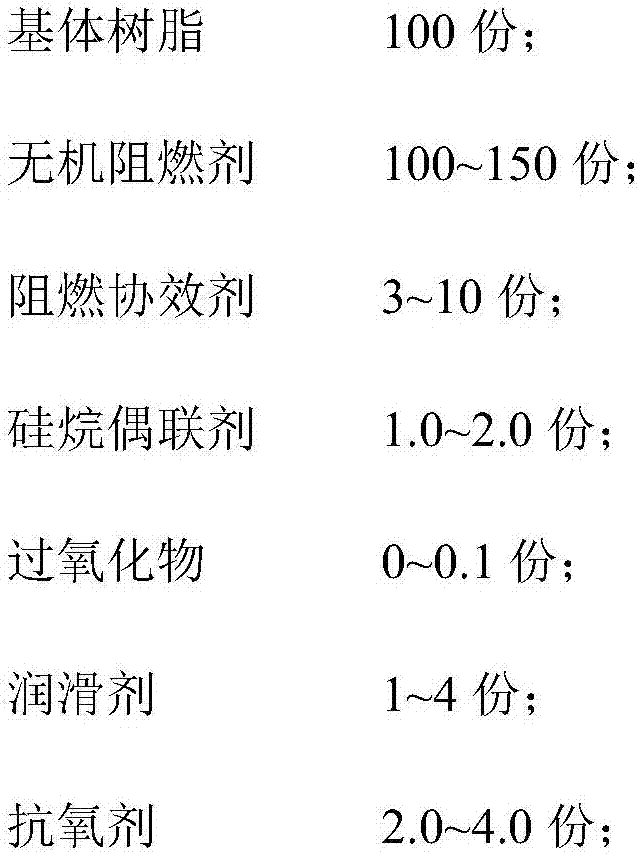

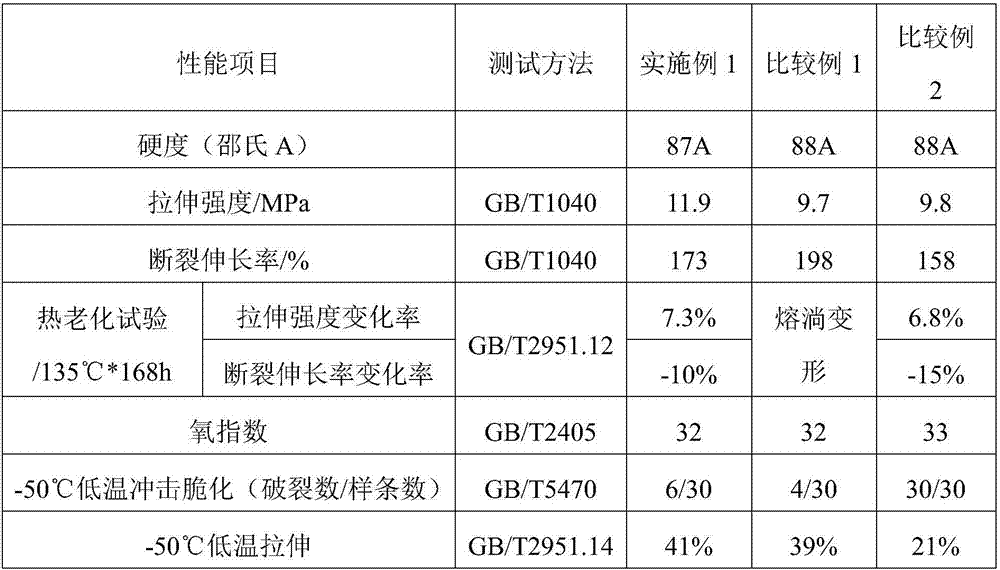

High-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material

ActiveCN106867090AGuaranteed flame retardant performanceGood heat resistancePlastic/resin/waxes insulatorsOxideMaterial hardness

The invention discloses a high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material, and belongs to the technical field of cable sheath or insulation high-molecular material. The high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material is composed of 100 parts of a matrix resin, 100 to 150 parts of inorganic fire retardant, 3 to 10 parts of a flame-retardant synergistic agent, 1.0 to 2.0 parts of a silane coupling agent, 0 to 0.1 part of a peroxide, 1 to 4 parts of a lubricant, and 2.0 to 4.0 parts of an anti-oxidant; the matrix resin is composed of, by weight, 25 to 60 parts of an ethylene copolymer, 20 to 55 parts of an alkene segmented copolymer, and 10 to 25 parts of a compatilizer. The flame resistance and softness of the high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material are ensured; the high-temperature-resistant soft thermoplastic low-smoke halogen-free flame-retardant polyolefin cable material prepared via blending possesses excellent heat resistance and low temperature performance; material mechanical performance is ensured; and material hardness is reduced.

Owner:CHANGSHU ZHONGLIAN PHOTOELECTRICITY NEW STUFF

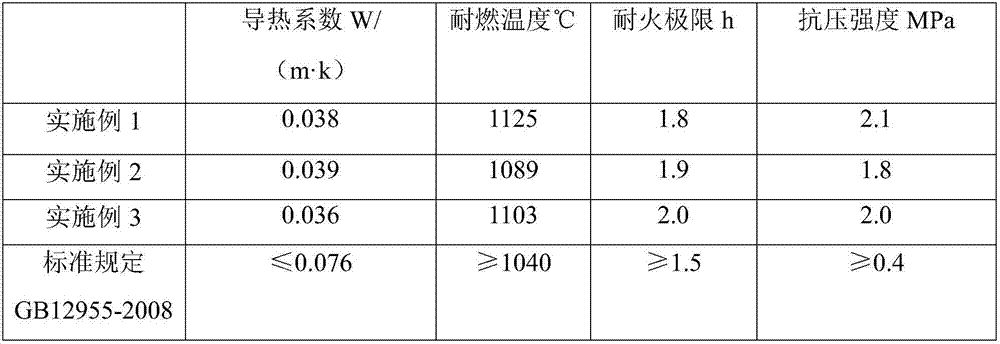

High-temperature-resistant high-strength fireproof door panel and manufacturing method thereof

The invention discloses a high-temperature-resistant high-strength fireproof door panel. The high-temperature-resistant high-strength fireproof door panel comprises the following raw materials in parts by weight: 50-80 parts of foaming agent, 30-40 parts of perlite powder, 20-30 parts of ore filler, 10-14 parts of magnesium sulfate, 14-18 parts of magnesium oxide, 3-5 parts of expansible graphite, 4-6 parts of zinc borate, 8-12 parts of calcium hydroxide, 25-35 parts of adhesive, 10-16 parts of desulfurized gypsum, 4-6 parts of boron oxide, 15-25 parts of reinforced fibers and 10-14 parts of anti-cracking fibers. The fireproof door panel disclosed by the invention has relatively good high temperature resistance and waterproof performance, is relatively strong in heat insulation and fire smoke resistance, is relatively good in mechanical performance indexes such as pressing resistance and bending resistance, is green and environmentally friendly, is light and is high in strength, and achieves the requirements of fireproof combustion and safety; and meanwhile, raw material components are safe and reliable, are harmless on environment, and are easily available, the cost is relatively low, the process is simple and clear, operation is easy and industrial production is easily realized, a practical value is higher and the application prospect is good.

Owner:合肥市旺友门窗有限公司

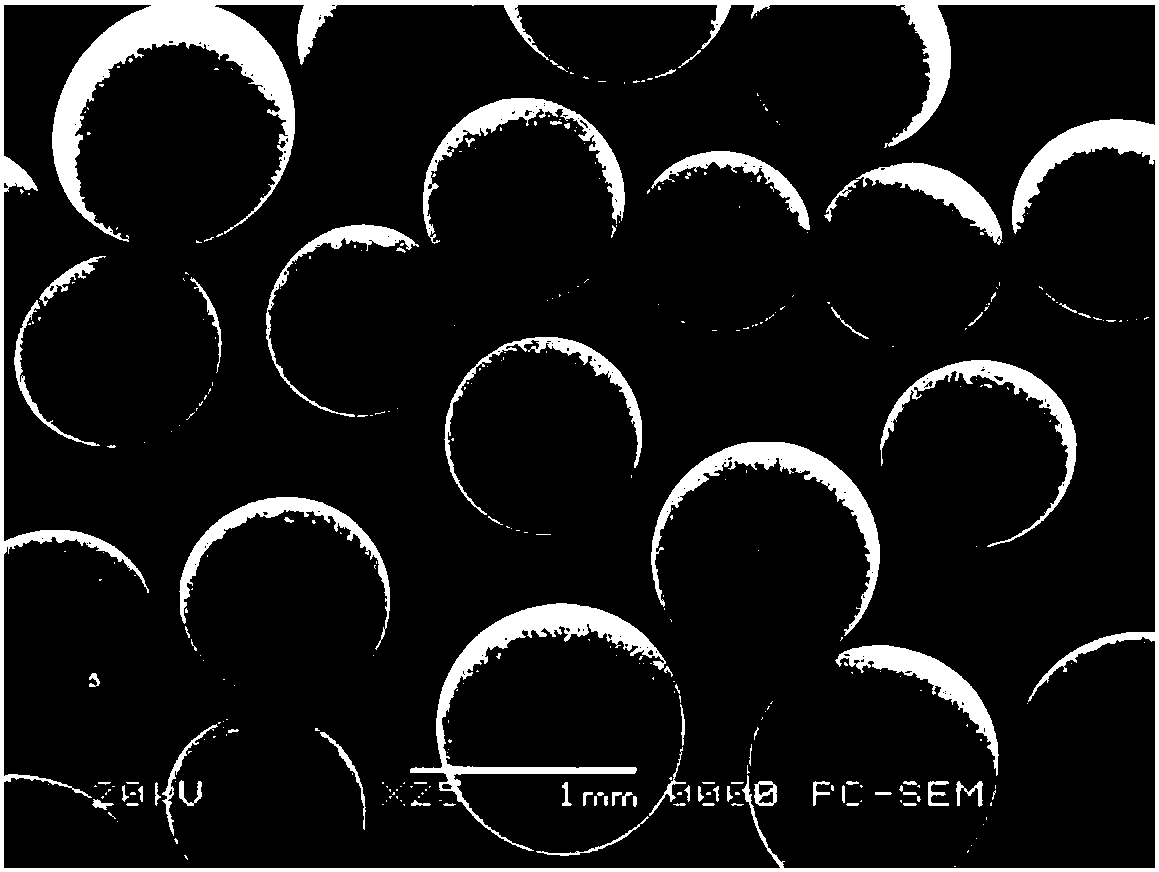

Application of iron-based catalyst with porous film structure in Fischer-Tropsch reaction

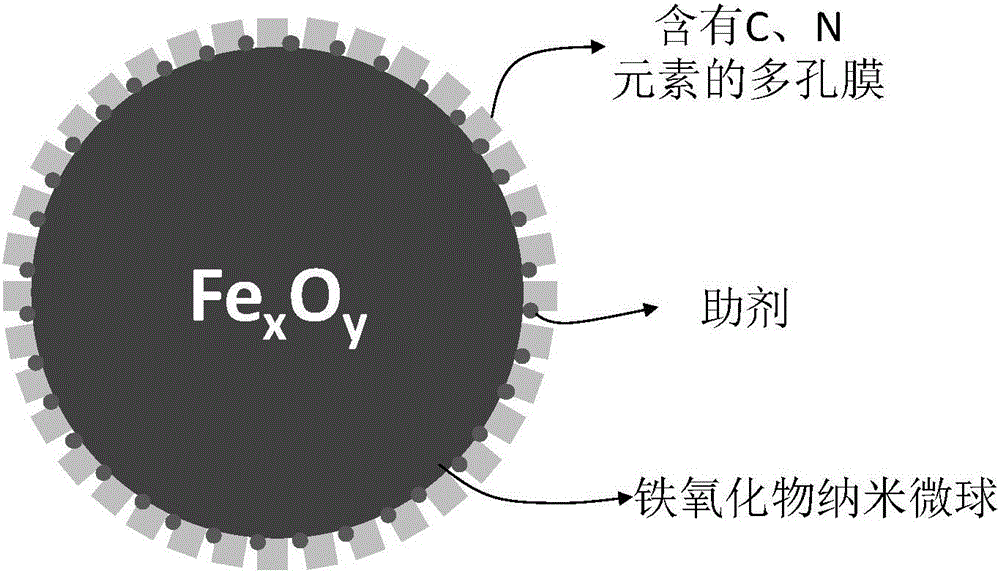

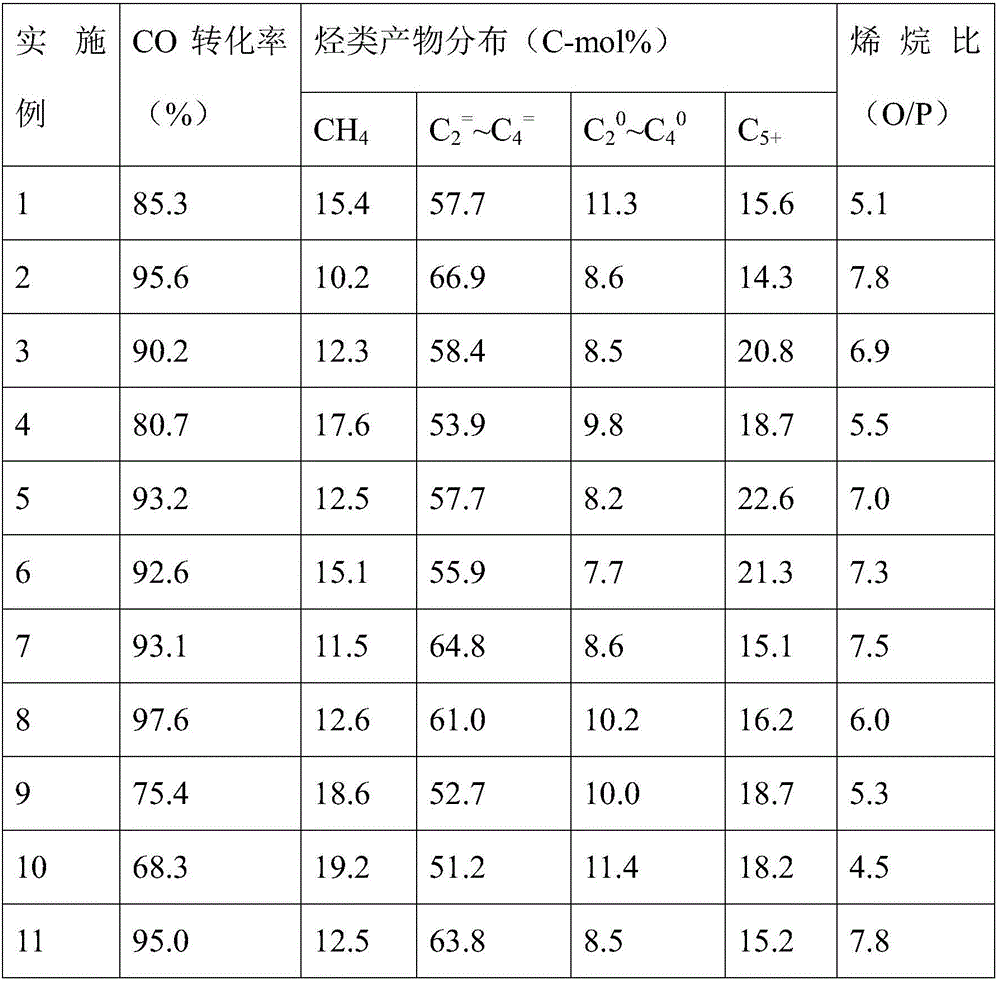

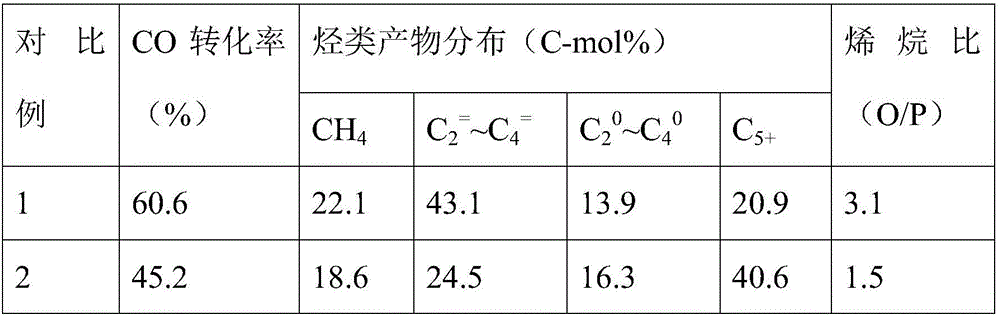

ActiveCN105817254APrevent carbon depositionPrevent sinteringHydrocarbon from carbon oxidesCatalystsIron nanoparticleSpherical form

The invention discloses an application of an iron-based catalyst with a porous film structure in Fischer-Tropsch reaction. According to the invention, the iron nano-particle with spherical or sphere-like feature and porous C and N films is taken as the catalyst and is added into auxiliaries; the catalyst is applied to the Fischer-Tropsch reaction of the synthesis gas; the catalyst has higher catalytic activity and low carbon olefin selectivity; the catalyst deactivation caused by the carbon deposition and sintering of the iron nano-particles in the reaction process can be effectively restrained; the service life of the catalyst is prolonged; the application has industrial application prospect.

Owner:JIANGNAN UNIV

Precoated sand and preparation method thereof

ActiveCN107282869AImprove heat resistanceHigh bulk densityFoundry mouldsMould handling/dressing devicesCarbonizationEthyl acetate

The invention discloses precoated sand and a preparation method thereof, and belongs to the technical field of the foundry industry. The precoated sand comprises, by weight, 100-110 parts of roughing sand, 2-4 parts of modified phenolic resin, 1-3 parts of a coupling agent, 0.3-0.5 part of urotropine, 0.6-0.8 part of modified lignin, 1-3 parts of a dry material, and 1-3 parts of ethyl acetate. The precoated sand is formed by combining the specific components, especially, 1-Hydroxyethylidene-1,1-diphosphonic acid can be catalyzed by ceric oxide to perform dehydration reaction with the modified phenolic resin during heating, resin carbonization is promoted, thus, the binding force between the resin and the sand is reduced, and the collapsibility of the precoated sand is improved; and in addition, the ceric oxide can also stop the modified phenolic resin from performing free radical reaction caused by oxidation, so that the heat resistance of the precoated sand is improved. Meanwhile, the invention further discloses the preparation method of the precoated sand. The method adopts the specific steps and the specific material adding sequence, and thus, the precoated sand which is good in heat resistance and prone to collapsing can be obtained quickly.

Owner:山西科瑞再生资源综合利用有限公司

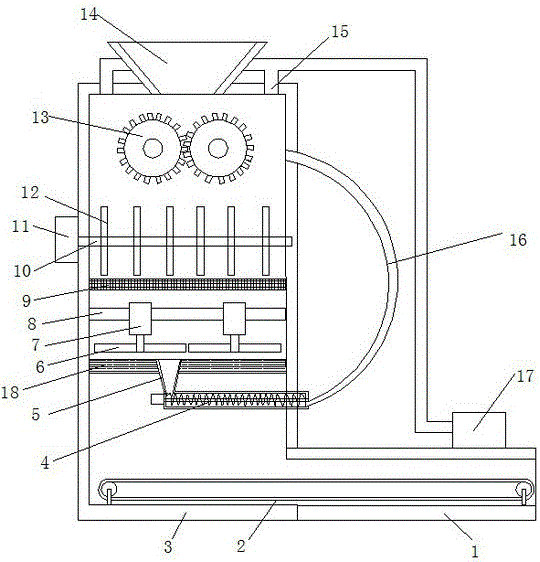

Feeding device for production of activated carbon

PendingCN106824482AImprove crushing effectSame sizeCarbon compoundsDirt cleaningActivated carbonStructural engineering

The invention discloses a feeding device for production of activated carbon. The feeding device comprises a crushing box body; a feeding bin is arranged at the top end of the crushing box body; the crushing box body communicates with the feeding bin; two driving motors are fixed on the outer side wall of the crushing box body through screws; output shafts of the driving motors are connected with a crushing roller; the crushing roller is rotatably connected with the internal part of the crushing box body; a second motor is fixed on the outer side wall of the crushing box body through a screw; an output shaft of the second motor is connected with a first rotating shaft arranged horizontally; the first rotating shaft is positioned in the crushing box body; a second pulverizing blade is welded on the side wall of the first rotating shaft; the second pulverizing blade is positioned below the crushing roller; and a first filter screen, a fixed frame and a first filter screen are arranged below the second pulverizing blade. The feeding device is compact in structure and small in occupied space, and can crush and screen to-be-processed wood before transportation of the activated carbon production material to facilitate subsequent processing.

Owner:从江县胜达活性炭有限公司

Pressure resistant, fire prevention and smoke abatement chlorinated polyvinyl chloride (CPVC) tube, fittings and valve composition for fire-fighting

InactiveCN101451009AIncrease temperaturePromote carbonizationPipe elementsRigid pipesMasterbatchChlorinated polyvinyl chloride

The invention relates to a pressure-proof, waterproof and smoke-removed chlorinated polyvinyl chloride (CPVC) pipeline for fire fighting, a fitting part and a valve composition. Manufacturing materials of the pipeline consists of a chlorinated polyvinyl chloride resin finished product material, a toughener and an inorganic flame retardant; and the chlorinated polyvinyl chloride resin finished product material, the toughener and the inorganic flame retardant (a master batch) are mixed to prepare a finished product according to proportion 1:0.05:0.05-0.1. The invention determines to use the chlorinated polyvinyl chloride (CPVC) resin as a main material and use the toughener and the organic flame retardant for assistance to prepare the product through corresponding processing equipment; and the product has good fireproof performance, low flame expansibility, low smog production, automatic extinguishment, no production of fire drops and the like.

Owner:上海佑利积水管业有限公司 +1

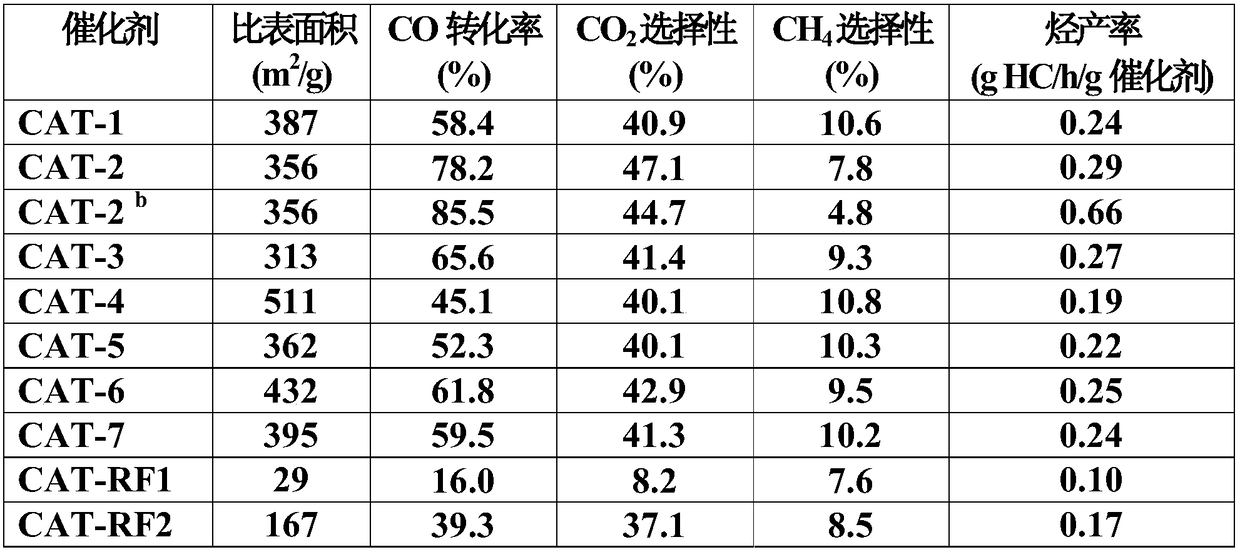

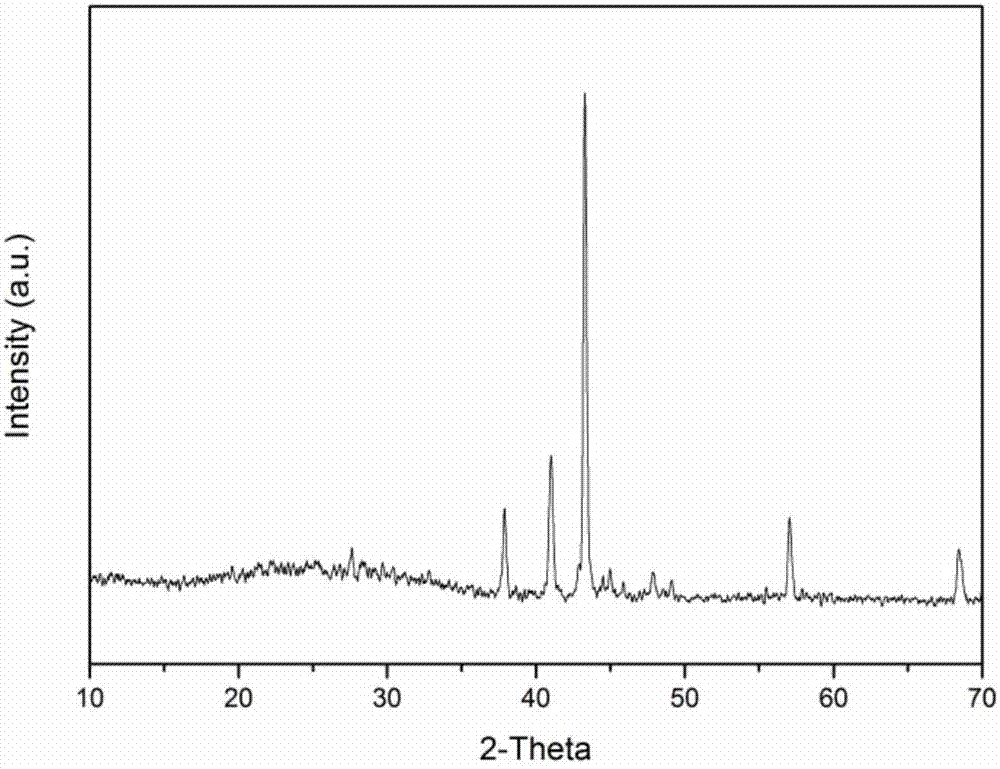

Supported iron-based Fischer-Tropsch catalyst as well as preparation and application thereof

ActiveCN108067231AHigh strengthSmall synthetic pressure dropCatalyst activation/preparationLiquid hydrocarbon mixture productionActive componentMesoporous carbon

The invention relates to a supported iron-based Fischer-Tropsch catalyst. The supported iron-based Fischer-Tropsch catalyst contains a spherical mesoporous carbon support, an active component iron located on the support and an optional catalyst promoter, wherein the specific surface area of the spherical mesoporous carbon support is 500-1000 m<2> / g, pore volume is 1.5-3.5 cm<3> / g, and average porediameter is 9-30 nm. According to the catalyst, spherical mesoporous carbon with high pore volume and large pore diameter is taken as the support, not only can high loading capacity of iron be realized, but also when the prepared catalyst is applied to the Fischer-Tropsch reaction, high Fischer-Tropsch reactivity and high productivity can be obtained, and particularly, CO conversion rate is remarkably increased and hydrocarbon productivity is improved. The invention further relates to preparation of the catalyst and an application of the catalyst to the Fischer-Tropsch reaction.

Owner:HIGHCHEM +1

Water-proof, high-strength, weather resistance, flame-retardant and environment-friendly thermal insulation board and preparation method thereof

InactiveCN108358589AHigh tensile strengthImprove flexural performanceCeramicwareCellulosePolyvinyl alcohol

The invention discloses a water-proof, high-strength, weather resistance, flame-retardant and environment-friendly thermal insulation board and a preparation method thereof. The thermal insulation board is prepared from the following raw materials in parts by weight: 30-40 parts of modified straw, 6-8 parts of fly ash, 7-9 parts of calcined gypsum powder, 10-14 parts of ore filler, 8-12 parts of silica sol, 6-8 parts of thermal insulation additive, 7-9 parts of polyvinyl alcohol, 4-6 parts of acrylic emulsion, 3-5 parts of modified nano additive, 5-7 parts of a gel material, 0.3-0.5 part of cellulose ether and 7-9 parts of fire-proof and flame-retardant additive. The thermal insulation board disclosed by the invention adopts a large amount of wastes, saves the resources, protects the environment, is high in material compressive strength, superior in weather resistance and excellent in humidity resistance, low in heat conductivity coefficient and good in thermal insulation effect, and also has a certain sound insulation effect at the same time; and furthermore, the preparation method disclosed by the invention has the advantages that the material cost is lower, the raw materials areeasy to obtain, the process is concise, the practical value is higher, and the application prospects are good.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Preparation method for carbon-loaded iron nitride compound sodium ion battery negative electrode material doped with nitrogen

ActiveCN107068994AImprove sodium storage performanceSimple methodCell electrodesSecondary cellsAlcoholIron nitride

The invention discloses a preparation method for a carbon-loaded iron nitride compound sodium ion battery negative electrode material doped with nitrogen. The preparation method comprises the steps of firstly, dissolving a nitrogen source, a carbon source and an iron source in deionized water according to a mass ratio being 40:1:(10-40), and performing uniform stirring, wherein 6g nitrogen source is added into the deionized water per 40mL; secondly, freezing and drying the mixture to obtain a product A; thirdly, performing pyrolysis reaction on the product A to obtain a product B; and finally, washing the product B with the deionized water and ethyl alcohol, thereby obtaining the carbon-loaded iron nitride compound sodium ion battery negative electrode material doped with the nitrogen. The product is prepared from a conventional and cheap compound by a one-step pyrolysis method, the method is simple, is low in cost and is easy to operate, and mass production is expected to be achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Excitant for preparing construction material by carbonized curing wastes

InactiveCN101337786APromote carbonizationHigh carbonation rateSolid waste managementGypsumGreenhouse gas

The invention belongs to the technical field of a constructional material, and relates to an excitant used for carbonizing and curing offal prepared constructional materials. The excitant comprises not less than 50 percent of excitable components by weight which are one or more than one of NaHCO3, soluble glass, plaster, Ca(HCO3)2, NaCl and Na2CO3. The excitant has the advantages that when offal prepared constructional materials are carbonized and cured, the excitant can promote carbonization in carbonization materials through the excitable components by adding the excitant of proper amount, thus increasing the carbonization ratio and reducing the discharged carbon dioxide as a greenhouse gas to great extent, preparing products for carbonizing and curing constructional materials having good performance, and reducing the production cycle with good economic benefit.

Owner:UNIV OF JINAN

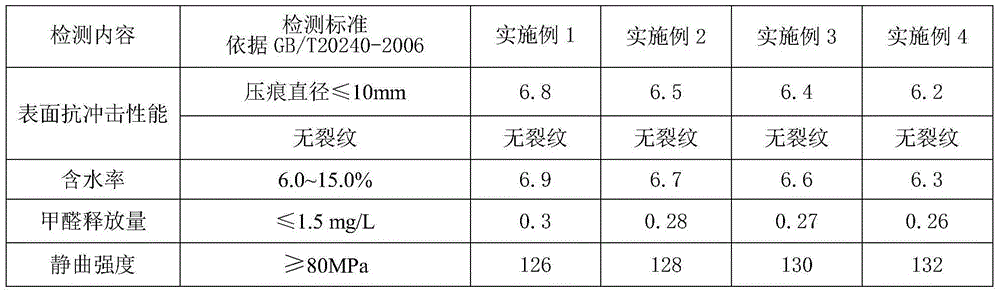

Furniture reconsolidated bamboo preparation method

ActiveCN104960069APromote carbonizationThere will be no cracking, etc.Reed/straw treatmentFlat articlesWater contentWood production

The invention relates to the technical field of furniture bamboo wood production and particularly relates to a furniture reconsolidated bamboo preparation method. The preparation method includes the steps of sectioning, bamboo chip preparing, rolling, binding, carbonization, cooling, impregnation, primary drying, secondary drying, compression and forming, so that a reconsolidated bamboo finished product can be prepared. The reconsolidated bamboo produced by the preparation method can be widely applied to various pieces of furniture, is small in surface impression diameter, less in formaldehyde release amount, large in static bending intensity, low in water content, and not easy to crack or deform, and has the advantages of excellent shock resistance, greening and environmental protection, good elasticity, and anticorrosion and mothproofing. The development and research of the reconsolidated bamboo can alleviate resource shortage and perform the advantage of bamboo wood resources, and moreover, improve the utilization value and added value of bamboo wood and can meet the needs of furniture market environmental protection.

Owner:官宝瑛

Low-smoke bittern-free flame-retardant polyolefin material and braided fabric manufactured thereby

ActiveCN101230162ATo achieve the purpose of flame retardantIncrease temperatureCane mechanical workingHalogenPolyolefin

The invention relates to low smoke non-halogen flame-resistant polyolefine material and compound weaved cloth made of the low smoke non-halogen flame-resistant polyolefine material. The low smoke non-halogen flame-resistant polyolefine material is composed of polyolefine resin and inorganic flame retardant. The manufacturing process of the weaved cloth comprises the following steps: on one hand, polyolefine material is taken to be filled into a plastic extrusion molding machine, film is extruded through the plastic extrusion molding machine, and then cooled and cut, heated and directionally stretched, the pre-heating treatment is performed to the film to be shaped, and then the film is rolled, and woven in across warp and warp direction into plastic cloth; on the other hand, the low smoke non-halogen being flame-resistant polyolefine material is taken to be filled into a clothes rack type flat frame head plastic extrusion molding machine, and film coating is extruded through the clothes rack type flat frame head plastic extrusion molding machine; after two aspects are accomplished, the film coating is hot melt and continuously compressed into the low smoke non-halogen flame-resistant polyolefine weaved cloth through a compound rolling drum. The technology of the invention can improve the low smoke non-halogen flame-resistant performance and the anti-aging performance of the polyolefine plastic weaved cloth.

Owner:上海亚都塑料有限公司

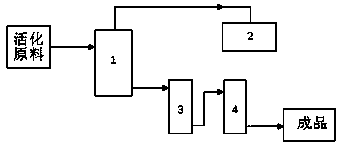

Continuous type preparation method of biomass activated carbon

InactiveCN103466618AFast swelling rateProlonged activation processCarbon compoundsActivated carbonO-Phosphoric Acid

The invention discloses a continuous type preparation method of biomass activated carbon. The continuous type preparation method comprises the following steps of (1) activating, namely activating biomass raw materials by using phosphoric acid under the assistance of ultrasonic waves; (2) carrying out microwave heating carbonization at the microwave power of 500-800W for 3-10 minutes so as to obtain an activated carbon crude product, and meanwhile leading gas obtained after reaction into a gas absorber containing water; (3) purging and washing by using water vapor, condensing and drying, namely, purging and washing the activated carbon by using water vapor, then enabling the activated carbon to enter a condensation drier so as to be dried, thus obtaining an activated carbon finished product; and (4) recycling phosphoric acid, namely collecting an absorption liquid in the gas absorber and water vapor purging residual gas condensate in the step (3), namely recycling a phosphoric acid solution. The continuous type preparation method has the advantages of being simple in process, high in production efficiency, low in cost, economic and environment-friendly and can be used for preparing the activated carbon with excellent absorption performance, recovering the phosphoric acid at high efficiency so as to be recycled and realizing the industrial continuous type large-scale production.

Owner:WUXI BAOHE BIOTECH

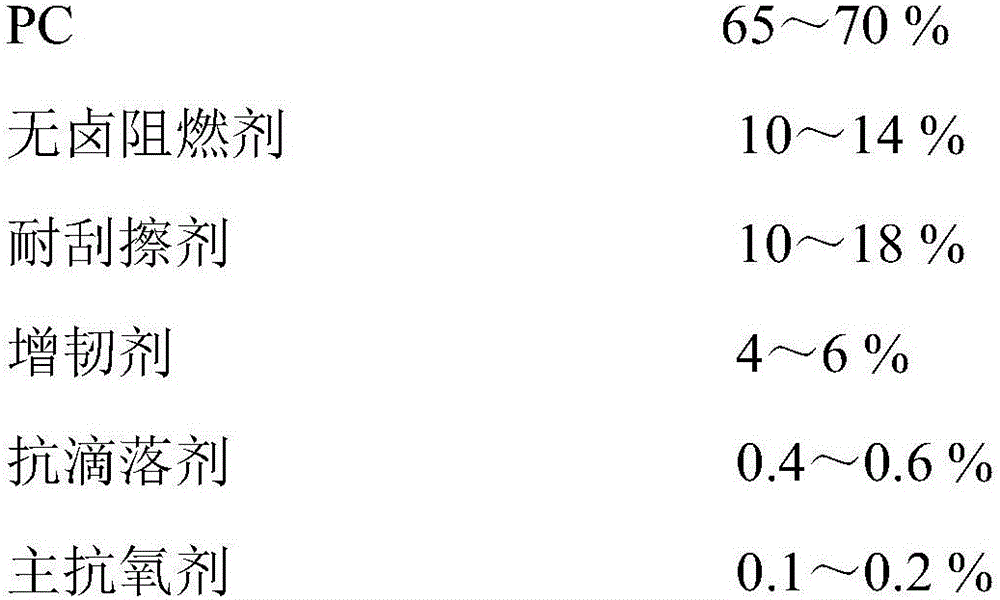

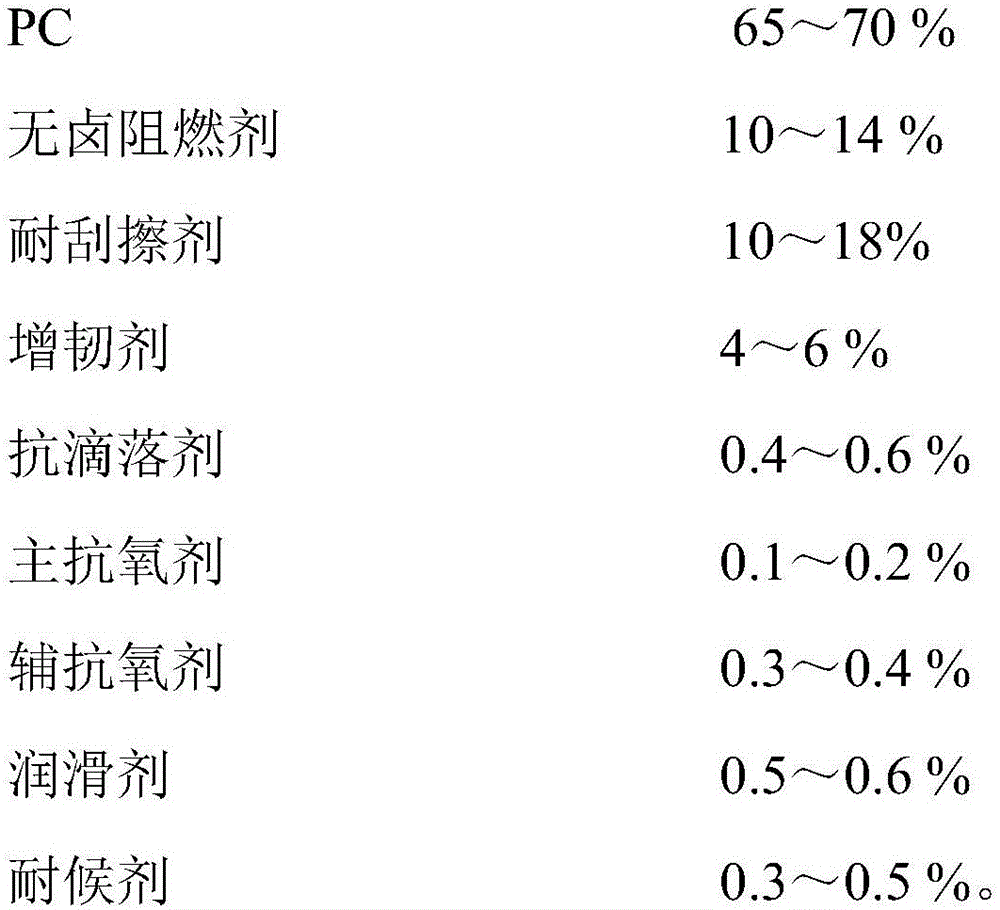

High-glowing filament scratch-resistant PC material suitable for tablet computer shell and preparation method thereof

The invention discloses a high-glowing filament scratch-resistant PC material suitable for a tablet computer shell and a preparation method thereof. The material is prepared from, by weight, 65-70% of PC, 10-14% of flame retardant, 10-18% of scratch-resistant agent, 4-6% of toughening agent, 0.4-0.6% of anti-dripping agent, 0.1-0.2% of primary antioxidant, 0.3-0.4% of auxiliary antioxidant, 0.5-0.6% of lubricating agent and 0.3-0.5% of weather-proof agent. Engineering plastic PC is used as a main material, the halogen-free flame retardant, the toughening agent, the scratch-resistant agent, anti-dripping agent, the antioxidants, the weather-proof agent and the lubricating agent are added, all the materials are subjected to melt blending through a double-screw extruder, and the high-glowing filament scratch-resistant PC material suitable for the tablet computer shell is prepared. The material has the advantages of low price, low weight, scratch resistance, good weather fastness, halogen-free flame retardation, high-glowing filaments, excellent mechanical properties, high practicability and the like. Meanwhile, the preparation method of the material is simple and easy to implement and can be widely applied to industrial production.

Owner:GUANGZHOU SUPER DRAGON ENG PLASTICS

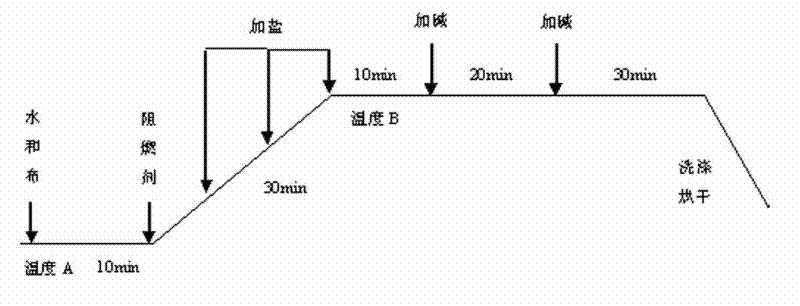

Preparation method for durable and inflaming retarding after-finishing chinlon fabric

The invention relates to a preparation method for a durable and inflaming retarding after-finishing chinlon fabric and belongs to the field of inflaming retarding modification of fabrics. The preparation method comprises the following steps: firstly, carrying out surface hydroxymethylation modification on a pre-treated fabric and introducing active hydroxymethyl; and then carrying out a sufficient immersing and common padding finishing process on the fabric and a fire retardant, and baking and grafting the fire retardant on the fabric to realize the durable and inflaming retarding aims. The invention aims to provide the preparation method for the durable and inflaming retarding after-finishing chinlon fabric so as to overcome the defects in the prior art that halogen is included, the water washing resistance is poor and the like; the inflaming retardance of a prepared inflaming retarding nylon fabric is improved obviously and the appearance and the hand feeling of the fabric are not changed obviously; the water washing resistance is good. An experiment result shows that the oxygen index of the fabric subjected to the fire retardant treatment of the method can be improved to 46.2% from 21.6%; after the fabric is washed for 50 times, the level of 44.5% can also be kept. In a vertical combustion test, molten drops are not formed and the damage length is less than 3cm. The heat stability is obviously improved and the carbon forming performance is improved obviously. According to the preparation method, use amount of the fire retardant is less, process is simple, the cost is low and the fabric can be used in fields with high inflaming retarding requirements.

Owner:BEIJING UNIV OF CHEM TECH

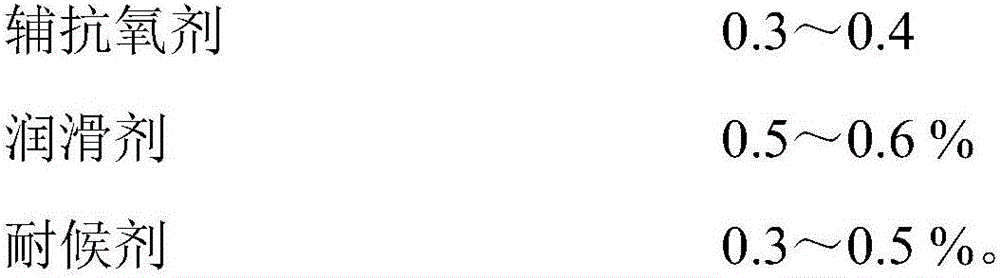

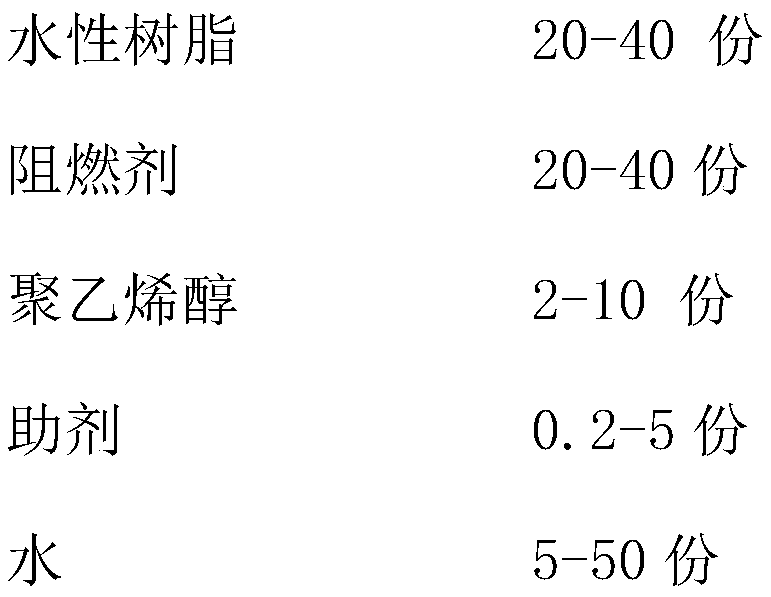

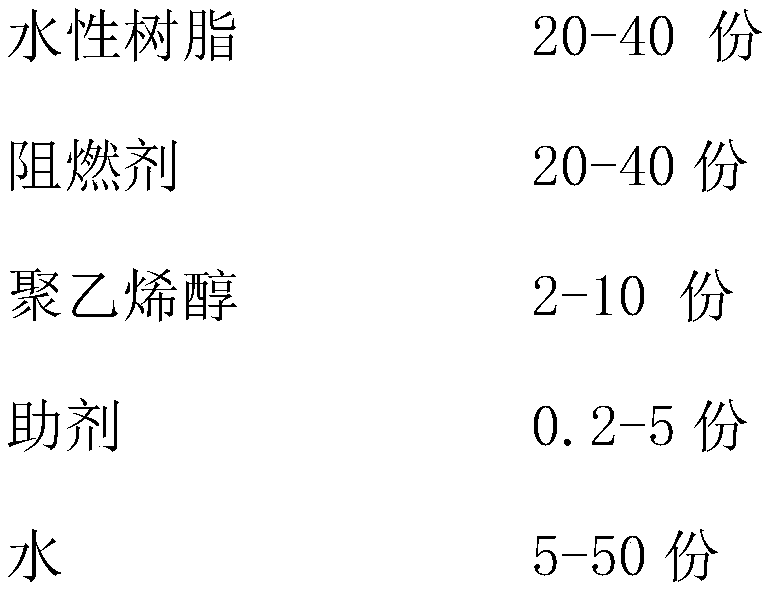

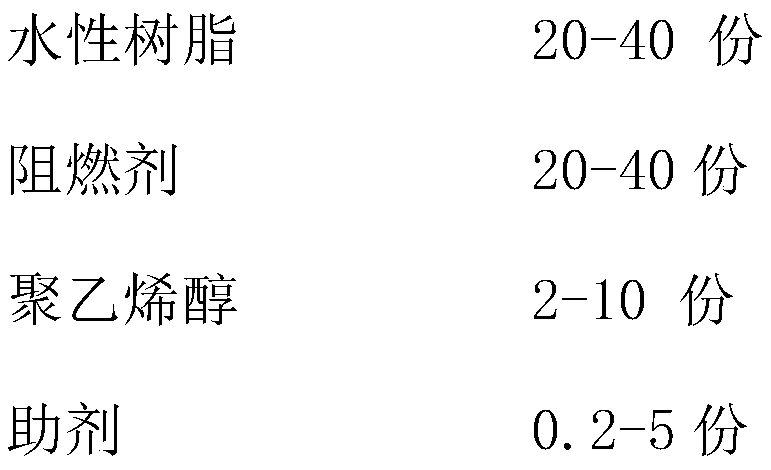

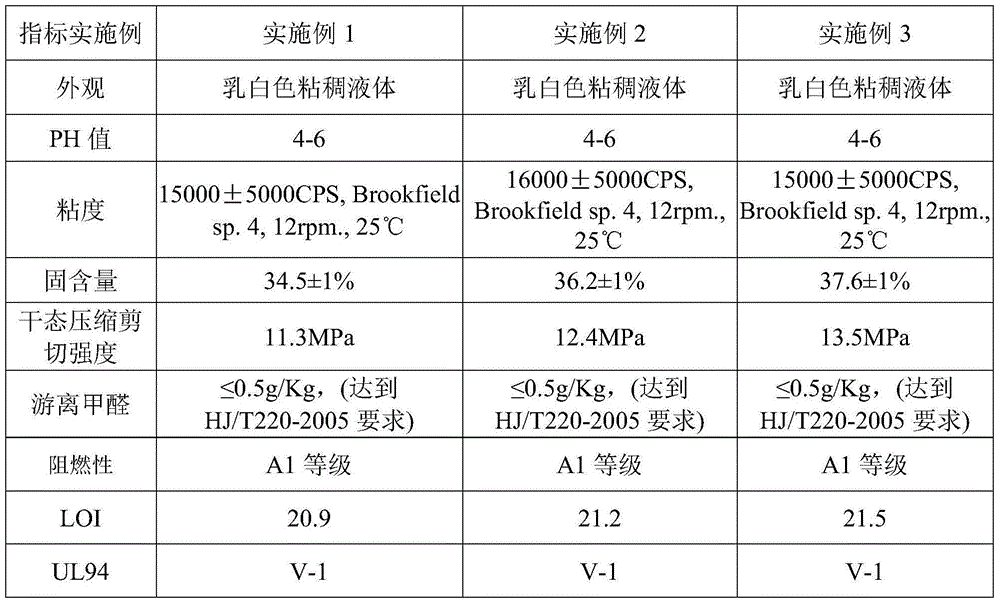

Method for preparing antimony-free burnthrough-resistant waterborne flame-retardant adhesive for fabric coatings

InactiveCN110629561AAvoid adverse health effectsPromote carbonizationTextiles and paperPolymer sciencePhosphate

The invention belongs to the technical field of waterborne flame-retardant adhesives for fabric coatings and particularly relates to a method for preparing an antimony-free burnthrough-resistant waterborne flame-retardant adhesive for the fabric coatings. The method includes: step one, raw material preparation, to be specific, preparing, by weight, 20-40 parts of waterborne resin, 20-40 parts of aflame retardant, 2-10 parts of polyvinyl alcohol, 0.2-5 parts of auxiliary agents and 5-50 parts of water, wherein the total weight parts of the raw materials are 100. A finished product is preparedby procedures of polyvinyl alcohol solution preparation, powdery flame retardant aqueous dispersion preparation, phosphate flame retardant pretreatment, mixing and filtration. The method for preparingthe antimony-free burnthrough-resistant waterborne flame-retardant adhesive for the fabric coatings has advantages that without use of antimony trioxide, harms of residual heavy metals in antimony trioxide to human health are reduced; by adoption of polyvinyl alcohol as a carbonizing agent, excellent carbonization performance, burnthrough resistance and dripping resistance of fabrics are achieved, and the adhesive is especially applicable to the fabric flame-retardant coatings of mattresses, sofas, furniture covers, carpets, protective garments and the like.

Owner:嘉兴市新加新化工有限公司

Organic montmorillonite and application thereof

ActiveCN105219306AIncrease spacingGood dispersionMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses organic montmorillonite and application thereof. The organic montmorillonite is obtained by modifying montmorillonite so that adhesives can be prepared, wherein the organic montmorillonite has effects on gel protection and emulsification in the copolymerization process of vinyl acetate. Layered montmorillonite is dispersed in a polymer matrix and has the advantages of being high in storage stability, uniform in dispersion and high in interface bonding strength. Meanwhile, montmorillonite belongs to inorganic flame retardant and has the advantages of being excellent in mechanical performance, gas barrier property and fire retarding effect, low in cost, convenient to machine and the like, the mechanical performance of polymers is improved, and a new approach is created for polymer fire retardance.

Owner:顶立新材料科技股份有限公司

Cement kiln tail gas carbonization non-autoclaved aerated concrete wall material product and preparation method thereof

ActiveCN113956070AQuick buildGood mechanical propertiesSolid waste managementCeramicwareFoaming agentPortland cement

The invention relates to a cement kiln tail gas carbonized non-autoclaved aerated concrete wall material product and a preparation method thereof. The concrete wall material product comprises the following components: 30-50 parts of carbonized active cement, 1-5 parts of a reinforcing material, 5-10 parts of lime, 5-10 parts of Portland cement, 20-60 parts of concrete aggregate tailing powder, 30-50 parts of water, 0.2-2 parts of a water reducing agent, 0.1-2 parts of a foaming agent and 0.02-0.5 part of a foam stabilizer. The preparation method comprises the following steps: uniformly stirring the components or directly adding the components into slurry and uniformly stirring; molding the stirred slurry, demolding, and curing at 50-60 DEG C for 4-8 hours; and feeding the mixture into a carbonization curing kettle filled with cement kiln tail gas, curing for 8-24 hours under the conditions that the temperature is 10-50 DEG C, the relative humidity is 50-100%, the CO2 volume concentration is 15-30% and the pressure is 2-4 atmospheric pressure, and then curing for 3-14 days under the natural conditions that the temperature is 10-30 DEG C and the relative humidity is 50-90%. The non-autoclaved aerated concrete carbonized through the cement kiln tail gas absorbs a large amount of CO2, does not need autoclaved curing, is fast in strength development and low in water absorption rate, and has good heat preservation, heat insulation, sound insulation and fireproof performance.

Owner:HUAXIN CEMENT

Zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material

InactiveCN107286494APromote cross-linking into charReduce generationPhosphorus compoundsPlasticizerPhosphate

The invention discloses a zinc phosphomolybdate flame retarding and smoke suppressing PVC sheet material which is prepared from the following components in parts by weight: 100 parts of PVC resin, 4 to 5 parts of a heat stabilizer, 5 to 20 parts of a plasticizer, 3 to 7 parts of a flame retarding and smoke suppressing agent, 0.5 to 3 parts of a phosphate coupling agent and 0.4 to 0.6 part of PE wax. According to the PVC sheet material, by the flame retarding action of phosphorus and the smoke suppressing action of molybdenum and zinc, the synergistic effect of phosphorus, molybdenum and zinc can effectively improve the flame retarding and smoke suppressing performance of the PVC sheet material.

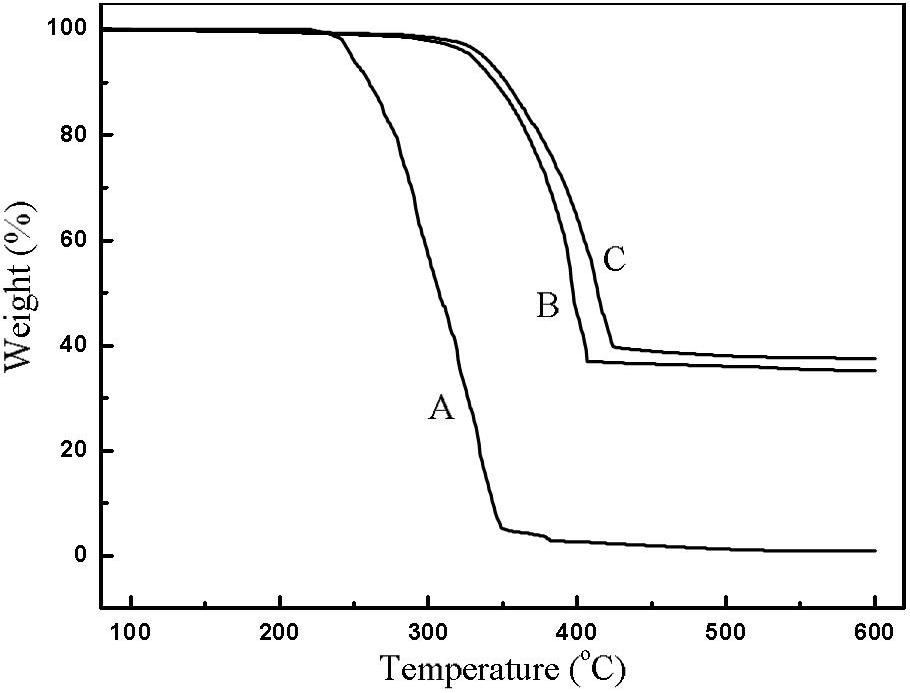

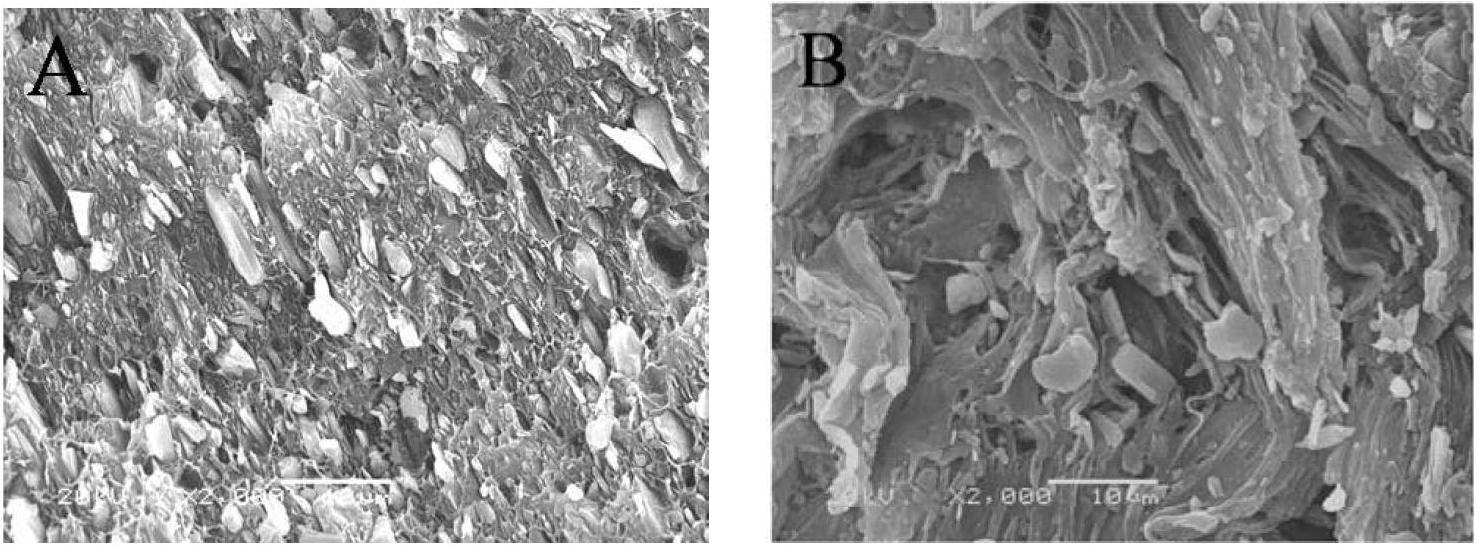

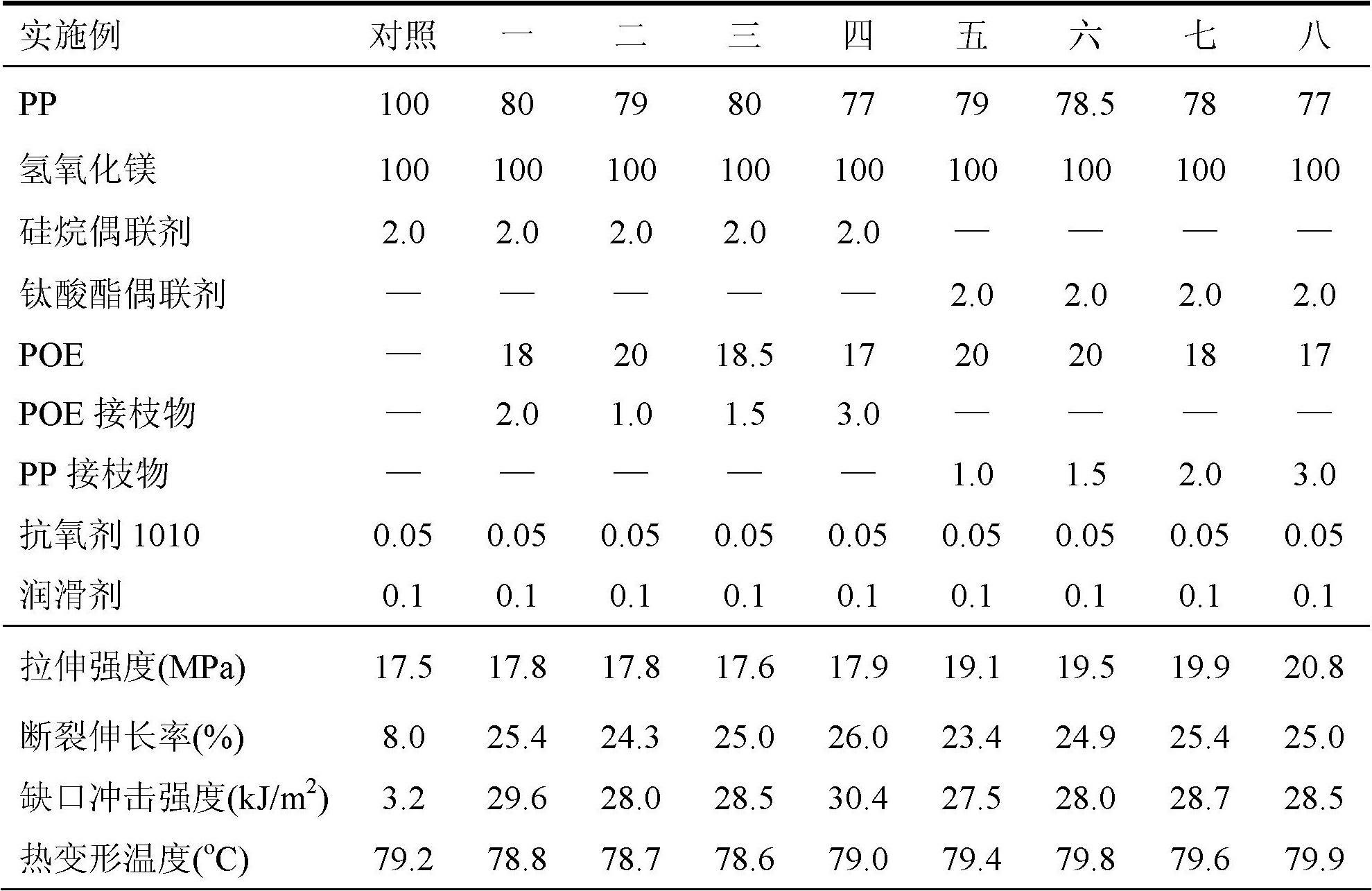

Preparation method of halogen-free flame-retardant toughening polypropylene composite material

InactiveCN102675739AEasy to processOvercome the shortcomings of the decrease in the mechanical toughness of the matrixElastomerPolyolefin

The invention discloses a preparation method of halogen-free flame-retardant toughening polypropylene composite material, which mainly comprises the steps of: carrying out surface modification on 100 parts by weight of magnesium hydroxide by 2.0 parts by weight of surface modifier in a high-speed mixer, wherein the modification temperature is 80-120 DEG C, the time is 25-35min and the rotating speed is 1500-2000rpm; evenly mixing the modified magnesium hydroxide with 77-80 parts by weight of dry polypropylene, 17-20 parts by weight of dry polyolefin elastomer, 1.0-3.0 parts of by weight of maleic anhydride graft copolymer, 0.05 parts by weight of antioxidant and 0.1 parts of lubricating agent to obtain mixture; and then, mixing and pelleting the mixture in a double-screw extruder, drying the extruded aggregates and carrying out injection molding on the aggregates in an injection molding machine. The method is simple in technology and good in repeatability; and the prepared halogen-free flame-retardant toughening polypropylene composite material has good mechanical toughness and flame-retardant property.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com