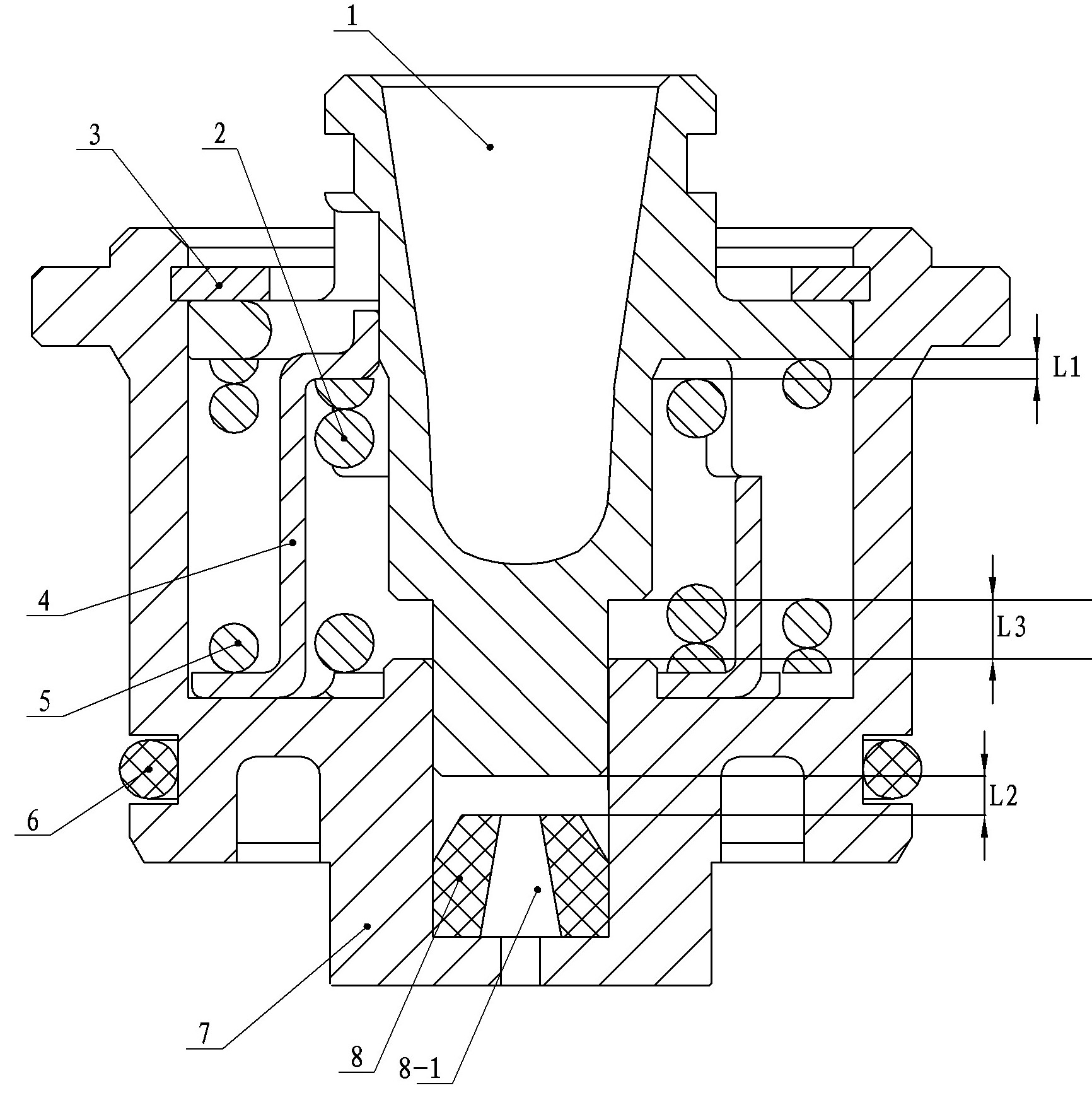

Three-level balance piston assembly

A technology of balancing pistons and assemblies, applied in the directions of brake components, control valves and bleed valves, brakes, etc., can solve the problems of heavy-duty emergency braking instability, affecting the friction coefficient or friction between the brake hub and the brake pads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

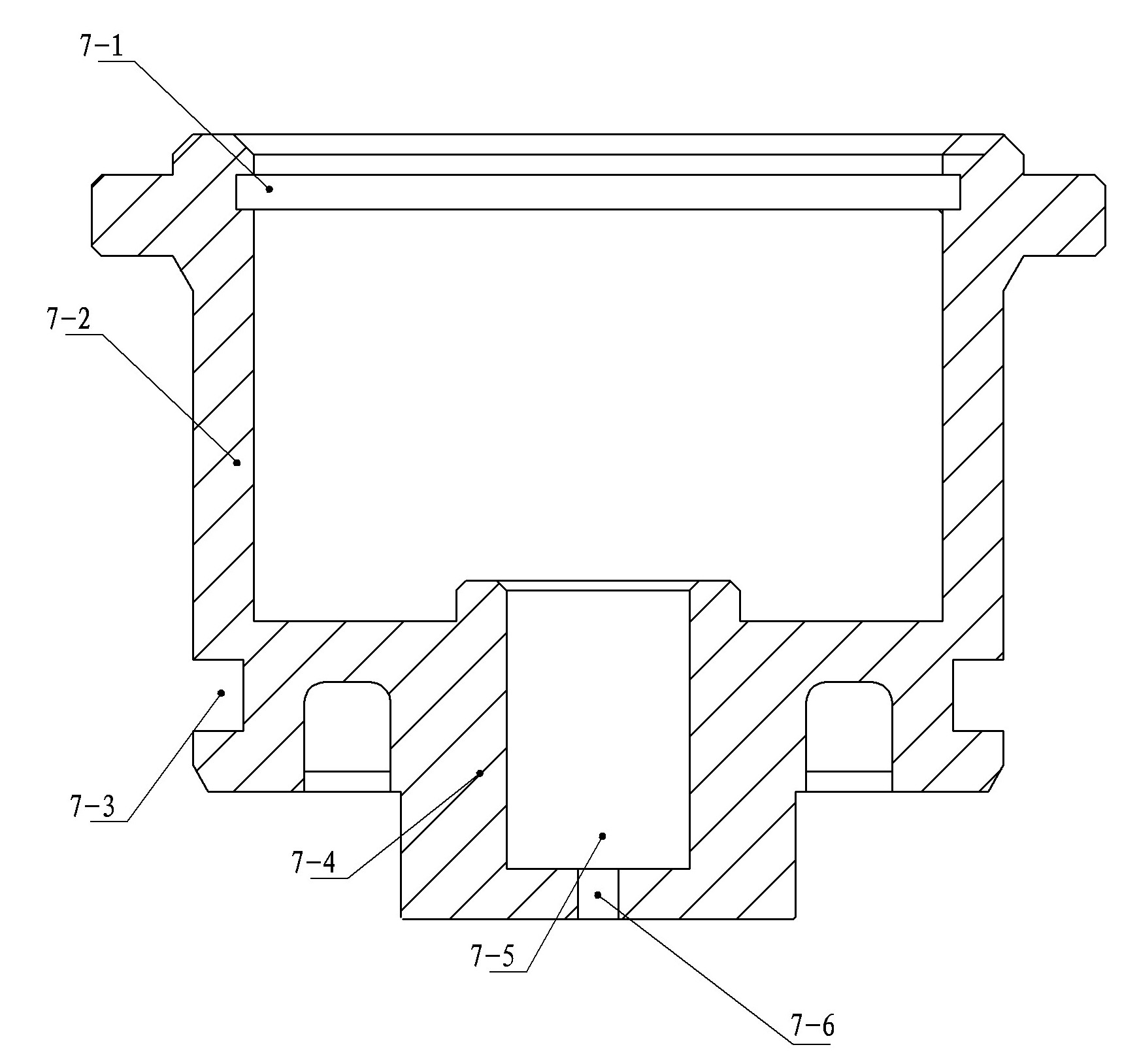

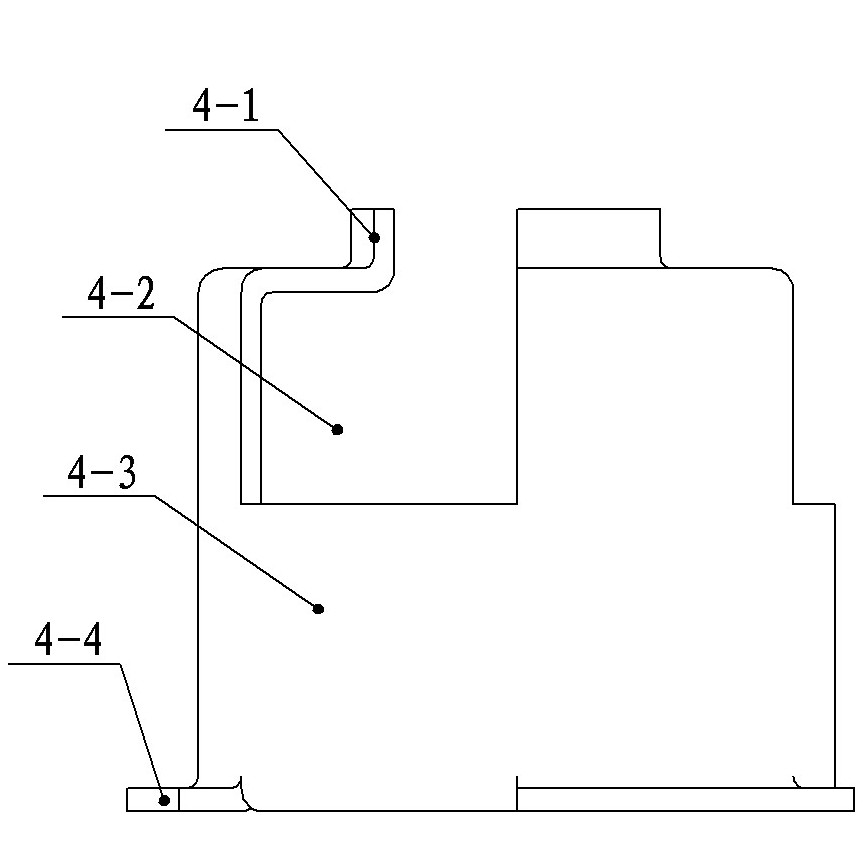

[0022] Embodiment: a three-stage balance piston assembly, including a balance piston, a spring clasp, and a push rod seat. In the cavity of the push rod body at the lower part of the balance piston, there is a disc-shaped disc on the upper periphery of the push rod seat, and the spring clasp is a cylindrical structure, and the upper wall is provided with a constriction. The diameter of the constriction is Matching the diameter of the rod body of the ejector rod base, there are three gaps connected to the shrinkage on the upper half of the side wall and the top of the spring pack, so that the upper part of the spring pack forms three protrusions, and the lower edge of the spring pack is respectively provided with three gaps. The inner and outer flanging, the three inner flangings correspond to the three gaps, the three outer flangings correspond to the three protruding parts; the web plate corresponding to the protruding parts is provided on the disc of the ejector pin seat. ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com