Method for preparing antimony-free burnthrough-resistant waterborne flame-retardant adhesive for fabric coatings

A flame retardant adhesive and coating technology, applied in textiles and paper making, etc., can solve the problems of reduced burn through resistance, reduced flame retardant performance, and high flame retardant cost, and achieve good burn through resistance and good burn through resistance. , good carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

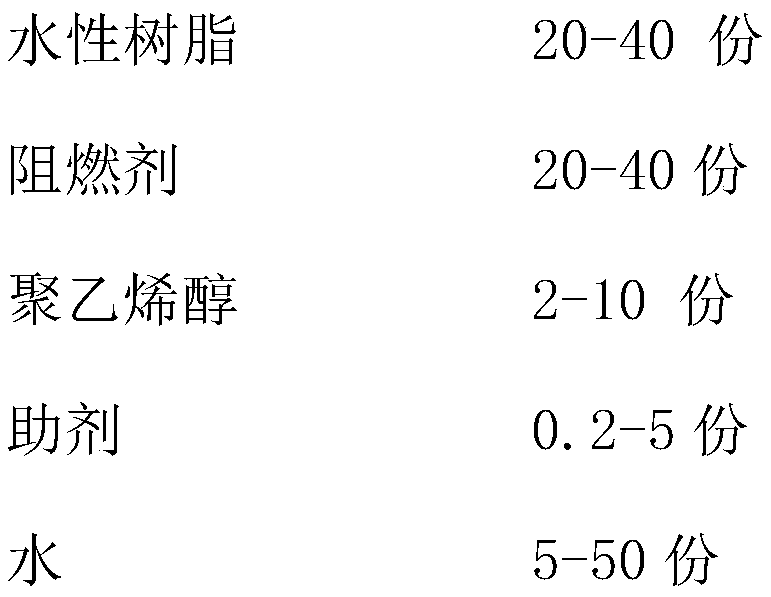

[0028] A method for preparing antimony-free burn-through-resistant water-based flame-retardant adhesive for fabric coating, step 1, raw material preparation, calculated by weight, including:

[0029]

[0030]

[0031] The total weight of raw materials is 100 parts;

[0032] The water-based resin in step 1 includes one or more of ethylene-vinyl acetate copolymer emulsion, acrylate emulsion, polyurethane emulsion, styrene-butadiene emulsion and nitrile emulsion, and the solid content of the water-based resin is 20%-60%;

[0033] Flame retardants in step 1 include hexabromocyclododecane (HBCD), decabromodiphenyl ether, decabromodiphenylethane, three (2,3-dibromopropyl) isocyanurate, bromine Triazine, ethylene bis-tetrabromophthalimide, tetrabromobisphenol A, octabromoether, methyl octabromoether, ammonium polyphosphate (APP), guanidine phosphate, amidinourea phosphate, melamine cyanide Urate (MCA), melamine phosphate, melamine pyrophosphate, chlorine ester resin, chlorinat...

Embodiment 1

[0048] A preparation method of antimony-free water-based flame-retardant adhesive for fabric coating,

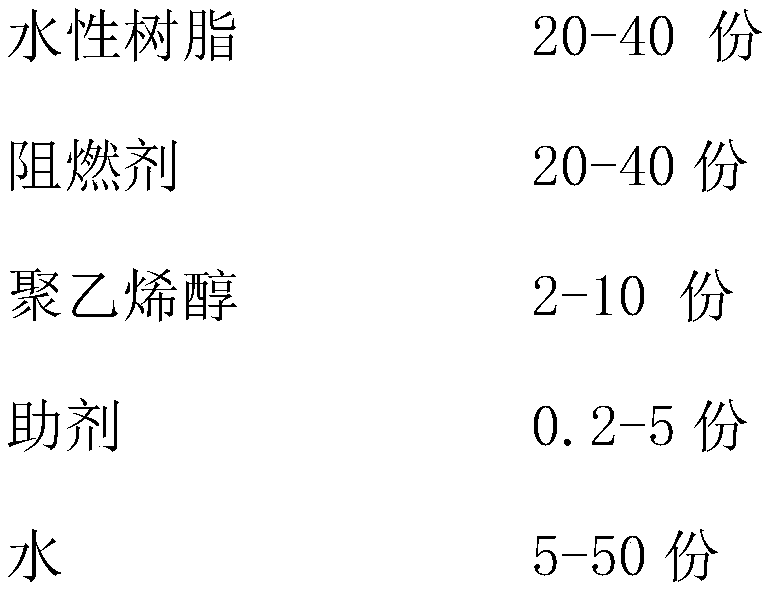

[0049] Step 1, raw material preparation, calculated by weight, including:

[0050]

[0051]

[0052] The total weight of raw materials is 100 parts

[0053] Step 2, the preparation of polyvinyl alcohol solution,

[0054] In a container with a stirring device and a heating device, add 6 parts of polyvinyl alcohol, add 30 parts of water, start the agitator, stir at a slow speed for 1-4 hours, start the heating device, raise the temperature to 50-95 ° C, continue Stir for 2 hours to fully dissolve the polyvinyl alcohol. Continue to stir at a slow speed, add bactericide, defoamer and crosslinking agent to obtain polyvinyl alcohol aqueous solution, and discharge for later use;

[0055] Step 3, preparation of powder flame retardant aqueous dispersion,

[0056] In a container with a stirring device, add 10 parts of water, add the dispersant and wetting agent in the auxili...

Embodiment 2

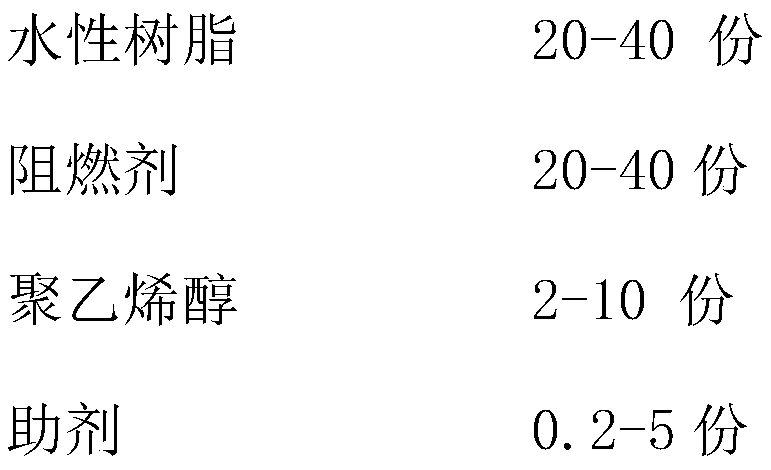

[0062] A method for preparing antimony-free water-based flame-retardant adhesive for fabric coating, step 1, raw material preparation, calculated by weight, including:

[0063]

[0064] Step 2, the preparation of polyvinyl alcohol solution,

[0065] Add the polyvinyl alcohol (PVA 2488) in step 1 into the container with stirring device and heating device, add 30 parts of water, start the agitator, and stir at a slow speed for 1-4 hours. Start the heating device, raise the temperature to 80-95°C, continue to stir for 2 hours to fully dissolve the polyvinyl alcohol, add the crosslinking agent, bactericide and defoamer in the auxiliary agent in step 1, and continue to stir for 10-30 minutes. Prepare polyvinyl alcohol aqueous solution, stand-by;

[0066] Step 3, preparation of powder flame retardant aqueous dispersion,

[0067] In a container with a stirring device, add 15 parts of the water in step 1 to the dispersant and wetting agent in the auxiliary agent in step 1, stir f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com