Chemical industry powder accurate weighing device

A weighing device and powder technology, applied in the direction of measuring device, weighing, and weighing equipment for materials with special properties/forms, etc., can solve the problems of high operator proficiency, high production costs of enterprises, and easy absorption by the human body and other issues to achieve the effect of saving human resources, less manual intervention, and improving mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

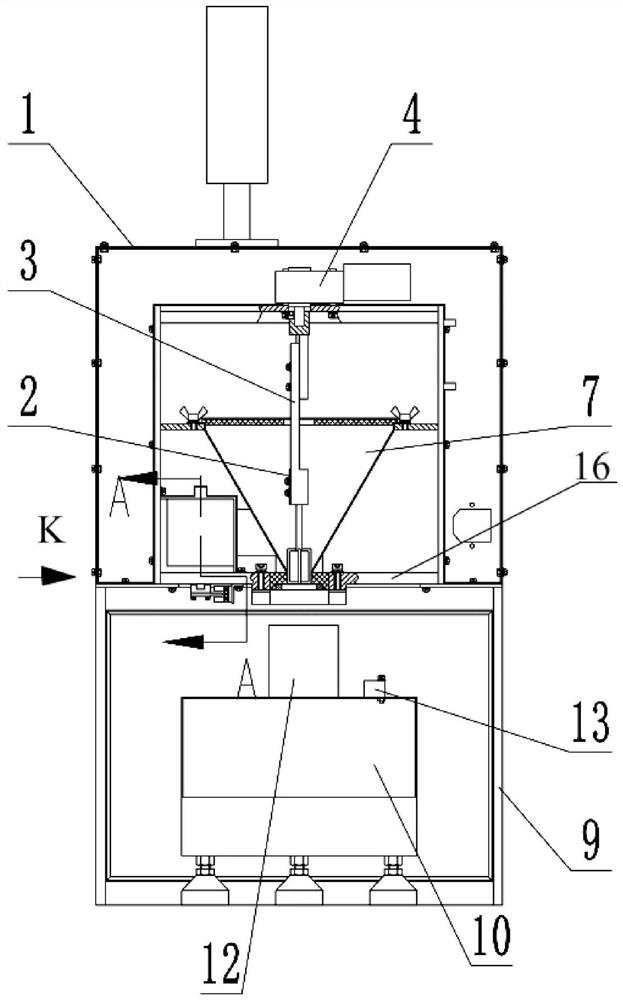

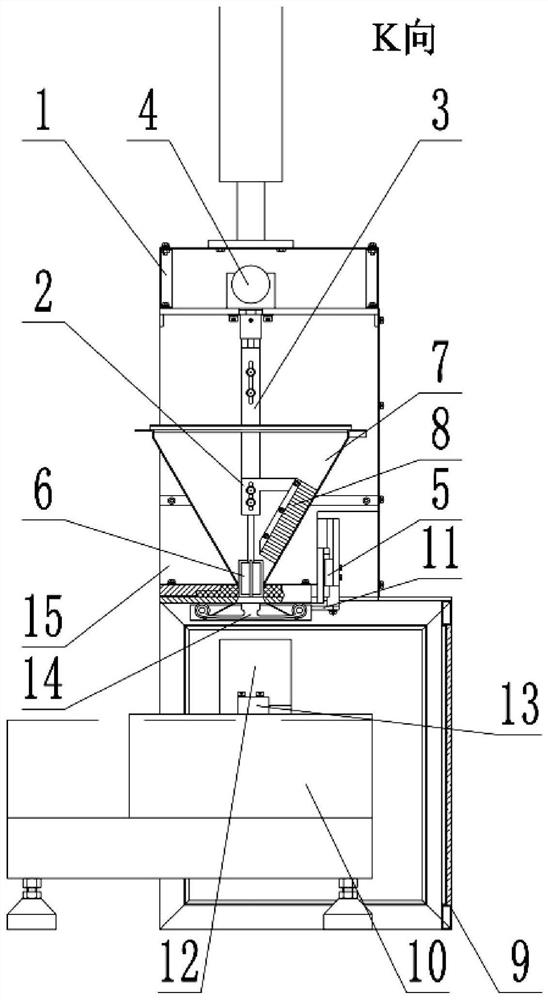

[0021] Such as Figure 1~2 As shown, the present invention provides an accurate weighing device for chemical powder, including a weighing mechanism and a blanking mechanism located above the weighing mechanism. The charging mechanism includes a hopper 7, a stirring assembly and a powder falling assembly, wherein the stirring assembly is installed In the hopper 7, the powder falling assembly is installed at the outlet of the hopper 7; At the bottom of the mouth, the valve plate 11 is installed at the discharge port of the hopper 7, and the valve plate 11 is connected to the output shaft of the lead screw motor 15 through transmission parts; the compression spring 14 is arranged between the bottom of the valve plate 11 and the supporting structure.

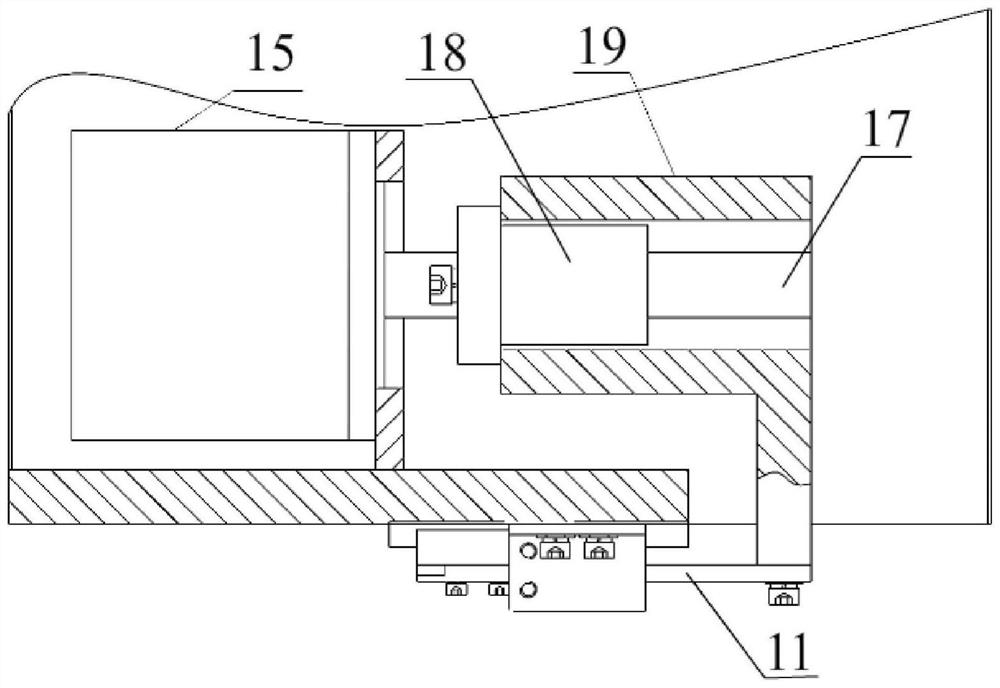

[0022] Such as image 3 As shown, the transmission part includes a linear guide rail 5, a lead screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com