Ternary Metal Modified Molecular Sieve Selective Catalytic Reduction Catalyst for Lean Burn Engine

A ternary metal and molecular sieve technology, used in molecular sieve catalysts, combustion engines, internal combustion piston engines, etc., can solve the problem that low temperature activity cannot meet the requirements of low temperature activity of SCR catalysts, avoid adverse effects, improve thermal aging resistance, The effect of improving low temperature catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

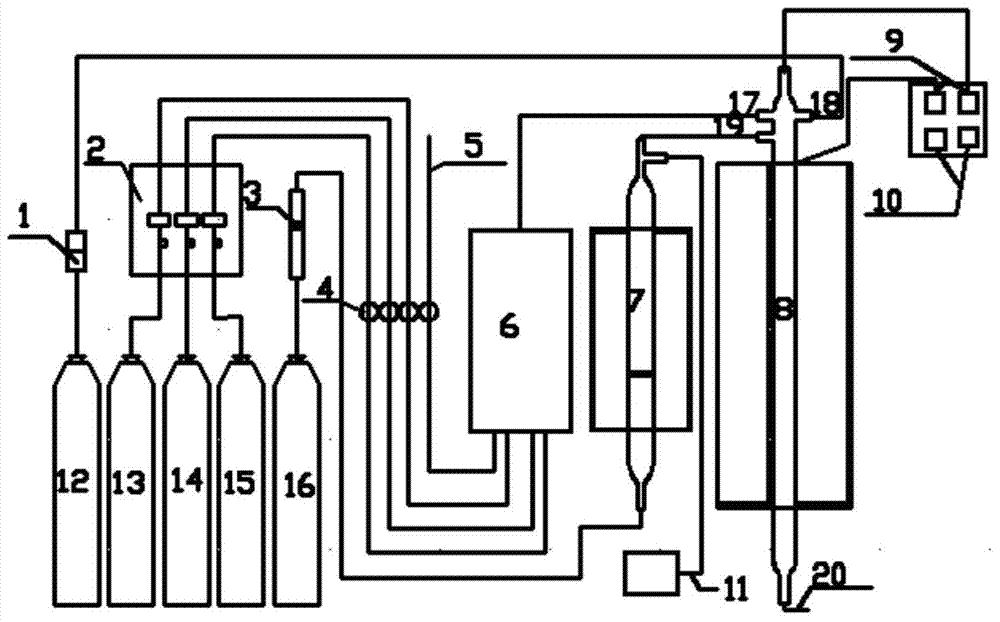

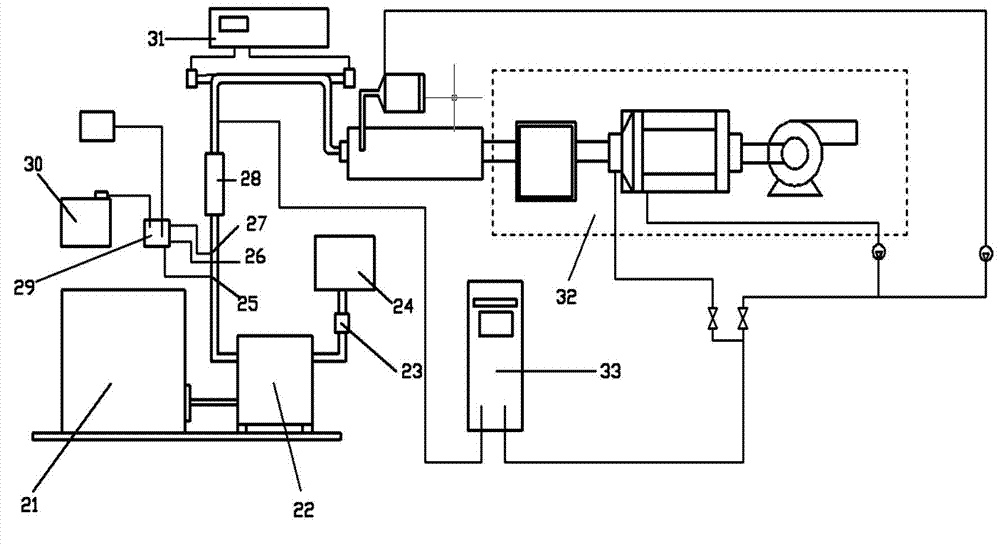

Method used

Image

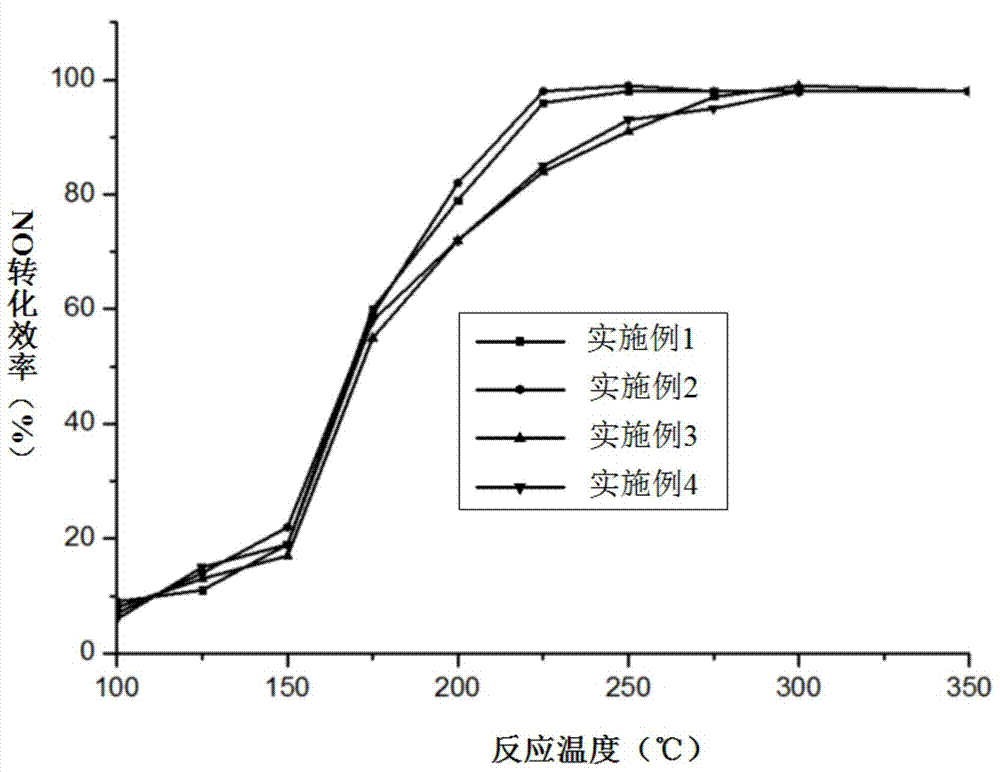

Examples

Embodiment 1

[0034] (1) Determination of the amount of catalyst raw materials used

[0035] The design needs to prepare the ratio of the molar quantity of cerium oxide in the catalyst to the molar quantity of zirconia: 30%:70%; the ratio of the mass sum of copper oxide, cerium oxide and zirconia to the mass of ZSM-5 molecular sieve is: 10.9%:89.1 %; active ingredient and coating matrix γ-Al 2 o 3 The mass ratio is: 40%:60%; pure γ-Al 2 o 3 γ-Al produced by calcination of powder and pseudoboehmite 2 o 3 The mass ratio is: 50%:50%. Determine the total mass of the planned coating to be 50,000g, and calculate that there are 796g of copper oxide, 516g of cerium oxide, 862g of zirconia, 17,826g of ZSM-5 molecular sieve, and pure γ-Al in the coating. 2 o 3 15000g powder, pseudo-boehmite is calcined to generate γ-Al 2 o 3 The mass of 15000g. According to the conversion ratio, it can be calculated that 1997g of copper acetate, 1302g of cerium nitrate and 3005g of zirconium nitrate are req...

Embodiment 2

[0043] (1) Determination of the amount of catalyst raw materials used

[0044] The design needs to prepare the ratio of the molar quantity of cerium oxide in the catalyst to the molar quantity of zirconia: 70%:30%; the ratio of the mass sum of copper oxide, cerium oxide and zirconia to the mass of ZSM-5 molecular sieve is: 23.7%:76.3 %; active ingredient and coating matrix γ-Al 2 o 3 The mass ratio is: 20%:80%; pure γ-Al 2 o 3 γ-Al produced by calcination of powder and pseudoboehmite 2 o 3 The mass ratio is: 50%:50%. It is determined that the total mass of the planned coating is 50000g, and it is calculated that there are 796g of copper oxide, 1205g of cerium oxide, 370g of zirconia, 7629g of ZSM-5 molecular sieve, pure γ-Al 2 o 3 20000g powder, pseudo-boehmite calcined to generate γ-Al 2 o 3 The mass of 20000g. According to the conversion ratio, it can be calculated that 1997g of copper acetate, 3039g of cerium nitrate and 1288g of zirconium nitrate are required to ...

Embodiment 3

[0052] (1) Determination of the amount of catalyst raw materials used

[0053] The ratio of the molar quantity of cerium oxide to the molar quantity of zirconia in the design needs to be prepared is: 30%:70%; the ratio of the mass sum of copper oxide, cerium oxide and zirconia to the mass of ZSM-5 molecular sieve is: 21.7%:78.3 %; active ingredient and coating matrix γ-Al 2 o 3 The mass ratio is: 20%:80%; pure γ-Al 2 o 3 γ-Al produced by calcination of powder and pseudoboehmite 2 o 3The mass ratio is: 70%:30%. Determine the total mass of the planned coating to be 50,000g, from which it is calculated that there are 796g of copper oxide, 516g of cerium oxide, 863g of zirconia, 7825g of ZSM-5 molecular sieve, pure γ-Al 2 o 3 28000g powder, pseudo-boehmite calcined to generate γ-Al 2 o 3 The mass of 12000g. According to the conversion ratio, it can be calculated that 1997g of copper acetate, 1302g of cerium nitrate and 3005g of zirconium nitrate are required to prepare t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com