Au nano catalyst for exhaust purification of internal-combustion engine and preparation method thereof

A nano-catalyst and exhaust gas purification technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. The effect of sustainable development, improved catalytic activity, high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the test sample of the exhaust gas purification catalyst for an internal combustion engine selects a quartz flake with silicon dioxide as the main component as the base material prepared by the Au nanocatalyst. Silica is a common carrier material for exhaust gas purification catalysts for internal combustion engines. Au nanocatalysts supported on ZnO nanowires were prepared by vapor deposition method based on VLS mechanism on a quartz substrate with silica as the main component. The raw materials used are as follows:

[0026] ZnO powder: purity: 99.95%, particle size: 10~100nm;

[0027] Graphite powder: fixed carbon purity: 90~99.9%, specification: 100~2000 mesh;

[0028] Quartz sheet sample: silica content: 99.9%, specifications: length × width × height: 20 × 70 × 3mm;

[0029] Au: purity 99.9%.

[0030] The specific preparation steps are as follows:

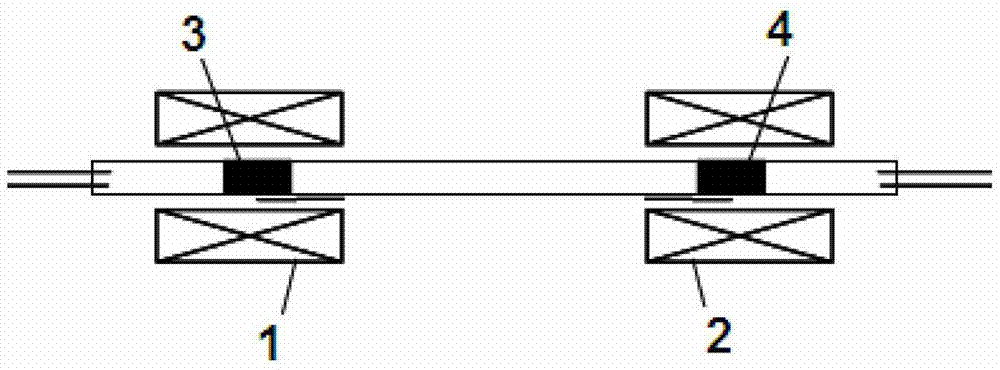

[0031] Step 1, using the magnetron sputtering technology to prepare an Au nanoparticle lattic...

Embodiment 2

[0038] Same as Example 1, with the following differences:

[0039] In step (3), the distance between the two heating tanks is set to 10cm; the gas flow rate is 40ml / min;

[0040] In step (4), the temperature of the upstream tubular heating furnace 1 is controlled at 1150°C, and the temperature of the downstream tubular heating furnace 2 is controlled at 950°C;

[0041] The reaction time in step (5) is 120 minutes.

[0042] Using scanning electron microscope (SEM) observation, the Au nanocatalyst particles are very small and uniform in size, with a particle size between 5 and 10 nm, and the diameter of the ZnO nanowires grown under its catalytic induction is between 10 and 50 nm.

[0043] The catalytic performance of the catalyst was tested by the same method as in Example 1, and the catalytic performance of the Au nanocatalyst was tested by using propane and carbon monoxide with a concentration of 1000 ppm respectively as the sample gas. The experimental results show that fo...

Embodiment 3

[0045] Same as Example 1, with the following differences:

[0046] In step (3), the distance between the two heating tanks is set to 8cm; the gas flow rate is 50ml / min;

[0047] In step (4), the temperature of the upstream tubular heating furnace 1 is controlled at 1100°C, and the temperature of the downstream tubular heating furnace 2 is controlled at 1000°C;

[0048] The reaction time in step (5) is 100 minutes.

[0049] Using scanning electron microscope (SEM) observation, the Au nanocatalyst particles are very small and uniform in size, with a particle size between 5 and 10 nm, and the diameter of the ZnO nanowires grown under its catalytic induction is between 10 and 50 nm.

[0050] The catalytic performance of the catalyst was tested by the same method as in Example 1, and the catalytic performance of the Au nanocatalyst was tested by using propane and carbon monoxide with a concentration of 1000 ppm respectively as the sample gas. The experimental results show that fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com