Patents

Literature

92results about How to "Uniform and small size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

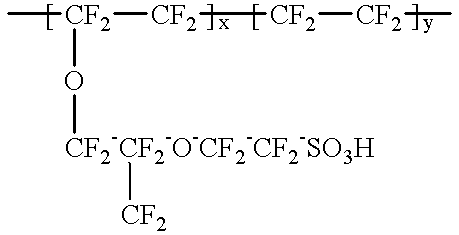

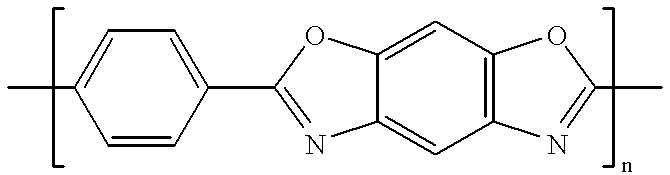

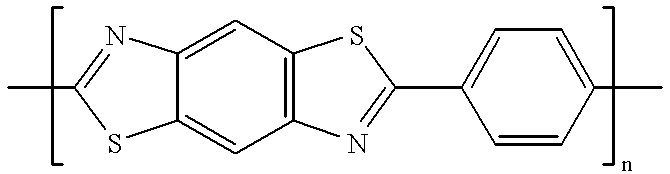

Composite solid polymer elecrolyte membranes

InactiveUS20020045085A1Optimize swellingOptimize fuel crossover resistanceElectrolyte holding meansFinal product manufacturePolymer electrolytesPolymer science

The present invention relates to composite solid polymer electrolyte membranes (SPEMs) which include a porous polymer substrate interpenetrated with an ion-conducting material. SPEMs of the present invention are useful in electrochemical applications, including fuel cells and electrodialysis.

Owner:FOSTER-MILLER

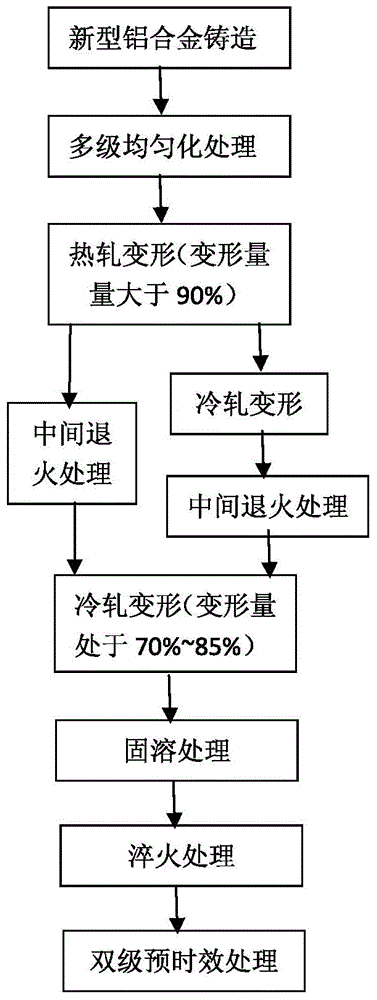

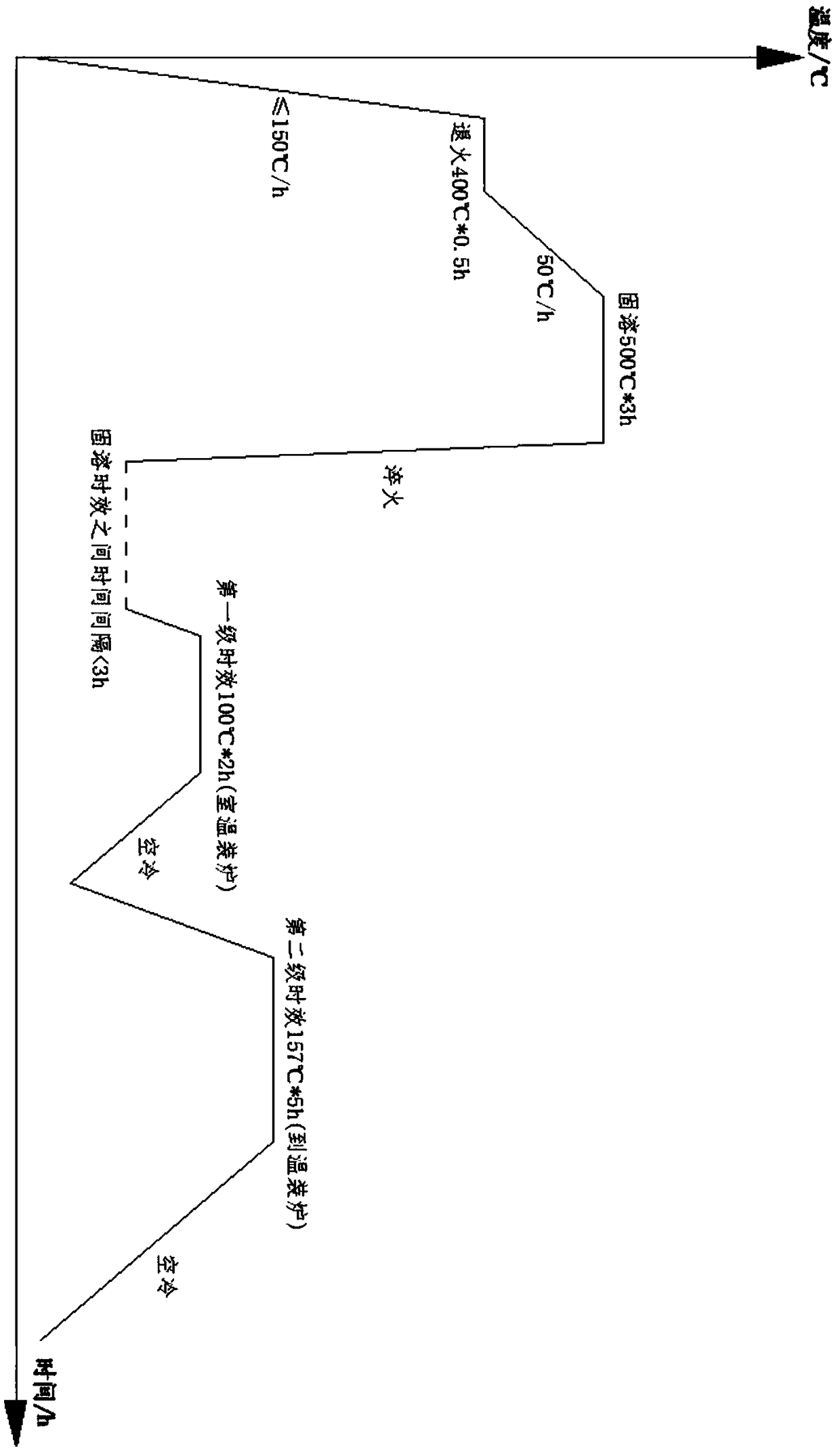

Automotive high-formability aluminum alloy material and preparation method thereof

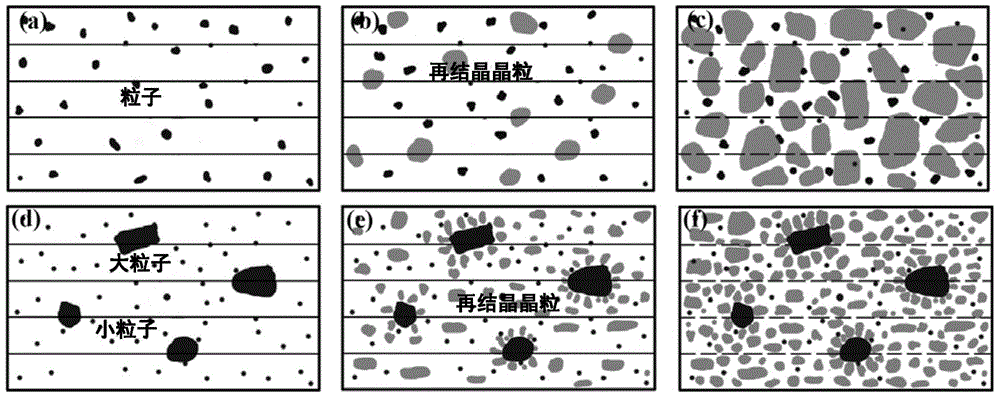

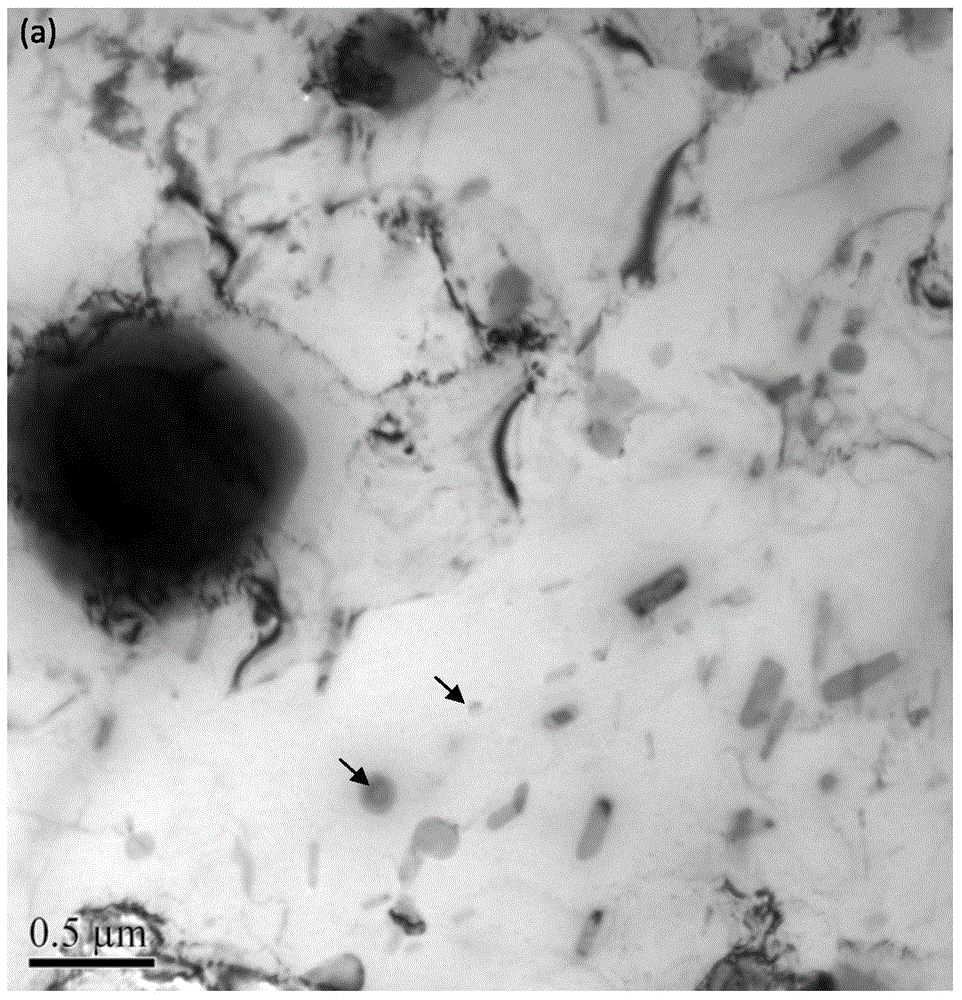

The invention provides an automotive high-formability aluminum alloy material and a preparation method thereof. The preparation method comprises the steps of selection of novel aluminum alloy components, alloy preparation and melting-casting, homogenization, hot rolling deformation, intermediate annealing or cold rolling deformation and intermediate annealing, intermediate annealing, solution treatment, quenching and multistage pre-ageing treatment. By using the double effects that a certain quantity of multi-scale particles can be formed among different solute elements in the alloy material and then oversize particles are stimulated, re-crystallized and nucleated while fine particles block the growth of the re-crystallized grains in the high-temperature heat treatment process, so that the structure of an alloy plate is formed by the fine and uniformly distributed re-crystallized grains, the anisotropy of the alloy plate is well controlled, and the stamping forming performance is relatively excellent. Meanwhile, the novel aluminum alloy with high formability and high baking varnish hardening increment is very suitable for manufacturing of automotive body outer plates, particularly manufacturing of parts having relatively high requirements for stamping formability and baking varnish hardening increment and having complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

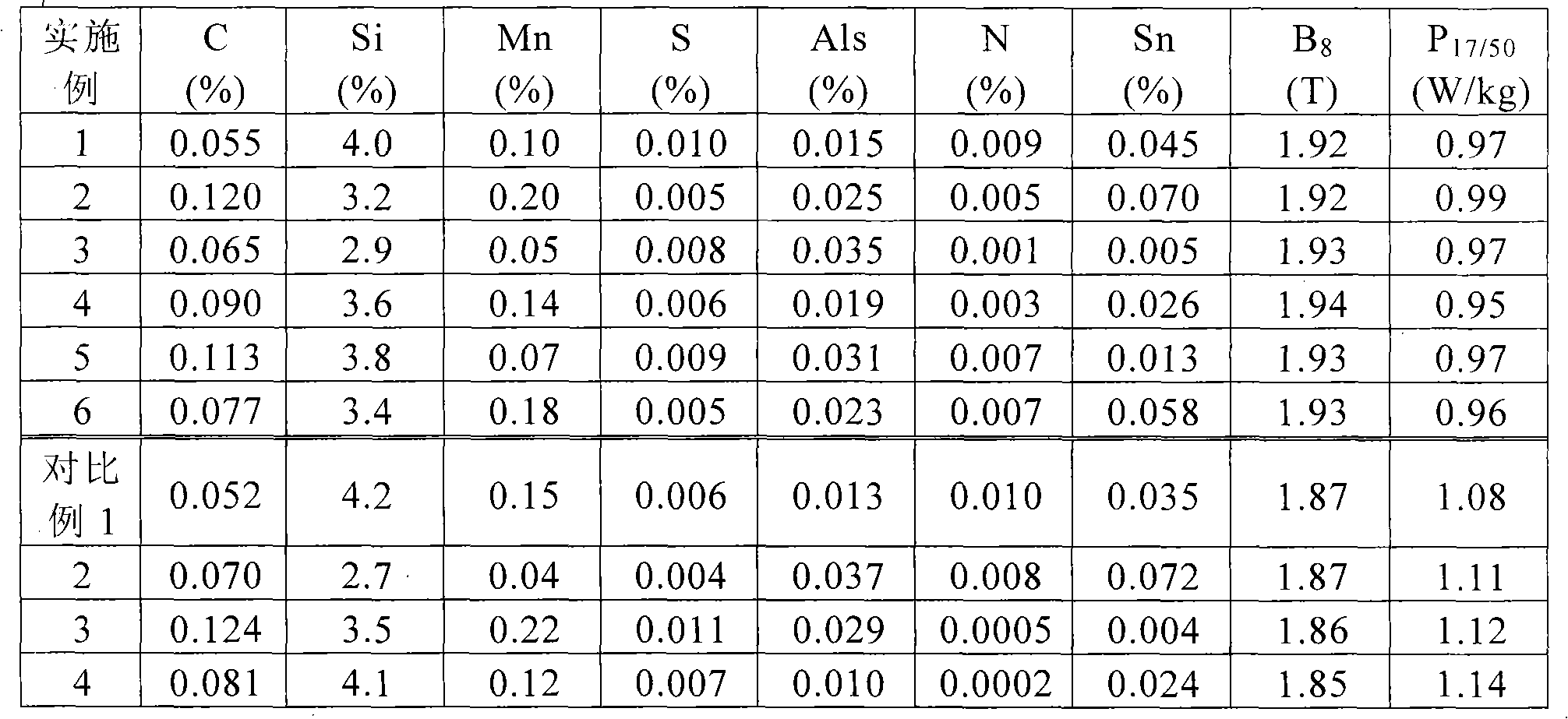

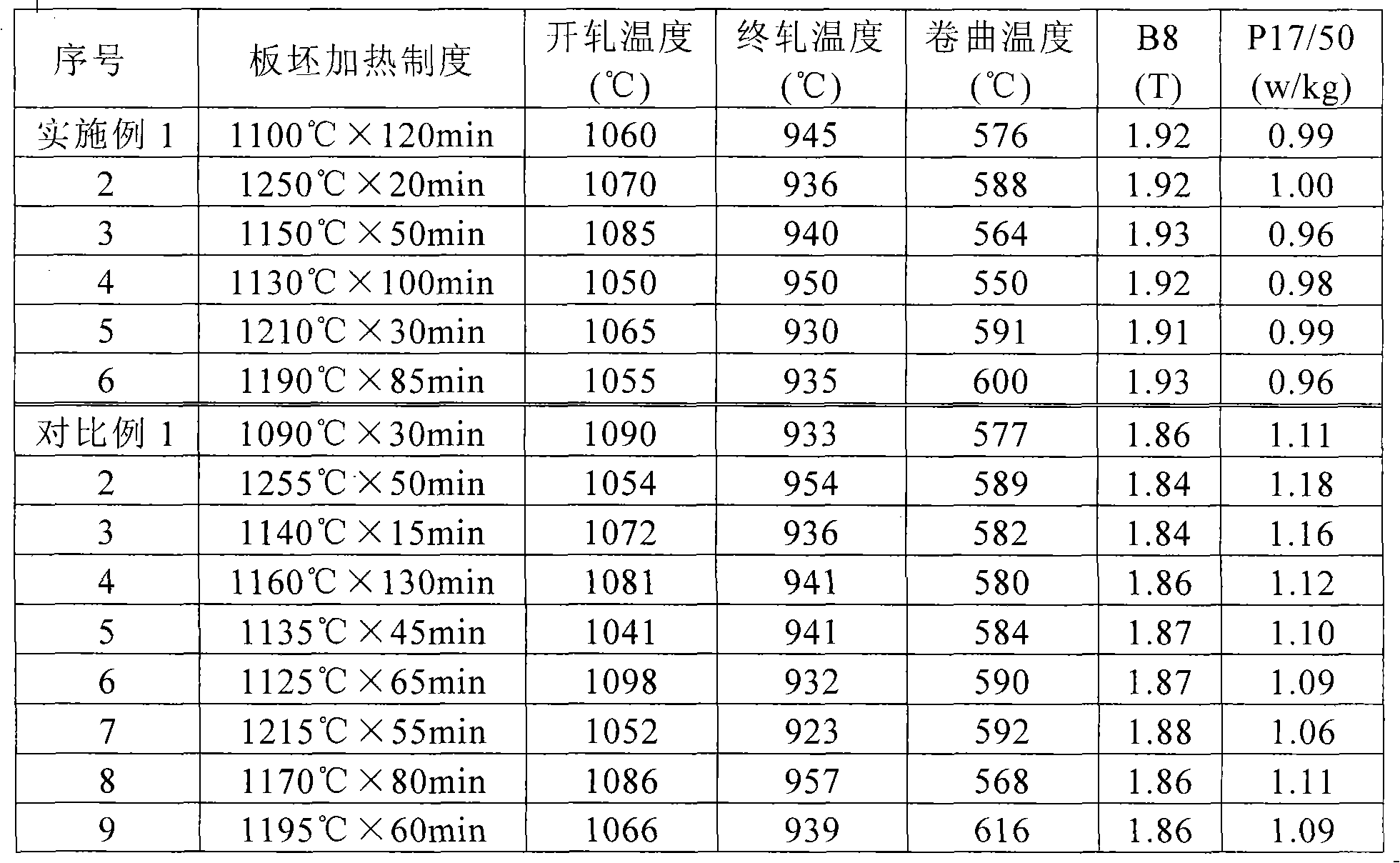

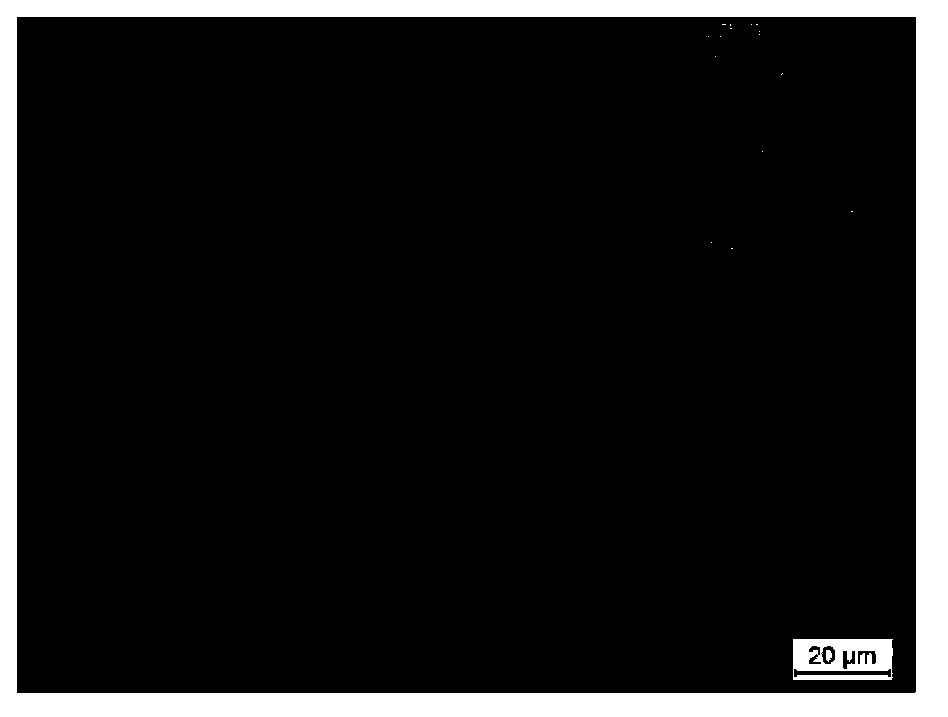

Production method of high magnetic induction oriented silicon steel

ActiveCN101845582AIncrease contentPrevent transverse crackingSolid state diffusion coatingSiliconAtmosphere

The invention relates to a production method of high magnetic induction oriented silicon steel, comprising the steps of smelting, continuous casting, hot rolling, normalization, decarbonization and annealing, MgO coating, high-temperature annealing and insulation coating, wherein the normalization comprises the steps that: normalization is carried out on a hot rolling plate, nitridation is finished synchronously, the temperature of normalization and nitridation is 1050-1150 DEG C, the atmosphere is 5-35% NH3 (volume percentage), and the balance of gas is N2; after the normalization and nitridation, the N content nitrided into the hot rolling plate is 60-250ppm; and normalization cooling is carried out, the initial temperature of fast cooling is 700-950 DEG C, and the fast cooling speed with the temperature of being reduced to 550 DEG C is 15-40 DEG C / sec. The production method solves the problem of difficult nitridation in the decarbonization procedure when a low-temperature plate blank heating technology is used for producing the high magnetic induction oriented silicon steel, carries out synchronous nitridation on the hot rolling plate in the normalization procedure, and leads the following procedure of decarbonization and annealing techniques to be simplified and easily controlled, thus not only being capable of obtaining a high magnetic induction oriented silicon steel product with excellent performance and simultaneously leading the production cost to be reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

390 MPa class low-temperature hull steel having excellent toughness and manufacturing method thereof

ActiveCN103882297ALow elemental contentReduce contentTemperature control deviceReduction rateNiobium

The invention discloses 390 MPa class low-temperature hull steel having excellent toughness and a manufacturing method thereof. The hull steel comprises, by weight, 0.05-0.12% of carbon, 0.08-0.30% of silicon, 1.0-1.40% of manganese, not more than 0.01% of phosphorus, not more than 0.01% of sulphur, 0.01-0.05% of aluminum, 0.02-0.04% of niobium, 0.005-0.020% of titanium with the balance being ferrum and unavoidable impurities. A first stage rolling temperature is 1050-1100 DEG C, a total reduction rate is not less than 60% and a finish rolling temperature is 900-940 DEG C; a second stage rolling temperature is 850-900 DEG C, the total reduction rate is not less than 60% and the finish rolling temperature is 790-880 DEG C. The steel is the steel is subjected to ultra-rapid cooling at a cooling speed of larger than 30 DEG C per second and is cooled at a cooling speed of larger than 10 DEG C per second in a manner of laminar flow; a self-tempering temperature of the steel ranges from 580-640 DEG C and the final cooling temperature of the steel ranges from 500-630 DEG C; and the steel is air cooled to the room temperature.

Owner:ANGANG STEEL CO LTD

Ferrous phosphate (II) powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

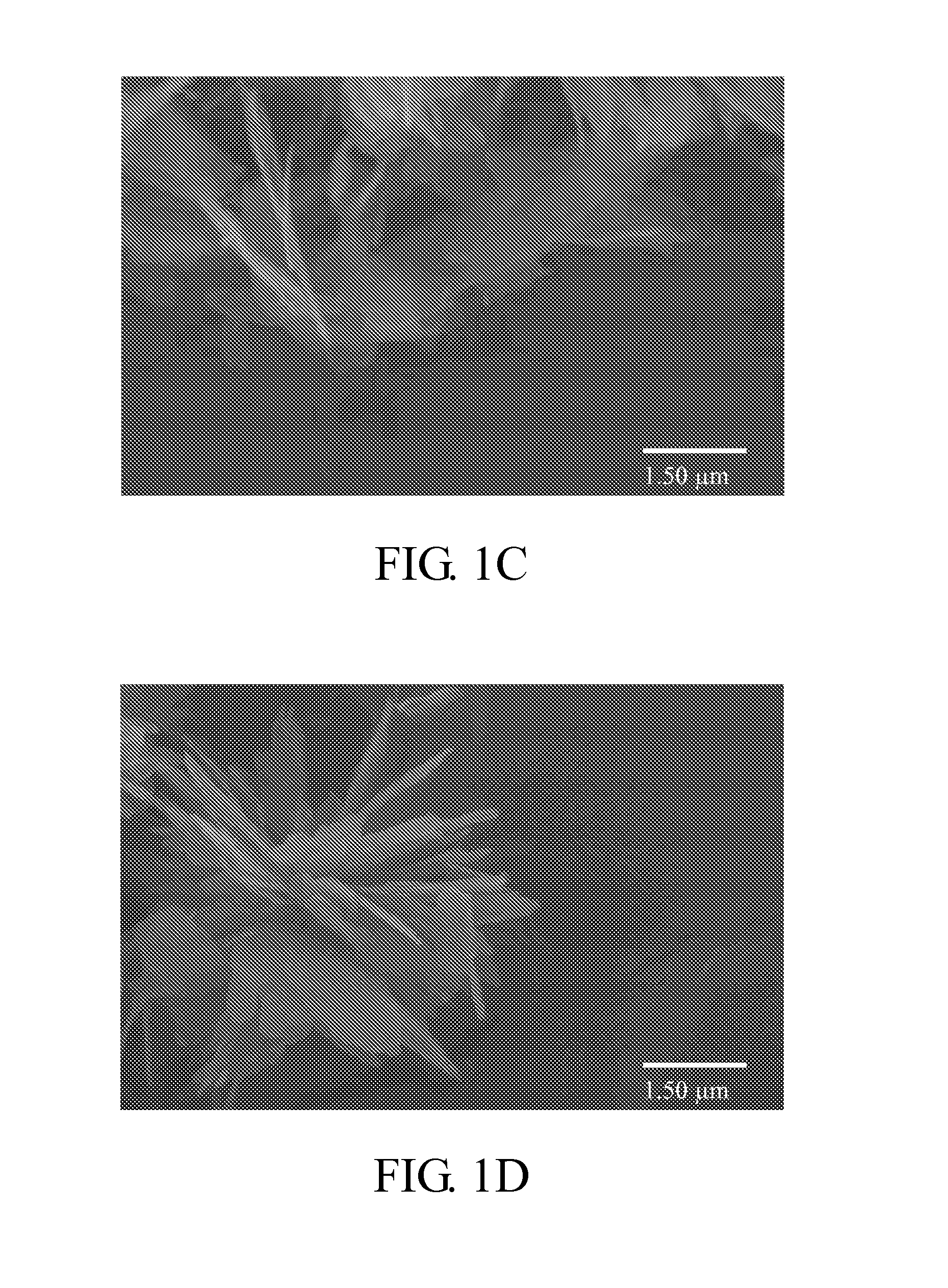

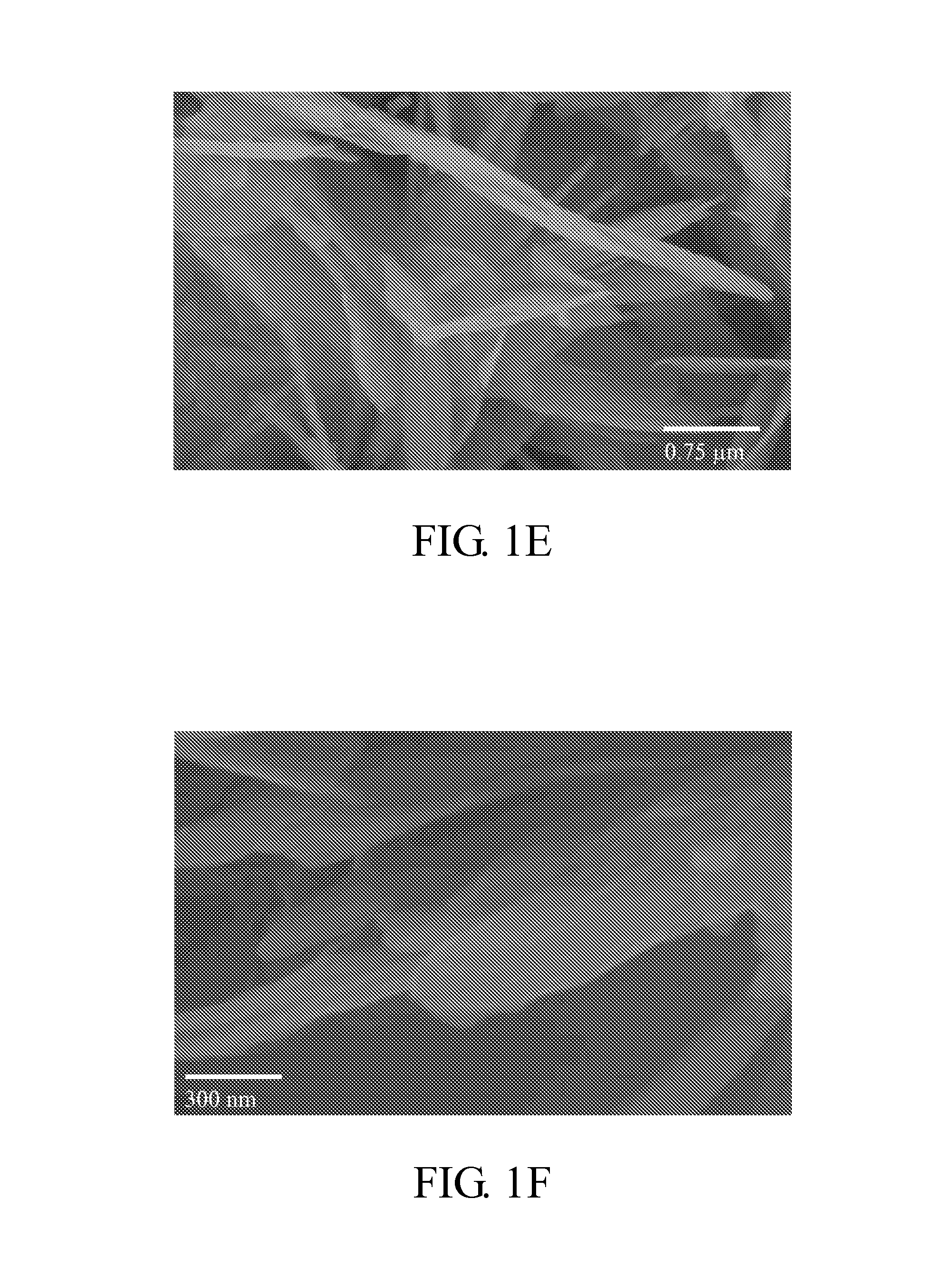

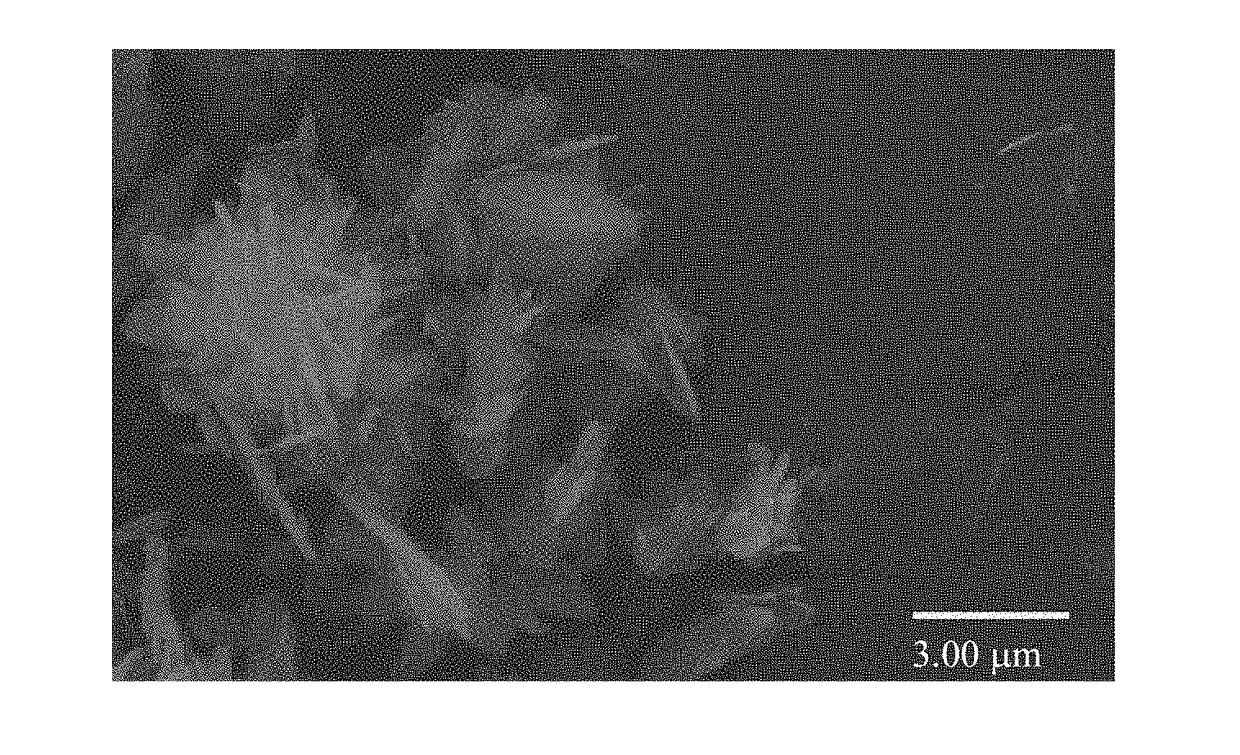

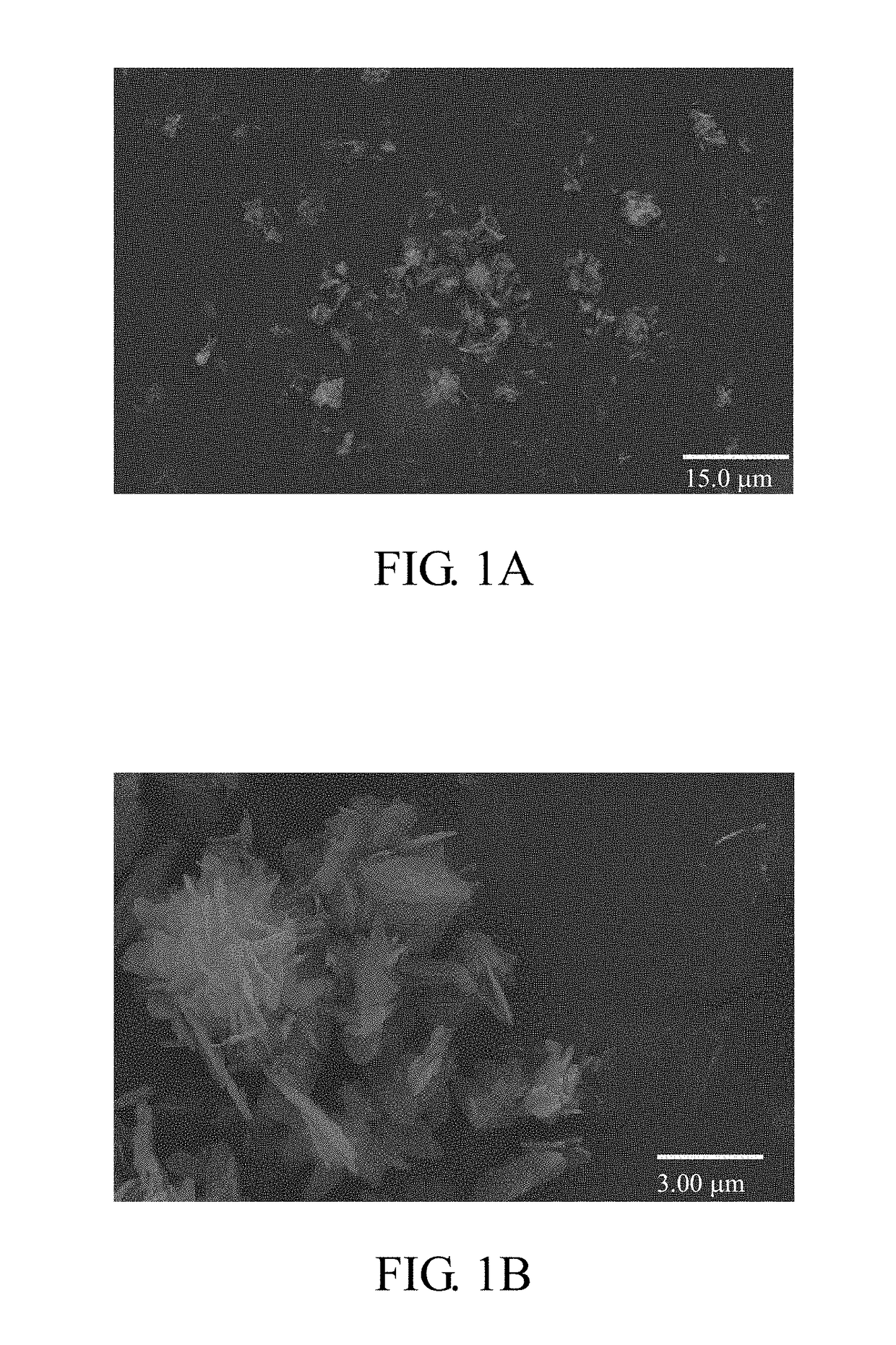

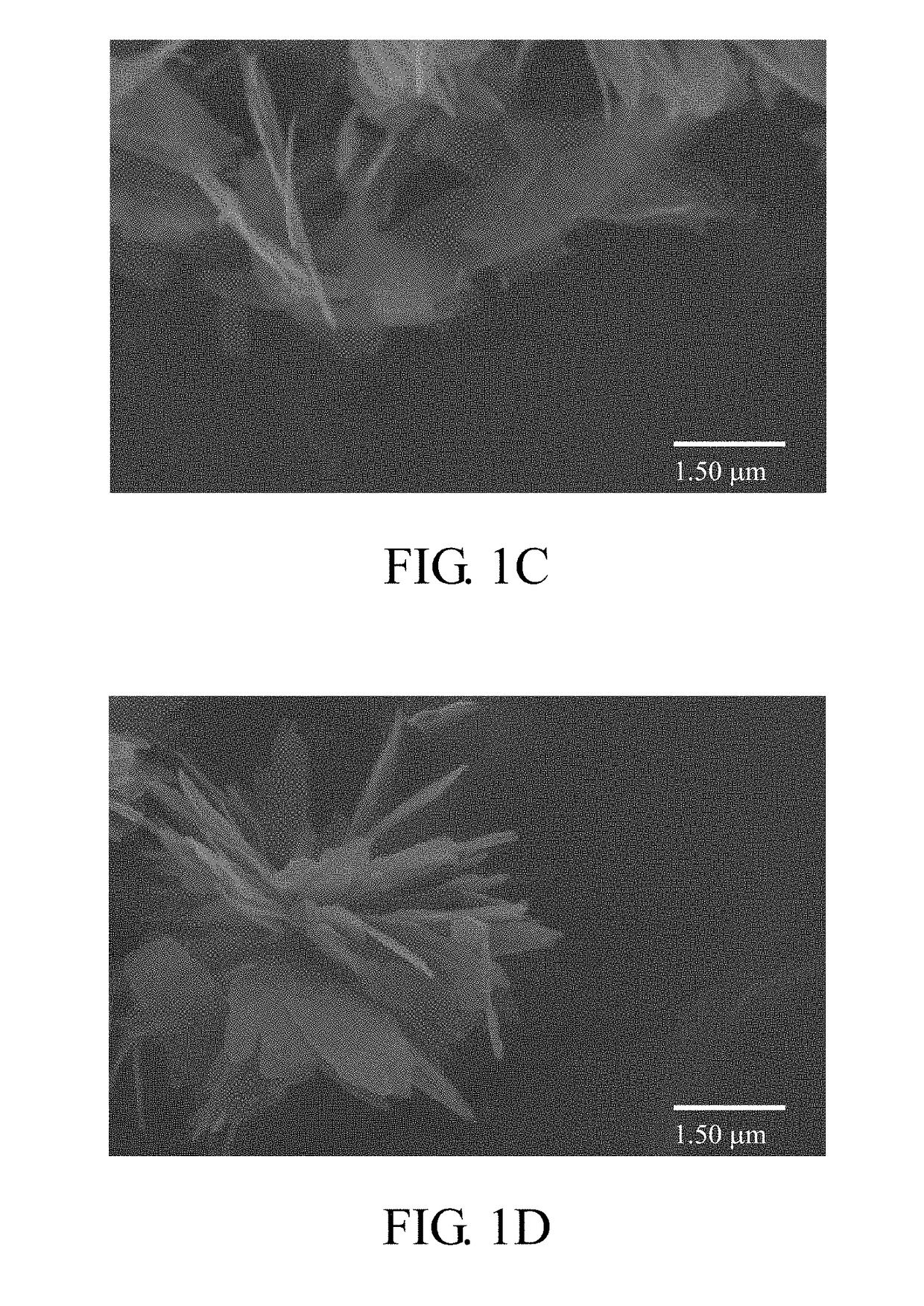

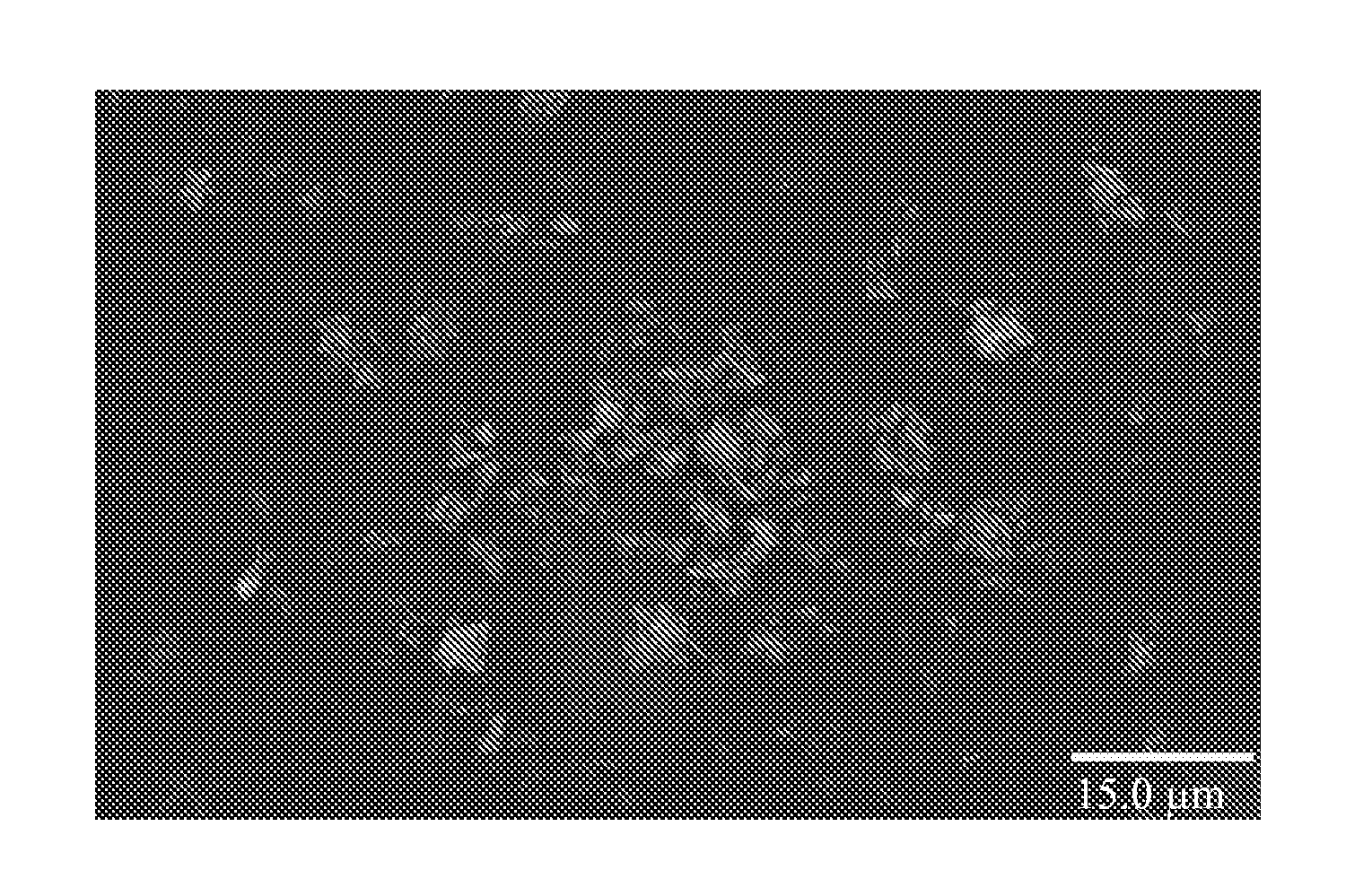

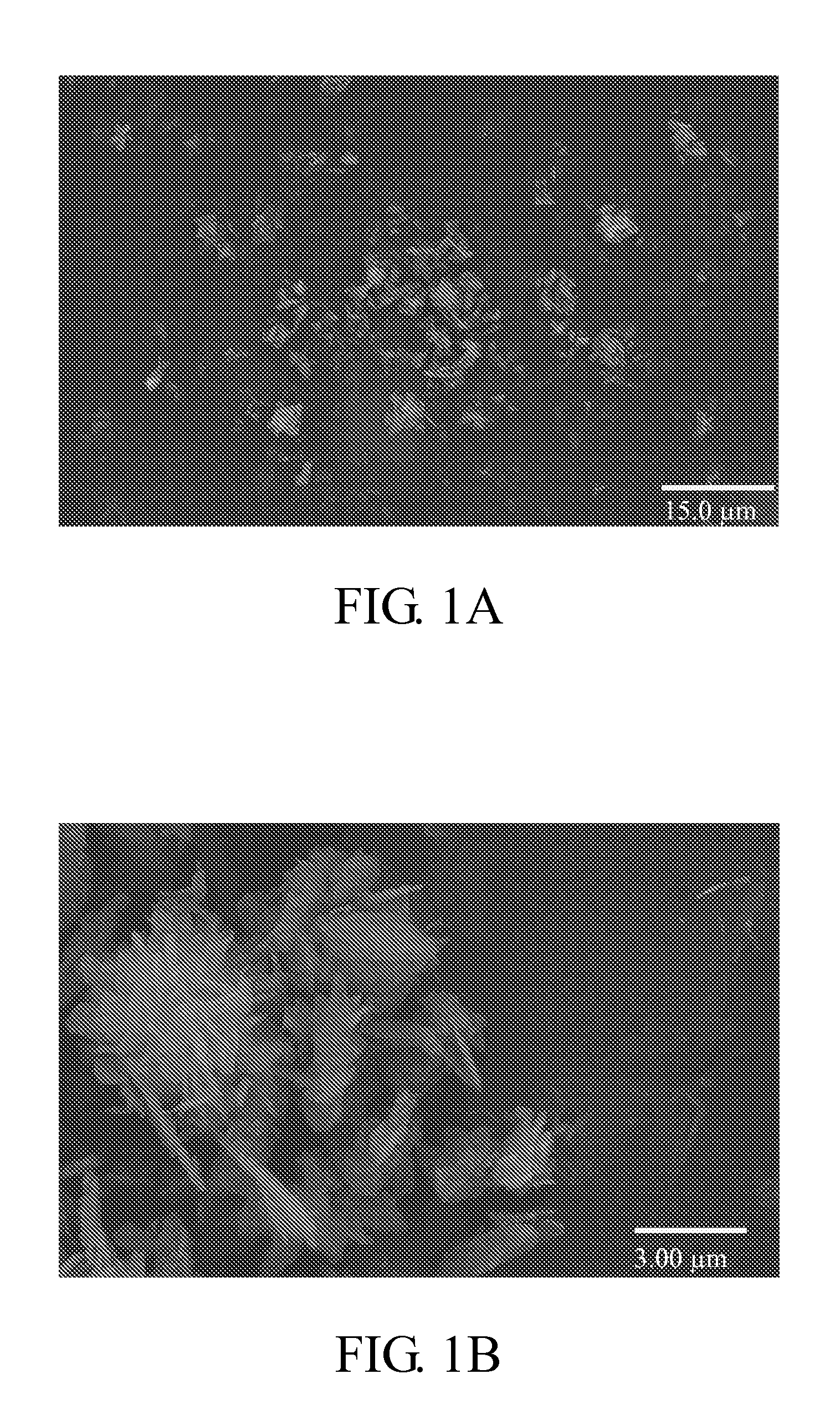

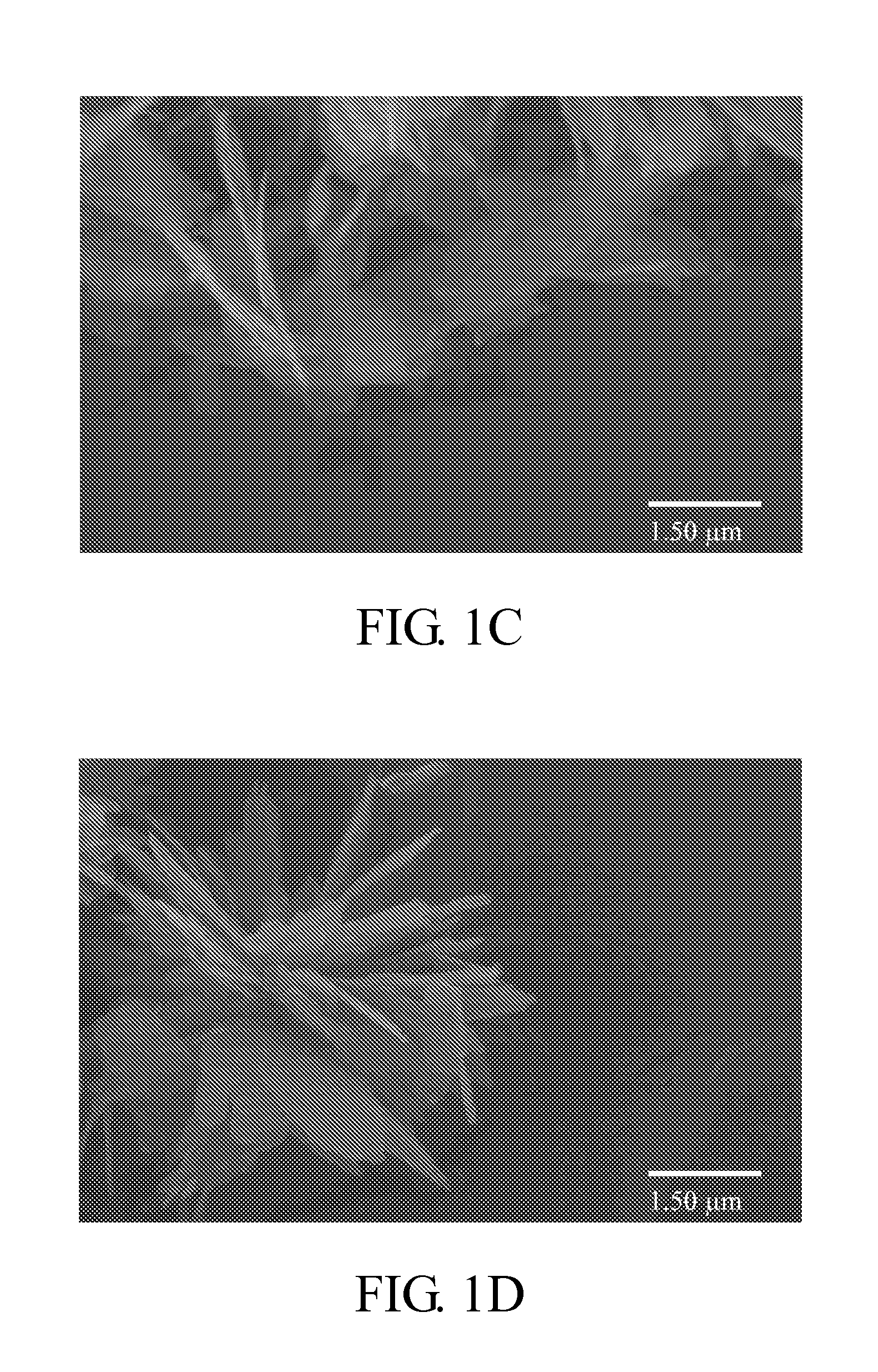

ActiveUS20120321958A1Uniform and small grain sizeUniform and small sizePhosphatesConductive materialLithium iron phosphatePhosphate

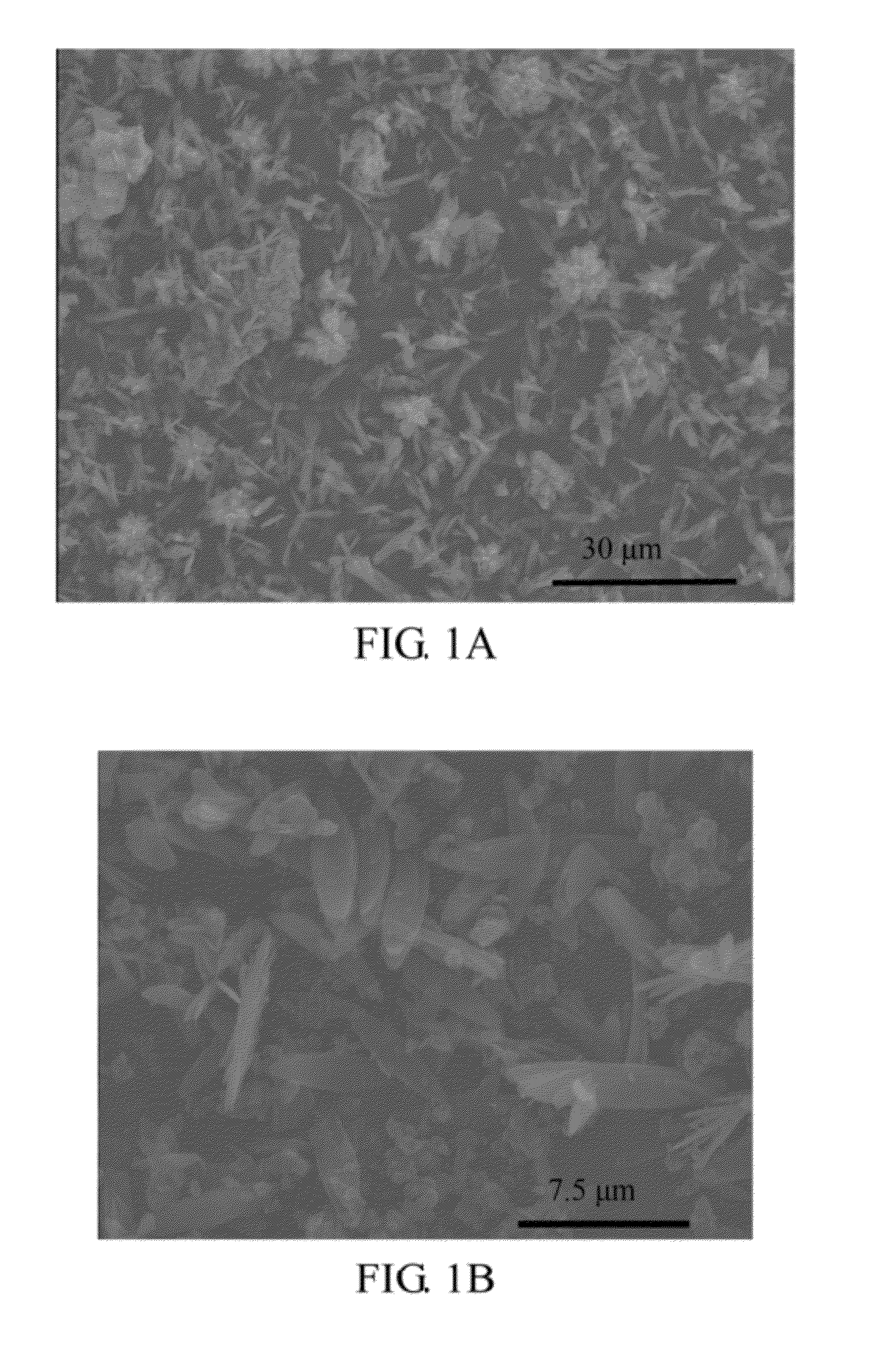

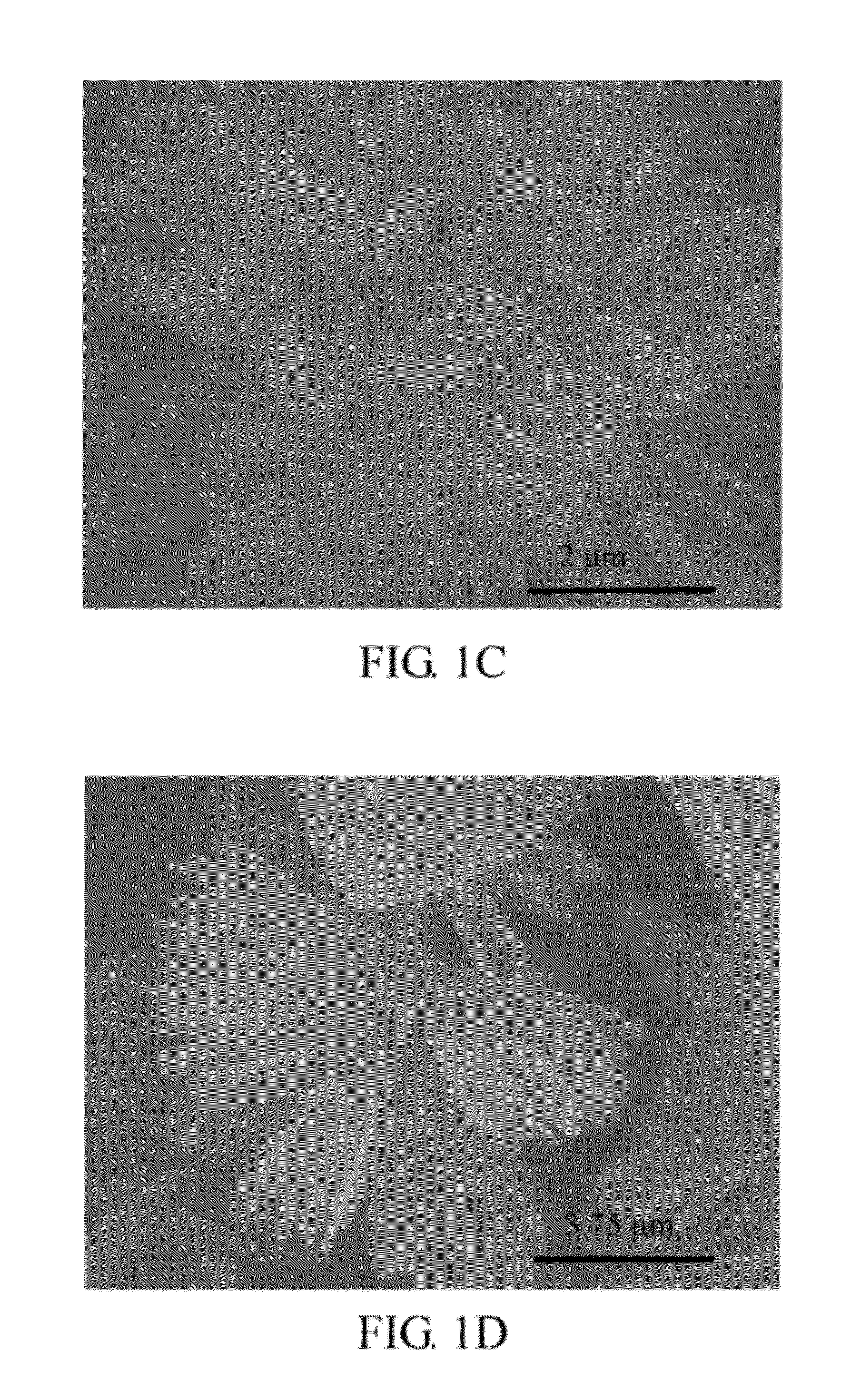

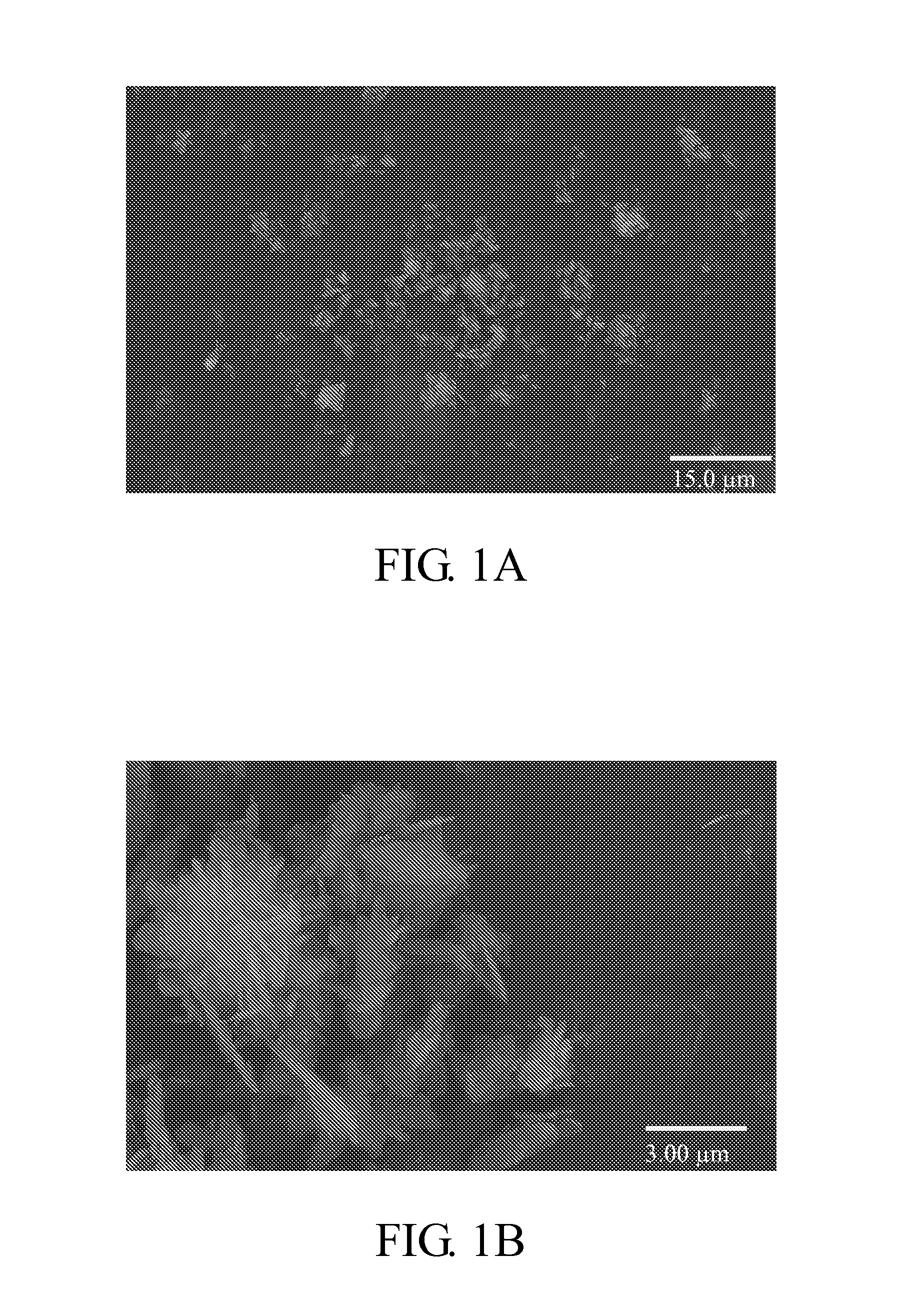

Ferrous phosphate (II) (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The ferrous phosphate (II) powders are represented by the following formula (I):Fe(3-x)Mx(PO4)2.yH2O (I)wherein, M, x, and y are defined in the specification, the ferrous phosphate (II) powders are composed of plural flake powders, and the length of each of the flake powders is 0.5-10 μm.

Owner:NATIONAL TSING HUA UNIVERSITY +1

Trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof

The invention belongs to the field of powder metallurgy sintering, in particular refers to a trace cobalt-containing tungsten carbide without bonding phase and preparation method thereof. A hard alloy comprises components, by weight, as follows: 0.20-1.00% of Co, 0.01-0.50% of Cr3C2, 0.01-0.50% of VC and the balance of WC with grain size of 0.2-0.8 mum. The preparation method comprises the steps of: carrying out feeding and high energy ball milling according to the above raw material powder ratio, until WC powder in the ball milling powder has an average grain size refined to less than 200nm; then sintering the cemented carbide powder rapidly after the high energy ball milling by discharge plasma. The tungsten carbide base cemented carbide powder of the invention has reasonably designed components and a simple preparation method; the powder gives out heat uniformly and has fast heating and cooling speed, low sintering temperature and short sintering time to save the energy greatly; and the obtained ultrafine-grained WC cemented carbide has excellent integrated properties.

Owner:江西长裕硬质新材料有限公司

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

Direct contact quench crystallization process and cosmetic products produced thereby

Owner:PROCTER & GAMBLE CO

Surface or local gradient reinforced wear resistant manganese steel composite material and preparing process

InactiveCN1616706AUniform and small sizeGood wettabilitySolid state diffusion coatingWear resistantHardness

The present invention relates to surface or locally gradient reinforced antiwear composite manganese steel material and its preparation process. The composite material has matrix of austenite with relatively high toughness; reinforcing layer comprising TiC with relatively high hardness, martensite and metastable austenite; and intermediate transition layer comprising gradient varying TiC, martensite and austenite. The preparation process includes the following steps: designing metastable austenite manganese steel matrix composition with C 0.8-1.3 wt% and Mn 6-13 wt%; setting Ti-Fe alloy powder as composite medium in special parts of the cast mold and casting high temperature manganese steel melt to obtain the surface or local TiC reinforcement plus metastable austenite as-cast structure; and liquid nitrogen deep cooling the surface or local to obtain phase changed gradient martensite layer. The present invention can raise comprehensive mechanical performance of manganese steel.

Owner:JILIN UNIV

Direct contact quench crystallization process and cosmetic products produced thereby

InactiveUS20070092541A1Improve uniformityUniform and small sizeCosmetic preparationsToilet preparationsSolventCrystallization

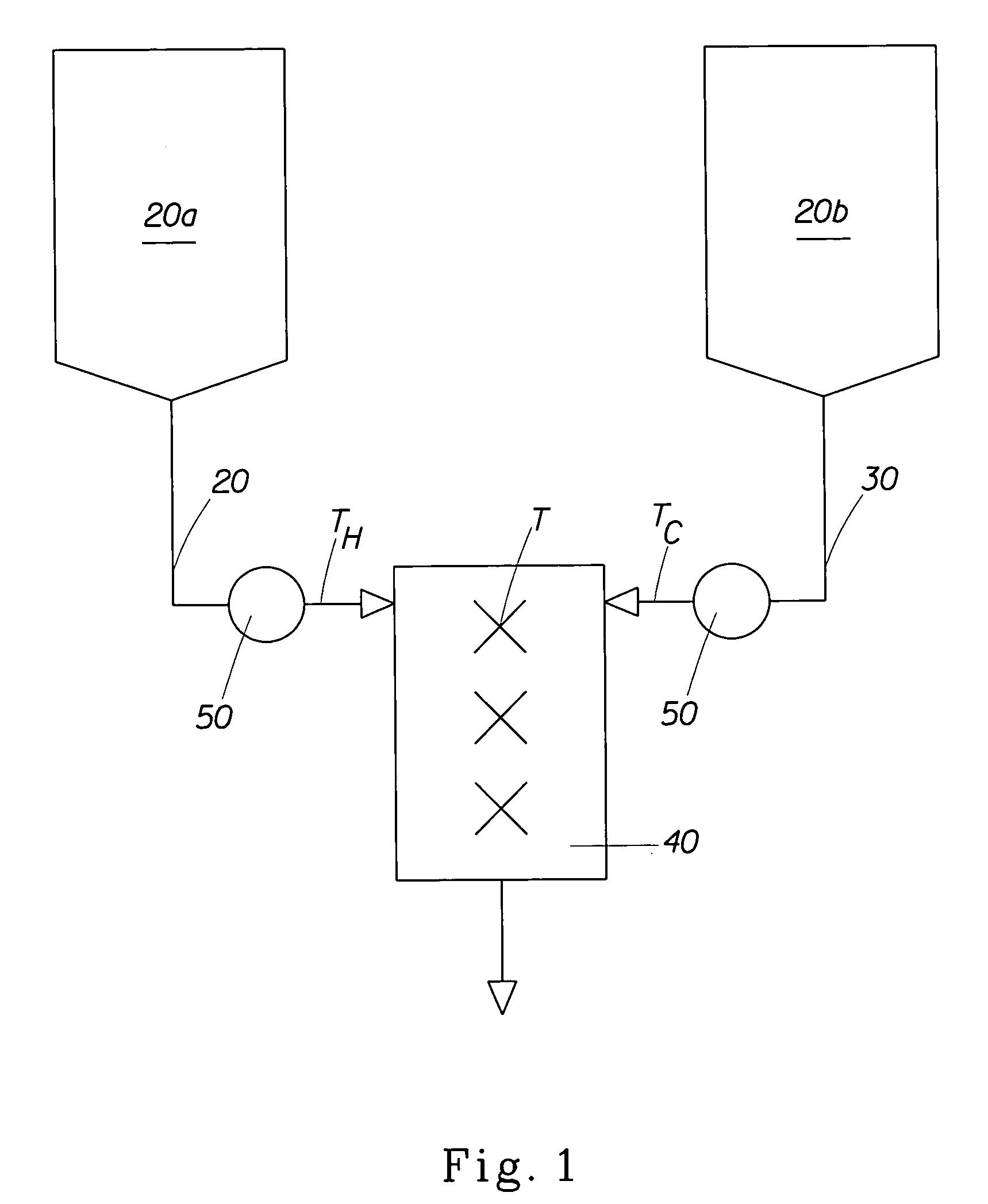

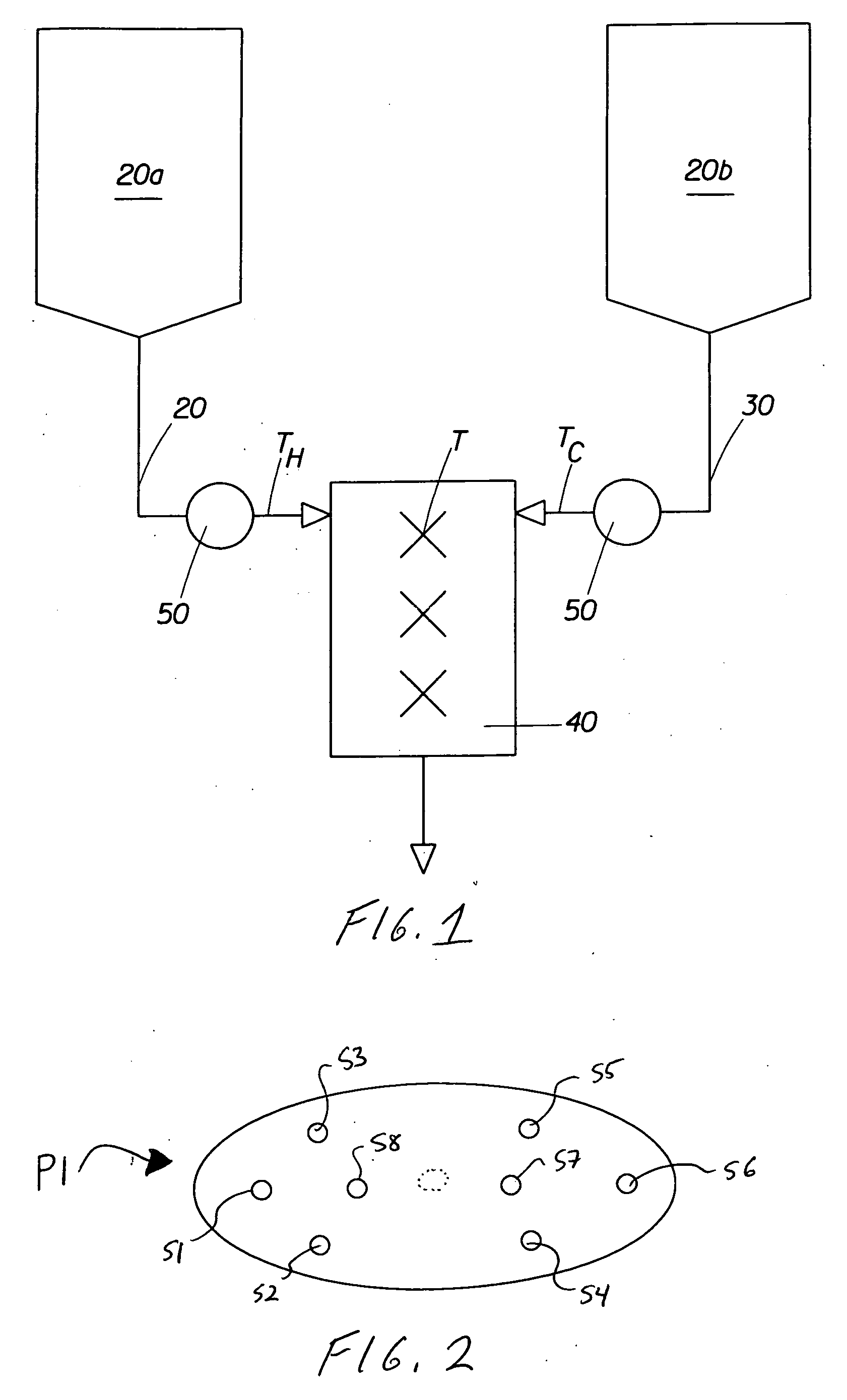

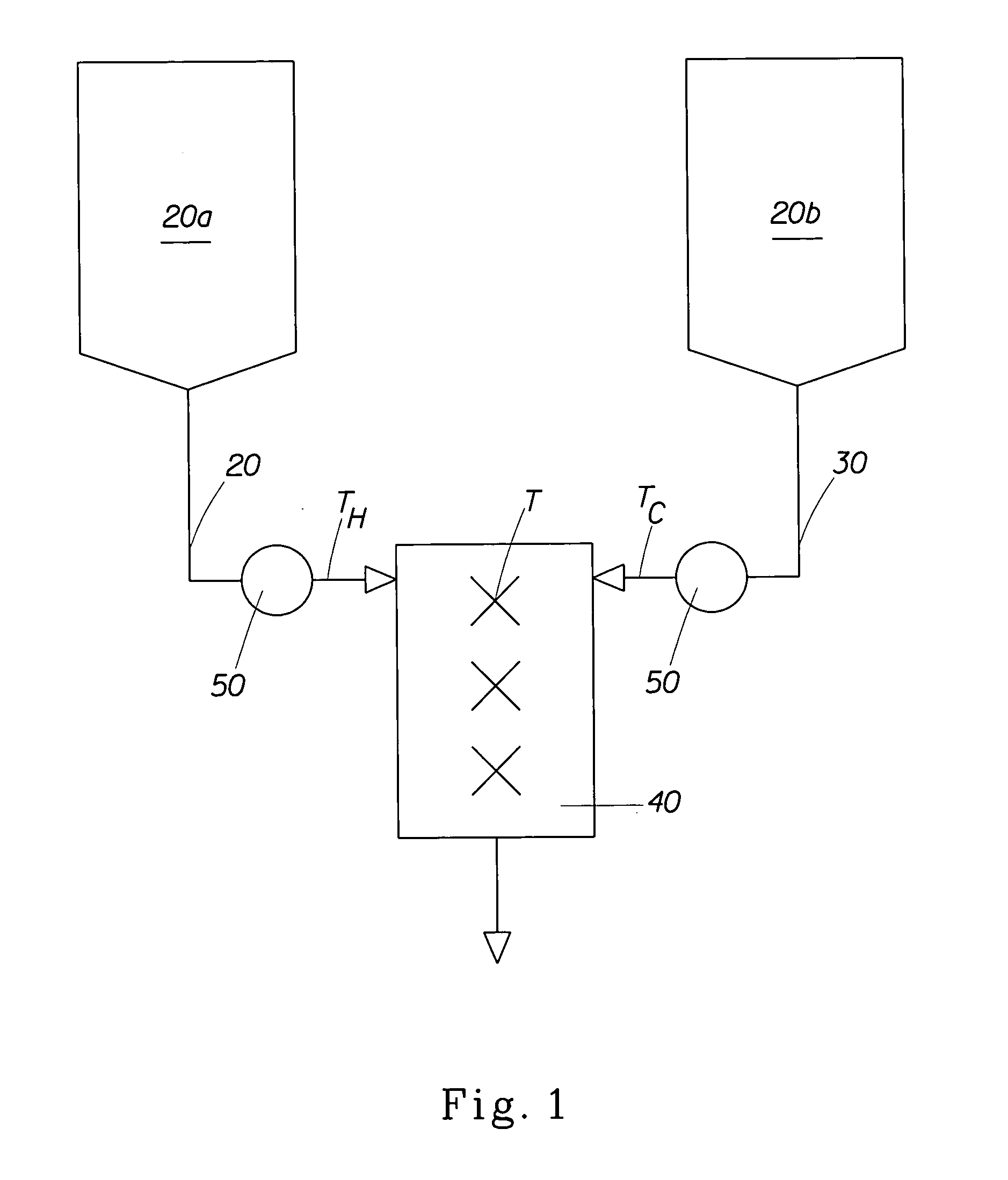

A process for making a solid cosmetic composition comprising the steps of: forming at least one hot process stream comprising a solvent and a gellant dissolved therein, the hot process stream having a first temperature; forming at least one cold process stream comprising a cosmetic active having a second temperature lower than the first temperature; and combining the at least one hot process stream and the at least one cold process stream together in a mixing chamber.

Owner:THE PROCTER & GAMBLE COMPANY

Direct contact quench crystallization process and cosmetic products produced thereby

A process for making a solid cosmetic composition, the process comprising the steps of: forming at least one hot process stream comprising a solvent and a gellant dissolved therein, the hot process stream having a first temperature; forming at least one cold process stream comprising a cosmetic active having a second temperature, wherein the second temperature is at least 5 degrees C. below the first temperature; combining the at least one hot process stream and the at least one cold process stream together in a mixing chamber having no moving parts therein and without applying external source of cooling, to form a substantially homogeneous product stream.

Owner:THE PROCTER & GAMBLE COMPANY

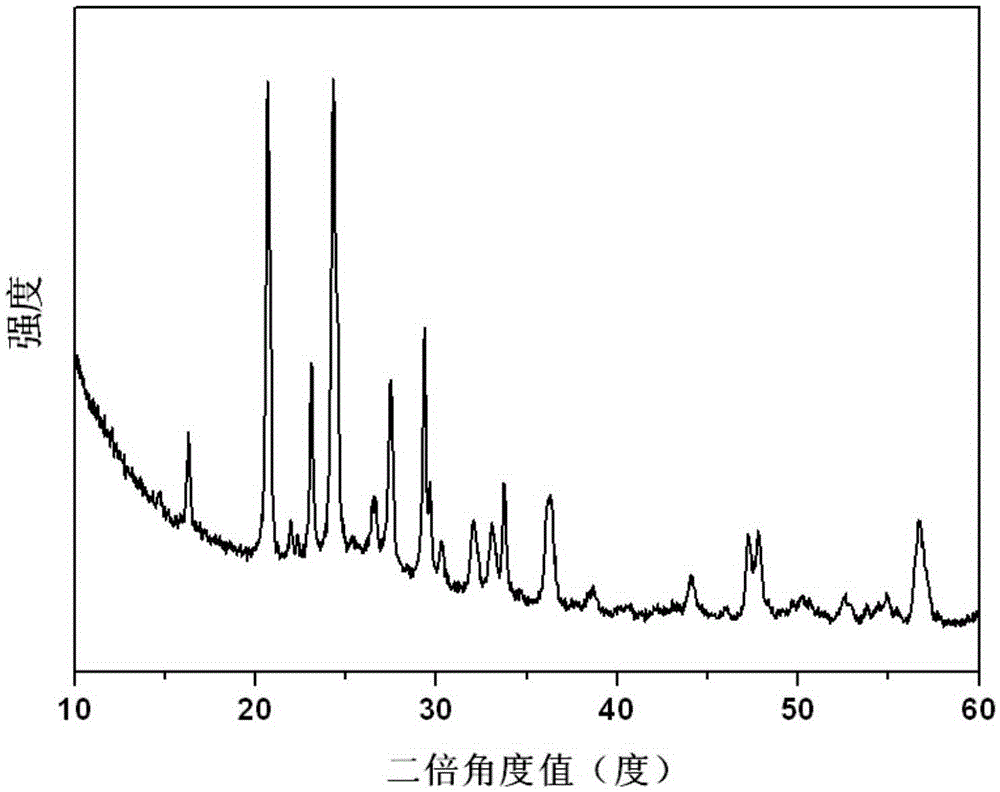

Ferrous phosphate powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20150232338A1Improve conductivitySmall sizeNon-metal conductorsCell electrodesLithium iron phosphatePhosphate

Ferrous (II) phosphate (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The lithium iron phosphate powders are represented by the following formula (II):LiFe(1-a)MaPO4 (II)wherein, M, and a are defined in the specification, the lithium iron phosphate powders are composed of plural flake powders, the length of each of the flake powders is 0.1-10 μm, and a ratio of the length and the thickness of each of the flake powder is in a range from 11 to 400.

Owner:NATIONAL TSING HUA UNIVERSITY

Ferrous phosphate powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20180118569A1Improve conductivitySmall sizeNon-metal conductorsCell electrodesLithium iron phosphatePhosphate

Ferrous (II) phosphate (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The lithium iron phosphate powders are represented by the following formula (II):LiFe(1-a)MaPO4 (II)wherein, M, and a are defined in the specification, the lithium iron phosphate powders are composed of plural flake powders, the length of each of the flake powders is 0.1-10 μm, and a ratio of the length and the thickness of each of the flake powder is in a range from 11 to 400.

Owner:NATIONAL TSING HUA UNIVERSITY

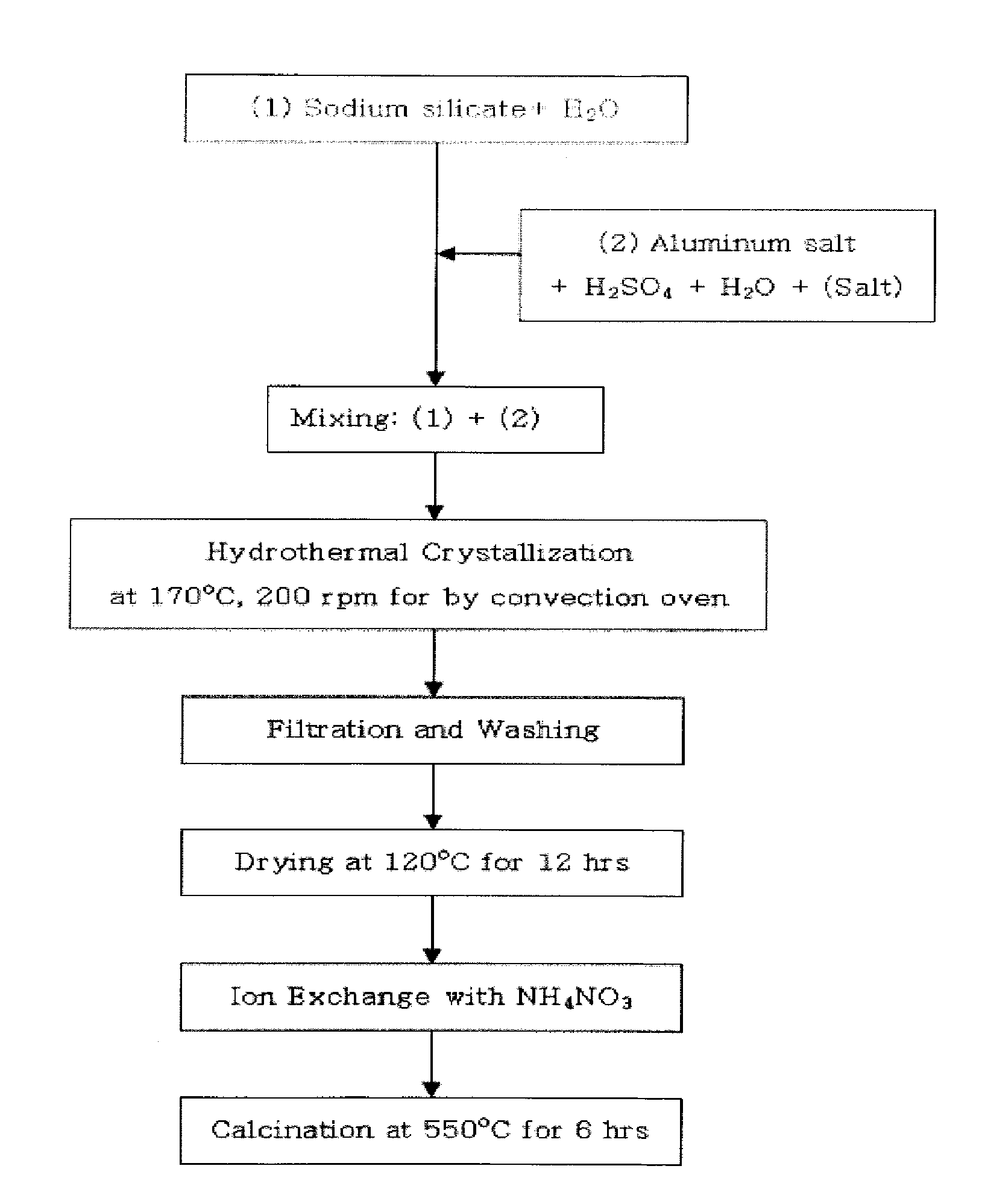

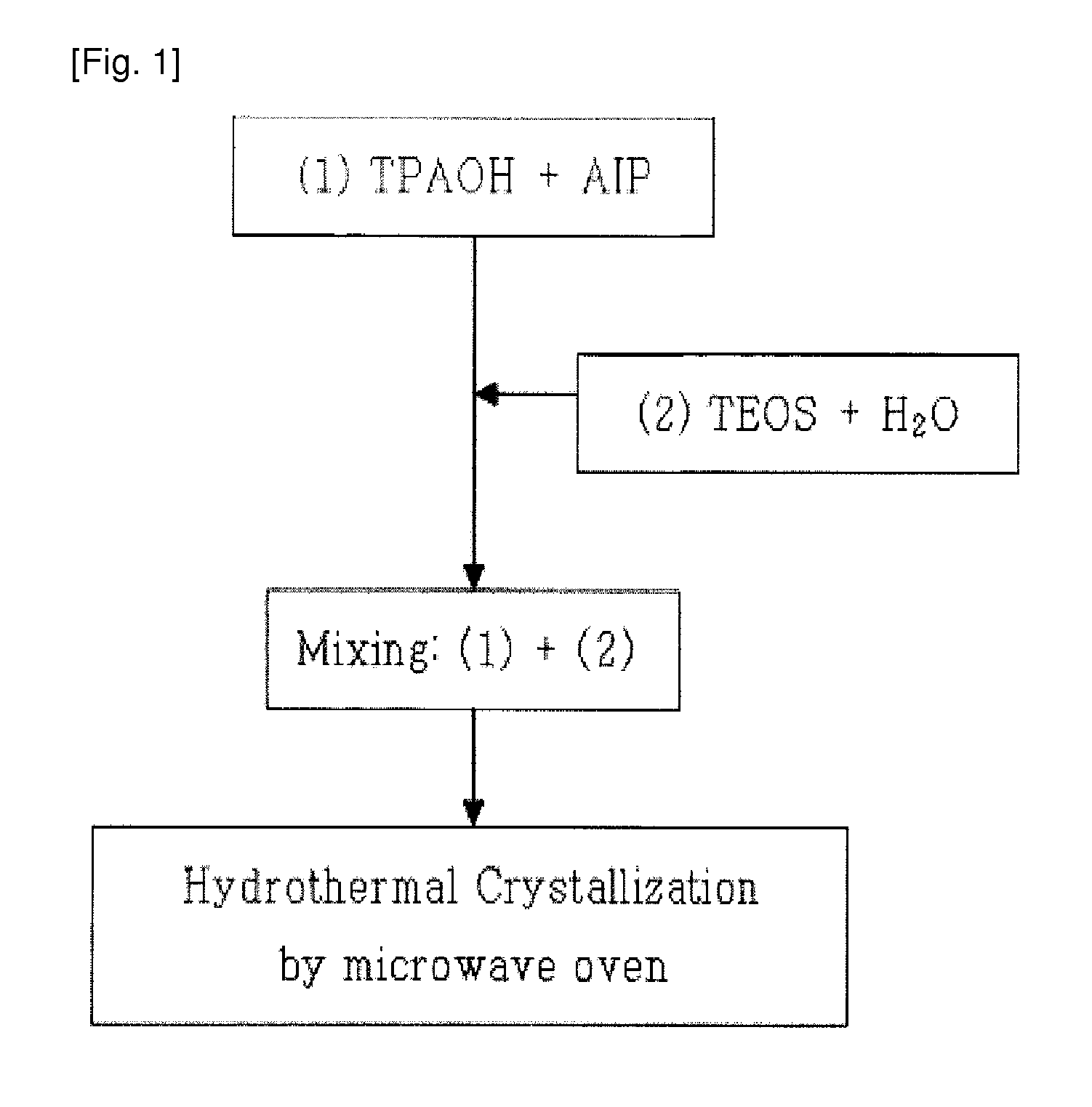

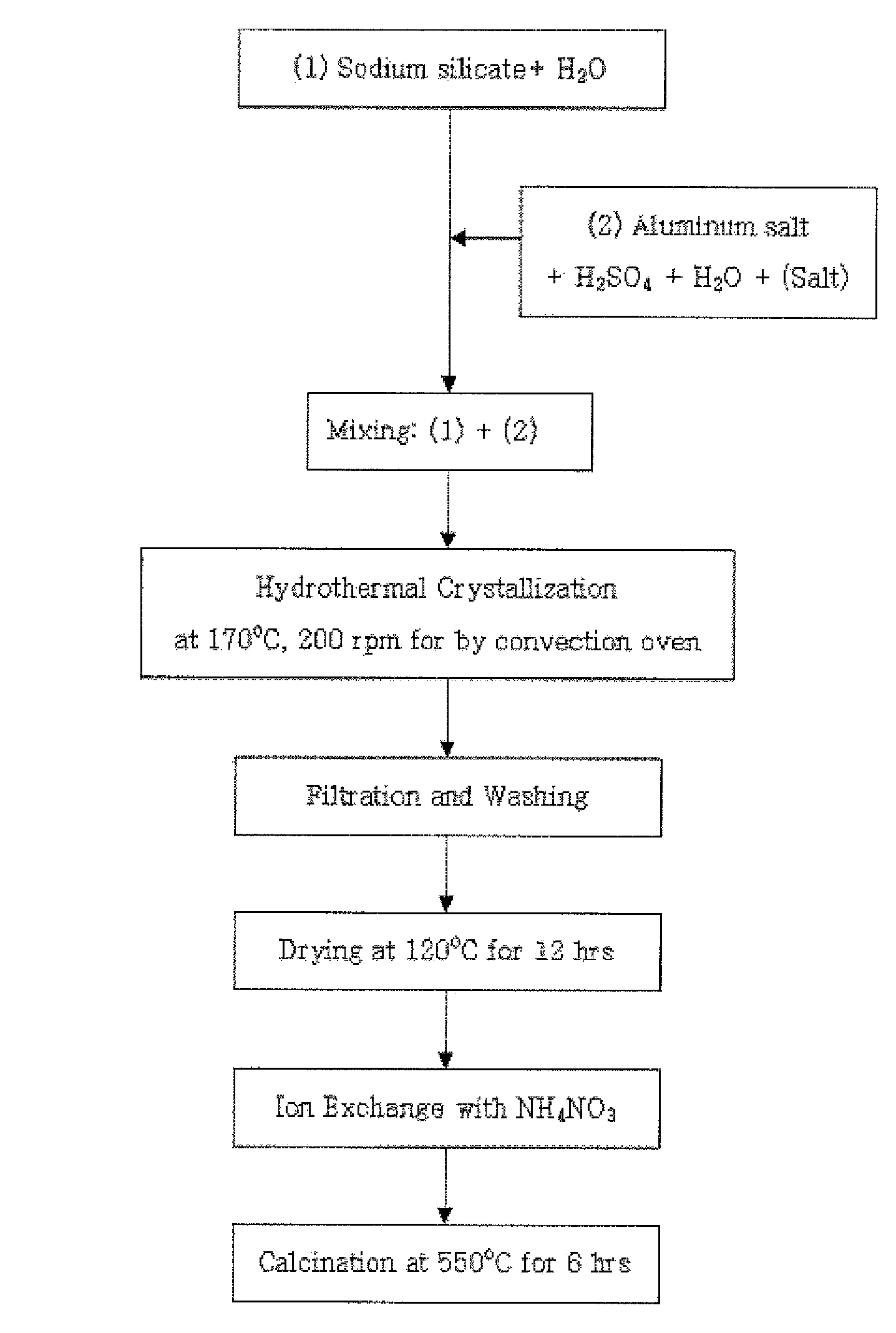

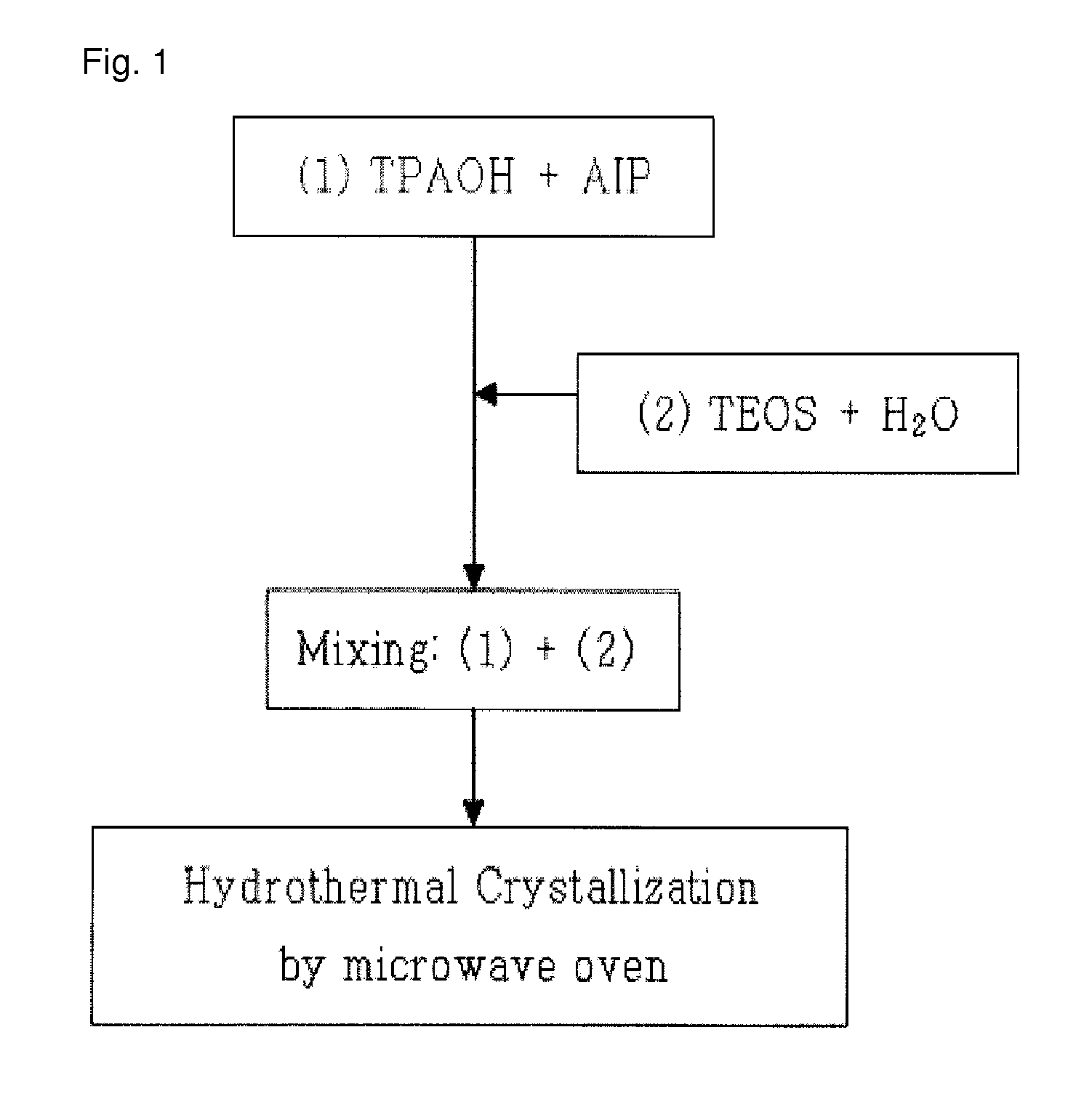

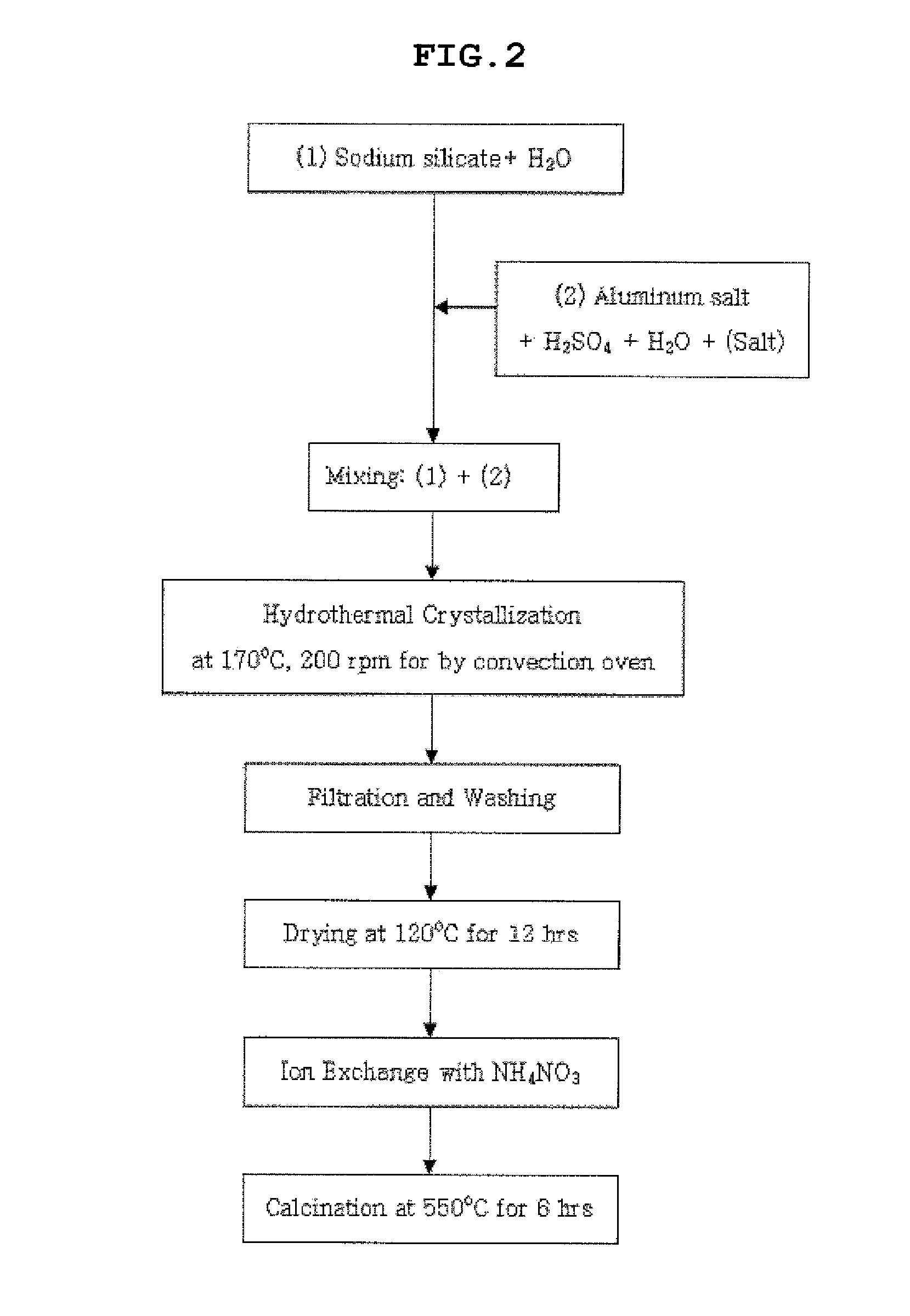

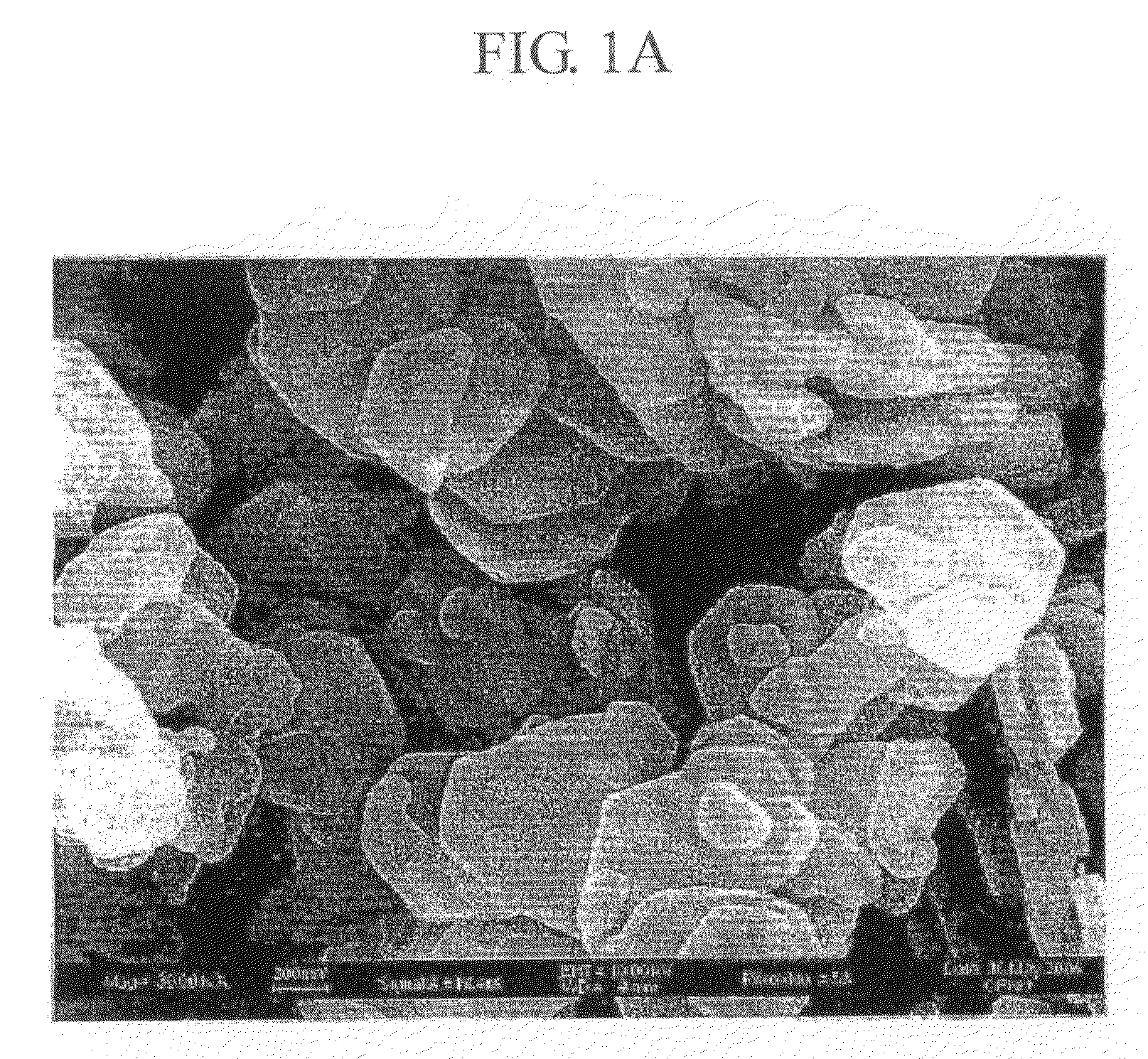

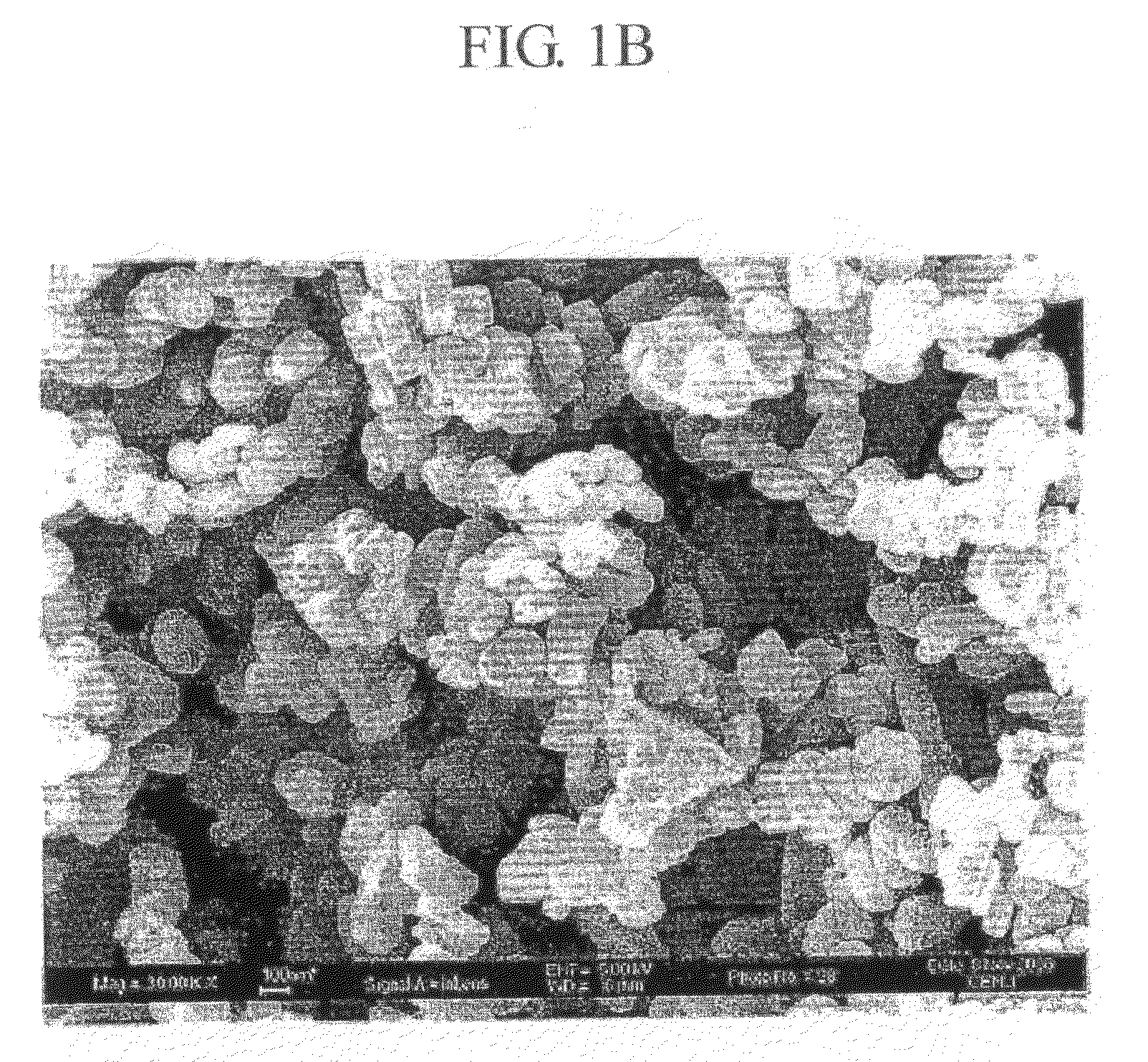

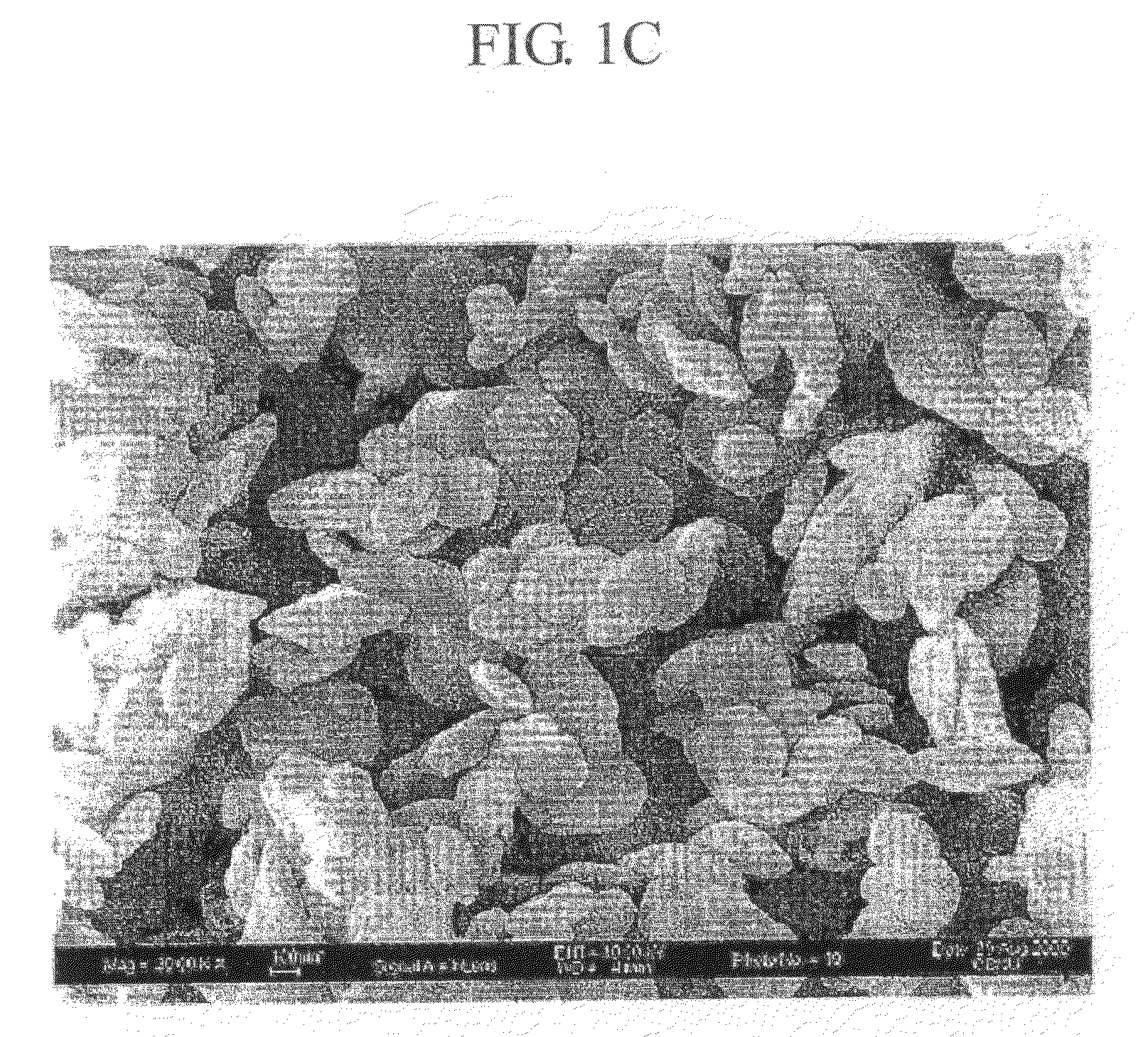

Method of preparing zsm-5 zeolite using nanocrystalline zsm-5 seeds

ActiveUS20120230910A1Easily synthesizeCrystal size be small and uniformAluminium compoundsMolecular sieve catalystsZSM-5 zeoliteStock solution

Disclosed herein is a method of preparing ZSM-5, including: providing a nanocrystalline ZSM-5 seed having a size of 70˜300 nm; adding the nanocrystalline ZSM-5 seed to a stock solution including water glass as a silica source, an alumina source, a neutralizer and water to form a reaction mixture; and maintaining the reaction mixture at 150˜200° C. to crystallize the reaction mixture. The method is advantageous in that ZSM-5 having small and uniform crystal sizes and including no impurities can be synthesized in a short period of time.

Owner:SK INNOVATION CO LTD

Refractory high-entropy alloy and forming method thereof

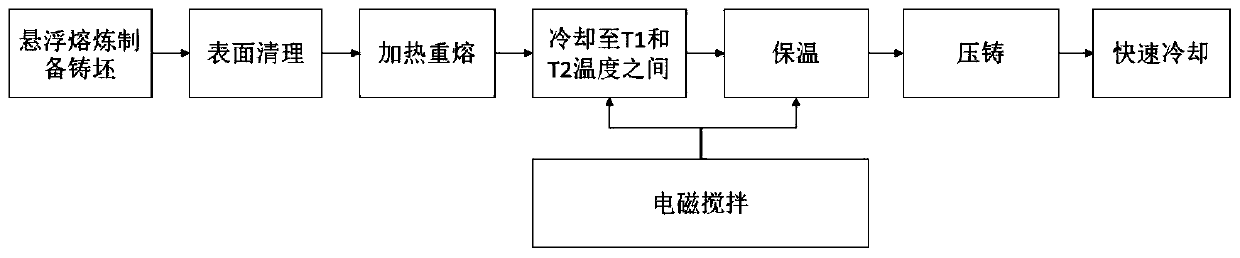

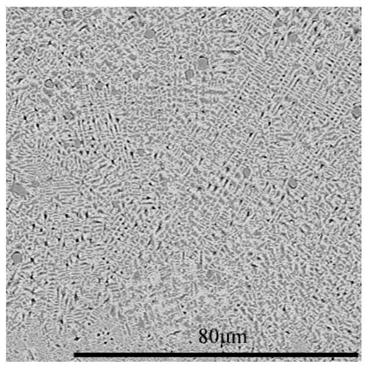

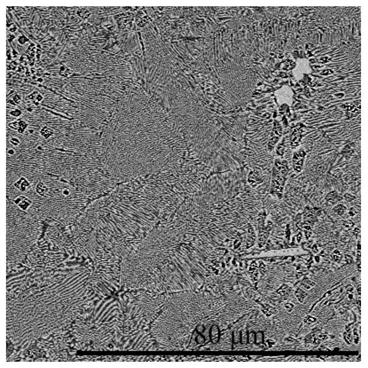

The invention relates to a refractory high-entropy alloy and a forming method thereof. The forming method comprises the steps of preparation of a refractory high-entropy alloy raw material, electromagnetic induction suspension smelting, high-frequency electromagnetic stirring of semi-solid slurry and die-casting forming. According to the method, suspension smelting, electromagnetic stirring and semi-solid forming are combined, the problem of serious component segregation commonly existing in high-entropy alloy is avoided, and a product with a fine and uniform microstructure and high density can be obtained.

Owner:苏州天峰动立合金科技有限公司

Preparation of nano rare-earth oxide doping molybdenum alloys

The invention discloses a method for preparing a nano rare earth oxide doped molybdenum alloy. In the method, by taking rare earth ammonium dimolybdate crystals as raw materials and adopting the roasting and hydrogen reduction method, molybdenum alloy powder is obtained, the powder after reduction is in press-forming by the isostatic cool pressing with a pressure of between 180 and 200 Mpa, the formed blank materials are presintered in a muffle furnace with a temperature of between 1, 100 and 1, 300 DEG C, and sintered in a vacuum intermediate frequency induction sintering furnace at a temperature of between 1, 600 and 1, 900 DEG C for 10 to 24 hours; the materials sintered can be made by the prior mechanical processing methods into materials and products with different shape such as molybdenum alloy bar materials or plate materials, etc. as required. The molybdenum alloy containing nano rare earth oxide, prepared by the method of the invention, has the advantages of high intensity, ductility and toughness and wide application.

Owner:临沂明华管业有限公司

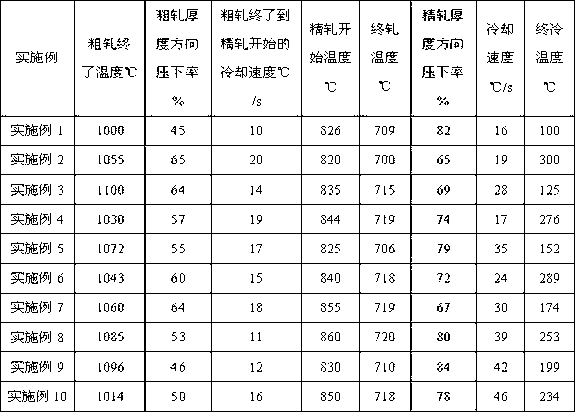

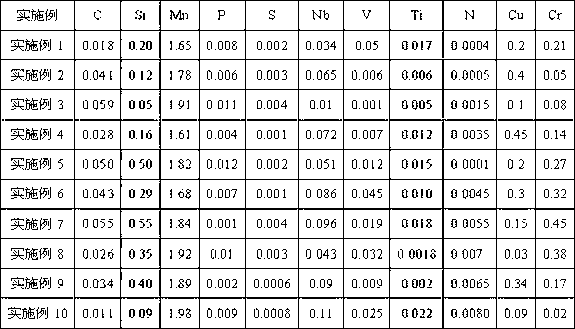

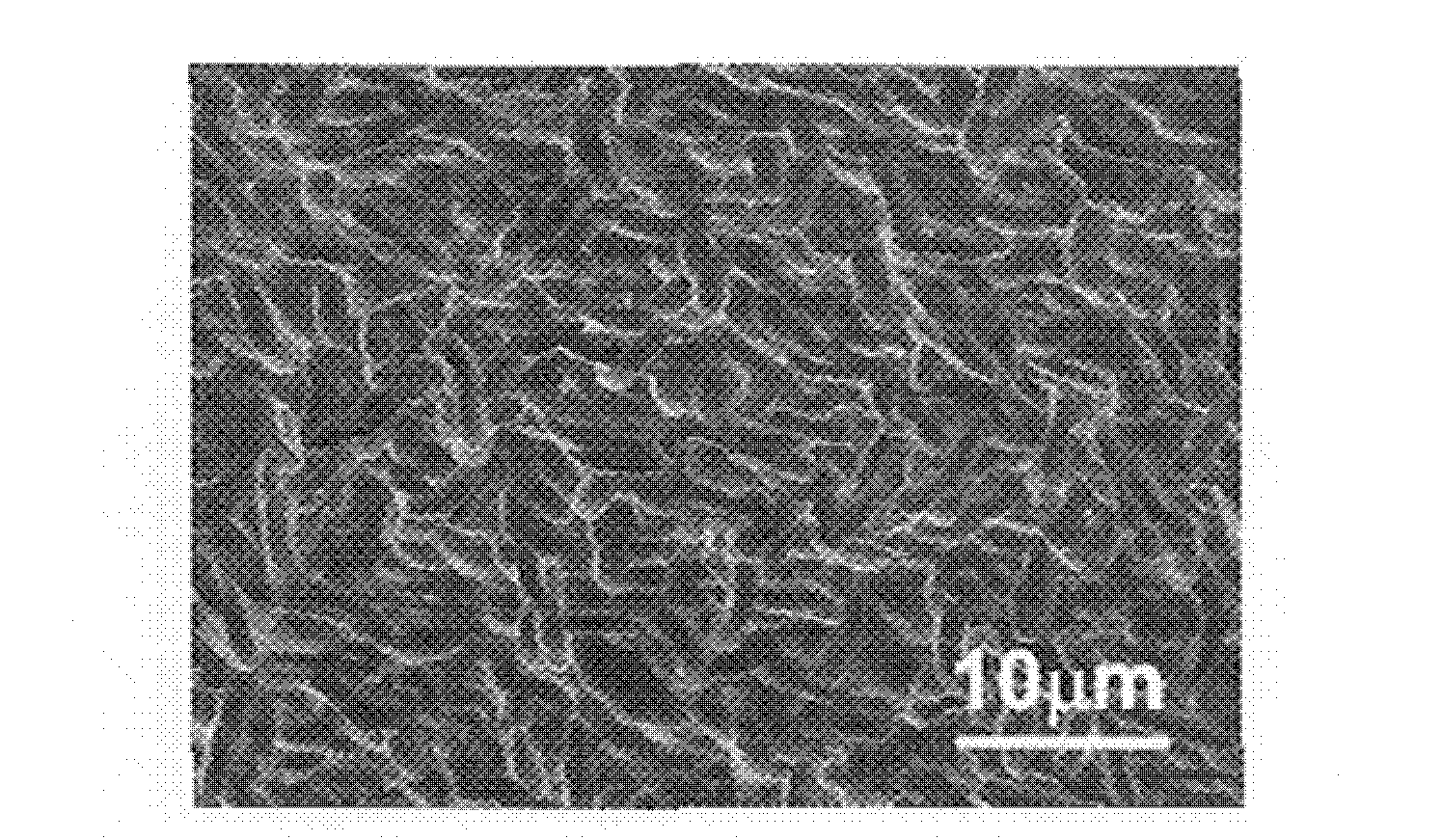

Manufacturing method of pipeline steel with high strength and toughness and high deformability

ActiveCN103160756AImprove toughnessImprove deformation abilityRoll mill control devicesMetal rolling arrangementsLine tubingYield ratio

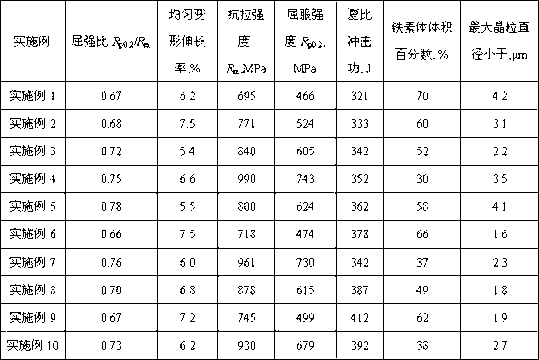

The invention discloses a manufacturing method of pipeline steel with high strength and toughness and high deformability. The steel comprises the following components in percentage by weight: 0.01-0.06% of C, 0.05-0.55% of Si, 1.60-2.00% of Mn, not more than 0.012% of P, not more than 0.005% of S, not more than 0.11% of Nb, not more than 0.06% of V, not more than 0.025% of Ti, not more than 0.0080% of N, not more than 0.50% of Cu, not more than 0.50% of Cr and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: performing pretreatment of molten iron, smelting, refining and continuous casting to prepare a plate blank comprising the components in percentage by weight, being in line with the requirements; and manufacturing a steel plate through thermal mechanical control of rolling and control of cooling process so as to get the pipeline steel. The pipeline steel disclosed by the invention is very small in crystal grains and appropriate in soft phase-hard phase proportion and can get higher strength and toughness and excellent deformability under the situation of not containing Ni, Mo and other alloy elements and containing lower C content. The tensile strength Rm is not less than 695 and not more than 990, the yield ratio Rp0.2 / Rm is not more than 0.8, the uniform deformation elongation rate is not less than 5%, and the Charpy impact energy is not less than 300J. The pipeline steel disclosed by the invention is low in cost, and the obtained steel plate has the advantages of excellent deformability, strength, toughness and excellent welding performance.

Owner:NANJING IRON & STEEL CO LTD

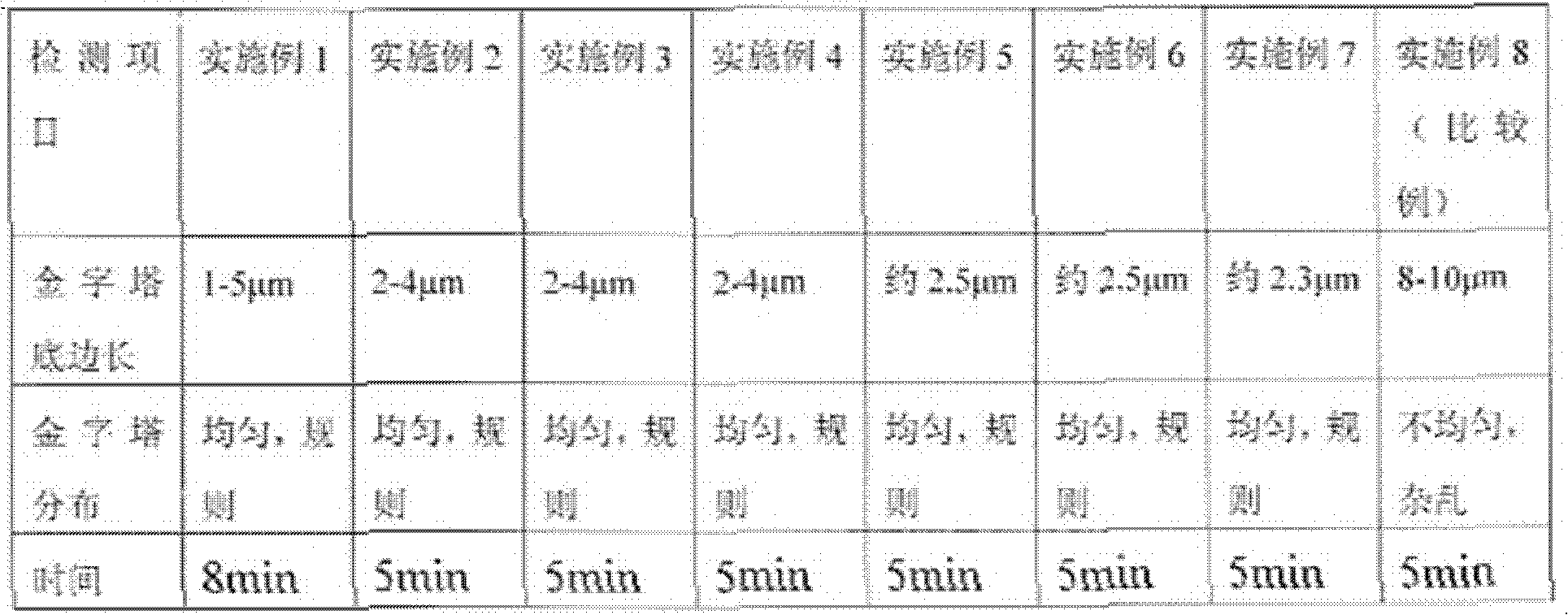

Acidic texturing solution for texturing of polycrystalline silicon chip and using method thereof

ActiveCN102330154ATo achieve the purpose of making cashmereThe reaction conditions are mild and controllableAfter-treatment detailsSolar cellProcess conditions

The invention provides an acidic texturing solution for texturing of a polycrystalline silicon chip and a using method thereof. The acidic texturing solution is characterized in that: when the acidic texturing solution is used for surface texturing of the polycrystalline silicon chip for a solar cell, excellent texturing effect can be achieved. The technical problems of environmental pollution of the texturing solution and textured surface non-uniformity caused by instable states of the texturing solution and the process conditions in the prior art are solved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Acid texturing additive for polysilicon film and use method thereof

InactiveCN104294369AEasy to cleanReduce in quantityAfter-treatment detailsActive agentCell fabrication

The invention belongs to the field of manufacture of solar batteries, relates to an acid texturing additive for a polysilicon film and a use method thereof, and the additive comprises the components of a perfluorinated nonionic surfactant, polyalcohol, citric acids and the balance of water. A method for acid texturing by using the additive comprises the following steps: (1) preparing the perfluorinated nonionic surfactant, the polyalcohol, the citric acids and the water to obtain the acid texturing additive for the polysilicon; (2) preparing hydrofluoric acids, nitric acids and the water to obtain an acid texturing solution; (3) adding the additive into the acid texturing solution which is obtained in the step (2); and (4) putting a silicon film into the acid texturing solution which is obtained in the step (3) for texturing. Through the use of the additive, a texturing surface is more uniform, an etch pit is finer, and compared with the conventional texturing, the reflectivity can be reduced by 2-3%.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

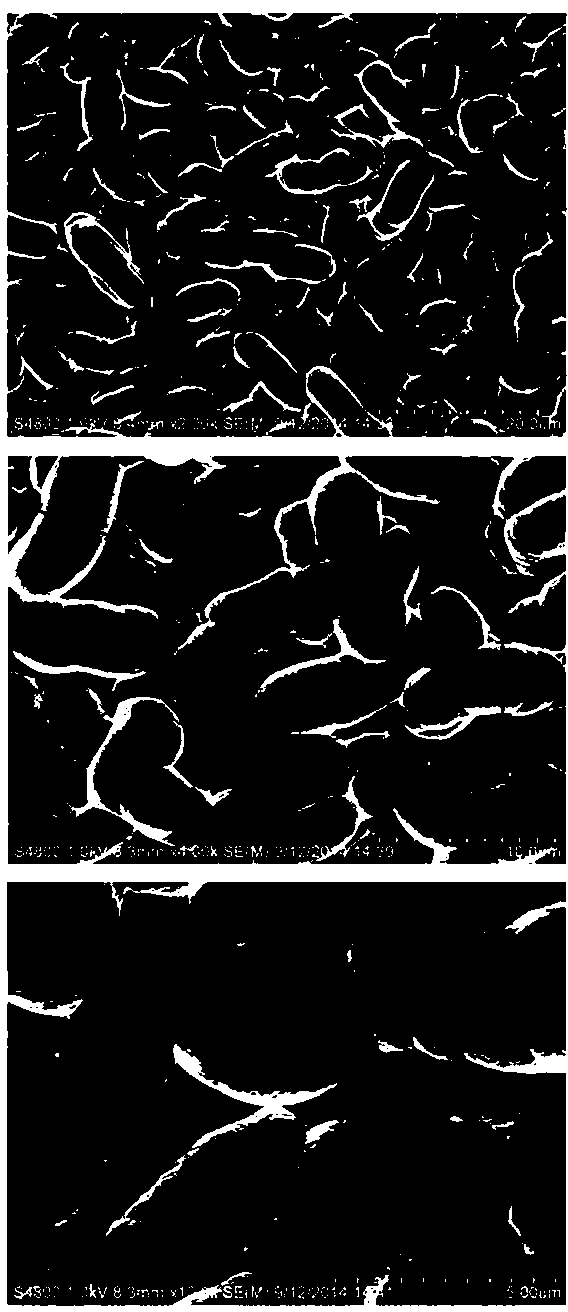

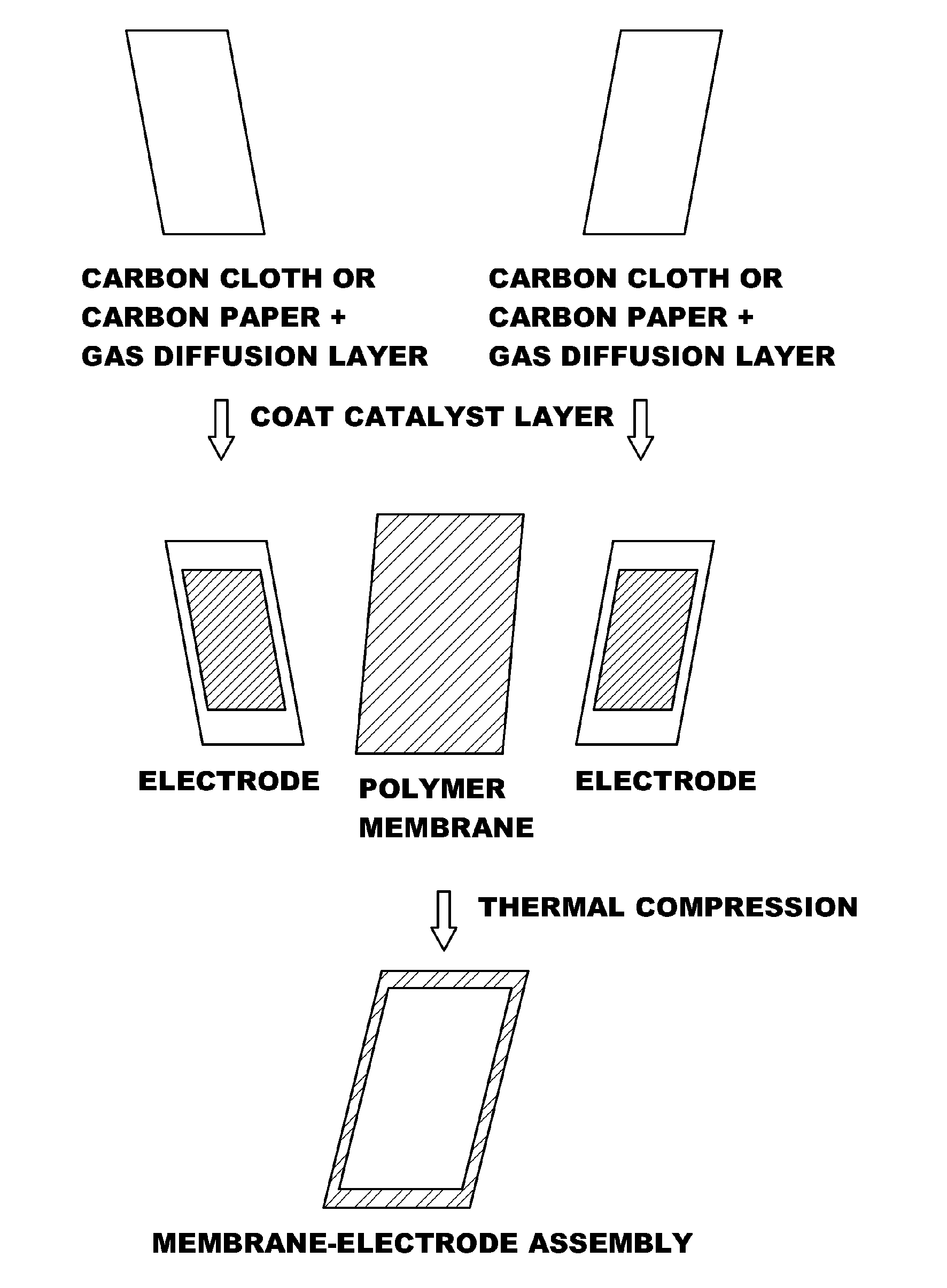

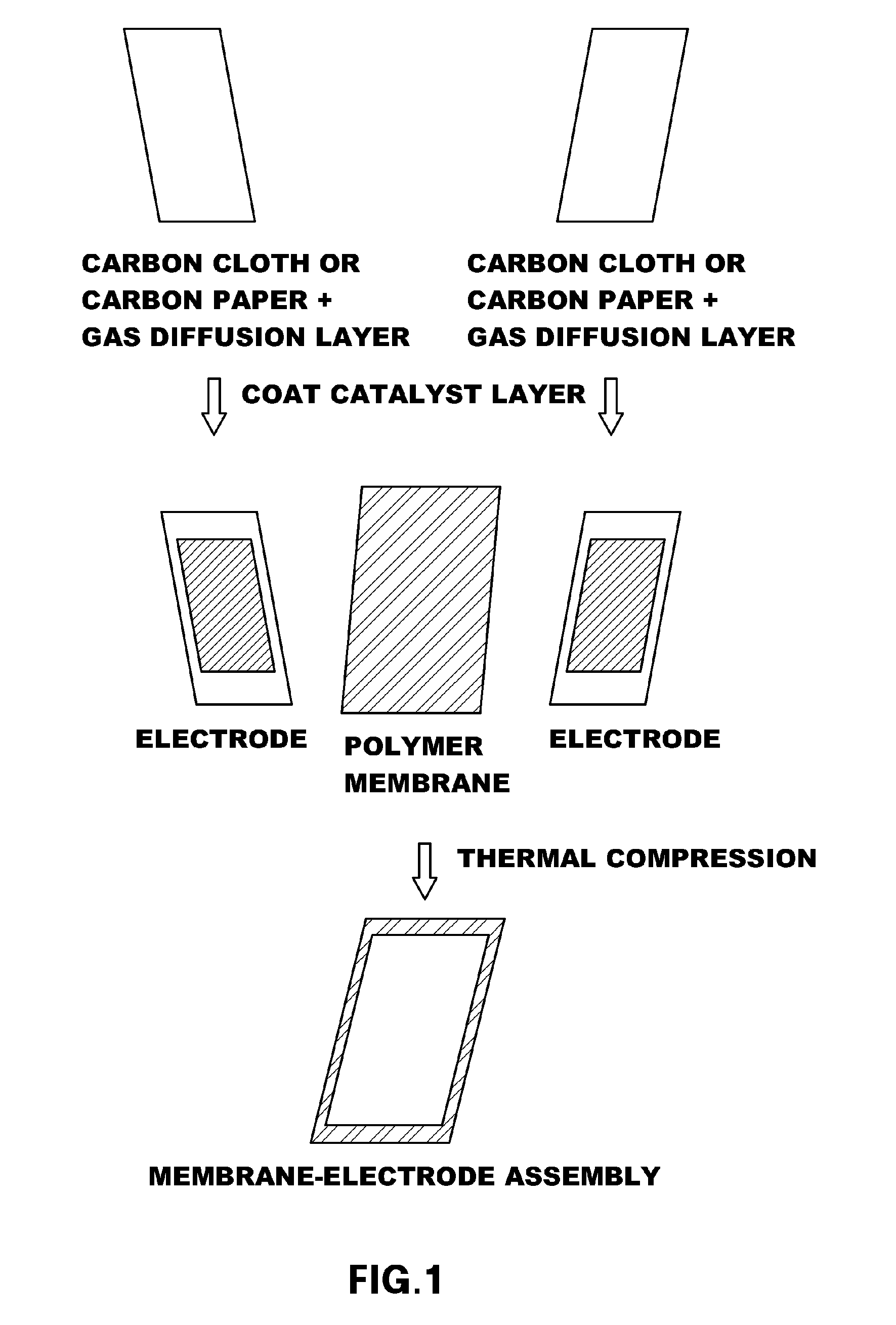

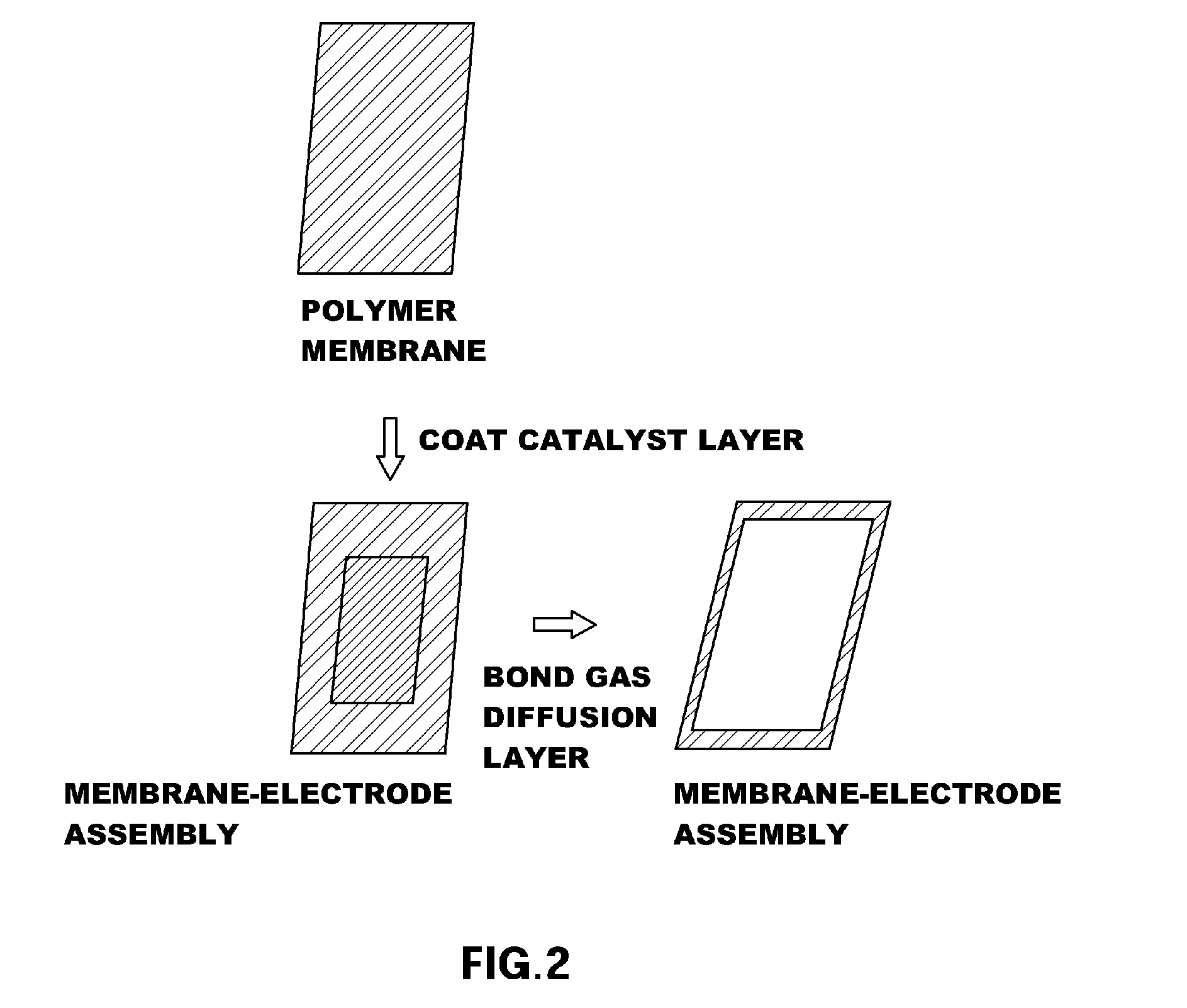

Electrode for polymer electrolyte membrane fuel cell and method for forming membrane-electrode assembly using the same

InactiveUS20110129759A1High mechanical strengthPhysical durability can be degradedOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesFiberCerium

The present invention provides an electrode for a polymer electrolyte membrane fuel cell (PEMFC) and a method for forming a membrane-electrode assembly (MEA) using the same, in which carbon nanofibers are added to a catalyst layer to increase the mechanical strength of the catalyst layer and to maintain the thickness of the catalyst layer after operation for a long time, thus preventing a reduction in physical durability of the fuel cell, and cerium-zirconium oxide (CeZrO4) as a radical inhibitor is added to the catalyst layer, thus preventing a reduction in chemical durability of the fuel cell. As a result, it is possible to physically and chemically increase the performance and durability of the fuel cell membrane-electrode assembly in a robust manner and minimize the reduction in performance after operation for a long time.

Owner:HYUNDAI MOTOR CO LTD

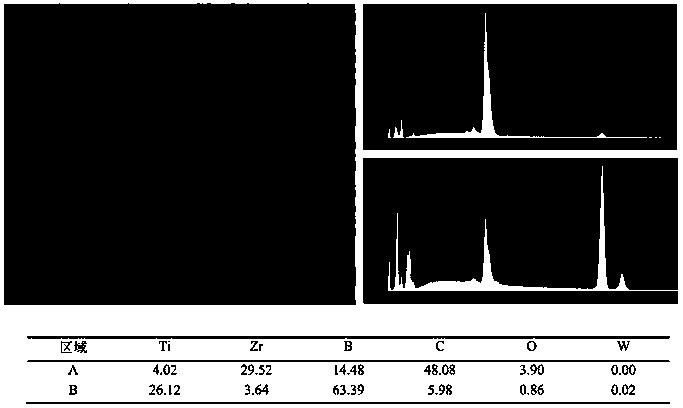

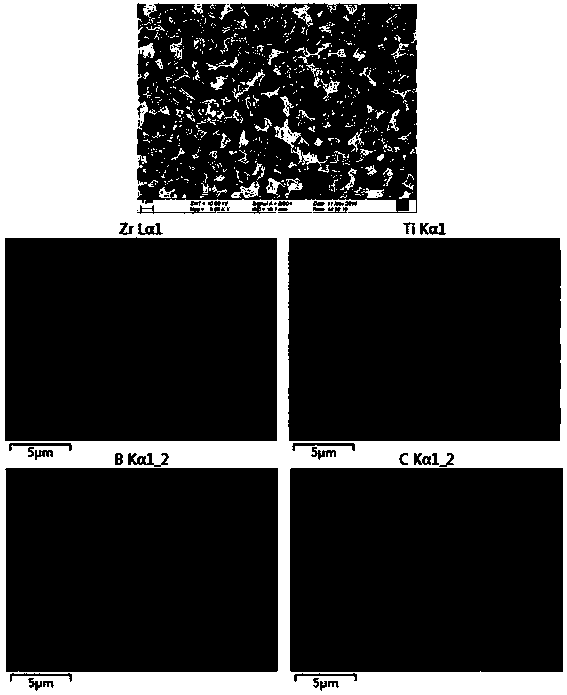

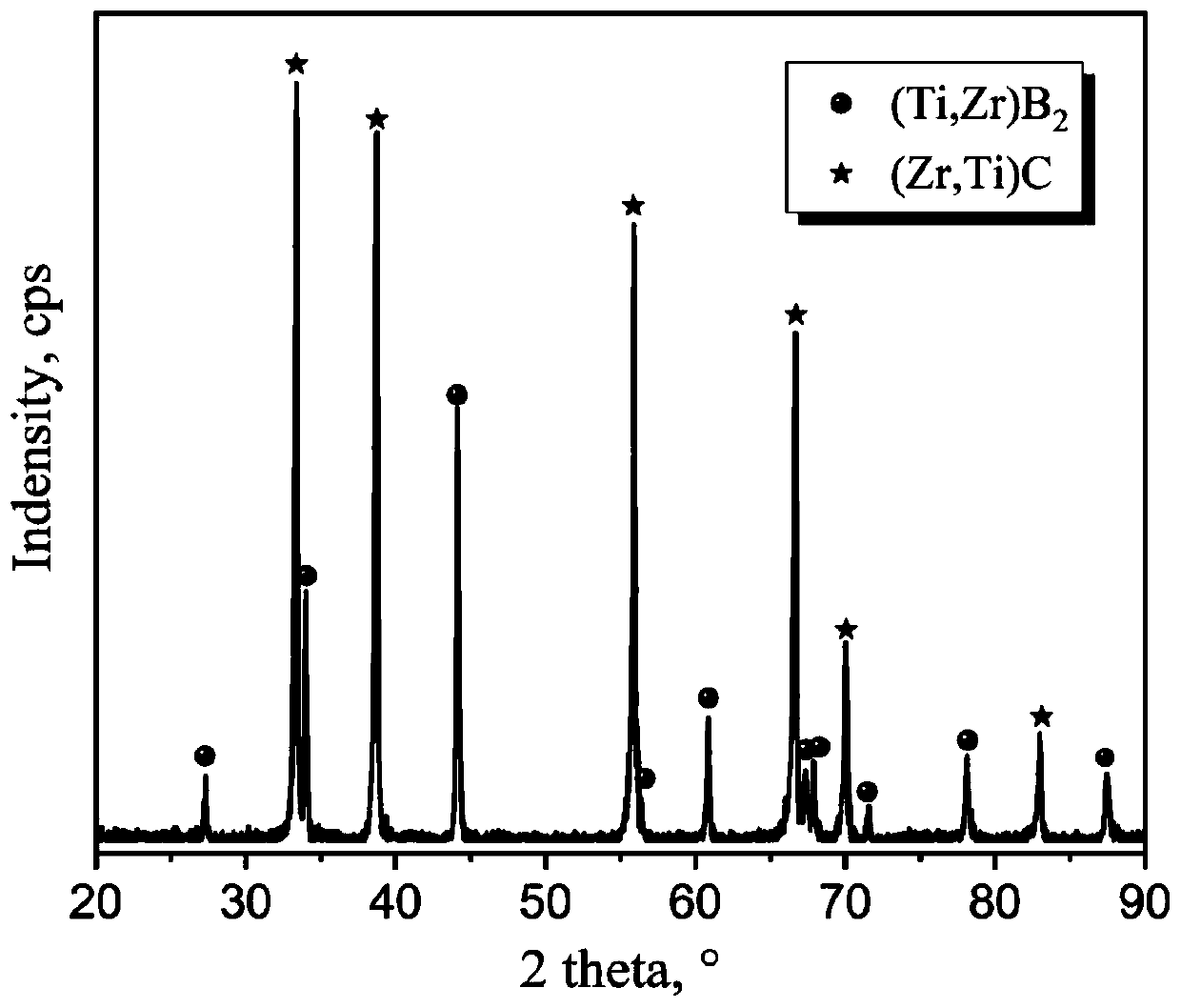

Method for low temperature preparation of diboride-carbide solid solution multiphase ceramic by reaction hot press sintering method

The invention relates to a method for low temperature preparation of a diboride-carbide solid solution multiphase ceramic by a reaction hot press sintering method, and belongs to the technical field of multiphase ceramic materials. The problem of high sintering temperature of an existing diboride-carbide multiphase ceramic is solved. According to the method for the low temperature preparation of the diboride-carbide solid solution multiphase ceramic by the reaction hot press sintering method, transition metal diboride and carbide which can produce solid phase exchange are selected, a compositepowder body is prepared by a high energy ball milling process, under the protection of vacuum or inert atmosphere, and the reaction hot press sintering is carried out to prepare the dense diboride-carbide solid solution multiphase ceramic. The solid-phase reaction and solid solution coupled synergistic process in the sintering process is fully used, compared with traditional hotpress sintering process for the preparation of multiphase ceramic materials directly using target diboronized and carbide powder bodies, the sintering temperature of the materials can be reduced by 250 DEG C to 400 DEGC, it is ensured that the material grain size is uniform and small by low temperature sintering, and the strength and toughness of the multiphase ceramic obtained are significantly improved.

Owner:HARBIN INST OF TECH

Ferrous phosphate powders, lithium iron phosphate powders for li-ion battery, and methods for manufacturing the same

ActiveUS20130266864A1Uniform and small grain sizeImprove efficiencySilver accumulatorsNon-metal conductorsLithium iron phosphatePhosphate

Ferrous (II) phosphate (Fe3(PO4)2) powders, lithium iron phosphate (LiFePO4) powders for a Li-ion battery and methods for manufacturing the same are provided. The ferrous (II) phosphate powders are represented by the following formula (I):Fe(3-x)Mx(PO4)2.yH2O (I)wherein, M, x, and y are defined in the specification, the ferrous (II) phosphate powders are composed of plural flake powders, and the length of each of the flake powders is 0.2-10 μm.

Owner:NATIONAL TSING HUA UNIVERSITY

6-series alloy anode aluminum oxide board strip for mobile phone frame and preparation method of 6-series alloy anode aluminum oxide board strip

The invention belongs to the field of preparation of aluminum and aluminum alloy, and particularly relates to a 6-series alloy rolled aluminum board strip and a preparation method thereof. The 6-series alloy rolled aluminum board strip can meet the requirement that the yield strength is larger than or equal to 300 mpa of the mobile phone frame, and no obvious bank marks are generated after anodizing. The ingredients of alloy comprise 0.5-0.7% of Si, 0.08% of Fe, 0.45-0.55% of Cu, 0.1-0.2% of Mn, 0.8-1.0% of Mg, 0.025% of Ti and the balance AL and inevitable impurities, wherein Mg / Si is equal to 1.3-1.6. The product has the characteristics of high strength and an excellent anodizing appearance, after the product is subjected to aging thermal treatment, the yield strength exceeds 300 mpa, due to strip type production and high thickness progress, the strip is very suitable for directly obtaining products shaped like a Chinese character 'kou' in a coiled material continuous stamping manner, the cost is reduced by greatly reducing CNC, and the production efficiency is improved.

Owner:CHINALCO RUIMIN

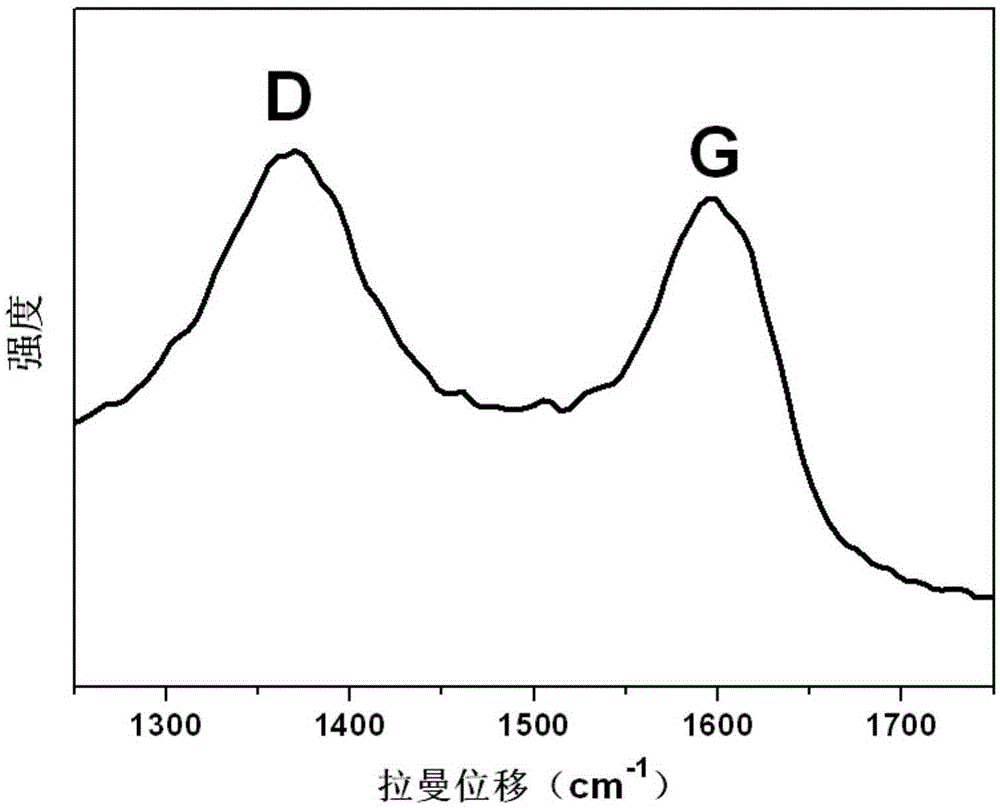

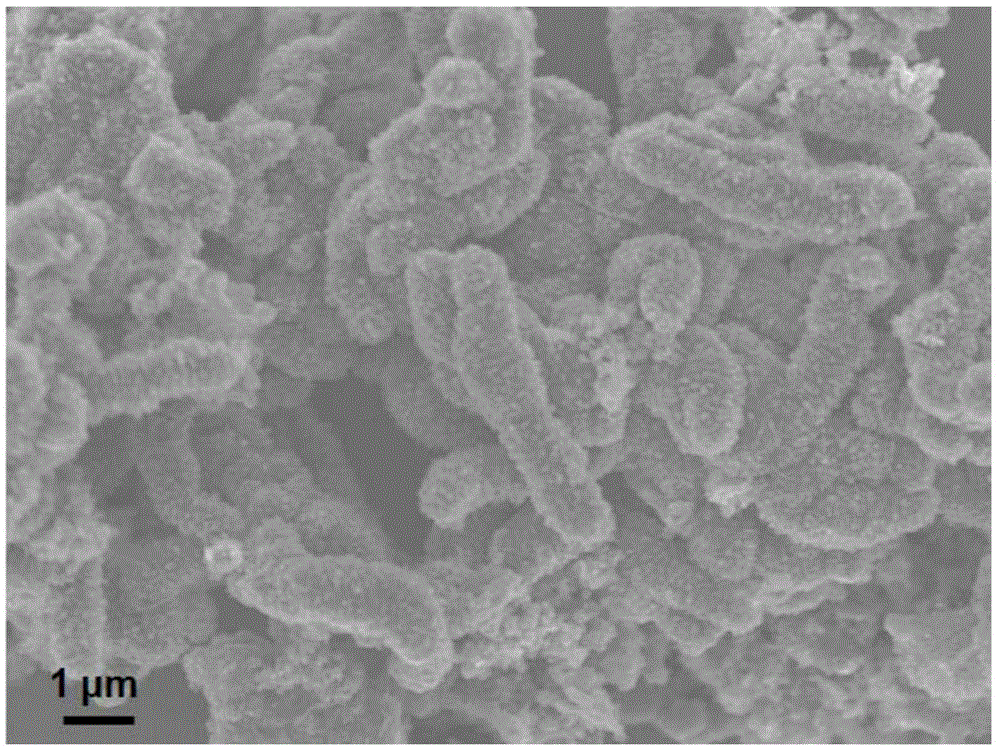

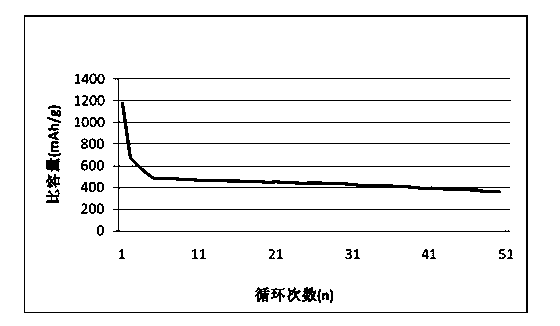

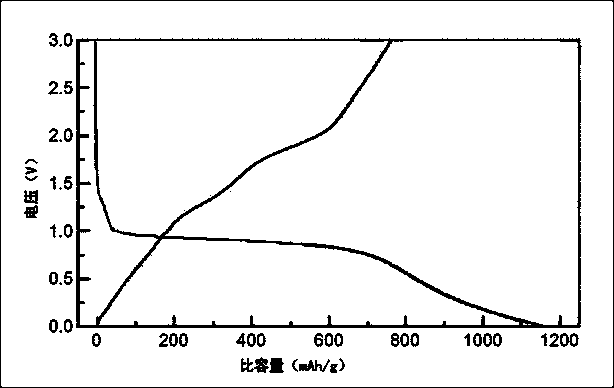

High-rate lithium vanadium phosphate positive electrode material, and preparation method and application thereof

ActiveCN105406071AShorten Diffusion TimeImproved magnification performanceCell electrodesSecondary cellsCarbon compositesLithium electrode

The invention discloses a high-rate lithium vanadium phosphate positive electrode material, and a preparation method and application thereof, belonging to the technical field of electrochemistry. The lithium vanadium phosphate positive electrode material is a lithium vanadium phosphate / carbon composite positive electrode material composed of a great number of caterpillar-like hierarchical structures. The preparation method for the lithium vanadium phosphate positive electrode material comprises the following steps: adding a lithium source, a vanadium source, a phosphorus source and oleic acid into absolute ethyl alcohol; carrying out ultrasonic dissolving and then placing the substances into a high pressure reaction vessel for a complete reaction so as to obtain a precursor; successively subjecting the precursor to centrifugal cleaning and vacuum drying; and then calcining the precursor in a mixed atmosphere of argon and hydrogen so as to obtain the caterpillar-like lithium vanadium phosphate / carbon composite positive electrode material. When used as a lithium ion battery positive electrode material, the lithium vanadium phosphate / carbon composite positive electrode material has high specific capacity, good cycle stability and excellent rate capability and can meet the requirement of a power battery for high performance.

Owner:MAANSHAN YUCHI NEW ENERGY MATERIALS CO LTD

Preparation method of calcium-cobalt oxide compound as anode material for lithium ion batteries

InactiveCN103746092AHigh purityMix well enoughSecondary cellsPositive electrodesHYDROSOLLithium-ion battery

The invention discloses a preparation method of a lamellar calcium-cobalt oxide compound as an anode material for lithium ion batteries. The method comprises the steps of dissolving reactants including Ca(CH3COO)2, Co(CH3COO)2 and a chelate to prepare a mixed solution, stirring the mixed solution till the mixed solution is in a sol state, drying the sol to obtain xerogel, and then grinding and sintering the xerogel to obtain a finished product Ca3Co4O9. The prepared material is uniform in grains, has high specific capacity and has good charge and discharge efficiency.

Owner:中国东方电气集团有限公司

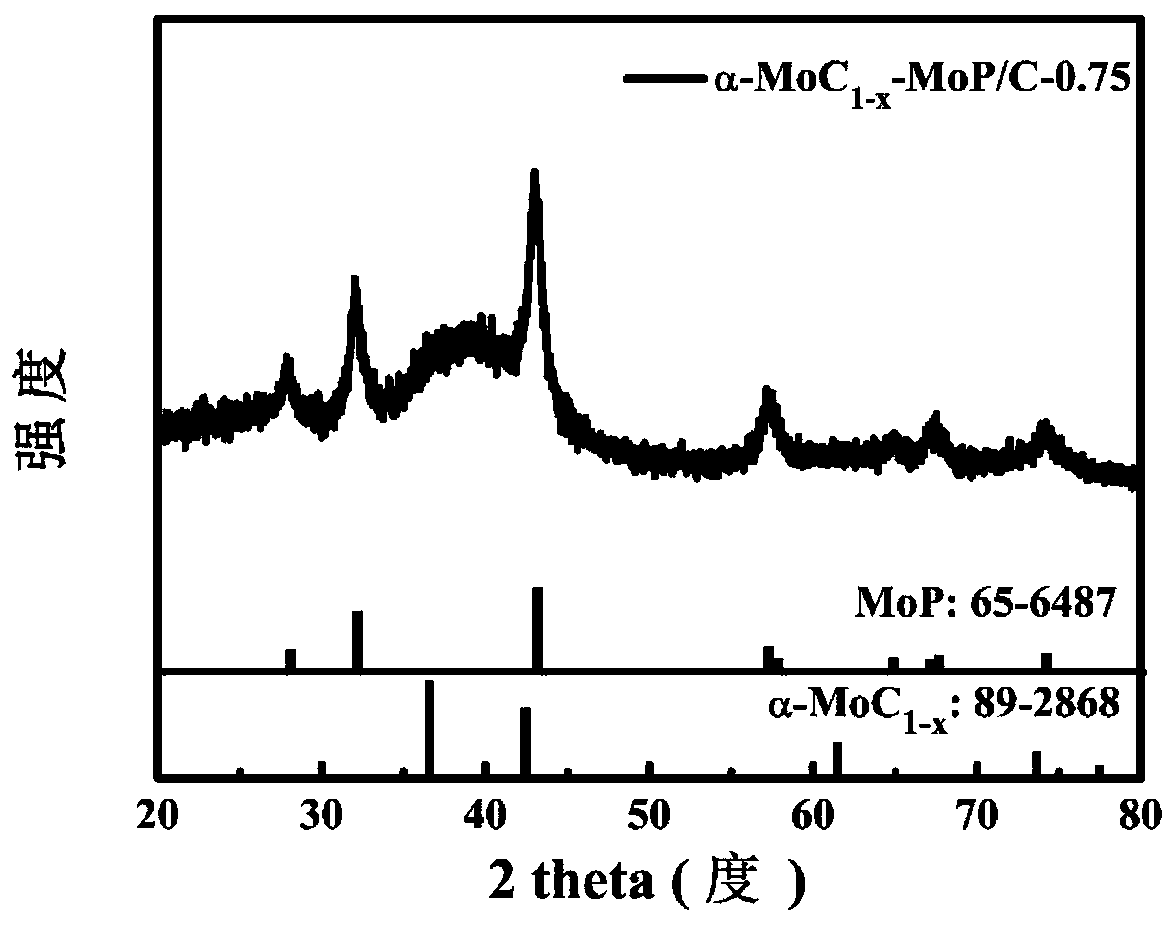

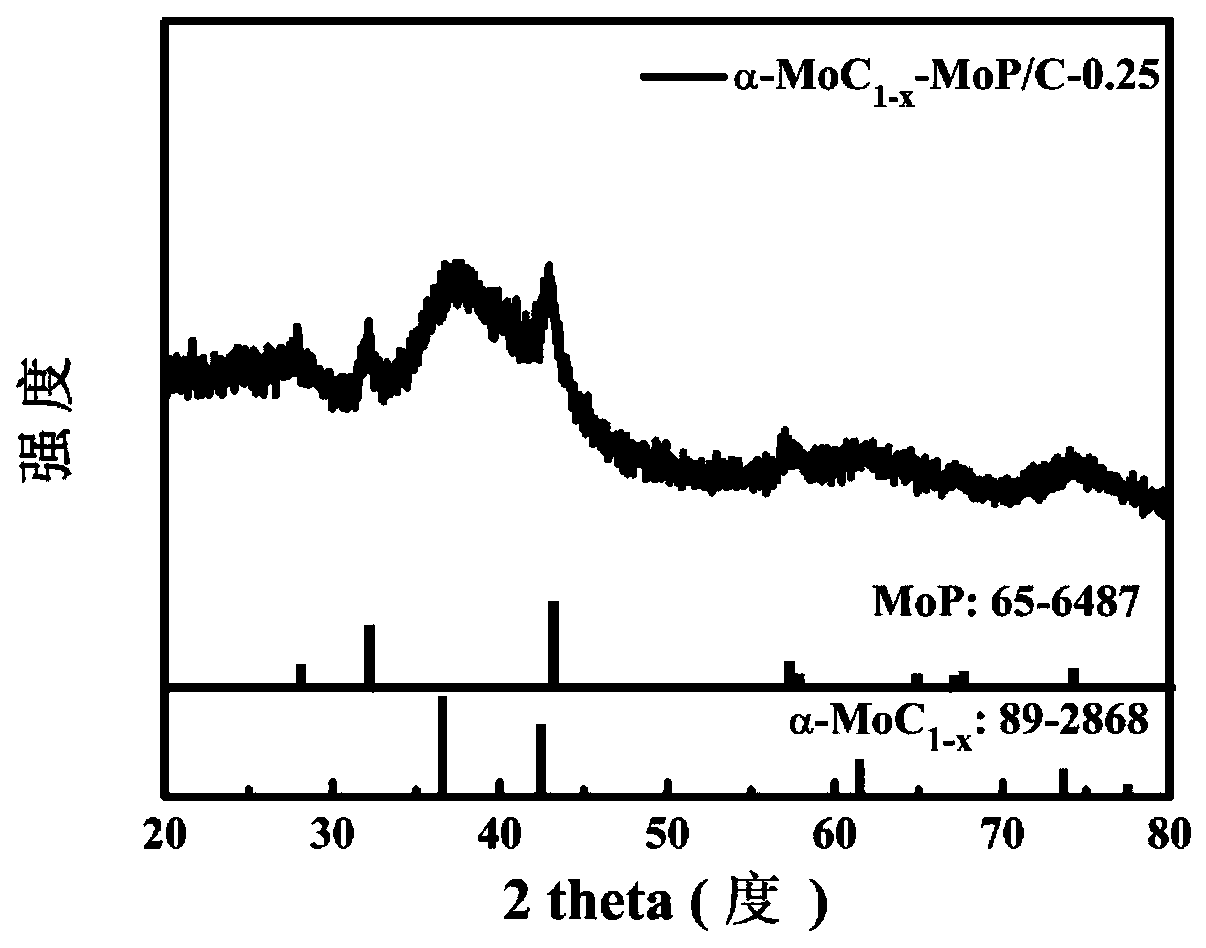

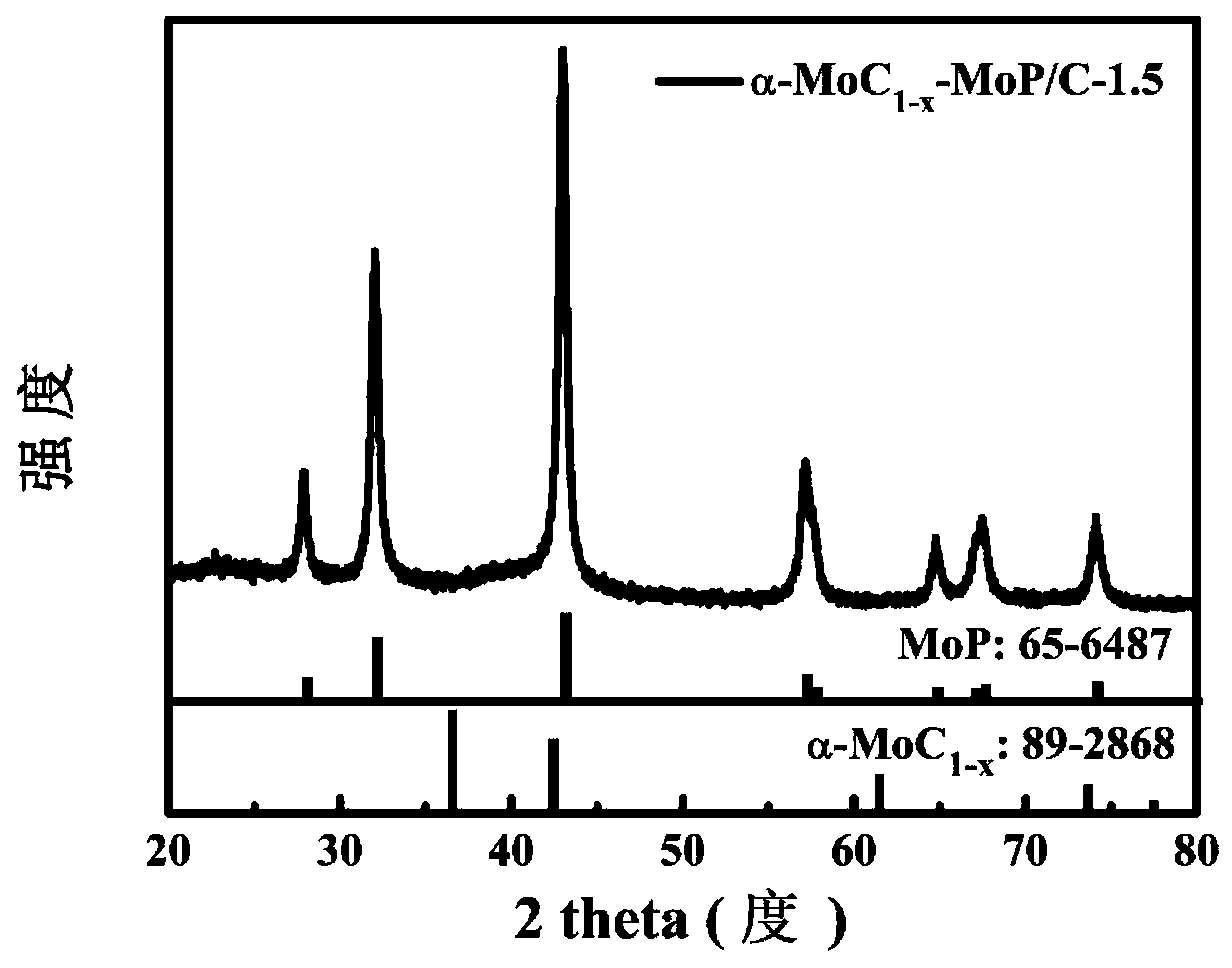

Preparation method for carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material

ActiveCN110227523AUniform and small sizeIncrease exposurePhysical/chemical process catalystsHeterojunctionWhite powder

The invention discloses a preparation method for a carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material, belonging to the technical field of nanomaterial preparation. The preparation method comprises the following steps: (1) adding ammonium molybdate and dicyandiamide into water, carrying out heating and stirring to allow the ammonium molybdate to be completely hydrolyzed, and carrying out drying and grinding successively to obtain white powder; and (2) separately placing the white powder and sodium hypophosphite in sealed space, carrying out heat-preserved treatment in an inert atmosphere, and performing cooling to obtain the carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material. The preparation method of the invention is simple in process and short in synthesis cycle; by controlling the amount of a precursor, the ratio of the alpha phase molybdenum carbide to the molybdenum phosphide can be controlled; and prepared molybdenum carbide-molybdenum phosphide heterojunction nano-dots are uniform and small in size, which is beneficial for the exposure of catalytic active sites, so the composite material has good application prospects.

Owner:CENT SOUTH UNIV

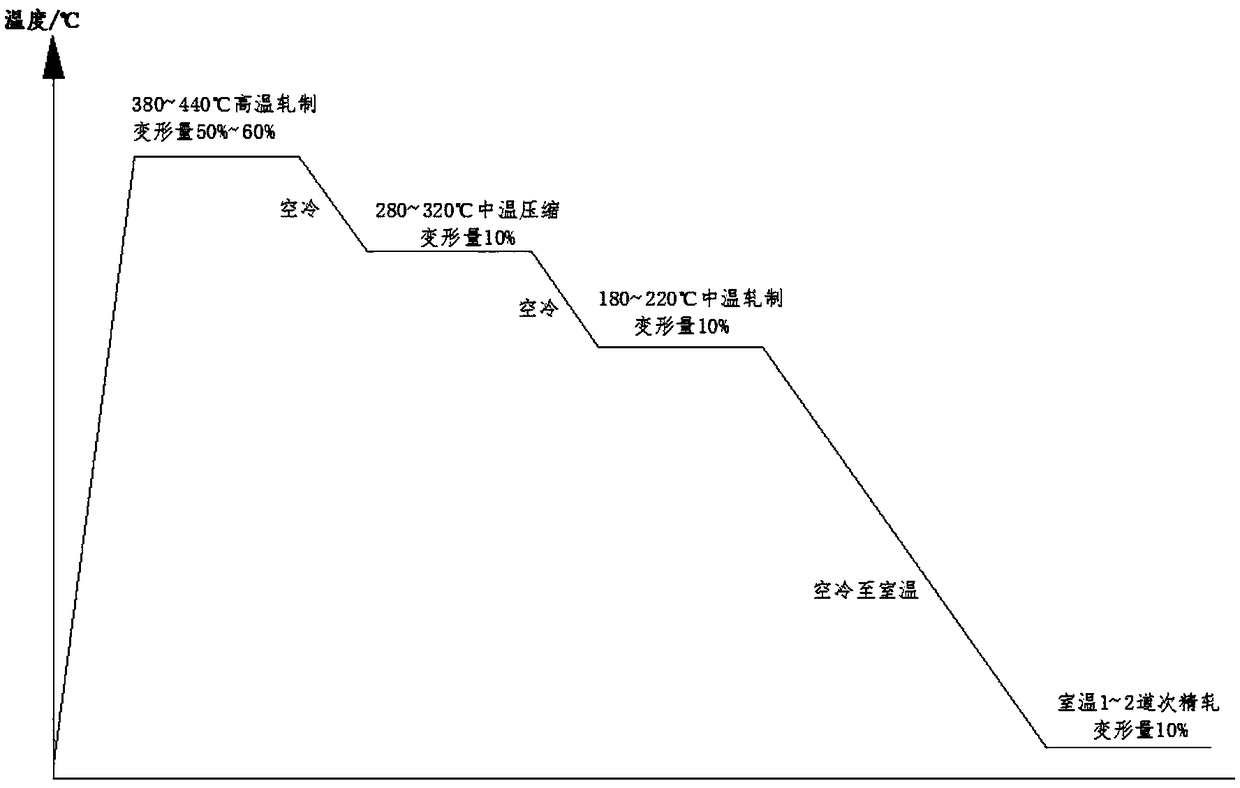

Process method for improving comprehensive mechanical performance of aluminum alloy boards

The invention discloses a process method for improving the comprehensive mechanical performance of aluminum alloy boards. The process method comprises the following steps of preparation, soaking, multi-axial forging, machining, surface milling, heating, deformation of different temperature sections, heat treatment, straightening, saw cutting and the like, specifically, the deformation of the different temperature sections comprises the following steps that heated forging stocks are subjected to high-temperature rolling and medium-temperature heat compression in a hot mill, the boards subjectedto heat compression are transferred to the hot mill to be subjected to medium-temperature rolling, precision cold rolling is conducted, and the deformation of the precision cold rolling is controlledto be about 10% of the total machining rate.

Owner:JIANGSU UNIV OF TECH

Method of preparing ZSM-5 zeolite using nanocrystalline ZSM-5 seeds

ActiveUS8840864B2Easy to synthesizeUniform and small sizeAluminium compoundsMolecular sieve catalystsSilicon dioxideStock solution

A method of preparing ZSM-5, including: providing a nanocrystalline ZSM-5 seed having a size of 70-150 nm; adding the nanocrystalline ZSM-5 seed to a stock solution including water glass as a silica source, an alumina source, a neutralizer and water to form a reaction mixture; and maintaining the reaction mixture at 150-200° C. to crystallize the reaction mixture. The method is advantageous in that ZSM-5 having small and uniform crystal sizes and including no impurities can be synthesized in a short period of time.

Owner:SK INNOVATION CO LTD

Oxide-Like Hydrotalcite and Manufacturing Process Thereof

InactiveUS20100187473A1Increase heatHigh chlorine-resistanceOther chemical processesCalcium/strontium/barium compoundsManufacturing technologyMicrowave

An oxide-like hydrotalcite having a certain structure and uniform size can be prepared by a method comprising milling and heat or microwave post-treatment, and it is capable of providing synthetic resins with high heat- and chlorine-resistance.

Owner:DOOBON

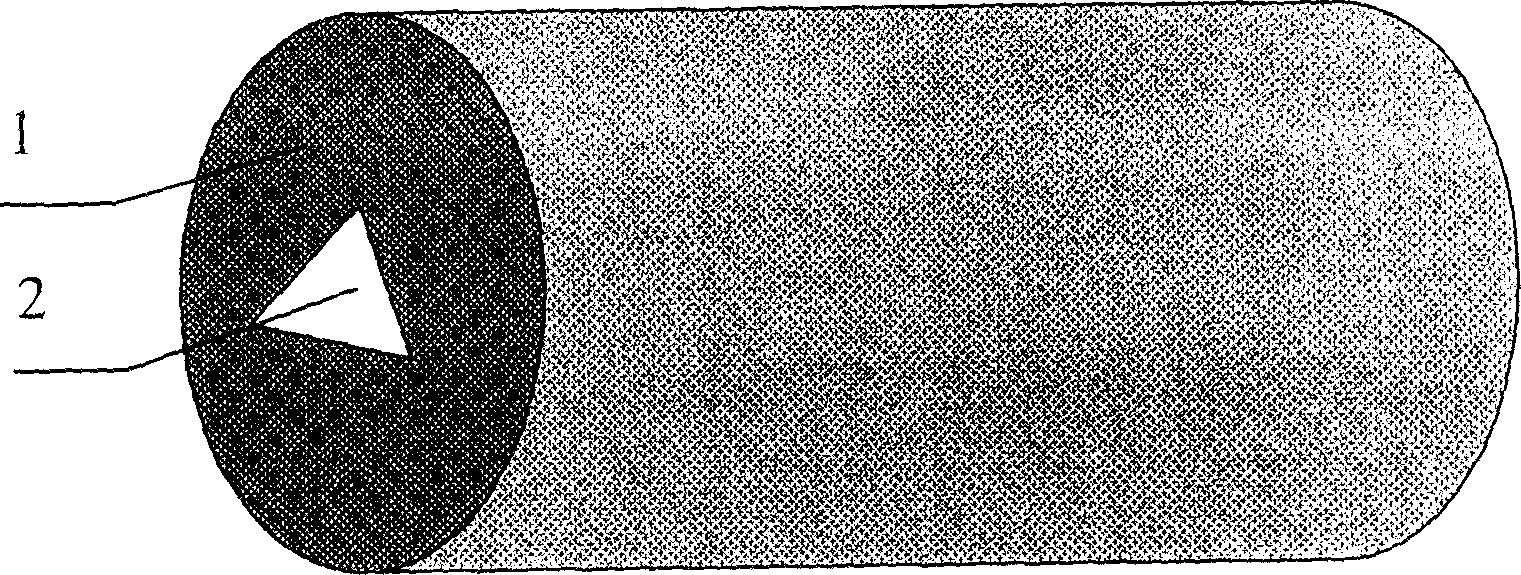

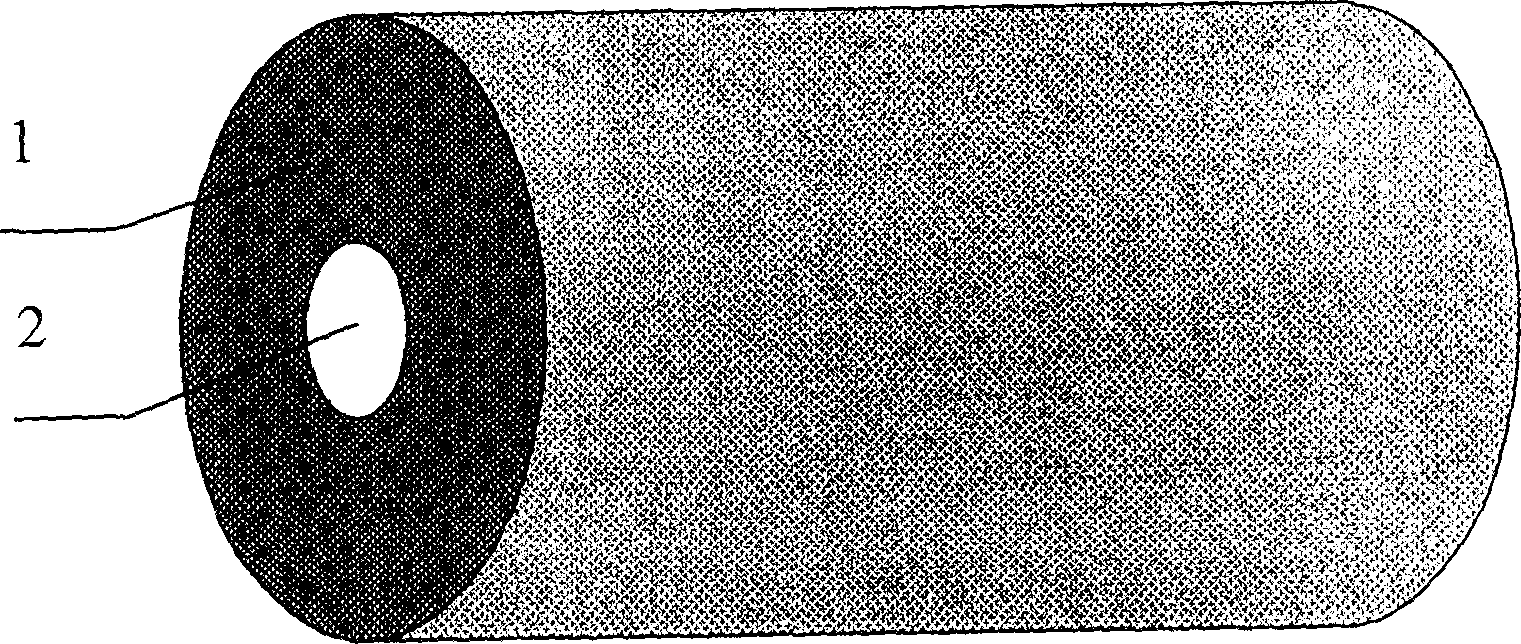

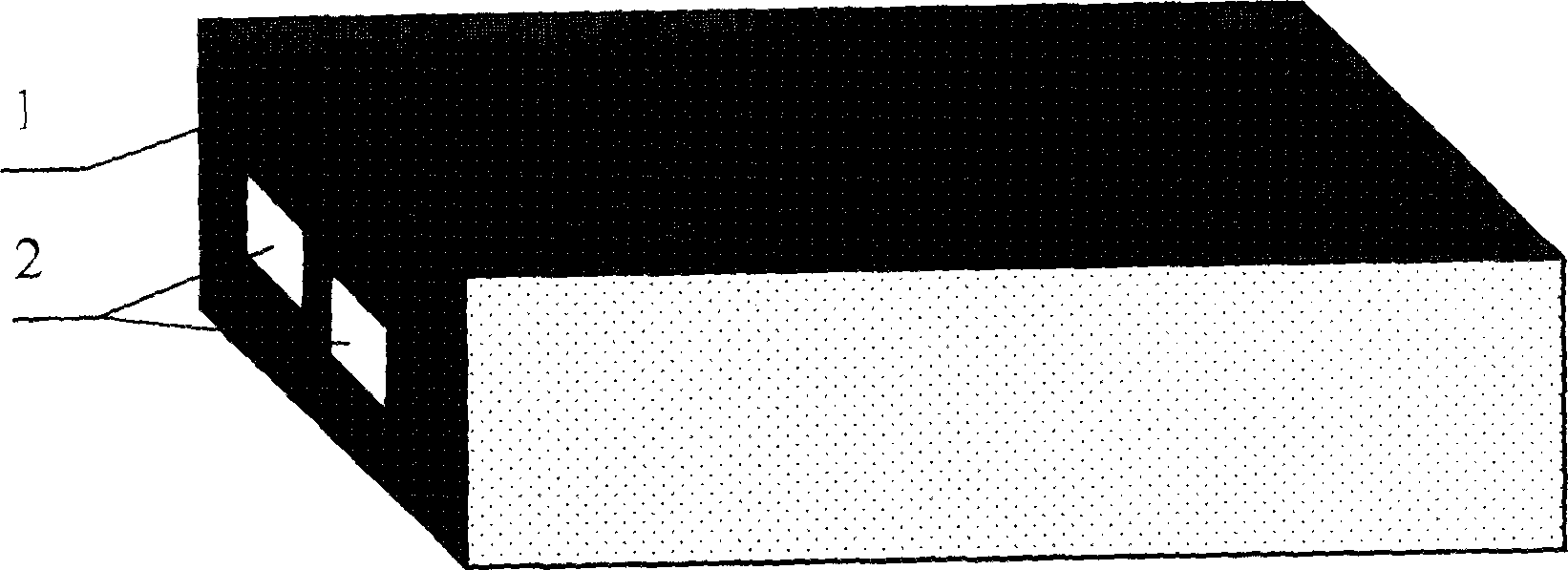

Method for synthesizing isotropic silicon nitride powder adopting hollow type annular material-distribution

InactiveCN1799994AUniform fine permeabilityImprove permeabilityNitrogen compoundsCombustionMetallic materials

The invention discloses a homogeneous silicon nitride powder synthetic method of hollow ring-shaped cloth combustion in the inorganic non-metal material domain, which is characterized by the following: grinding to mix the silicon powder and silicon nitride powder at different proportions; placing the material in the combustion synthetic reaction device with poromeric hollow pipe according to the hollow ring-shaped cloth method after drying; charging 1-20 Mpa nitrogen gas in the vacuum device; inducing the combustion synthetic reaction through igniting. The invention realizes the complete nitridation of whole reactant at isothermal pattern, which improves the uniformity of silicon nitride powder.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com