Preparation method for carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material

A nano-composite material and supported technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult simultaneous realization, achieve good application prospects, simple preparation method, small size Uniform and fine effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, a method for preparing a carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material comprises the following steps:

[0036] (1) Weigh 0.5g ammonium molybdate and 4g dicyandiamide so that the mass ratio of ammonium molybdate to dicyandiamide is 1:8, dissolve them in a beaker with 100mL distilled water, and place the beaker on a magnetic stirrer , heated and stirred, and a white mixed precipitate was obtained after the distilled water volatilized, and the white mixed precipitate was placed in a constant temperature drying oven for drying, and ground into a white powder;

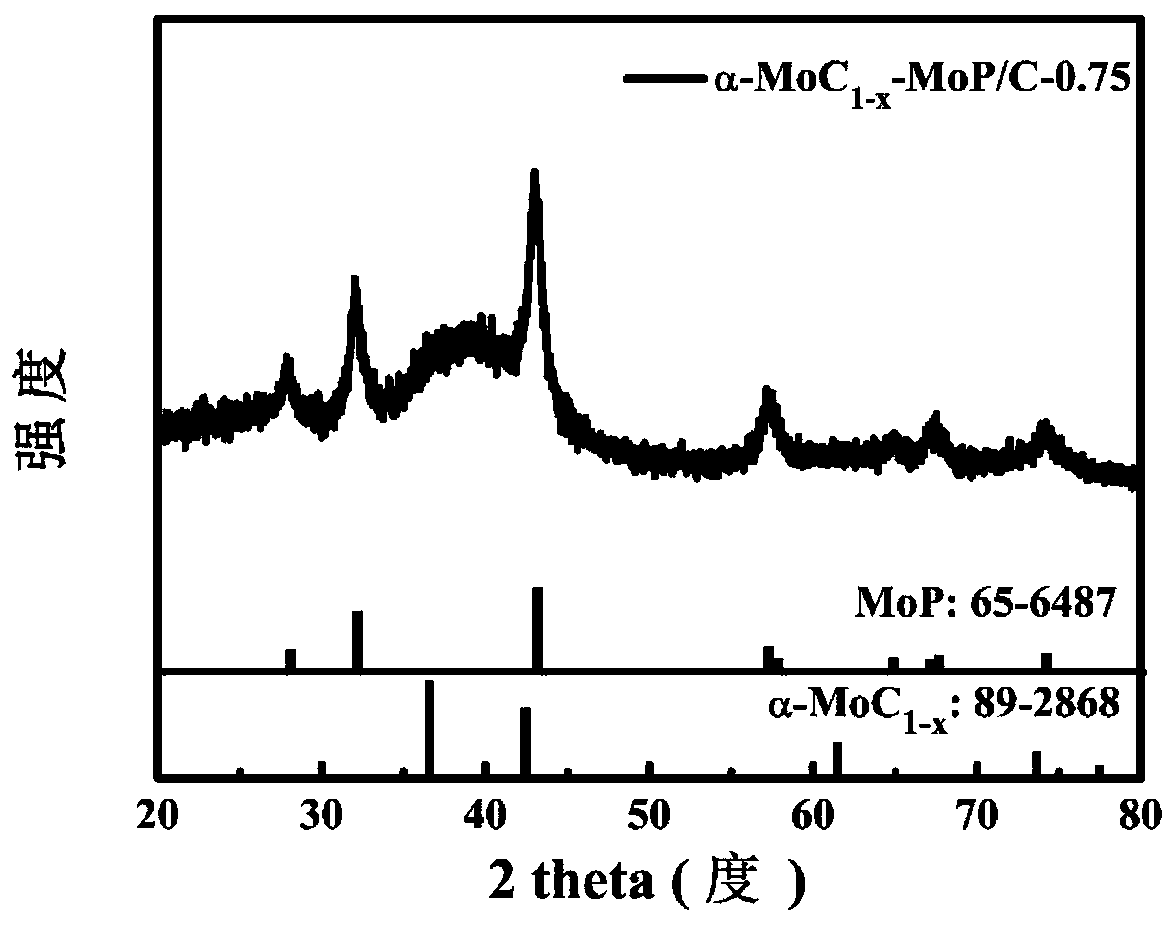

[0037] (2) Weigh 2g of white powder and 0.75g of sodium hypophosphite so that the mass ratio of white powder and sodium hypophosphite is 8:3, and place the two in two porcelain boats respectively, and then place the two porcelain boats Placed in a tube furnace, the porcelain boat containing sodium hypophosphite is located on the upstream side of the in...

Embodiment 2

[0041] In this embodiment, a method for preparing a carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material comprises the following steps:

[0042] (1) Weigh 0.5g ammonium molybdate and 4g dicyandiamide so that the mass ratio of ammonium molybdate to dicyandiamide is 1:8, dissolve them in a beaker with 100mL distilled water, and place the beaker on a magnetic stirrer , heated and stirred, and a white mixed precipitate was obtained after the distilled water volatilized, and the white mixed precipitate was placed in a constant temperature drying oven for drying, and ground into a white powder;

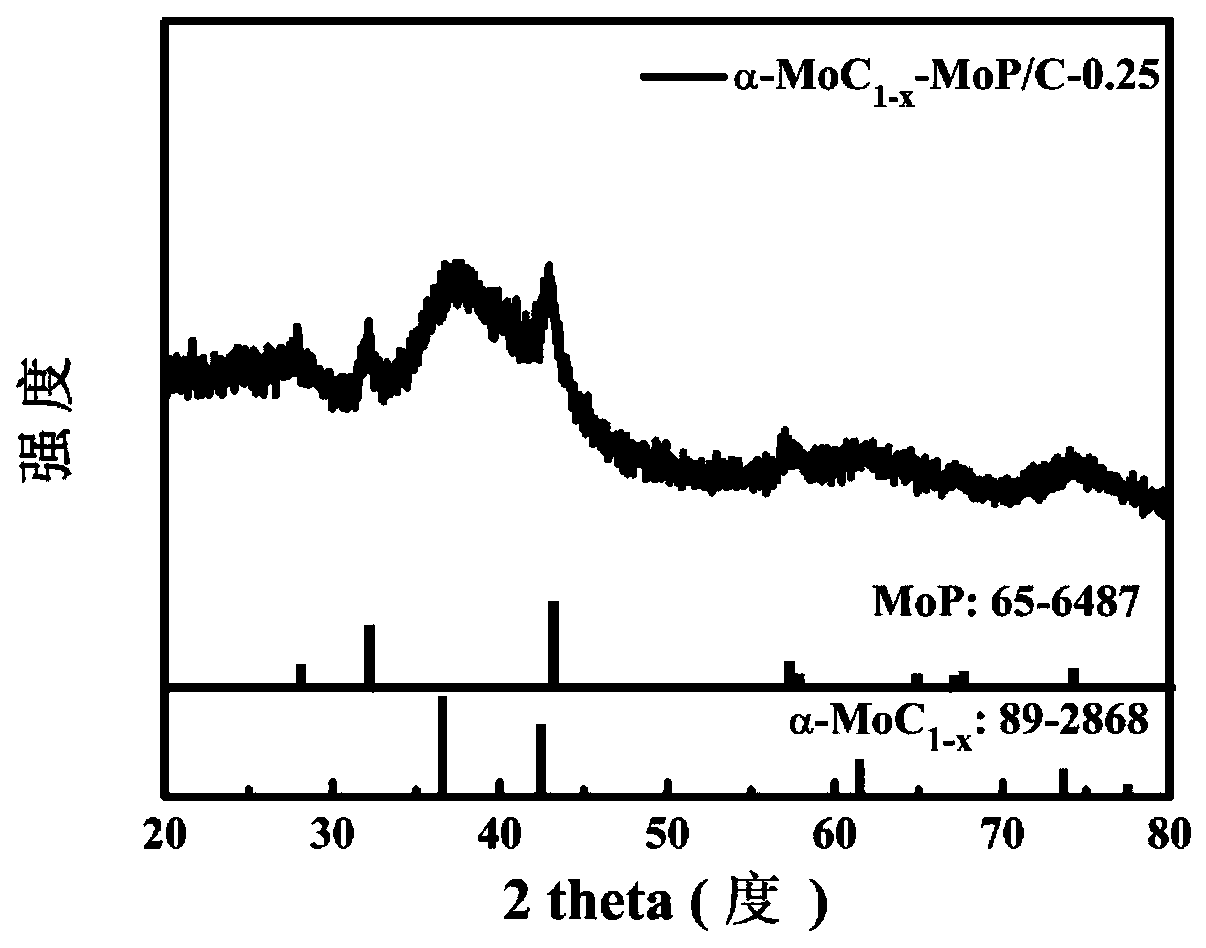

[0043] (2) Weigh 2g of white powder and 0.25g of sodium hypophosphite so that the mass ratio of white powder and sodium hypophosphite is 8:1, and place the two in two porcelain boats respectively, and then place the two porcelain boats Placed in a tube furnace, the porcelain boat containing sodium hypophosphite is located on the upstream side of the in...

Embodiment 3

[0045] In this embodiment, a method for preparing a carbon-supported alpha phase molybdenum carbide-molybdenum phosphide nanocomposite material comprises the following steps:

[0046] (1) Weigh 0.5g ammonium molybdate and 4g dicyandiamide so that the mass ratio of ammonium molybdate to dicyandiamide is 1:8, dissolve them in a beaker with 100mL distilled water, and place the beaker on a magnetic stirrer , heated and stirred, and a white mixed precipitate was obtained after the distilled water volatilized, and the white mixed precipitate was placed in a constant temperature drying oven for drying, and ground into a white powder;

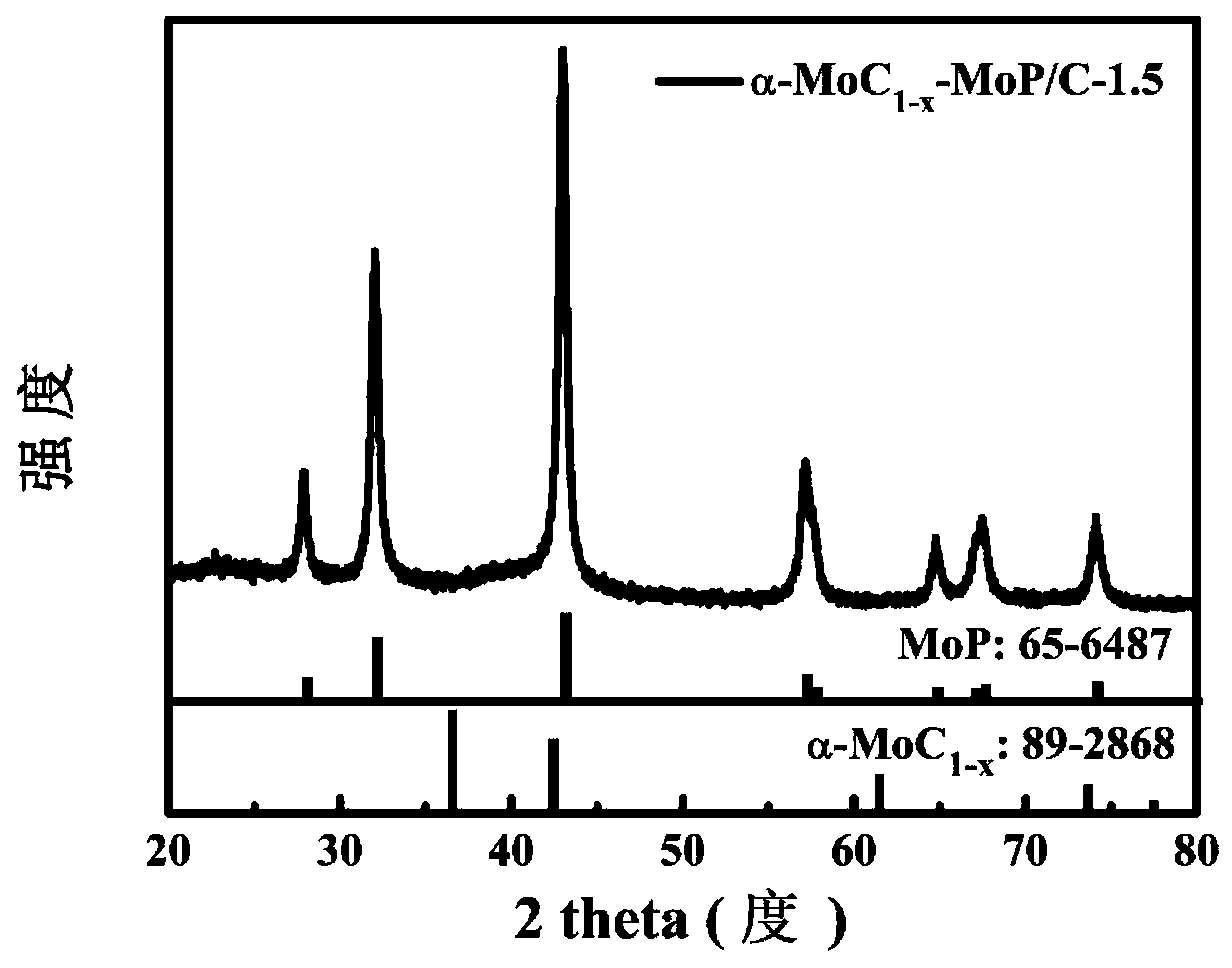

[0047](2) Weigh 2g of white powder and 1.5g of sodium hypophosphite so that the mass ratio of white powder and sodium hypophosphite is 4:3, and place the two in two porcelain boats respectively, and then place the two porcelain boats Placed in a tube furnace, the porcelain boat containing sodium hypophosphite is located on the upstream side of the inta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com