Process method for improving comprehensive mechanical performance of aluminum alloy boards

A technology of aluminum alloy plate and process method, which is applied in the field of aluminum alloy forming and heat treatment, can solve the problems of coarse grain, uneven deformation, incomplete precipitation, etc., achieve fine and uniform grain size, improve strength and plasticity, and promote crushing and the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

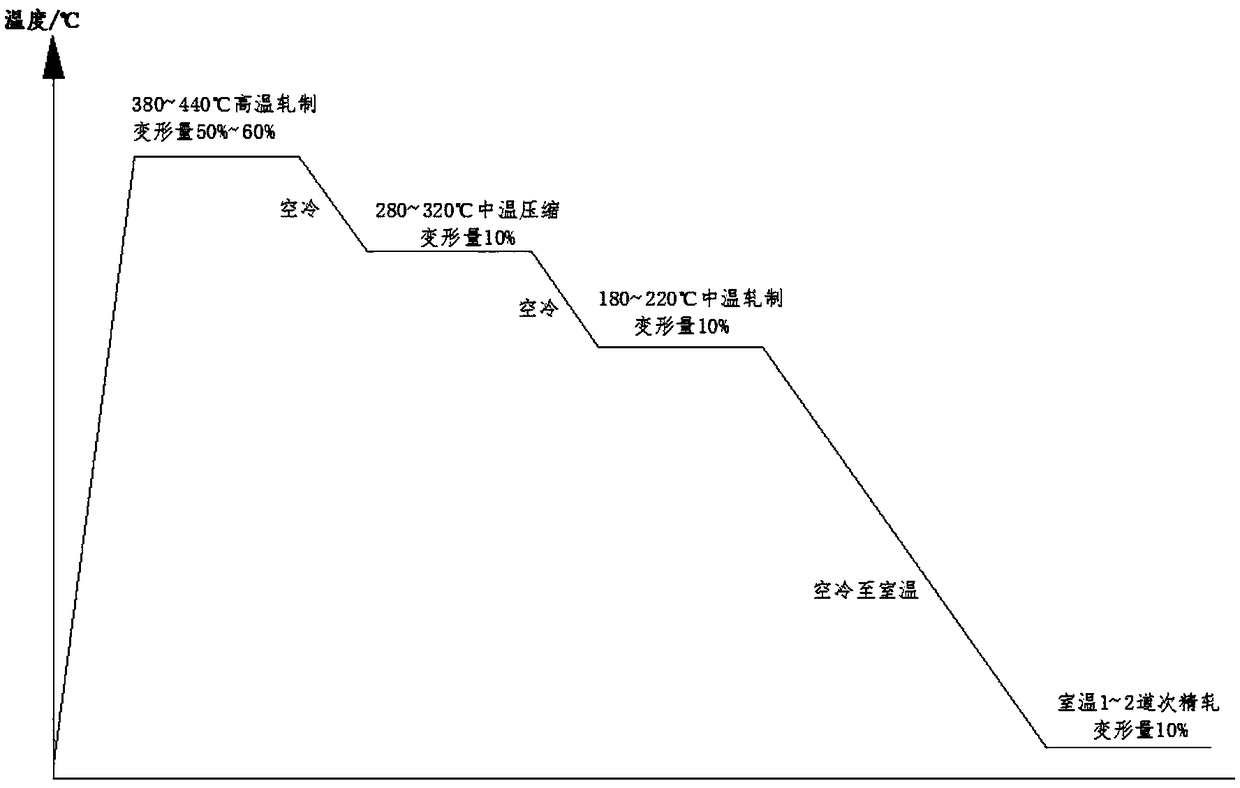

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of process method that improves the comprehensive mechanical property of 2A14 aluminum alloy plate is as follows:

[0027] (1) Raw material preparation: Cut the semi-continuously cast aluminum alloy square ingot to the required weight and size according to the process requirements, and mark the end face of the billet with a marker pen before forging to distinguish the three directions during forging to obtain raw materials;

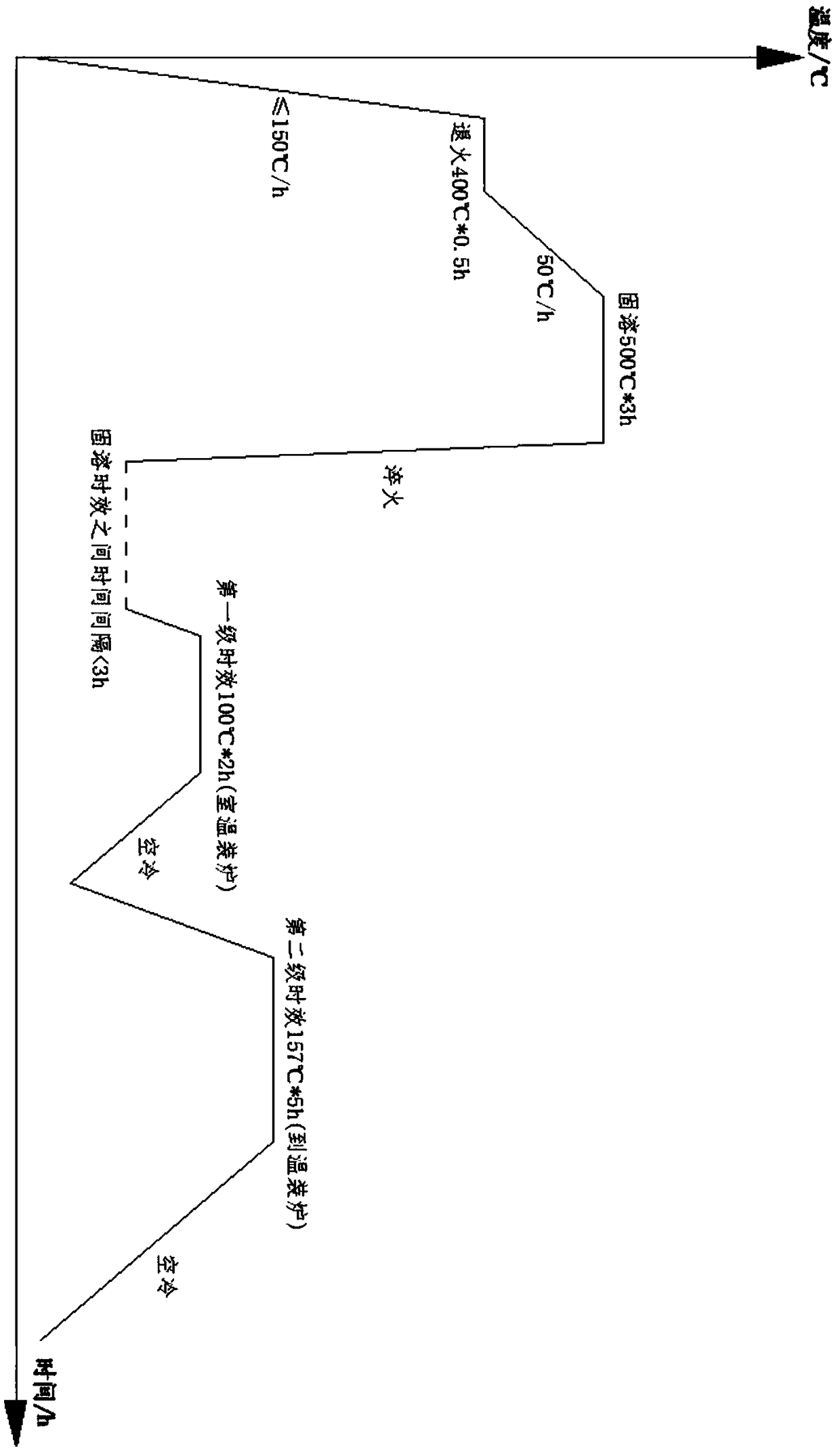

[0028] (2) Soaking: Put the raw materials obtained in step (1) into a furnace at room temperature, heat up to 490±5°C for 7.5 hours according to the power (≤150°C / h); then heat up to 530±5°C after 2 hours, and hold for 4 After 4 hours, the temperature was lowered to 460±5°C, and the homogenization heat treatment was carried out at this temperature for 2 hours, and the uniformity of the furnace temperature was ensured, so that the raw materials for homogenization heat treatment were obtained;

[0029] (3) Multi-axis forging: For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com