High-rate lithium vanadium phosphate positive electrode material, and preparation method and application thereof

A technology of lithium vanadium phosphate and cathode material, applied in the field of electrochemistry, can solve the problems of low ion diffusion coefficient, limitation, poor conductivity of lithium vanadium phosphate, etc., and achieve the effects of improving cycle performance, preventing agglomeration, and improving rate performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

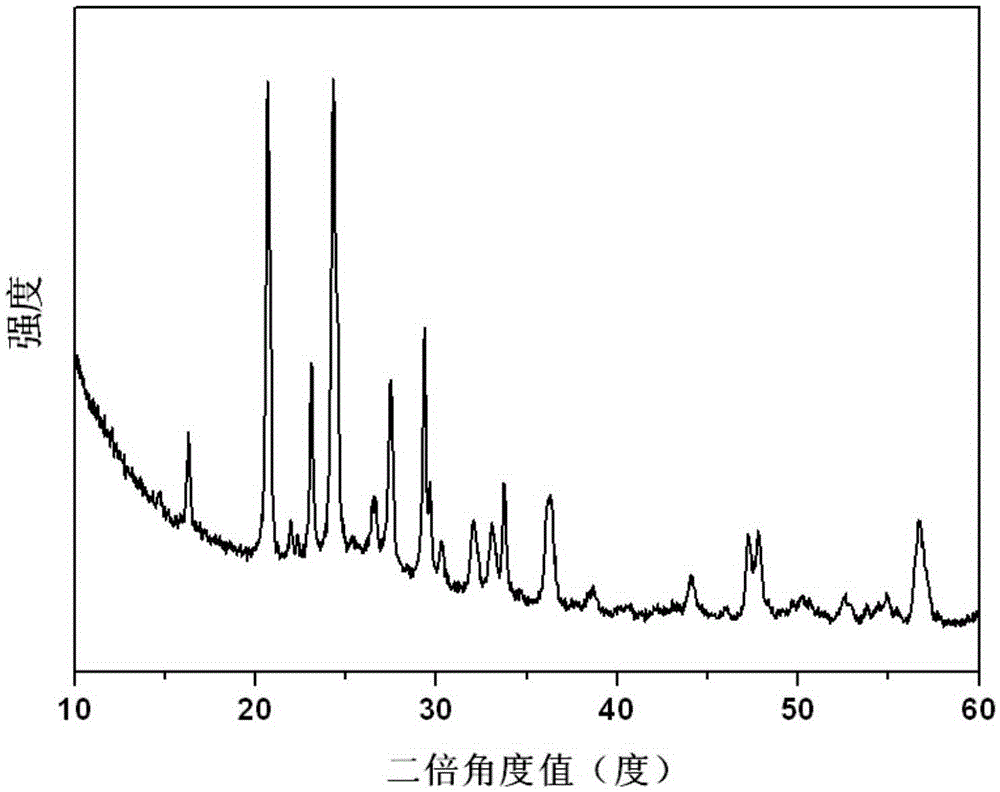

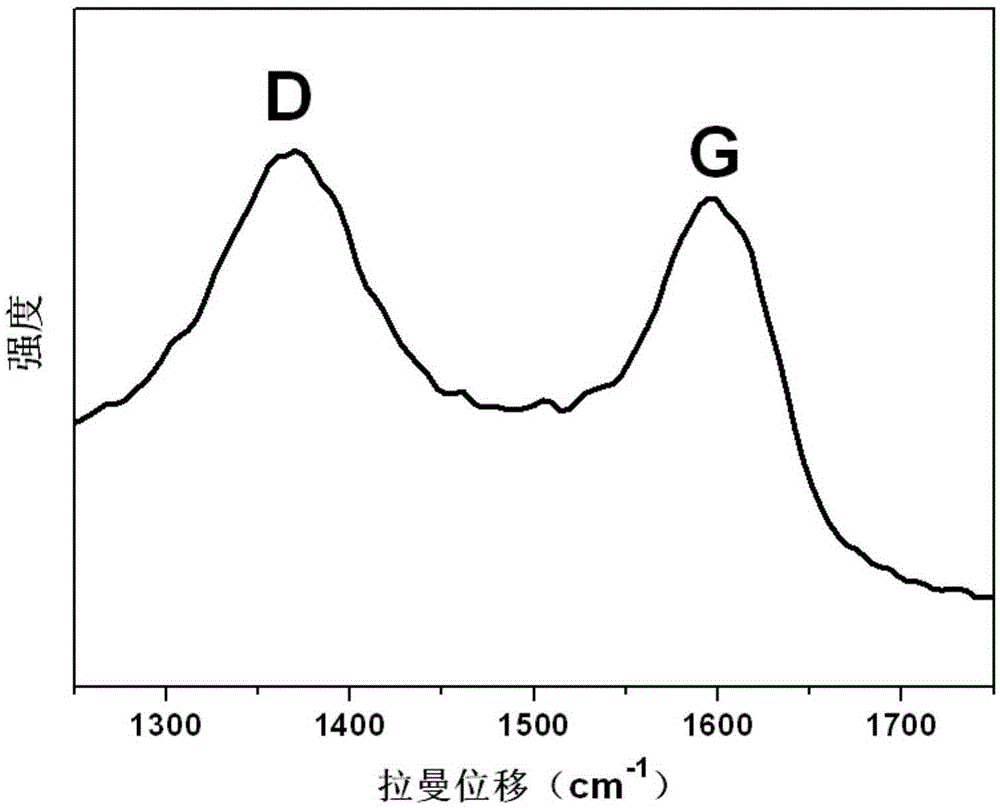

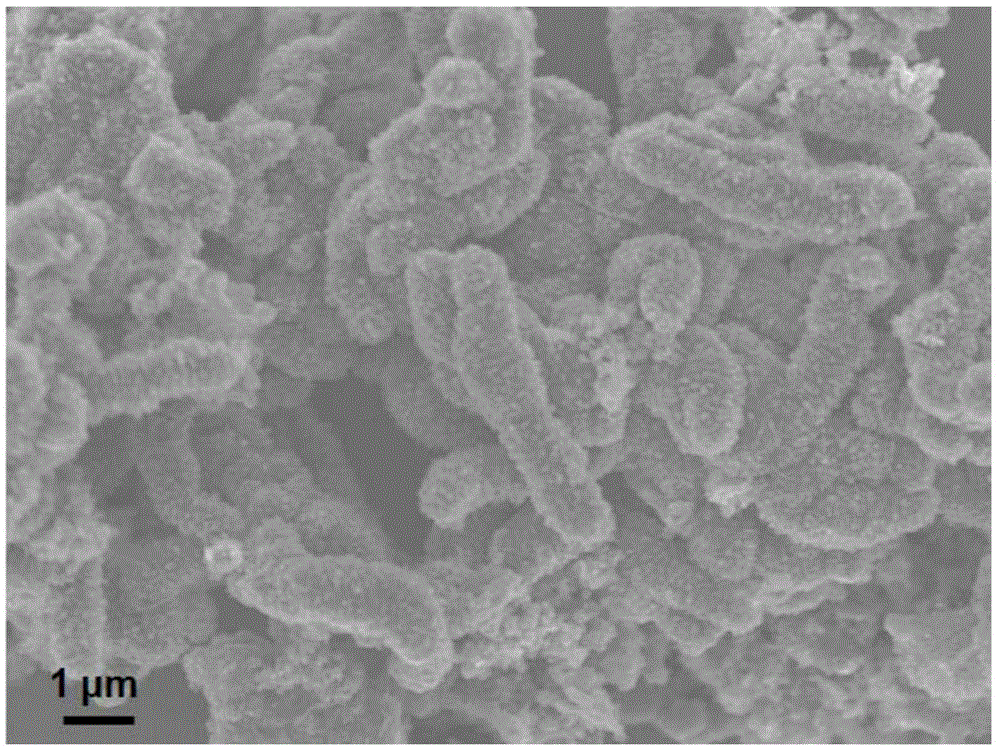

[0041] A method for preparing a high-rate lithium vanadium phosphate positive electrode material in this embodiment is prepared by using a solvothermal method at high temperature and high pressure, and the specific steps are as follows:

[0042] (1) First accurately weigh 400mg (1.5mmol) of tributyl phosphate, 153mg (1.5mmol) of lithium acetate dihydrate, and 348mg (1mmol) of vanadium acetylacetonate into 40mL of absolute ethanol solvent, and then add 1.0mL of oil Acid, ultrasonically dissolved for 20 minutes and then put into the autoclave, at a temperature of 400°C (control the heating rate at 2°C min -1 ), the reaction was carried out for 1 h under a pressure of 6 MPa to obtain the precursor of lithium vanadium phosphate positive electrode material.

[0043] (2) After taking out the precursor of the above-mentioned lithium vanadium phosphate positive electrode material, adopting a volume fraction of 95% ethanol to carry out centrifugal cleaning for 3 times (during centrifug...

Embodiment 2

[0049] The preparation method of a kind of high-rate lithium vanadium phosphate cathode material of the present embodiment, its specific steps are:

[0050] (1) First weigh 400mg (1.5mmol) of tributyl phosphate, 153mg (1.5mmol) of lithium acetate dihydrate, and 348mg (1mmol) of vanadium acetylacetonate into 40mL of absolute ethanol solvent, and then add 2.0mL of oleic acid , ultrasonically dissolved for 20 minutes and then placed in a high-pressure reactor, at a temperature of 500°C (controlling the heating rate at 2°C min -1 ), under the pressure of 2MPa, the reaction was carried out for 0.5h to obtain the precursor of lithium vanadium phosphate cathode material.

[0051] (2) After taking out the precursor of the above-mentioned lithium vanadium phosphate positive electrode material, adopting a volume fraction of 95% ethanol to carry out centrifugal cleaning for 3 times (during centrifugation, the rotating speed is 7000rpmmin -1 , the time is 10 min), and then put it into a ...

Embodiment 3

[0055] The preparation method of a kind of high-rate lithium vanadium phosphate cathode material of the present embodiment, its specific steps are:

[0056](1) First weigh 400mg (1.5mmol) of tributyl phosphate, 153mg (1.5mmol) of lithium acetate dihydrate, and 348mg (1mmol) of vanadium acetylacetonate into 40mL of absolute ethanol solvent, and then add 0.2mL of oleic acid , ultrasonically dissolved for 20 minutes and then placed in a high-pressure reactor, at a temperature of 250°C (controlled heating rate: 2°C min -1 ), the reaction was carried out for 5 h under a pressure of 10 MPa to obtain the precursor of lithium vanadium phosphate cathode material.

[0057] (2) After taking out the precursor of the above-mentioned lithium vanadium phosphate positive electrode material, adopting a volume fraction of 95% ethanol to carry out centrifugal cleaning for 3 times (during centrifugation, the rotating speed is 7000rpmmin -1 , the time is 10 min), and then put it into a vacuum ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com