Method for preparing carbon coated nanometer LiFePO4

A lithium iron phosphate and nano iron phosphate technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems affecting the large-scale production and application of lithium iron phosphate materials, poor conductivity of lithium iron phosphate cathode materials, Cathode material purity and non-uniform particle size, etc., to achieve the effect of easy implementation, improved ion mobility and electrical conductivity, and wide particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Take nano-iron phosphate, nano-lithium carbonate and stearic acid according to the ratio of molar ratio Fe:Li:C=1:1:2.5, wherein iron phosphate is 0.005mol. Dissolving stearic acid in ethanol, and then adding nano-iron phosphate and nano-lithium carbonate thereto. The resulting suspension was sonicated for 15 min to obtain a stable and uniform nanofluid. The nanofluid was dried in a constant temperature oven at 80° C. for 30 minutes, and the solvent was removed to obtain a solid particle reaction mixture.

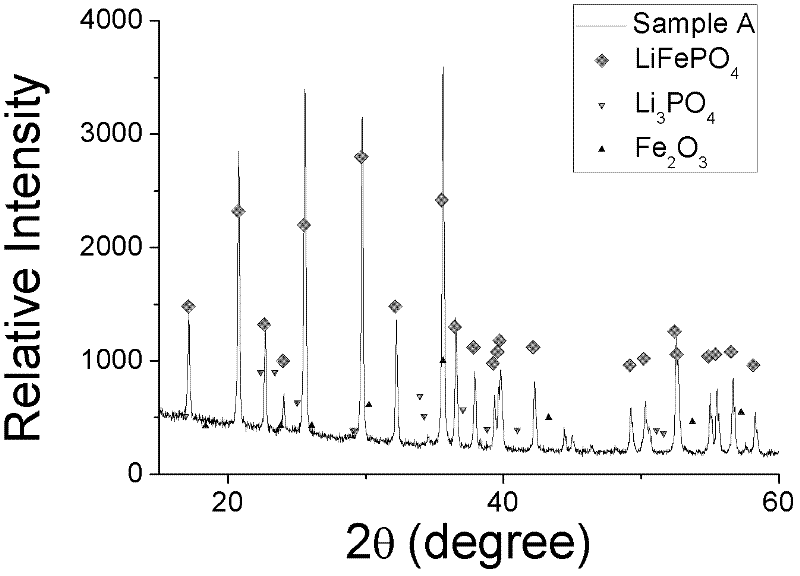

[0028] 2) The obtained solid particle reaction mixture was placed in a tubular reactor, pre-calcined at 300° C. for 1 h in an inert gas Ar atmosphere atmosphere, and calcined at 700° C. for 6 h, wherein the heating rate was 5 K / min. Lithium iron phosphate particles were obtained after natural cooling, which was designated as sample A.

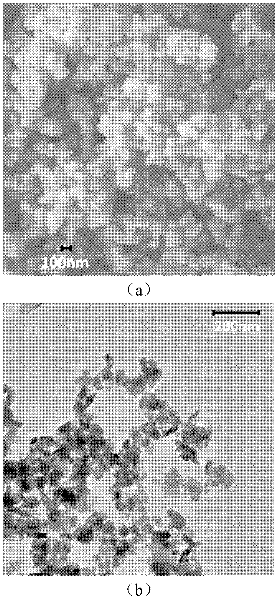

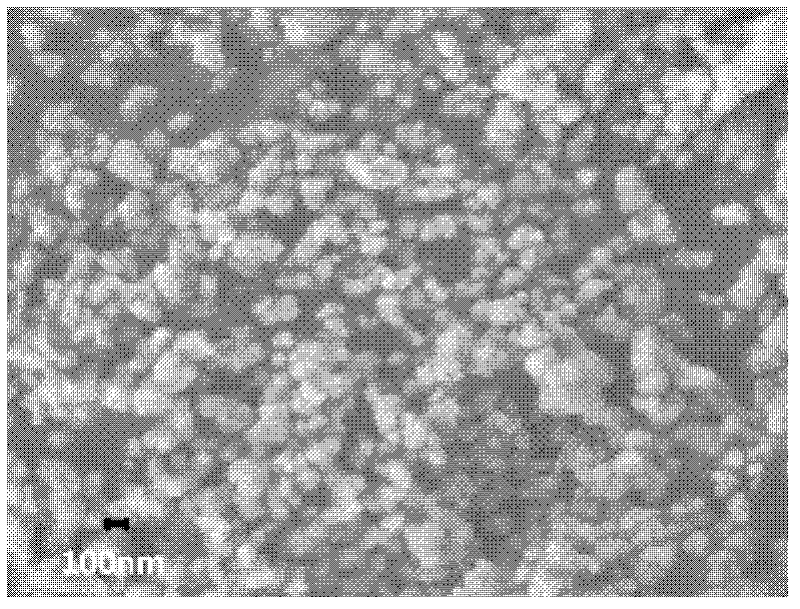

[0029] figure 1 The SEM image of the nano-iron phosphate and the TEM image of the nano-lithium carbonate used in Example 1 sho...

Embodiment 2

[0031] 1) Take nano-iron phosphate, nano-lithium carbonate and vitamin C according to the ratio of molar ratio Fe:Li:C=1:1:5, wherein iron phosphate is 0.005mol. The vitamin C is dissolved in an aqueous solution of acetone containing 50% of acetone, and then nano iron phosphate and nano lithium carbonate are added thereto. The resulting suspension was sonicated for 15 min to obtain a stable and uniform nanofluid. Send the nanofluid into a vacuum desiccator to remove the solvent to obtain a solid particle reaction mixture.

[0032] 2) The obtained solid particle reaction mixture was placed in a tubular reactor, pre-calcined at 300° C. for 1 h in an inert gas Ar atmosphere atmosphere, and calcined at 700° C. for 6 h, wherein the heating rate was 5 K / min. Lithium iron phosphate particles were obtained after natural cooling.

Embodiment 3

[0034] 1) Take nano-iron phosphate, nano-lithium carbonate and oxalic acid according to the ratio of molar ratio Fe:Li:C=1:1:3, wherein iron phosphate is 0.005mol. Dissolving oxalic acid in isopropanol aqueous solution containing 30% isopropanol, and then adding nano iron phosphate and nano lithium carbonate thereto. The resulting suspension was mechanically ground for 15 min to obtain a stable and uniform nanofluid. The nanofluid is sent to a flash evaporator to remove the solvent to obtain a solid particle reaction mixture.

[0035] 2) The obtained solid particle reaction mixture is placed in a tubular reactor, pre-calcined at 300° C. for 1 h in a hydrogen atmosphere, and calcined at 700° C. for 6 h, wherein the heating rate is 10 K / min. Lithium iron phosphate particles were obtained after natural cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com