Solid Rare Earth Nitriding Catalyst

A permeation accelerator and nitriding technology, which is applied in the field of solid rare earth nitriding and permeation catalyst, can solve the problems of high power consumption, low efficacy, and long time, and achieve the effects of low production cost, convenient use, and improved brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] An enterprise in Chengdu uses the solid rare earth nitriding catalyst of the present invention:

[0023] (1) Equipment and process:

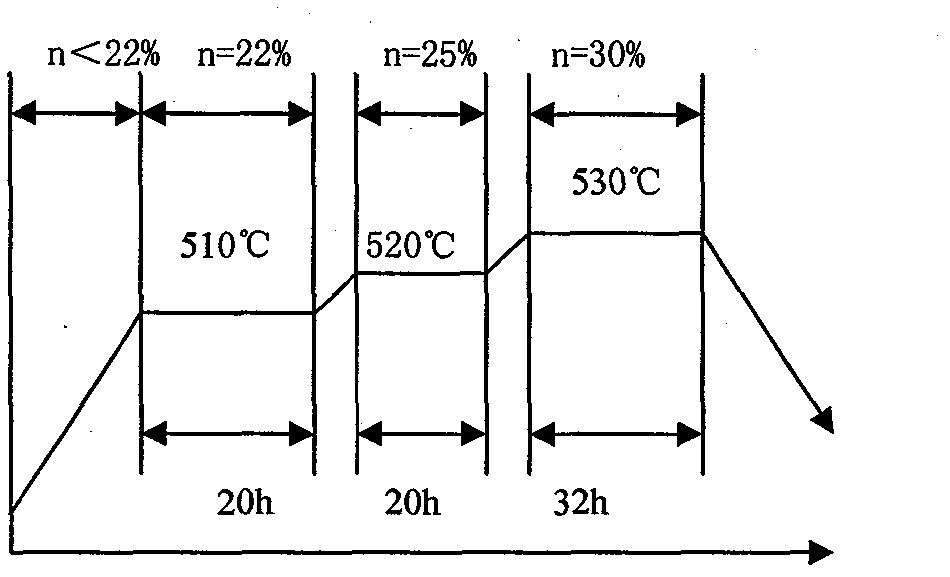

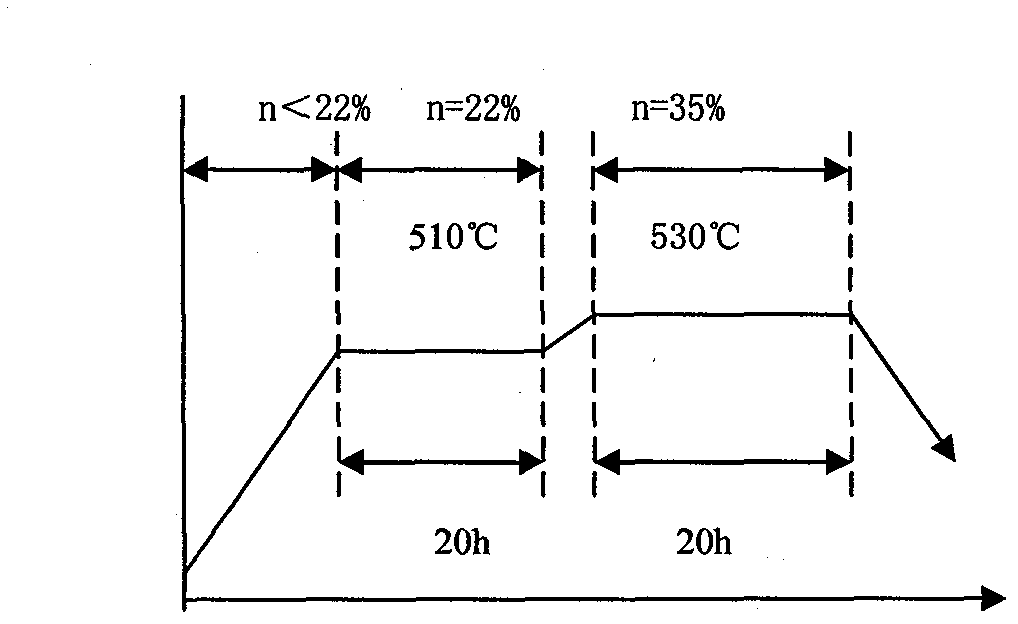

[0024] Production equipment: controllable well type nitriding furnace, 80KW; parts material 38CrMoAl; technical quality requirements: permeated layer 0.4mm, hardness above HV850; original production process see figure 1 Shown: Nitriding holding time is 72 hours. The production process using rare earth nitriding is figure 2 , The nitriding holding time used is 40 hours. Shorten the time by 32 hours, increase the permeation rate by more than 40%; save ammonia consumption by 2 times, and have obvious energy-saving and emission-reduction effects.

[0025] (2) use 5 rare earth infiltrating agents of the present invention, pack into the nitriding furnace together with the workpiece, adopt the production process of the rare earth nitriding described in (1) in the example 1 to produce, can obtain the (1) in the example 1 ) of the results des...

example 2

[0027] An enterprise in Chongqing uses the rare earth infiltrator of the present invention:

[0028] (1) Equipment and process:

[0029] Production equipment: controllable well type nitriding furnace, 90KW; parts material 42CrMo; technical quality requirements: permeated layer 0.4mm, hardness above HV580; the original production process adopts 520°C, and the nitriding holding time is 40 hours. After nitriding, the surface hardness can reach HV620; after nitriding with rare earth, the rare earth infiltration accelerator of the present invention is used, the production process is 540°C, and the nitriding holding time is 16 hours. The penetration layer reaches 0.4mm, the surface hardness reaches HV730, and the brittleness: 0--1 level. Compared with the original process, the time is shortened by 24 hours and the permeation rate is increased by 60%.

[0030] (2) use 5 rare earth infiltrating agents of the present invention, be placed in iron can, pack into nitriding furnace toget...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com