Nitriding processing technology for sewing machine presser foot piece

A sewing machine presser foot and processing technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems that cannot meet the high-precision technical requirements, the surface hardness of the presser foot parts is low, and the hardness of the workpiece is low. , to achieve the effect of saving quenching and tempering treatment process before nitriding, reducing production cost and increasing nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

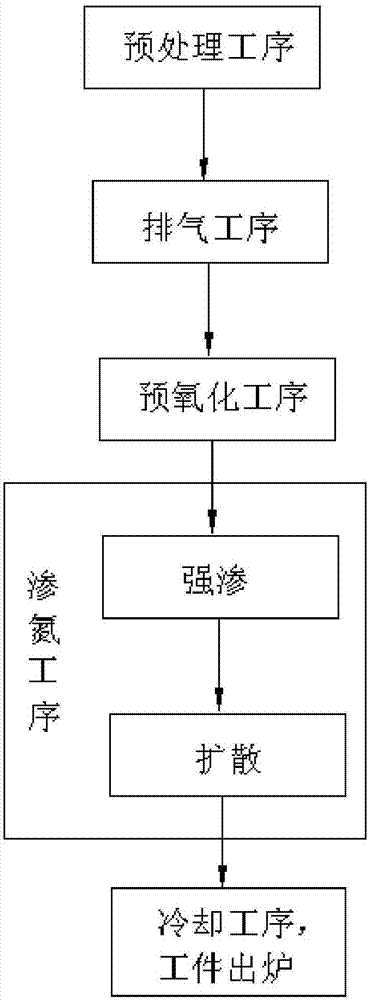

[0024] A nitriding processing technology for a sewing machine presser foot, comprising the following processing steps:

[0025] (1) Pretreatment process; the sewing machine presser foot made of 56CrNiMoV7 is placed in an ultrasonic cleaning machine for cleaning to remove the oil stains on the surface of the sewing machine presser foot; rack, and hoisted into the well-type nitriding furnace model RN-75-6;

[0026] (2) Exhaust process; after checking that the lid of the nitriding furnace is covered correctly, the nitriding furnace is heated up, and nitrogen gas with a purity of more than 99.99% is introduced during the heating process to exhaust the air in the nitriding furnace. The nitrogen flow rate is set to 1m 3 / h, and at the same time control the furnace pressure to 0.01Pa;

[0027] (3) Pre-oxidation process; when the furnace temperature in the nitriding furnace rises to 300°C, keep it warm for 1 hour to ensure that the temperature of the sewing machine presser foot also...

Embodiment 2

[0032] A nitriding processing technology for a sewing machine presser foot, comprising the following processing steps:

[0033] (1) Pretreatment process; the sewing machine presser foot made of 56CrNiMoV7 is placed in an ultrasonic cleaning machine for cleaning to remove the oil stains on the surface of the sewing machine presser foot; rack, and hoisted into the well-type nitriding furnace model RN-75-6;

[0034] (2) Exhaust process; after checking that the lid of the nitriding furnace is covered correctly, the nitriding furnace is heated up, and nitrogen gas with a purity of more than 99.99% is introduced during the heating process to exhaust the air in the nitriding furnace. The nitrogen flow rate is set to 1m 3 / h, and at the same time control the furnace pressure to 0.02Pa;

[0035] (3) Pre-oxidation process; when the furnace temperature in the nitriding furnace rises to 300°C, keep it warm for 1 hour to ensure that the temperature of the sewing machine presser foot also...

Embodiment 3

[0040] A nitriding processing technology for a sewing machine presser foot, comprising the following processing steps:

[0041](1) Pretreatment process; the sewing machine presser foot made of 56CrNiMoV7 is placed in an ultrasonic cleaning machine for cleaning to remove the oil stains on the surface of the sewing machine presser foot; rack, and hoisted into the well-type nitriding furnace model RN-75-6;

[0042] (2) Exhaust process; after checking that the lid of the nitriding furnace is covered correctly, the nitriding furnace is heated up, and nitrogen gas with a purity of more than 99.99% is introduced during the heating process to exhaust the air in the nitriding furnace. The nitrogen flow rate is set to 1m 3 / h, and at the same time control the furnace pressure to 0.01Pa;

[0043] (3) Pre-oxidation process; when the furnace temperature in the nitriding furnace rises to 280°C, keep it warm for 1 hour to ensure that the temperature of the sewing machine presser foot also ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com