Nitrogen-enriched porous material/carbon nano structure composite material as well as preparation method and application thereof

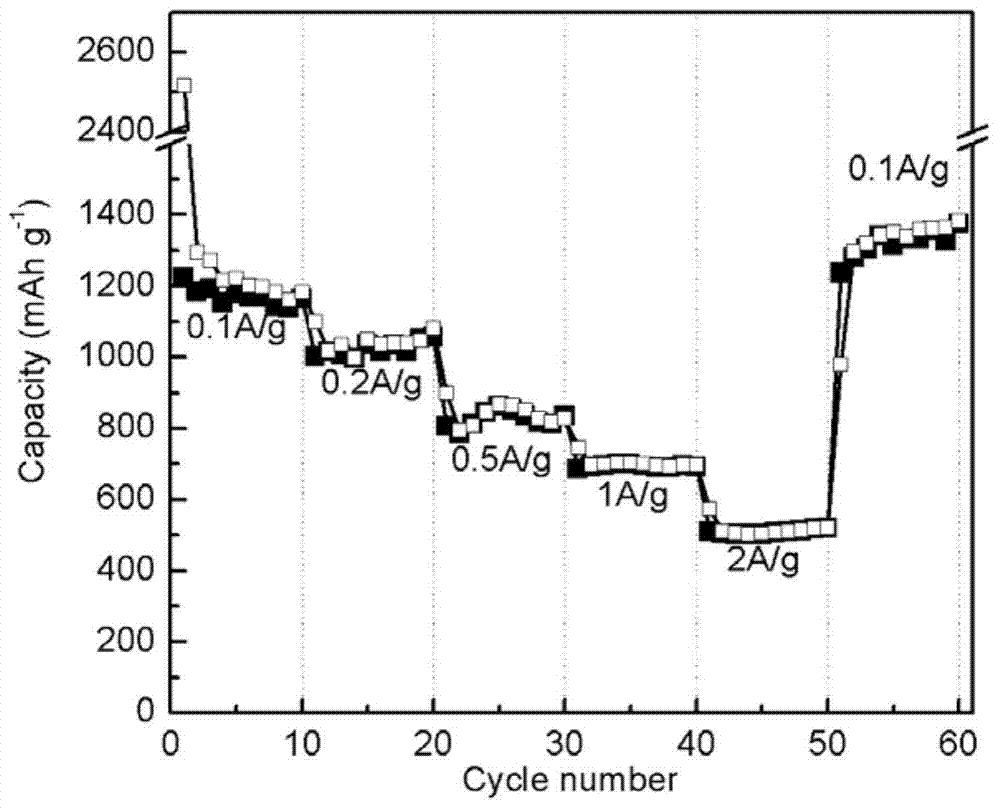

A carbon nanostructure and porous material technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of complex nitrogen atom doping process, limited doping degree, template method is not suitable for large-scale production, etc., to achieve superior Effect of cycle performance, rate performance, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

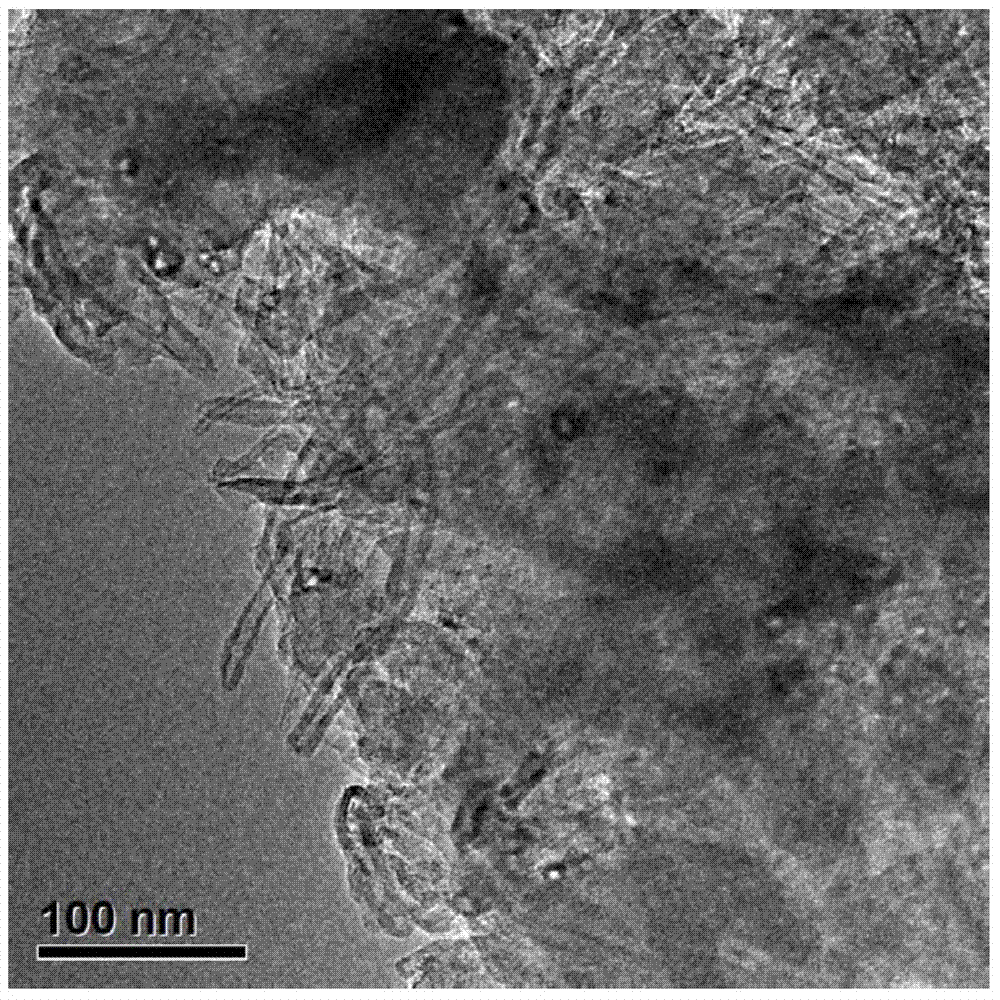

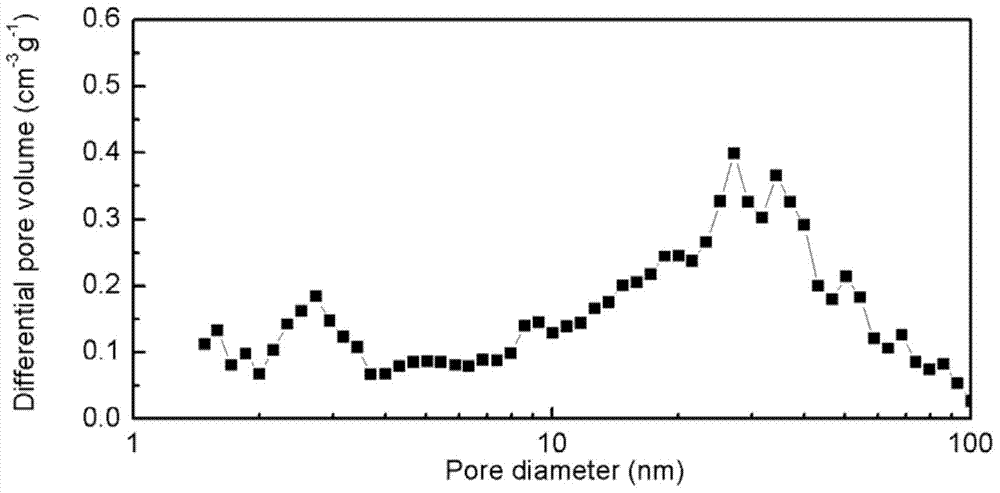

Embodiment 1

[0053]In a 20 ml thick-walled pressure-resistant reaction flask, add 0.5 g of melamine (purchased from Alfa Aisha (Tianjin) Co., with a purity of 99% by weight, the same below) and 0.4 g of terephthalaldehyde (purchased from Alfa Aisha (Tianjin) Co., Ltd. Sasha (Tianjin) Company, the purity is 99% by weight, the same below), 0.08g carbon nanotubes (purchased from Beijing Boyu Hi-Tech, the purity is 99% by weight, the same below) and 5mL dimethyl sulfoxide (purchased from Alpha Aisha (Tianjin) Co., the purity is 99% by weight, the same below), reacted at 180° C. for 72 hours under stirring, and separated the solid. Gained solid is mixed with zinc chloride (purchased from Alfa Aisha (Tianjin) Company, purity is 99% by weight, hereinafter the same) by 1:10 mass ratio, packed into a 10ml vacuum-sealed tube full of argon, pumped Vacuum seal. Afterwards, the sealed tube was heat-treated at 450°C for 6 hours at high temperature, washed three times with 0.1mol / L dilute hydrochloric a...

Embodiment 2

[0057] In 20 milliliters of thick-walled pressure-resistant reaction flasks, add 0.5 g of melamine and 0.4 g of terephthalaldehyde (purchased from Alfa Aisha (Tianjin) Company, the purity is 99% by weight, the same below) 0.08 g of carbon nanotubes ( Purchased from Beijing Boyu Hi-Tech, the purity is 99% by weight, the same below) and 5mL dimethyl sulfoxide (purchased from Alfa Aisha (Tianjin) Company, the purity is 99% by weight, the same below), under stirring at 180 ° C After 72 hours of reaction, a solid separated. Gained solid is mixed with zinc chloride (purchased from Alfa Aisha (Tianjin) Company, purity is 99% by weight, hereinafter the same) by 1:10 mass ratio, packed into a 10ml vacuum-sealed tube full of argon, pumped Vacuum seal. Afterwards, the sealed tube was heat-treated at 600°C for 4 hours at high temperature, washed three times with 0.1mol / L dilute hydrochloric acid and 10ml of distilled water, and then vacuum-dried at 80°C for 12 hours to obtain a nitrogen-...

Embodiment 3

[0060] In a 20 ml thick-walled pressure-resistant reaction flask, add 0.5 g of melamine (purchased from Alfa Aisha (Tianjin) Co., with a purity of 99% by weight, the same below) and 0.4 g of terephthalaldehyde (purchased from Alfa Aisha (Tianjin) Co., Ltd. Sasha (Tianjin) Company, the purity is 99% by weight, the same below) 0.12g carbon nanotubes (purchased from Beijing Boyu Hi-Tech, the purity is 99% by weight, the same below) and 10mL dimethyl sulfoxide (purchased from Alfa Sasha (Tianjin) Co., the purity is 99% by weight, the same below), reacted at 150° C. for 150 hours under stirring, and separated the solid. Gained solid is mixed with zinc chloride (purchased from Alfa Aisha (Tianjin) Company, purity is 99% by weight, hereinafter the same) by 1:10 mass ratio, packed into a 10ml vacuum-sealed tube full of argon, pumped Vacuum seal. Afterwards, the sealed tube was heat-treated at 600°C for 6 hours at high temperature, washed three times with 0.1mol / L dilute hydrochloric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com