Low-temperature ion nitriding method for synchronously improving wear resistance and fatigue resistance of titanium alloy

A technology of ion nitriding and titanium alloy, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems that it is difficult to simultaneously improve wear resistance and fatigue resistance, and achieve excellent hardness and toughness matching, Effects of resisting fretting wear and improving low-cycle fatigue and high-cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

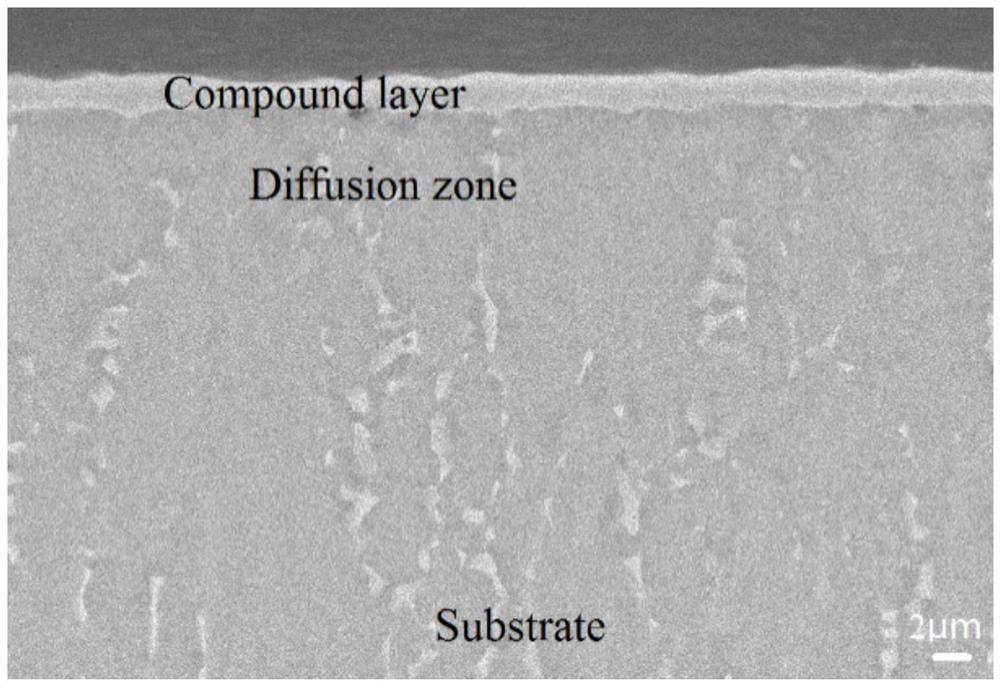

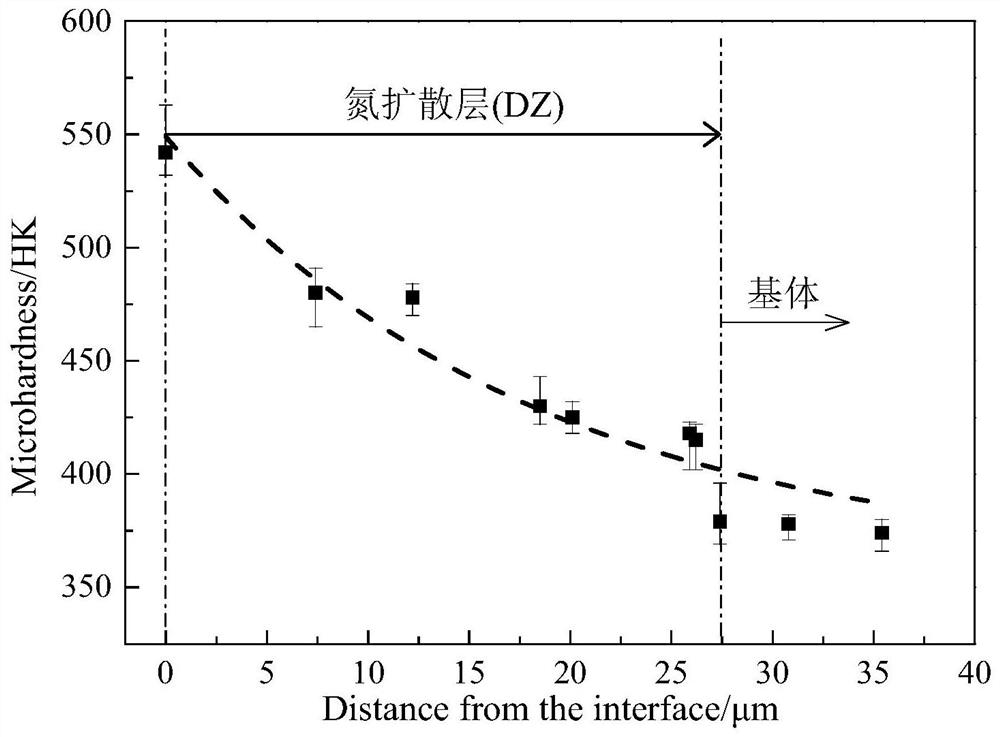

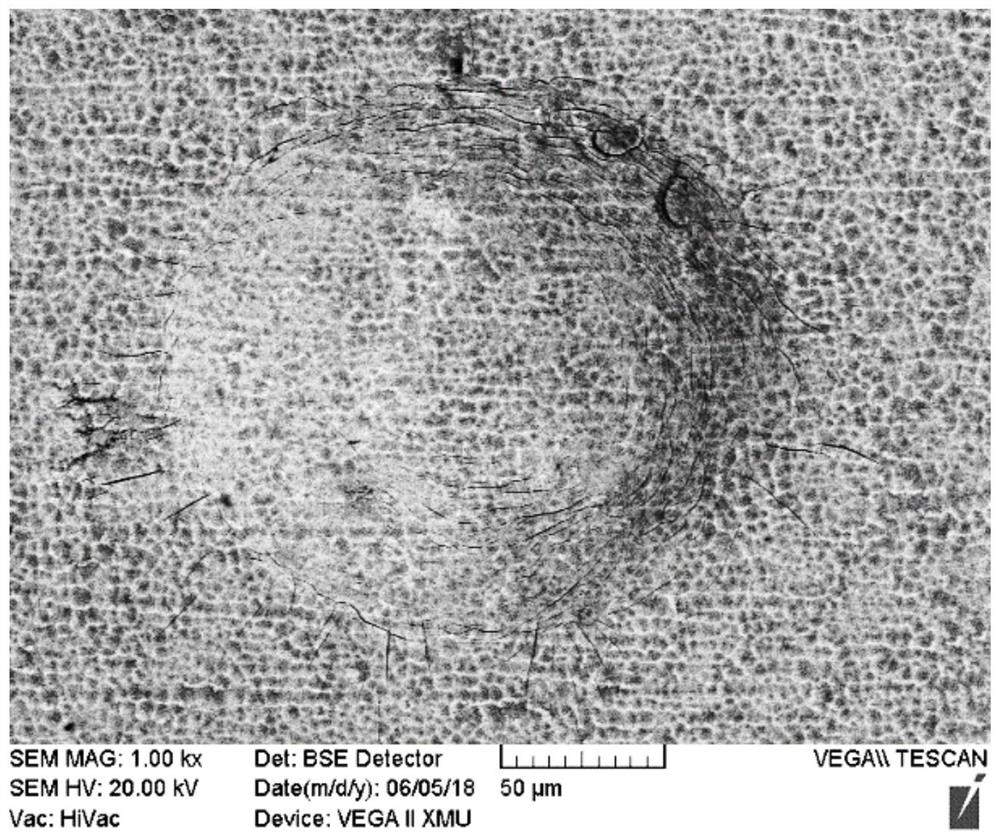

[0064] Nitriding treatment of TC4 titanium alloy disc samples and fatigue samples, the specific steps are as follows:

[0065] Step 1. Pretreatment of the substrate surface. The TC4 titanium alloy disc (size Φ30×8mm) used for hardness, toughness and wear testing was mechanically polished; the TC4 titanium alloy fatigue sample was mechanically polished along the axial direction; the polished sample was ultrasonically cleaned with acetone and alcohol Clean and dry after use.

[0066] Step 2. Place the workpiece and the auxiliary plate. Hang the cleaned TC4 titanium alloy disc and fatigue sample on the workpiece pole; hang two pure nickel plates (size 200×180×5mm, which can completely cover the sample) on the auxiliary poles on both sides of the sample; Adjust the distance between the pure nickel plate and the workpiece surface to 25mm.

[0067] Step 3. Sputter cleaning the workpiece and the auxiliary plate. After the vacuum chamber is pumped to high vacuum, argon gas with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com