Patents

Literature

105results about How to "Eliminate interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

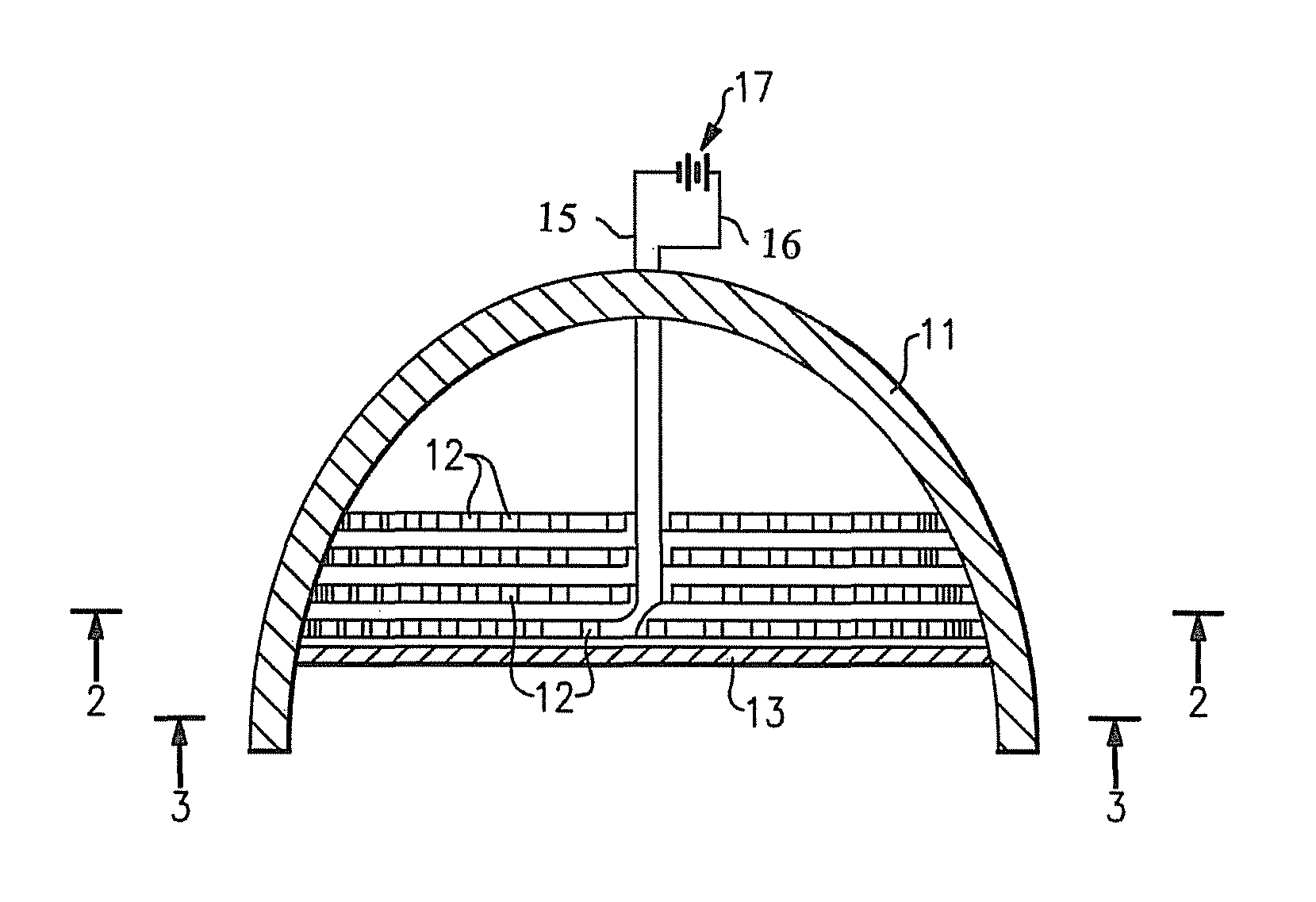

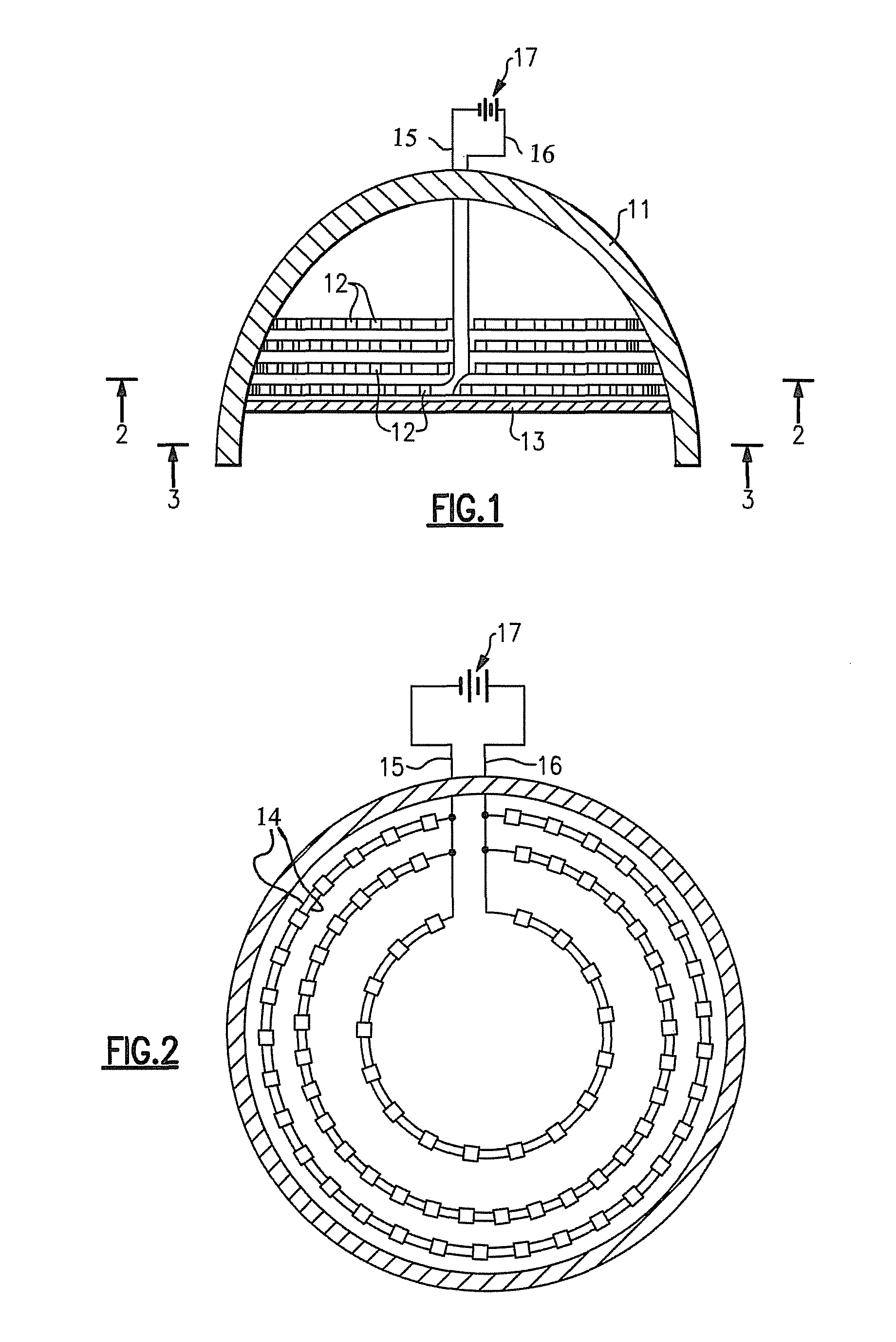

Lighting device

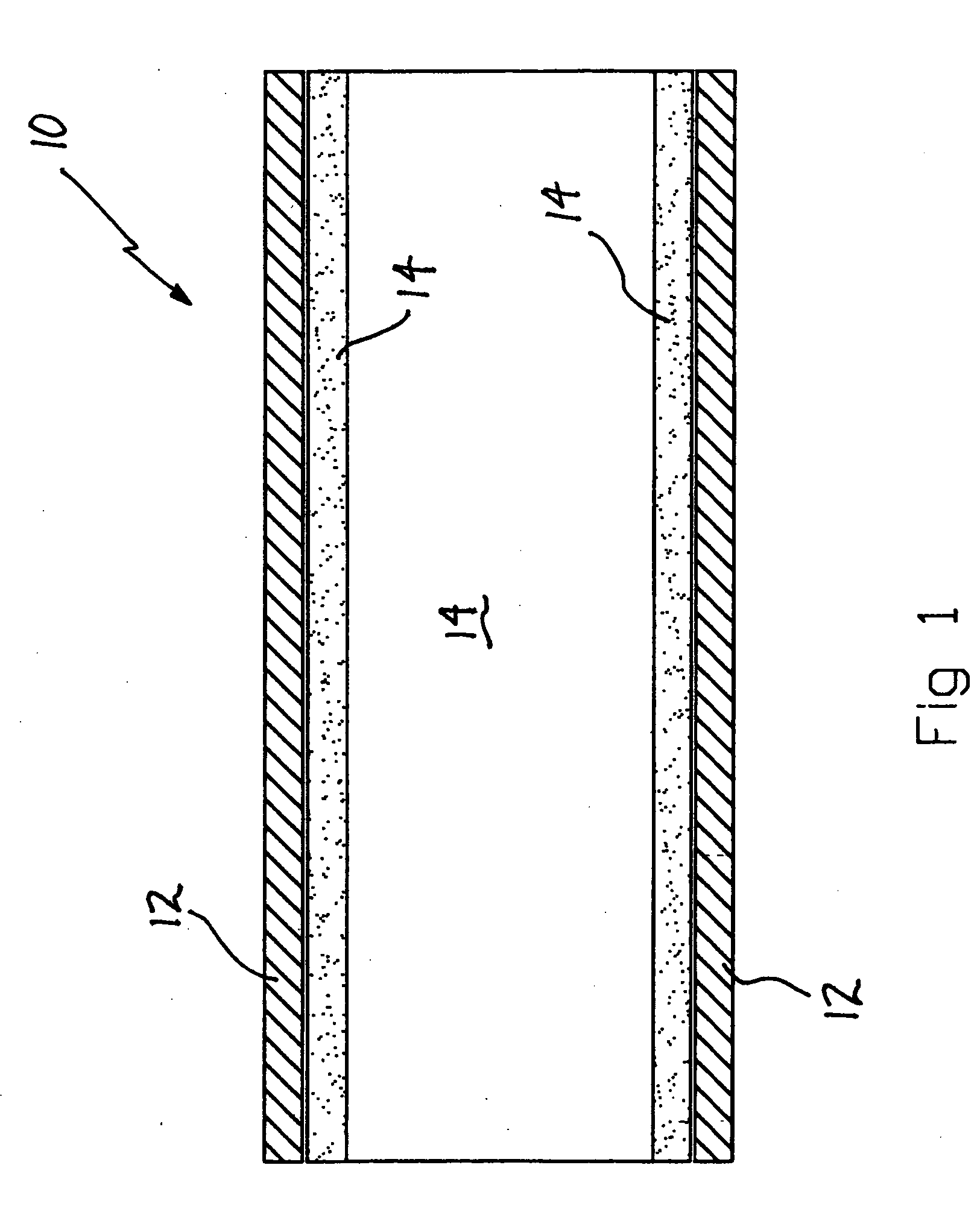

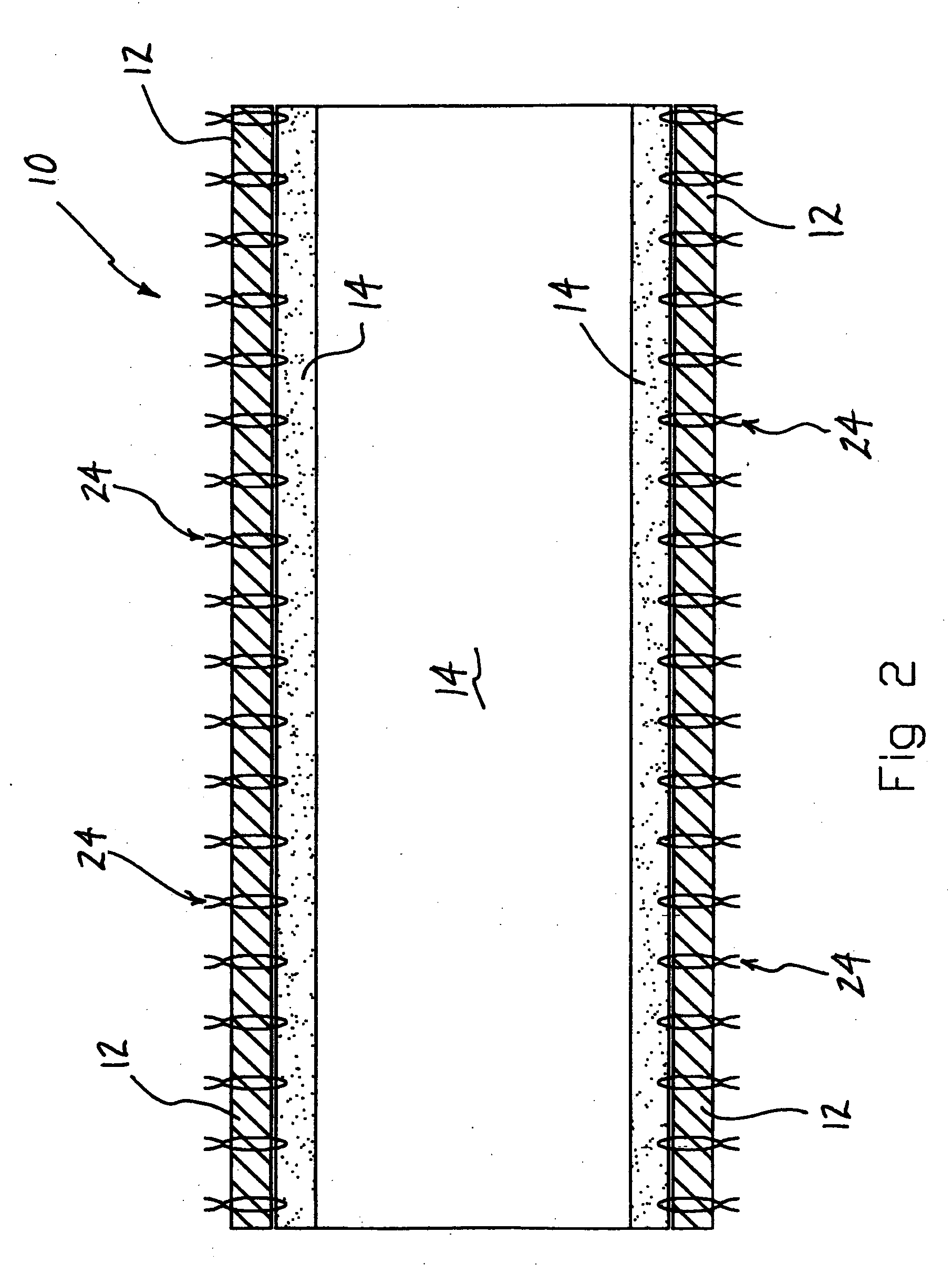

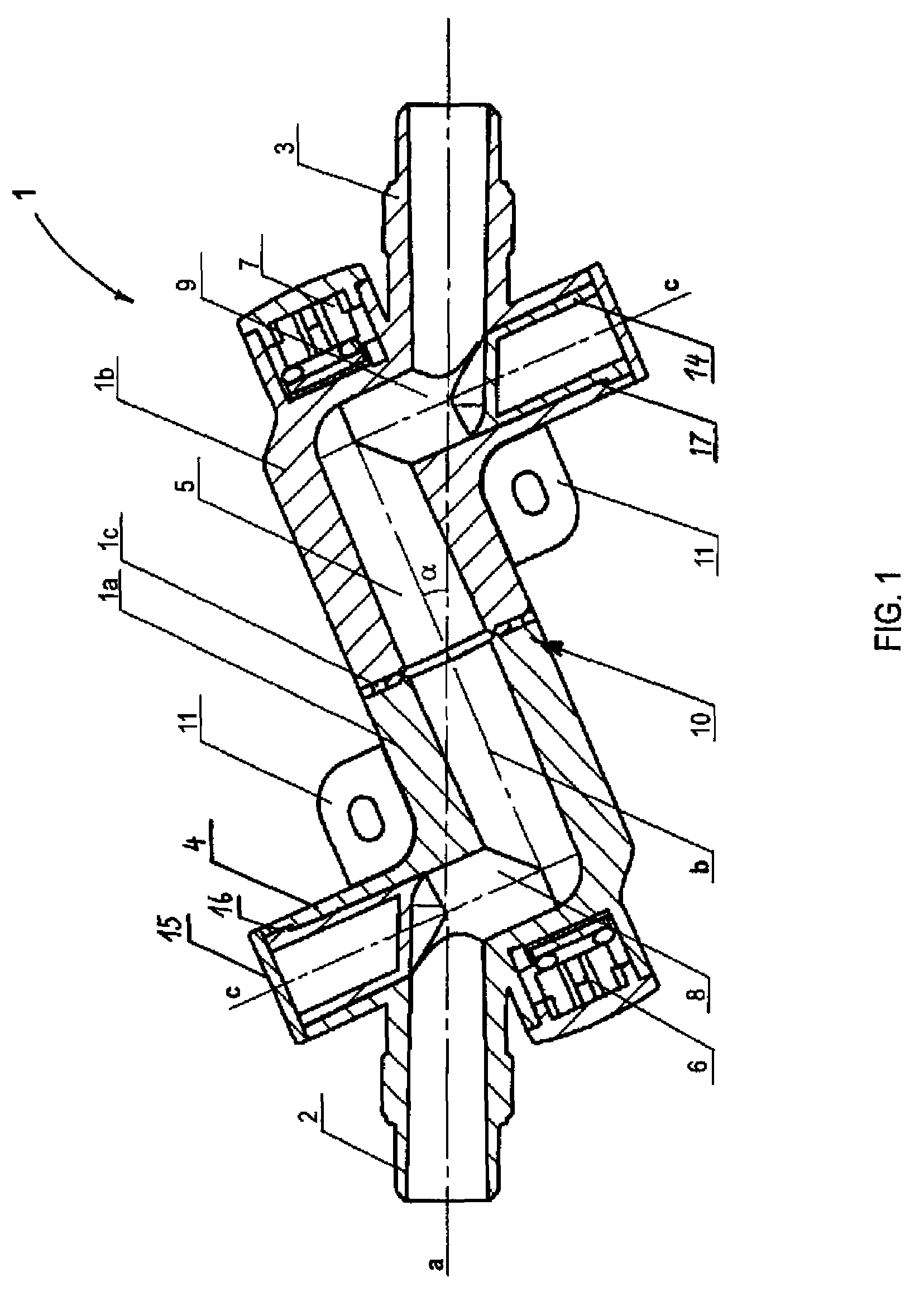

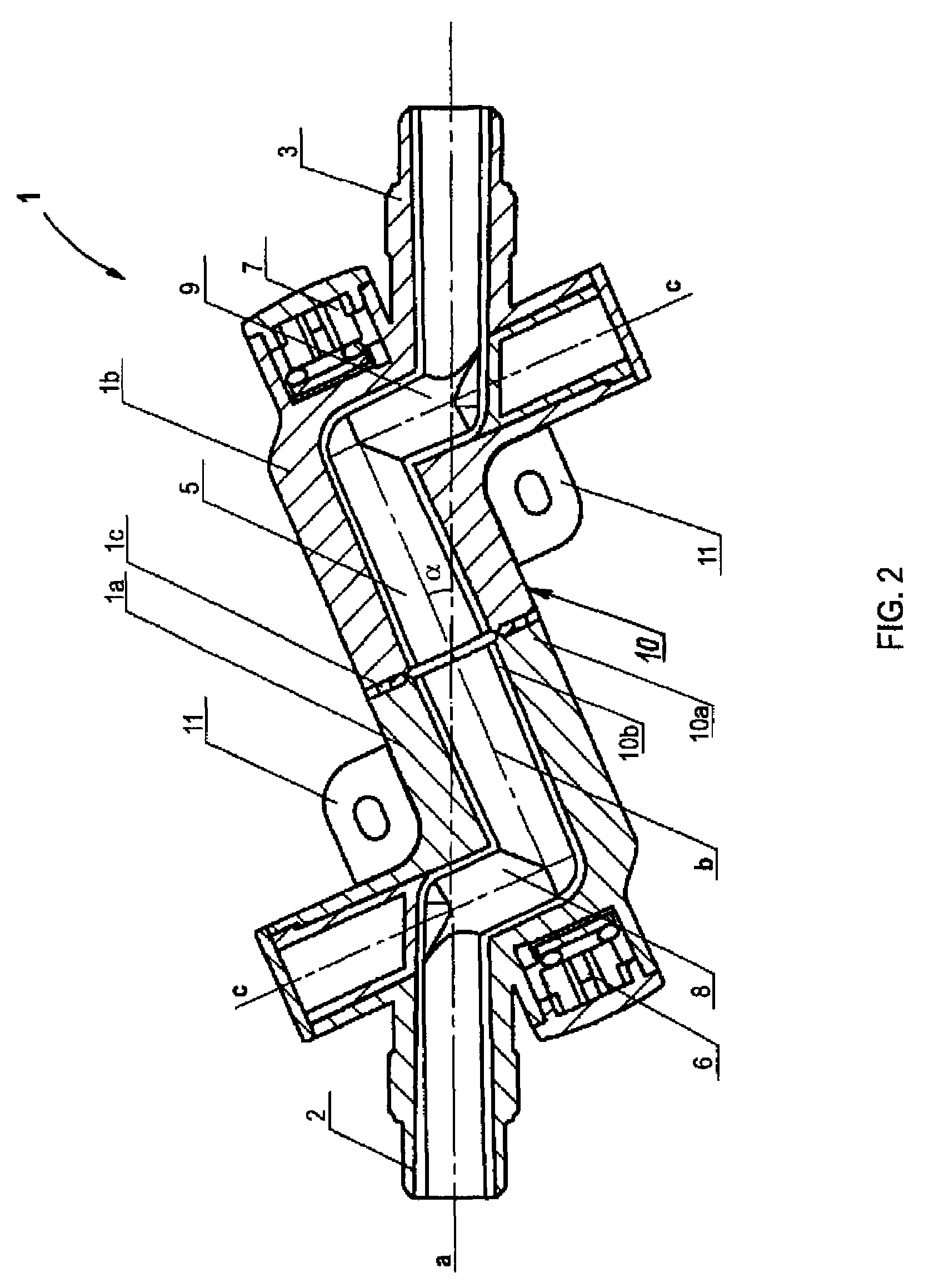

ActiveUS20070139923A1Eliminates thermal interfaceReduce the temperatureCoupling device connectionsPoint-like light sourceElectricityEffect light

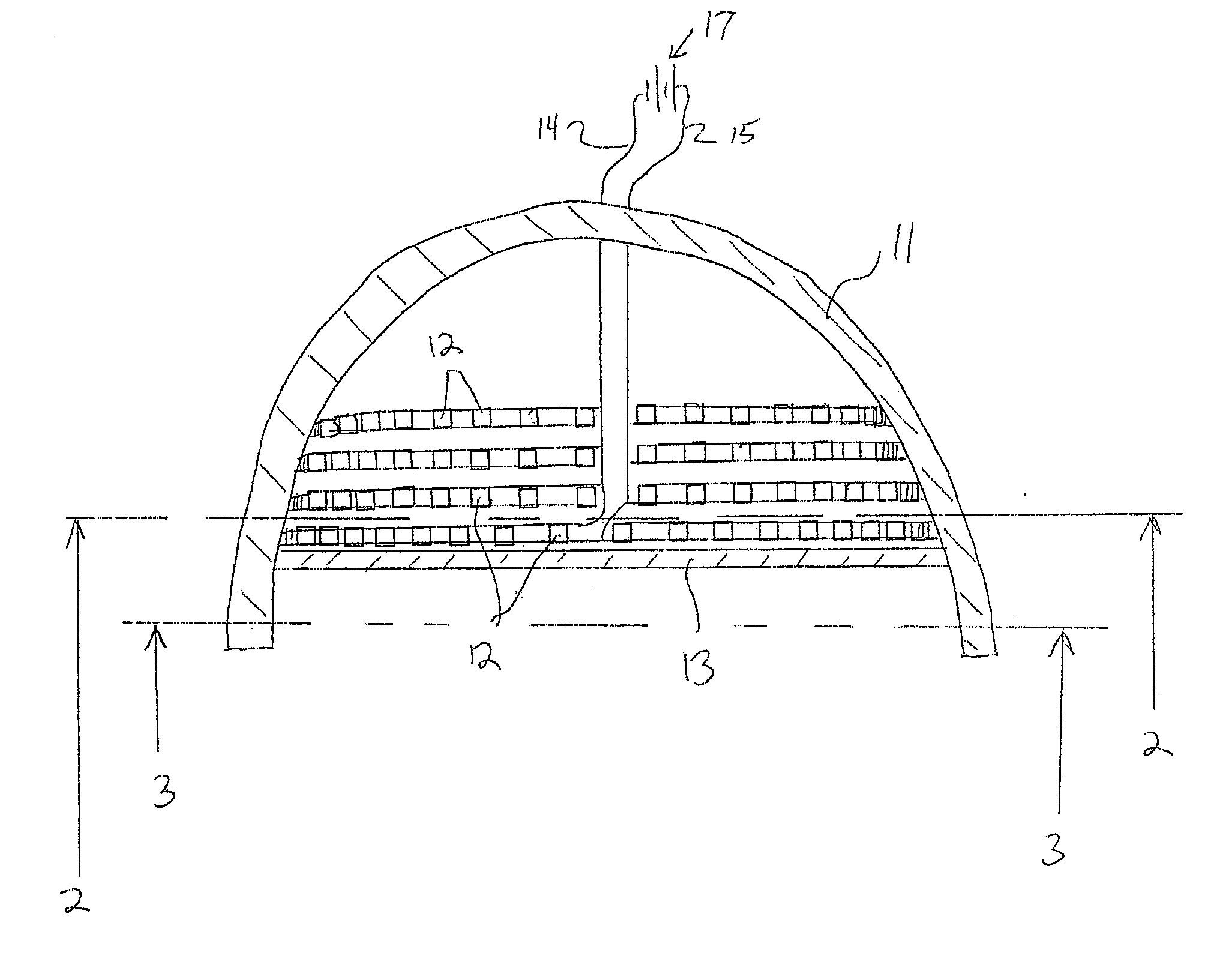

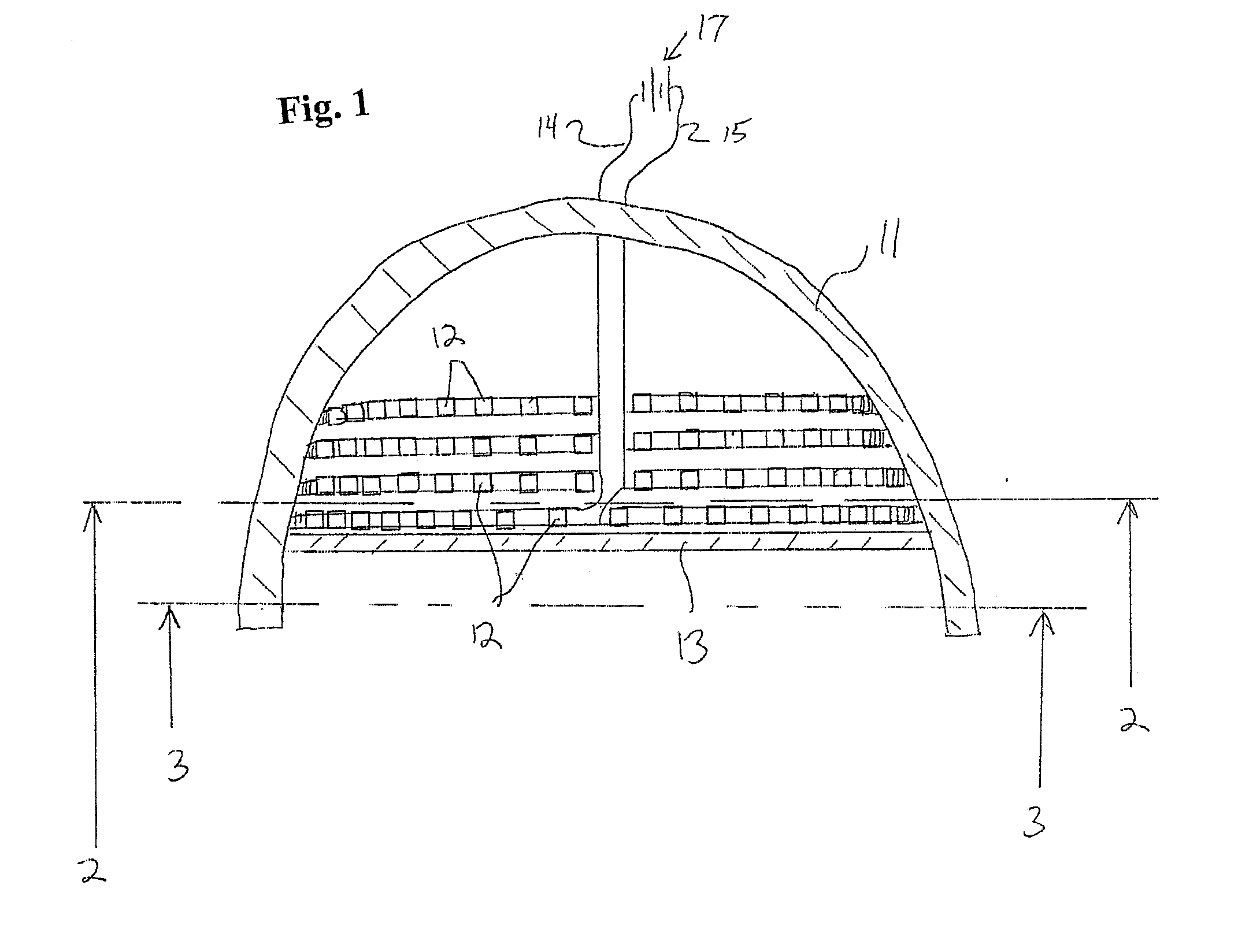

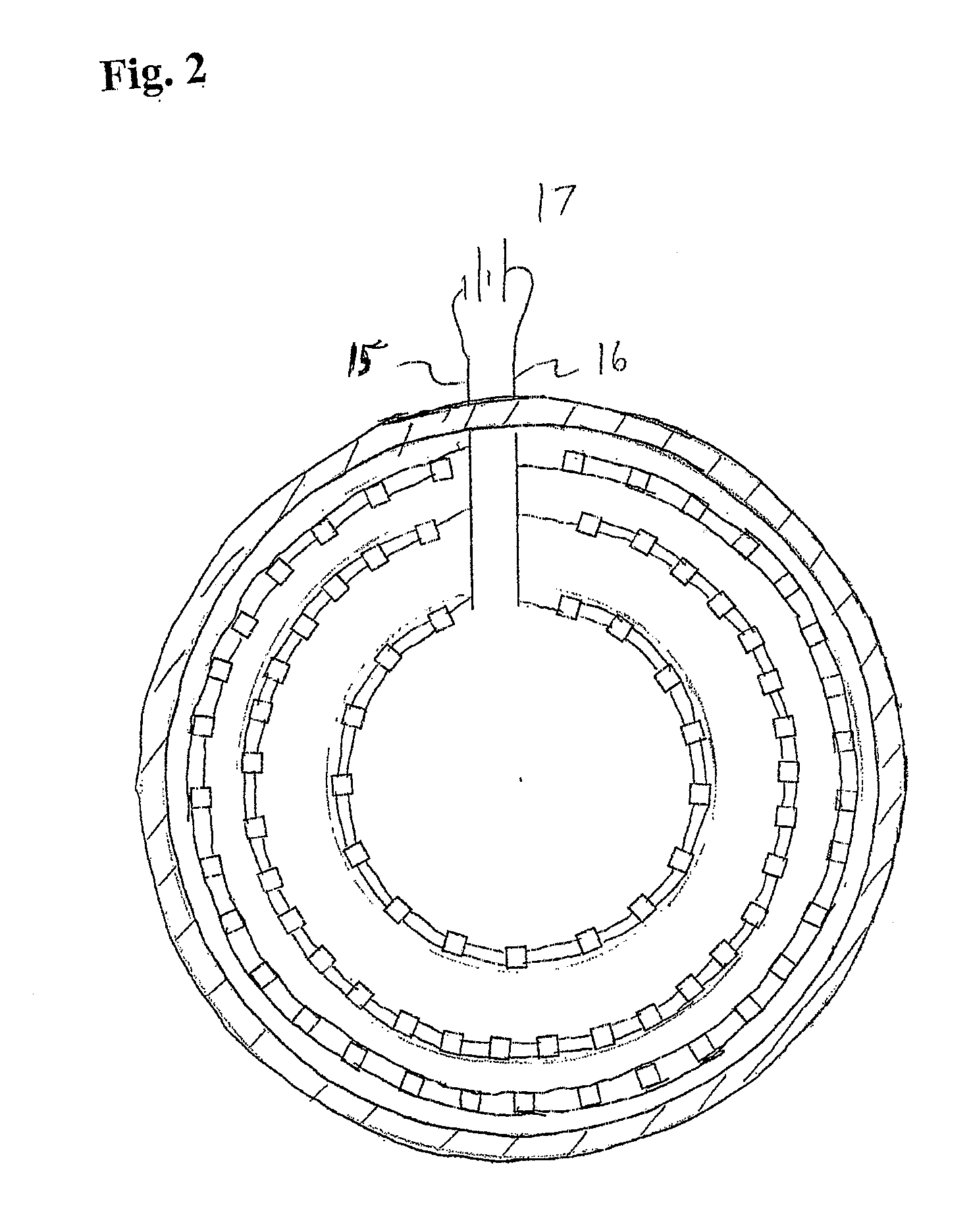

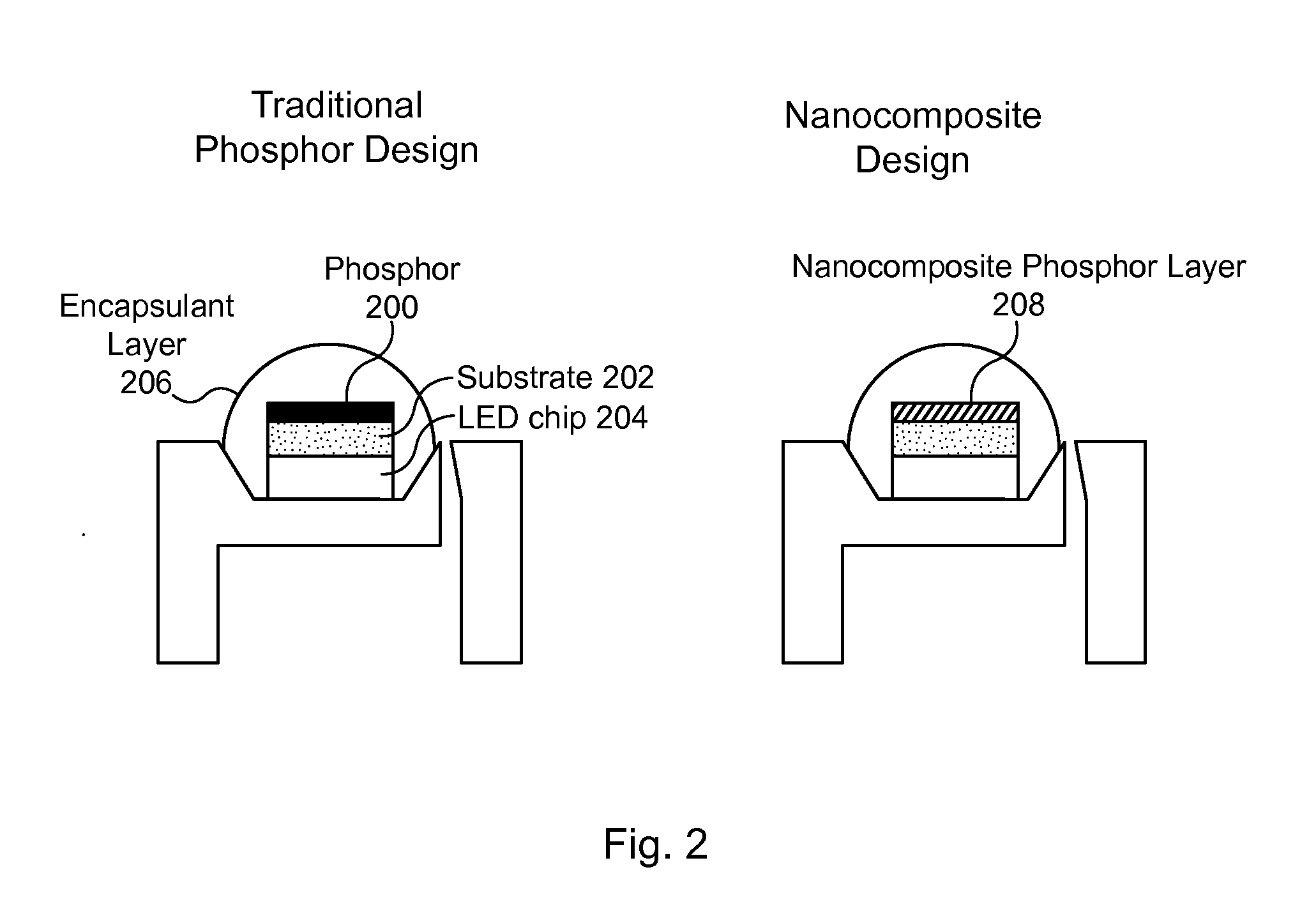

A lighting device comprises, or consists essentially of, a housing, a solid state light emitter and conductive tracks. The conductive tracks are positioned on the housing and are coupleable with a power supply. The conductive tracks comprise a positive conductive track and a negative conductive track. Each of the solid state light emitters is in electrical contact with a positive conductive track and a negative conductive track. Another lighting device comprises a fixture and a solid state light emitter in which the fixture comprises conductive elements which are coupleable to at least one power supply and the solid state light emitter is mounted on the fixture. There is also provided a lighting device which provides light of an intensity which is at least 50 percent of its initial intensity after 50,000 hours of illumination.

Owner:IDEAL IND LIGHTING LLC

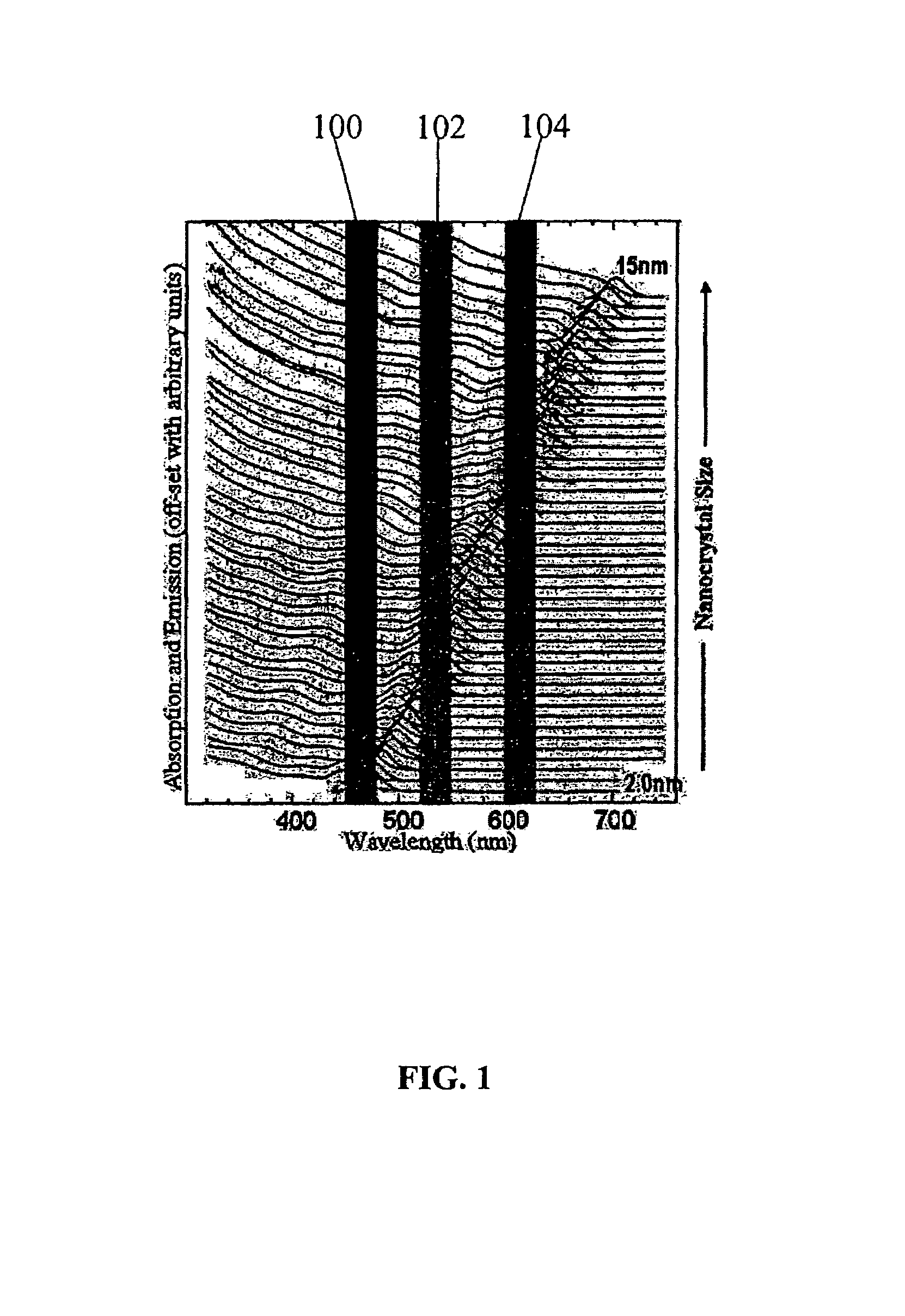

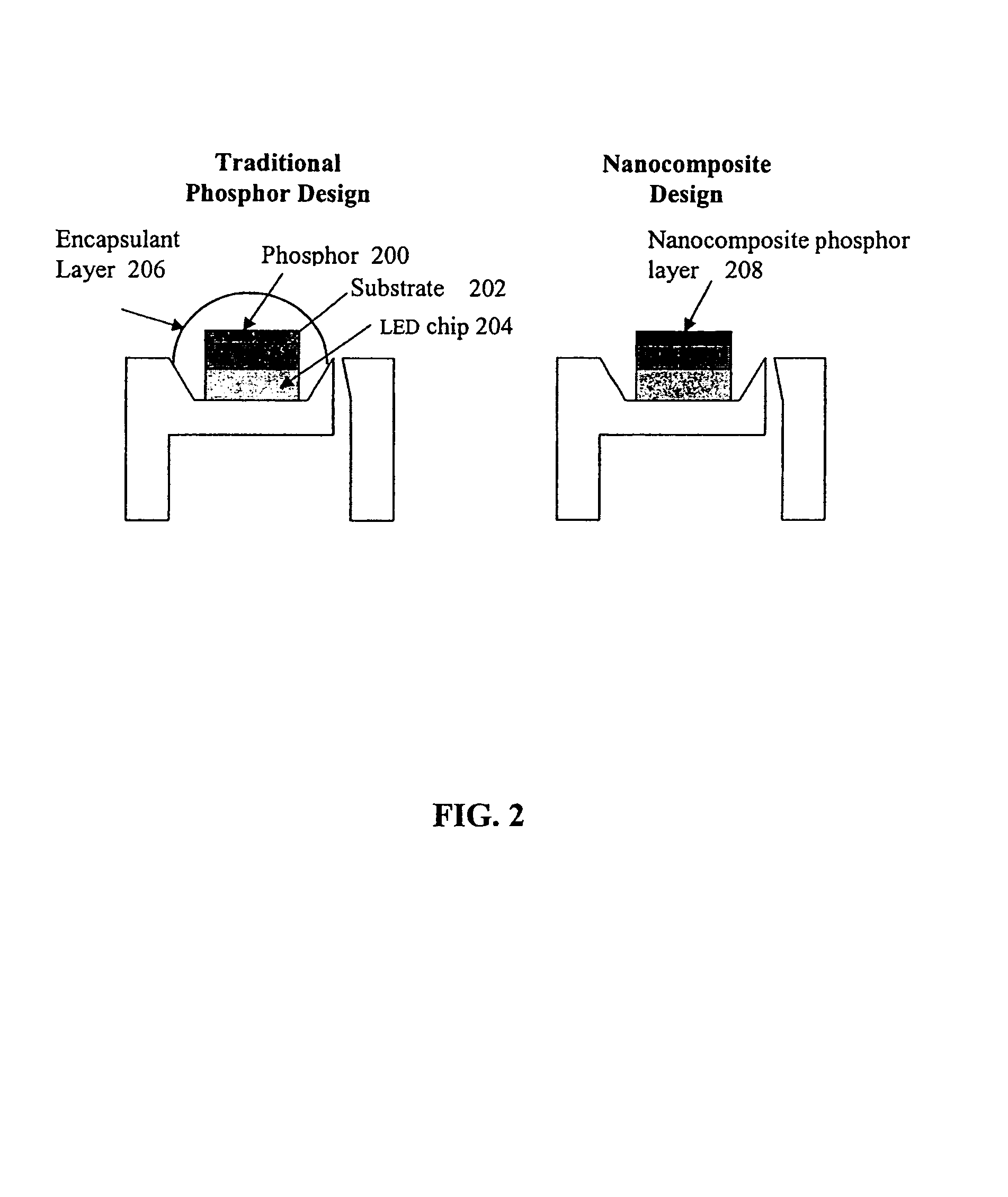

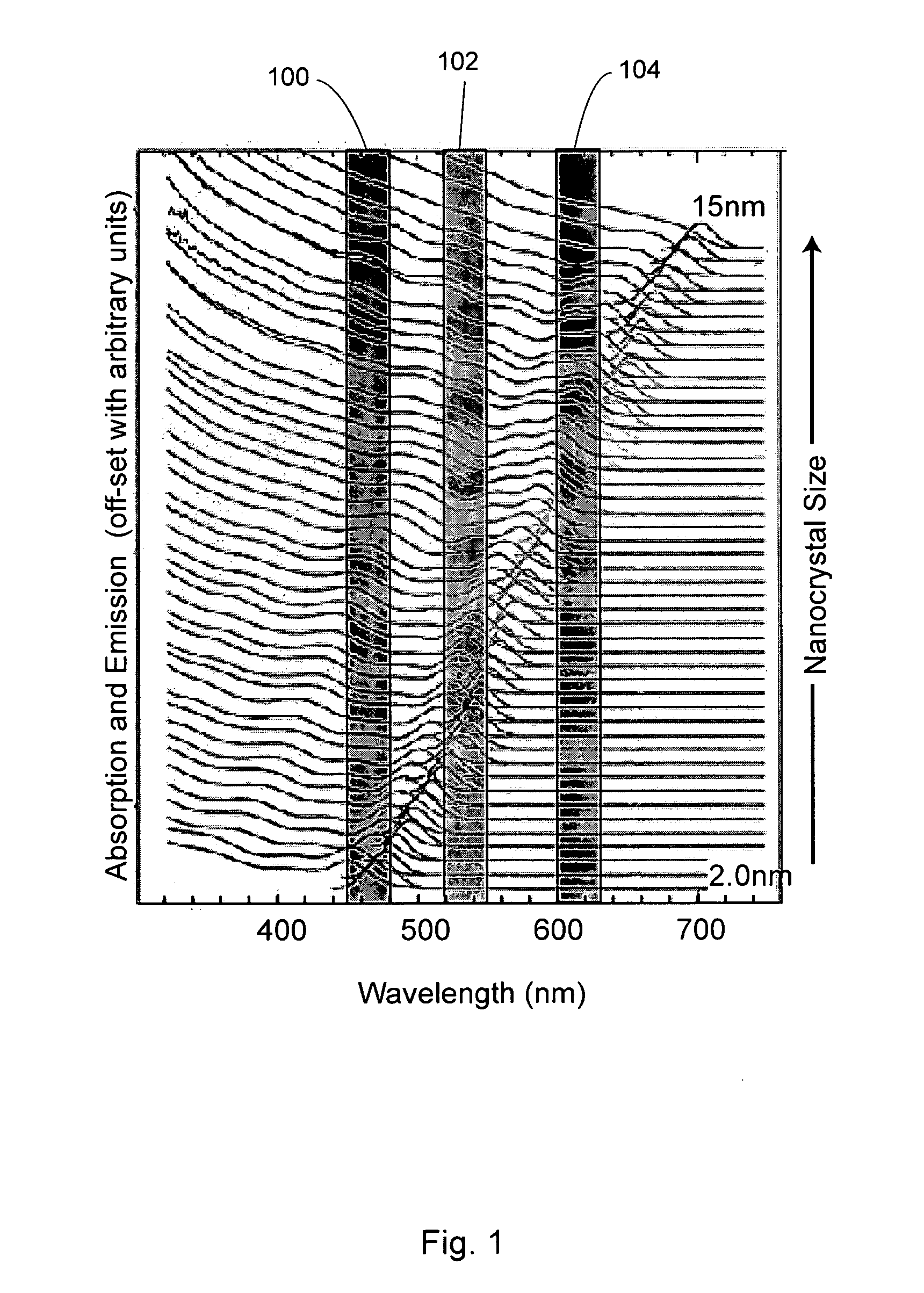

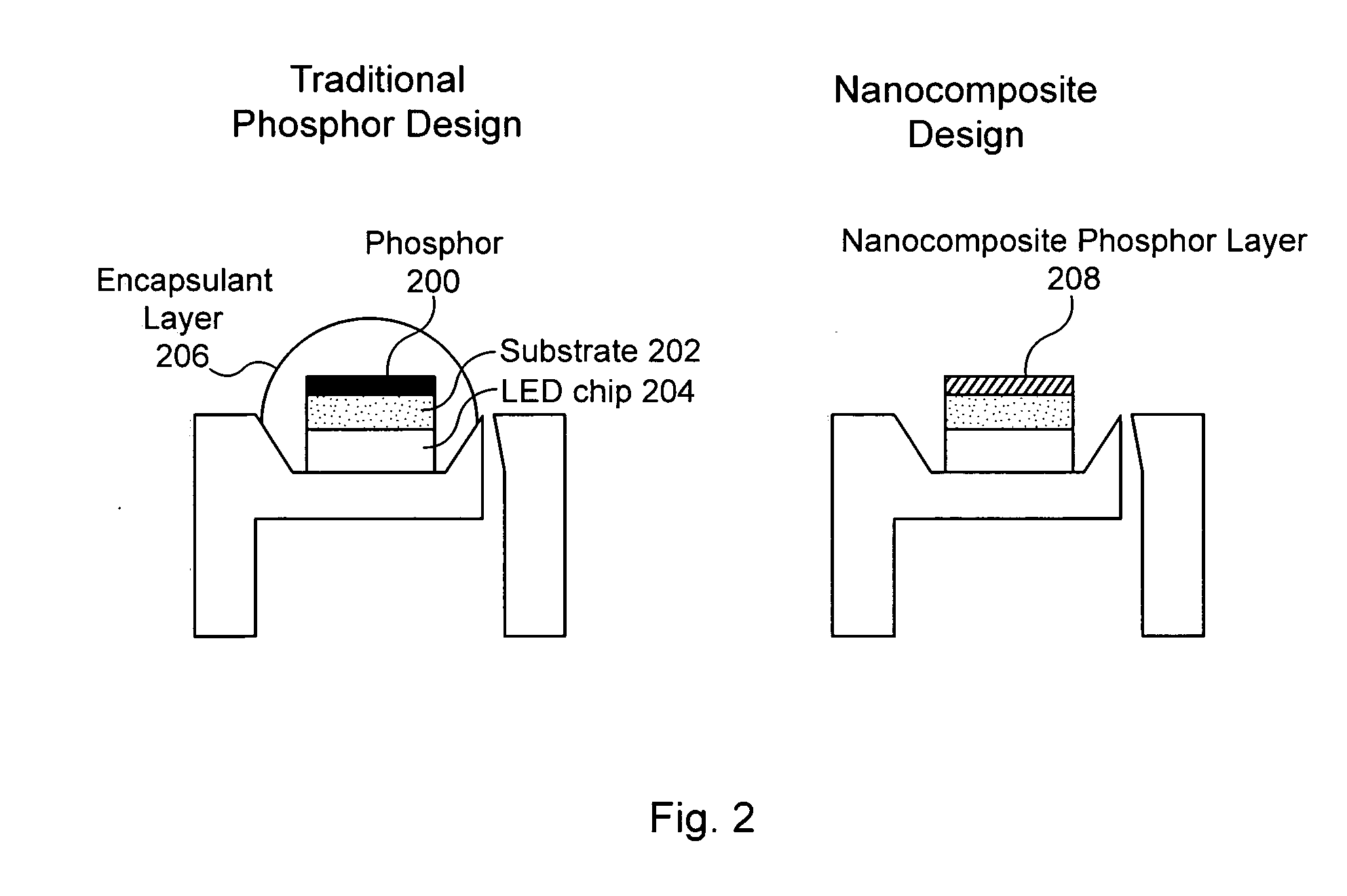

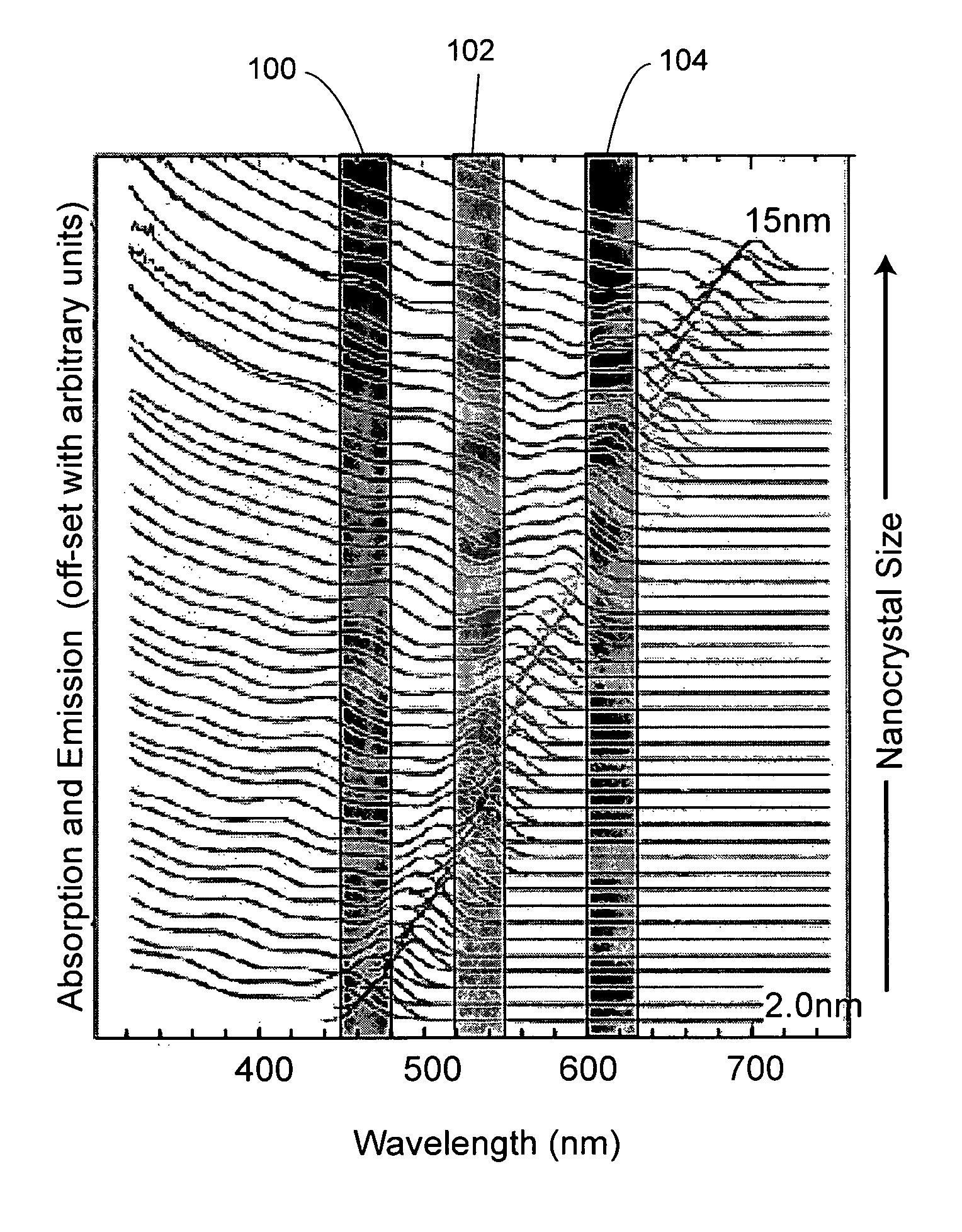

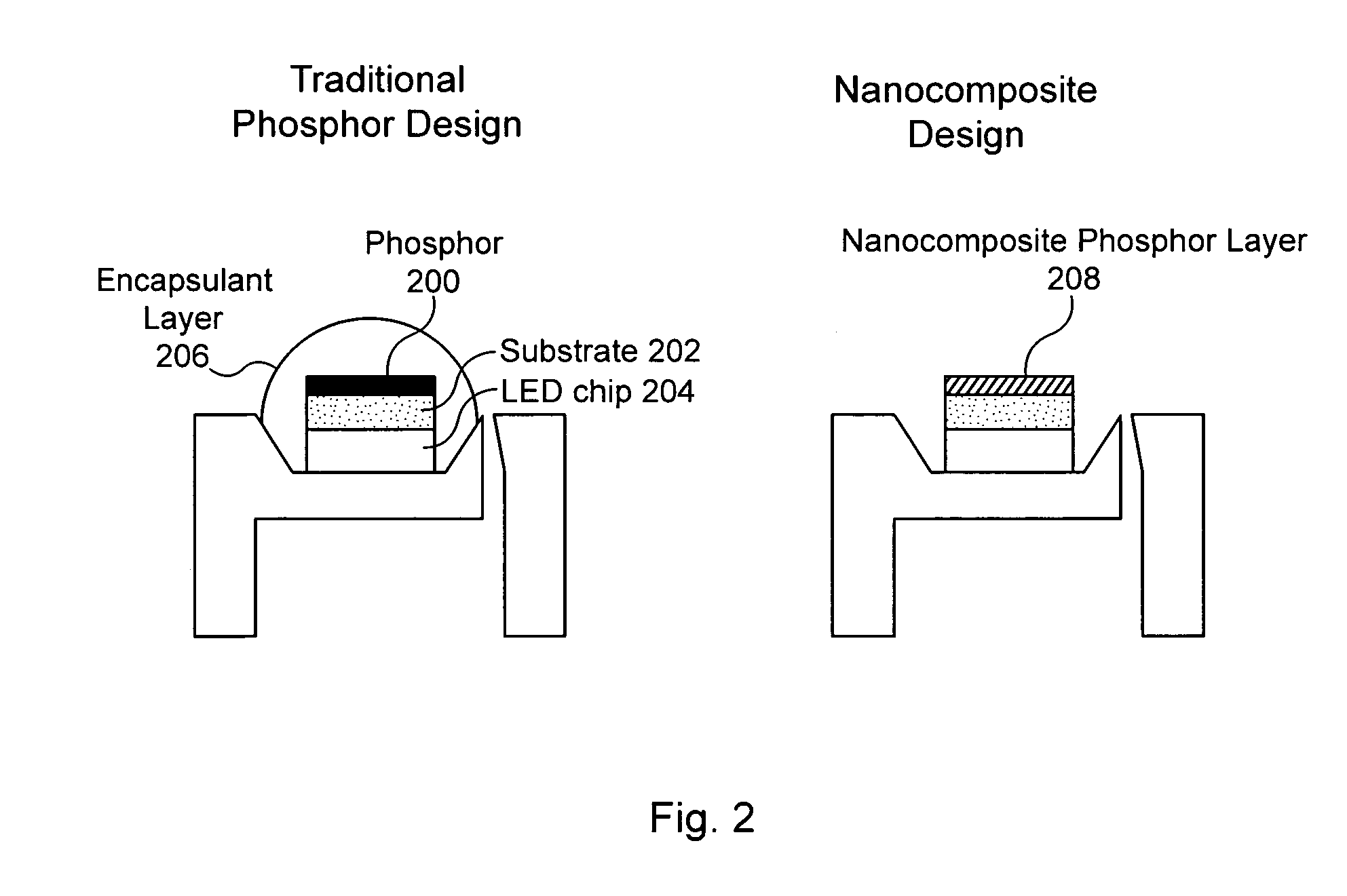

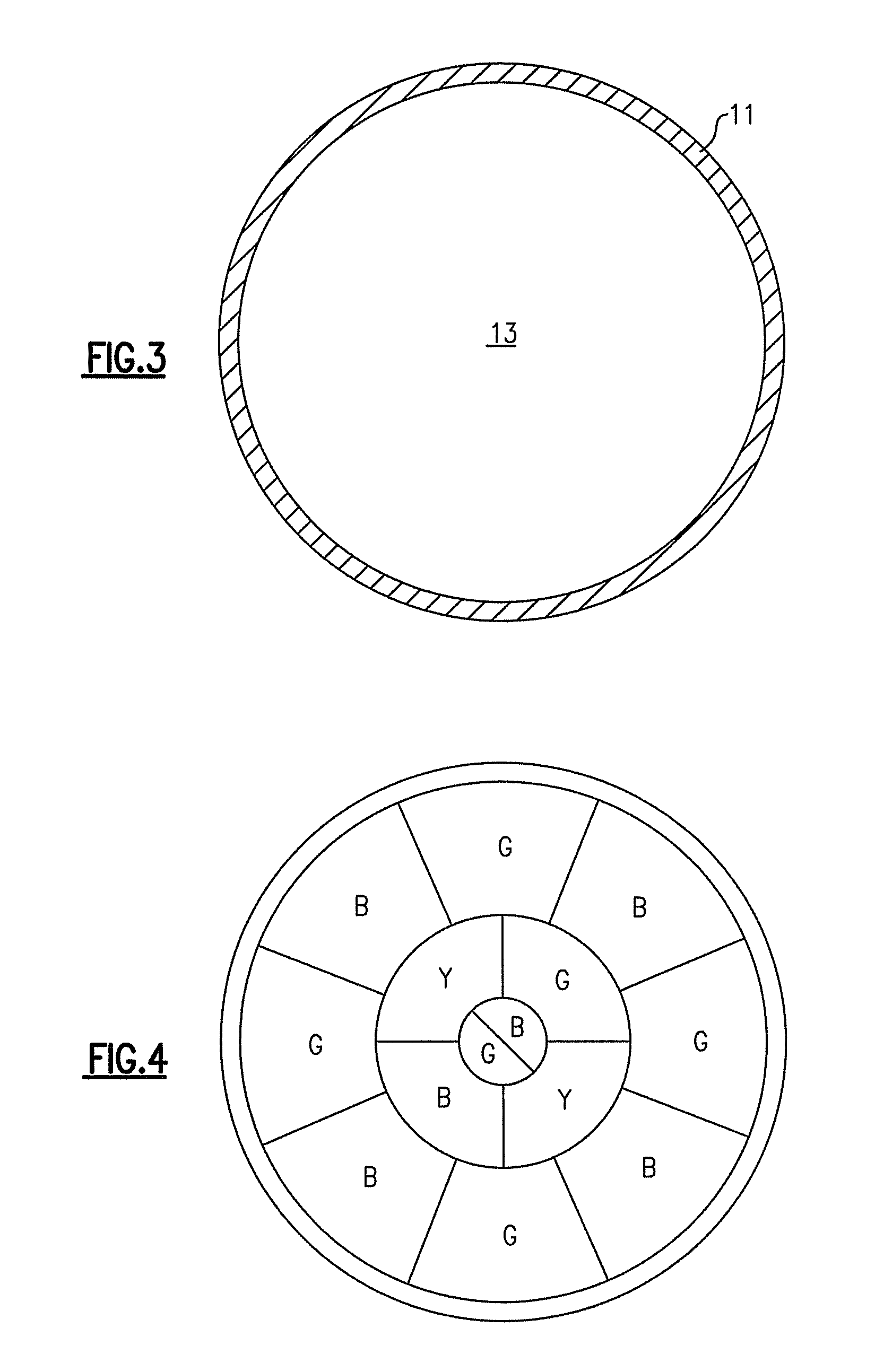

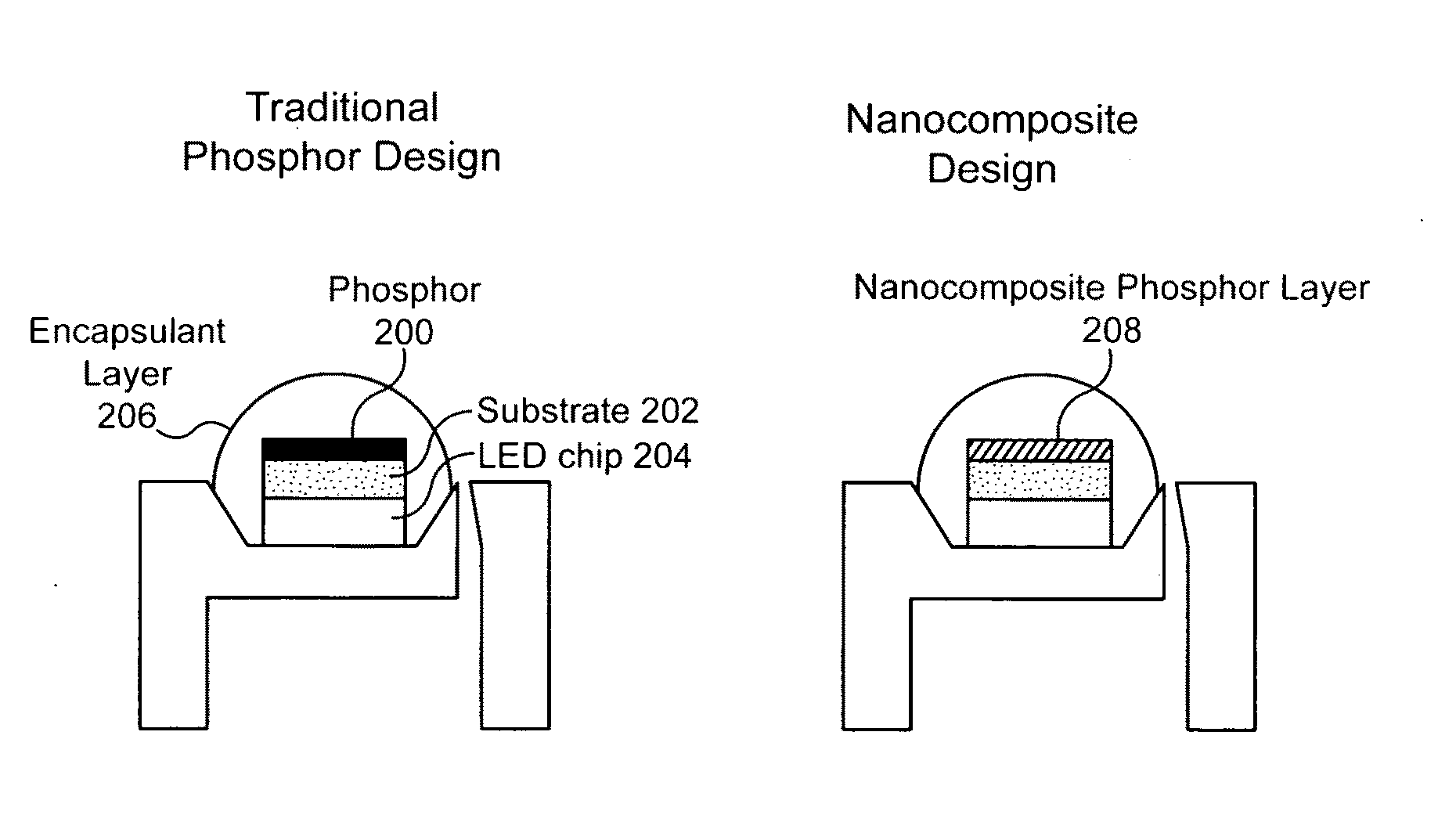

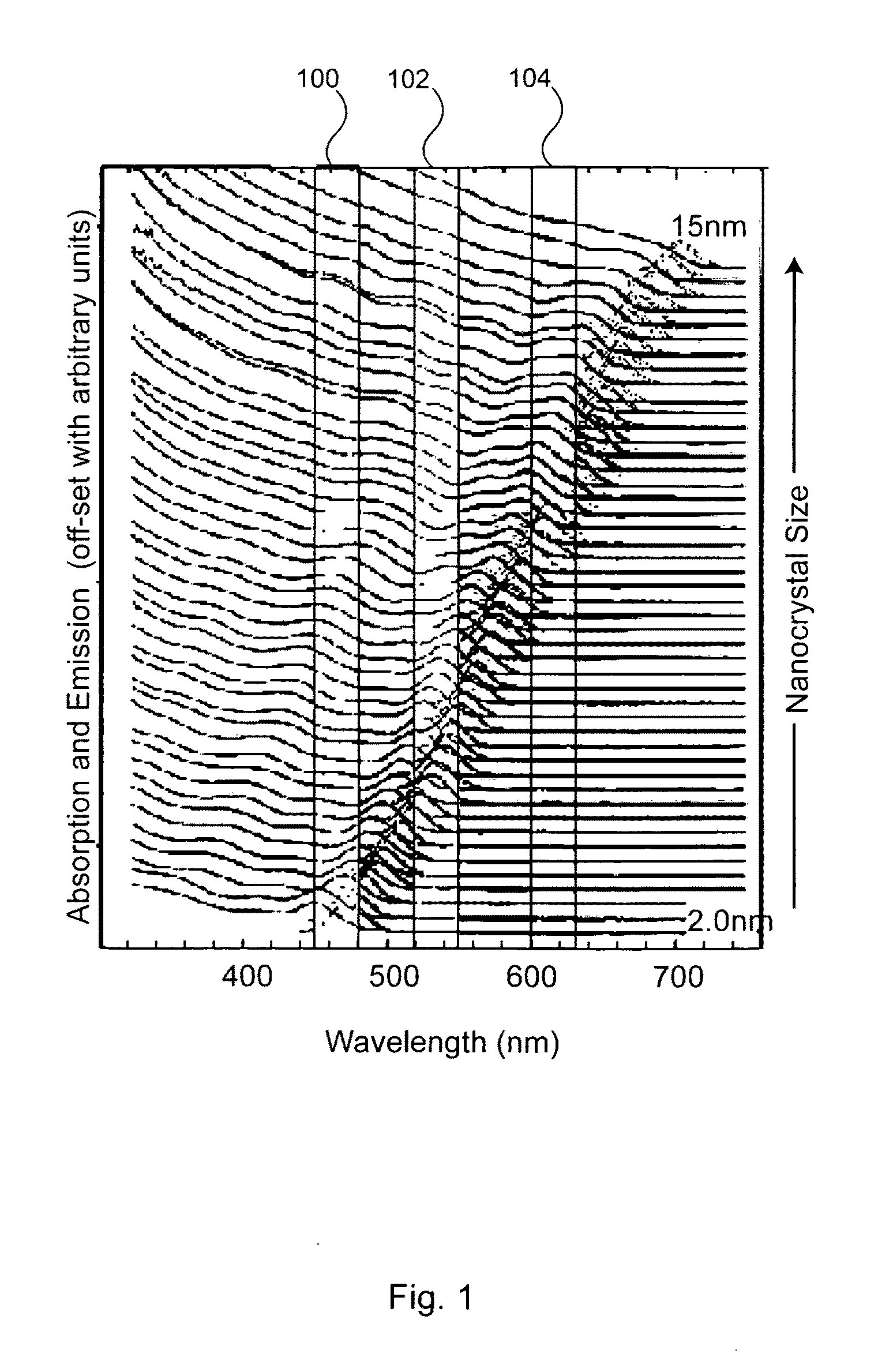

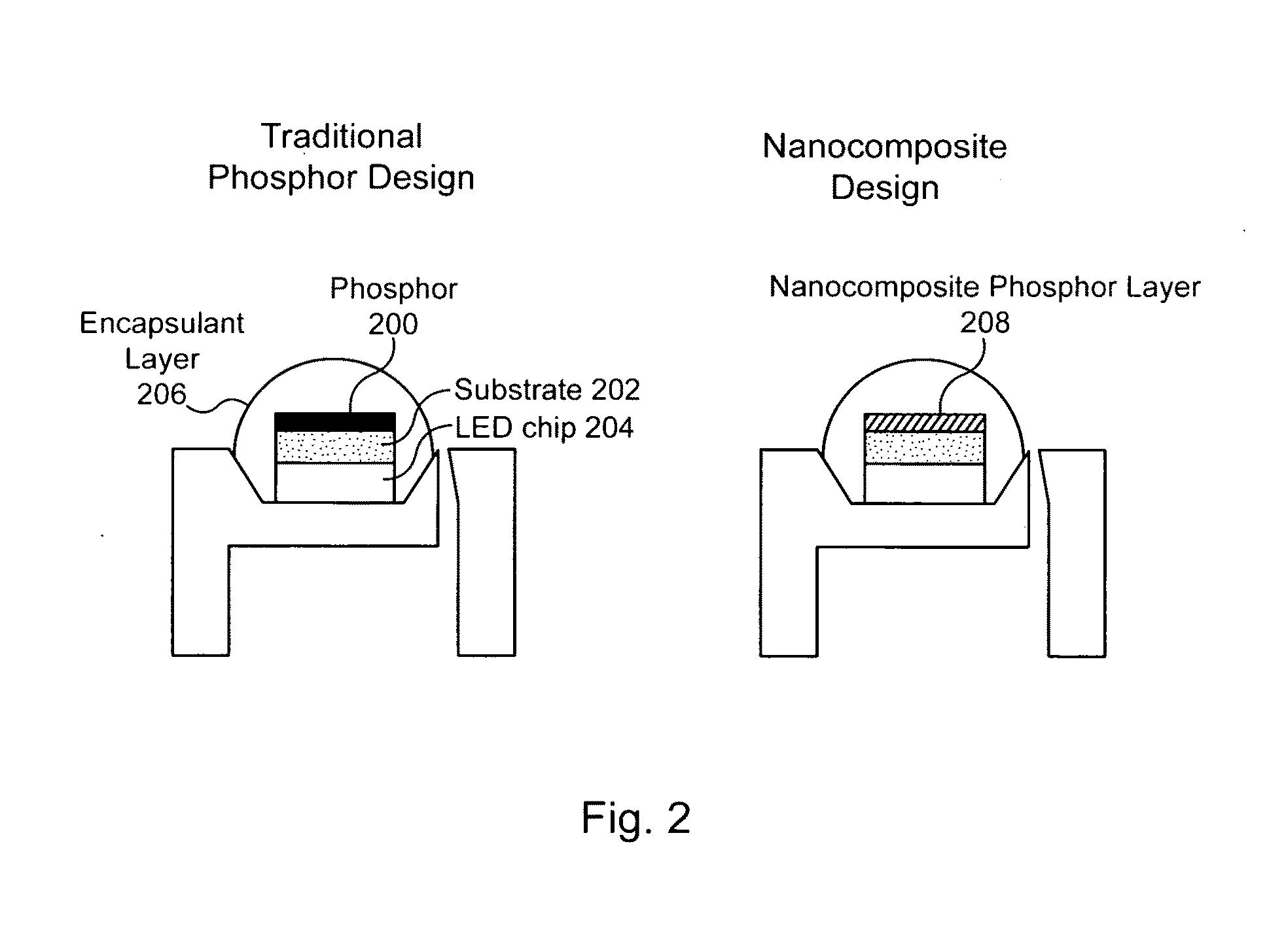

Nanocrystal doped matrixes

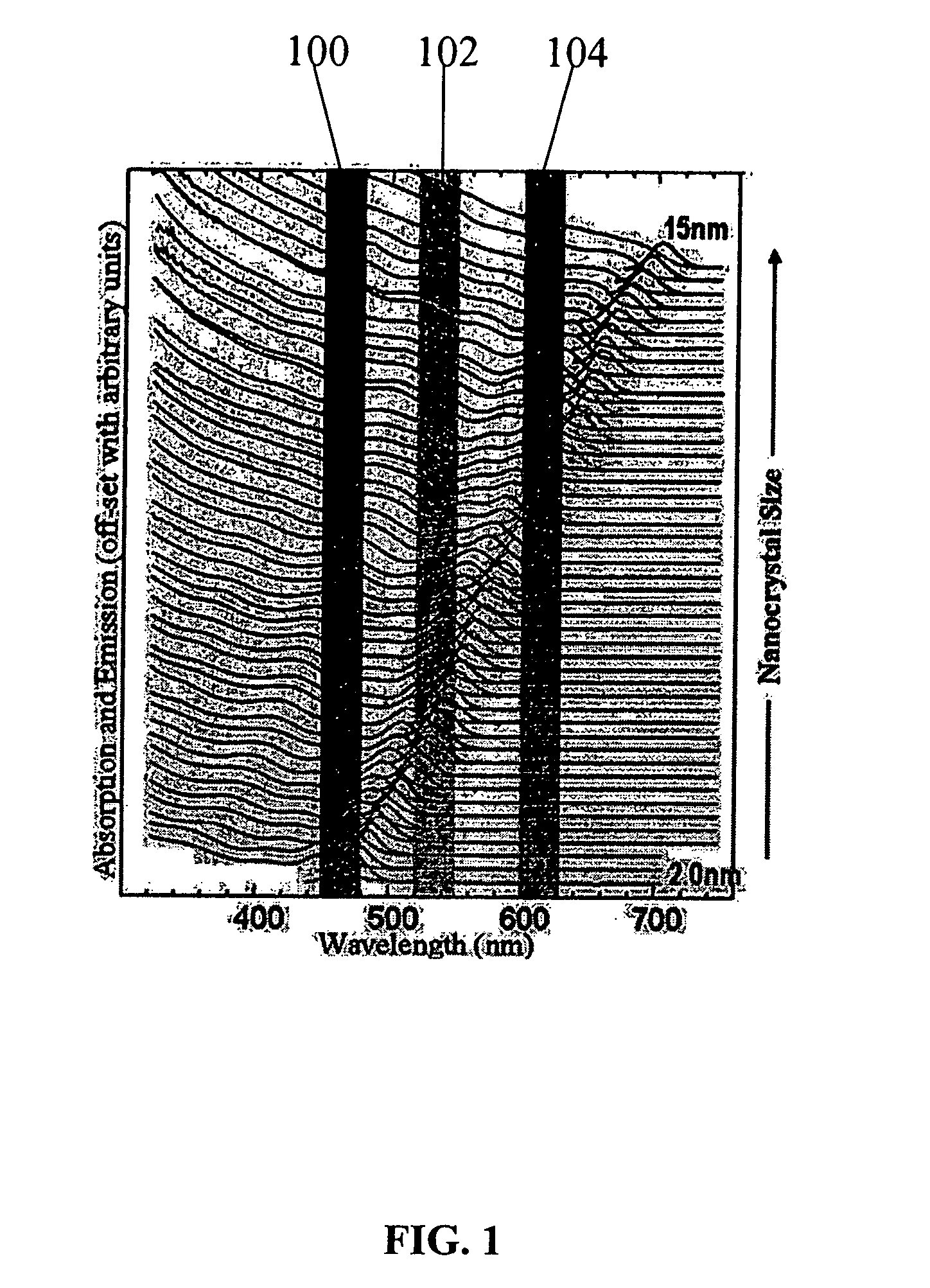

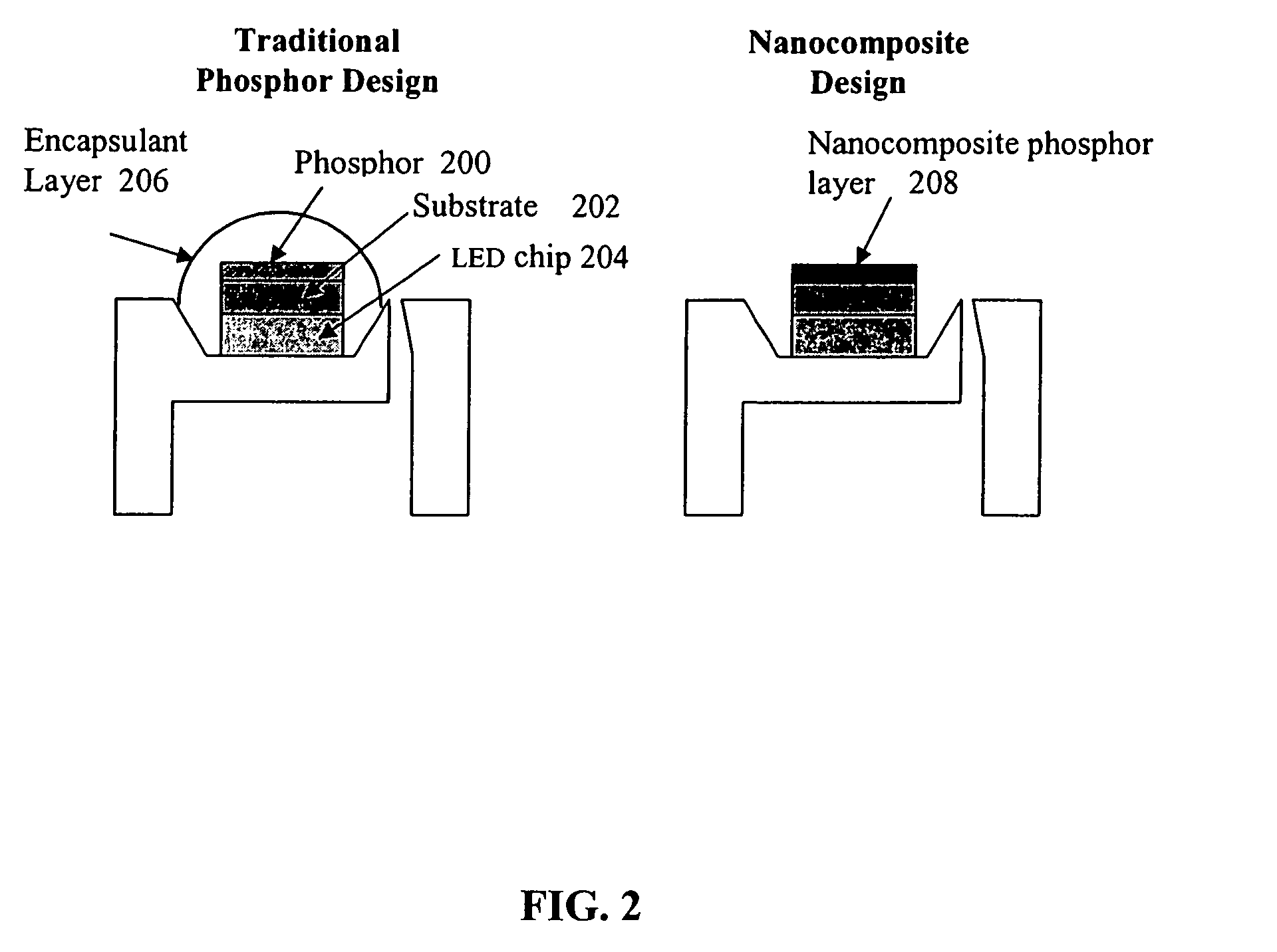

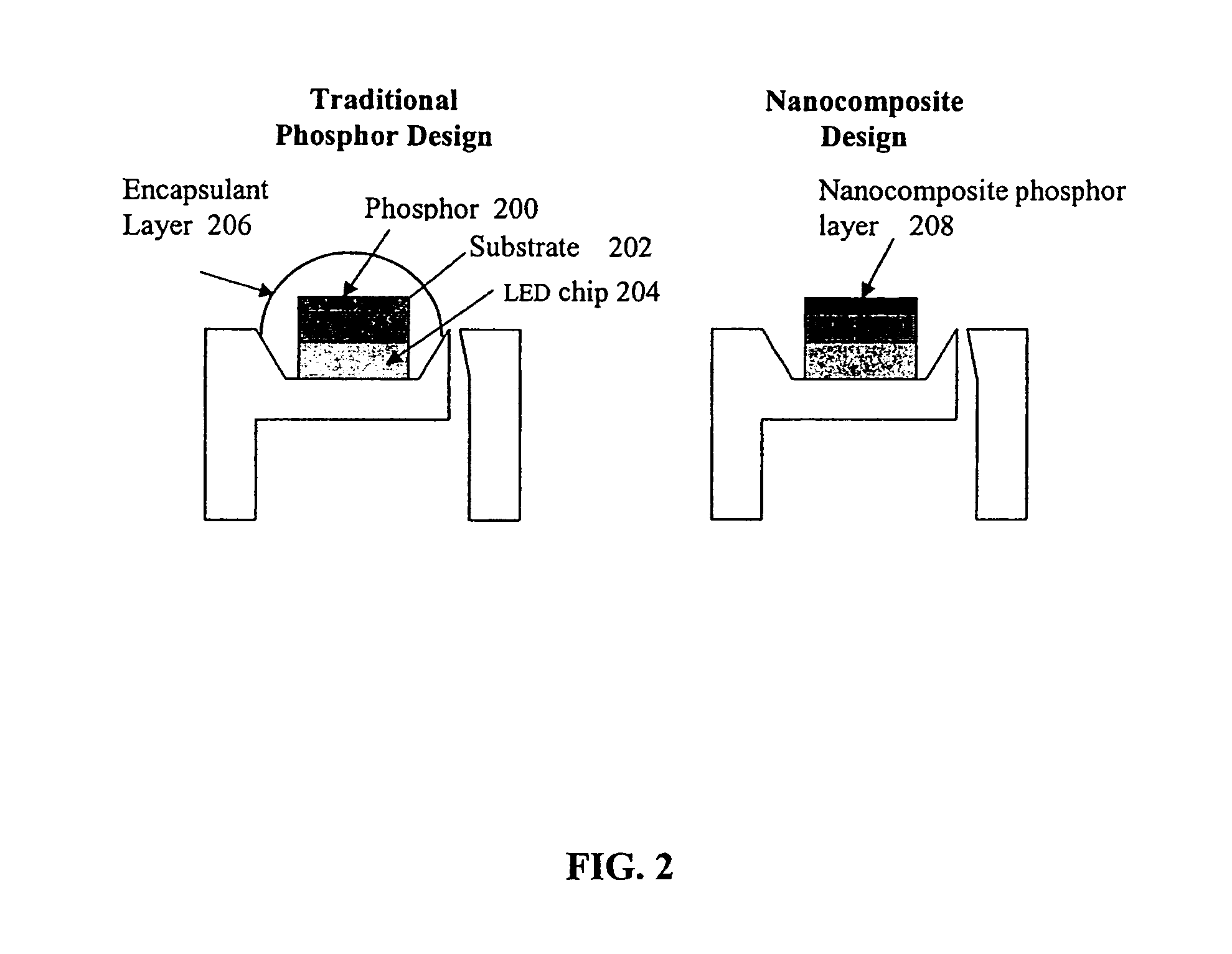

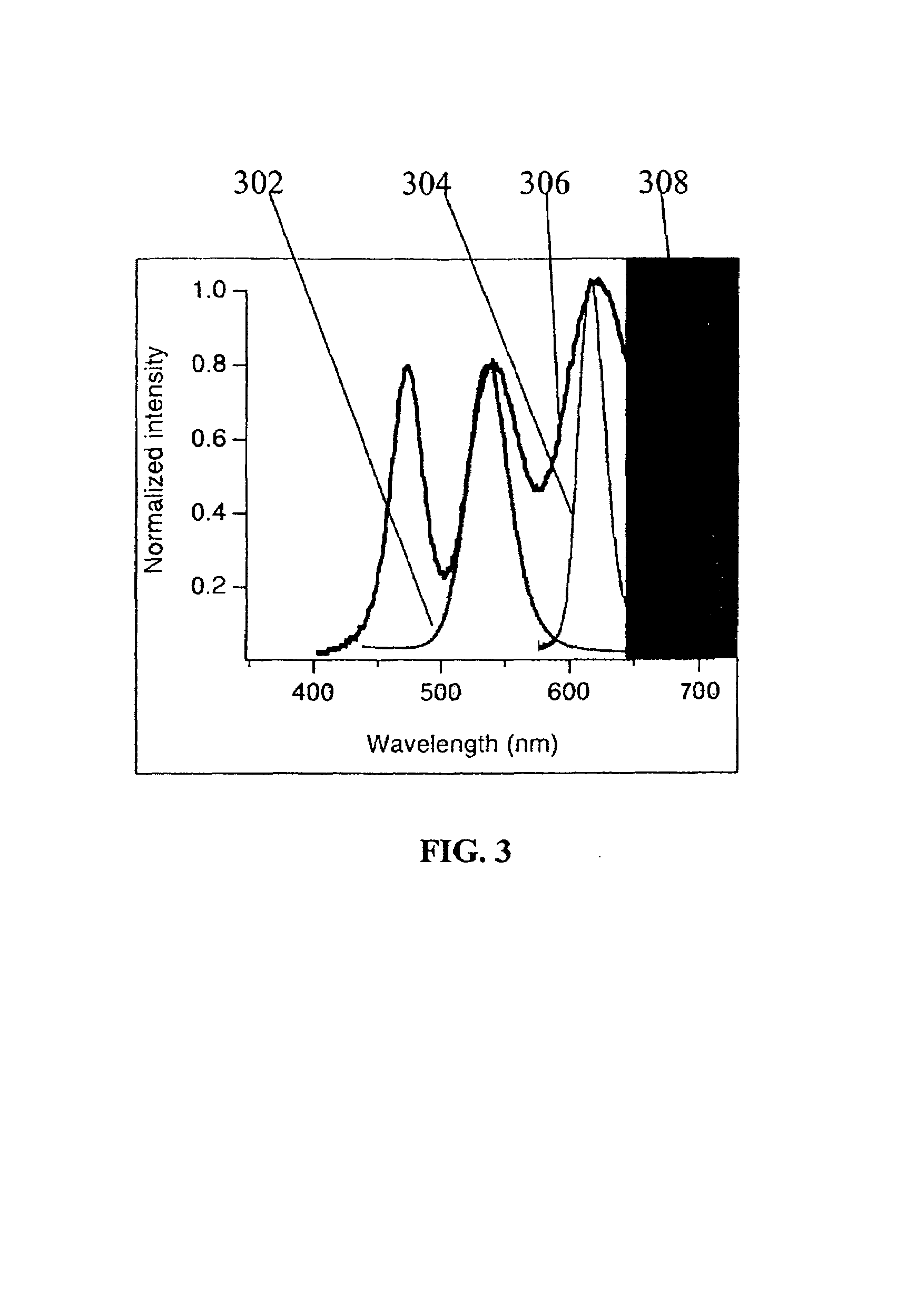

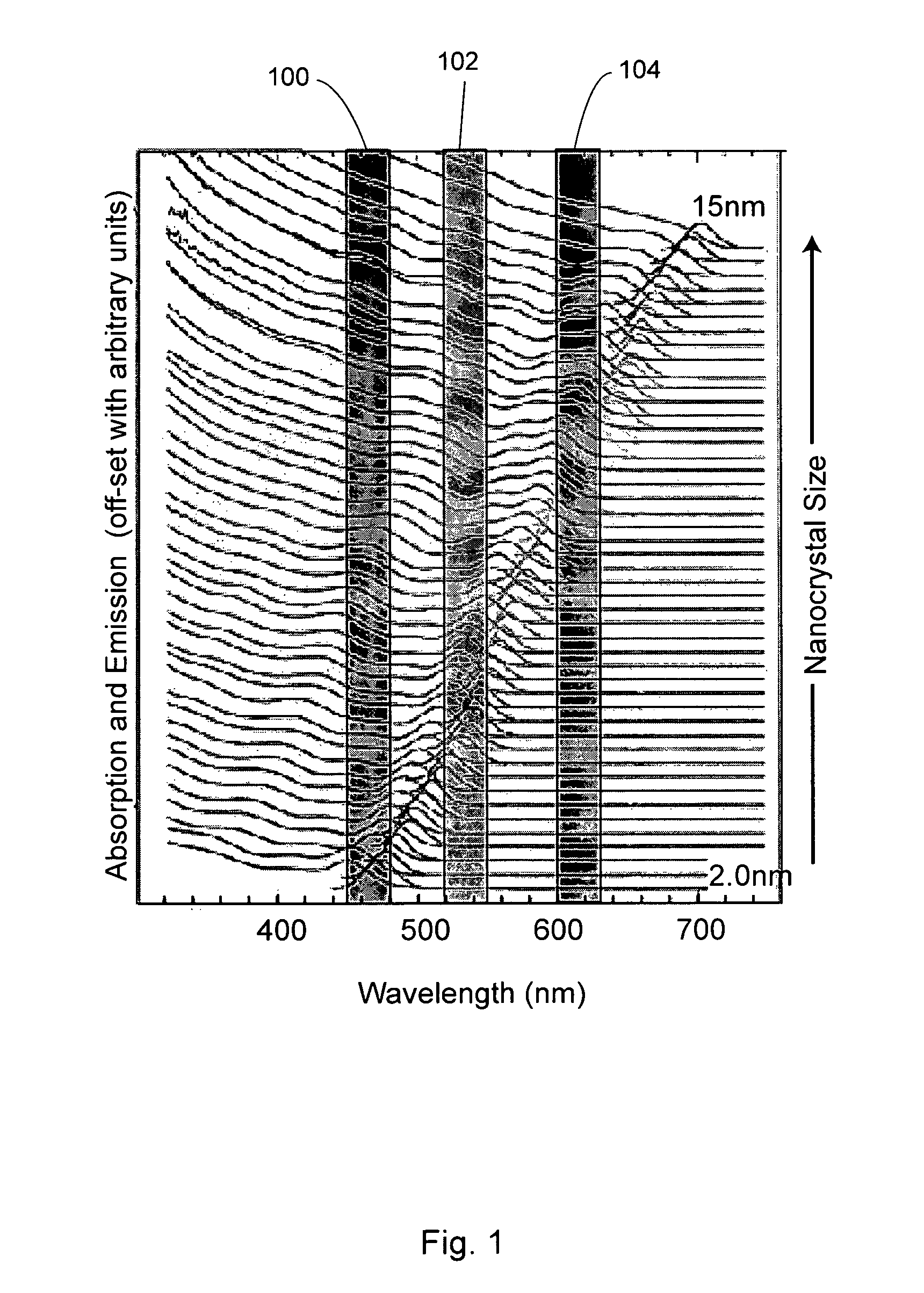

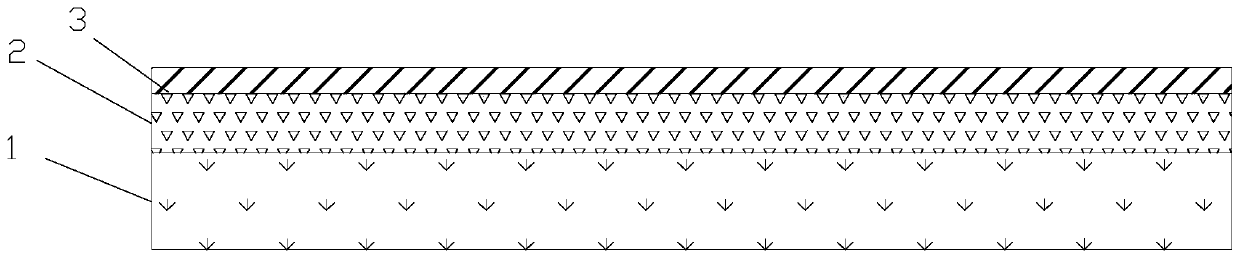

ActiveUS20060068154A1Different propertyHigh refractive indexMaterial nanotechnologyMirrorsNanometreRefractive index matching

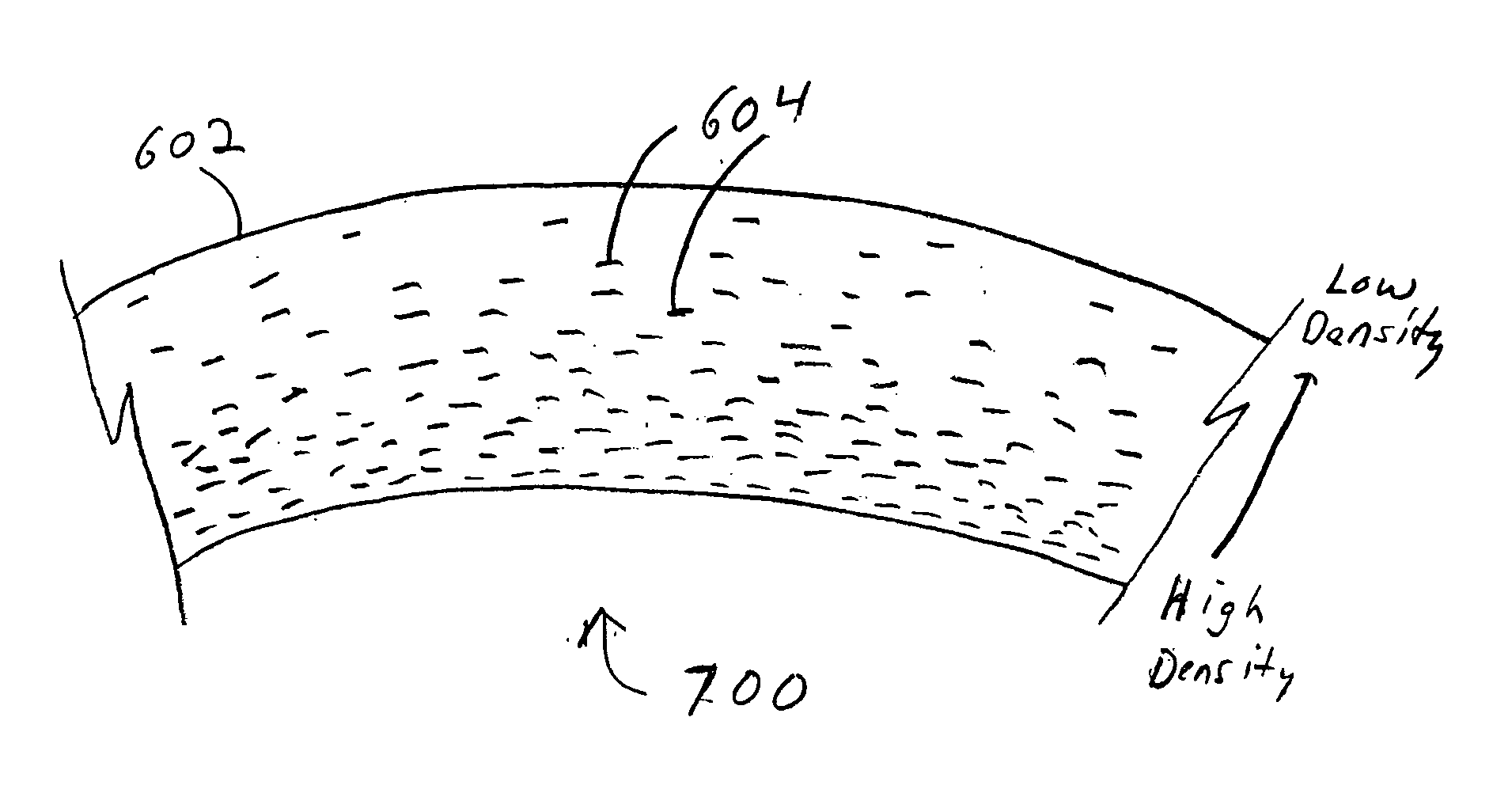

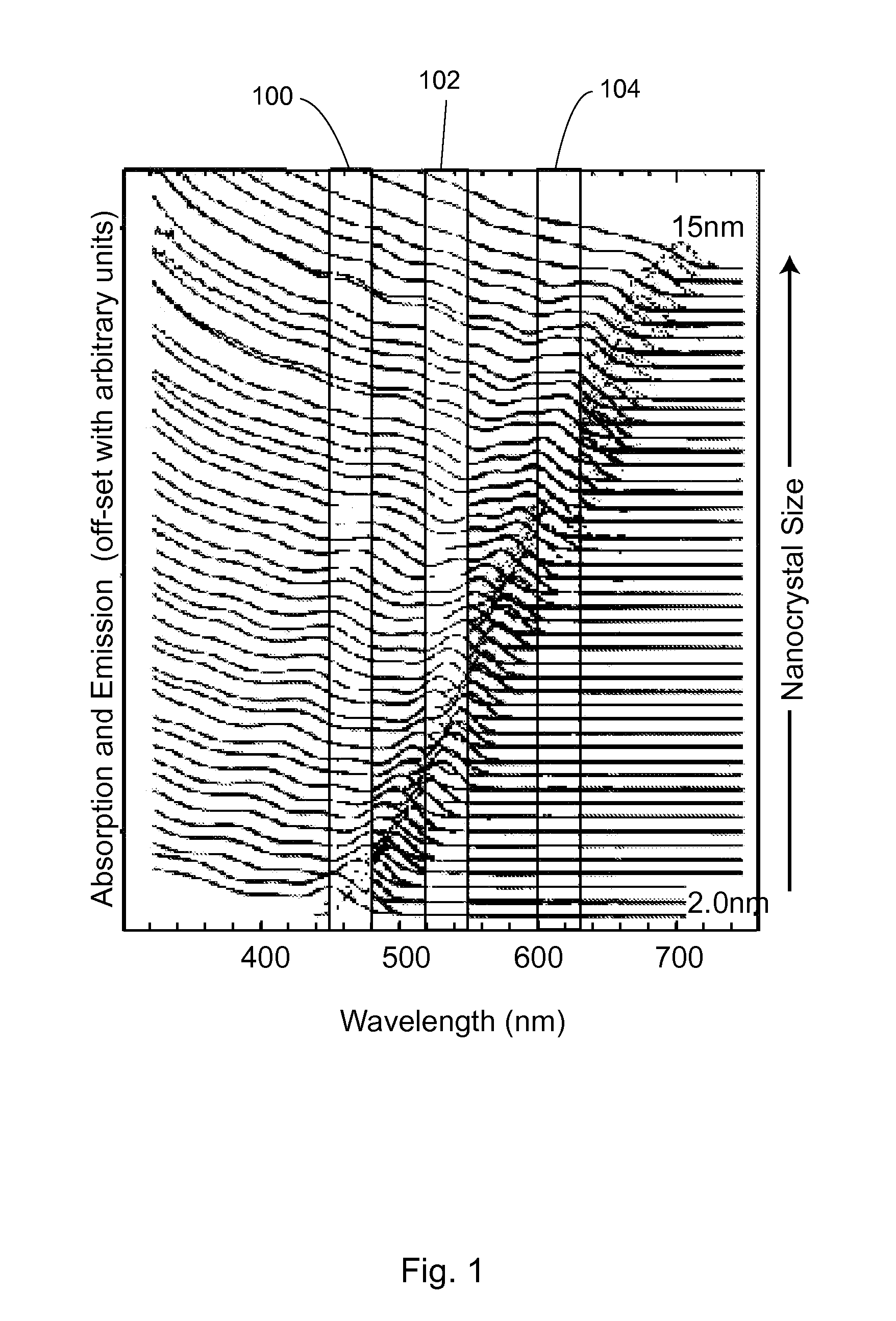

The present invention provides matrixes doped with semiconductor nanocrystals. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. The present invention also provides processes for producing matrixes comprising semiconductor nanocrystals.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanocrystal doped matrixes

ActiveUS20070034833A1Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

Nanocrystal doped matrixes

ActiveUS7645397B2Good miscibilityInhibit aggregationMaterial nanotechnologyIndividual molecule manipulationAnti-reflective coatingQuantum efficiency

Owner:SAMSUNG ELECTRONICS CO LTD

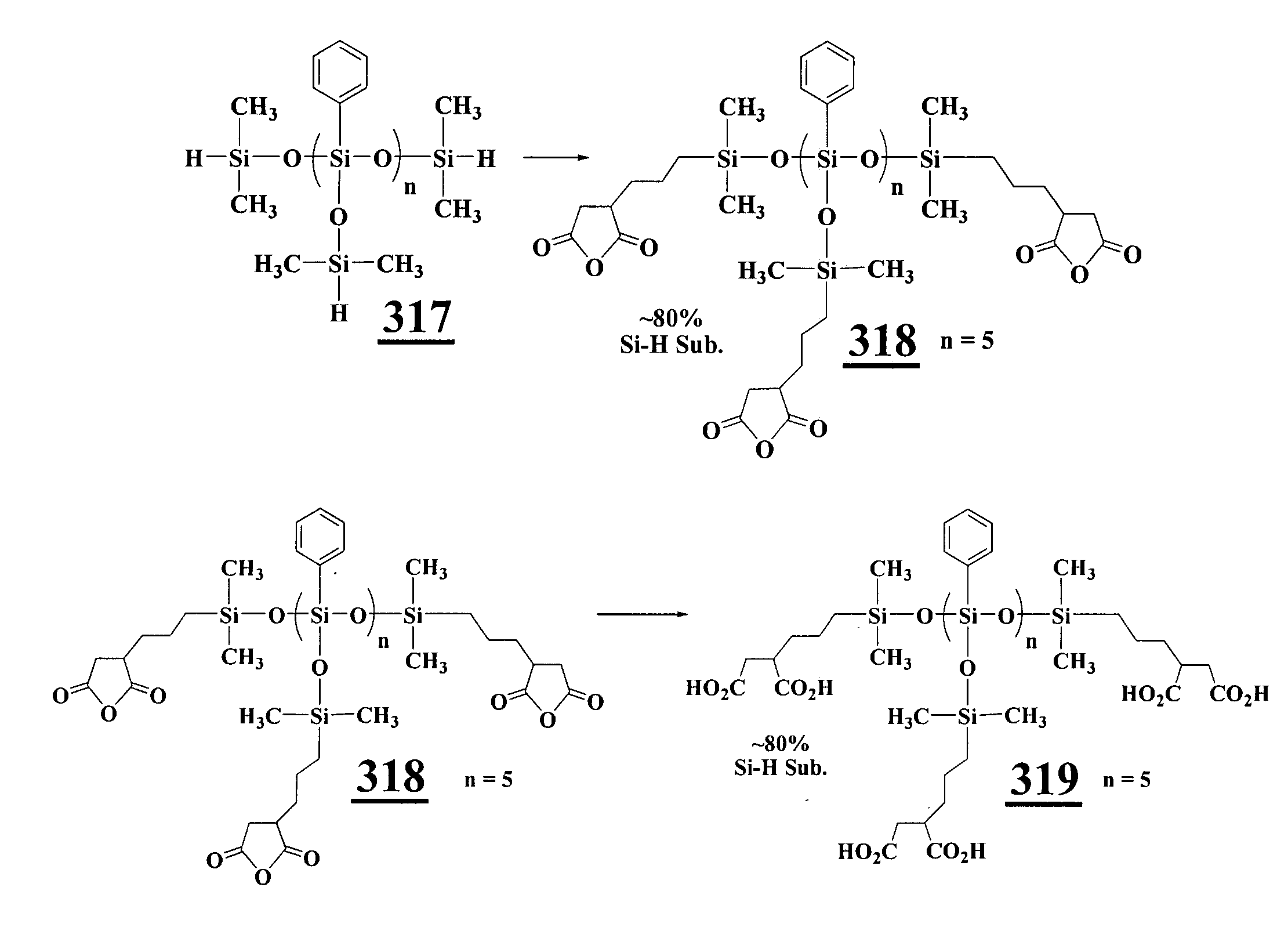

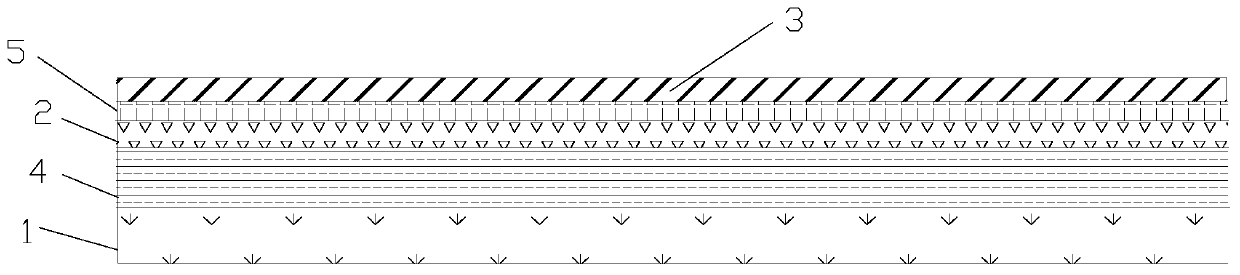

Functionalized matrixes for dispersion of nanostructures

ActiveUS20100276638A1High quantum yieldFacilitate device fabricationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingVolumetric Mass Density

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:NANOSYS INC

Functionalized matrices for dispersion of nanostructures

ActiveUS8283412B2Good miscibilityInhibit aggregationMaterial nanotechnologyGroup 4/14 element organic compoundsAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes are optionally formed from the ligands. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SHOEI CHEM IND CO LTD

Lighting device

ActiveUS8337071B2Reduce the temperatureReduce complexityCoupling device connectionsPoint-like light sourceEffect lightEngineering

A lighting device comprises, or consists essentially of, a housing, a solid state light emitter and conductive tracks. The conductive tracks are positioned on the housing and are coupleable with a power supply. The conductive tracks comprise a positive conductive track and a negative conductive track. Each of the solid state light emitters is in electrical contact with a positive conductive track and a negative conductive track. Another lighting device comprises a fixture and a solid state light emitter in which the fixture comprises conductive elements which are coupleable to at least one power supply and the solid state light emitter is mounted on the fixture. There is also provided a lighting device which provides light of an intensity which is at least 50 percent of its initial intensity after 50,000 hours of illumination.

Owner:IDEAL IND LIGHTING LLC

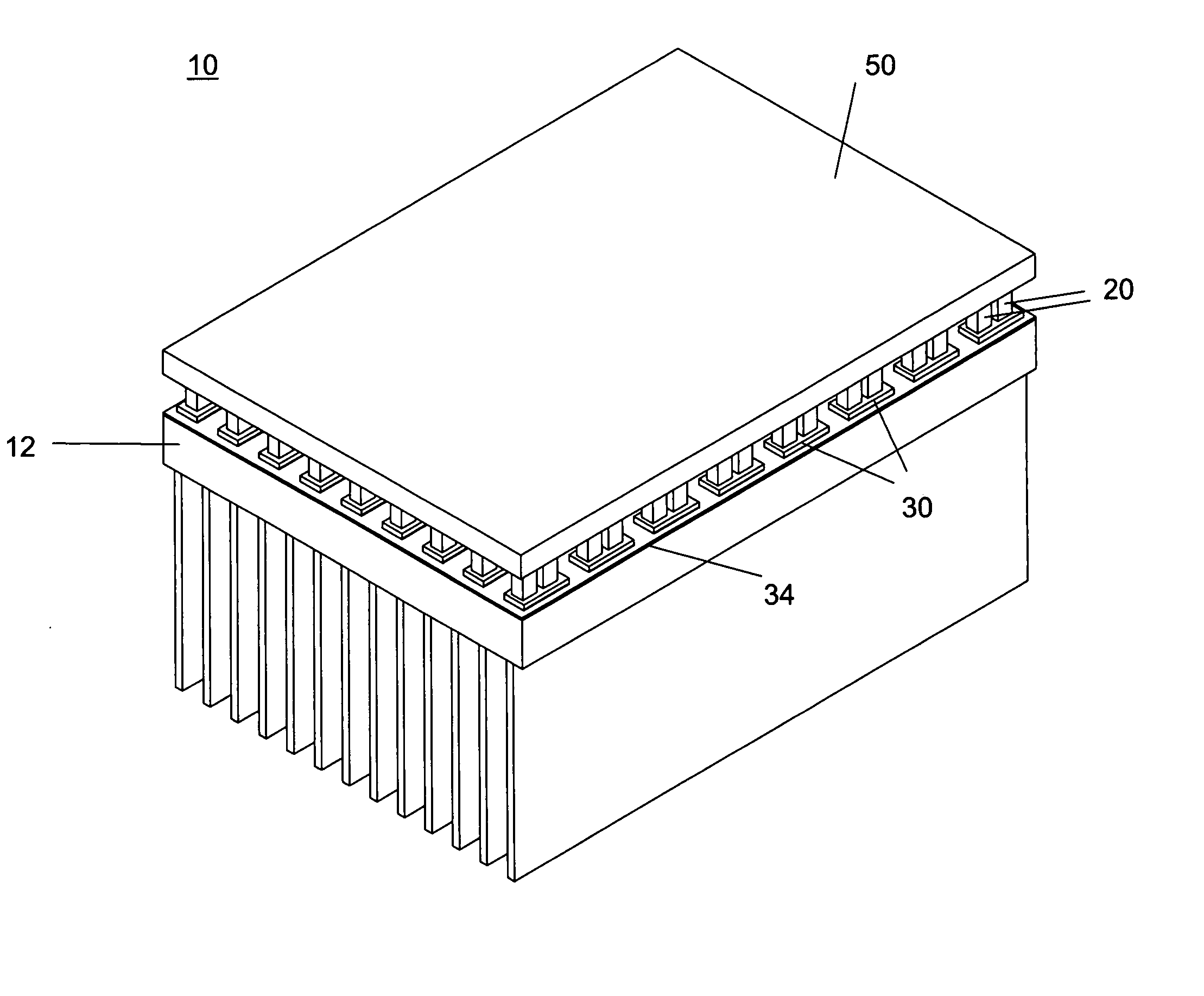

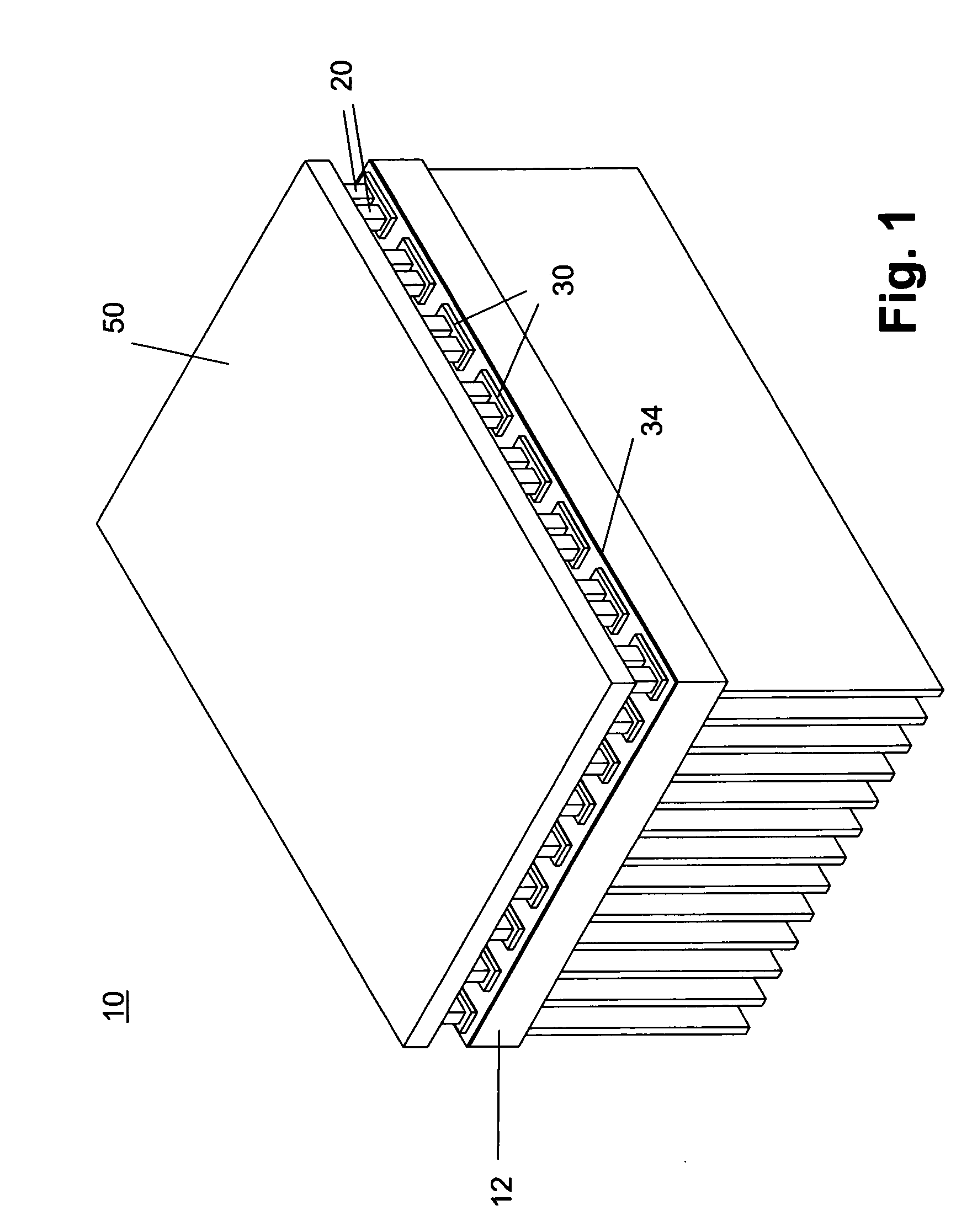

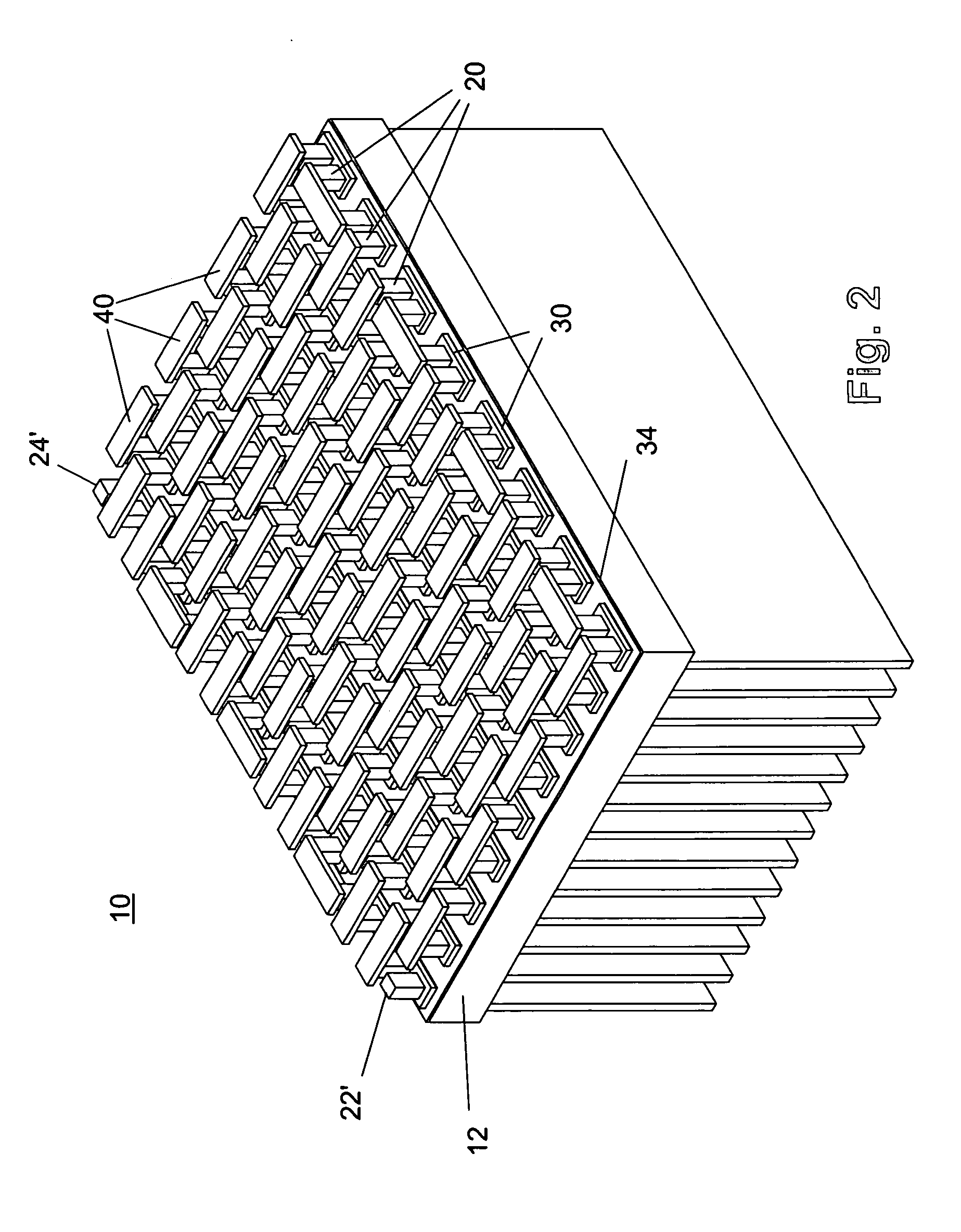

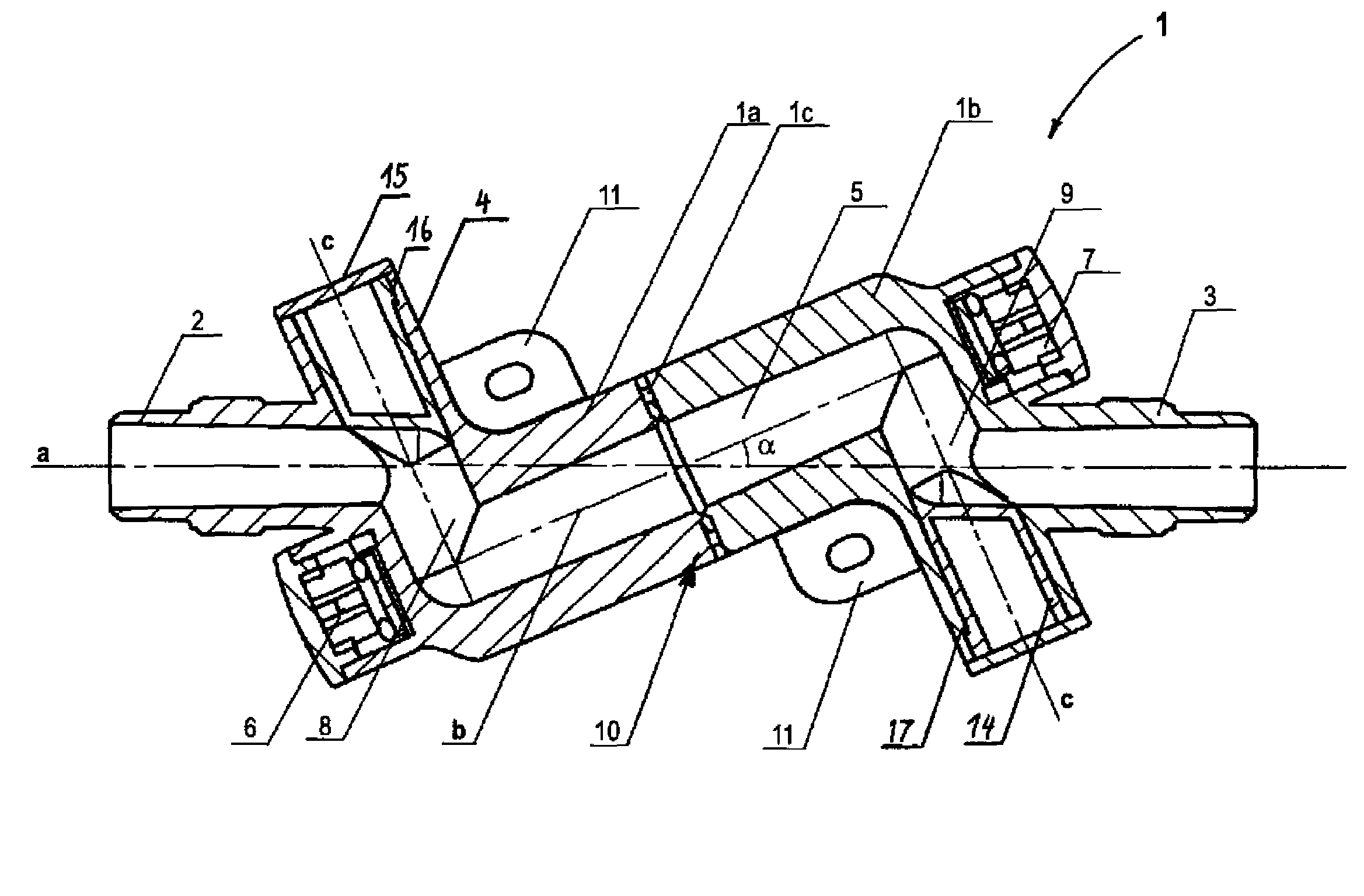

Thermoelectric module with directly bonded heat exchanger

InactiveUS20050121065A1Improve thermal efficiencyReduce thermal resistanceThermoelectric device with peltier/seeback effectEngineeringThermoelectric element

A thermoelectric device with an improved thermal efficiency has an object to be heated or cooled having a surface, at least one electrically conductive lower pad bonded directly to the surface of the object using a thermally conductive dielectric material, at least one thermoelectric element coupled on one end to the electrically conductive pad, at least one electrically conductive upper pad coupled to an opposite end of the thermoelectric element, and electrical power connections coupled to the device.

Owner:FERROTEC USA CORP

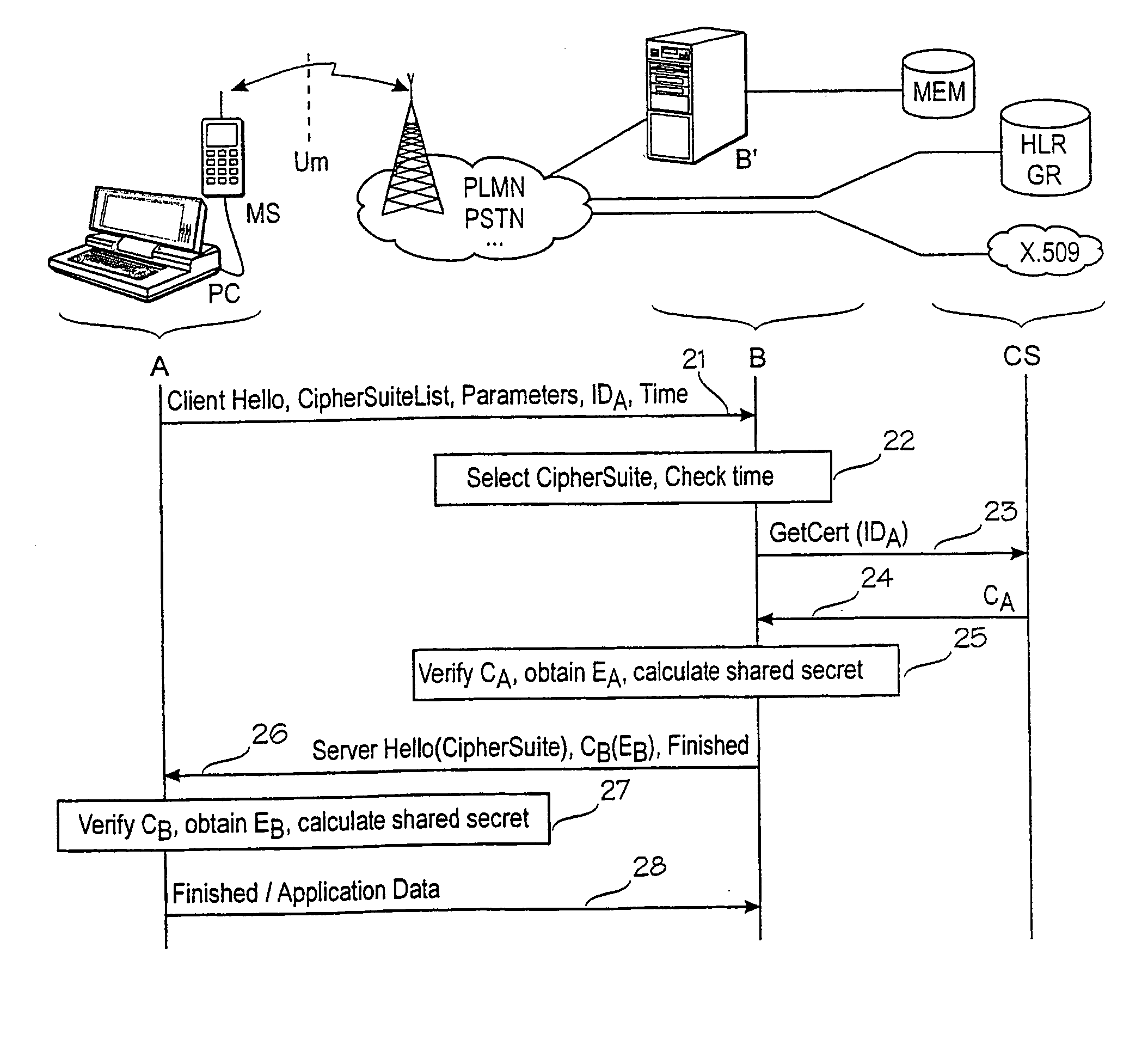

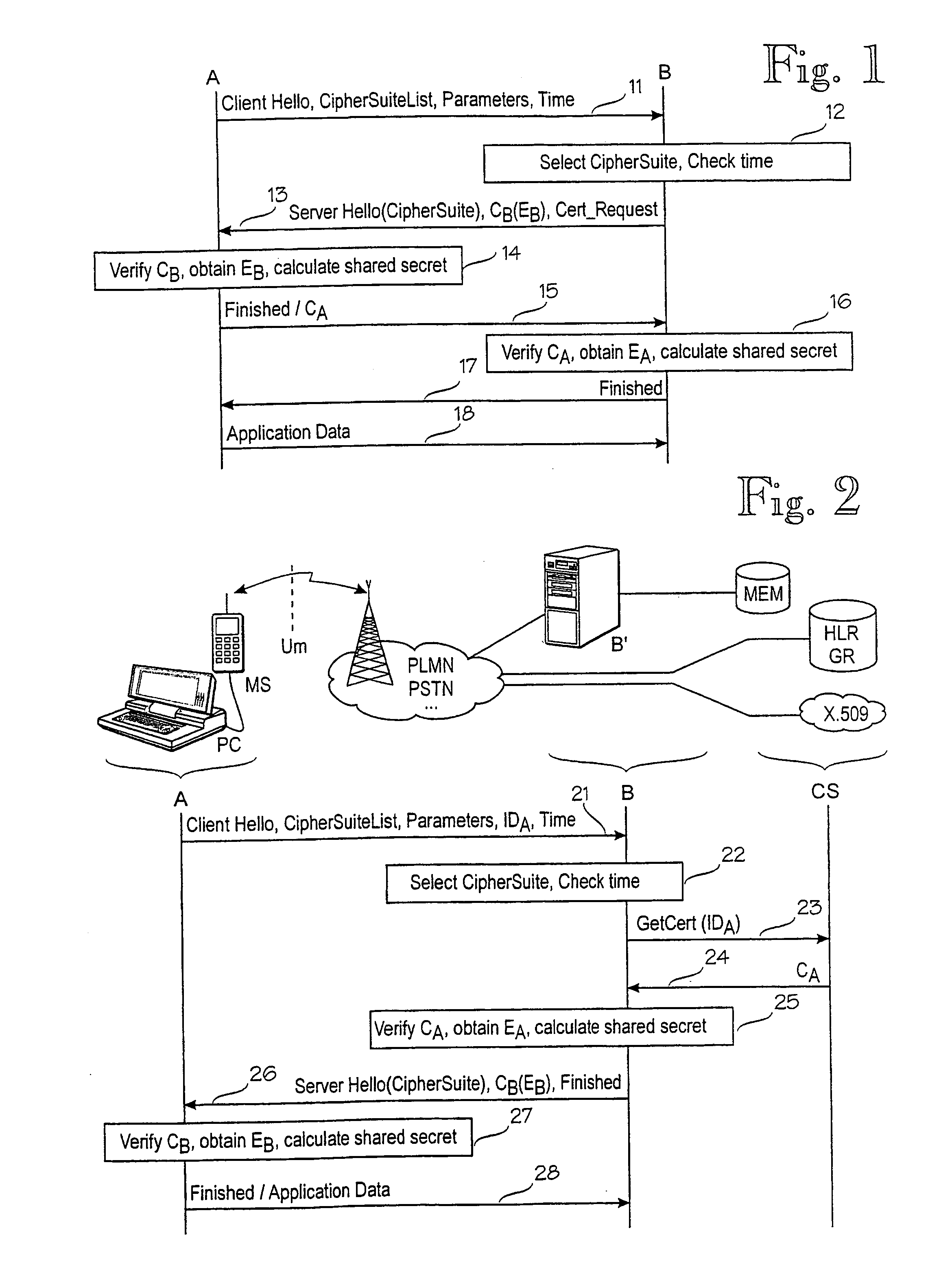

Secure handshake protocol

InactiveUS6931528B1Air interface can be eliminatedMinimize overheadKey distribution for secure communicationDigital data processing detailsProtocol for Carrying Authentication for Network AccessCipher suite

A method for a secure handshake protocol between A and B, connected by a slow channel is provided in which A sends a first message indicating a set of cipher suites with parameters, and its identifier and B selects a cipher suite, obtains A's certificate over a fast connection, verifies A's certificate and obtains A's public key. Next B sends a second message comprising B's certificate, and an indication that B has verified A's certificate, and an indication about the selected cipher suite. A begins to use the selected cipher suite, verifies B's certificate and obtains B's public key. Next A sends a third message indicating that A has verified B's certificate.

Owner:NOKIA TECHNOLOGLES OY

Nanocrystal doped matrixes

ActiveUS20100140551A1Good miscibilityInhibit aggregationMaterial nanotechnologyLiquid surface applicatorsAnti-reflective coatingSemiconductor nanocrystals

Matrixes doped with semiconductor nanocrystals are provided. In certain embodiments, the semiconductor nanocrystals have a size and composition such that they absorb or emit light at particular wavelengths. The nanocrystals can comprise ligands that allow for mixing with various matrix materials, including polymers, such that a minimal portion of light is scattered by the matrixes. The matrixes of the present invention can also be utilized in refractive index matching applications. In other embodiments, semiconductor nanocrystals are embedded within matrixes to form a nanocrystal density gradient, thereby creating an effective refractive index gradient. The matrixes of the present invention can also be used as filters and antireflective coatings on optical devices and as down-converting layers. Processes for producing matrixes comprising semiconductor nanocrystals are also provided. Nanostructures having high quantum efficiency, small size, and / or a narrow size distribution are also described, as are methods of producing indium phosphide nanostructures and core-shell nanostructures with Group II-VI shells.

Owner:SAMSUNG ELECTRONICS CO LTD

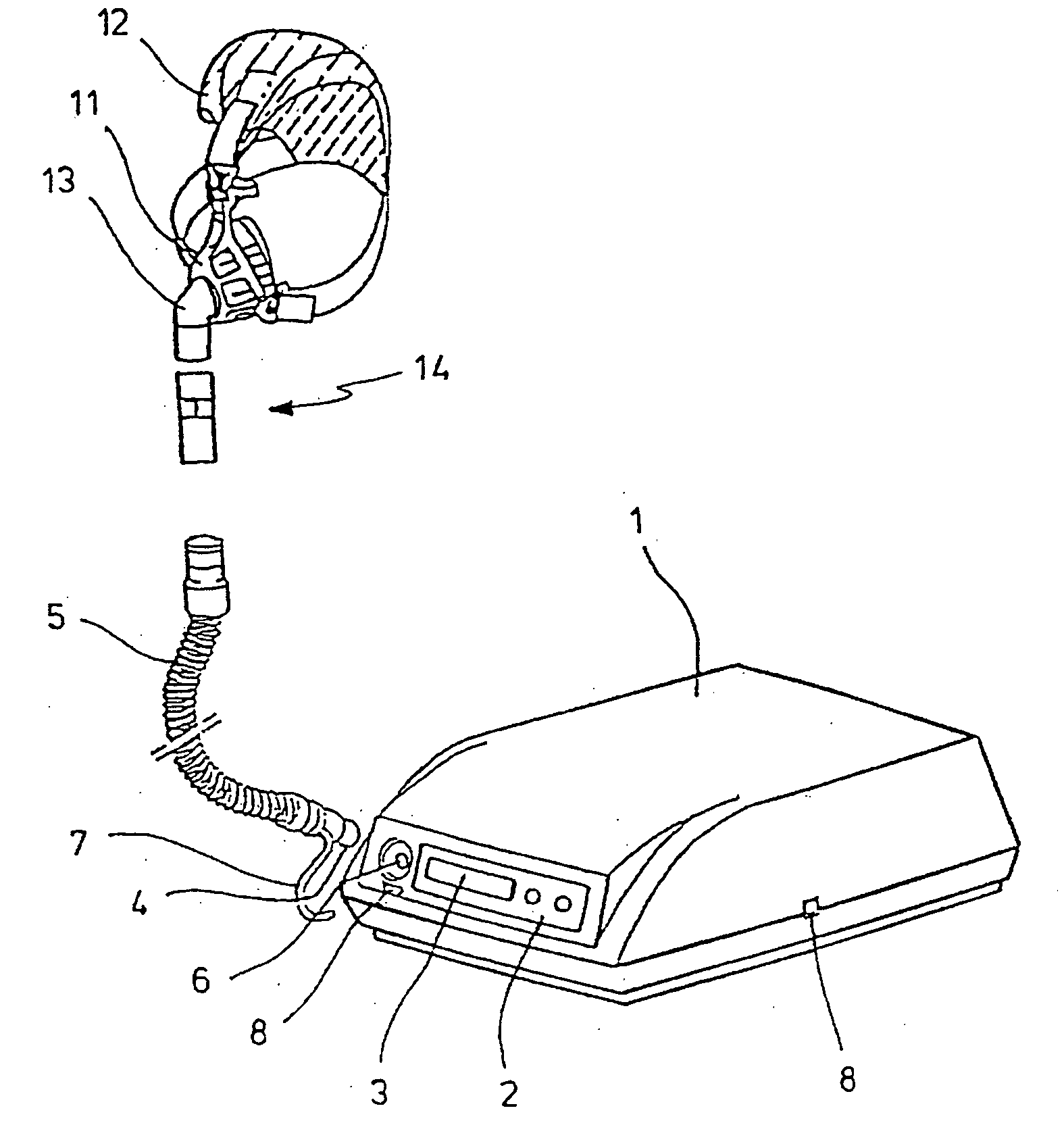

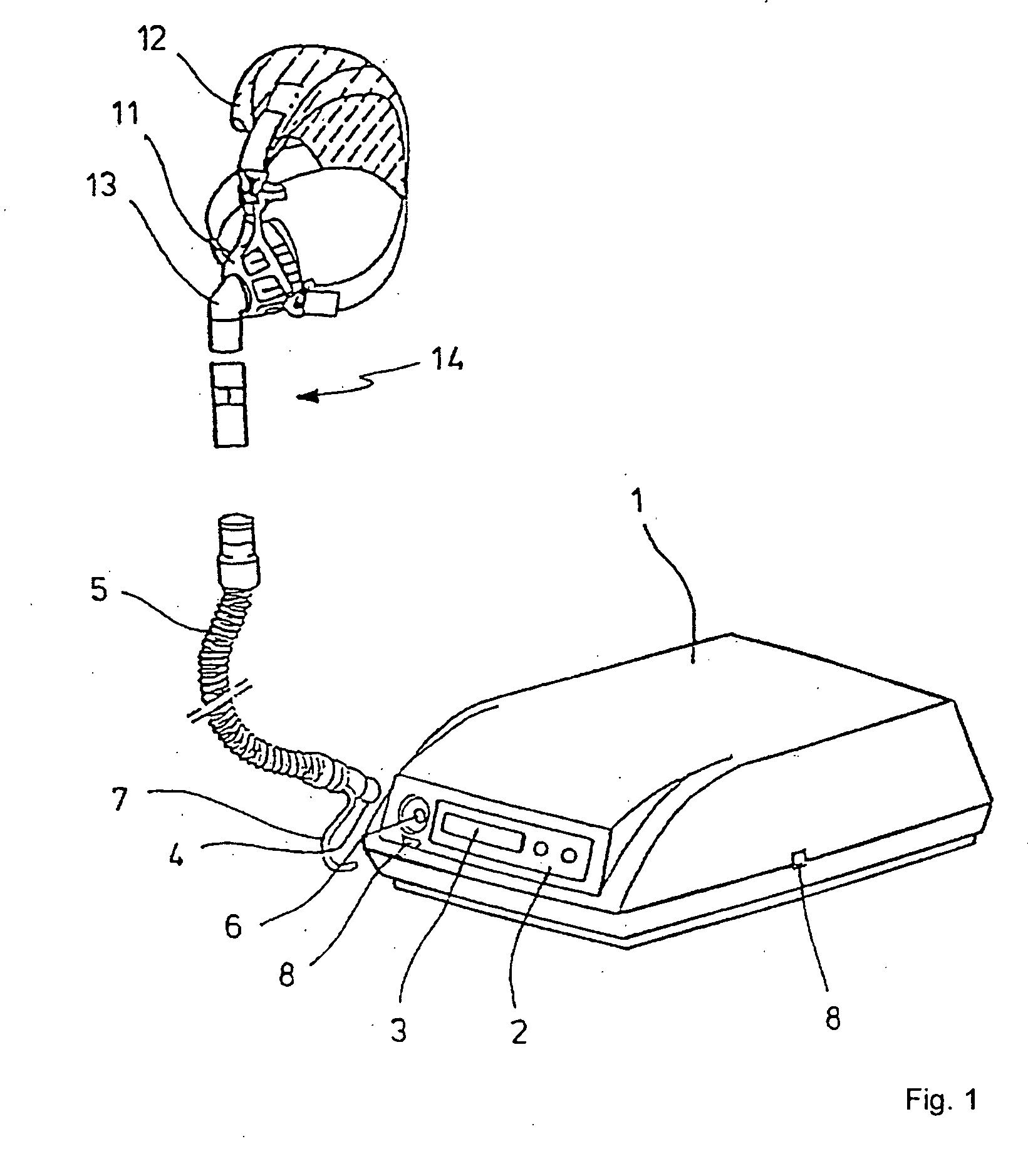

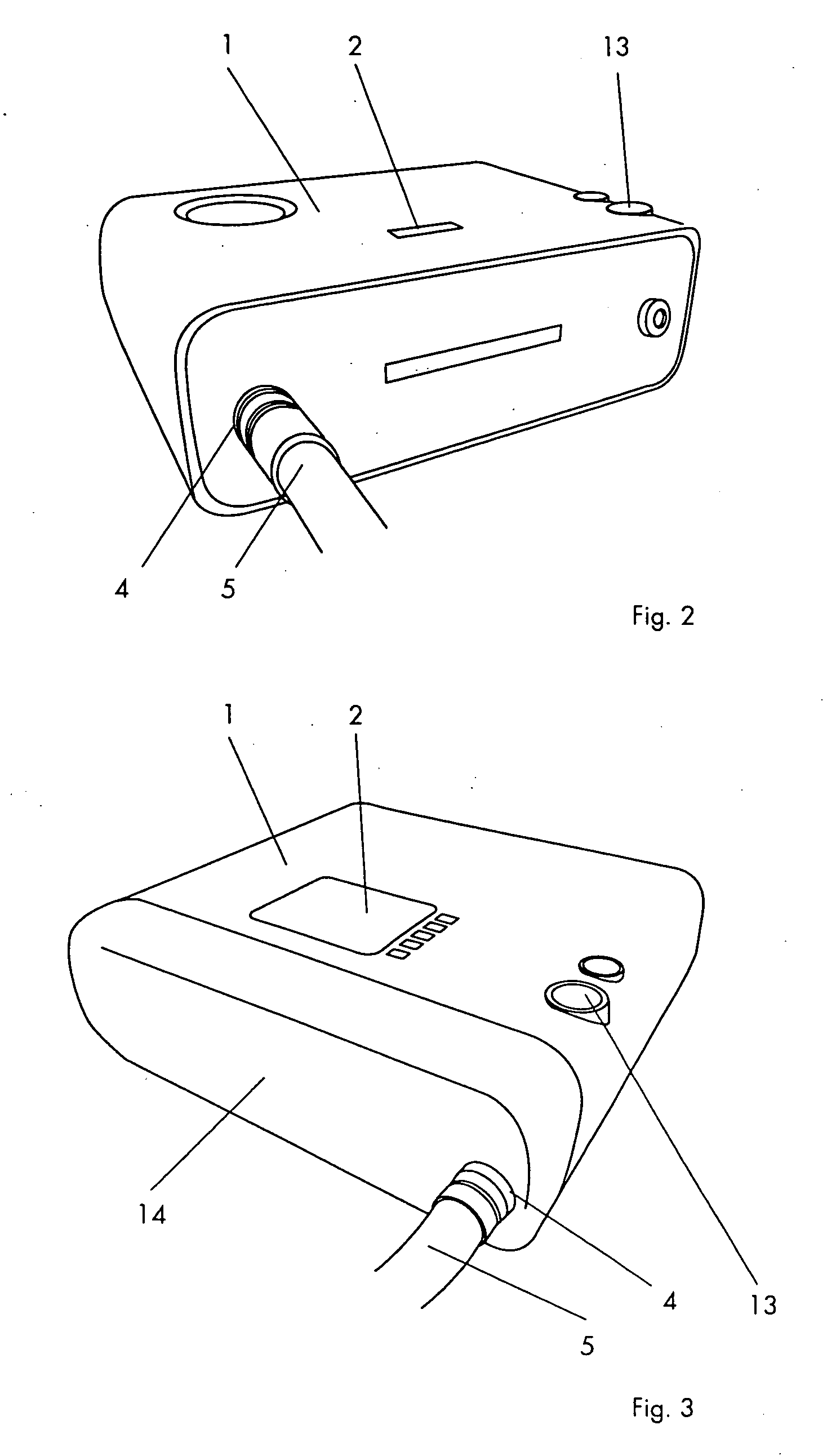

Ventilator with memory for operating data

InactiveUS20070215155A1Easy to optimizeEliminate interfaceRespiratorsOperating means/releasing devices for valvesBreathing gasData memory

A ventilator with memory for operating data has a control unit for a breathing gas source. The operating data memory is provided to store the current changeable operating data. The control unit is provided with a data-saving function which stores the current operating parameters during an intermission in the operation of the device. The control unit also has a memory readout function, by which the stored operating data can be read out after the end of an intermission to allow the ventilator to resume operation in correspondence with the saved operating data.

Owner:WEINMANN GERATE FUR MEDIZIN

Nanocrystal doped matrixes

InactiveUS20080020235A1Good miscibilityInhibit aggregationMaterial nanotechnologyMirrorsAnti-reflective coatingEngineering

Owner:NANOSYS INC

Systems and methods for overcoming or preventing vascular flow restrictions

InactiveUS20050143801A1Increase blood flowRestore blood flowStentsSurgeryPercent Diameter StenosisBiological materials

Systems and methods for overcoming or preventing vascular flow restrictions which involve: (1) providing at least one structural element within or about a vessel having a vascular flow restriction; and (2) equipping the structural element with bio-lining such that it restores blood flow and minimizes, if not eliminates, the interface between blood and non-biological materials to thereby prevent stenosis and / or restenosis.

Owner:ABOUL HOSN WALID NAJIB

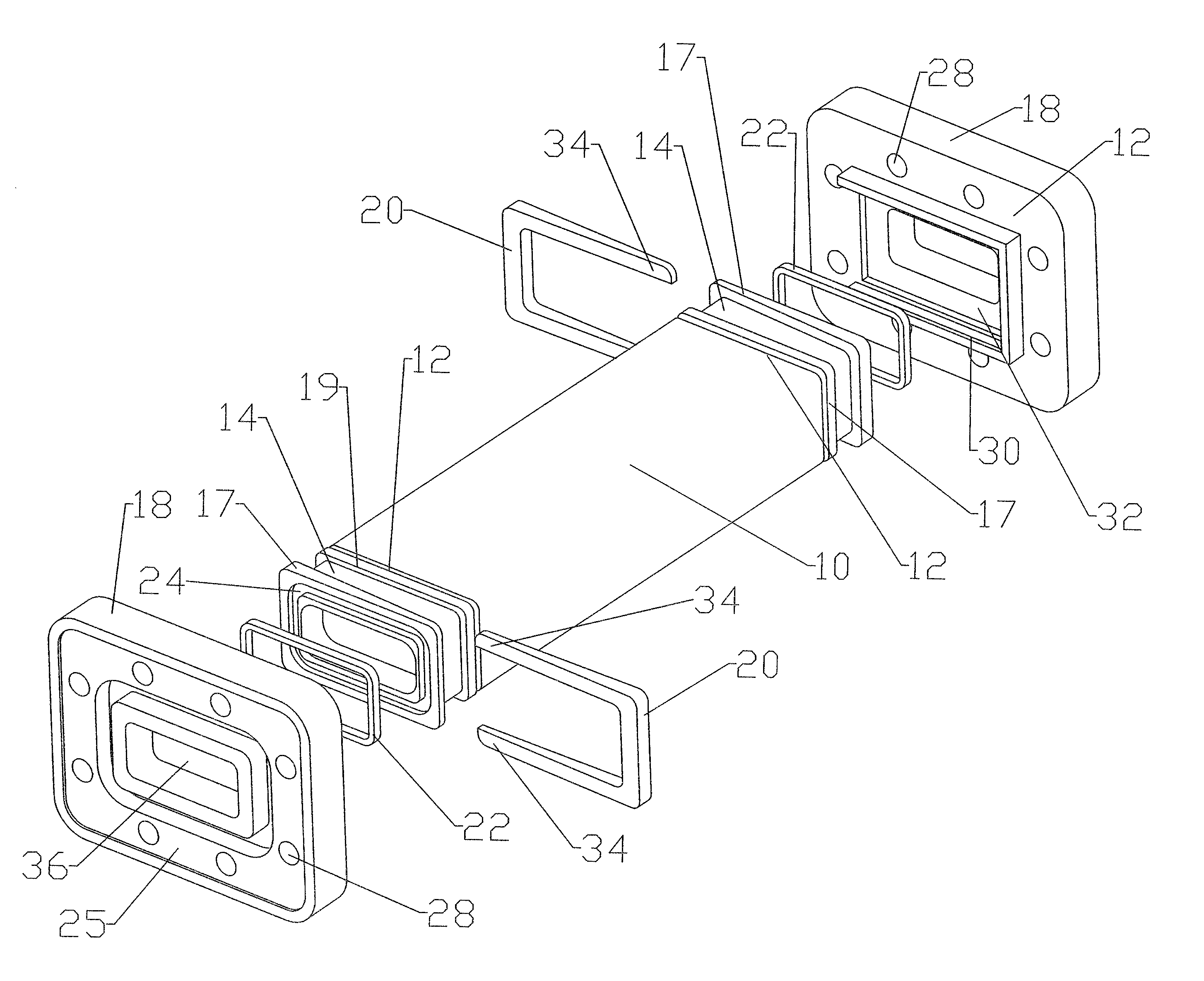

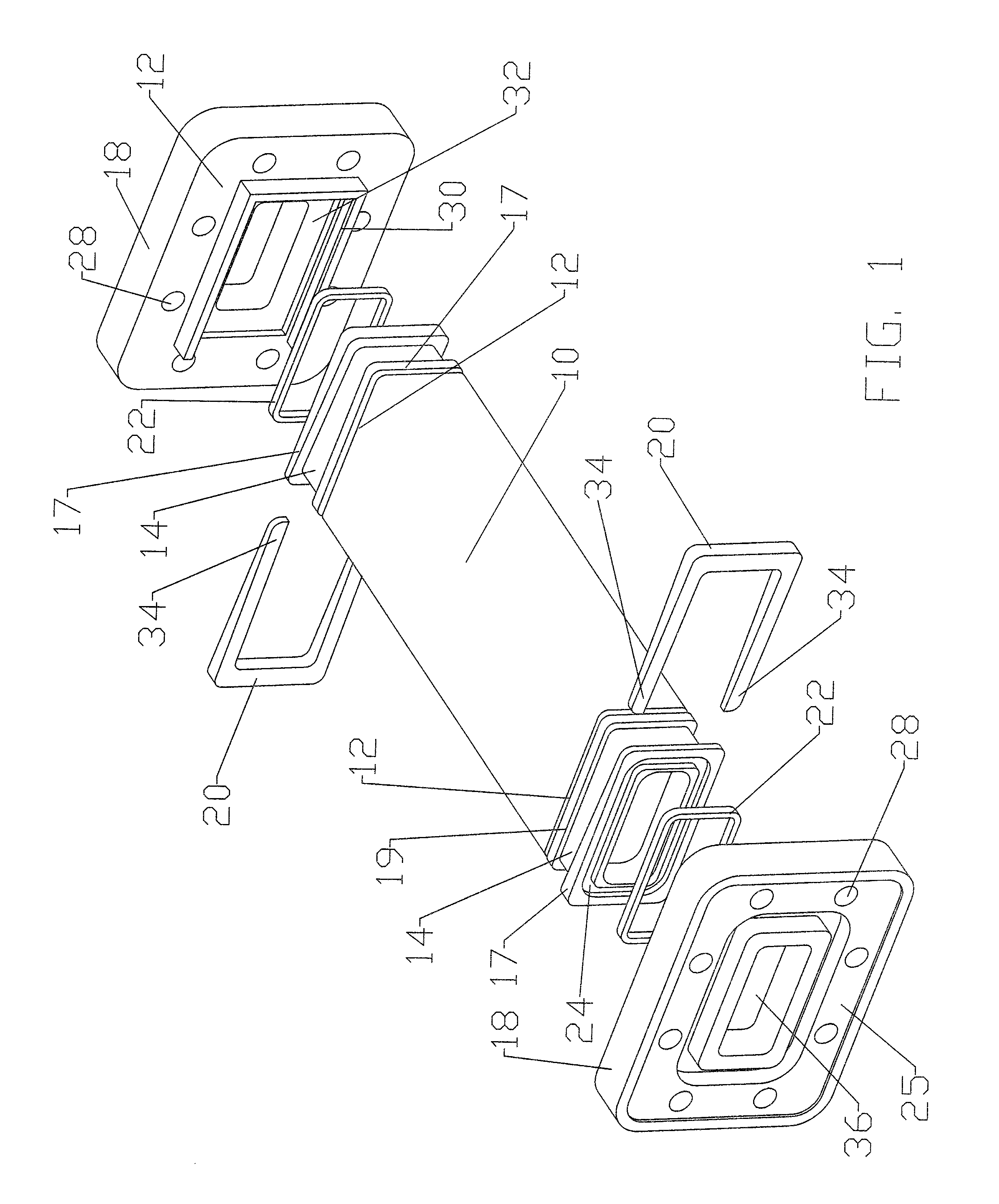

Universal waveguide interface adaptor

A waveguide adaptor assembly with interface and waveguide ends for coupling an end of a waveguide with a desired interface configuration. The assembly including a flange adaptor adapted to receive the end of the waveguide. An outer shoulder projecting radially from the interface end of the flange adaptor is adapted to mate with a recessed area formed in the waveguide end of an interface. A pair of retaining groove(s) on opposing sides of the recessed area co-operating with each other and adapted to receive a retainer that, pressing upon a waveguide end of the outer shoulder as it is inserted, biases the interface end of the flange adaptor against the recessed area. The interface having the desired interface configuration at the interface end.

Owner:ANDREW CORP

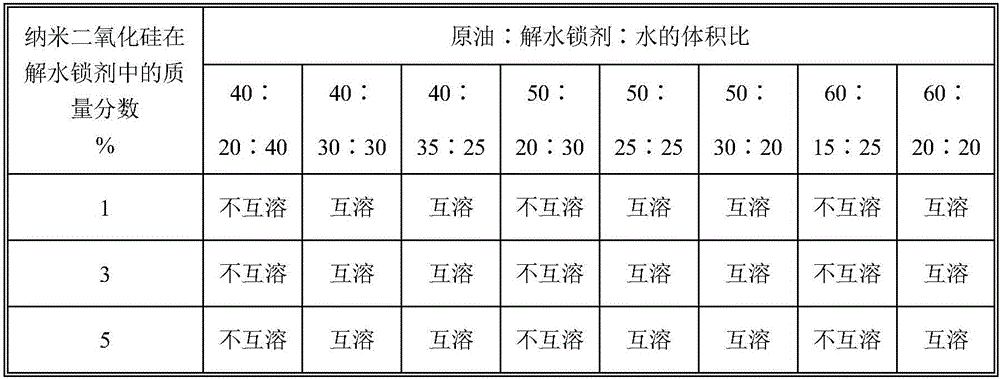

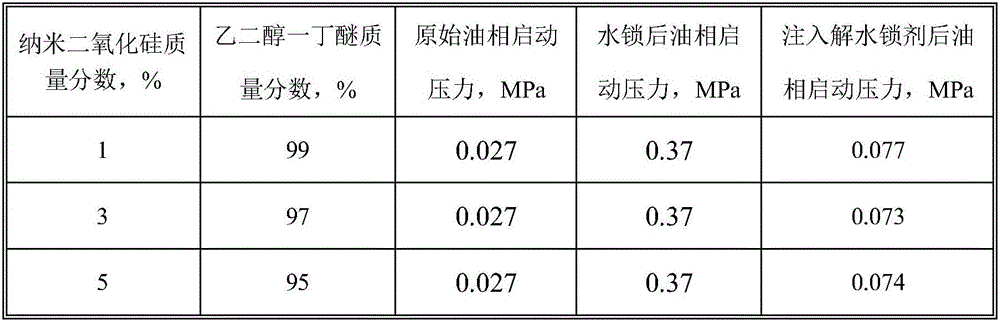

Water lock removal agent for low-water-content oil well

InactiveCN105733543AImprove permeabilityImprove hydrophilicityFluid removalDrilling compositionOil phaseSilicon dioxide

The invention provides a water lock removal agent for removing the water lock damage of a low-water-content oil well.The water lock removal agent is composed of nanometer silicon dioxide and ehtylene glycol monobutyl ether with initial granularity of 15-30 nm, wherein the weight of nanometer silicon dioxide accounts for 1-5% of the total weight.When the volume ratio of the water lock removal agent to water is 1:1, the oil phase and the water phase can be changed into one phase through the water lock removal agent within 6 hours by solubilizing the water phase and the oil phase, and therefore the permeation resistance of the two phases is eliminated; by means of the nanometer silicon dioxide, the hydrophily of rock surfaces can be enhanced, free water is adsorbed to rock surfaces to form water films, and therefore the relative permeation rate of the oil phase is increased, and the permeation start pressure of the oil phase is reduced.For the oil well suffering from water lock damage, the water lock removal agent with the same volume as the leakage volume is injected into a stratum through oil sleeve annulus according to the flushing fluid leakage volume recorded in the flushing work process; by closing the well for 6 hours or above and then opening the well for production, the water lock damage of the low-water-content oil well can be effectively relieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

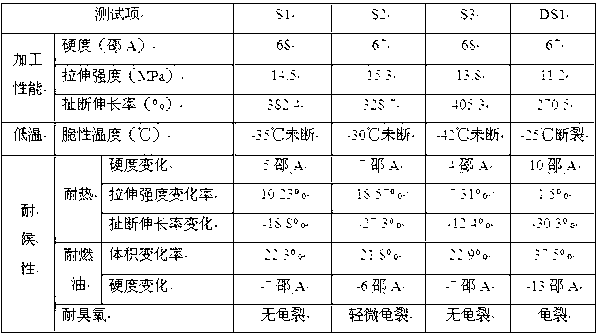

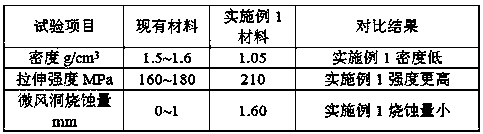

Preparation method of modified nitrile rubber and modified nitrile rubber

ActiveCN103304857APromotes uniform dispersion and stable distributionEliminate the two-phase interfaceEtherPlasticizer

The invention provides a preparation method of modified nitrile rubber. The method comprises the following steps of: A, plasticating chloric ether rubber, and adding a reinforcing filler, an antiaging agent and a plasticizer to mix so as to obtain masterbatch of chloric ether rubber; B, dispersing the masterbatch of chloric ether rubber in an organic solvent to form chloric ether rubber latex; C, plasticating the nitrile rubber, and adding a reinforcing filler, an antiaging agent and a plasticizer to mix so as to obtain masterbatch of nitrile rubber; D, blending masterbatches of chloric ether rubber and nitrile rubber, adding an acid absorber, an activating agent and a vulcanization accelerator to mix, and then adding a vulcanizer for open mill to obtain the modified nitrile rubber. The invention further provides modified nitrile rubber prepared by the preparation method. In the preparation method of modified nitrile rubber provided by the invention, first, chloric ether rubber is prepared as latex which is easy to disperse from nitrile rubber, so that modified nitrile rubber which is uniformly dispersed, and good in processing performance, low temperature and weather ability is prepared.

Owner:BYD CO LTD

Water block removal agent and preparation method thereof

ActiveCN107142098AImprove permeabilityImprove hydrophilicityFluid removalDrilling compositionInjection equipmentWater block

The invention relates to a water block removal agent and a preparation method thereof. The water block removal agent at least comprises the following components in percentages by mass: 0.1-0.5% of first modified nano silicon dioxide modified by a lipopeptid biological surfactant, 0.5-1.0% of second modified nano silicon dioxide modified by a fluorocarbon surfactant, 10-30% of ethylene glycol and the balance of water, wherein the first modified nano silicon dioxide, the second modified nano silicon dioxide, ethylene glycol and water are injected in proportion through injection equipment of the water block removal agent and the components are mixed in the injection equipment to form the water block removal agent. The water block removal agent provided by the invention has the advantages of being convenient to prepare, strong in surface activity, high-temperature-resistant, high-salt-resistant, strong in rock absorption, low in cost and the like.

Owner:成都百联油田技术服务有限公司

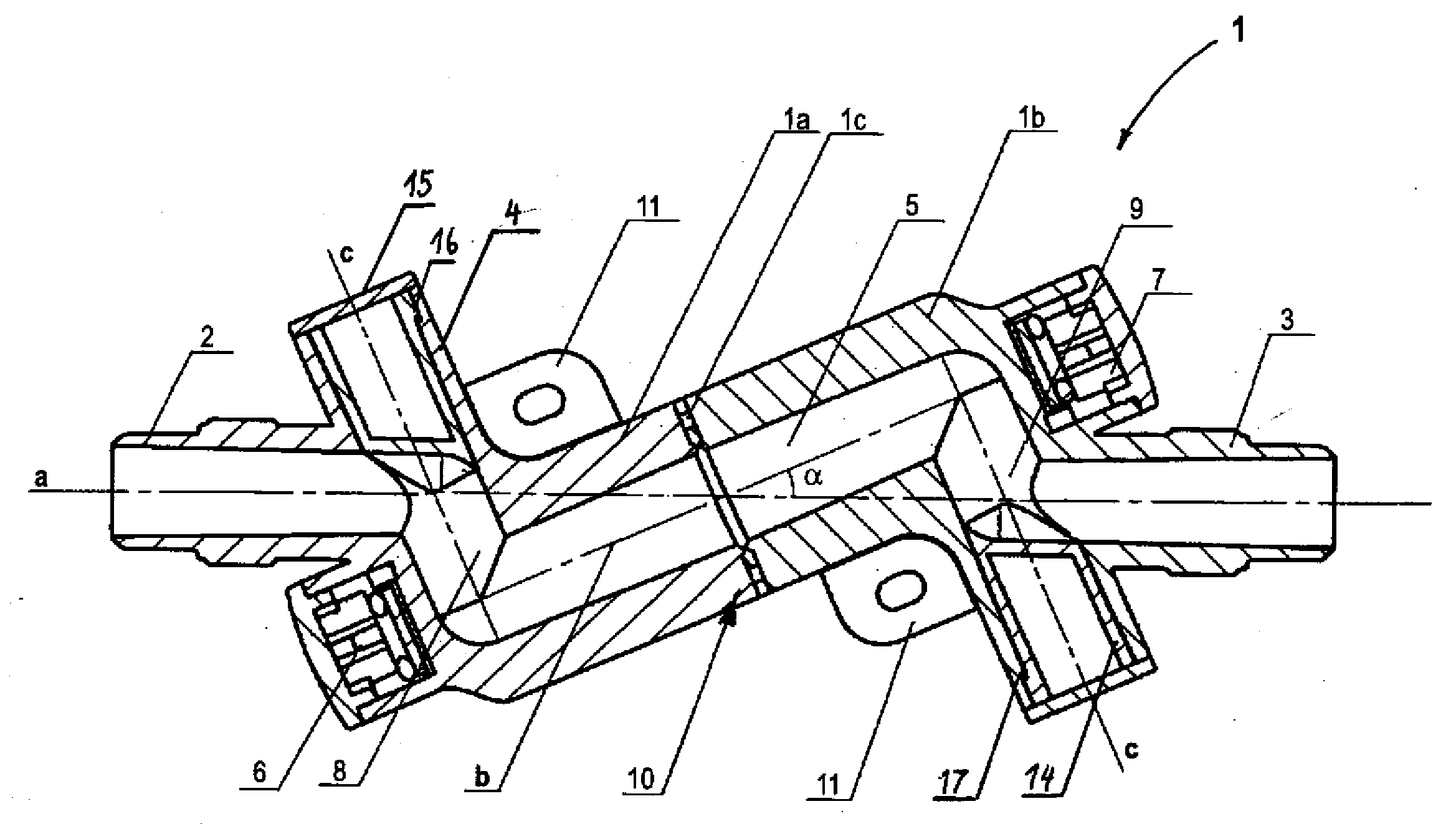

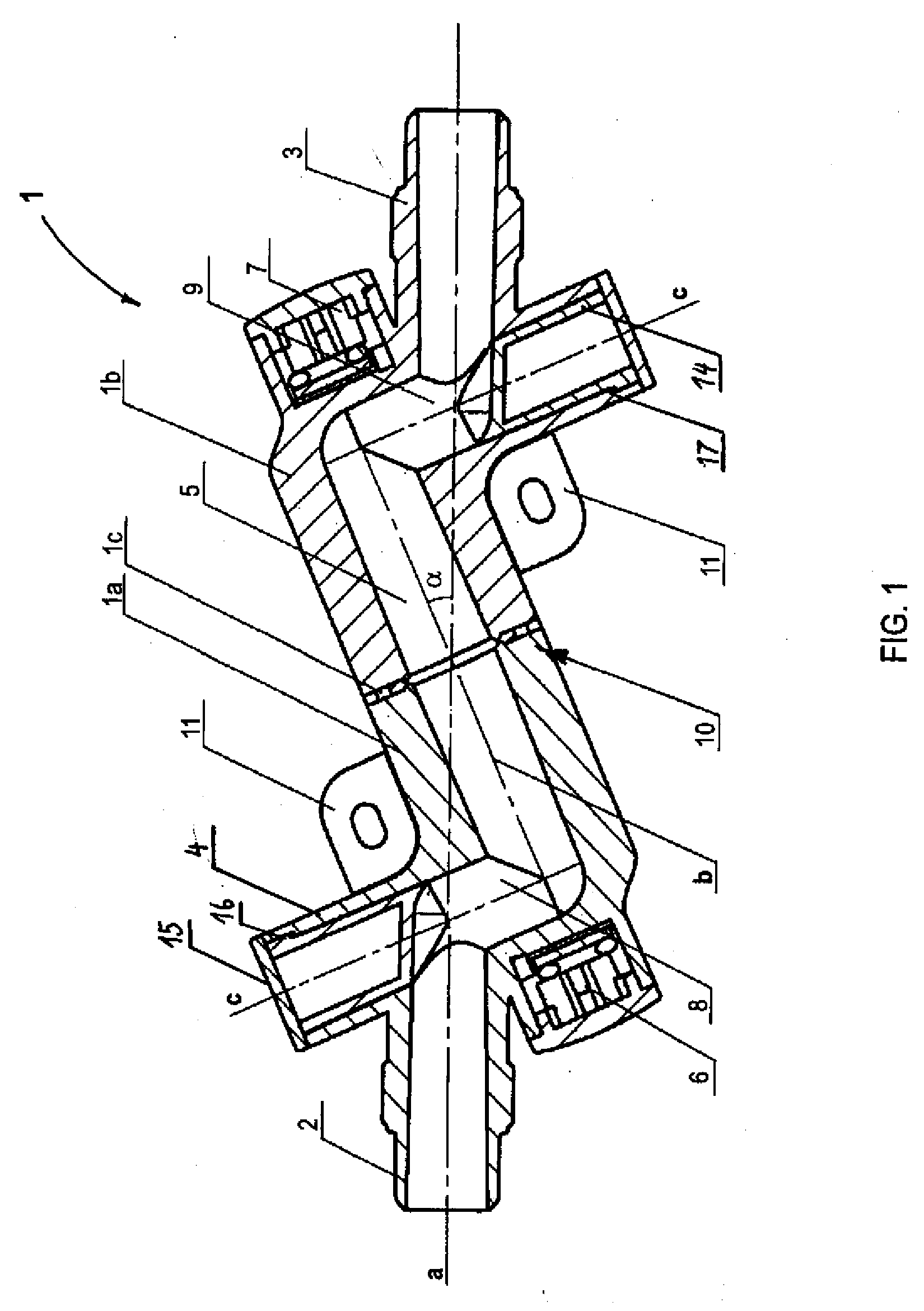

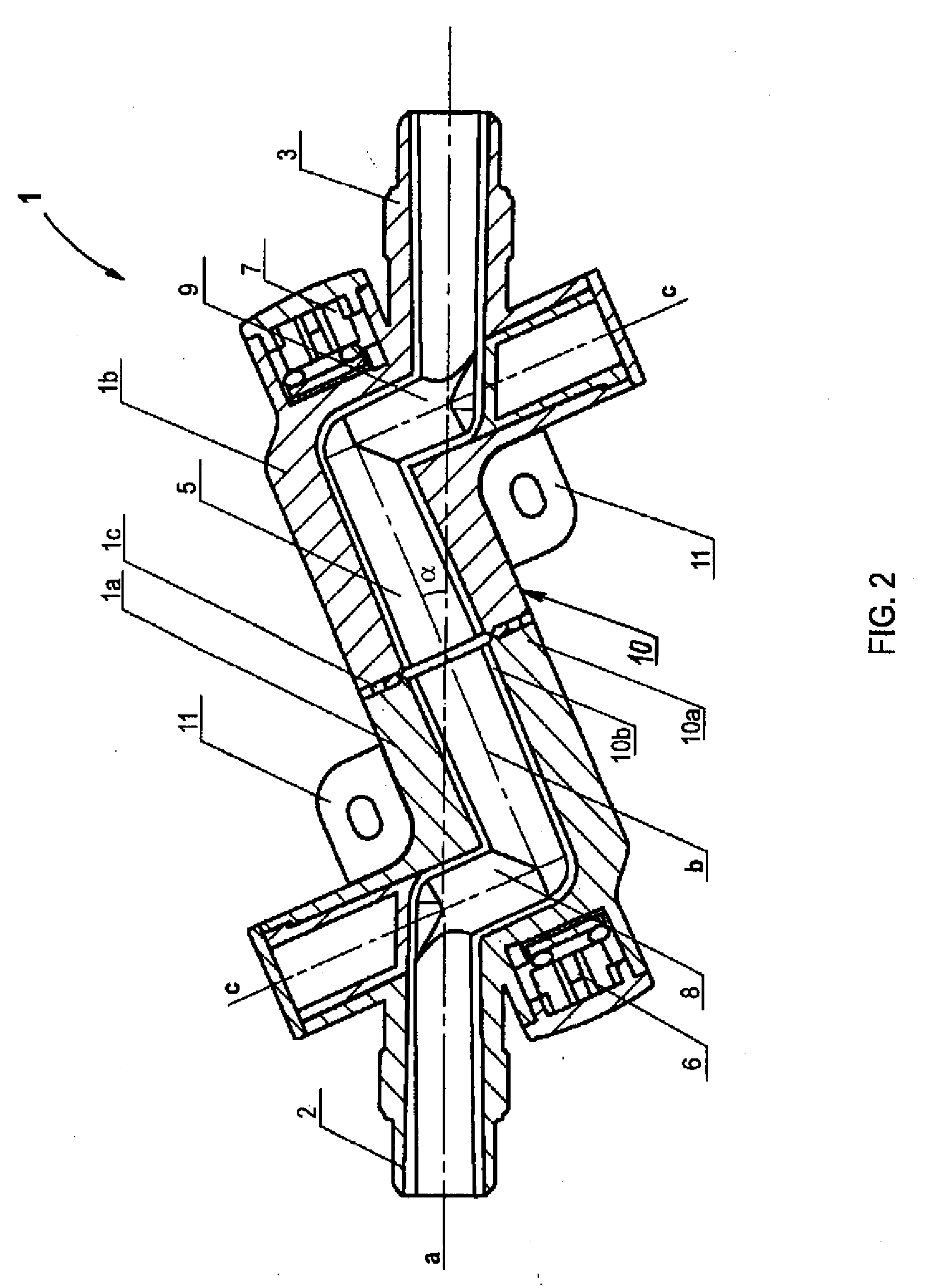

Flowmeter

InactiveUS20070062305A1Space minimizationEasy to installVolume/mass flow measurementVolume meteringUltrasonic sensorEngineering

Owner:GEBRUDER MULLER APPARATEBAU GMBH & CO KG

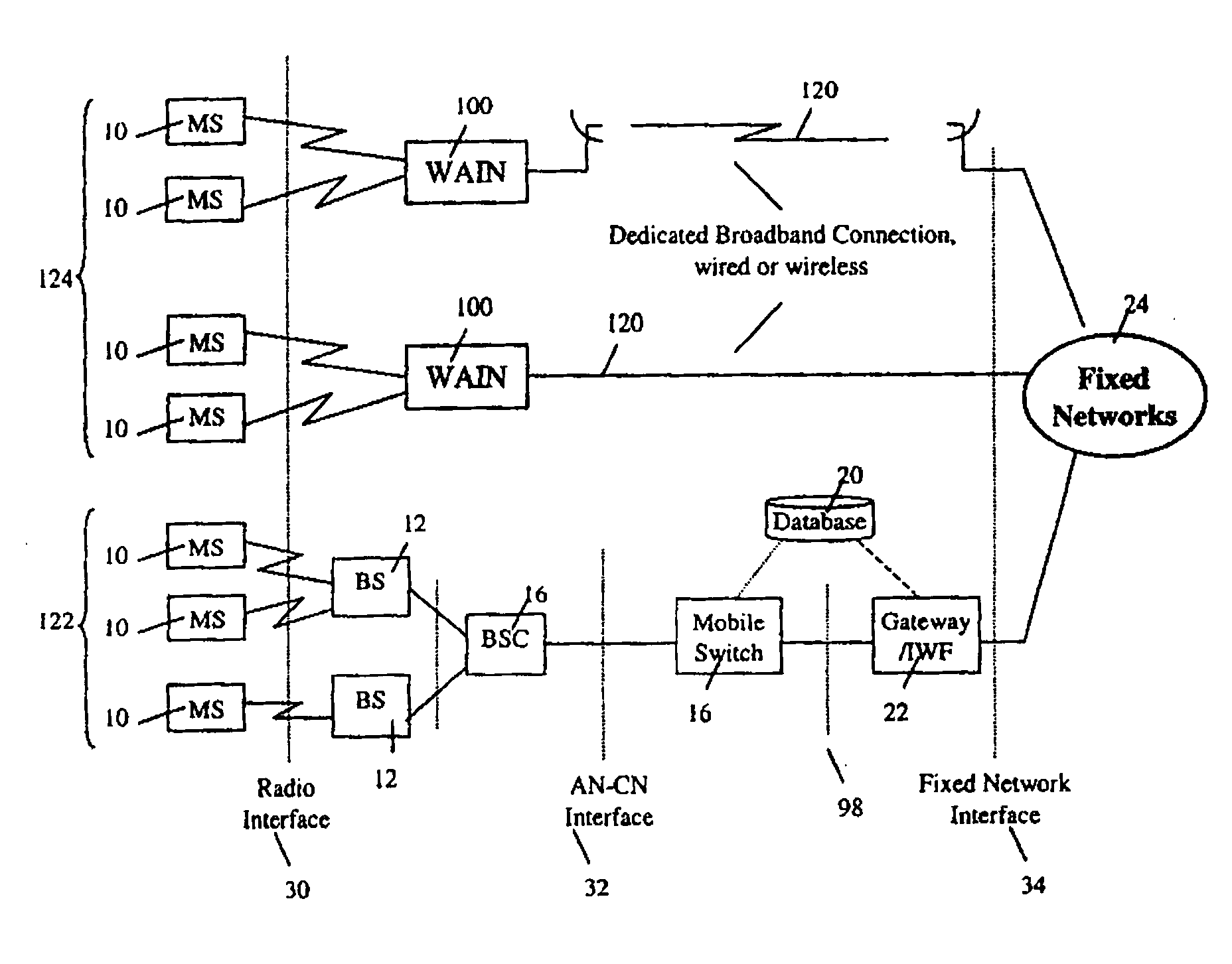

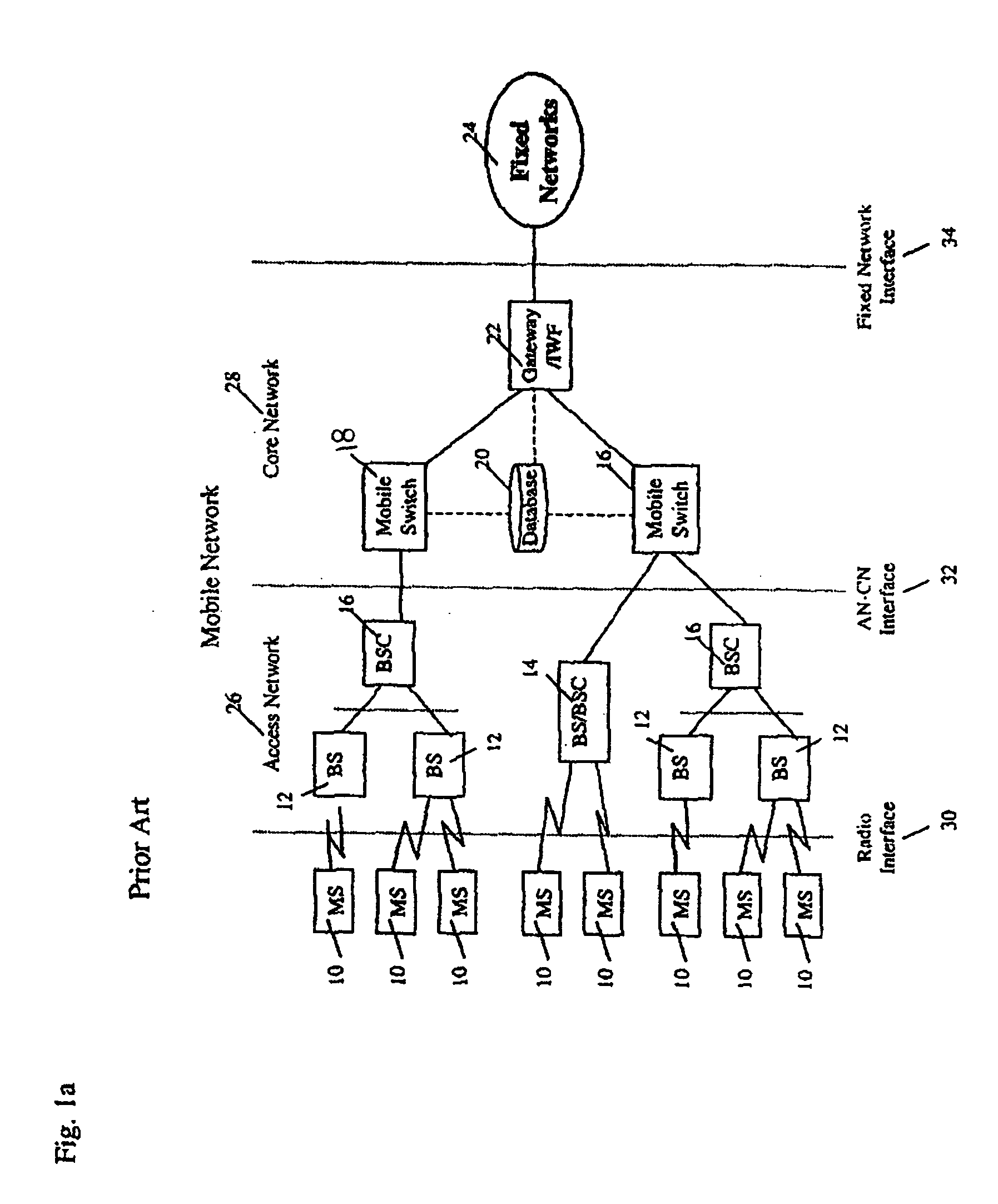

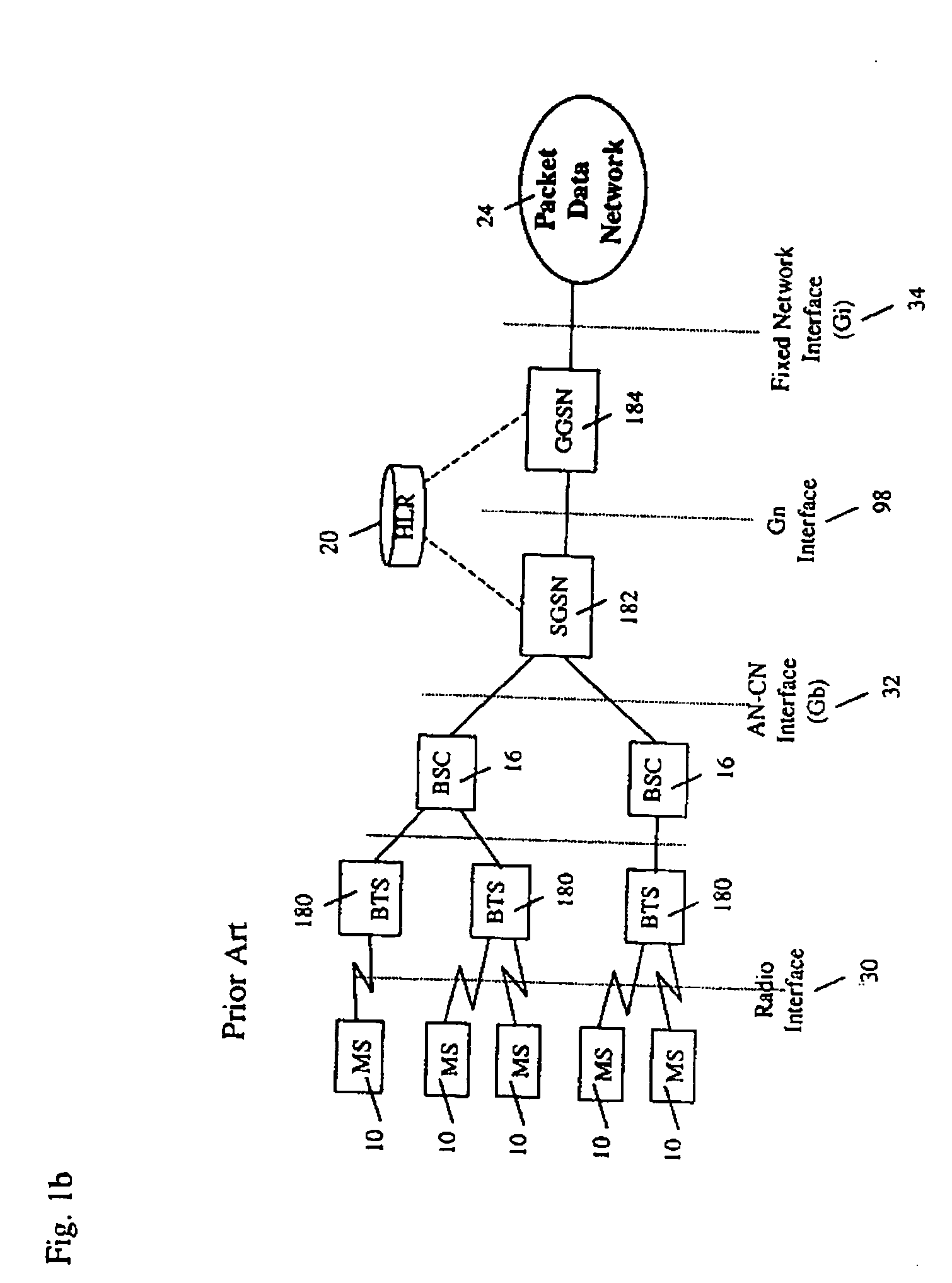

Apparatus and system to provide wireless data services through a wireless access integrated node

InactiveUS20050197155A1Improve efficiencyIncreases overall wireless system capacityAccounting/billing servicesData switching by path configurationRadio coverageAuto-configuration

An apparatus and system for providing wireless access to packet data networks and value-added services is disclosed. The wireless access integrated node (WAIN) offers a simplified internal architecture which eliminates unnecessary intermediate protocols contained in a multi-node hierarchical network architecture while still supporting the main functions of standard mobile networks and preserving standard external interfaces. The WAIN is essentially an integrated network element that provides local radio coverage and complements the capability of the public wireless network. The WAIN can automatically configure itself to minimize interference and achieve optimal performance.

Owner:BAKER JOHN +4

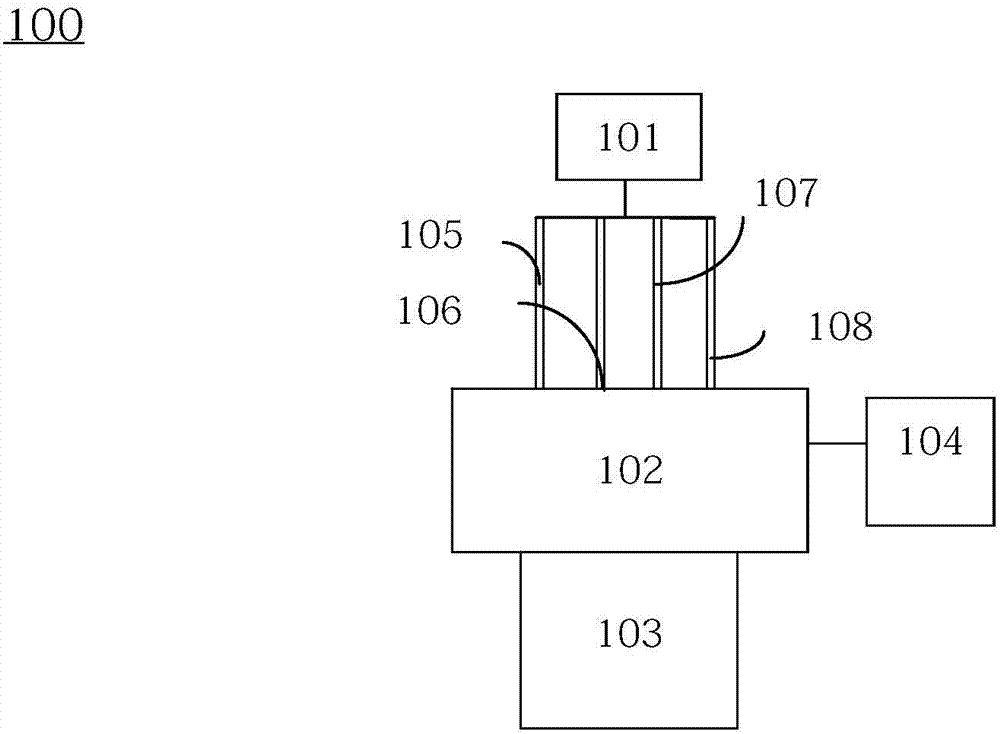

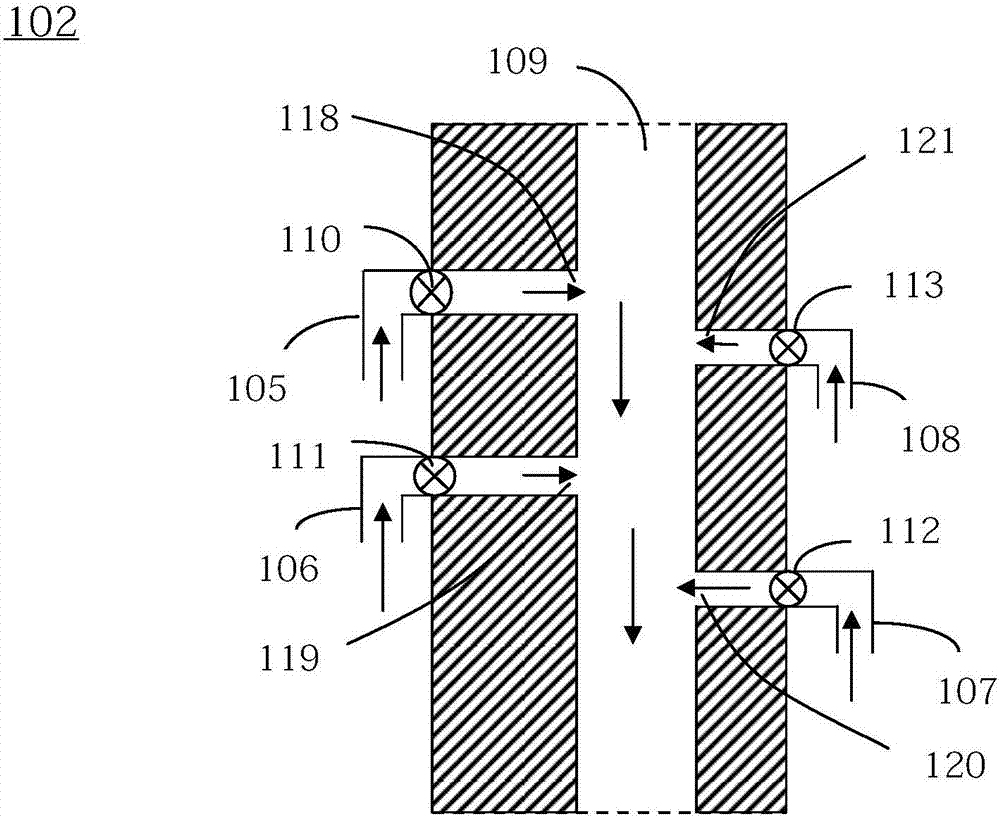

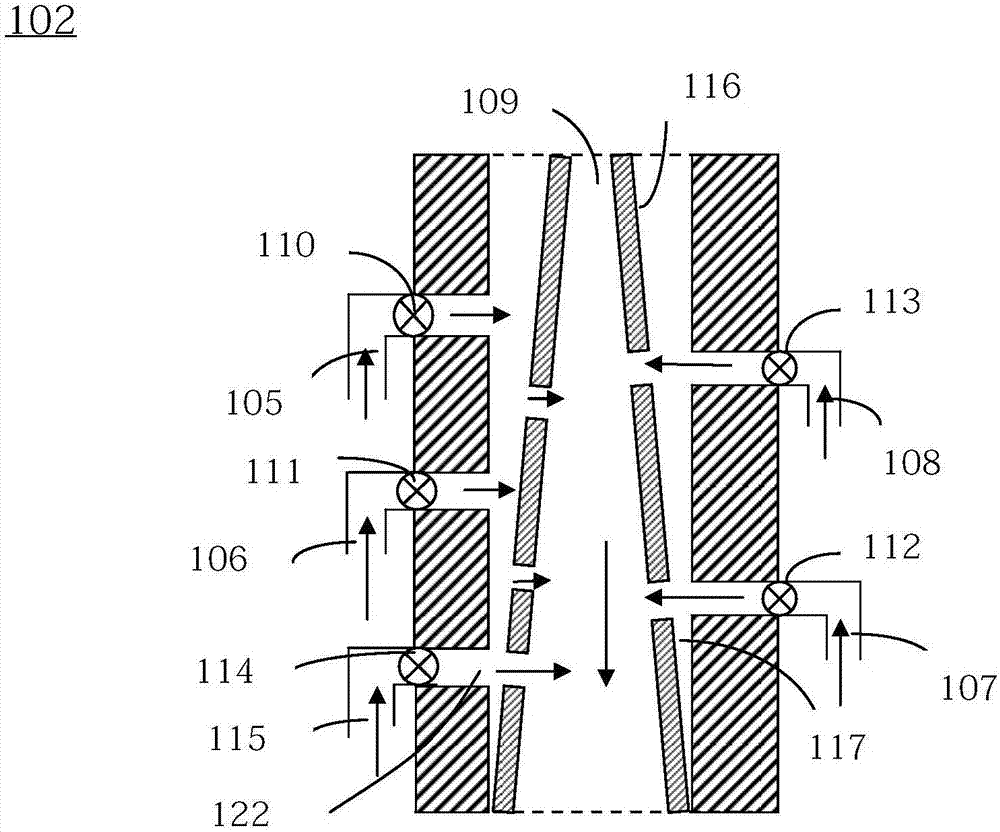

Frequency doubling self-regulating Q green laser inside double-doped chrome yttrium aluminum garnet composite photassium titanyl phosphate cavity

The invention discloses a frequency doubling self-regulating Q green laser inside a double-doped chrome yttrium aluminum garnet composite photassium titanyl phosphate cavity,and relates to a green laser. The self-regulating Q green laser is provided with a pumping source, a micro lens, a first column-shaped lens, a second column-shaped lens and a laser working medium Cr, Nd:YAG / KTP composite crystal. The pumping source, a micro lens, the first column-shaped lens, the second column-shaped lens and the laser working medium Cr, Nd:YAG / KTP composite crystal sequentially are arrayed on a same plain shaft from front to back. Anti-reflection film and a high-reflective film are plated on the rear surface of the laser working medium Cr, Nd:YAG / KTP composite crystal to serve as a back cavity lens of the laser cavity. High-reflective film and anti-reflection film are plated on the front surface of the laser working medium Cr, Nd:YAG / KTP composite crystal of the laser cavity. The number of optical elements used for the laser is small, the production cost is low, the structure is simple and compact, and the laser is convenient to produce and assemble and operate and use by a non-professional person.

Owner:XIAMEN UNIV

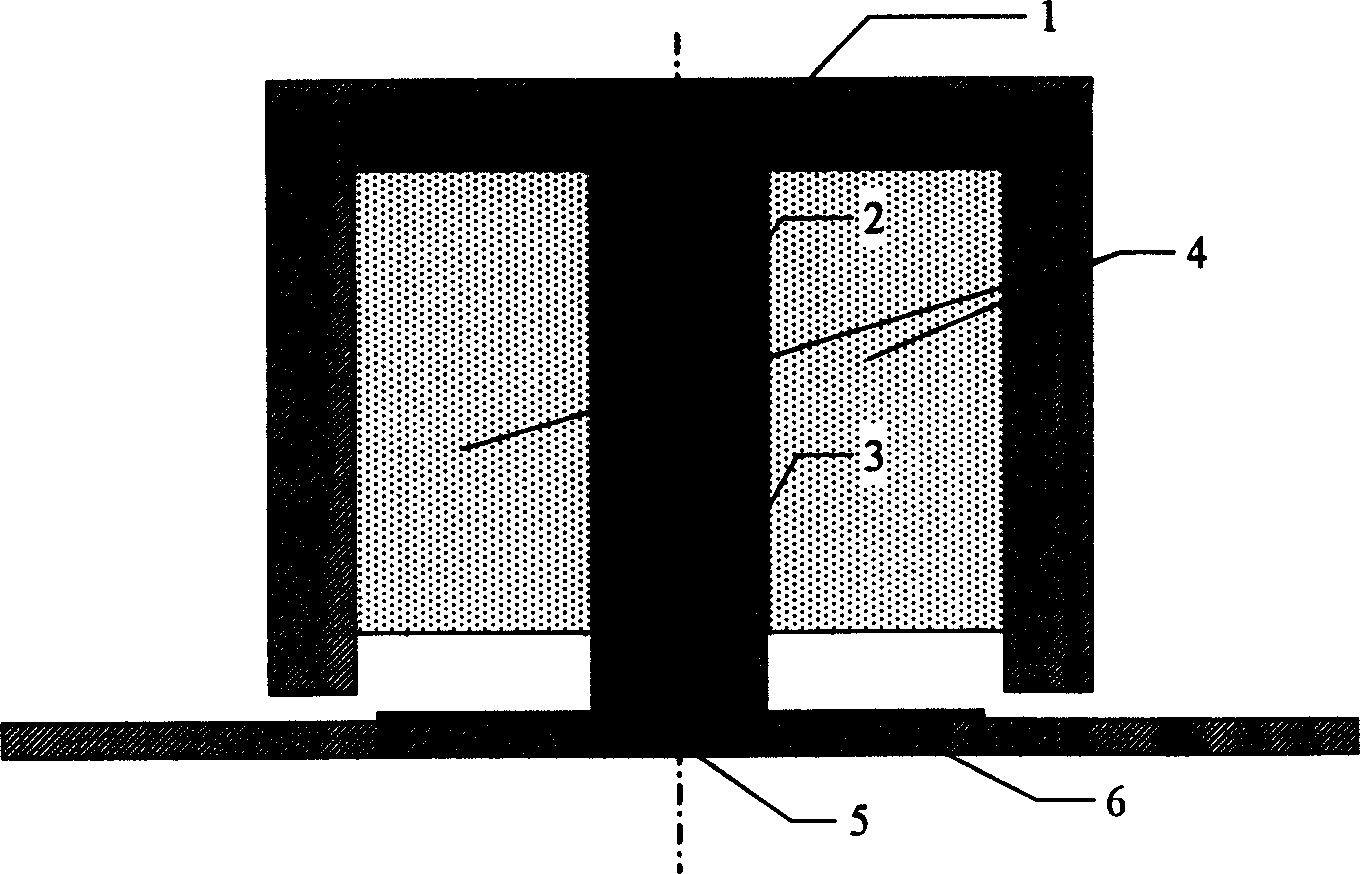

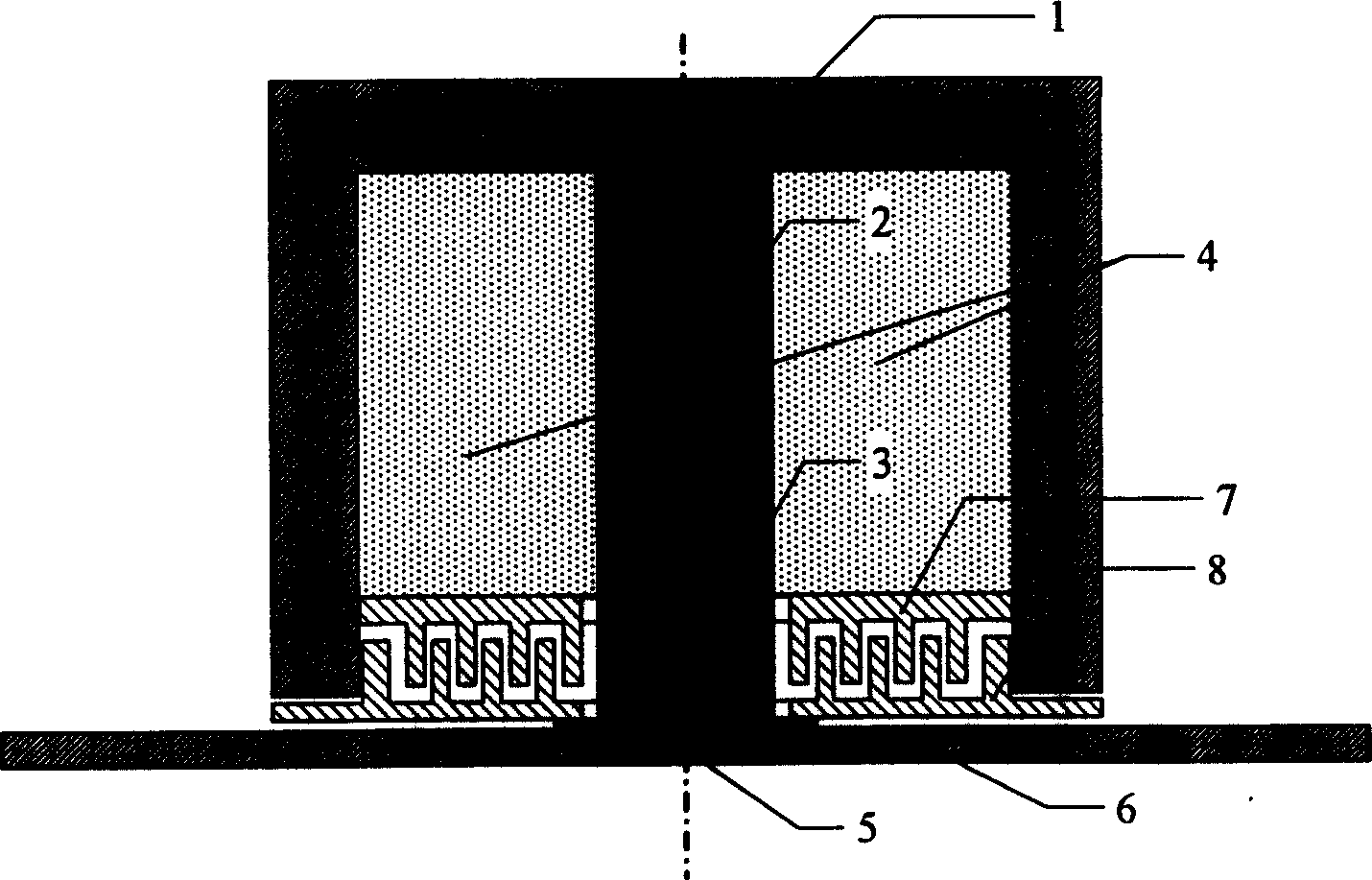

High voltage electrode device for space charge measuring system by electroacoustic pulse method

ActiveCN1749764AHigh breakdown strengthSimple structureTesting vessel constructionEngineeringHigh pressure

The present invention relates to high voltage electrode device for space charge measuring system operating on electroacoustic pulse method, and belongs to the field of electroacoustic pulse method space charge measuring technology. The device includes earthed shielding metal shell, insulator supporting column and high voltage metal electrode column connected to the lower end of the supporting column, insulating resin packing part around the high voltage metal electrode column and earthed electrode plate below the high voltage metal electrode column. The device features that it also includes one upper shielding disc inside the shielding metal shell and one lower shielding disc on the earthed electrode plate. These two shielding discs have center hole for the high voltage metal electrode column to pass through and mutual inserting uneven structures in the opposite surfaces. The present invention can eliminate interface between solid and air surface, increase air surface distance and raise the puncture voltage greatly.

Owner:TSINGHUA UNIV

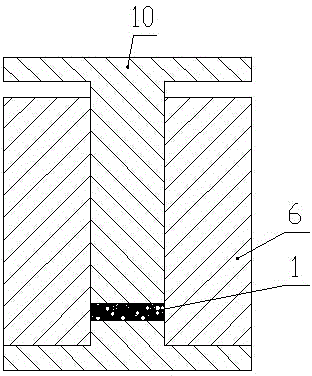

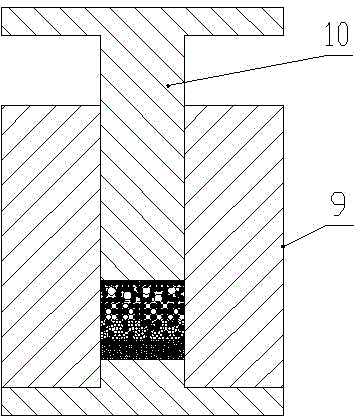

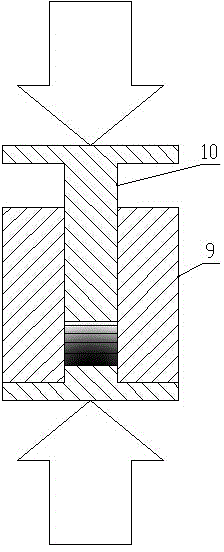

Preparation method of pyrite electrode

The invention discloses a preparation method of a pyrite electrode. The preparation method comprises the following steps: selecting pyrite particles; washing and drying the selected pyrite particles for standby use; weighing 0.6-0.8 g of the dried pyrite, grinding the dried pyrite into powder with more than 200 meshes, pressing the powder into pyrite cylinders under the condition of 0.5 MPa in a powder pressing machine, and then packaging the pyrite cylinders with tantalum foils; grinding sodium chloride into powder with more than 200 meshes, putting in a drying oven for drying for 2 hours at the temperature of 150 DEG C; using the dried sodium chloride powder to prepare sodium chloride cylinders containing the pyrite cylinders; putting the sodium chloride cylinders containing the pyrite cylinders into high-pressure assembly blocks, and carrying out warming pressure sintering; and polishing a sample after sintering is completed to obtain the pyrite electrode. The preparation method solves the technical problems that an existing pyrite electrode is extremely difficult to process and prepare caused by the facts that pyrite is crisp and poor in ductility and pyrite is symbiotic with other sulfide minerals to influence electrochemical corrosion results of pyrite in the prior art.

Owner:INST OF GEOCHEM CHINESE ACADEMY OF SCI

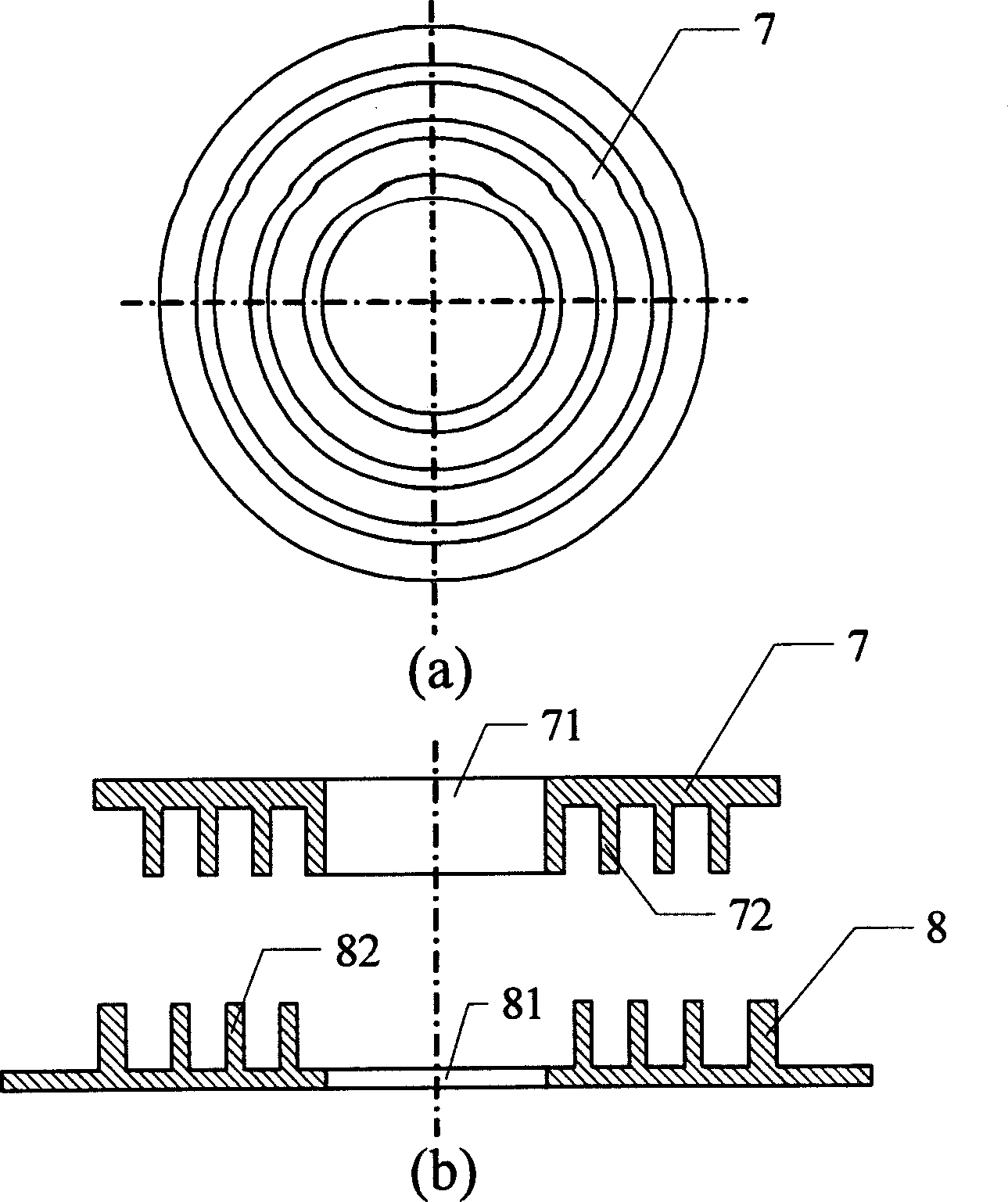

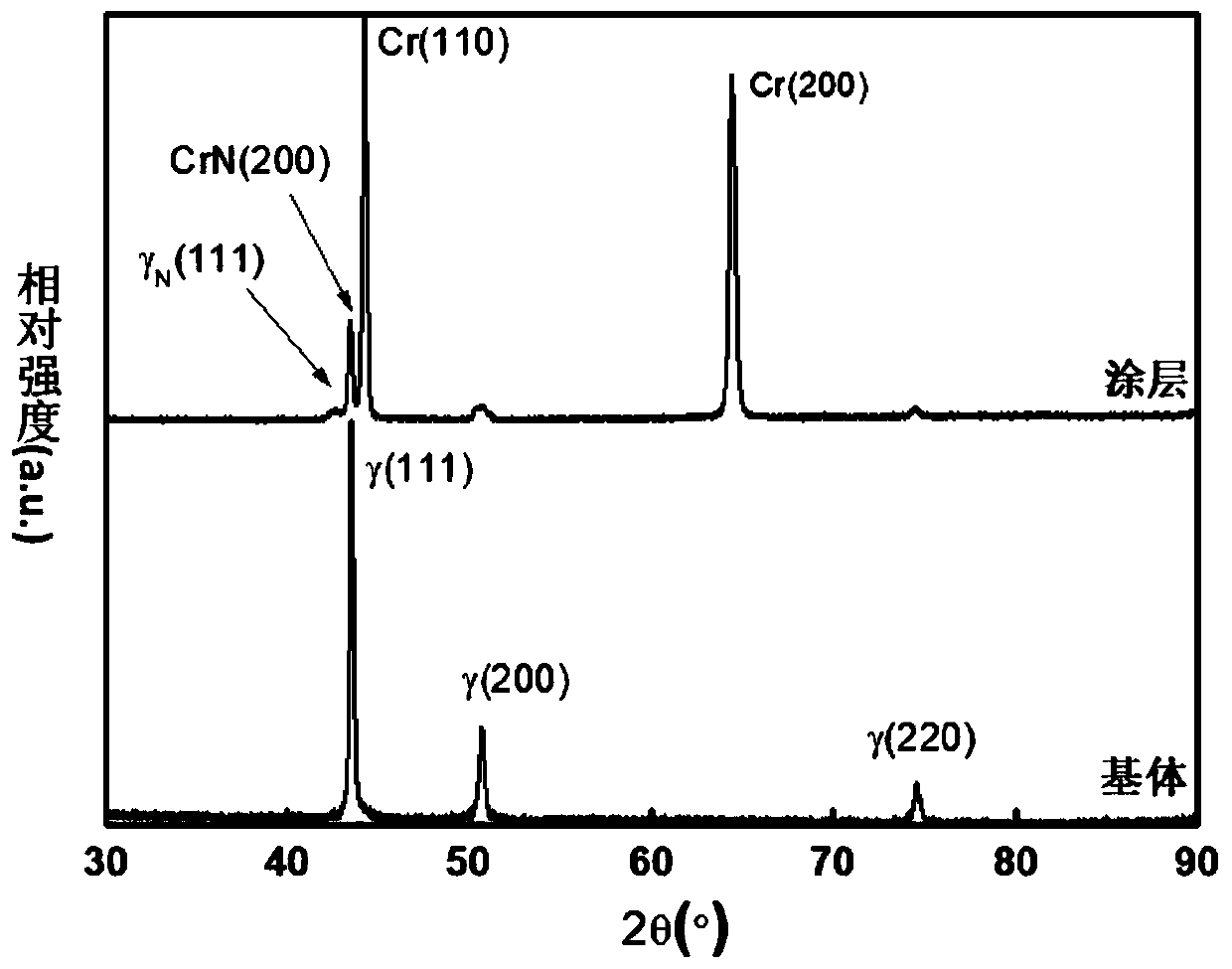

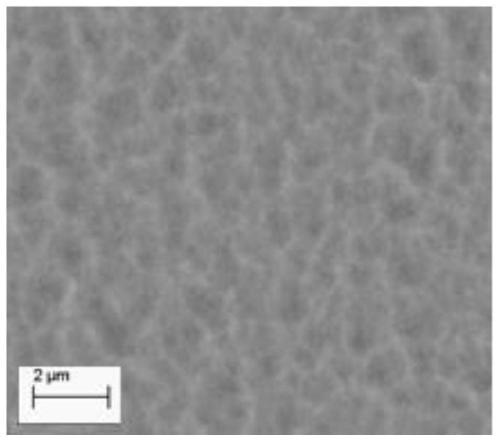

In-situ preparation method of composite modified layer on surface of stainless steel bipolar plate of proton exchange membrane fuel cell

ActiveCN111224121AReduce interface effectsExtended service lifeFinal product manufactureVacuum evaporation coatingSputteringMetallurgy

The invention relates to an in-situ preparation method of a composite modified layer on the surface of a stainless steel bipolar plate of a proton exchange membrane fuel cell. The in-situ preparationmethod comprises the steps of pre-treating at an earlier stage, vacuumizing and preheating, conducting plasma cleaning, preparing a pure metal Cr layer by non-equilibrium magnetron sputtering, performing plasma in-situ nitriding treatment, cooling and then taking out. The prepared composite modified layer on the surface of the stainless steel bipolar plate is a nitriding / CrNx composite modified layer, the inner layer is a nitriding layer, and the surface layer is a CrNx layer. According to the invention, a plasma enhanced magnetron sputtering system is adopted, in-situ nitriding is carried outon a pure metal Cr layer and a base body at the same time, and nitrogen atoms are diffused into the base body from the Cr layer, so that the pure metal Cr layer and the base body are enabled to havecontinuous gradient distribution. Compared with a traditional nitriding-coating composite treatment process, the composite modified layer has more excellent electrical conductivity, wear resistance and film-substrate bonding strength, so that the service life of the bipolar plate is prolonged.

Owner:UNIV OF SCI & TECH LIAONING

Flowmeter

InactiveUS7360450B2Accurate measurementEasily be attached to pipelineVolume/mass flow measurementVolume meteringUltrasonic sensorEngineering

Owner:GEMU GEBR MULLER APP GMBH & CO KGAA

High-quality polycrystalline diamond compact and preparation method thereof

InactiveCN110143021AImprove high temperature resistanceInhibit sheddingAdditive manufacturing apparatusIncreasing energy efficiencyPolycrystalline diamondCobalt

The invention relates to the technical field of super-hard composite materials, particularly to a high-quality polycrystalline diamond compact and a preparation method thereof. According to the invention, the high-quality polycrystalline diamond compact is manufactured by using double-beam 3D printing equipment which performs processing with high-power continuous beams and ultra-fast pulsed laserbeams alternately; and gradual transition layers are formed among layers, so bonding between a matrix and diamond and between the diamond and nickel is firm, and an interlayer interface is free of sudden changes in thermal and mechanical quantities. The polycrystalline diamond compact of the invention comprises, arranged from bottom to top, the matrix, a matrix-diamond gradual transition layer, adiamond layer, a diamond-nickel gradual transition layer, a nickel layer and a cobalt-free binder. The diamond-nickel gradual transition layer improves the heat dissipation performance of the polycrystalline diamond compact, prevents thermal stress corrosion from generating cracks on the surface of the diamond layer, and greatly improves the thermal stability of the polycrystalline diamond compact. Double-beam 3D printing technology used in the invention makes D-D bonding firm and ultra-high hardness to be obtained, so the polycrystalline diamond compact has high heat resistance, wear resistance and impact toughness, and thus has prolonged service life.

Owner:上海梁为科技发展有限公司

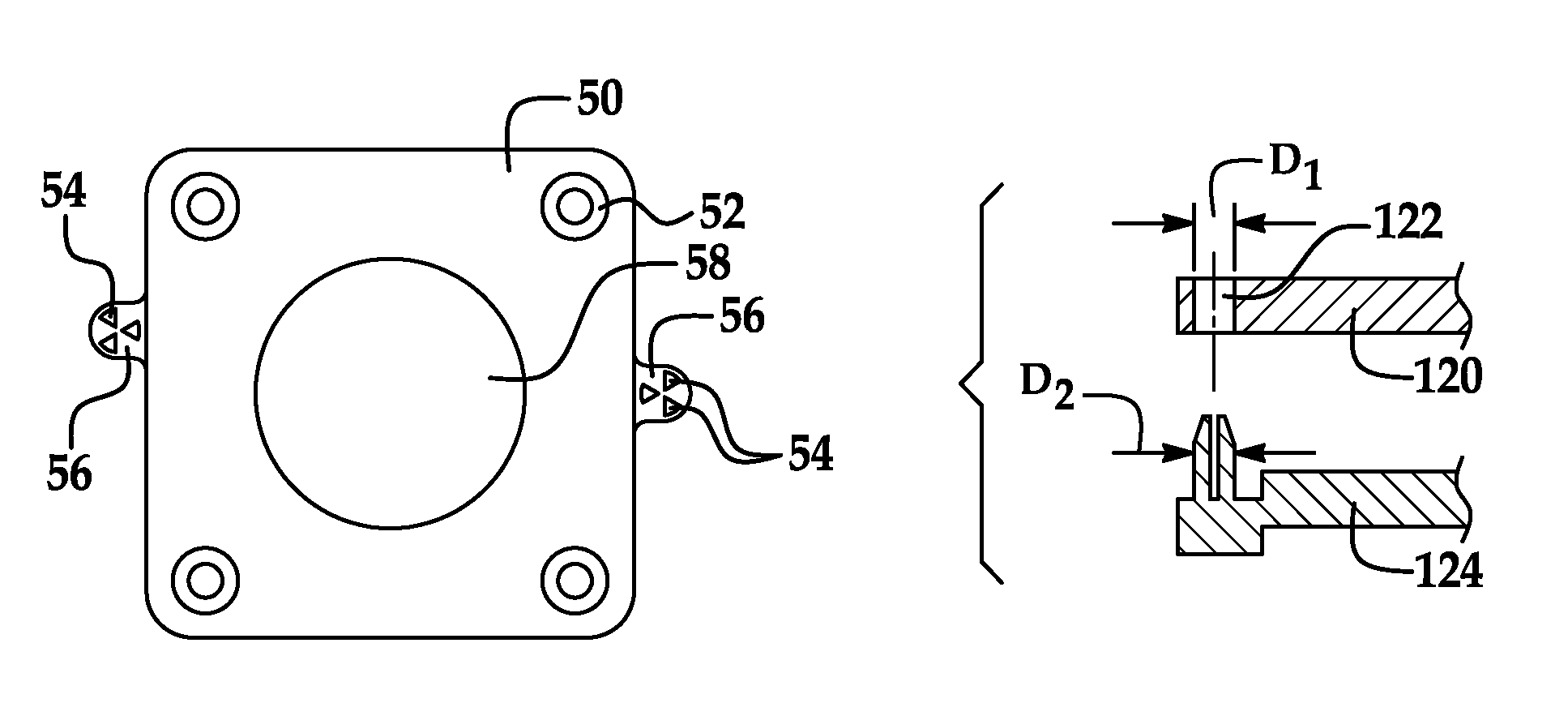

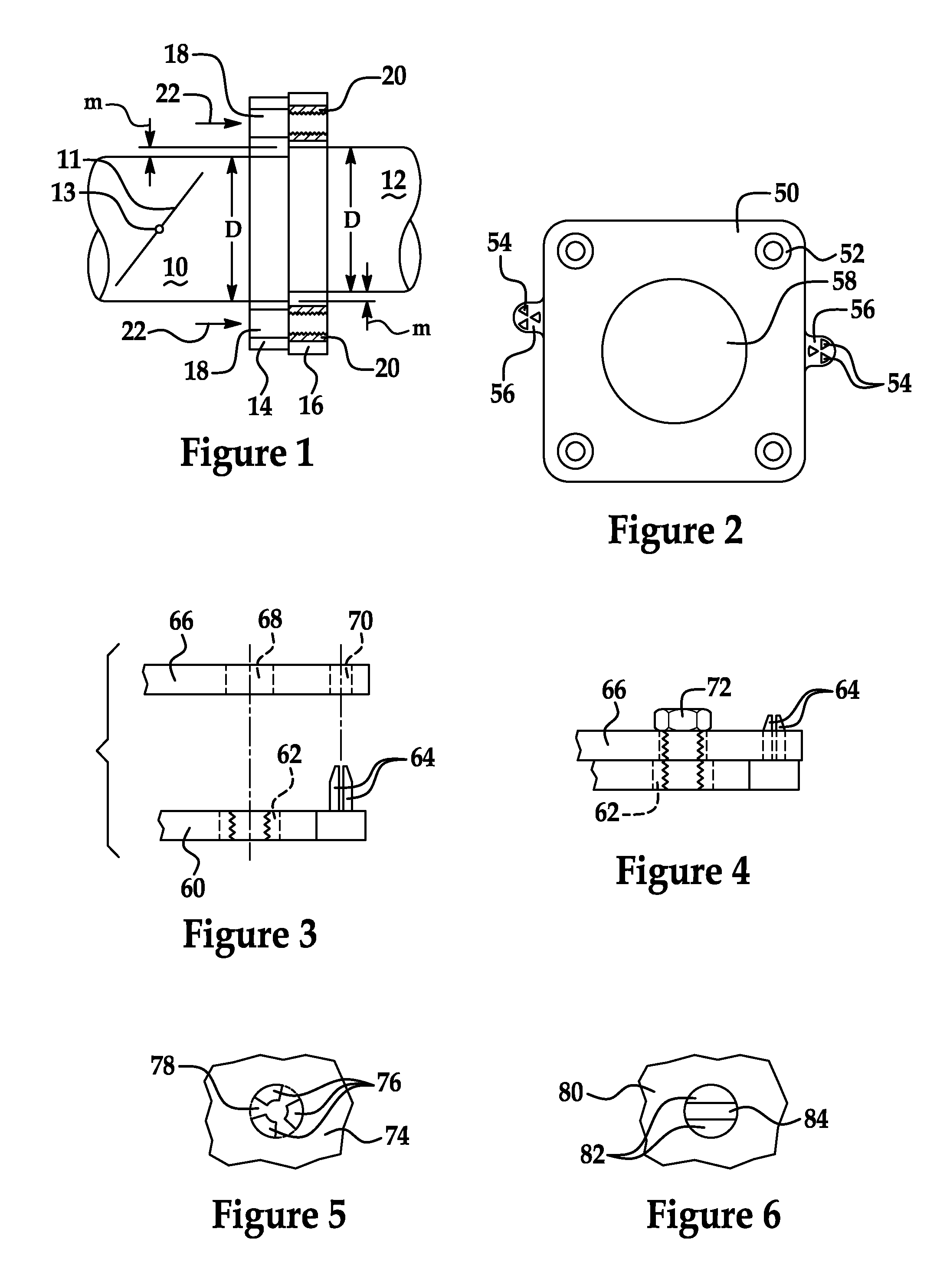

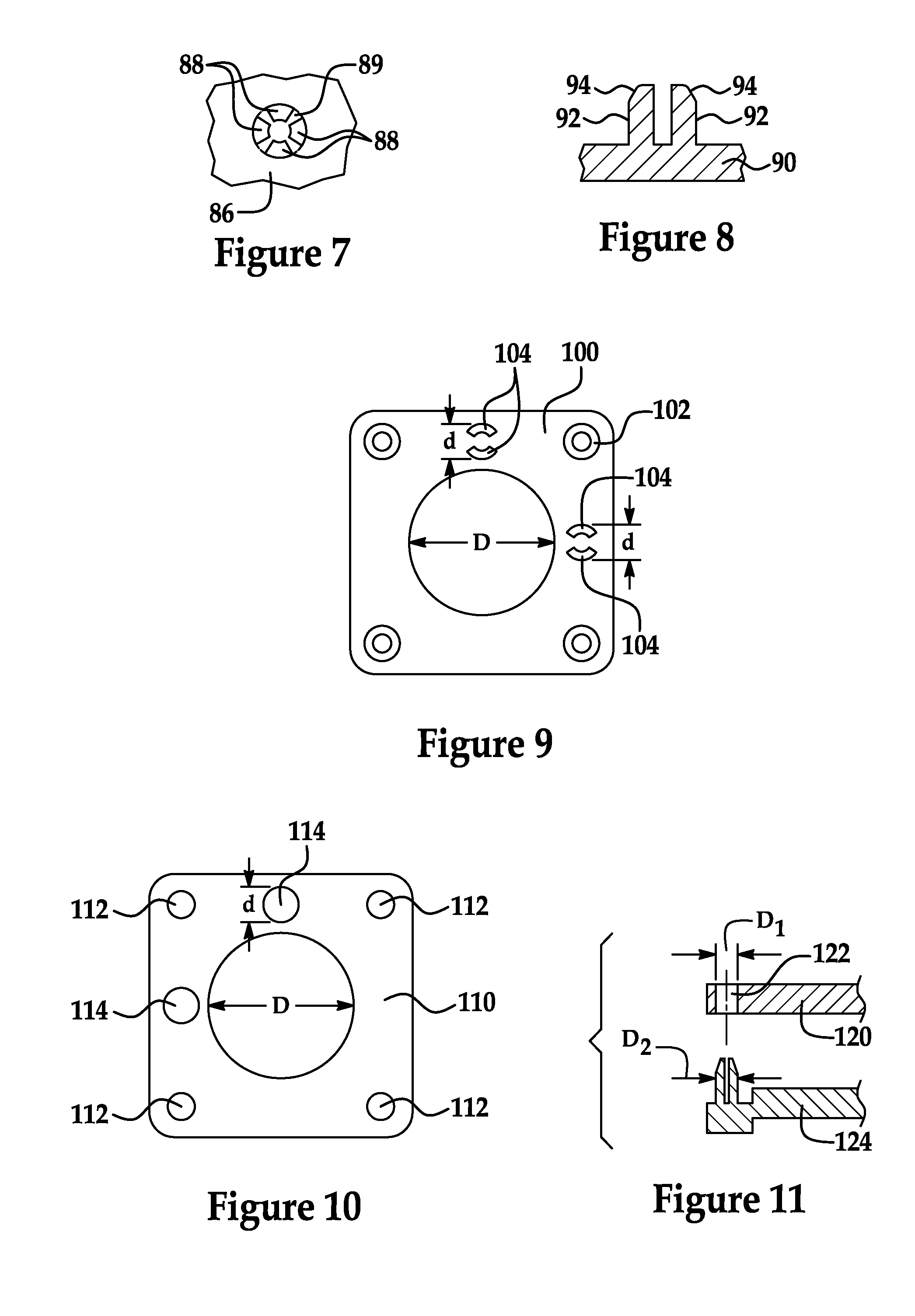

Throttle body to intake manifold mounting

ActiveUS8464689B2Eliminate interfacePrevent misassemblyCombustion-air/fuel-air treatmentEngine controllersControl theoryInlet manifold

At least one set of locator pins is provided on the flange of an intake manifold which couple with an orifice provided on the flange of a throttle body to align the two parts to ensure that they are properly oriented when assembled. In addition, through holes are provided on the throttle body flange and threaded inserts are provided on the flange of the intake manifold. The locator pins are coupled with the orifices prior to inserting a bolt through the through holes to engage with the threads of the threaded insert. By providing the locator pins, the two flanges are held in a desired orientation so that the ducts of the two flanges are properly aligned to substantially eliminate a step or mismatch at the interface.

Owner:FORD GLOBAL TECH LLC

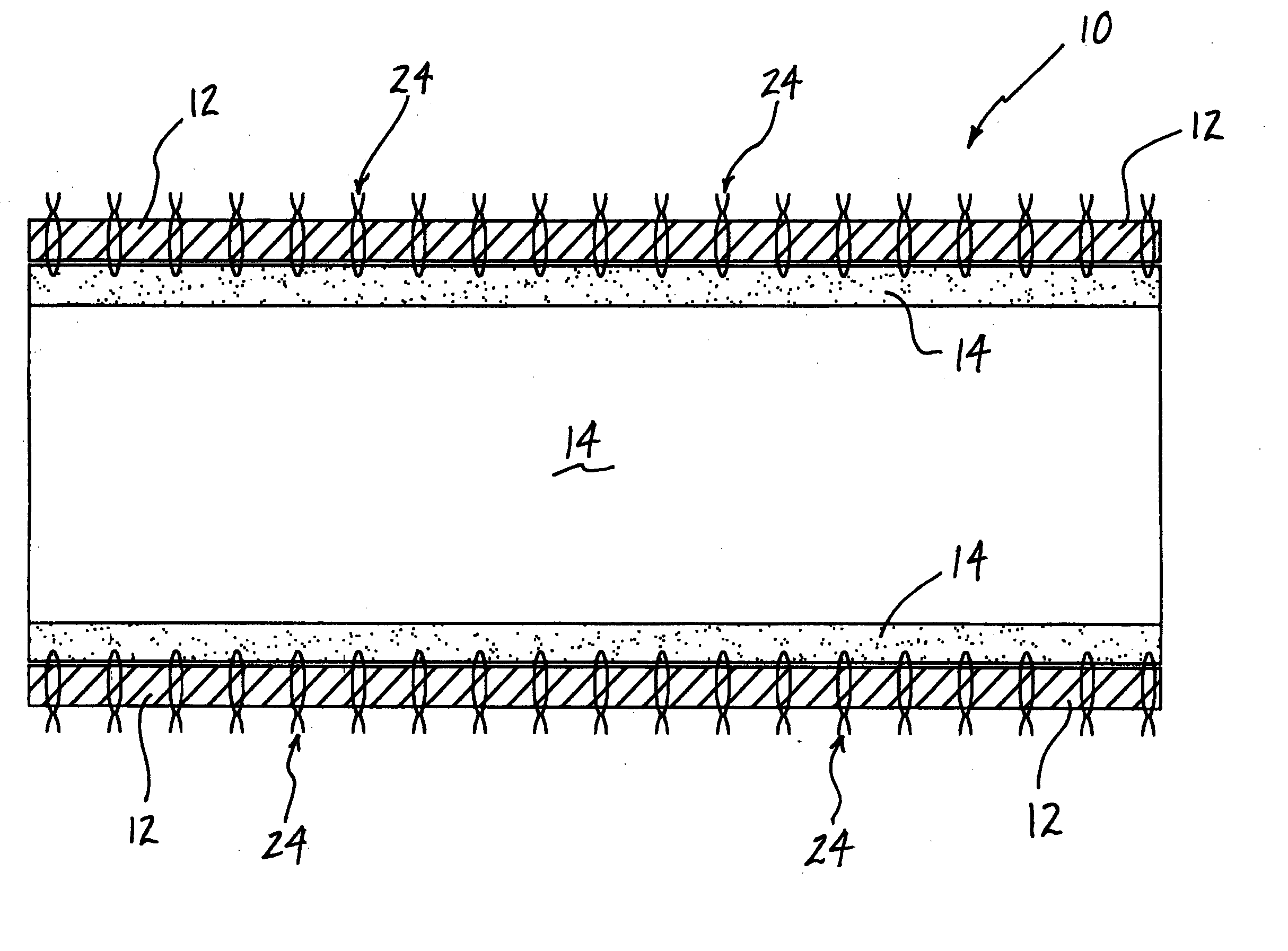

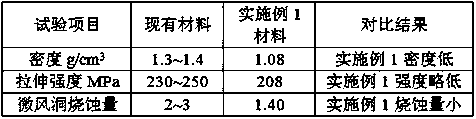

Preparation method of gradient density resin composite preform

ActiveCN109910390AAchieve anti-ablationThe method steps are simpleSynthetic resin layered productsLaminationVolumetric Mass DensityVacuum pump

The invention relates to a preparation method of a gradient density resin composite preform and belongs to the technical field of ablation thermal protective materials of hypersonic flight vehicles. Aprepared non-vitrified resin solution and vitrified resin dissolving pulp are paved on quartz fiber woven cloth respectively, a-type micro-vitrified prepreg, b-type micro-vitrified prepreg, c-type micro-vitrified prepreg and d-type micro-vitrified prepreg are prepared respectively after drying, the prepregs are paved in a forming cavity of a paving and stitching tool, and a finished product of the gradient density resin composite is prepared with a vacuum-pumping compacting method. The prepared gradient density material is divided into multiple layer in the aspect of plane composition, all layers of materials are in uniform transition, so that the interface problem is eliminated, the requirements of a thermal protection system of a hypersonic flight vehicle for an anti-ablation and anti-shear surface layer, a low-density and efficient thermal-insulating inner layer and a buffering and transition middle layer are realized, and the requirements of lightweight, low ablation and efficientthermal insulation of the thermal protection system of the hypersonic flight vehicle are met.

Owner:HUBEI FEILIHUA QUARTZ GLASS

Non-pressure infiltration preparation process of functionally graded piezoelectric material (FGPM)

The invention provides a non-pressure infiltration preparation process of a functionally graded piezoelectric material (FGPM). The process comprises the following steps: (1) raw material preparation; (2) prefabricated body forming, wherein a blank with the voidage continuously changing in the thickness direction within 35%-40% is obtained, and a layer of Fe powder of the particle size of 7 micrometers is laid on the prefabricated body; (3) sintering, wherein liquid Fe in each layer of mixed powder of a high Fe content is made to infiltrate into air voids in a lower layer of the prefabricated body, so that an interface gradient is formed; (4) FGPM densification; (5) polishing, wherein a prepared FGPM block is ground and polished, and finally the Fe / PZT-5 FGPM with material components continuously changing is obtained through preparation. The prefabricated body with the voidage continuously changing can be prepared by controlling the content of a binding agent and enhancing the change of the body particle diameter, and the ideal FGPM block with the components continuously changing can be obtained under the condition of sufficient layers.

Owner:HENAN POLYTECHNIC UNIV

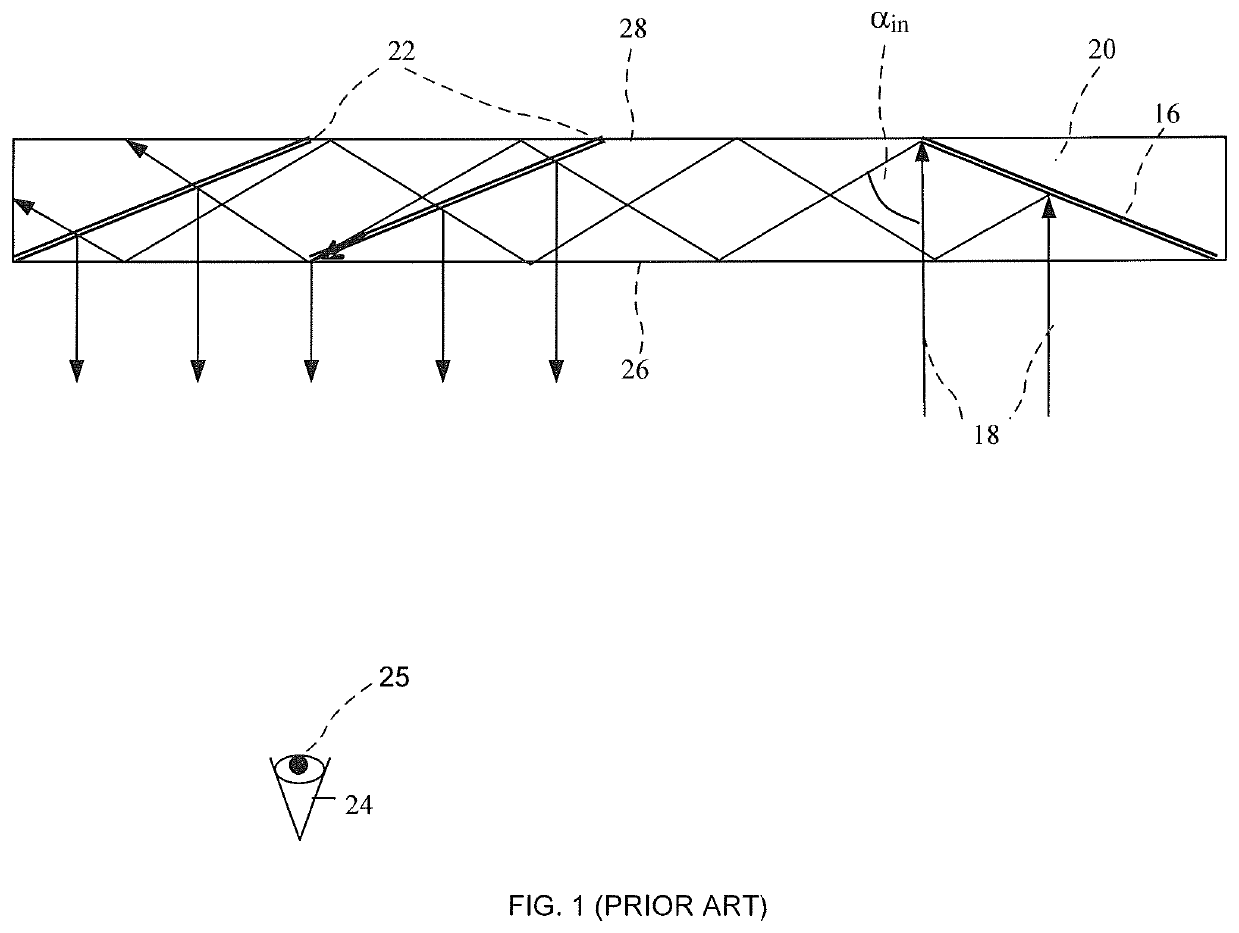

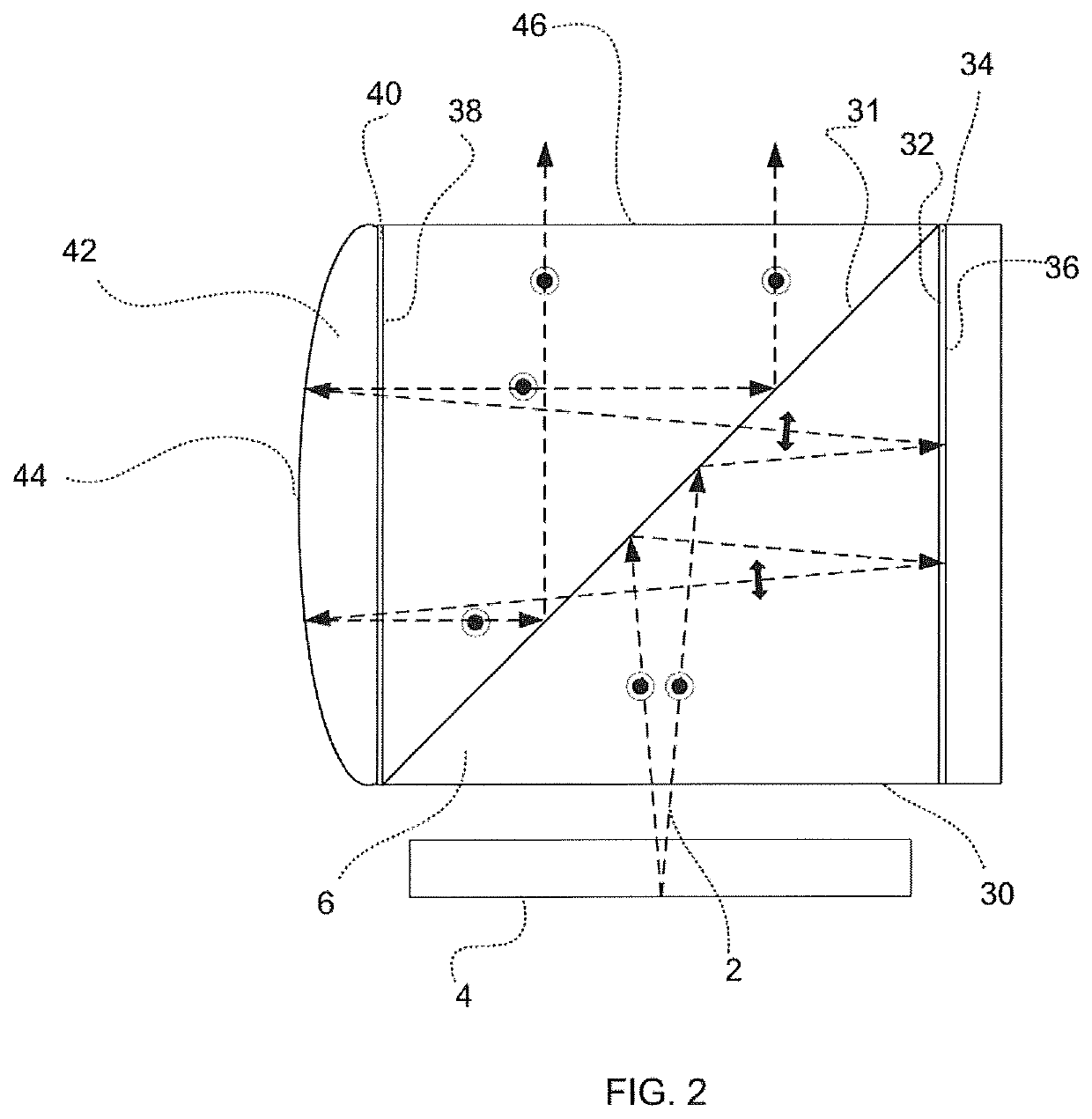

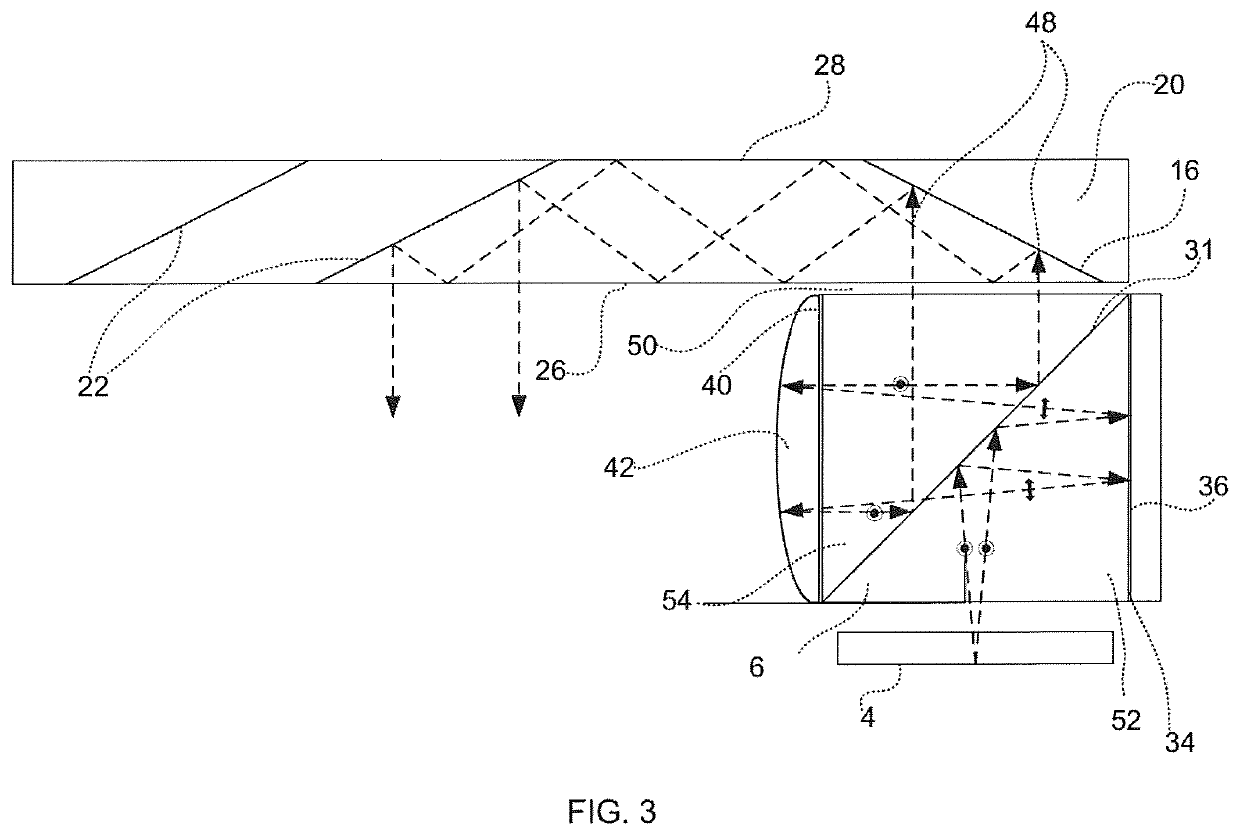

Compact head-mounted display system protected by a hyperfine structure

ActiveUS10520731B2Facilitates exploitationEasy to mergeCoupling light guidesOptoelectronicsLight wave

There is provided an optical system, including a light-transmitting substrate (20) having at least two external major surfaces and edges, an optical element for coupling light waves into the substrate (20) by internal reflection, at least one partially reflecting surface located in the substrate (20), for coupling light waves out of the substrate (20), at least one transparent air gap film (110) including a base (112) and a hyperfine structure (111) defining a relief formation, constructed on the base, wherein the air gap film is attached to one of the major surfaces of the substrate (20), with the relief formation facing the substrate (20) defining an interface plane (58), so that the light waves coupled inside the substrate (20) are substantially totally reflected from the interface plane (58).

Owner:LUMUS LTD

Metal/ceramic/metal symmetric gradient structure sealing insulating material and preparation method thereof

PendingCN112170852AAlleviate thermal stressStrong designabilityEngine sealsCorrosive substanceCermet

The invention relates to a metal / ceramic / metal symmetric gradient structure sealing insulating material and a preparation method thereof. The sealing insulating material comprises a high-machinabilitymetal layer (4), a high-melting-point metal layer (3), a gradient middle layer (2), a nitride ceramic layer (1), a gradient middle layer (2), a high-melting-point metal layer (3) and a high-machinability metal layer (4) from top to bottom in the thickness direction, wherein the gradient middle layer (2) is obtained by sintering high-melting-point metal powder and nitride ceramic powder; the content of high-melting-point metal in the gradient middle layer (2) is distributed in a gradient mode, and is gradually reduced in the direction from the high-melting-point metal layer (3) to the nitrideceramic layer (1); and the mass fraction is reduced to 0-10% from 90-100%. The sealing insulating material provided by the invention has very high designability, is suitable for extremely complex working environments such as long-time high temperature and strong corrosion, and has relatively high high-temperature stability, corrosion resistance and insulating sealing performance.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com