Water block removal agent and preparation method thereof

A technology for dehydrating water lock agent and active agent, which is applied in chemical instruments and methods, earthwork drilling, and fluid production, etc., can solve the problems of high development cost, low oil reservoir production efficiency, and single well productivity decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

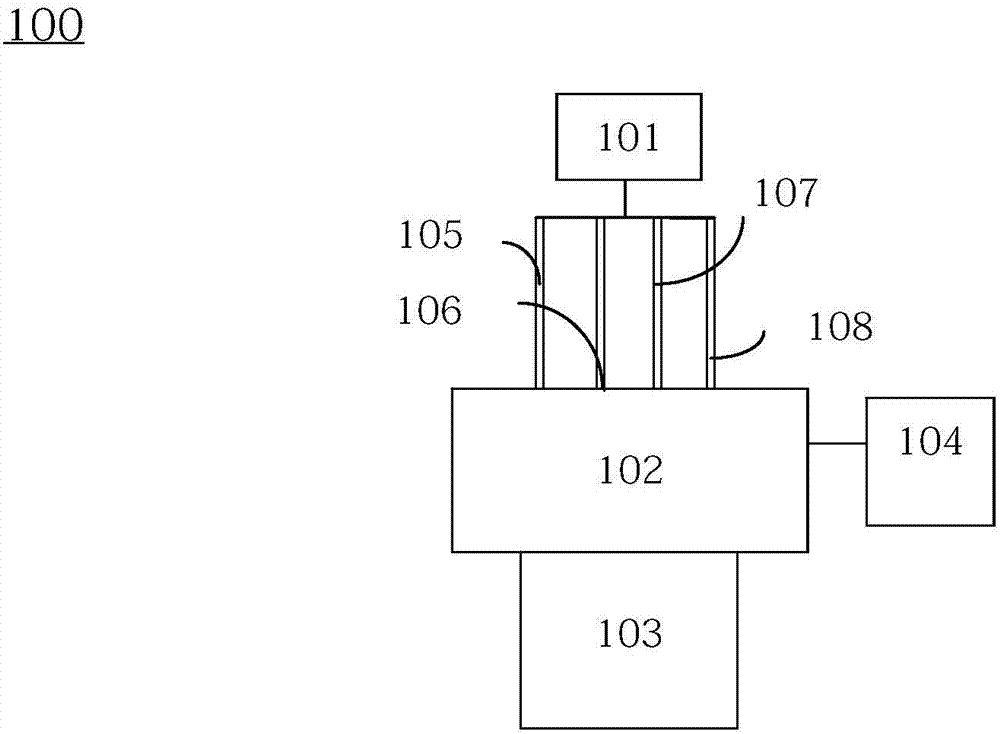

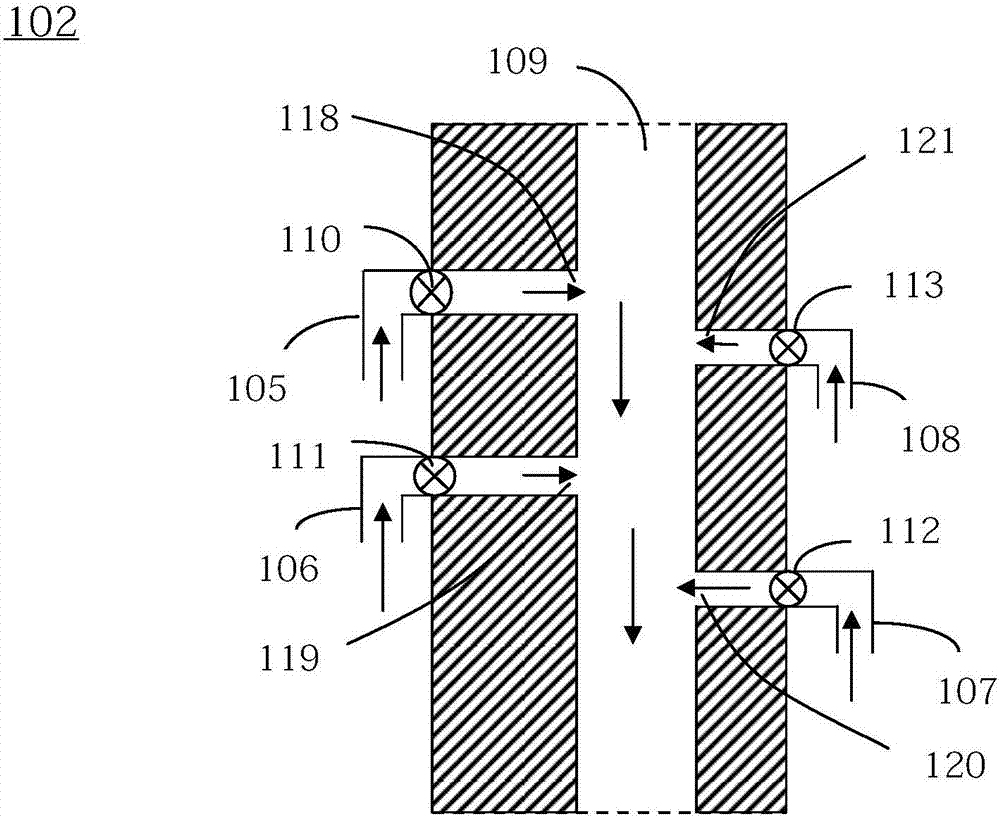

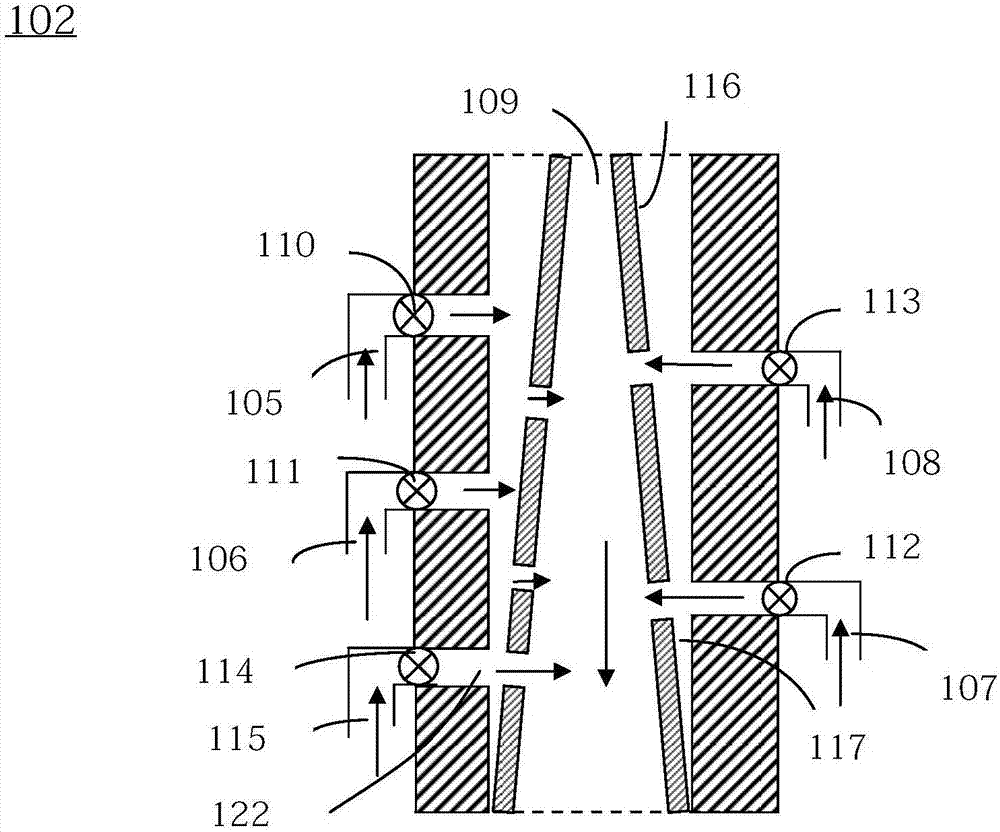

[0039] figure 1 A schematic diagram of a preferred implementation of the injection device 100 of this embodiment is shown. Such as figure 1 As shown, the injection device 100 at least includes a storage unit 101 , an injection unit 102 and a control unit 104 . The storage unit 101 is used for classifying and storing various components of the dehydrating agent. Preferably, the storage unit 101 at least includes a water storage chamber, a first modified nano-silica storage chamber, a second modified nano-silica storage chamber and an ethylene glycol storage chamber. The storage unit 101 injects the first modified nano-silicon dioxide, the second modified nano-silicon dioxide, ethylene glycol and water stored in separate chambers into the injection unit 102 in a pressurized manner through at least one injection pipeline. The injection unit 102 coupled to the wellhead 103 includes at least a main channel 109 and at least one input hole. Each input hole is provided with at leas...

Embodiment 2

[0047] This embodiment is a further improvement on the basis of Embodiment 1, and only the improved part will be described.

[0048] Wetting reversal refers to the phenomenon that the wettability of rock changes due to the adsorption of surfactants. The wettability of a liquid to a solid is sometimes altered by the addition of a third substance. Both the hydrophilicity and lipophilicity of a solid surface can be transformed under certain conditions, so the mutual transformation of the hydrophilicity and lipophilicity of a solid surface is called wetting inversion.

[0049] The lipopeptide biosurfactant used in this example is a purchased industrial grade product. Preferably, one or more lipopeptides are contained in the lipopeptide biosurfactant, and the molecular formula of the lipopeptide is C 51 h 89 o 13 N 7 、C 52 h 91 o 13 N 7 and / or C 53 h 93 o 13 N 7 . Preferably, lipopeptides of other molecular formulas may also be contained in the lipopeptide biosurfacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com