Water lock removal agent for low-water-content oil well

A water-releasing agent, low water content technology, applied in wellbore/well components, drilling composition, production fluid, etc., can solve the problem of not fundamentally eliminating the water-locking effect, high cost, and injecting surfactants to reduce two-phase It can eliminate the two-phase seepage resistance, reduce the starting pressure, and increase the relative permeability of the oil phase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take 10g of nano-silica with an original particle size of 15-30nm and 990g of ethylene glycol monobutyl ether and mix evenly to obtain a water-dissolving and locking agent with a mass fraction of nano-silica of 1%.

Embodiment 2

[0015] Take 30g of nano-silica with an original particle size of 15-30nm and 970g of ethylene glycol monobutyl ether and mix them evenly to obtain a water-splitting and locking agent with a mass fraction of nano-silica of 3%.

Embodiment 3

[0017] Take 50g of nano-silica with an original particle size of 15-30nm and 950g of ethylene glycol monobutyl ether and mix them evenly to obtain a water-splitting and locking agent with a mass fraction of nano-silica of 5%.

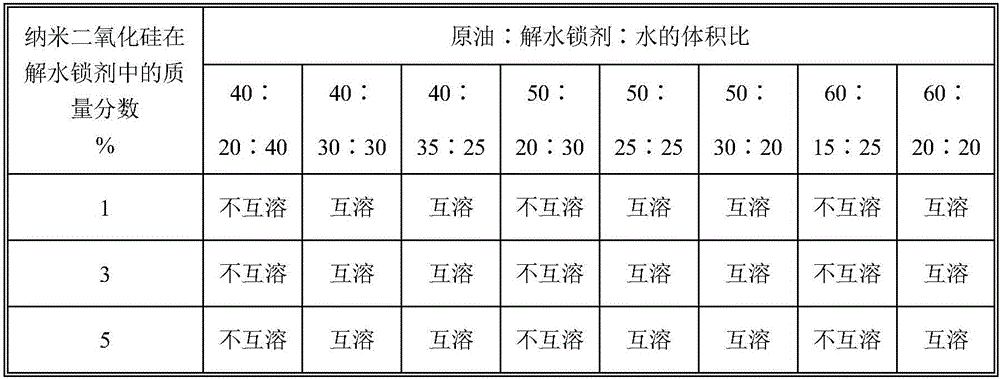

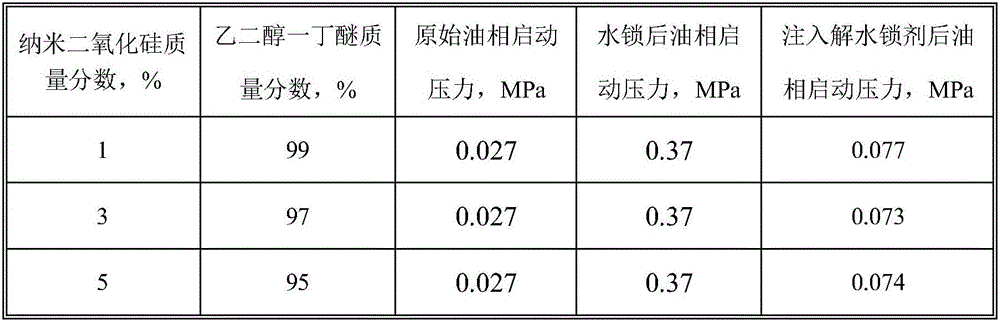

[0018] Add 1.5mL of water and 1.5mL of crude oil to each of the three graduated cylinders, then add 1.5mL of the hydrolysis-locking agents prepared in the above three examples to each of the three graduated cylinders, and put the graduated cylinders into a 70°C water bath , stand still and observe the dissolution status. Experiments show that without external stirring at 70°C, the interface between oil and water disappears obviously after 6-6.5 hours, and the whole system becomes a uniform and stable single-phase system, which shows that the oil-water interface can be eliminated by solubilizing oil and water with the water-dissolving and locking agent .

[0019] Table 1 system miscibility time

[0020] Nano silica mass fraction, %

Ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com