Preparation method of modified nitrile rubber and modified nitrile rubber

A nitrile rubber modification technology, which is applied in the field of modified nitrile rubber and modified nitrile rubber preparation, can solve the problems of poor comprehensive performance of modified rubber, difficulty in uniform dispersion of ECO and NBR, etc., and achieve good processing performance , promote uniform dispersion and stable distribution, and eliminate the effect of two-phase interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a kind of preparation method of modified nitrile rubber, comprises the following steps:

[0015] A, plasticizing the epichlorohydrin rubber, then adding reinforcing fillers, anti-aging agents and plasticizers for mixing to obtain the epichlorohydrin rubber masterbatch;

[0016] B, the chloroether rubber masterbatch that step A obtains is dispersed in organic solvent and forms chloroether rubber latex;

[0017] C, the nitrile rubber is masticated, then add reinforcing filler, anti-aging agent and plasticizer to mix, obtain the nitrile rubber masterbatch;

[0018] D. Blend the chloroether rubber latex and nitrile rubber masterbatch at a temperature higher than the melting point of the organic solvent, then add acid absorbing agent, active agent and vulcanization accelerator for banburying, and finally add vulcanizing agent for kneading , to obtain the modified nitrile rubber.

[0019] The preparation method of the modified nitrile rubber provided ...

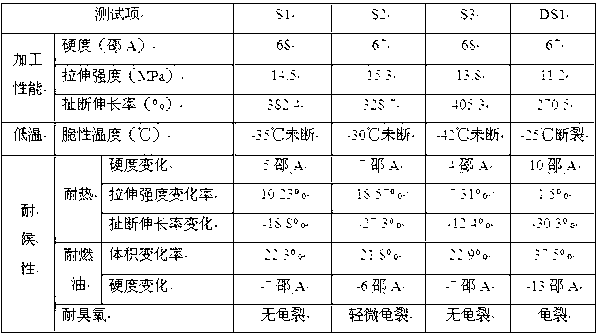

Embodiment 1

[0042] (1) Weigh raw materials: 85 parts by weight of nitrile rubber, 15 parts by weight of chloroether rubber, reinforcing filler: 50 parts by weight of carbon black (N550) + 20 parts by weight of ultrafine calcium carbonate, plasticizer: 25 parts by weight RS-107, antioxidant: 1.5 parts by weight of 445+0.5 parts by weight of NBC, acid absorbing agent: 10 parts by weight of ZnO+5 parts by weight of MgO+3 parts by weight of Pb3O4, active agent: 1 part by weight of zinc stearate, vulcanizing agent: 0.4 parts by weight of insoluble sulfur + 2 parts by weight of DOTG, vulcanization accelerator: 1.5 parts by weight of TMTD + 1 part by weight of CZ.

[0043] (2) Plasticize 15 parts by weight of chloroether rubber for 10 minutes, then add 15 parts by weight of reinforcing filler, 0.5 parts by weight of anti-aging agent and 7 parts by weight of plasticizer and knead for 25 minutes to obtain a masterbatch of chloroether rubber ; Then cut it into small pieces with a width of 1 mm, tra...

Embodiment 2

[0047] Adopt the step identical with embodiment 1 to prepare the modified nitrile rubber of present embodiment, difference is:

[0048] In step (1), the amount of each raw material is: 95 parts by weight of nitrile rubber, 5 parts by weight of chloroether rubber, reinforcing filler: 40 parts by weight of carbon black (N550) + 15 parts by weight of ultrafine calcium carbonate, plasticizer : 20 parts by weight of TP-90B, antioxidant: 1.5 parts by weight of 445+0.5 parts by weight of NBC, acid absorbing agent: 8 parts by weight of ZnO+5 parts by weight of MgO+2 parts by weight of Pb3O4, activator: 1.5 parts by weight of zinc stearate , vulcanizing agent: 0.4 parts by weight insoluble sulfur+2 parts by weight NA-22, vulcanization accelerator: 0.8 parts by weight TMTD+1.5 parts by weight CZ;

[0049] In step (2), the amount of reinforcing filler is 5 parts by weight, the amount of anti-aging agent is 0.3 parts by weight, the amount of plasticizer is 3 parts by weight; the amount of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com