High-quality polycrystalline diamond compact and preparation method thereof

A diamond composite sheet, high-quality technology, applied in chemical instruments and methods, additive manufacturing, layered products, etc., can solve the limitations of high wear resistance, high impact toughness and durability of diamond composite sheets, and the inability of diamond composite sheets Use under high temperature and high pressure, reduce the mechanical structure strength of diamond composite sheets, etc., to achieve the effect of increasing heat dissipation, eliminating interface effects, and eliminating sudden changes in thermal and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

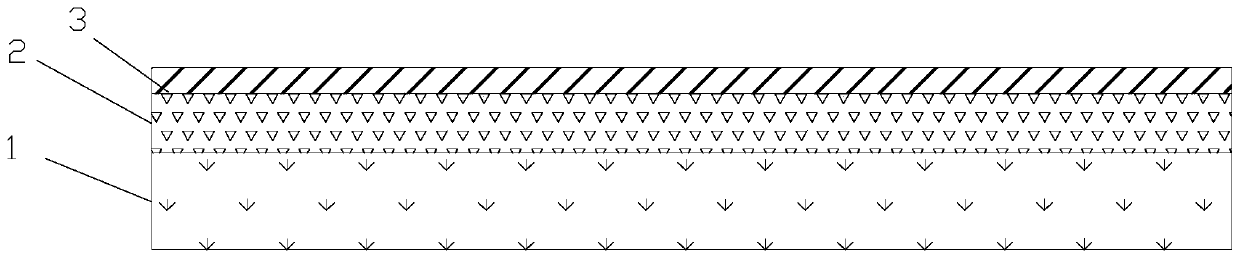

preparation example Construction

[0033] The preparation method of the above-mentioned high-quality diamond composite sheet is produced by using a dual-beam 3D printing device that alternately processes high-power continuous laser beams for thermal processing and ultrafast pulsed laser beams for cold processing.

[0034] Specifically, the preparation method of the above-mentioned high-quality diamond composite sheet includes the following steps:

[0035] 1) delivering the base material to the printing beam nozzle of the double-beam 3D printing device;

[0036] 2) driving the printing beam nozzle to move according to a preset trajectory and ejecting the base material to form a base;

[0037] 3) delivering the diamond powder material to the printing beam nozzle, driving the printing beam nozzle to move according to a preset trajectory and ejecting the diamond powder material to form a diamond layer on the substrate;

[0038] 4) transporting the metal nickel powder material to the printing beam nozzle, driving t...

Embodiment

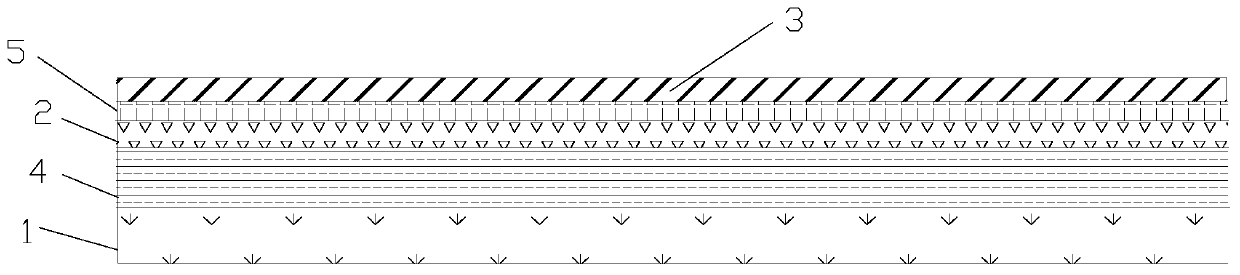

[0050] The diamond compact of the present embodiment, such as figure 2 As shown, it includes a substrate 1 , a substrate-diamond transition layer 4 , a diamond layer 2 , a diamond-nickel gradient transition layer 5 , and a nickel layer 3 from bottom to top.

[0051] The preparation method of the diamond compact of the present embodiment comprises the following steps:

[0052] 1) Conveying the base material chromium-molybdenum alloy powder to the printing beam nozzle of the double-beam 3D printing equipment;

[0053] 2) Drive the printing beam nozzle to move according to a preset trajectory and eject chromium-molybdenum alloy powder to form a chromium-molybdenum alloy matrix 1;

[0054] 3) Conveying nano-scale single crystal diamond powder or micron-scale polycrystalline diamond powder to the printing beam nozzle, driving the printing beam nozzle to move according to a preset trajectory and ejecting diamond powder to form a diamond layer on the chromium-molybdenum alloy subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com