Preparation method of gradient density resin composite preform

A technology of resin composite materials and gradient density, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve catastrophic, interface problems, heat protection system failure and other problems, achieve simple steps, eliminate interface problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

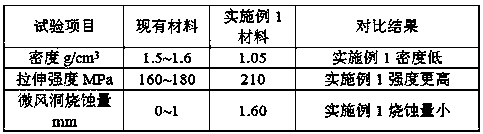

Embodiment 1

[0019] Dissolve boron phenolic formaldehyde and barium phenolic formaldehyde with alcohol to obtain a non-ceramic resin solution (slurry), wherein the mass ratio of alcohol, boron phenolic formaldehyde and barium phenolic formaldehyde is: 1.0:1.0:1.0 After the dissolution is completed, stir evenly at room temperature , until the solution (slurry) has no precipitation and is uniform in color; that is, no precipitation or other visible foreign matter is allowed in the obtained non-porcelain resin solution (slurry), and it is set aside.

[0020] According to the mass ratio of non-ceramic resin solution: boron nitride 128.8:8.5, add boron nitride to the non-ceramic resin solution, then stir evenly at room temperature until there is no large group accumulation, and obtain micro-ceramic resin solution slurry, That is, no agglomerated particles or other visible foreign matters are allowed to exist in the obtained microceramic resin solution; set aside.

[0021] Place a-type high-dens...

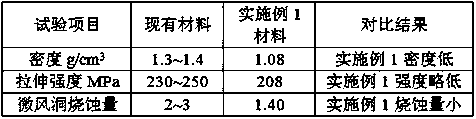

Embodiment 2

[0040] Dissolve boron phenolic formaldehyde and barium phenolic formaldehyde with alcohol to obtain a non-ceramic resin solution (slurry), wherein the mass ratio of alcohol, boron phenolic formaldehyde and barium phenolic formaldehyde components is: 1.0:1.0:0.8; after the dissolution is completed, stir at room temperature Uniformly, until the solution has no precipitation and is uniform in color; that is, no precipitation or other visible foreign matter is allowed in the obtained non-porcelain resin solution, and it is set aside.

[0041] According to the mass ratio of non-ceramic resin solution: boron nitride 128.8:8.0, add boron nitride to the non-ceramic resin solution; then stir evenly at room temperature until there is no large group accumulation, and obtain micro-ceramic resin solution slurry, That is, no agglomerated particles or other visible foreign matters are allowed to exist in the obtained microceramic resin solution; set aside.

[0042] Place a-type high-density ...

Embodiment 3

[0061] Dissolve boron phenolic formaldehyde and barium phenolic formaldehyde with alcohol to obtain a non-ceramic resin solution (slurry), wherein the mass ratio of alcohol, boron phenolic formaldehyde and barium phenolic formaldehyde is: 1.0:1.1:0.9 After the dissolution is completed, stir evenly at room temperature , until the solution has no precipitation and is uniform in color; that is, no precipitation or other visible foreign matter is allowed in the obtained non-porcelain resin solution, and it is set aside.

[0062] According to the mass ratio of non-ceramic resin solution: boron nitride 128.8:8.2, add boron nitride to the non-ceramic resin solution; then stir evenly at room temperature until there is no large group accumulation to obtain micro-ceramic resin solution slurry, That is, no agglomerated particles or other visible foreign matters are allowed to exist in the obtained microceramic resin solution; set aside.

[0063] Place a-type high-density 2.5D quartz fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com