Thermal protection composite coating and manufacturing method thereof

A composite coating, thermal protection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

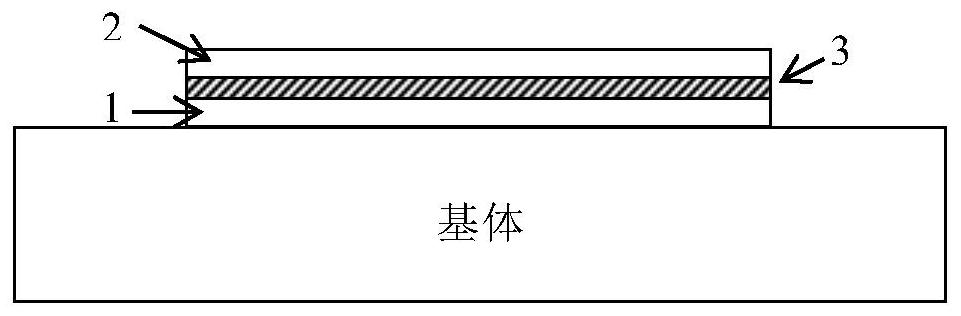

Image

Examples

Embodiment 1

[0048]The powder mixed with 70% zirconia and 30% metal bonding phase is pre-placed on the surface of the metal matrix by plasma spraying, and then the treatment of 1100 °C insulation for 20 min in the vacuum heating furnace is carried out to obtain the first ceramic heat-resistant layer; subsequently, the slurry brush prepared by 25% graphene, 50% silicon carbide and 25% water glass is fully mixed to the surface of the first ceramic heat-resistant layer, and then after curing at room temperature, it is placed into an inert gas shielding furnace for 900 °C insulation for 30 min treatment to form a graphene thermal conductive layer Finally, the slurry brush prepared by the full mix of 55% zirconia, 30% quartz fiber and 15% aluminum dihydrogen phosphate was applied to the surface of the thermal conductive layer, and then cured at room temperature, it was put into an inert gas shielding furnace for 800 °C insulation for 30 min treatment, and a second ceramic heat-resistant layer was ...

Embodiment 2

[0050] The powder mixed with 80% alumina and 20% metal bonding phase was pre-placed on the surface of the metal matrix by plasma spraying, and then the treatment of 900 °C insulation for 20 min in the vacuum heating furnace was carried out to obtain the first ceramic heat-resistant layer; subsequently, the slurry brush prepared by 25% graphene, 50% silicon carbide and 25% water glass was fully mixed to the surface of the first ceramic heat-resistant layer, and then after curing at room temperature, it was placed in an inert gas protection furnace for 900 °C insulation for 30 min to form a graphene thermal conductive layer Finally, the slurry brush prepared by the full mix of 75% alumina, 10% silicon carbide fiber and 15% aluminum dihydrogen phosphate is applied to the surface of the thermal conductive layer, and then cured at room temperature, it is put into an inert gas shielding furnace for 800 °C insulation for 30min treatment, and a second ceramic heat-resistant layer is obtai...

Embodiment 3

[0052] The slurry mixed with 80% silicon oxide, 15% metal bonding phase and 5% water glass is pre-placed on the surface of the metal matrix by brushing, and after curing at room temperature, the first ceramic heat-resistant layer is obtained by 850 °C insulation in an inert gas protection furnace for 20 min treatment, and subsequently, the slurry brush prepared by 25% graphene, 50% silicon carbide, and 25% water glass is fully mixed to the surface of the first ceramic heat-resistant layer, and then after curing at room temperature, it is placed into the inert gas protection furnace for 800 °C insulation for 30 min treatment. Finally, the slurry brush prepared by the full mixing of 75% silica, 10% quartz fiber and 15% aluminum dihydrogen phosphate is applied to the surface of the thermal conductive layer, and then cured at room temperature, it is placed in an inert gas shielding furnace for 800 °C insulation for 30 min treatment, and a second ceramic heat-resistant layer is obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com