Metal/ceramic/metal symmetric gradient structure sealing insulating material and preparation method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention relates to a metal / ceramic / metal symmetrical gradient structure sealing insulating material and a preparation method thereof. The ceramic materials are mainly nitride ceramics, including one or more of AlN, Si3N4, and BN. Metal materials include two types, one of high melting point metal W and Mo, one of expansion alloy (4J33 alloy), Kovar alloy (4J29 alloy) and stainless steel 304 (SUS304) with good additivity. The preparation method of the material includes two stages: in the first stage, the ceramic and metal powders are uniformly mixed according to the proportion of each group, and the layer-by-layer stacking is designed according to the gradient structure and combined with the hot-pressed co-firing technology to obtain a metal / ceramic / metal gradient composite material; the second stage In the first stage, welding technology is used to connect dissimilar metals to the metal sides at both ends of the composite material, combined with mechanical drilling...

Embodiment 1

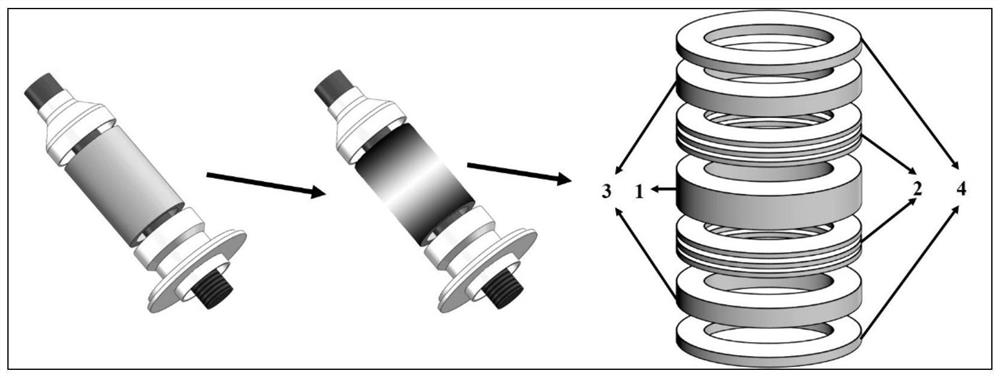

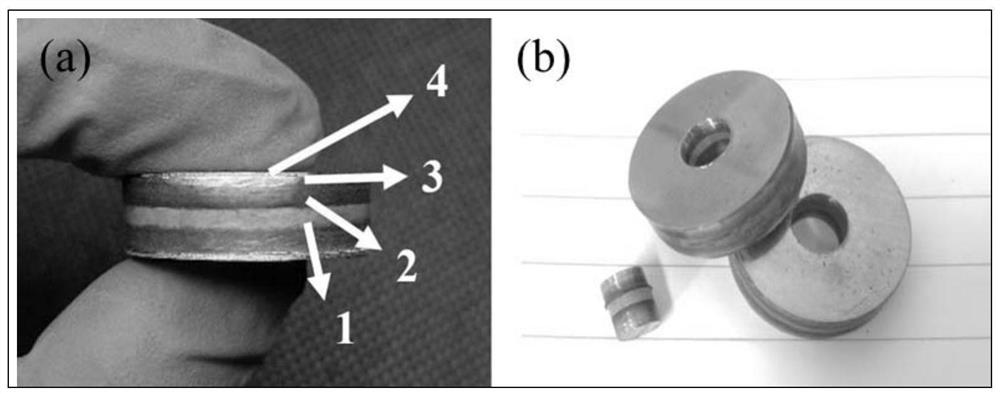

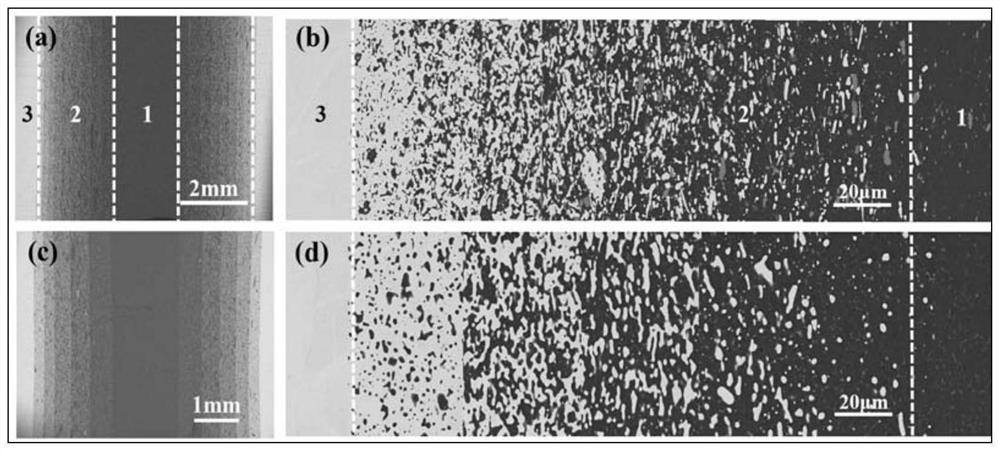

[0040] A metal / ceramic / metal symmetric gradient structure sealing insulating material, the structure schematic diagram is as follows figure 1 Shown, its preparation method concrete steps are as follows:

[0041] Select an appropriate amount of AlN ceramic powder and Mo powder to prepare the gradient intermediate layer 2 raw materials, according to the mass percentage of AlN ceramic powder and Mo powder: 1:9, 2:8, 3:7, 4:6, 5:5, 6:4, 7 : 3, 8: 2, 9: 1 ratio to prepare 9 parts of mixed powder, each mixed powder 0.5g, after ball milling, it will be used as the raw material of each layer of gradient middle layer 2 for later use.

[0042] The high melting point metal layer 3 (Mo, the dosage is 4g), the gradient intermediate layer 2, the nitride ceramic layer 1 (AlN ceramic powder, the dosage is 2g), the gradient intermediate layer 2, the high melting point metal layer 3 (Mo, the dosage is 4g ) raw material powder according to figure 1 The structures shown are sequentially stacked...

Embodiment 2

[0047] A metal / ceramic / metal symmetric gradient structure sealing insulating material, the specific steps of its preparation method are as follows:

[0048] Select an appropriate amount of AlN ceramic powder and Mo powder to prepare the gradient intermediate layer 2 raw materials, and prepare 5 parts according to the mass percentage of AlN ceramic powder and Mo powder: 1:9, 3:7, 5:5, 7:3, 9:1 Mixed powder, 1g of mixed powder per part, after ball milling, it will be used as the raw material of each layer of gradient middle layer 2 for later use.

[0049] The high melting point metal layer 3 (Mo, the dosage is 4g), the gradient intermediate layer 2, the nitride ceramic layer 1 (AlN ceramic powder, the dosage is 2g), the gradient intermediate layer 2, the high melting point metal layer 3 (Mo, the dosage is 4g ) raw material powder according to figure 1 The structures shown are sequentially stacked into a graphite mold with an inner diameter of 25mm, and the raw materials of each...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com