Fibre-reinforced composite lattice sandwich plate and its preparing process

A fiber-reinforced, fiber-composite technology, applied in the direction of sheet/board, building elements, etc., can solve the problems of limited use of materials in metal materials, difficulty in forming lattice sandwich panels, etc., to achieve easy forming, high specific stiffness, high The effect of specific strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

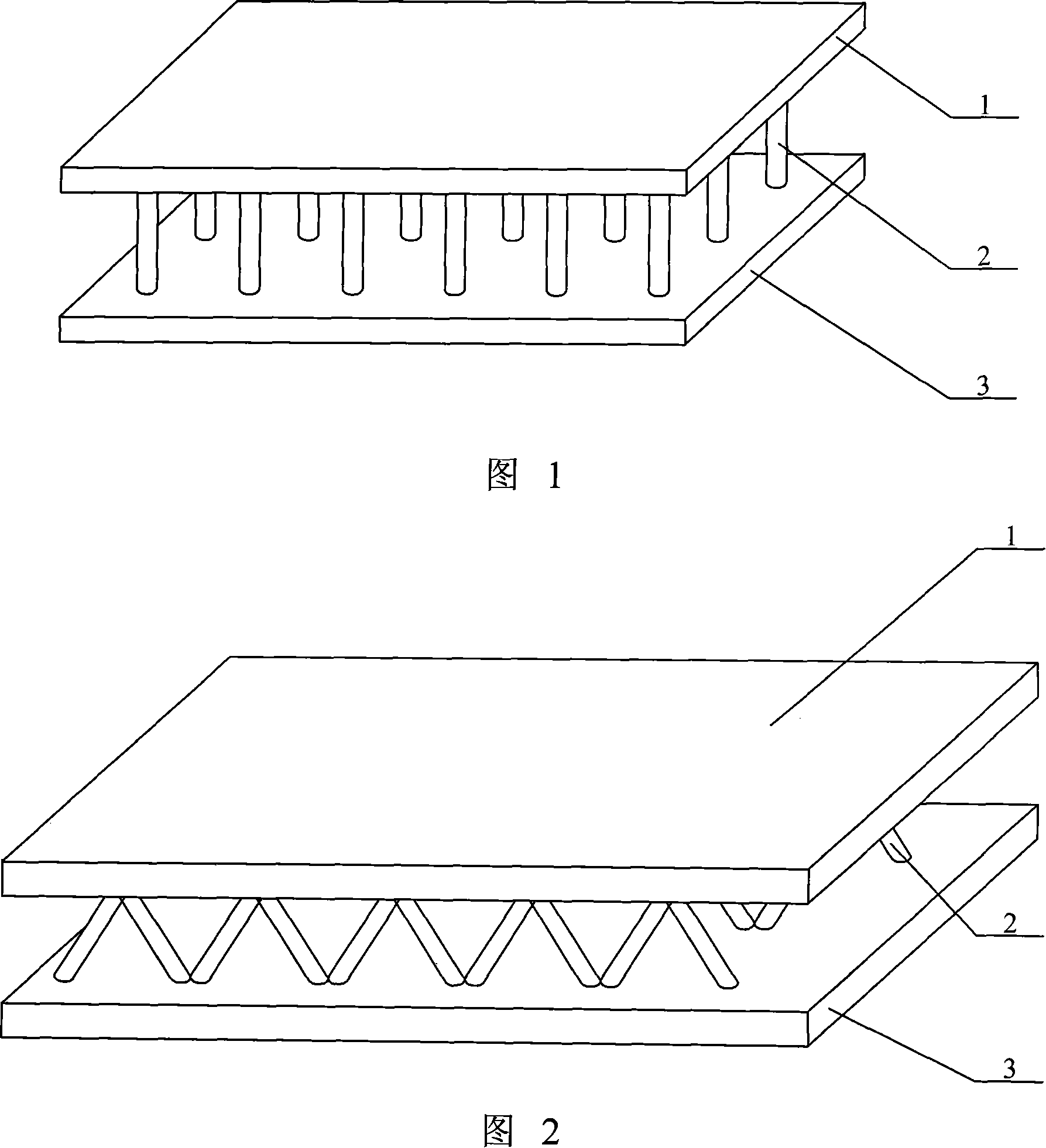

[0021] Specific implementation manner 1: This implementation manner is described in conjunction with FIG. 1 . This embodiment is composed of a fiber composite upper panel 1, a fiber composite lower panel 3, and a lattice. The lattice is arranged between the fiber composite upper panel 1 and the fiber composite lower panel 3. The lattice is composed of several fiber composite columns 2. The upper end of the composite column 2 is fixedly connected to the fiber composite upper panel 1 , and the lower end of the fiber composite column 2 is fixedly connected to the fiber composite lower panel 3 .

specific Embodiment approach 2

[0022] Specific embodiment 2: This embodiment is described in conjunction with Fig. 1 and Fig. 2, and the columns in this embodiment are vertical or inclined at 45 degrees.

specific Embodiment approach 3

[0023] Specific implementation mode three: the steps of the manufacturing method of the fiber-reinforced composite lattice sandwich panel in this implementation mode are as follows:

[0024] Step 1, (dry method) design and clean the mold, clean the surface of the designed mold, and apply a release agent. The model of the release agent is XTEND818;

[0025] Step 2. Cut the prepreg into the designed size, fold it into a rod along the direction of 0 degrees, and put the folded rod into the mold hole;

[0026] Step 3: Mainly install the mould; lay prepreg with half the thickness of the panel between the mold surface and the prepreg rod, divide the prepreg rod into several equal parts, fill in the gap between each layer of prepreg, and lay Halfway through, the prepreg rod ends are buried within these four layers of prepreg, and the remaining layers are placed;

[0027] Step 4. Put the fiber body laid in step 3 on a hydraulic press to heat and pressurize to cure. The curing tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com