Patents

Literature

172results about How to "High specific stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength plasticity aluminum-base composite material employing TiB2 particles and preparation method thereof

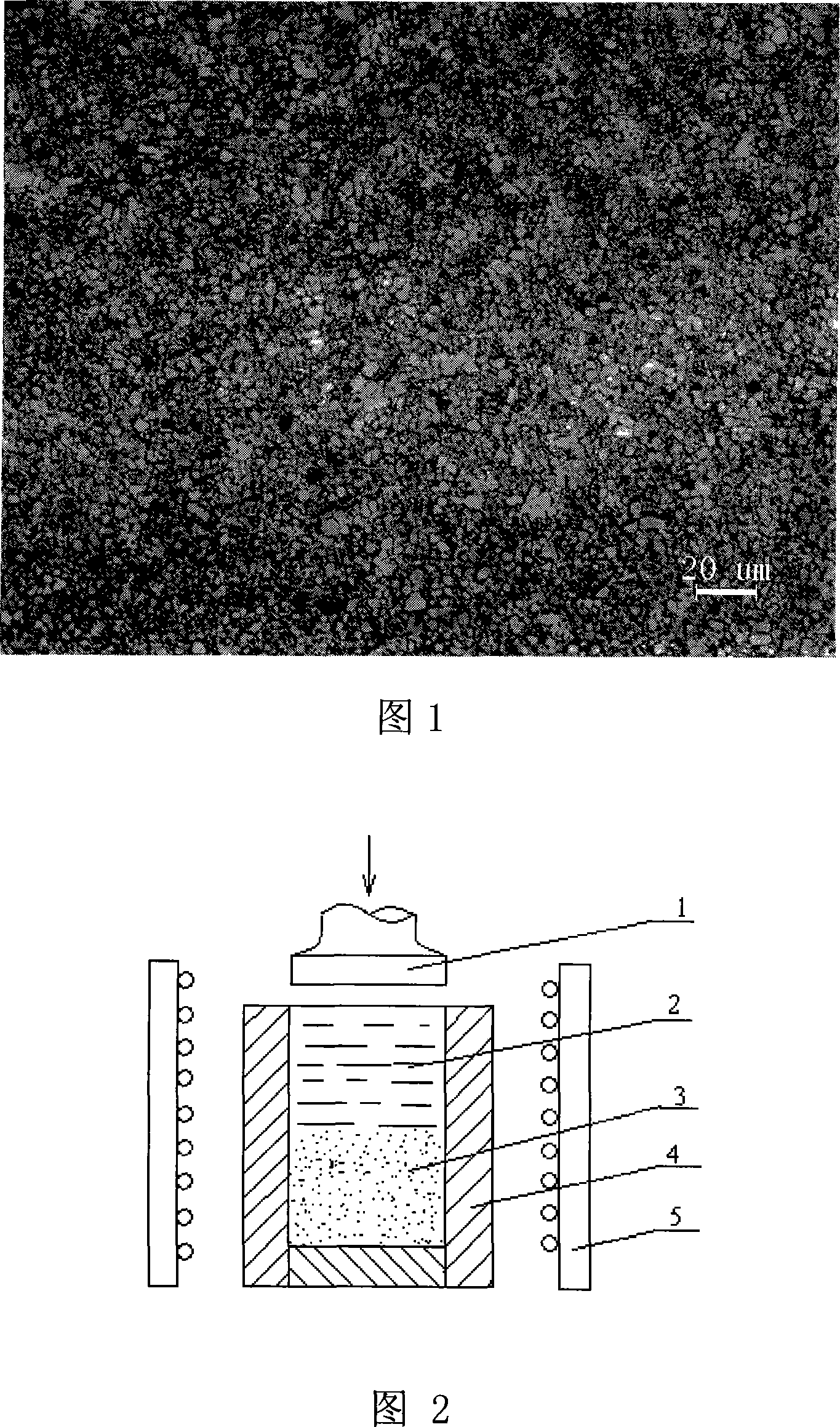

The invention provides a high-plasticity aluminum-based composite material containing TiB2 particles and a preparation method thereof, and relates to an aluminum-based composite material and a preparation method thereof. The invention solves the problems of the prior art, such as poor plasticity and toughness and difficulty in secondary processing. The composite material contains (by volume) titanium diboride reinforcement particles 10-25 percent, aluminum particles 25-35 percent, and aluminum alloy matrix in balance. The preparation method comprises: (1) weighing titanium diboride reinforcement particles, aluminum particles and aluminum alloy matrix; (2) mixing by mechanical dry method to obtain a reinforcement powder; (3) placing the reinforcement powder in a die and compression-molding; (4) heating the die; (5) melting aluminum alloy and casting in the die; (6) applying a pressure on the die with molten aluminum and maintaining the pressure for a period of time and cooling; (7) demoulding and taking the cast ingot, that is reinforced aluminum-based composite material. The inventive aluminum-based composite material has high plasticity and good wear resistance and is adapted to secondary processing and machining.

Owner:HARBIN INST OF TECH

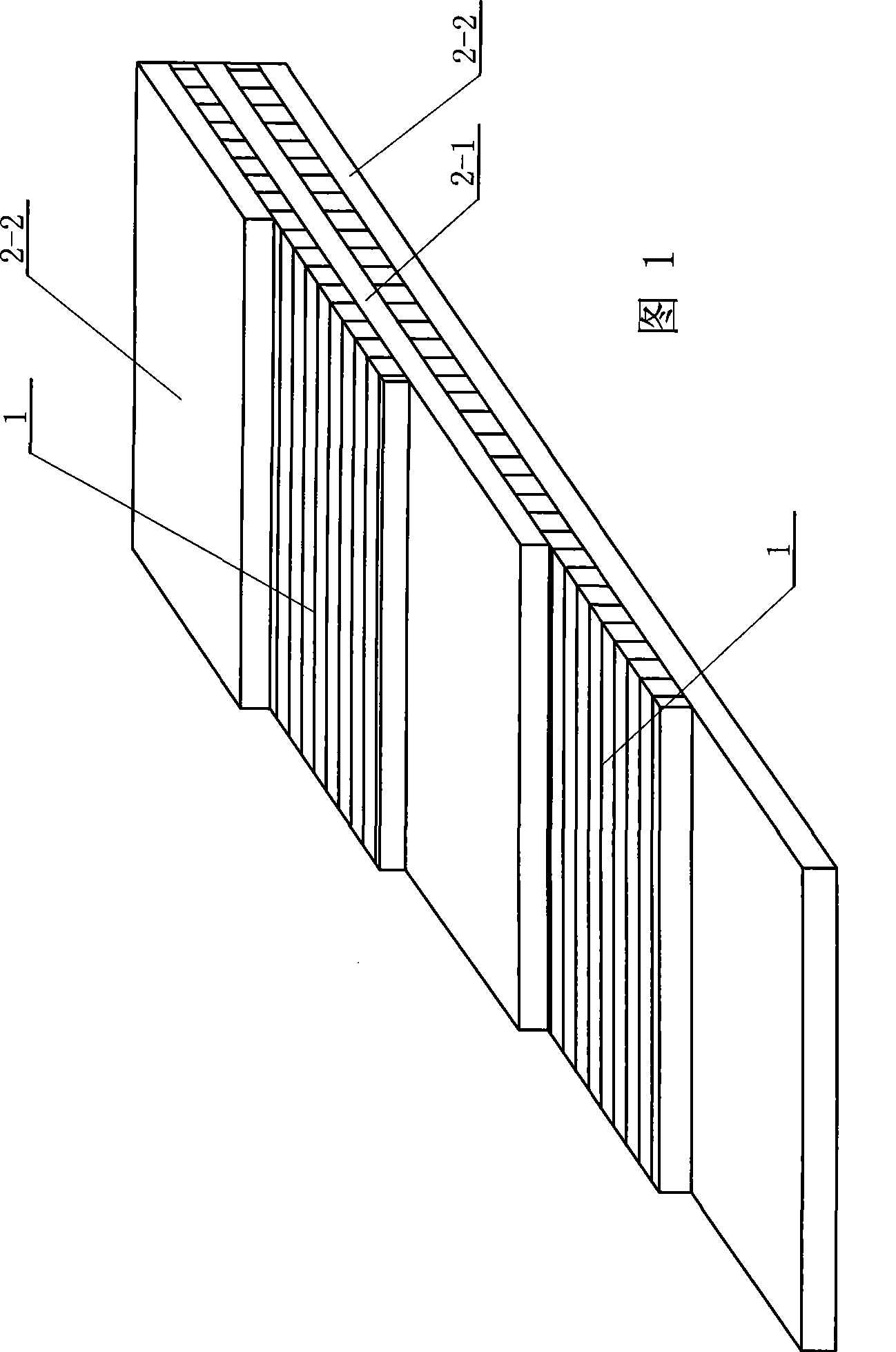

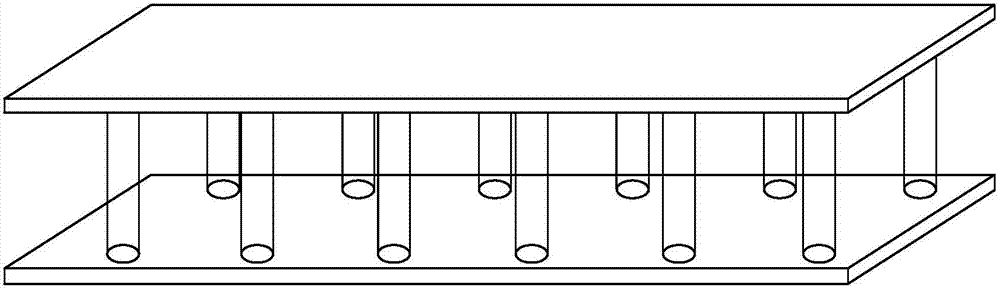

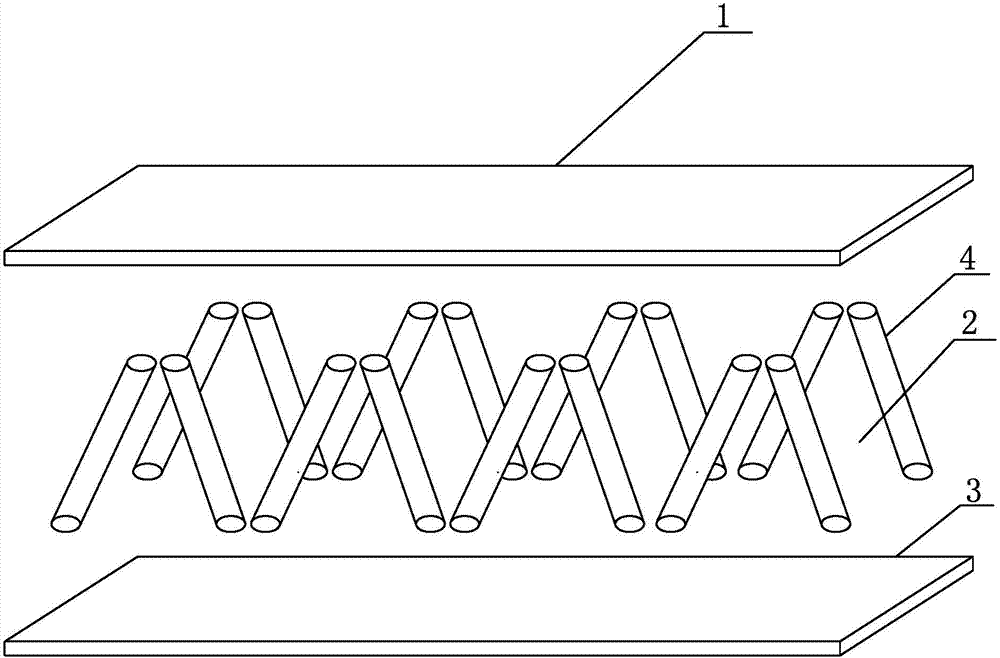

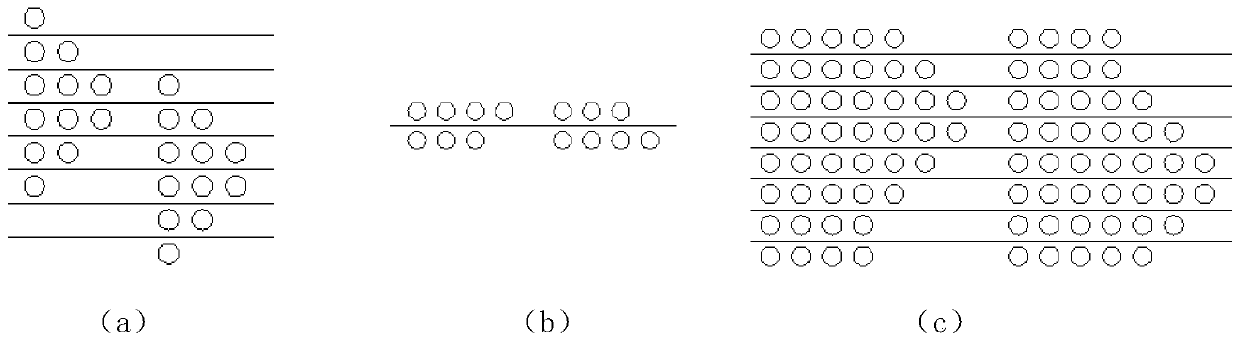

Fibre-reinforced composite lattice sandwich plate and its preparing process

The invention is a lattice sandwich plate made of reinforced composite fiber material and a manufacture method of the sandwich plate, and relates to a lattice sandwich plate and a manufacture method of the sandwich plate. The invention settles the problem that a prior lattice sandwich plate is difficult to be molded and materials used are limited to metal materials. A lattice of the invention is arranged between an upper fiber composite panel (1) and a lower fiber composite panel (3), and consists of a plurality of fiber composite columns (2). The upper ends of the fiber composite columns (2) are connected with the upper fiber composite panel (1) in a fixing way, while the lower ends of the fiber composite columns (2) is connected with the lower fiber composite panel (3) in a fixing way. The manufacture method is as follows: 1. a cleaning mould is designed and a demoulding agent is applied on the mould; 2. a pre-immersed material is cut into the designed size and filed into a pole, which is put into a mould hole; 3. the upper panel and the lower panel are laid; (4) solidification by heating and pressurizing is done, and the reinforced composite fiber material lattice sandwich plate is made. Compared with a traditional metal lattice sandwich plate, the reinforced composite fiber material lattice sandwich plate of the invention is provided with the higher intensity and rigidity, and can be designed easily.

Owner:HARBIN INST OF TECH

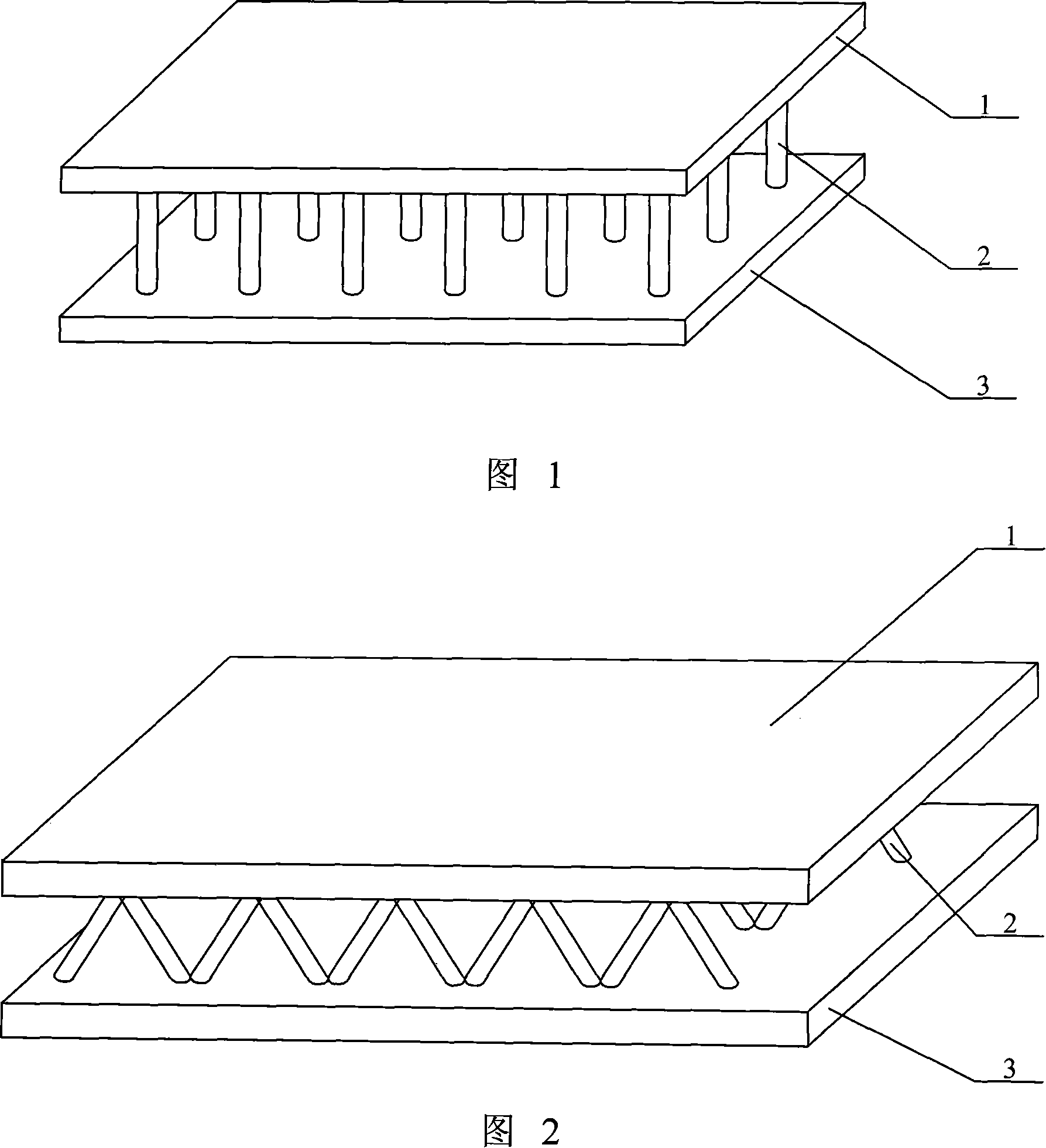

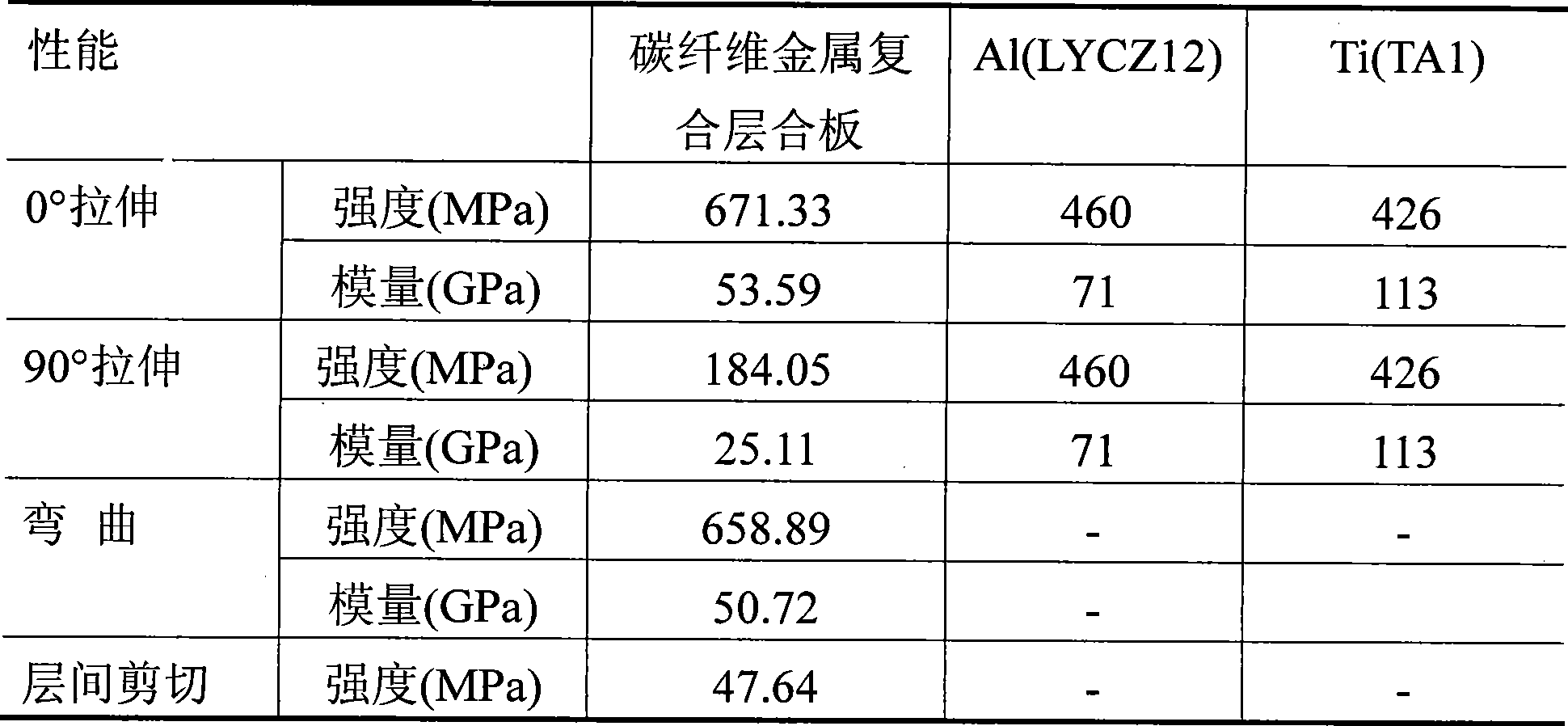

Manufacture method of carbon fiber metal composite laminated plate

InactiveCN101417524AFlame retardantImpact resistantLamination ancillary operationsLaminationFiberEpoxy

A manufacturing method of a carbon fiber metal composite laminated plate relates to a manufacturing method of a fiber metal composite laminated plate. The method aims at solving the problems that no manufacturing methods for manufacturing aircraft structural material with high specific stiffness, high specific strength, tenacity and workability exist in China. The method comprises the following steps of: carrying out surface treatment to three pieces of metal plates; winding a carbon fiber composite material layer which is soaked in liquid cement on one of the metal plates, wherein, the liquid cement is prepared by epoxy resin, a metaphenylene diamine curing agent and an anhydrous alcohol solvent according to the mass ratio of 1:0.1 to 0.18:0.15 to 0.2; fixedly arranging another two metal plates on the upper surface and the lower surface of the carbon fiber composite material layer so as to be integrally put into a mould, and then treated with mould assembling, drying, solidification by adopting the method of gradient temperature increasing, and demoulding. The manufacturing method of the invention is simple and is easy for operation. The carbon fiber metal composite laminated plate manufactured by the method of the invention has the advantages of high specific stiffness, high specific strength, also high tenacity and workability of metal material, good fatigue property, and good damage tolerance capability.

Owner:HARBIN INST OF TECH

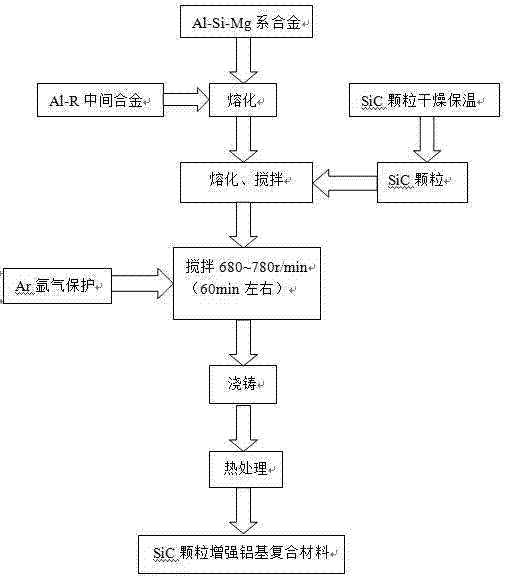

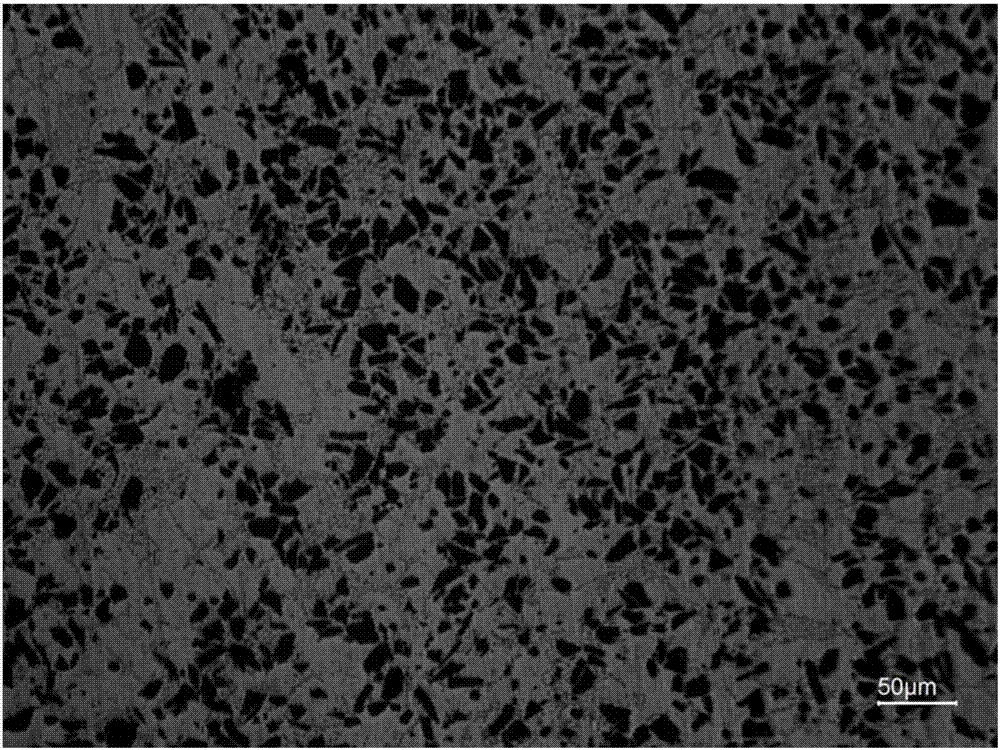

Preparation method for SiC particle reinforced aluminum-based composite material

InactiveCN103484707AGood physical propertiesImprove mechanical propertiesThermal insulationMetal mold

The invention provides a preparation method for SiC particle reinforced aluminum-based composite material. The preparation method comprises the steps as follows: step 1, the Al-Si-Mg alloy is placed into a homemade dry pot resistance furnace, after the Al-Si-Mg alloy is completely melted, 1-17 parts of intermediate alloy Al-R by weight, which is prepared in advance, is added into the melt, wherein the intermediate alloy is prepared in advance through a surface modification technology; step 2, the melt is stirred to enable rare-earth elements to be uniformly distributed into the melt; step 3, SiC is added into the melt; step 4, the melt is poured into a metal mould for formation; step 5, quenching is performed in water with the temperature of 50-60 DEG C; step 6, quenching is performed in water with the temperature of 70-80 DEG C; step 7, air cooling is performed after aging thermal insulation is performed for 6.5-7.5 h at the temperature of 165-175 DEG C. The thermal shock performance of the aluminum-based composite material can be greatly enhanced, the dimensional stability of the material is maintained when the material is used in temperature varying places, the service life of the material is prolonged, and the material has a broad market prospect when being applied to parts requiring weight reduction and excellent abrasion resistance.

Owner:TONGJI UNIV

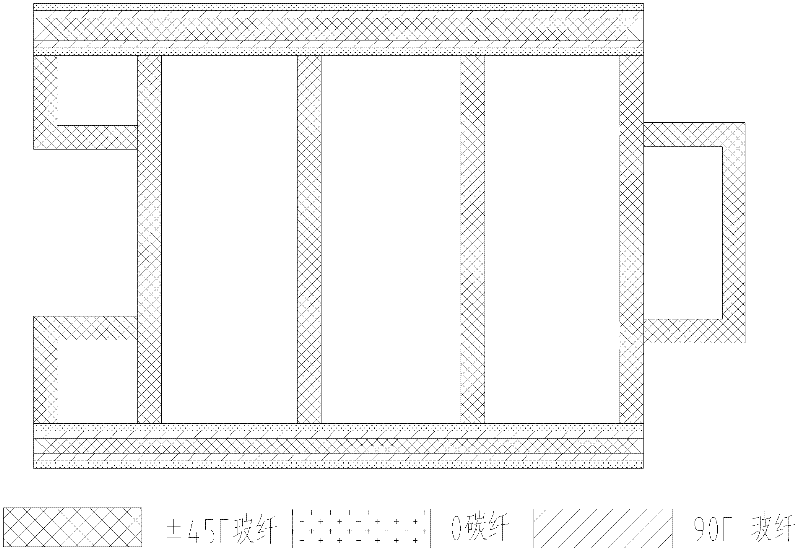

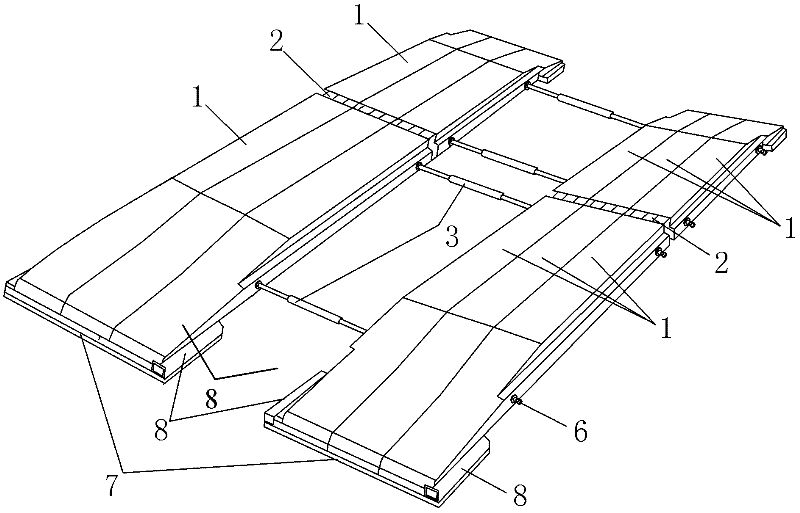

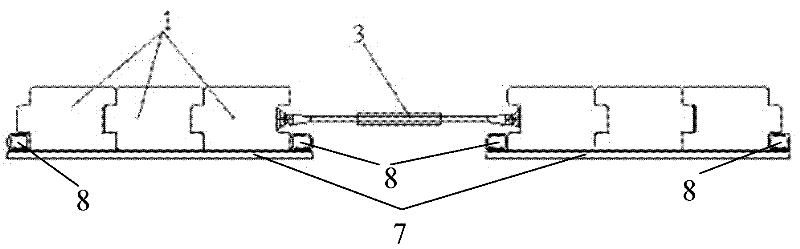

Detachable type emergency bridge made of composite material

ActiveCN102561171AHigh specific strengthHigh specific stiffnessPortable bridgeBridge materialsEpoxyGlass fiber

The invention provides a detachable type emergency bridge made of a composite material. The emergency bridge is of a wheel rut structure, and is formed by splicing a plurality of bridge segments, wherein each bridge segment is of the structure of a multi-cavity box beam, and is made from a resin matrix composite, particularly an epoxy resin matrix hybrid fiber reinforced composite material; each bridge segment comprises an upper faceplate, a lower faceplate and a plurality of intermediate webs, intermediate layers of the upper faceplate and the lower faceplate are made from + / -45DEG E-glass fiber, one 90DEG E-glass fiber layer is arranged at each of both the upper side and the lower side of each intermediate layer, and a 0DEG carbon fiber layer is arranged at the outer side of each 90DEG E-glass fiber layer; and the webs employ a composite material layer made from + / -45DEG E-glass fiber. According to the invention, main bodies of a bridge body are made from the composite materials, and are assembled to form a whole through metal connectors, so that the bridge body is light in weight, and convenient and quick to assemble, and can be manually assembled and disassembled quickly.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A +1

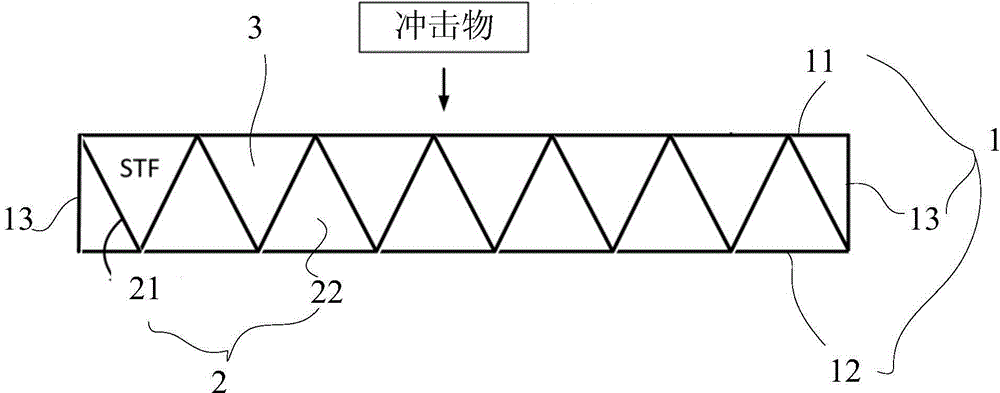

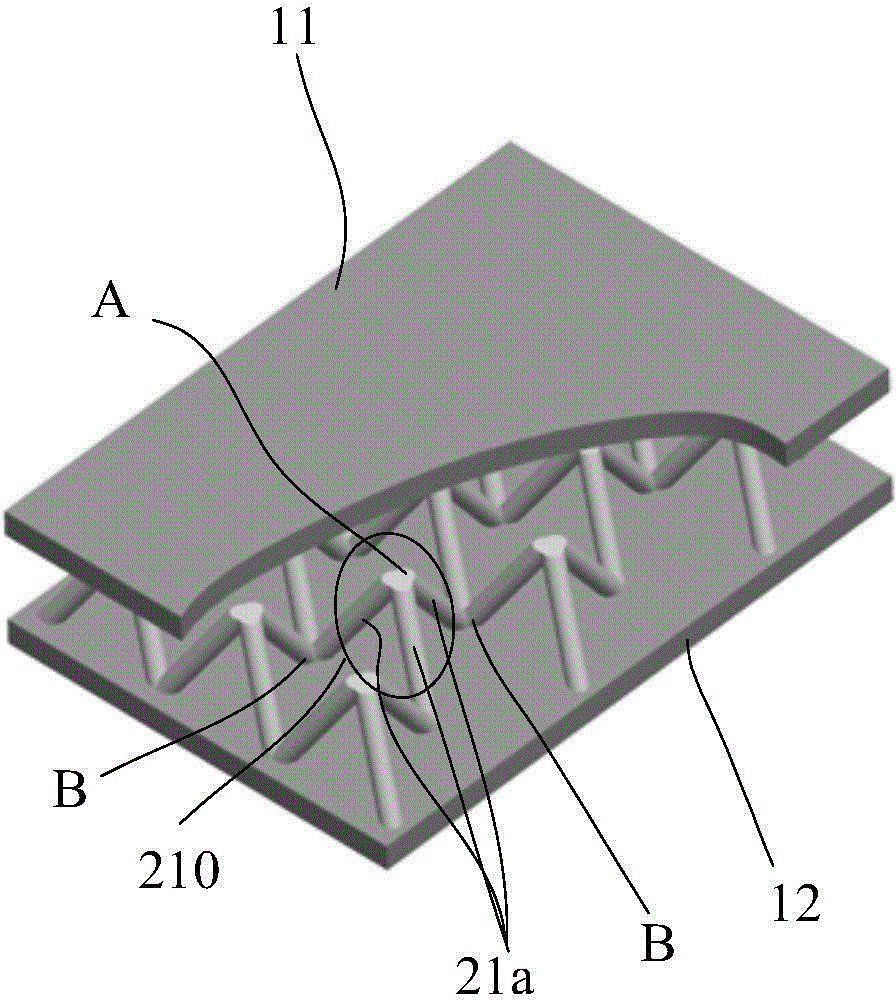

Sandwich energy-absorbing device

InactiveCN104476828AImprove energy absorptionHigh viscosityLayered productsNuclear engineeringEnergy absorption

The invention provides a sandwich energy-absorbing device which comprises an upper panel, a lower panel, lateral plates and a core plate layer, wherein the core plate layer is fed in a closed space formed by enclosing the upper panel, the lower panel and the lateral plates, and the core plate layer comprises core materials and a shear thickening fluid material fed between the core materials and / or fed between the core materials and the closed space. When an energy-absorbing device suffers from an action an external impact, structures of the upper panel, the lower panel, the lateral plates and the core materials rapidly deform, so that a quick shear action is applied to the shear thickening fluid material fed in a core plate, the viscosity of the shear thickening fluid material with a relatively high shear strain rate is rapidly improved, and thus impact energy is rapidly dissipated, and relatively high specific strength, specific stiffness and vibration resistance and energy absorption capabilities are achieved.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

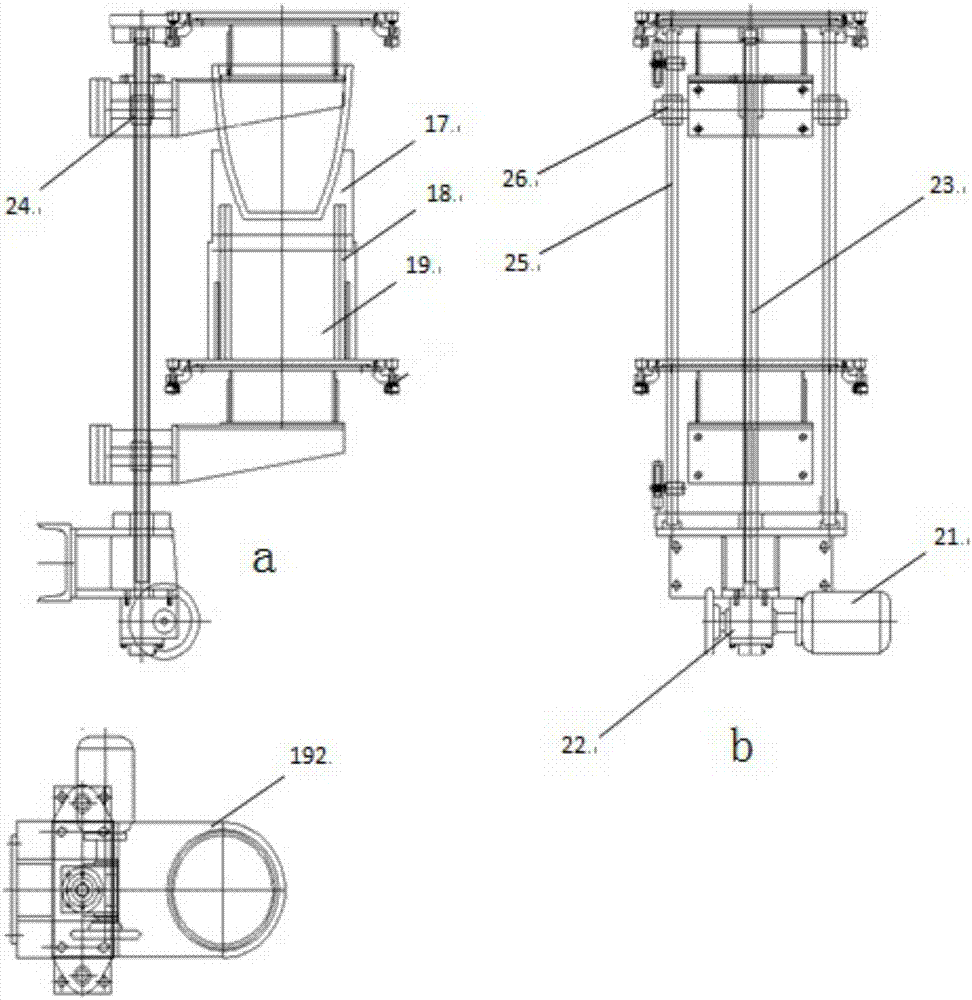

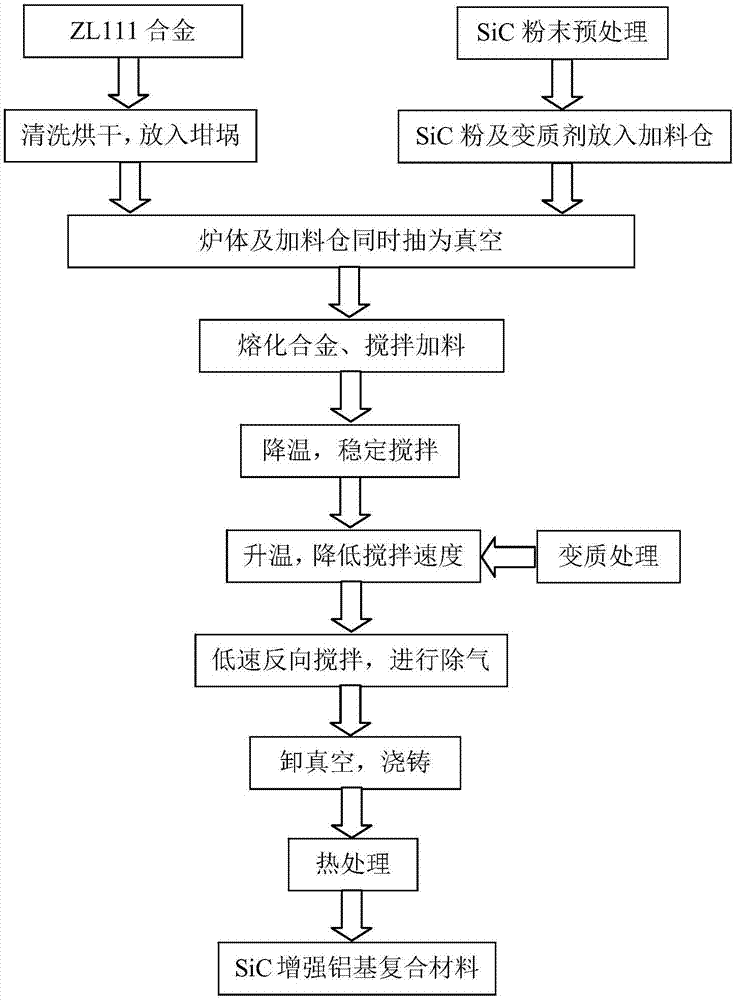

Preparing method for SiC particle enhanced aluminum-base composite material

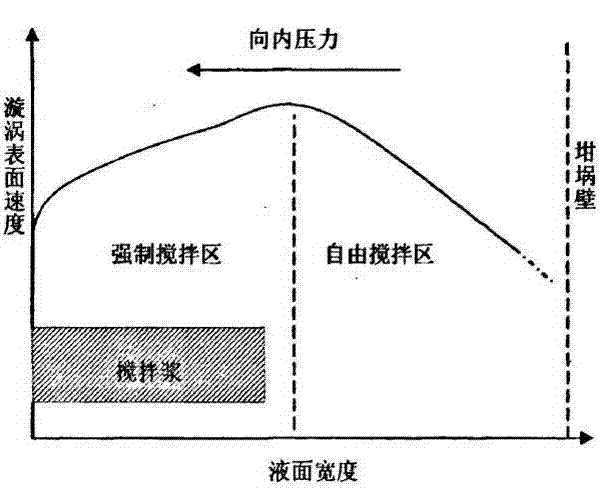

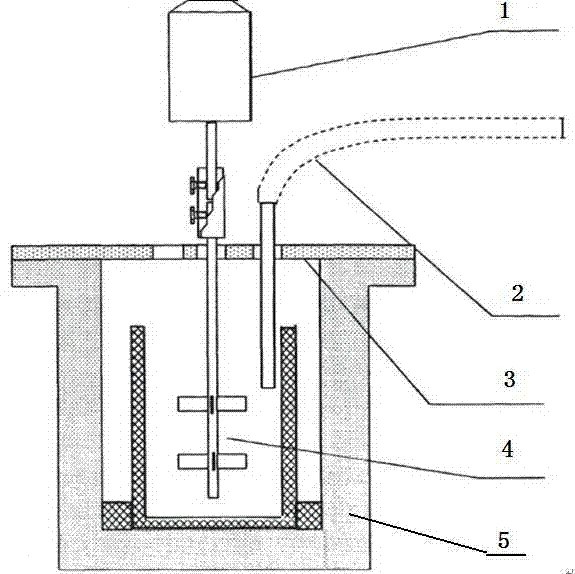

The invention aims at disclosing a specially-made vacuum smelting furnace and a preparing technology for a SiC particle enhanced aluminum-base composite material. A certain component proportion and a special smelting casting technology are adopted. The vacuum smelting furnace is adopted in the technology, overall closing and vacuum-state charging can be achieved, the inner temperature of melt can be measured in real time, the particles accurately fall into a melt vortex center with a certain speed and are evenly distributed in the melt under powerful stirring, the functions of deoxygenation and degassing can be effectively achieved on the composite material melt, and therefore the composite material uniform in component, low in porosity, high in mechanical performance and excellent in heat-conducting property can be produced through the technology. The crucible lifting type vacuum smelting furnace comprises a crucible composite device and lifting platform system, a stirring device and lifting platform system, a charging device, a vacuum system, a handheld lifting thermocouple, a sealing system and an electric control system.

Owner:SUZHOU WUCHUANG MATERIAL TECH DEV CO LTD

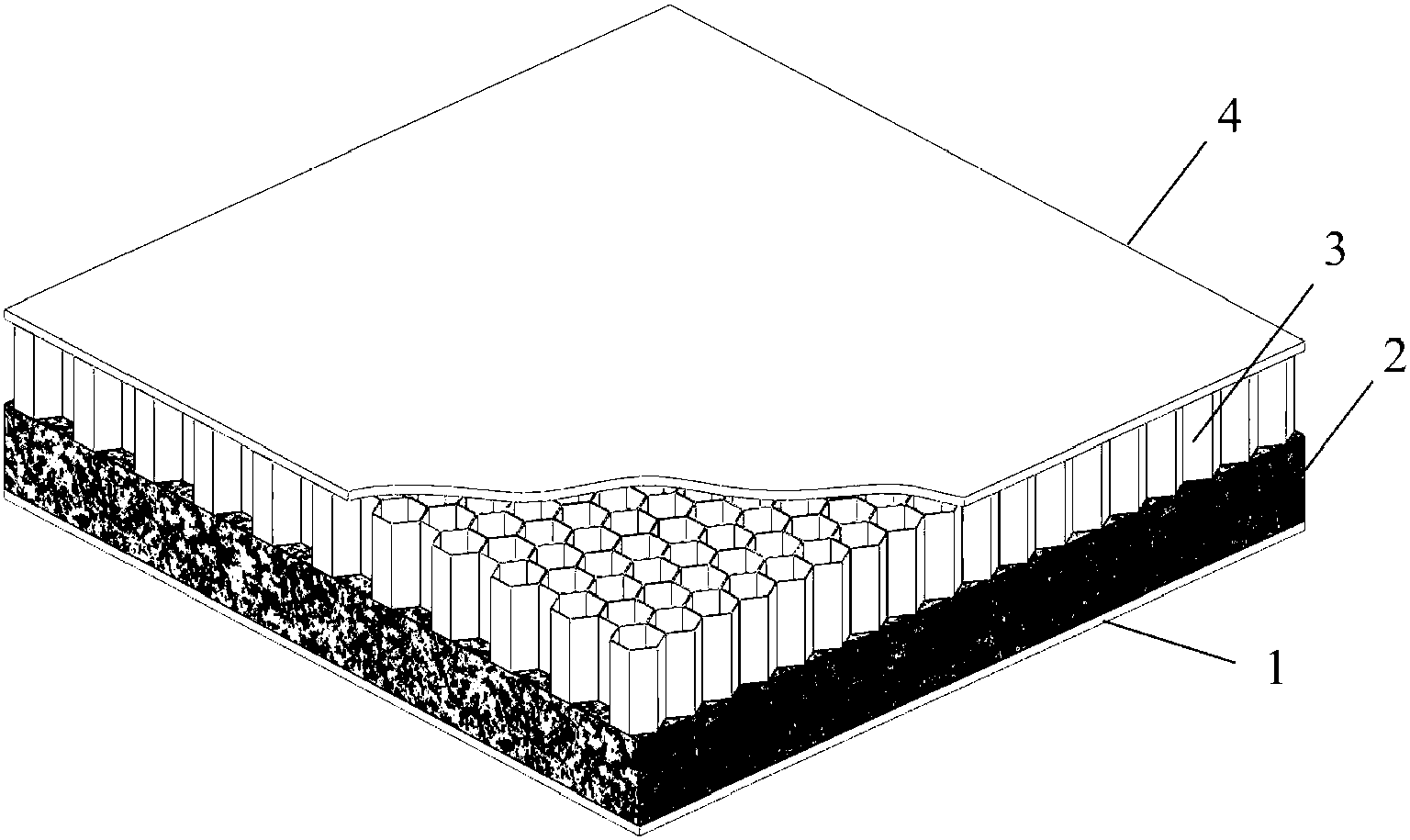

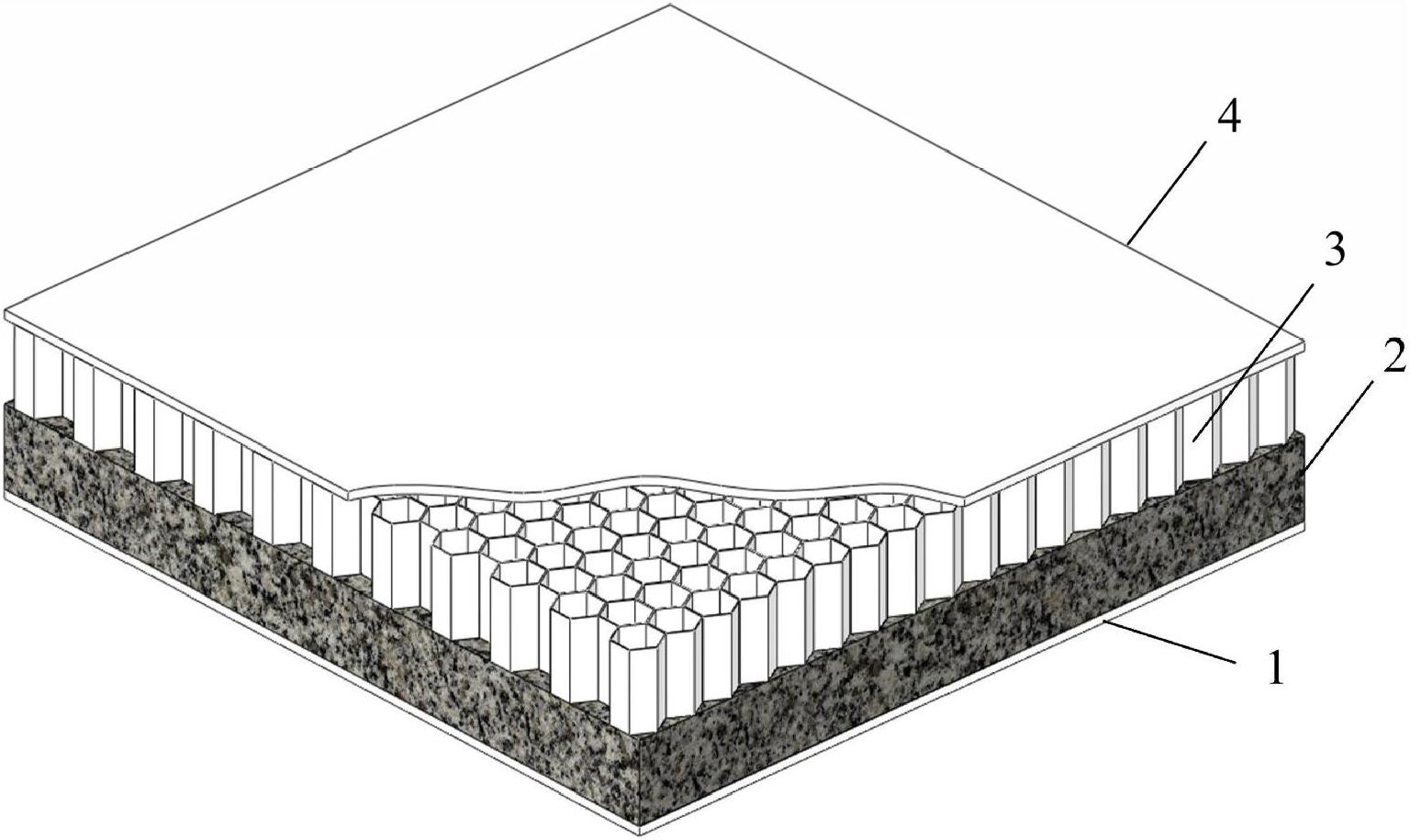

Light multifunctional composite structure

InactiveCN102700181AReduce weightGive full play to excellent performanceMetal layered productsMetallurgyAluminum honeycomb

The invention discloses a light multifunctional composite structure. The composite structure comprises a first outer surface plate, a second surface plate, a metal foam sandwich layer and a honeycomb sandwich layer, wherein the metal foam sandwich layer and the honeycomb sandwich layer are arranged between the first outer surface plate and the second surface plate, and the honeycomb sandwich layer is hexagonal aluminum honeycombs or square aluminum honeycombs. According to the sandwich structure through the composition of metal foams with the hexagonal aluminum honeycombs or the square aluminum honeycombs, the weight can be obviously reduced, and a plurality of functions such as load bearing, sound absorption, sound and heat insulation and shock resistance are provided.

Owner:XI AN JIAOTONG UNIV

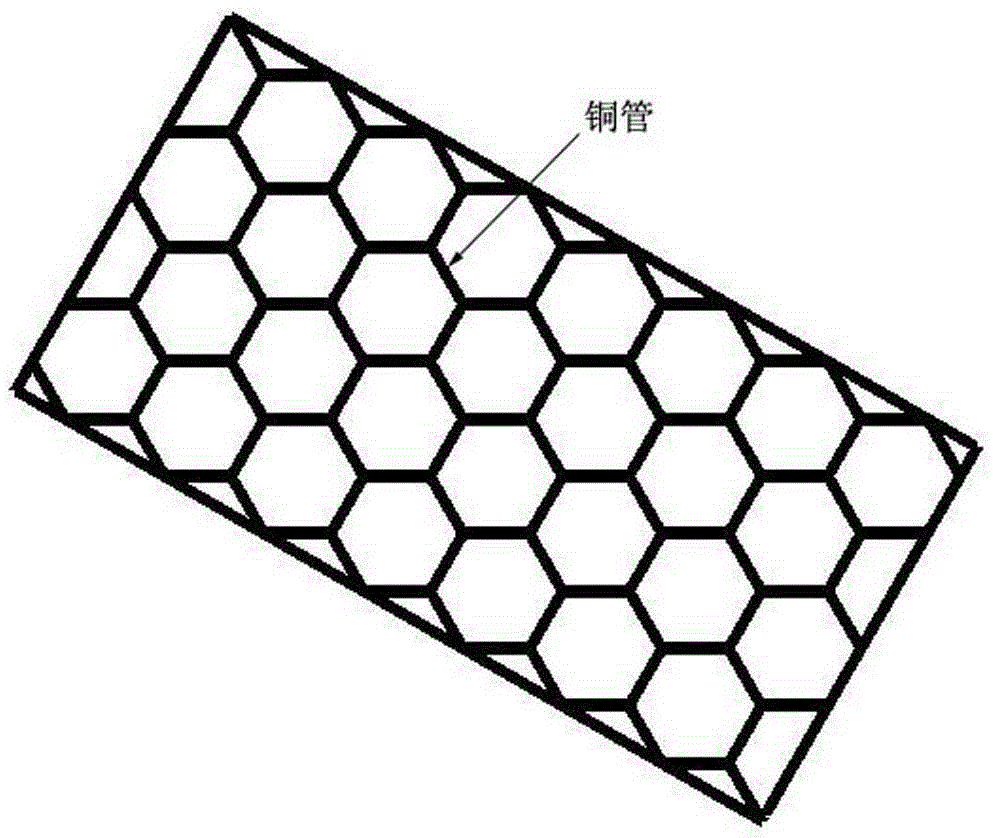

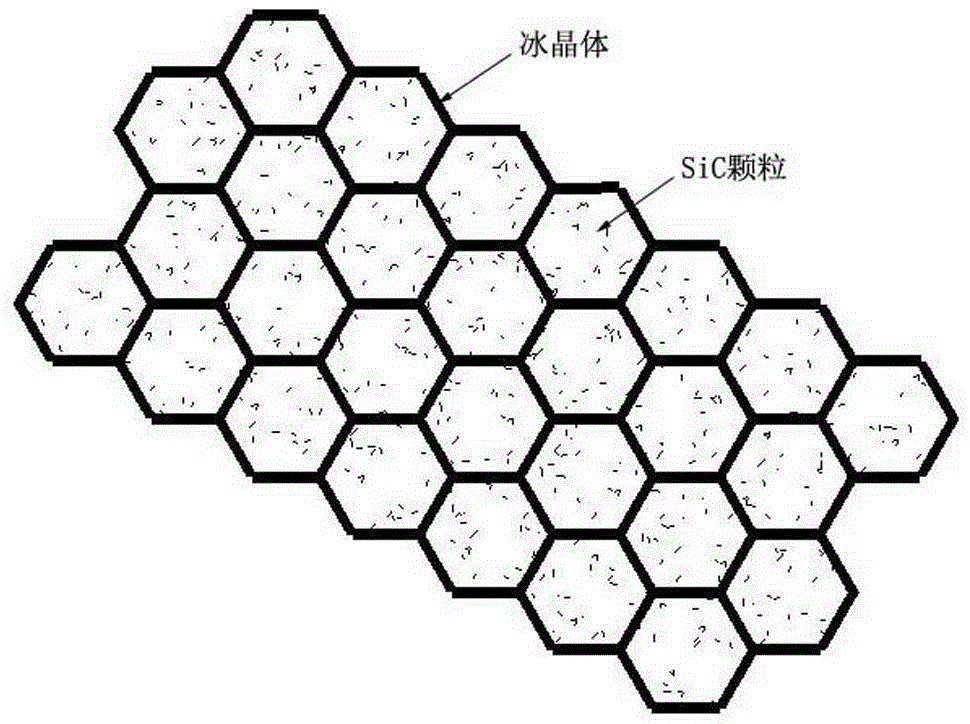

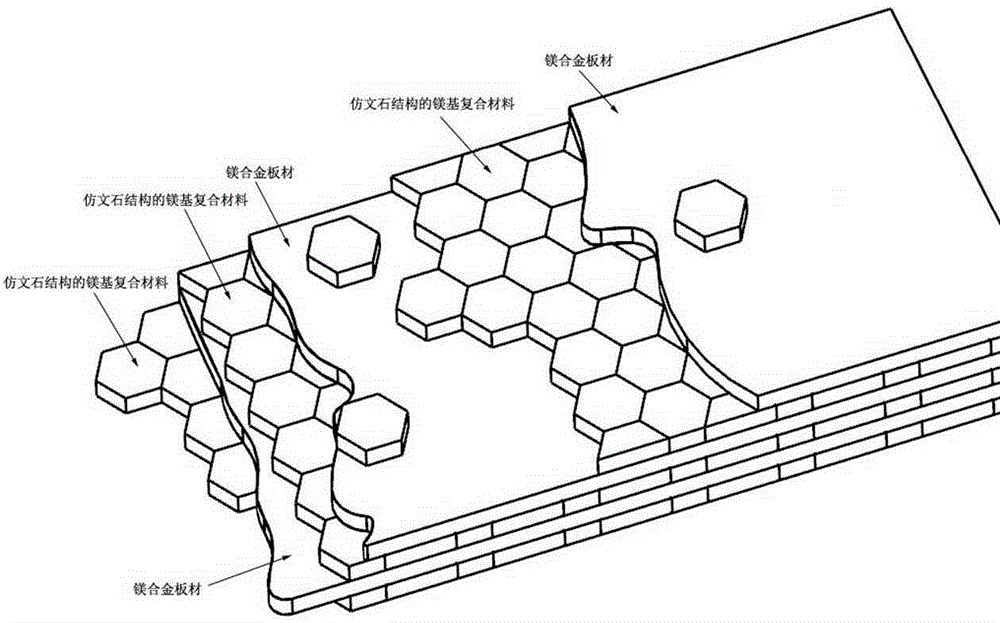

Preparation method for shell-nacreous-layer-imitating magnesium-based composite material

The invention discloses a preparation method for a shell-nacreous-layer-imitating magnesium-based composite material. A SiC particle reinforced magnesium-based composite material of a distinct shell-nacreous-layer structure can be prepared through the preparation method. A shell-nacreous-layer microstructure serves as a model, and a directional freeze thawing ice template method and a laminated hot pressing technique are adopted for preparing a biomimetic SiCp / Mg composite material with distinct shell-nacreous-layer microstructure characteristics and a controllable organizational structure. According to the novel preparation technique for biomimetic metal-based composite materials, the route is unique and the production efficiency is high. Compared with traditional magnesium-based composite materials, the prepared magnesium-based composite material of the shell-nacreous-layer-imitating structure not only has good mechanical properties such as high specific strength, high specific stiffness, good abrasion resistance, but also has good toughness and plasticity.

Owner:ZHONGBEI UNIV

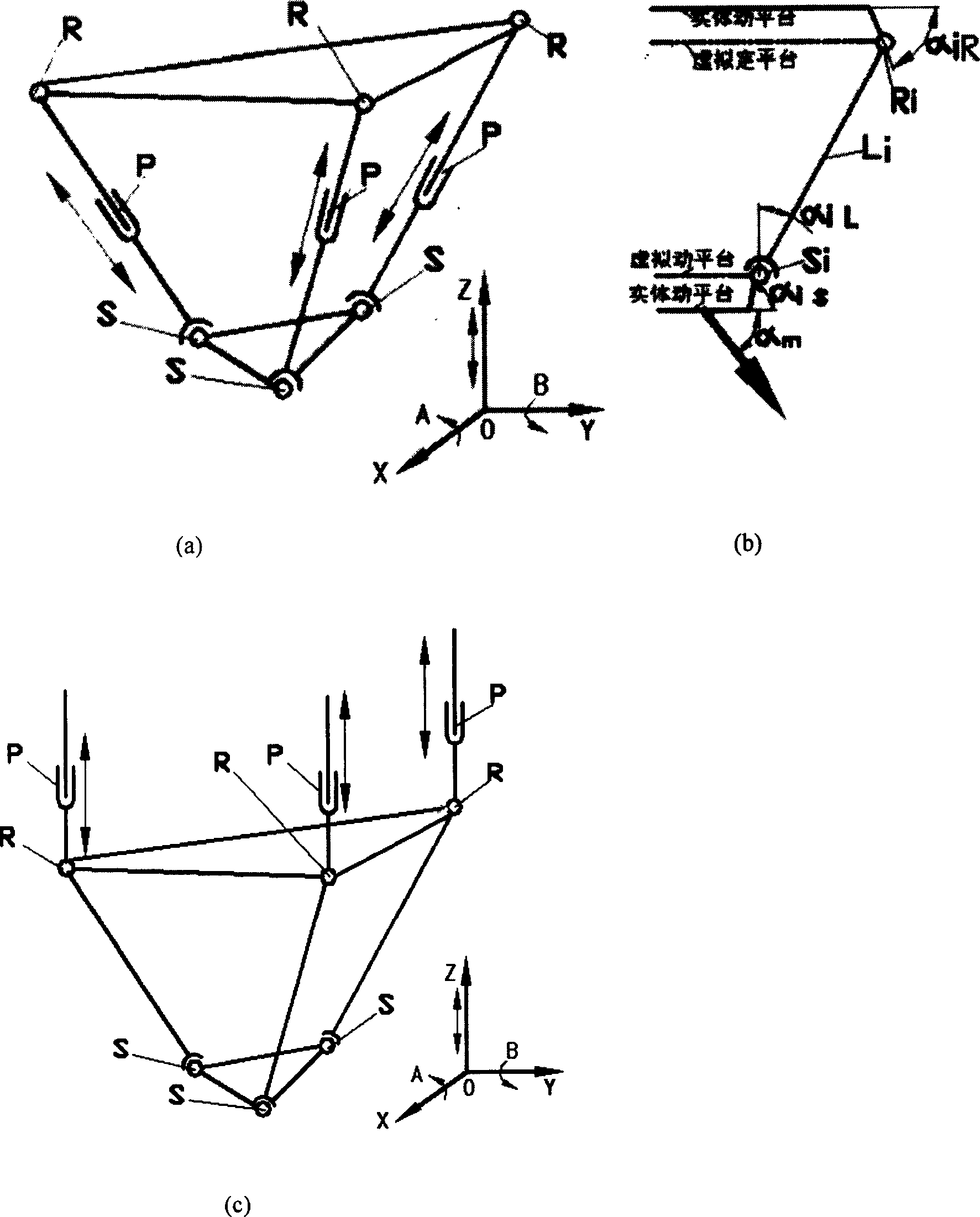

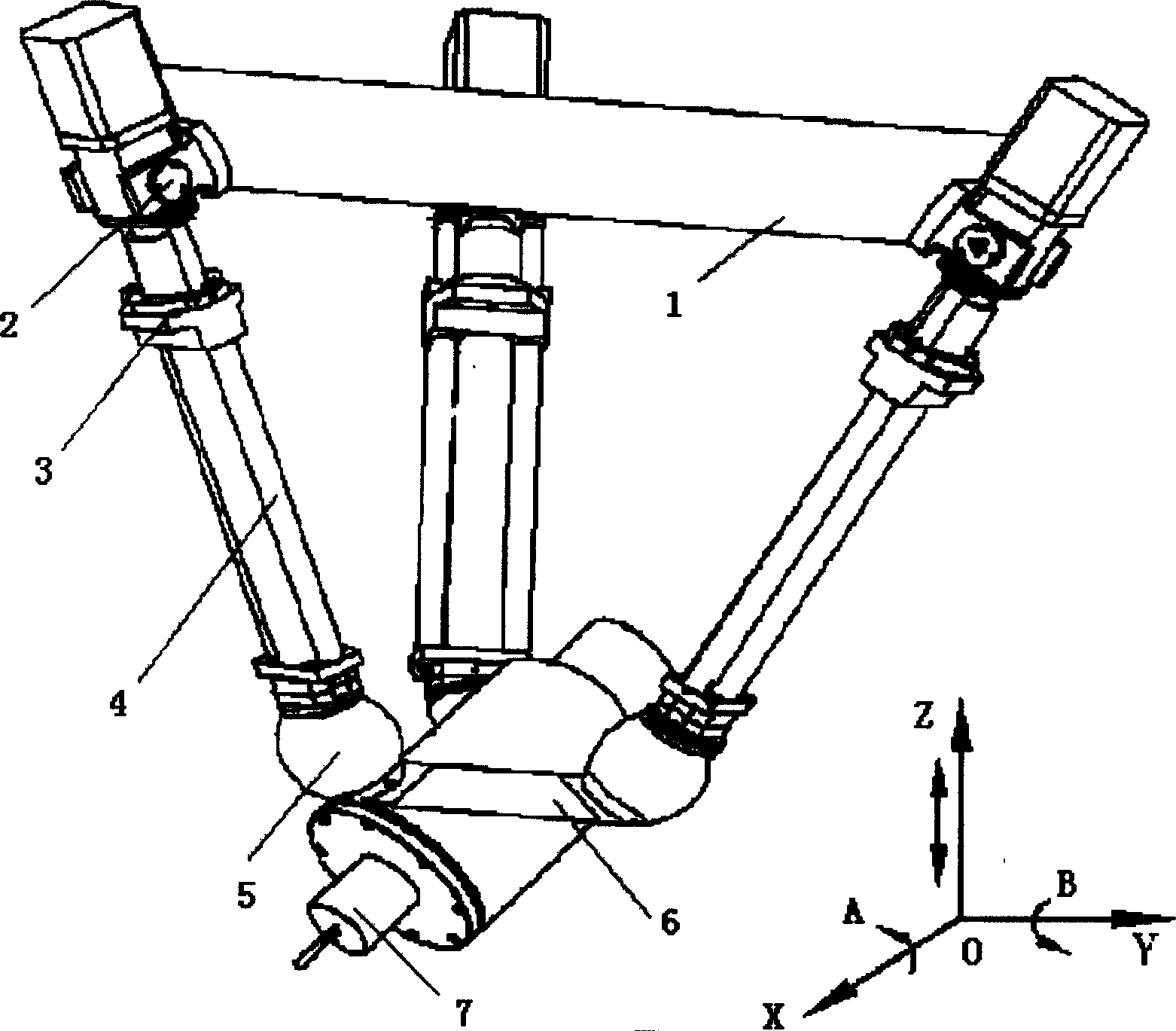

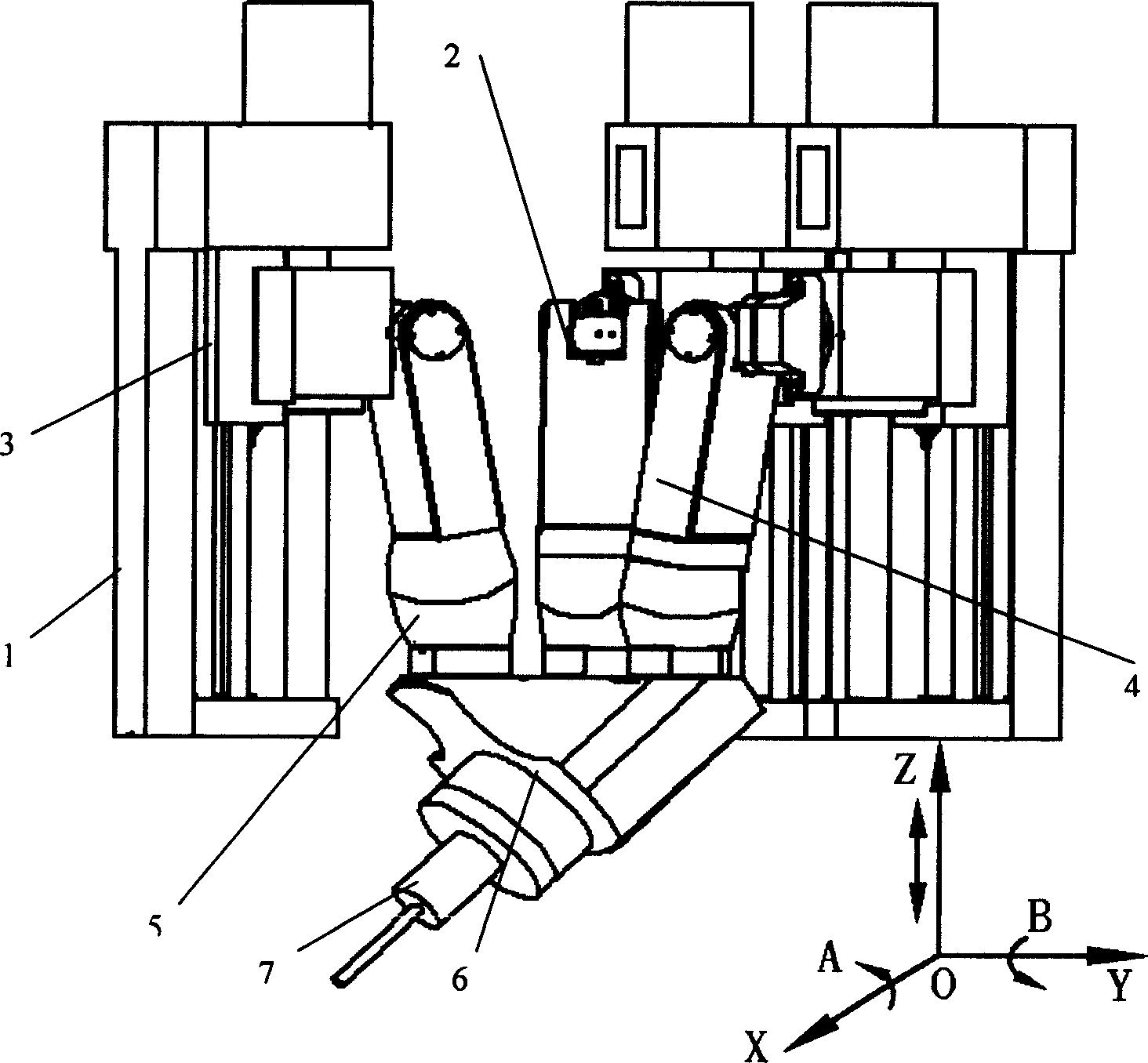

Three-axle parallel mainshaft head structure for implemonting multidirection verticel-horizontal processing

InactiveCN1559753AIncrease feed rateHigh specific stiffnessLarge fixed membersMetal working apparatusEngineeringMachining

A mainshaft head mechanism with parallel three shafts for performing multi-direction vertical and horizontal machining is composed of a fixed platform, threerotary sets distributed by 120 deg and connected to said fixed platform, three moving sets respectively linked to the rotay sets, three rod sets respectively linked to three moving sets, three spherical sets respectively linked to three rod sets, movable platform, and mainshaft unit installedon said movable platform. Said mainshaft unit can do longitudinal movement along Z axis and rotations around A axis and B axis.

Owner:XIAN UNIV OF TECH

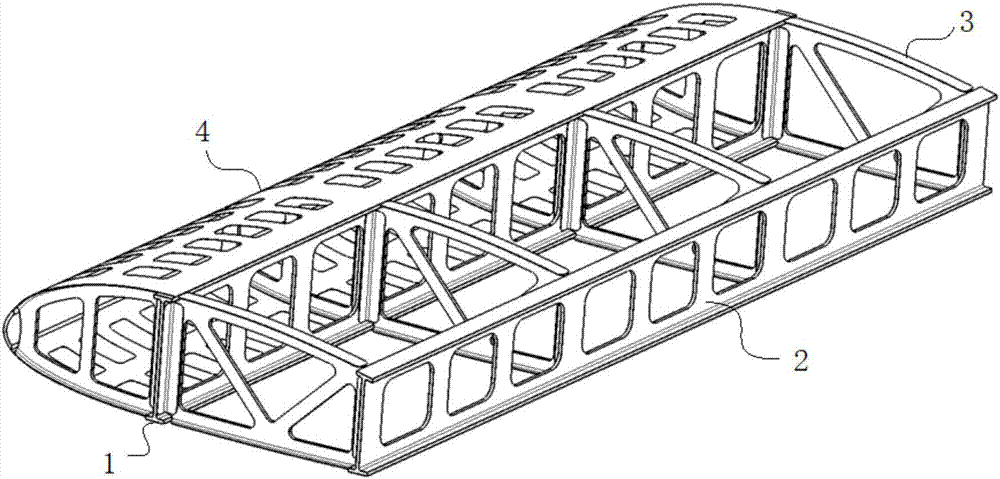

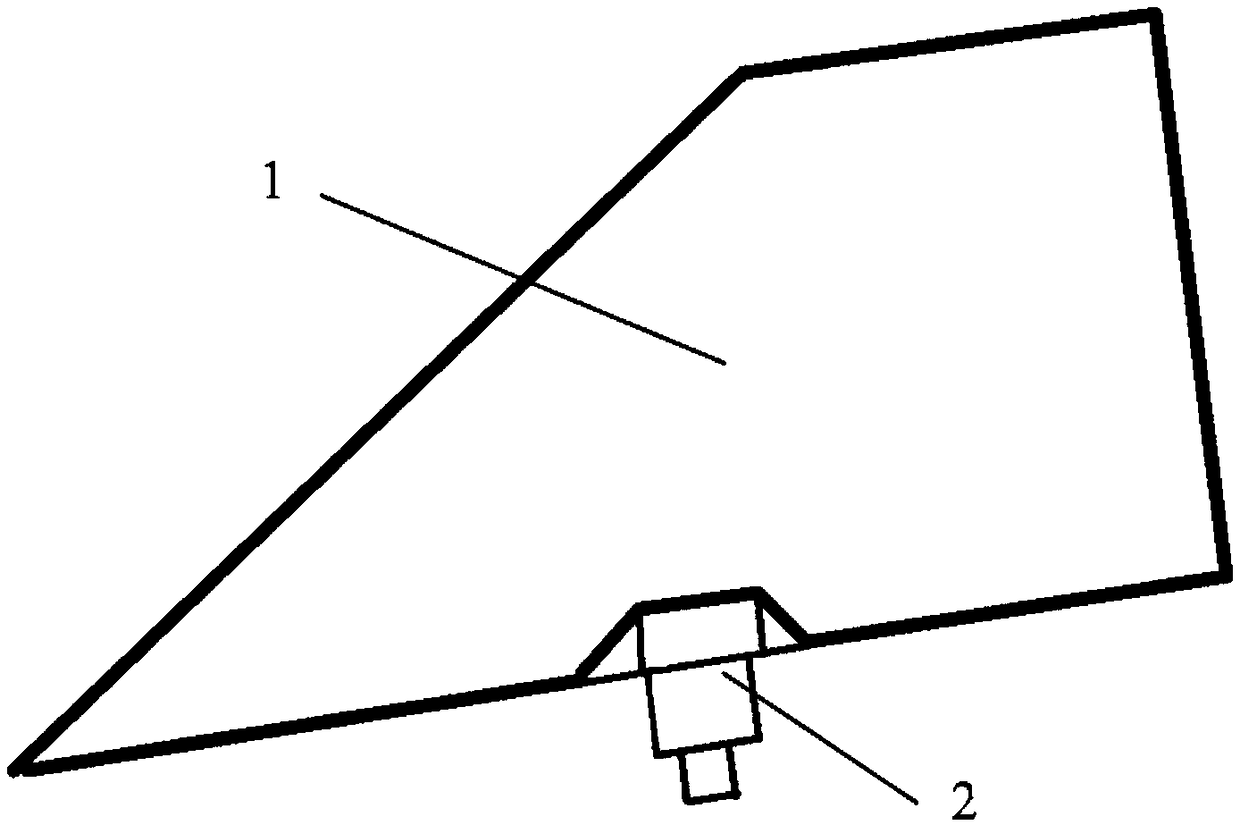

Truss type ultralight overall wing structure

ActiveCN107571985AHigh specific stiffnessSignificant Weight Loss GainsSpars/stringersDesign technologyAirplane

The invention relates to a truss type ultralight overall wing structure, and belongs to the technical field of aircraft structure design. The truss type ultralight overall wing structure includes a front beam, a back beam, at least two wing ribs, a hard skin and a flexible skin, wherein the front beam and the back beam are in parallel and are arranged in the flight direction; each wing rib includes a front wing rib and a back wing rib, the front wing ribs are arranged between the front beam and the back beam, the back wing ribs are fixed to the front beam and provided with wing-shaped camberedsurfaces, and the wing ribs are in parallel. The hard skin is installed on the windward side between the front beam and the leading edge of a wing. The hard skin is provided with a wing-shaped cambered surface. The flexible skin is installed on the front beam, the back beam and the hard skin in a paved mode to maintain aerodynamic configuration. According to the truss type ultralight overall wingstructure, a novel layout mode of 'thin film skin-sandwich skeleton' is put forward in layout, and strict weight index requirements are met on the basis of meeting requirements of strength and rigidity.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

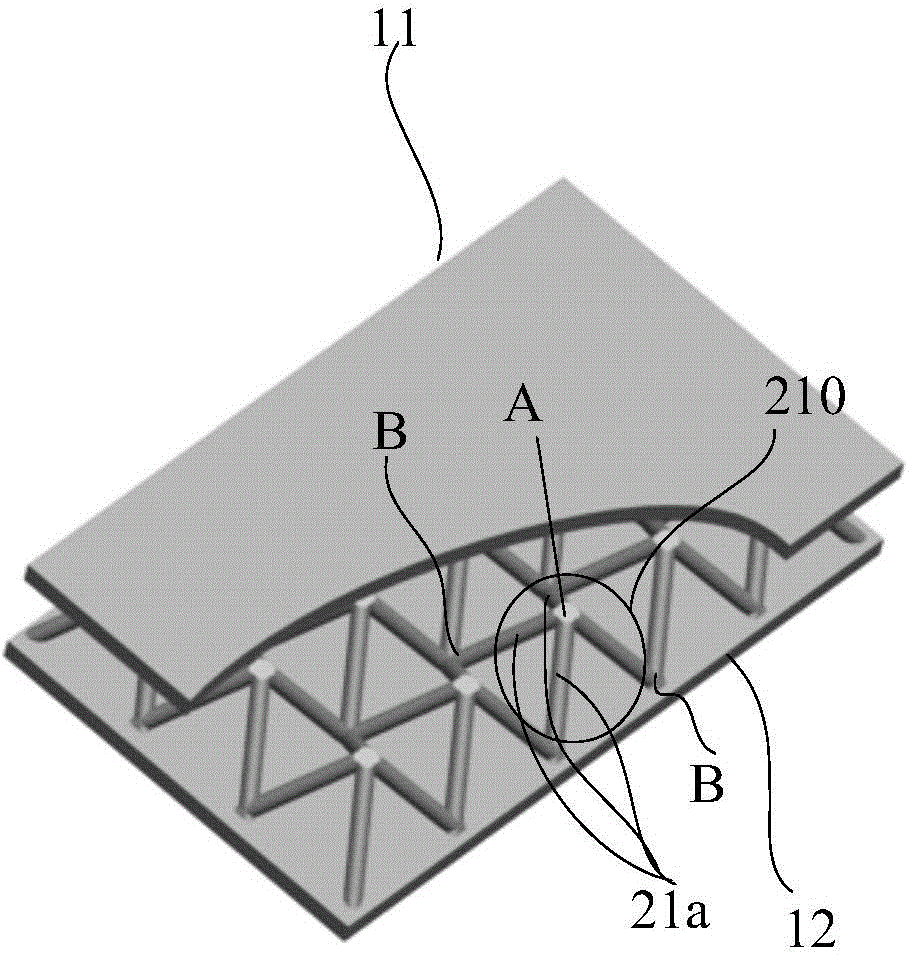

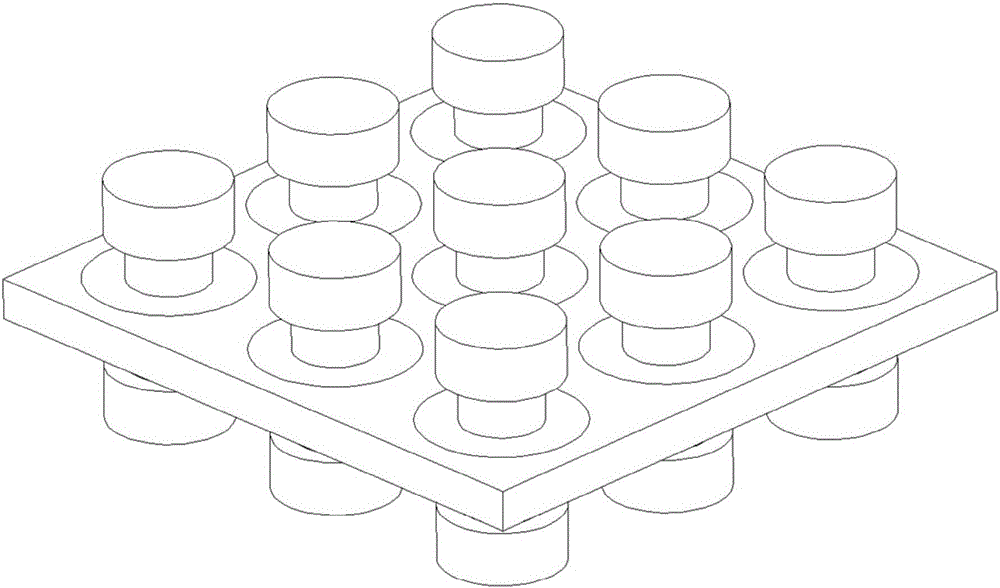

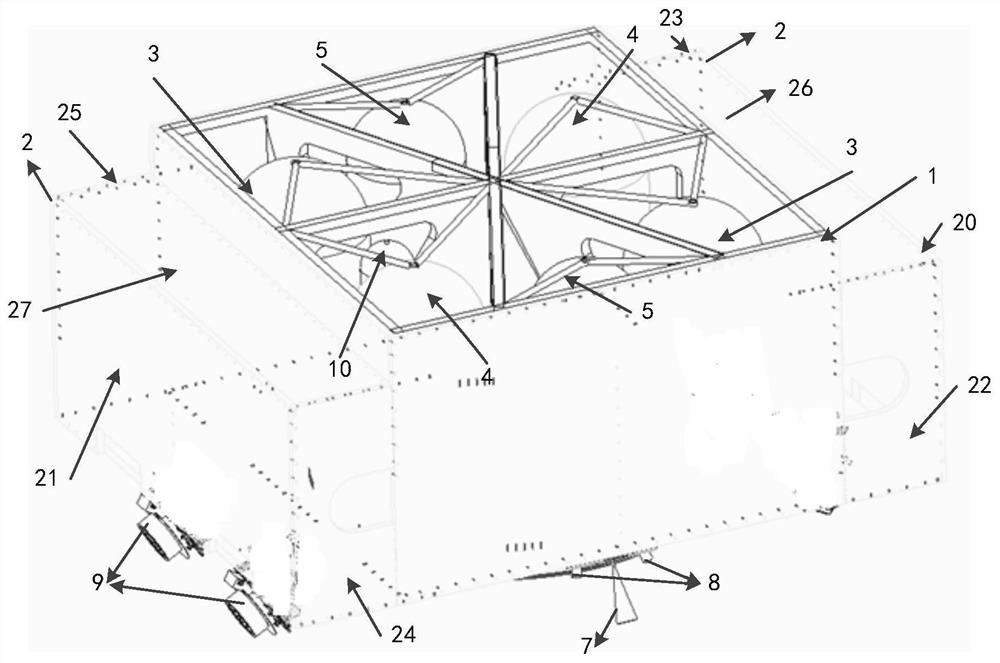

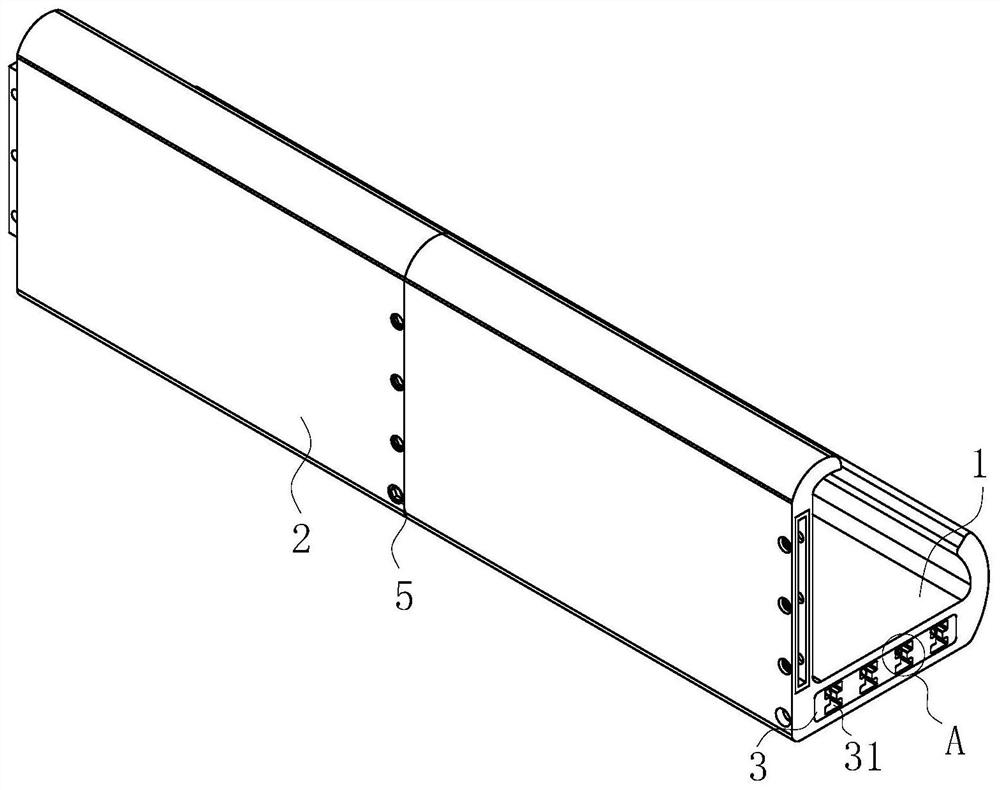

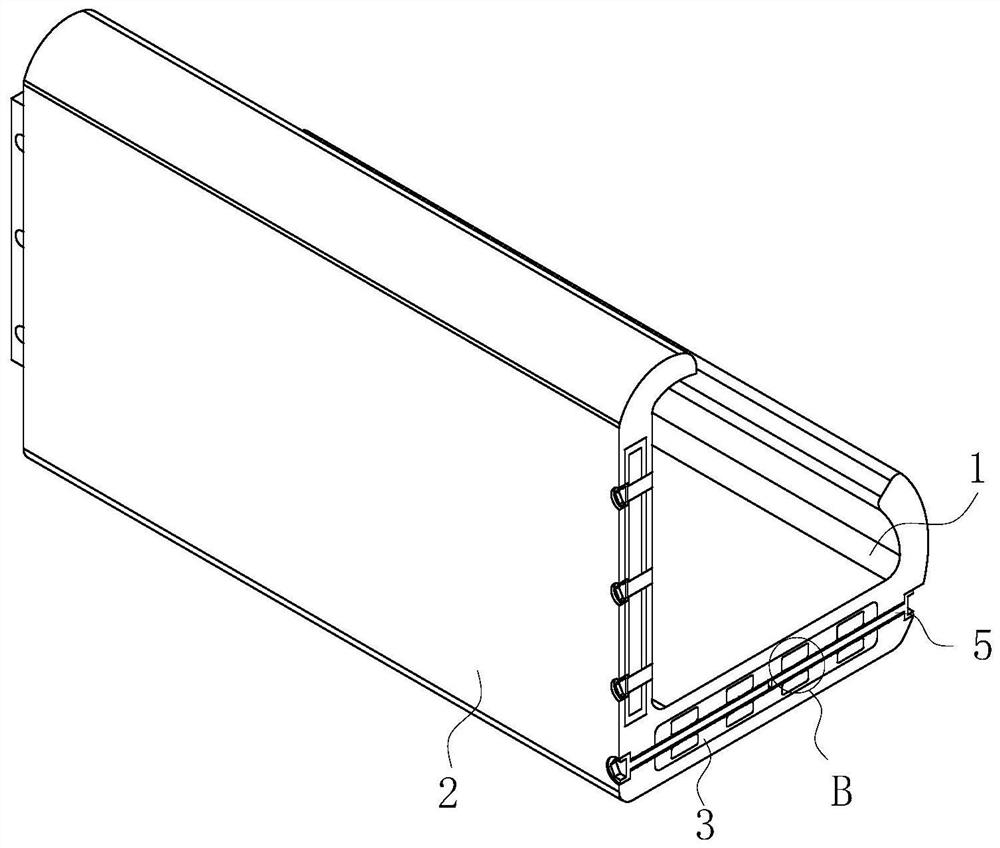

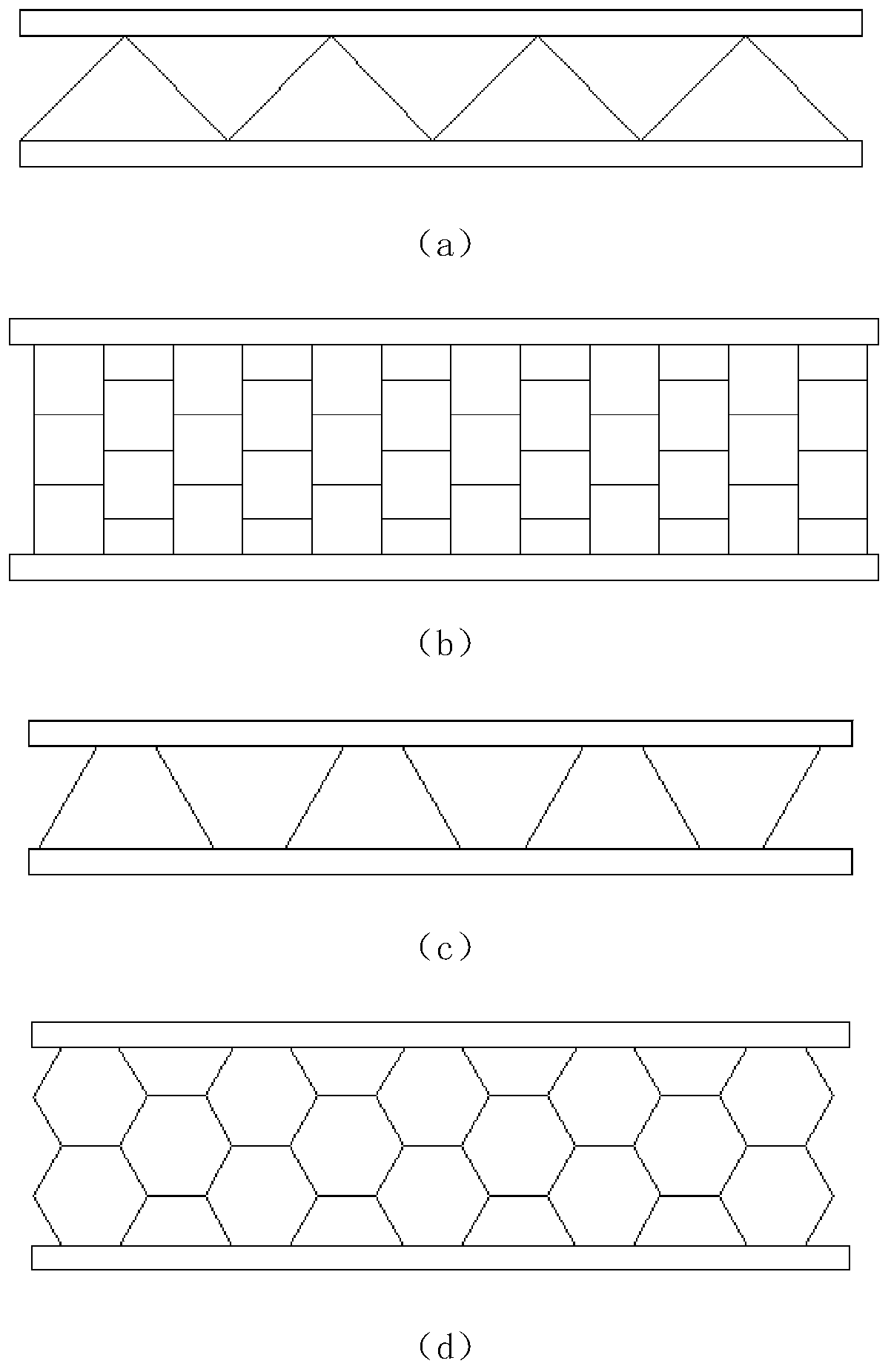

Dot matrix sandwich structure of wooden engineering composite material

The invention discloses a dot matrix sandwich structure of a wooden engineering composite material. The dot matrix sandwich structure comprises a panel I (1), a core layer (2) and a panel II (3), wherein the panel I (1), the core layer (2) and the panel II (3) are formed by gluing through joggle joint; the core layer (2) comprises a dot matrix structures (4) and fillers filling the dot matrix structures (4); partial enhancement is performed through gluing of an adhesive by using a fiber reinforced material; the dot matrix structures (4) are periodically distributed on the core layer according to reasonable unit specification design. The dot matrix sandwich structure can bear high static load and cyclic load for a long time, is light in weight, high in specific strength and high in specific stiffness, endows the wooden engineering composite material with multifunctional characteristic and can be widely applied to the fields of constructional engineering, vehicle engineering, bridge engineering and the like requiring structure load and multifunction.

Owner:NORTHEAST FORESTRY UNIVERSITY

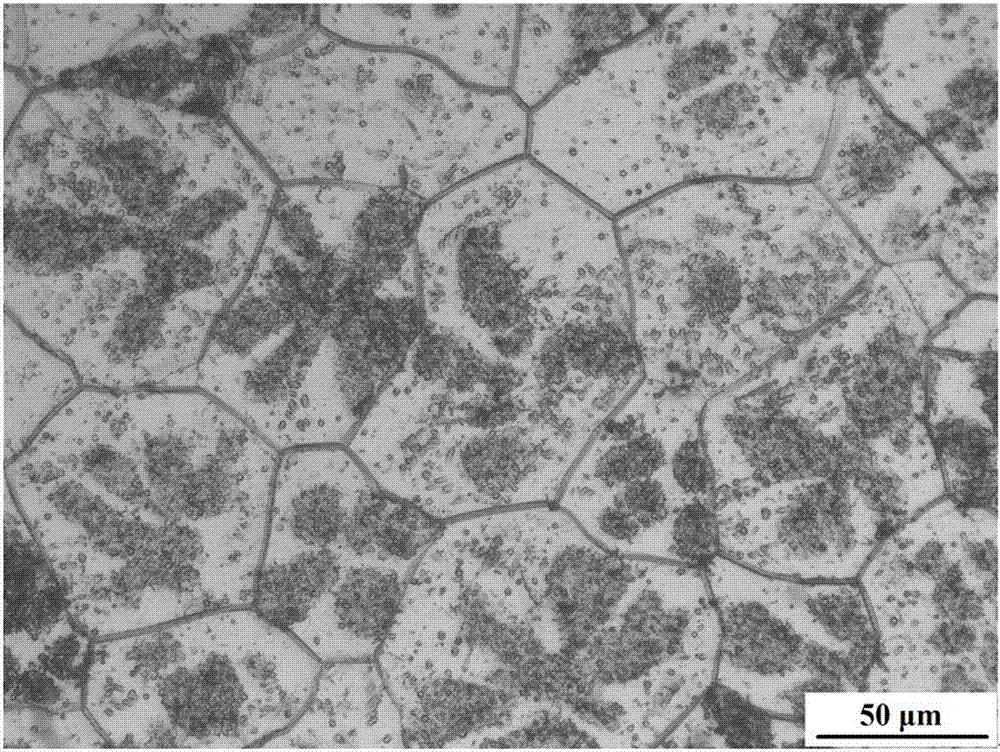

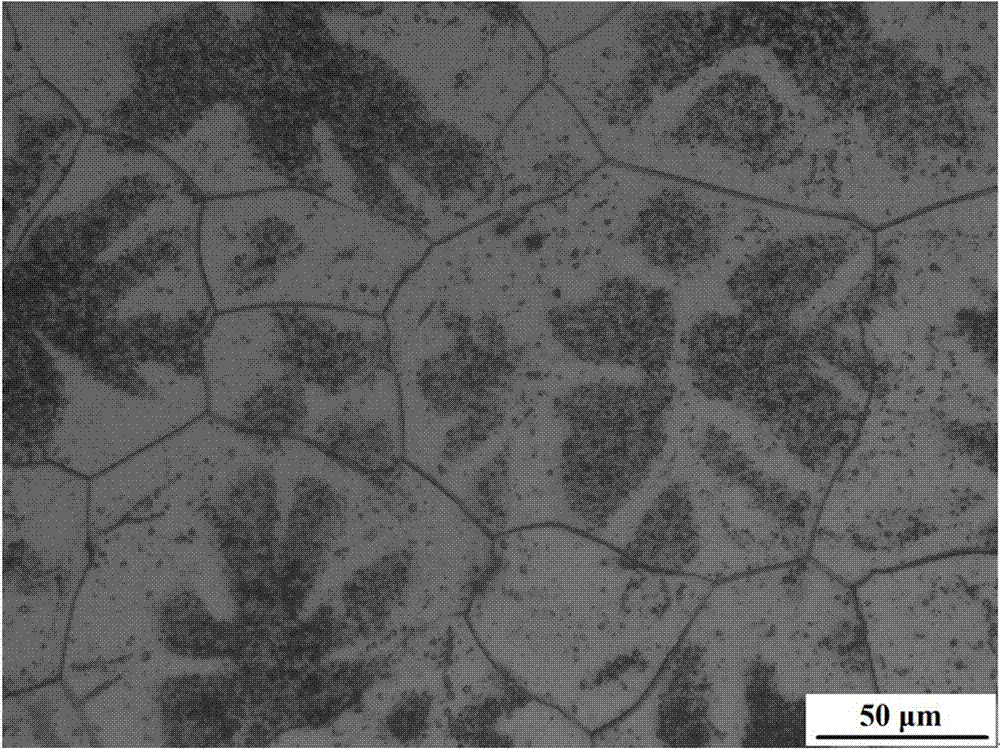

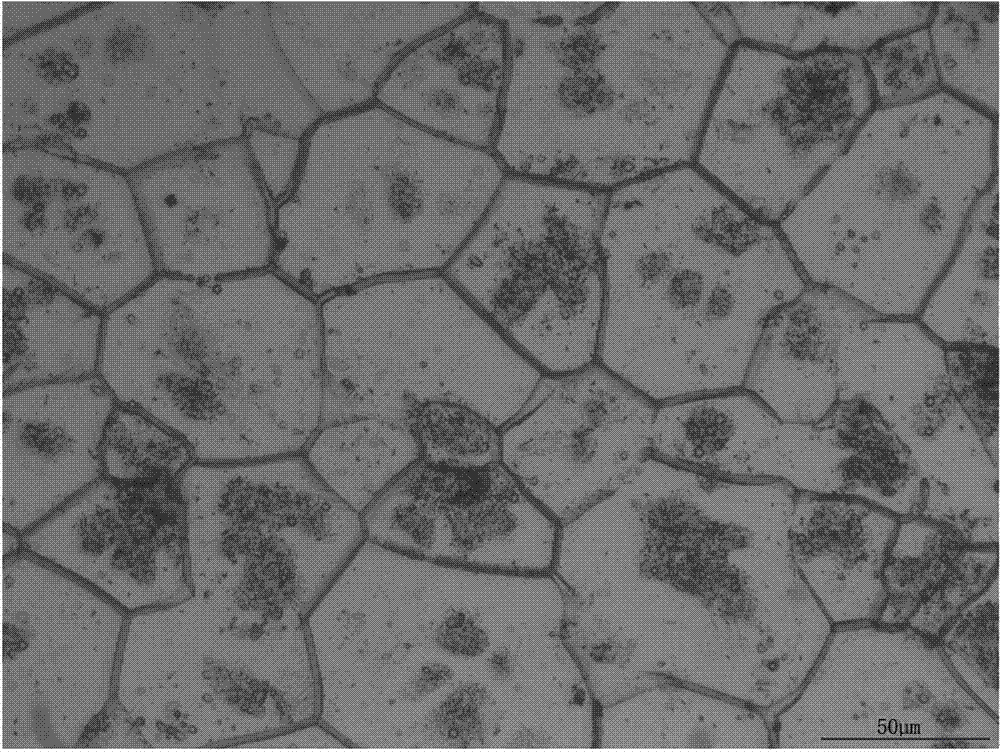

Multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and manufacturing method thereof

ActiveCN107083508AImprove room temperature and high temperature mechanical propertiesImproves strength and hardnessRare-earth elementCorrosion resistant

The invention discloses a multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and a manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy. The ingredients of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy comprise pure magnesium ingots, pure zinc ingots, Mg-Gd alloy, Mg-Y alloy, Mg-Nd alloy, Mg-Ca alloy, Mg-Zr alloy and nanometer-scale NdN particles. The elements in the raw materials comprise, by mass, 3.5-5.0% of Gd, 1.0%-3.0% of Y, 0.5%-0.8% of Nd, 0.8%-1.5% of Zn, 0.3%-0.8% of Ca, 0.3%-0.6% of Zr, 0.5%-1.5% of nanometer-scale NdN particles and the balance Mg. The sequence of the mass percentage contents of the three rare earth elements of the Gd, the Y and the Nd from large to small is Gd>Y>Nd, and the mass percentage of the total addition amount of the three rare earth elements of the Gd, the Y and the Nd does not exceed 10%. The particle size of the nanometer-scale NdN particles is 80-150 nm. The steps of pretreatment and cladding of the NdN particles, preheating of the ingredients, smelting, refining, doping, pouring, sectioned solution treatment and artificial aging treatment are sequentially conducted, and then the fine, dispersive nanometer-precipitated-phase microscopic-structure heat-resistant corrosion-resistant magnesium alloy product is obtained. By the adoption of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy and the manufacturing method of the multielement-enhanced heat-resistant corrosion-resistant magnesium alloy, the manufacturing cost is low, and the heat resistance and corrosion resistance of the magnesium alloy are excellent.

Owner:YANGZHOU FENG MING METAL PROD +1

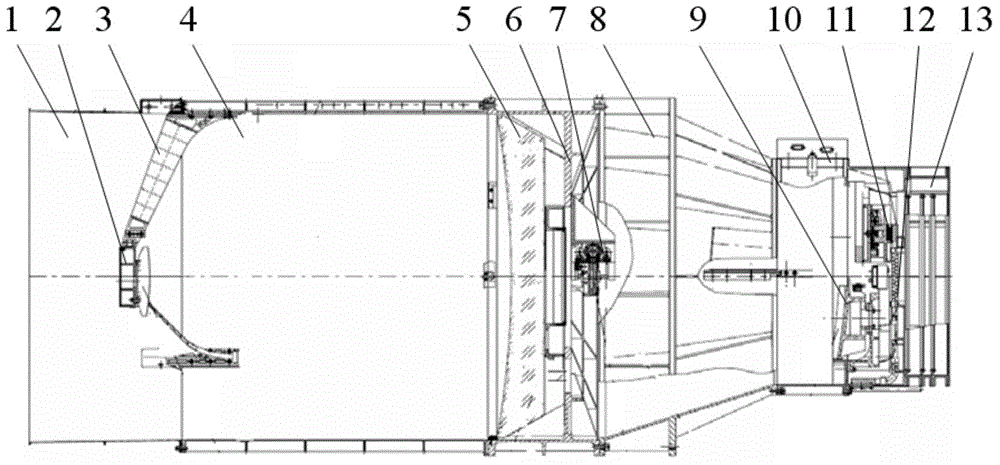

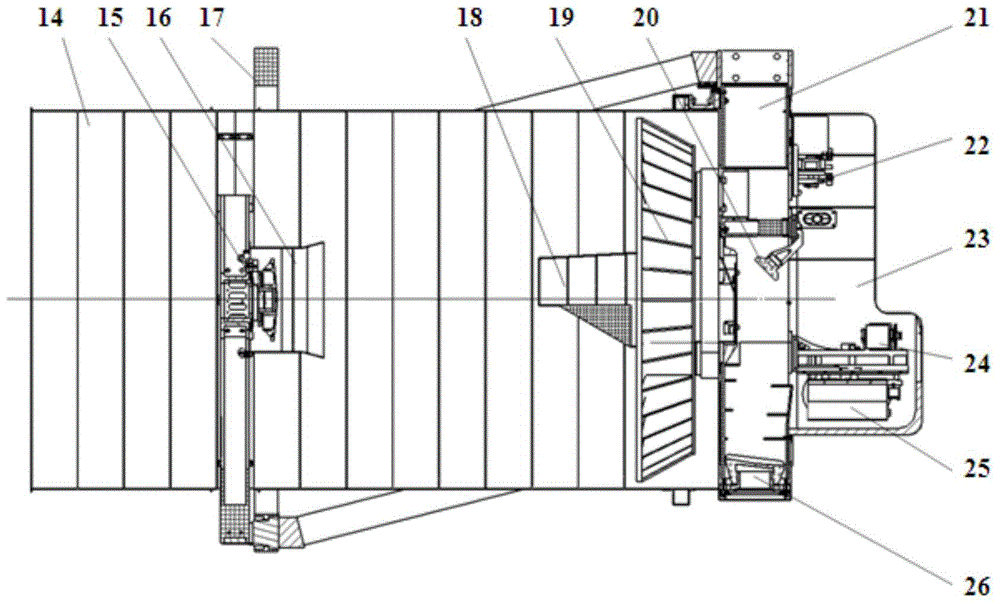

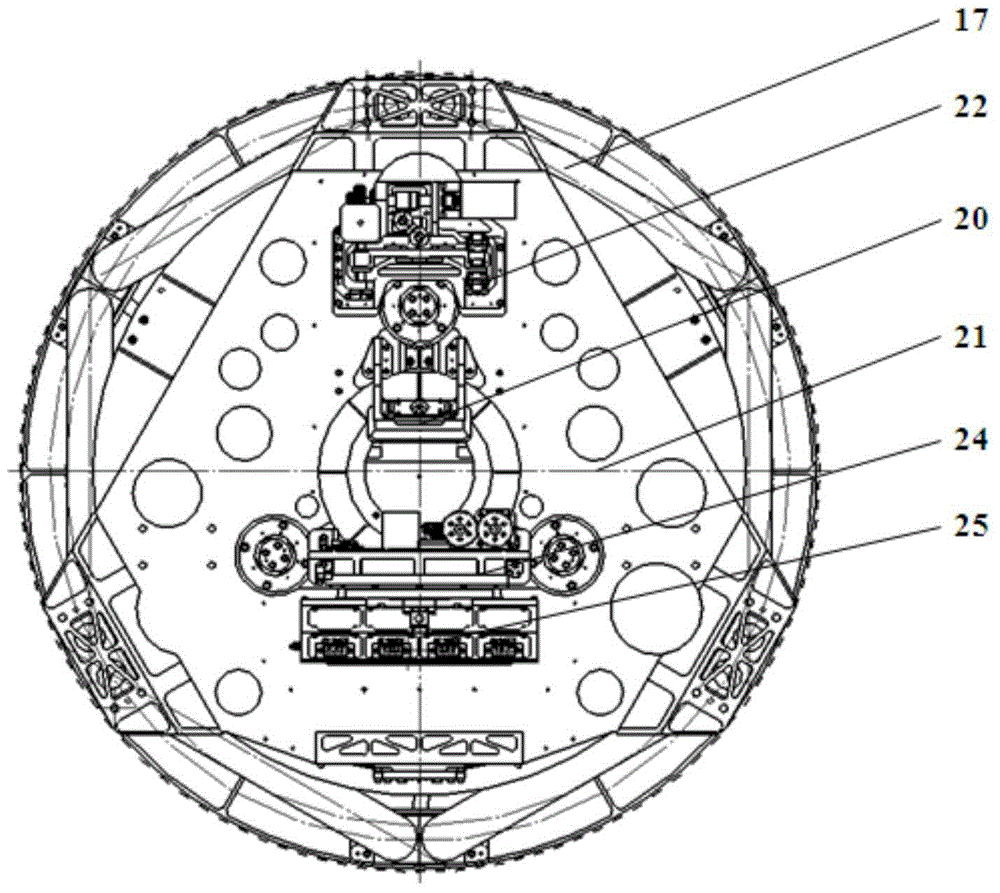

Light coaxial three-reflector spatial optical remote sensor structure

The invention relates to a light coaxial three-reflector spatial optical remote sensor structure. The light coaxial three-reflector spatial optical remote sensor structure comprises a fibre outer light shield component, a silicon carbide secondary lens component, a carbon fibre secondary lens light shield component, a carbon fibre truss component, a carbon fibre main lens light shield component, a silicon carbide main lens component, a folding lens component, a carbon fibre main back panel component, a focusing mechanism, a carbon fibre rear cover component, a bias current adjusting mechanism, a focal surface component and a silicon carbide ternary lens component. By utilizing the light coaxial three-reflector spatial optical remote sensor structure, the problems of heavy weight, low inherent frequency, poor mechanical and thermal stability and the like in the prior art are solved; the resolution of the spatial optical remote sensor can be improved to the international first-class level, and technical support is provided for acquiring high-quality images.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Silicon-containing heat-resistant rare earth magnesium alloy and preparation method thereof

The invention discloses a silicon-containing heat-resistant rare earth magnesium alloy and a preparation method thereof, wherein the alloy comprises the following components by weight percentage: 5-10% of Gd, 2-8% of Y, 0.3-2% of Si, 0.35-0.8% of Zr, 1-13% of Gd+Y1, less than 0.02% of impurities and the balance of magnesium. The invention also relates to a preparation method of the silicon-containing heat-resistant rare earth magnesium alloy; and the method comprises the steps of raw material preheating, smelting and subsequent heat treatment, wherein the smelting is carried out under protection of the mixed gases of SF6 and CO2; and the subsequent heat treatment comprises solid-solution treatment and aging treatment on the silicon-containing heat-resistant rare earth magnesium alloy. The preparation method of the silicon-containing heat-resistant rare earth magnesium alloy is simple in process, low in content of rare earth, and capable of guaranteeing excellent plasticity while improving the strength of the alloy; and a high-strength high-tenacity heat-resistant wearable magnesium alloy can be obtained by adjusting the constituents of the alloy and the heat treatment process; besides, the obtained magnesium alloy can be applied to a plurality of fields of automobile, aerospace, war industry and the like, and thereby is capable of meeting the requirements of a plurality of application occasions.

Owner:SHANGHAI JIAO TONG UNIV

Aluminum base carbon fiber graphite composite material and preparation method

The invention relates to an aluminum base composite material, in particular to an aluminum base carbon fiber graphite composite material and a preparation method. The method comprises the following steps of: firstly, adopting finely sorted, processed and checked graphite fluoride powder as raw materials for preparing spherical graphite particles through granulation and spheroidization; then, using a stainless steel plate as a cathode and pure aluminum as an anode, filling insert gas between the two electrodes, exerting voltage, soaking the spherical graphite particles by glucose amide containing 0.23 to 0.6 percent of boron, cleaning and baking the spherical graphite particles, placing the spherical graphite particles on a disc between the cathode and the anode, shaking the disc while exerting the voltage, and arranging latticed high-performance carbon fiber in a casting mold at the arrangement density determined according to the intensity requirement of the materials; filling the spherical graphite particles with the diameter between 1 and 5mm in the casting mold, finally, injecting aluminum liquid, applying pressure at the upper part of the mold so that the aluminum liquid can be filled between the spherical graphite particles, and obtaining products after cooling. The composite material is simple to prepare, and has the advantages of high product intensity, light weight, wear resistance, low raw material consumption and high production efficiency.

Owner:蔡乐勤

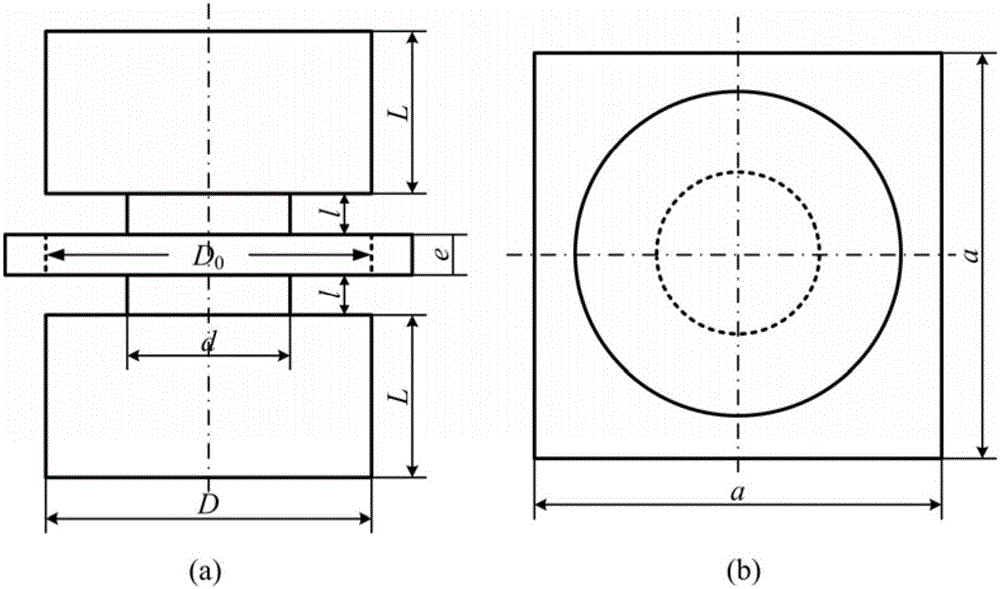

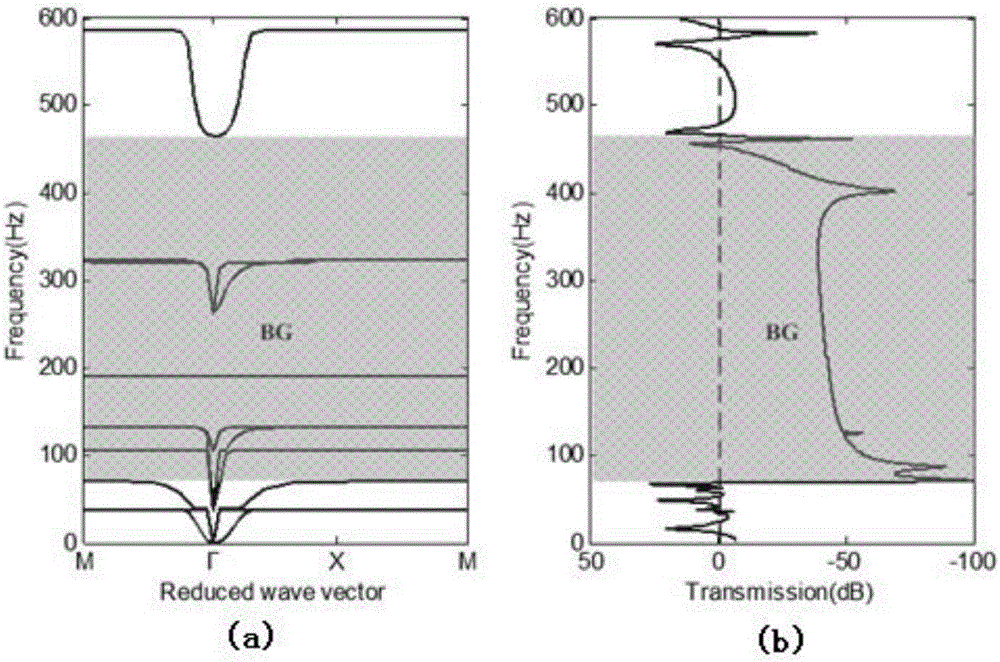

Metal-based foam-filling low-frequency broad-band-gap elastic metamaterial

InactiveCN106205586AAchieve low frequency bandgapGuaranteed StrengthSound producing devicesNoise controlMetallic materials

The invention relates to a metal-based foam-filling low-frequency broad-band-gap elastic metamaterial. The elastic metamaterial adopts a metal material as a matrix sheet material. Multiple round holes are arranged in the matrix sheet material in an array manner. Each round hole is filled with a foamed aluminium material to form a filling unit. Each filling unit is adhered to a local resonance unit. Each local resonance unit comprises two pairs of cylinders which are symmetrically arranged at two edges of the filling unit and are on the same straight line with the center of circle and the filling unit. The elastic metamaterial meets requirements for structural intensity and rigidity. A theoretical model of a prepared test piece has three complete band gaps in a low frequency range of below 500Hz and has a curved vibration band gap with the width of 400Hz. The lower boundary of the band gap is 66Hz. The metamaterial can be used for achieving low frequency broadband vibration noise control of a naval ship structure, and is significant for application of the elastic metamaterial in engineering vibration damping and noise reduction and naval ship acoustic stealth.

Owner:WUHAN UNIV OF TECH

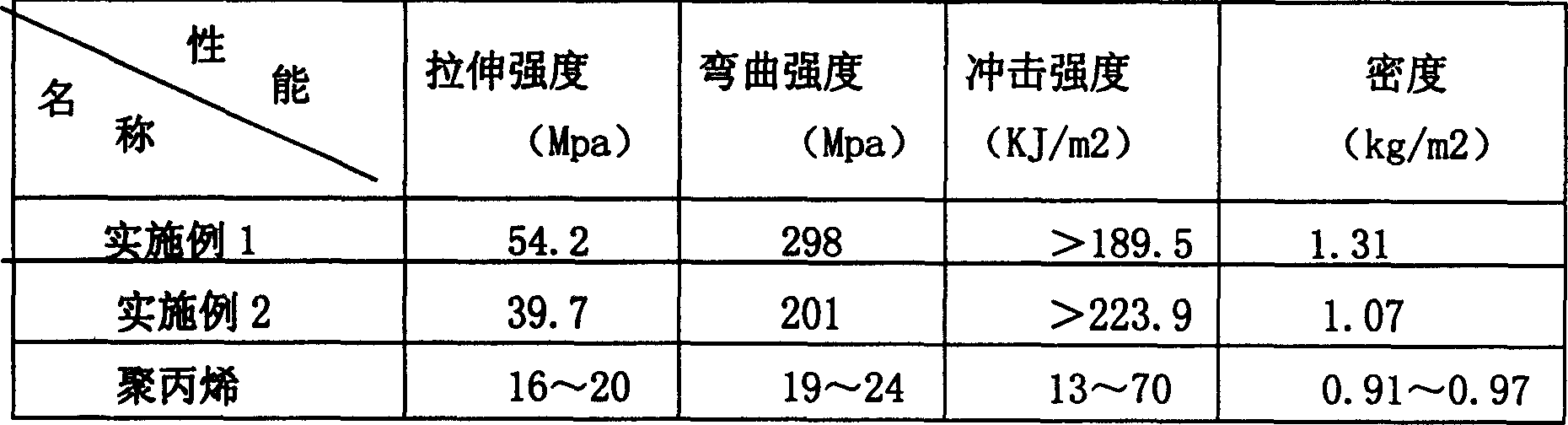

Foamed aluminium / PC resin / aluminum alloy laminate composite material and preparation method thereof

The present invention relates to collision-proof safety material, and is especially composite laminated foamed aluminum / resin / aluminum alloy material and its preparation process. The composite material is used in automobile bumper, casing and other parts. The composite material is prepared with type-LY12 aluminum alloy plate and foamed aluminum in the thick ratio of 1 to 3-5 as well as filled PC resin and through hot pressing curing process. The present invention has excellent impact performance, no technological problem of painting on the surface of aluminum alloy, simple technological process, small density, high specific strength, high specific rigidity, high performance / cost ratio and flexible performance design.

Owner:JIANGSU UNIV

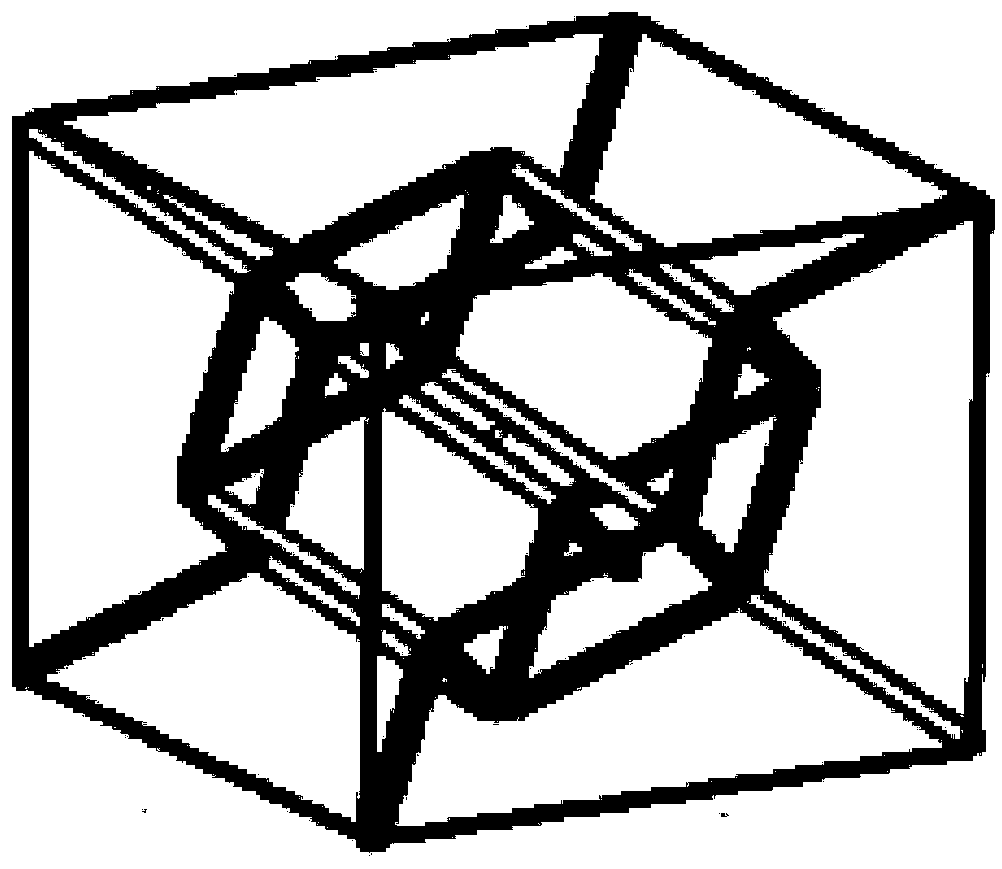

Airspace engine heat exchange component and preparation method thereof

InactiveCN109489467ALarge specific surface areaHigh specific stiffnessAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyComputer module

The invention relates to an airspace engine heat exchange component and a preparation method thereof, belongs to the technical field of airspace engine design and metal additive manufacturing, and particularly relates to a design and manufacturing method of the airspace engine heat exchange component. The design and manufacturing method comprises the following steps of: establishing a heat exchange component shell model without a heat exchange module; establishing a three-dimensional lattice heat exchange module model; assembling and combining the heat exchange component shell and the three-dimensional lattice heat exchange module to form a complete model of the heat exchange component; and designing the heat exchange module of the airspace engine heat exchange component as a three-dimensional lattice structure, and integrally manufacturing the heat exchange component by adopting the metal additive manufacturing method. The heat exchange performance and the manufacturing quality reliability of the heat exchange component are improved.

Owner:XIAN SPACE ENGINE CO LTD

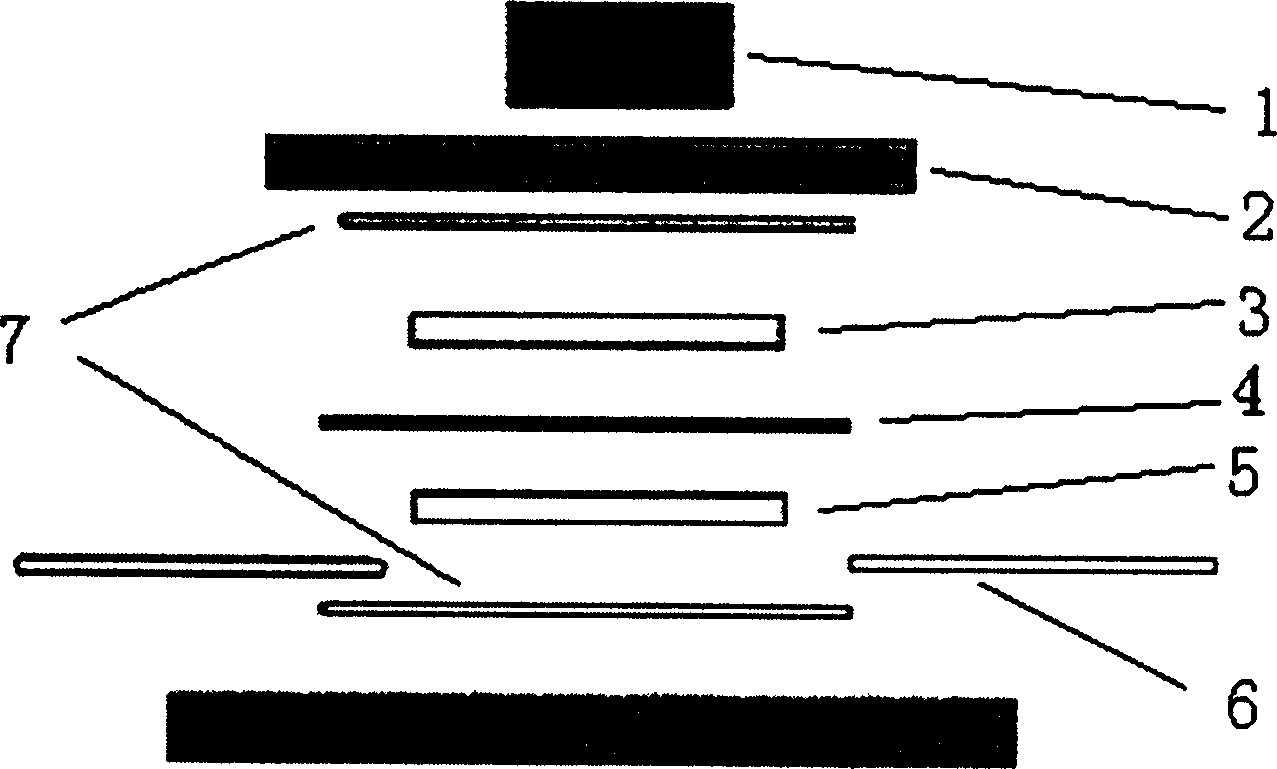

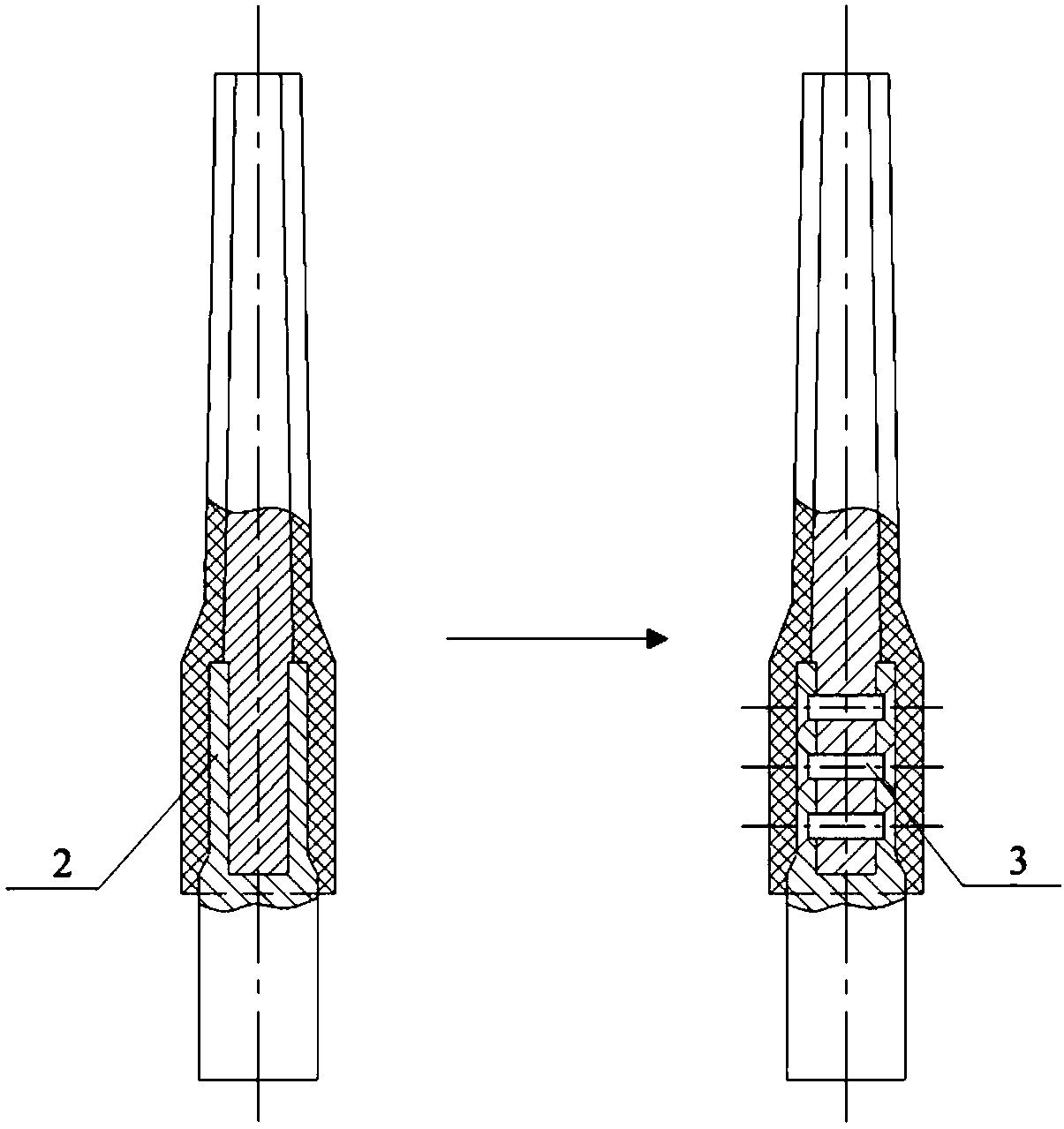

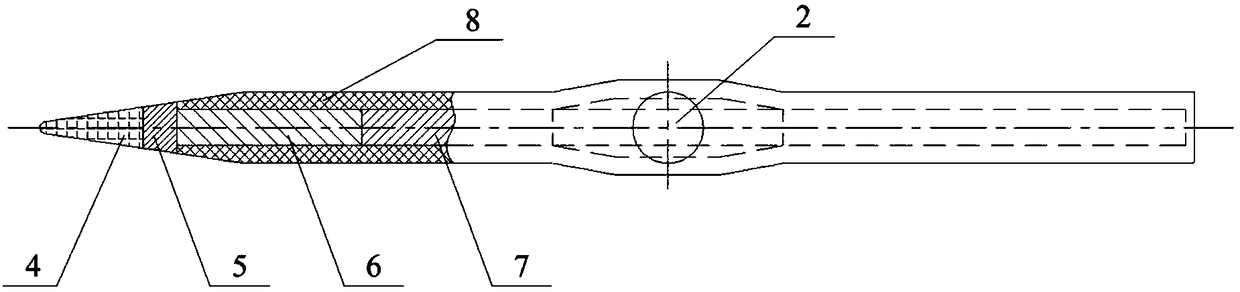

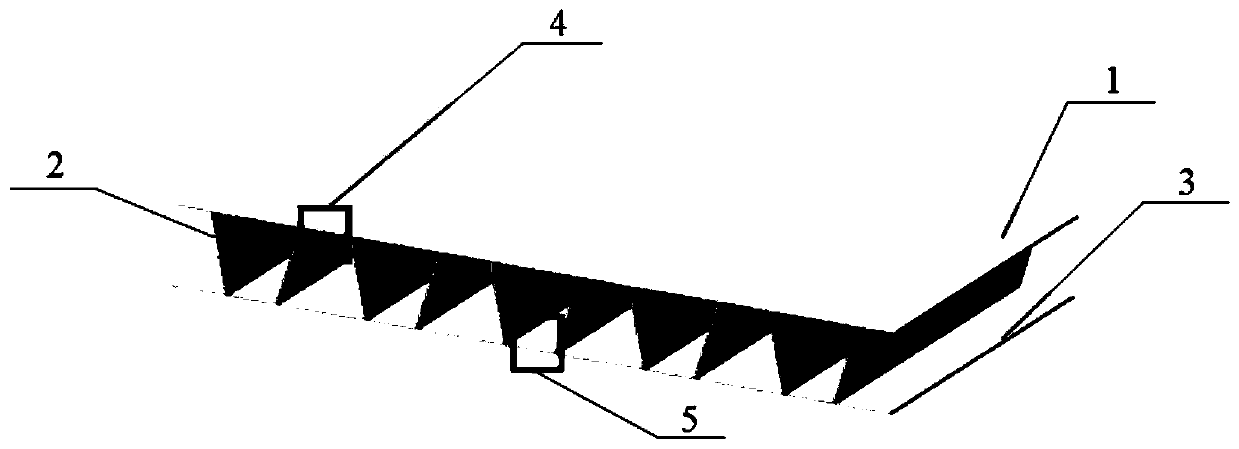

Air steering for a composite structure-

The invention provides an air rudder with a composite structure, which comprises a rudder surface (1) and a rudder shaft (2), wherein the rudder surface (1) and the rudder shaft (2) are connected witheach other through a fastener (3); Wherein the rudder surface (1) comprises a leading edge (4), a rudder core and a heat shield sleeve (8), the rudder core comprises a transition structure, a main structure (7), the transition structure comprises a transition strip (5) and an intermediate (6); The leading edge (4), the transition strip (5), the intermediate body (6) and the main body structure (7) are connected in turn, and the rudder surface (1) is connected with the rudder shaft (2) through the main body structure (7), wherein the intermediate body (6), the main body structure (7) are coated with a heat shield (8), the leading edge (4), the transition strip (5) and the heat shield (8) together constitute the aerodynamic shape of the air rudder. The invention has reasonable structure, adopts a plurality of low-density composite materials, and ensures the structural integrity and reliability of the air rudder under the condition of high-speed and large heat flux flight.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

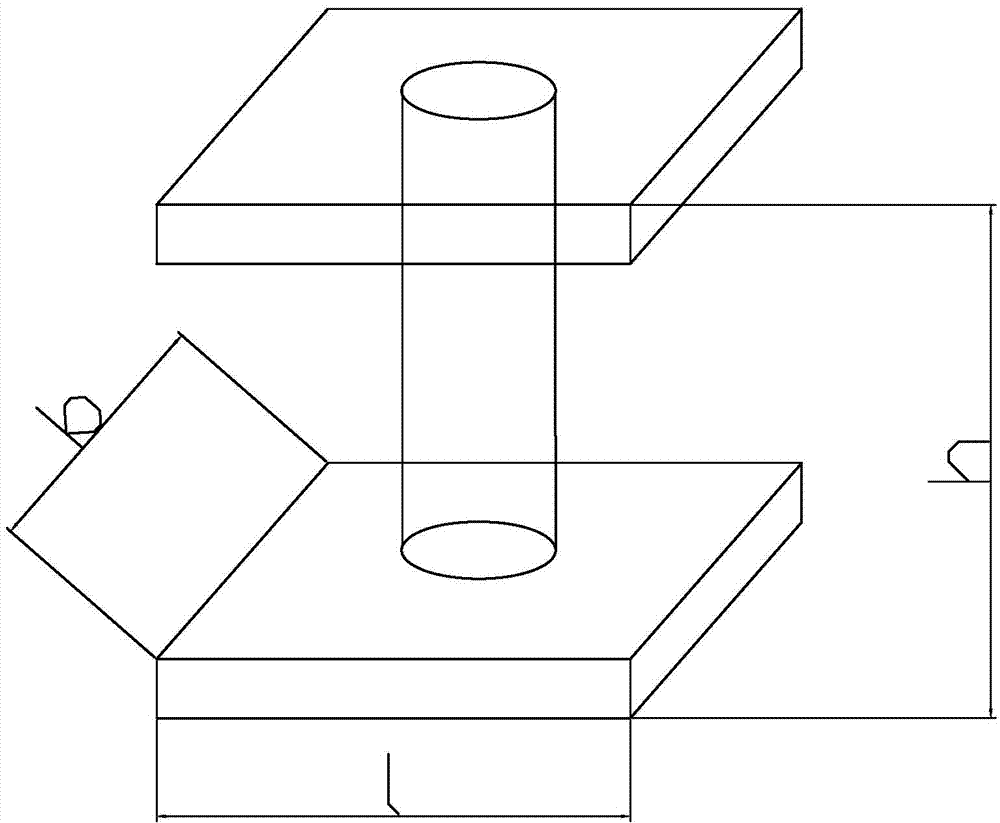

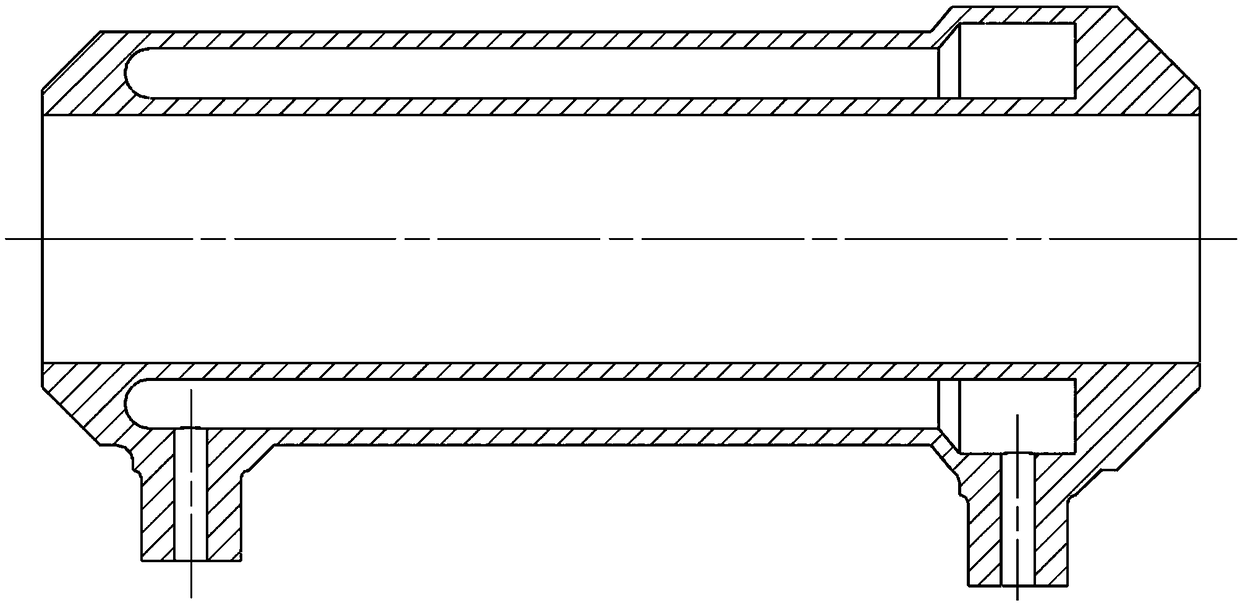

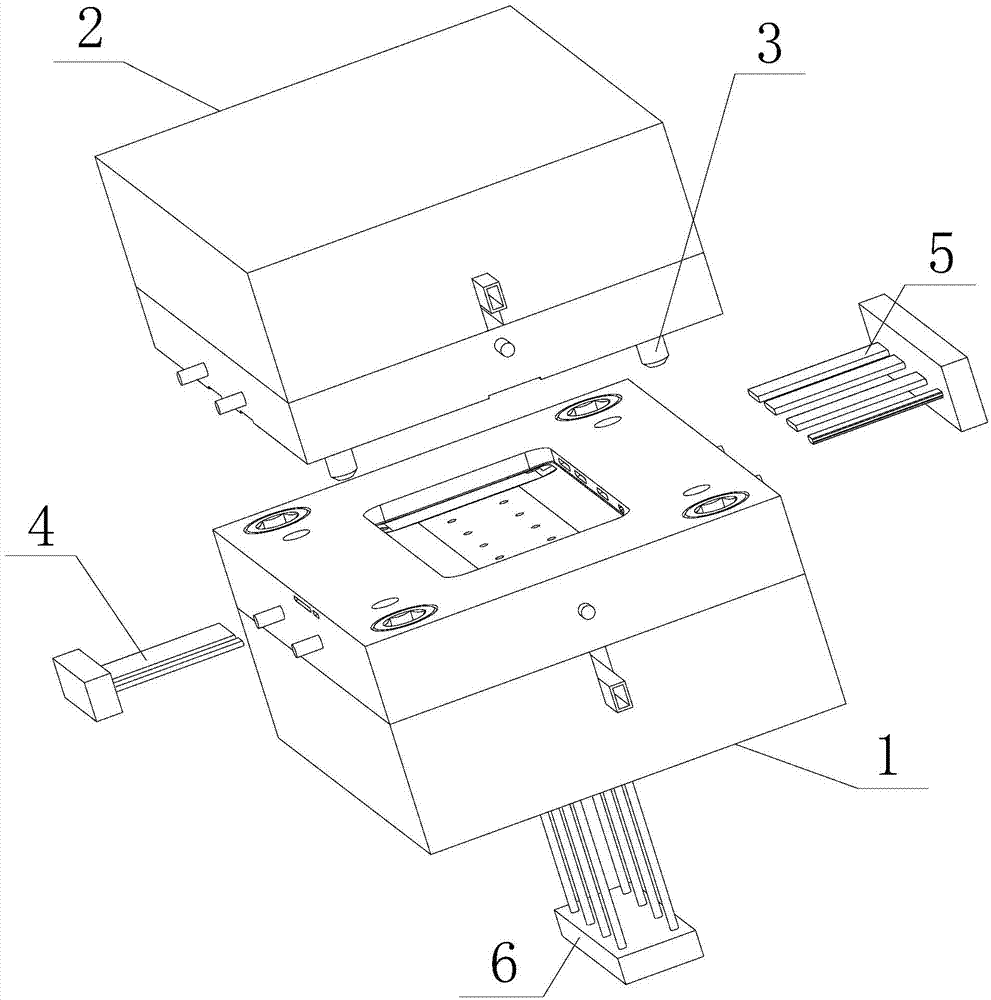

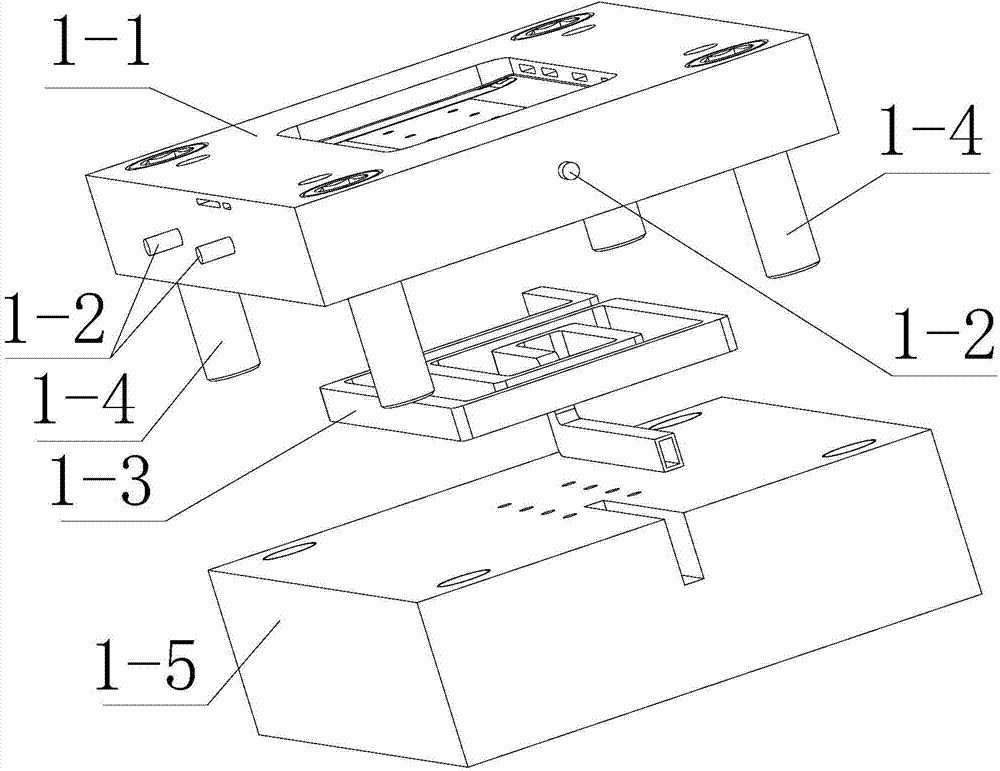

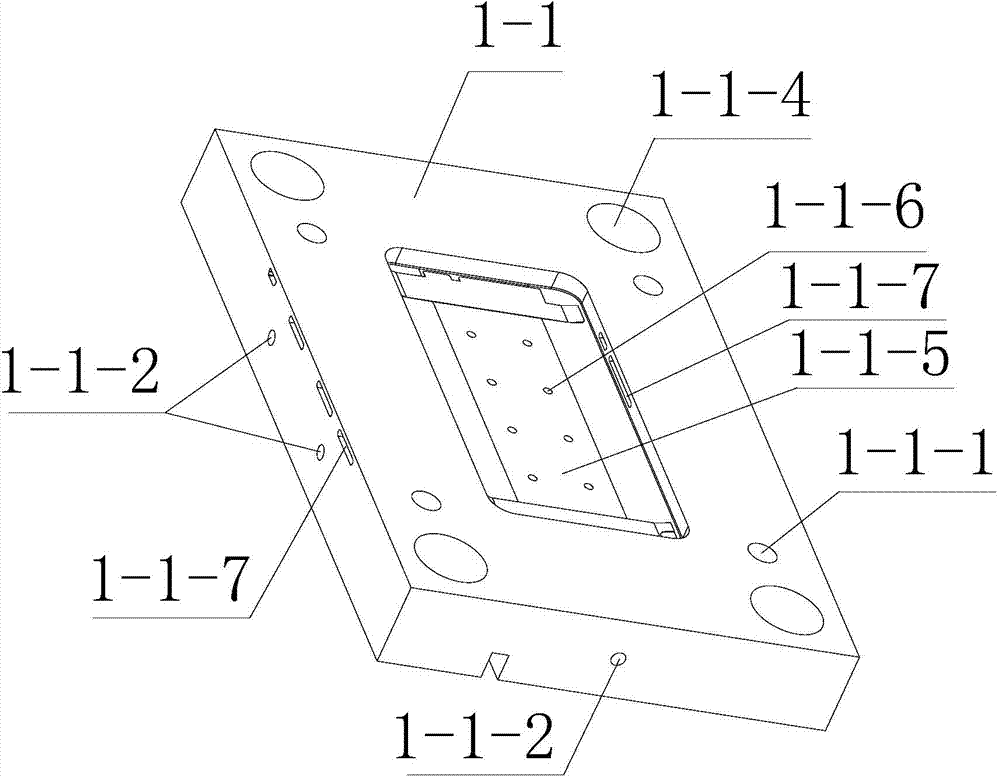

Strain-induced semi-solid forming process and die for magnalium mobile phone shells

InactiveCN104493429AHigh specific strengthGood machinabilityExtrusion diesAgricultural engineeringSemi solid

Disclosed is a strain-induced semi-solid forming process and die for magnalium mobile phone shells. The process includes cutting a magnalium plate with certain compressive deformation into the suitable size, performing semi-solid heat preservation on the cut magnalium plate, and then putting the obtained magnalium plate with semi-solid characteristics into the preheated die for extrusion forming. The die comprises a mobile phone shell bottom cavity die device, the upper side of the mobile phone shell bottom cavity die device is connected with a mobile phone shell top terrace die device, die guide rods are assembled on the mobile phone shell top terrace die device, a left mobile phone shell core-pulling slider is connected to the left of the mobile phone shell bottom cavity die device, a right mobile phone shell core-pulling slider is connected to the right of the mobile phone shell bottom cavity die device, and mobile phone shell ejection mechanism is connected to the lower side of the same. The magnalium mobile phone shells with superior performance can be produced, and the process and the die have the advantages of simple process, high forming speed, low cost and the like.

Owner:XI AN JIAOTONG UNIV

Hybrid propulsion cabin of small high-orbit satellite public platform

ActiveCN111891393ALow center of massEfficient force transmission characteristicsCosmonautic propulsion system apparatusArtificial satellitesHybrid propulsionRocket

The invention provides a hybrid propulsion cabin of a small high-orbit satellite common platform. The hybrid propulsion cabin comprises a platform cabin main force-bearing structure configured to provide an accommodating space, wherein the platform cabin main force-bearing structure comprises a satellite-rocket connecting ring; a plurality of storage tanks which are arranged in the accommodating space and are directly loaded on the satellite-rocket connecting ring; and an air path assembly which is arranged in the accommodating space so that the load of the air path assembly is transmitted tothe satellite-rocket connecting ring through the platform cabin main force bearing structure.

Owner:上海中科辰新卫星技术有限公司

Production of polyester elastic microfoaming board

The invention is concerned with the manufacture method of polyester elastomeric foaming plate that is with damping action, the characteristics is: the polyester elastomer is as the material, uses the microcapsule vesicant or the microcapsule vesicant mother grain to make the foaming plate by the extruder and the mould forming.

Owner:江苏联冠科技发展有限公司

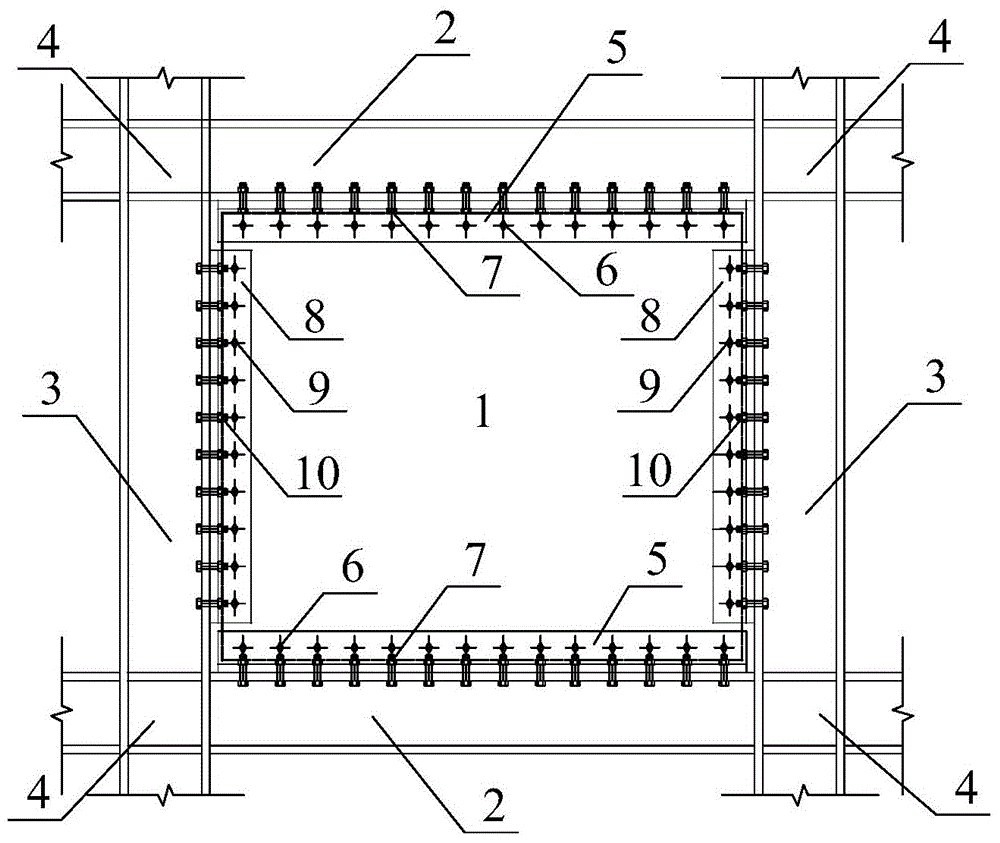

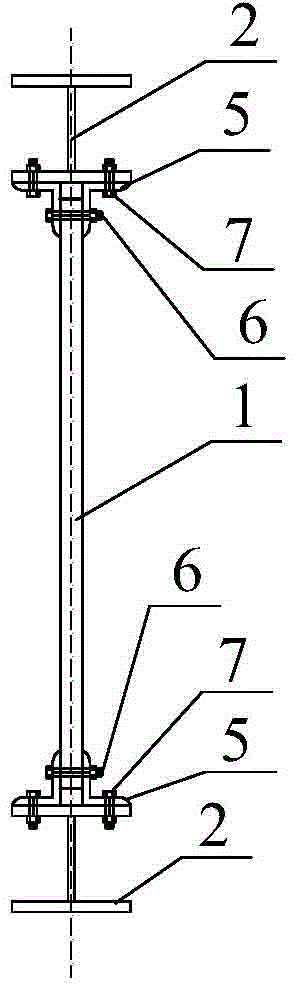

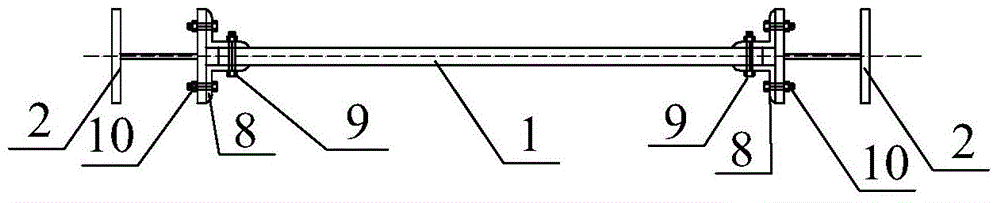

Foam steel board shear wall structure

The invention discloses a foam steel board shear wall structure. The foam steel board shear wall structure comprises steel beams and steel columns, wherein the steel beams and the steel columns are connected through beam column joints; foam steel boards are installed between the adjacent steel beams and the adjacent steel columns to form a shear wall steel board; the two sides of the foam steel boards are connected with the steel beams through horizontal angle iron; the two sides of the foam steel boards are connected with the steel columns through vertical angle iron; the foam steel boards and the horizontal angle steel are fastened and connected through transversely distributed vertical bolts; the horizontal angle steel and the steel beams are connected through transversely distributed parallel bolts; the foam steel boards and the vertical angle steel are connected through vertically distributed perpendicular bolts; the vertical angle steel and the steel columns are connected through vertically distributed parallel bolts. The foam steel board shear wall structure can overcome the defects of an ordinary steel board shear wall, can be prevented from buckling failure, and has the advantages of being large in lateral rigidity, good in anti-seismic property, high in ductility, full in energy consumption hysteresis hoop and the like.

Owner:ZHEJIANG UNIV

Manufacture method of titanium or titanium alloy laryngotracheal interventional stent

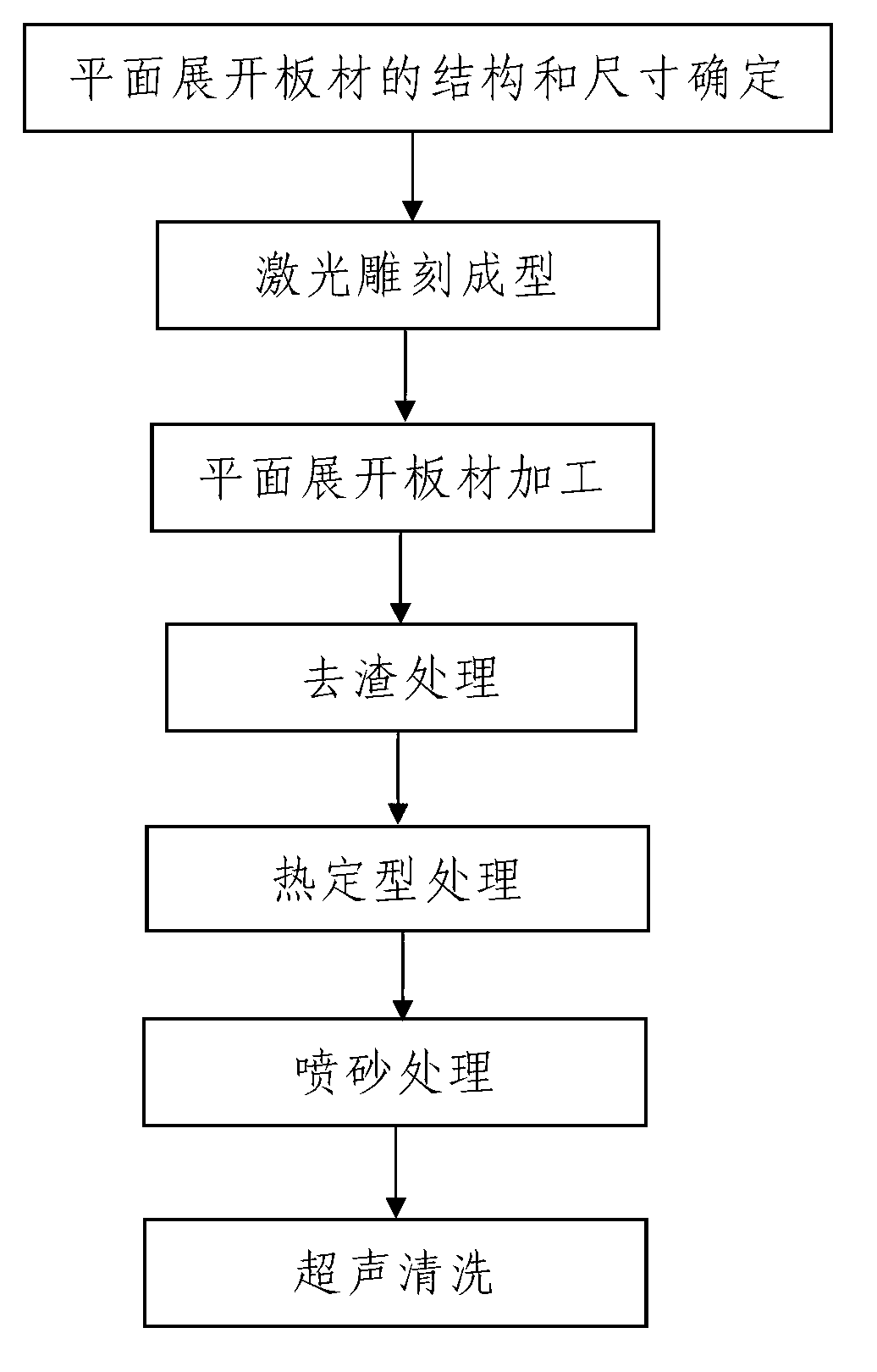

ActiveCN102988119AHigh dimensional accuracyThe preparation method is simple and easyTubular organ implantsTitanium alloyMechanical property

The invention discloses a manufacture method of a titanium or titanium alloy laryngotracheal interventional stent, comprising the following steps of: 1, determining the structure and the size of a plane spread plate; 2, forming by means of laser engraving: under the protection of inert gas, carrying out laser engraving on the plate to be treated by a laser engraving machine; 3, machining the plane spread plate; 4, deslagging; 5, carrying out heat setting, wherein the treatment process comprises the following steps of: 501, putting into a mould: putting the deslaged-plane plate into a forming cavity of the pre-machined thermal treatment mould; and 502: thermally treating; 6, blasting sand: blasting sand to the thermally-treated laryngotracheal interventional stent by a sand-blasting machine; and 7, ultrasonically cleaning. The manufacture method disclosed by the invention is simple in process step, reasonable to design, convenient to realize, and good in use effect, the oxidization of the stent in the process of machining can be effectively avoided, and the prepared interventional stent is high in dimensional accuracy and good in mechanical property.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

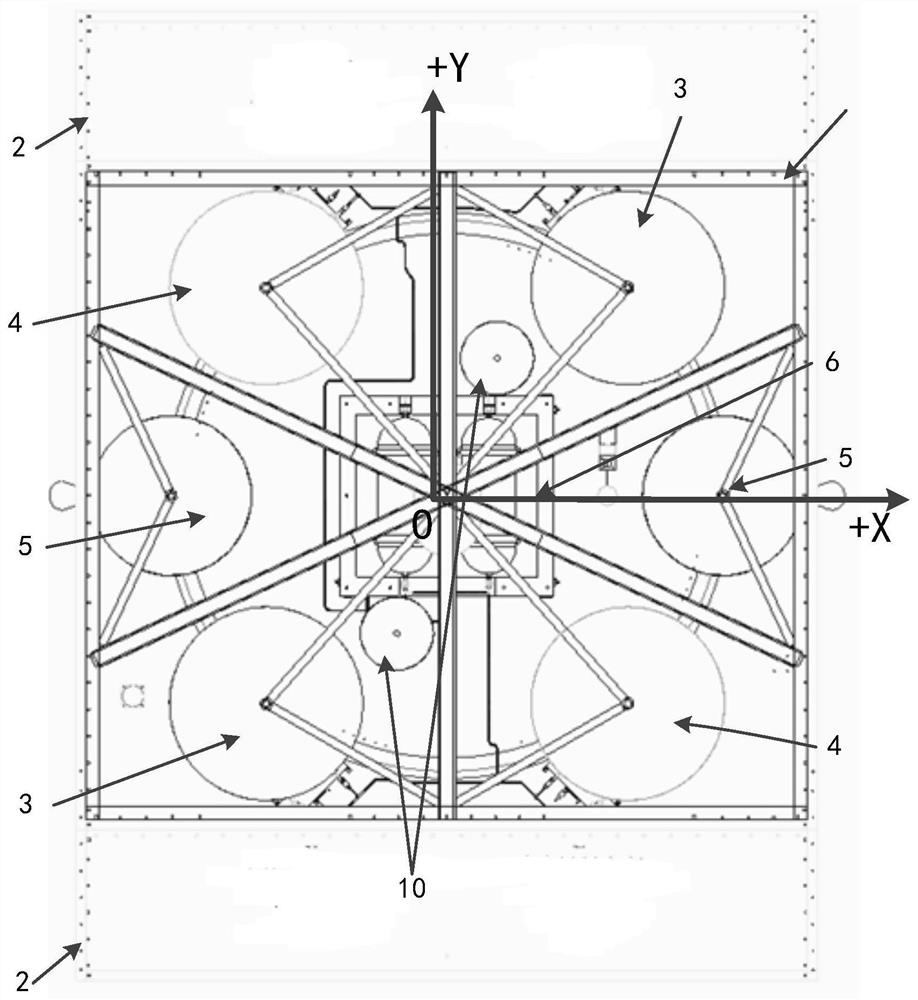

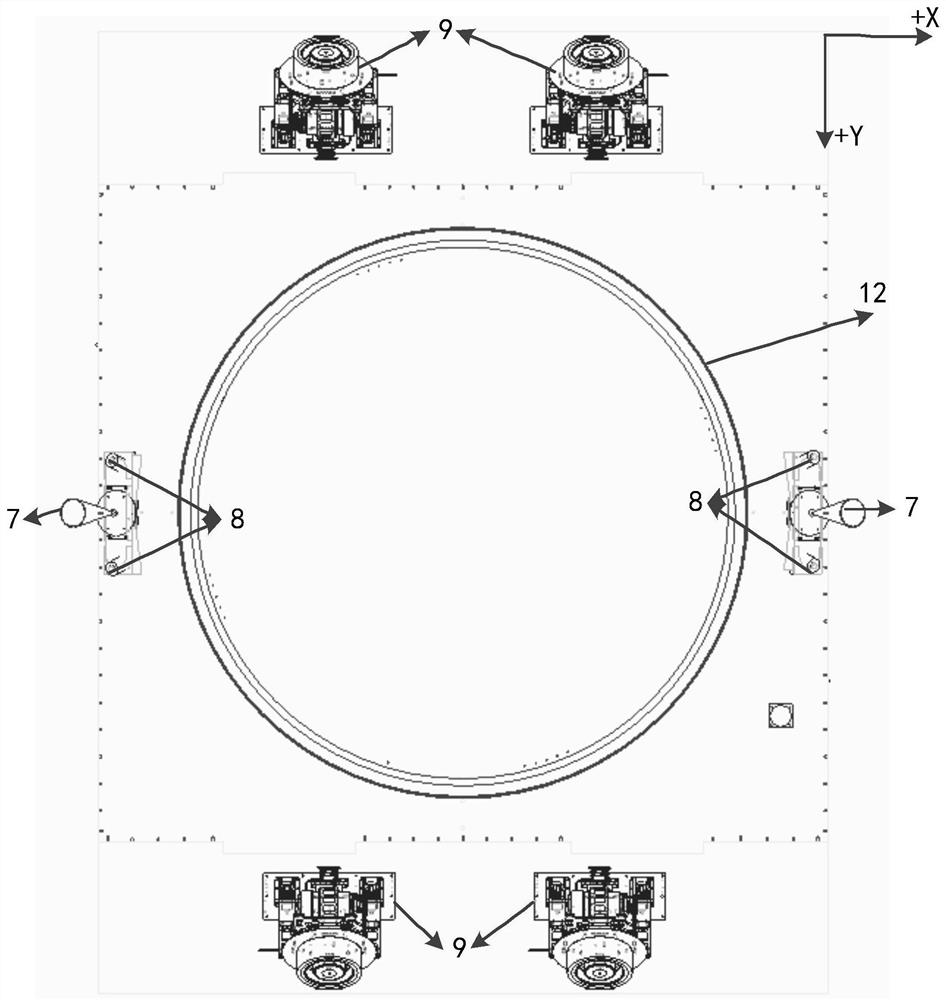

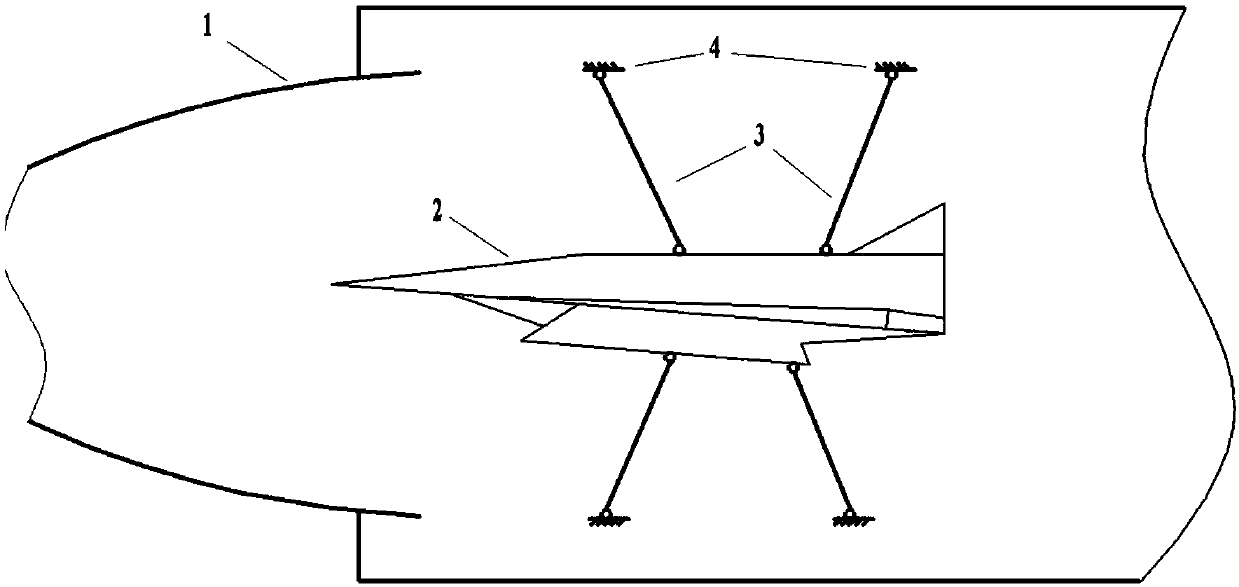

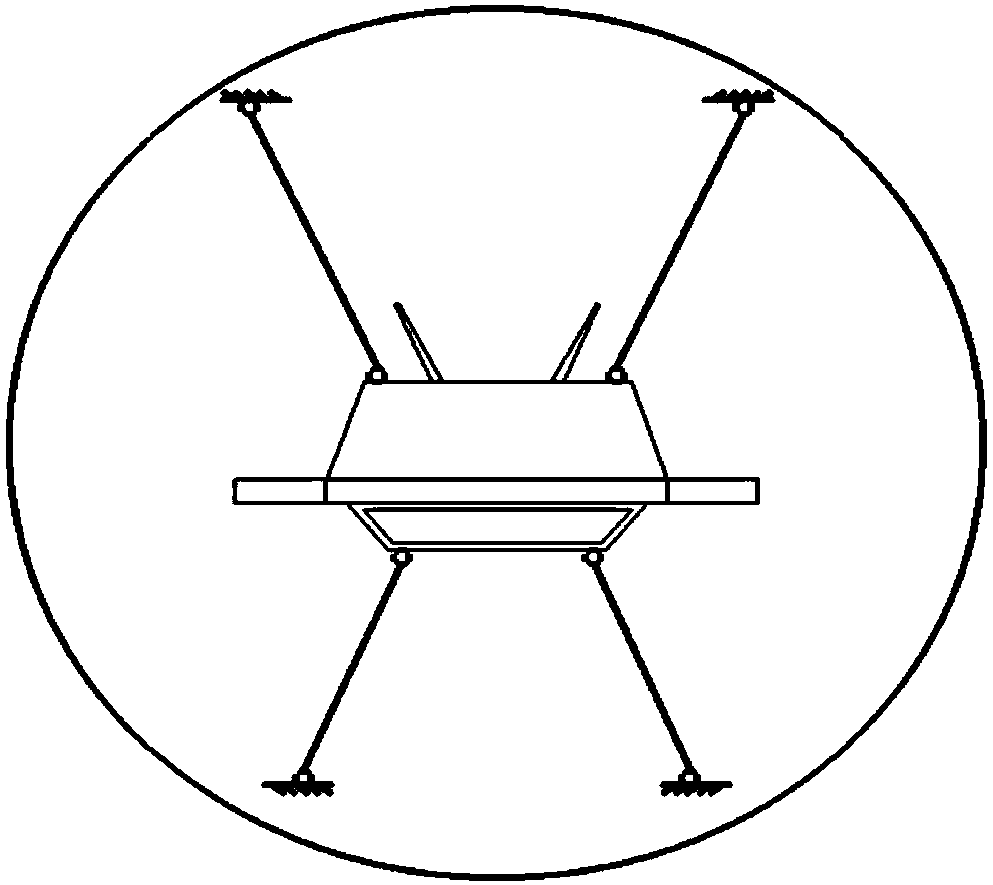

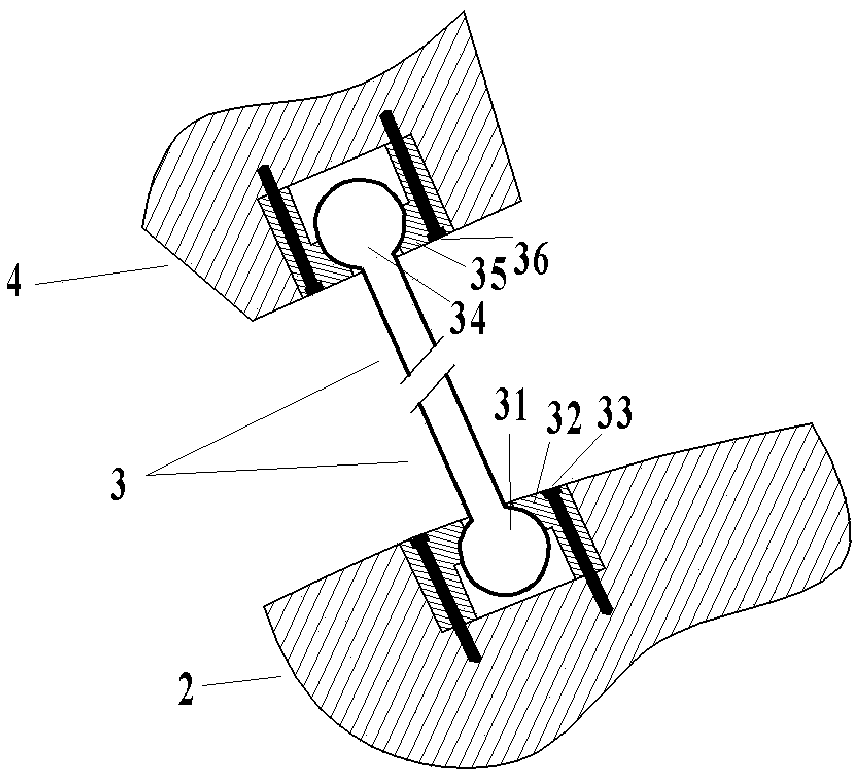

Support method for aircraft model in wind tunnel experiment

The invention discloses a support method for an aircraft model in a wind tunnel experiment. The method includes the following steps: 1) a wind tunnel and an aircraft model in the wind tunnel are connected and fixed through a spatial rod system, and the wind tunnel is not in direct contact with the aircraft model; and 2) according to requirements of experimental measurement and support system design, the diameter, length, number, material and spatial distribution form of support rods in the spatial rod system are adjusted, thereby realizing optimization of rigidity of an aircraft model supportsystem. By adoption of the support method provided by the invention, the support system further adapts to and meets the requirements of wind tunnel experiment content and measurement, thereby achieving the purpose of improving precision and reliability of pneumatic experiment data, and effectively solving the problems of insufficient rigidity, large flow field interference and complicated system internal force of a support system in a traditional support method, and the support method provided by the invention has obvious advantages and potential of innovative development in the aspect of a wind tunnel experiment, particularly in the aspect of a full-size large-model pneumatic experiment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

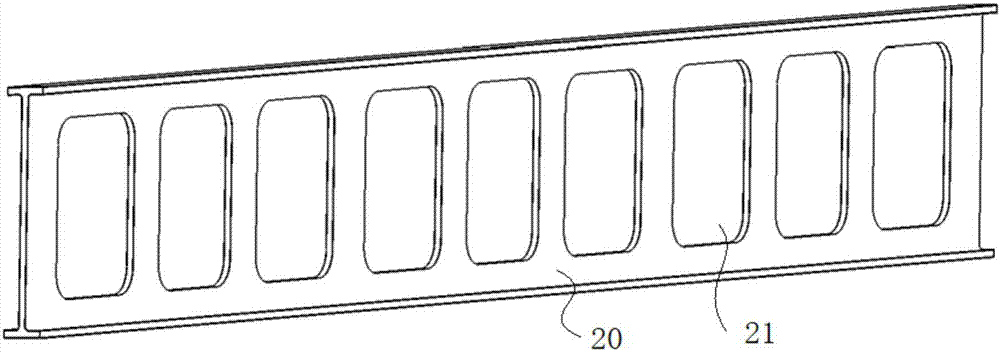

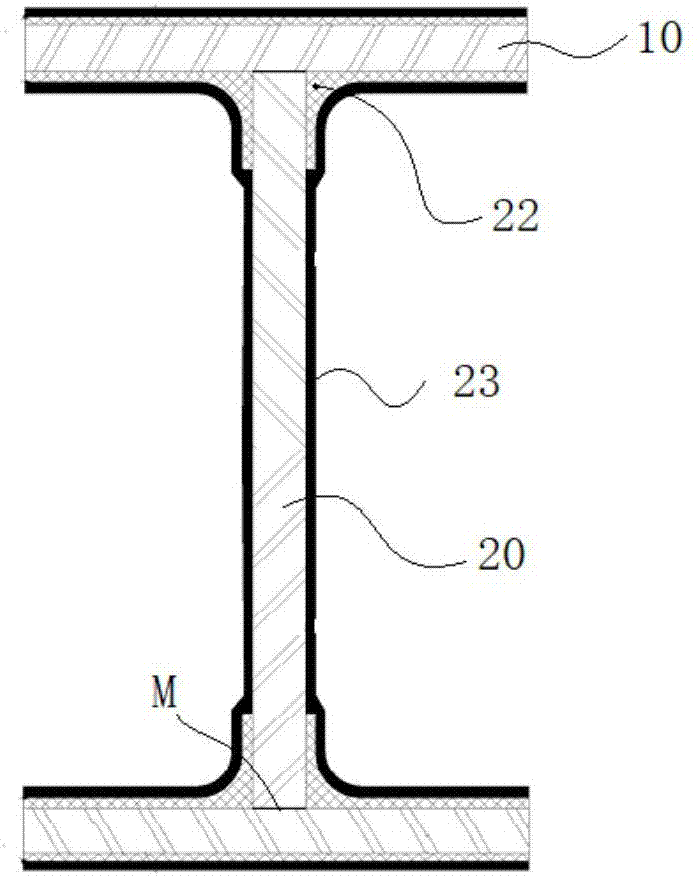

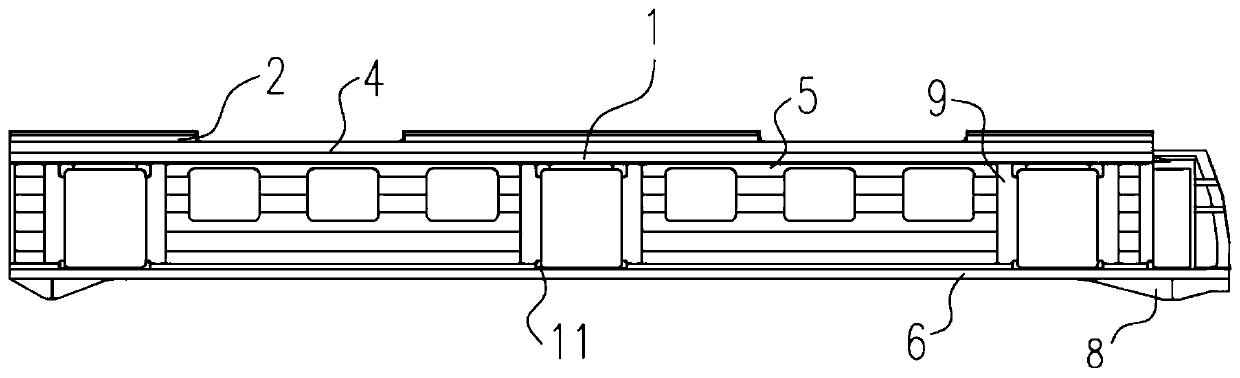

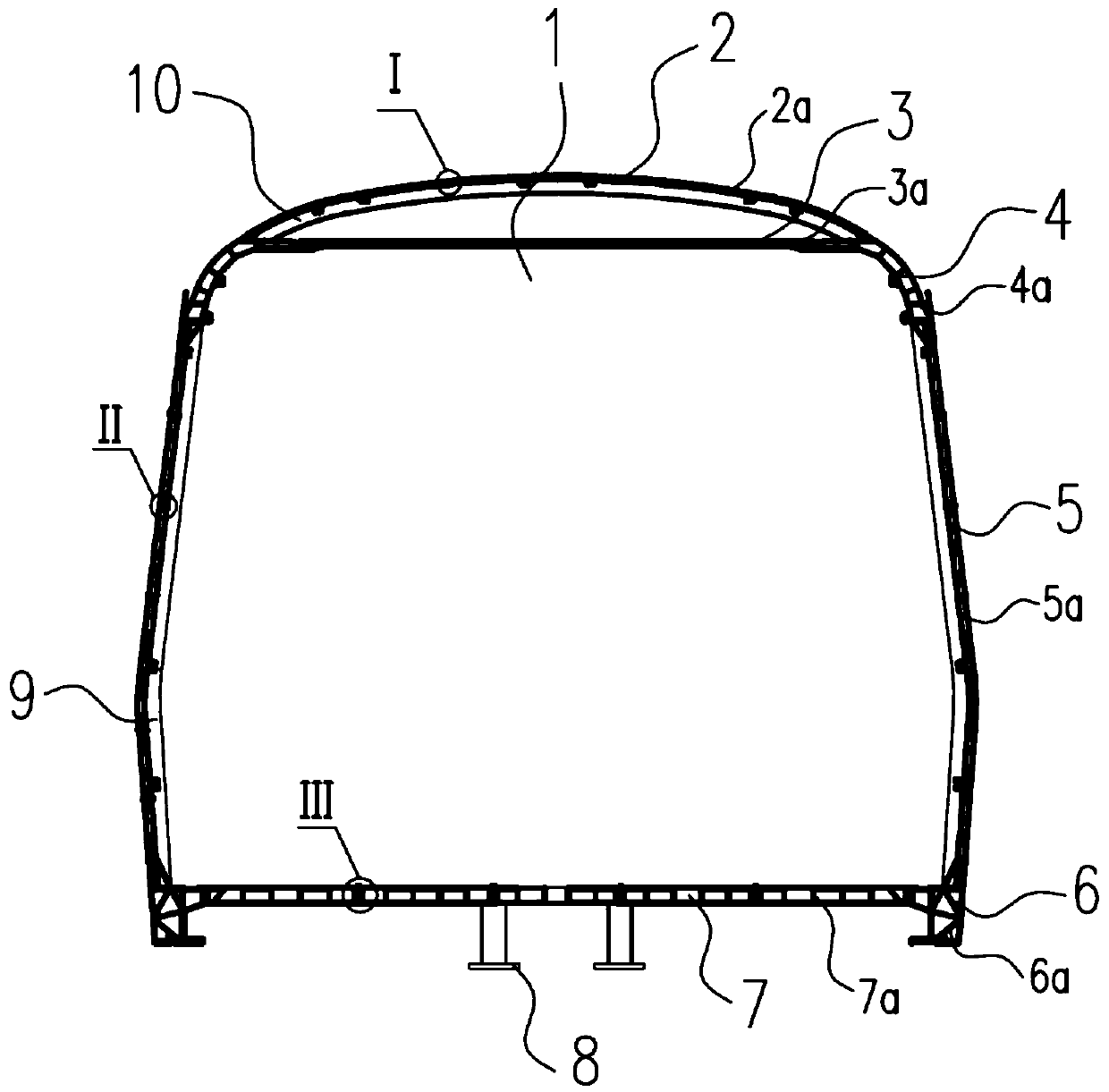

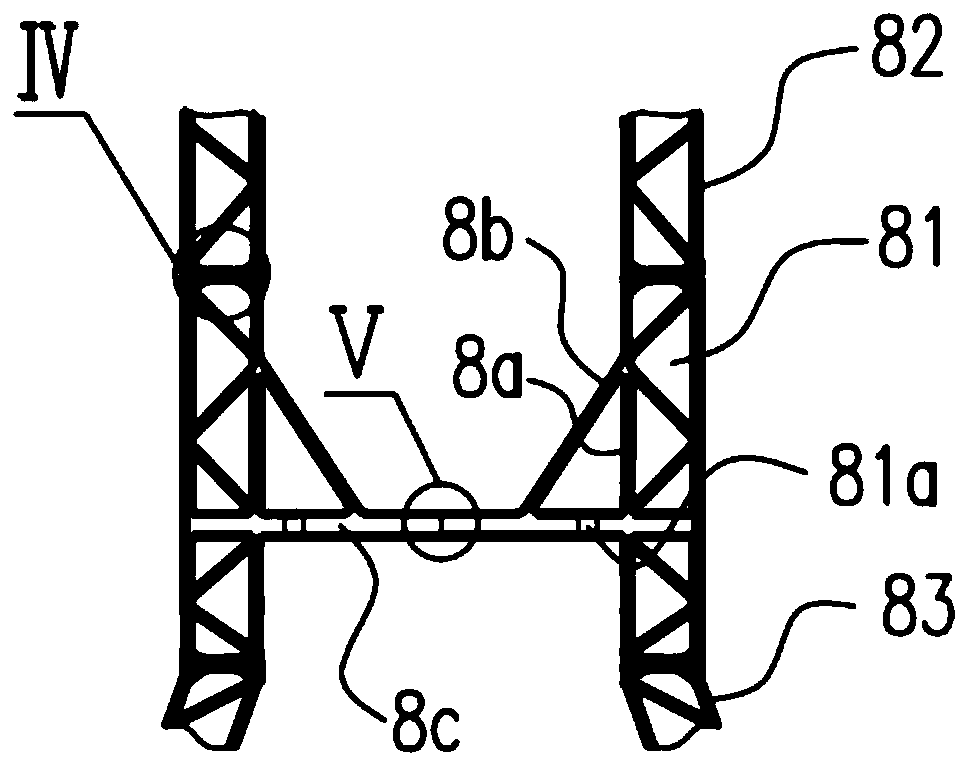

Rail train and train body thereof

ActiveCN109866788AHigh strengthIncrease stiffnessAxle-box lubricationRailway bodiesStrength of materialsEngineering

The invention discloses a rail train and a train body thereof. The train body mainly comprises a box body structure formed by connecting an arc roof profile, an air conditioner plate profile, a side wall plate profile, a bottom frame floor profile, a door vertical column bending profile, a roof camber beam bending profile, an overall door corner, roof side beam profiles and bottom frame side beamprofiles. A pulling buffering structure is mounted at the bottom of the bottom frame floor profile. The roof side beam profiles, the bottom frame side beam profiles, the arc roof profile, the air conditioner plate profile, the side wall plate profile, the bottom frame floor profile and the pulling buffering structure are made of nano-ceramic aluminum alloy materials. The problem that further weight reduction of a traditional aluminum alloy vehicle body is difficult due to the limitation of the strength of materials is solved, and the durability and the reliability are not affected.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

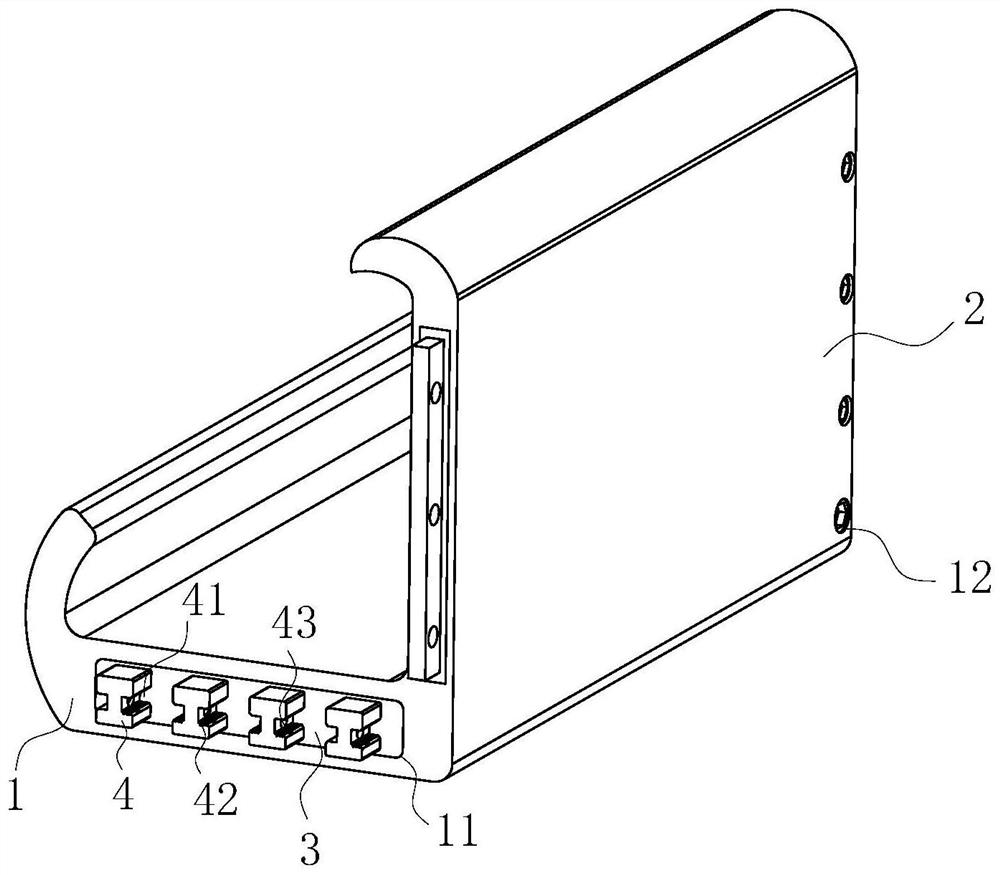

L-shaped edge sealing aluminum profile

ActiveCN111852258AImprove shock absorptionHigh yieldNoise insulation doors/windowsWing framesEngineeringMechanical engineering

Owner:池州市安安新材科技有限公司

Three-dimensional sandwich structure fabric and weaving method thereof

ActiveCN111058142AWide range of sizesImprove connection strengthMulti-ply fabricsAviationEngineering

The invention discloses a three-dimensional sandwich structure fabric and a weaving method thereof. The three-dimensional sandwich structure fabric comprises an upper panel layer formed by interweaving at least one layer of upper layer warp yarns and weft yarns, a lower panel layer formed by interweaving at least one layer of lower layer warp yarns and weft yarns, and a core layer formed by interweaving at least one layer of intermediate layer warp yarns and weft yarns; and the upper panel layer and the lower panel layer are connected with the core layer by layer connection structures, and thefabric is formed by integral continuous weaving. The three-dimensional sandwich structure fabric provided by the invention has the advantages of diversified tissue structures, large fabric size control range, diversified cross-sectional shapes, strong designability, suitability for continuous weaving and the like; and a fabric composite reinforced material has the characteristics of high specificstrength, high specific rigidity, good structural stability, fatigue resistance, vibration resistance, sound and heat insulation and the like, and can be widely applied to the fields of aviation, aerospace, ships, automobiles, buildings and the like.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

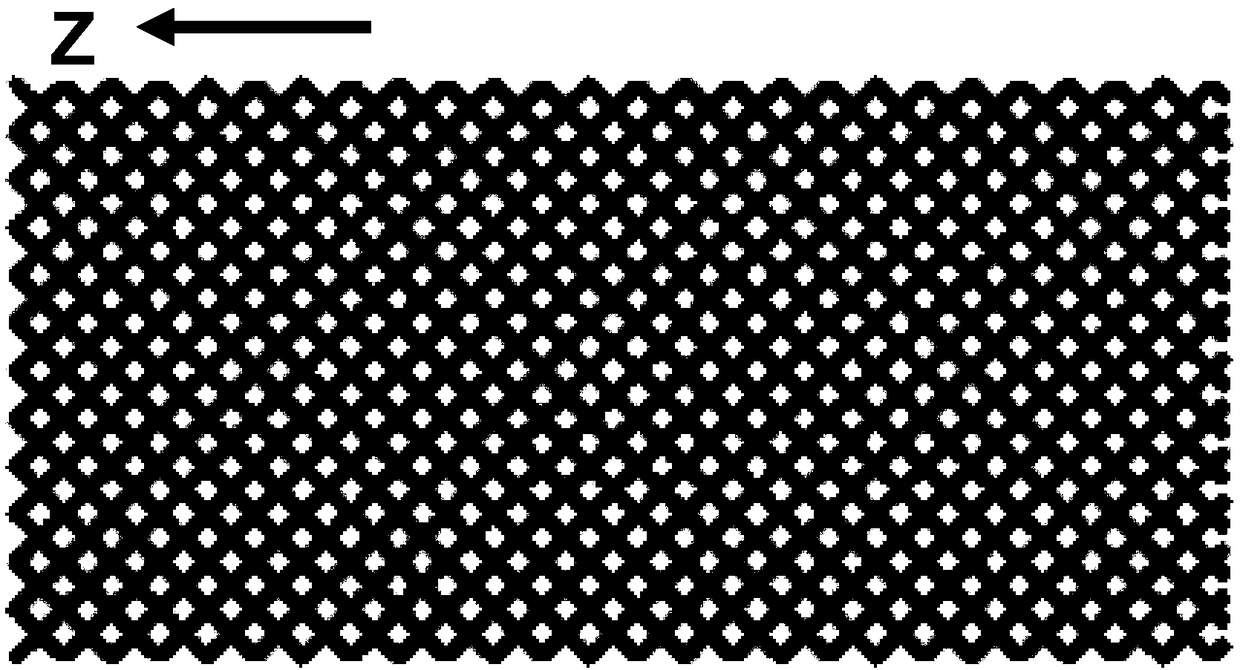

Reinforcing method for bonding interface of MgFe compound casting

ActiveCN108620561AHigh porosityHigh specific strengthAdditive manufacturingIncreasing energy efficiencyCopper platingFe based

The invention discloses a reinforcing method for a bonding interface of an MgFe compound casting. The reinforcing method comprises the following steps: (1) preparing a Fe-based dot matrix material onthe bonding surface of a Fe-based material by adopting a selective laser melting technology; (2) processing the surface of the dot matrix material by adopting a chemical deoiling-pickling and passivating-chemical electroless copper plating process; and (3) fixing the Fe-based material in a cast, pouring a magnesium alloy melt in the cast, and carrying out ultrasonic oscillating treatment in the casting process to achieve firm bonding of Mg and Fe. Different from a conventional plane combining mode, the reinforcing method provided by the invention is high in bonding strength, the bonding interface is unlikely to fall, and firm bonding between Mg and Fe is achieved. In addition, no complicated equipment is needed, and parameters are easily controlled.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com