Detachable type emergency bridge made of composite material

A technology for composite materials and emergency bridges, applied in bridge materials, portable bridges, bridges, etc., can solve the problems of accelerating lightweight high-strength composite materials, heavy equipment, easy to rust, etc., achieve excellent tensile strength, improve erection span, to avoid the effect of easy rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in further detail below in conjunction with accompanying drawing:

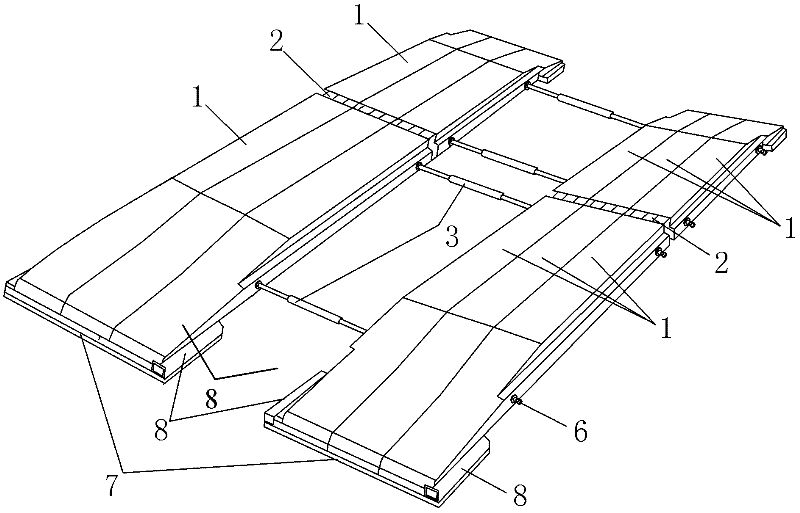

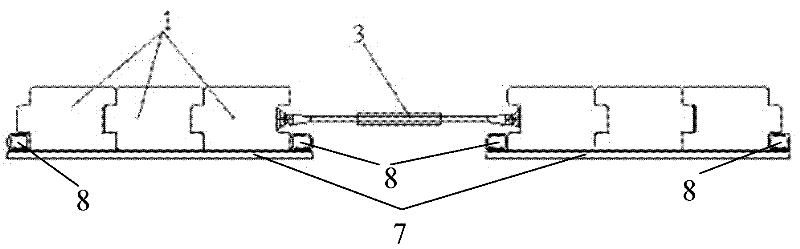

[0025] see figure 2 : this kind of dismountable composite material emergency bridge of the present invention is a rutting type single-span structure, and is formed by splicing bridge sections 1 of some multi-cavity box girder structures, and particularly bridge sections 1 of the present invention adopt resin-based composite materials .

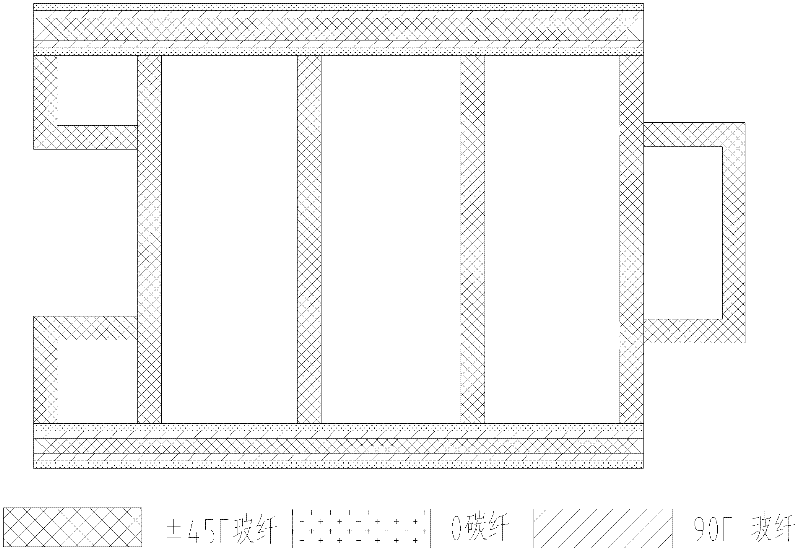

[0026] Such as figure 1 As shown: the bridge section 1 of the present invention adopts epoxy resin-based hybrid fiber reinforced composite material, and the bridge section 1 includes upper and lower panels and several webs in the middle; the middle layers of the upper and lower panels are ±45°E-glass A layer of 90° E-glass fiber is arranged on the upper and lower sides of the middle layer, and a layer of 0° carbon fiber is arranged on the outside of the 90° E-glass fiber; the web is paved with ±45° E-glass fiber composite material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com