Metal-based foam-filling low-frequency broad-band-gap elastic metamaterial

A foam-filled, metamaterial technology, applied in the direction of sounding equipment, instruments, etc., can solve the problems of insufficient mechanical strength, poor strength and stiffness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

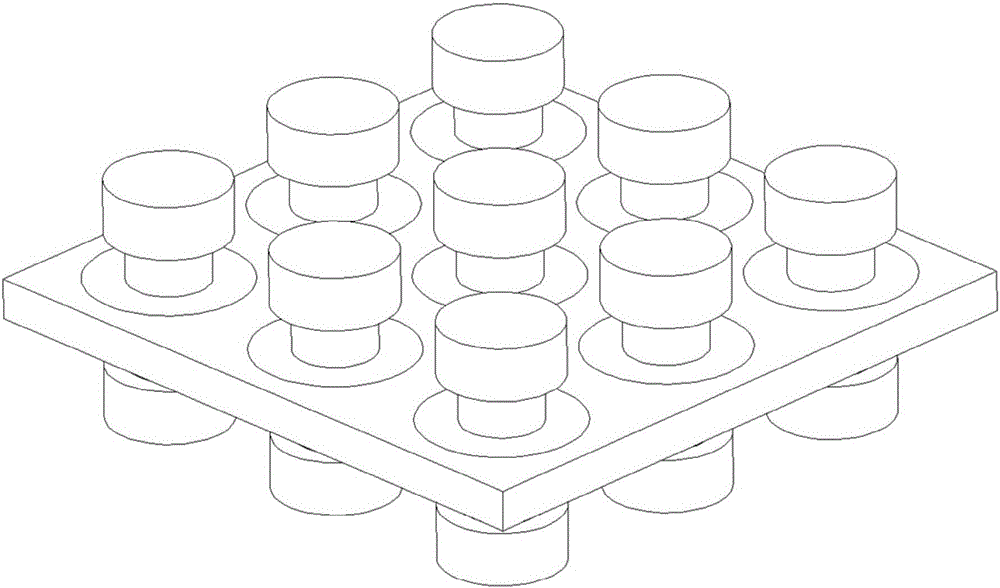

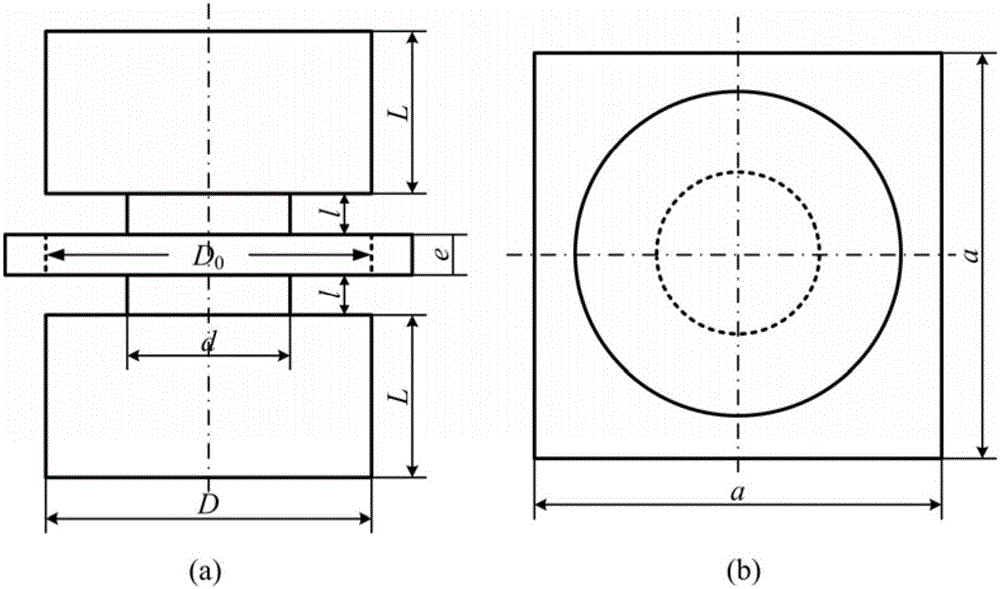

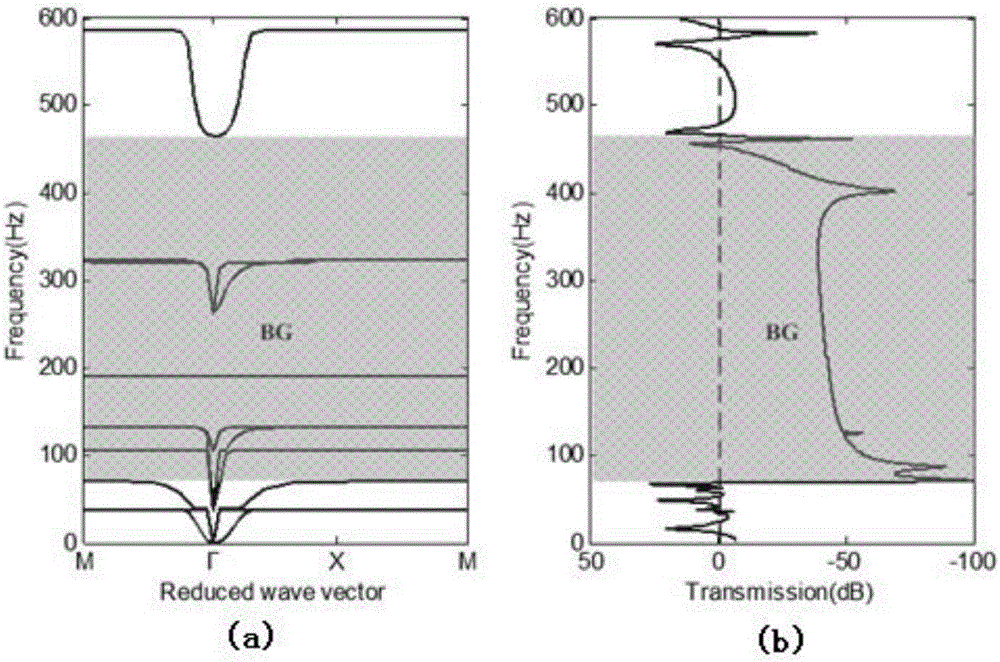

[0021] A metal-based foam-filled low-frequency wide-bandgap elastic metamaterial, the schematic diagram of which is shown in figure 1 As shown (3×3 finite periodic array structure), the original cell structure diagram is as follows figure 2 shown, where figure 2 (a) is the front view, figure 2 (b) is a top view. The lattice constant of the primary cell of the elastic metamaterial is a, and the metal aluminum plate with the thickness e is used as the base plate, and a plurality of diameters D are arrayed on the base plate. 0 Each circular hole is filled with foamed aluminum material to form a filling unit. The filling unit is periodically arranged in the form of a square lattice on the base plate, and a local resonance unit (steel material) is attached to each filling unit. The said The local resonance unit includes two pairs of cylinders symmetrically arranged on both sides of the filling unit and the center of the circle is on a straight line with the filling unit. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com