Patents

Literature

58results about How to "Low mass density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

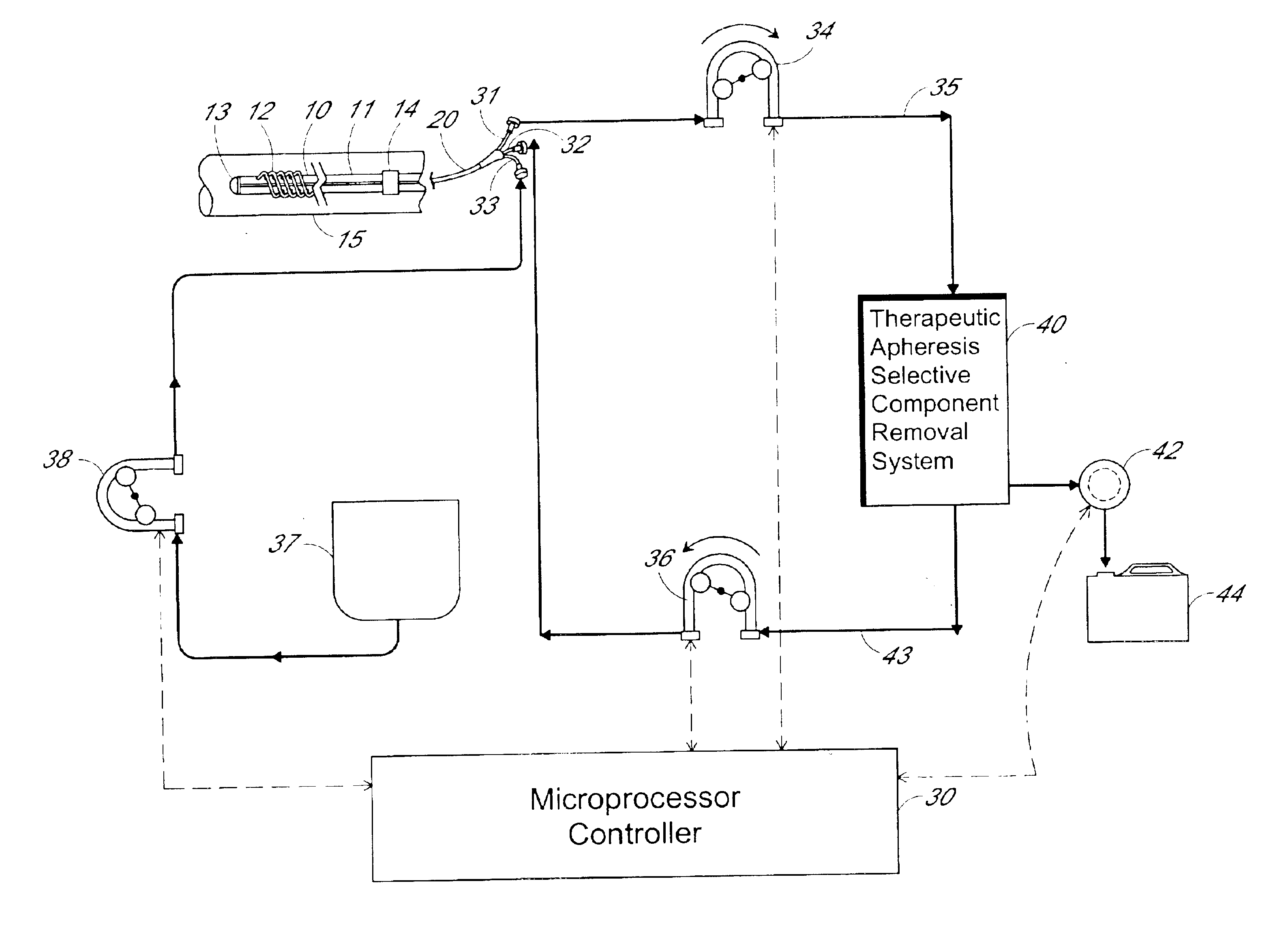

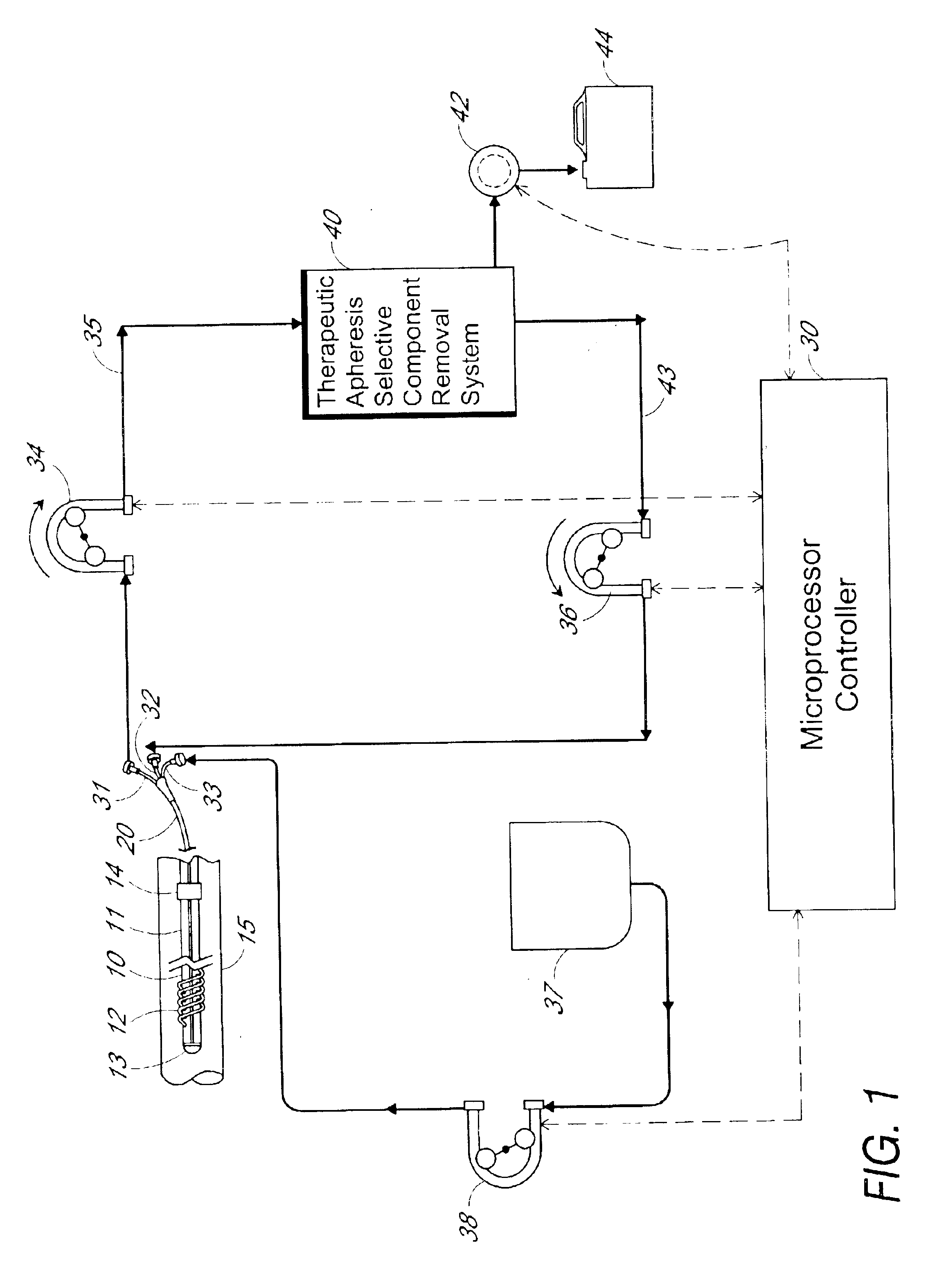

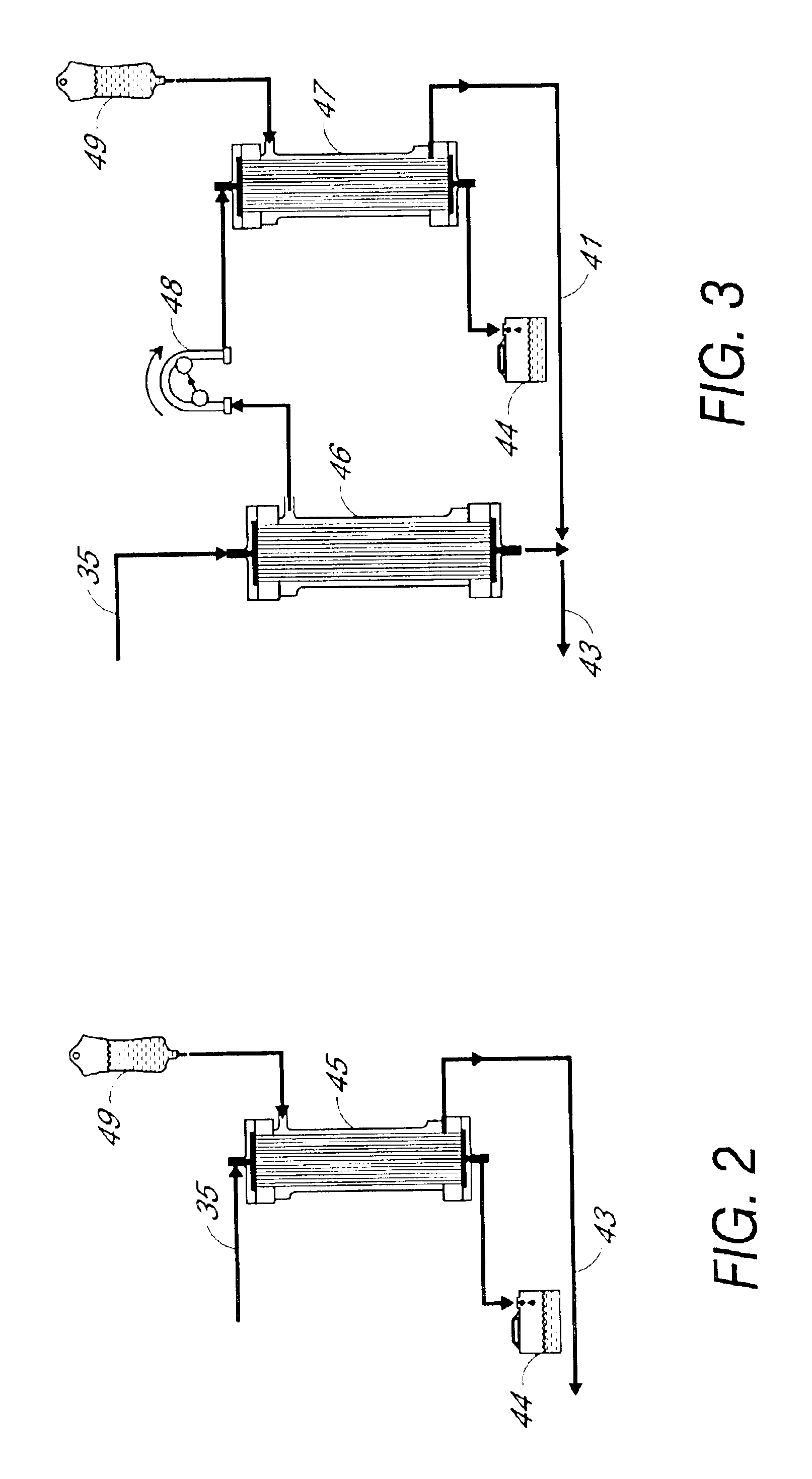

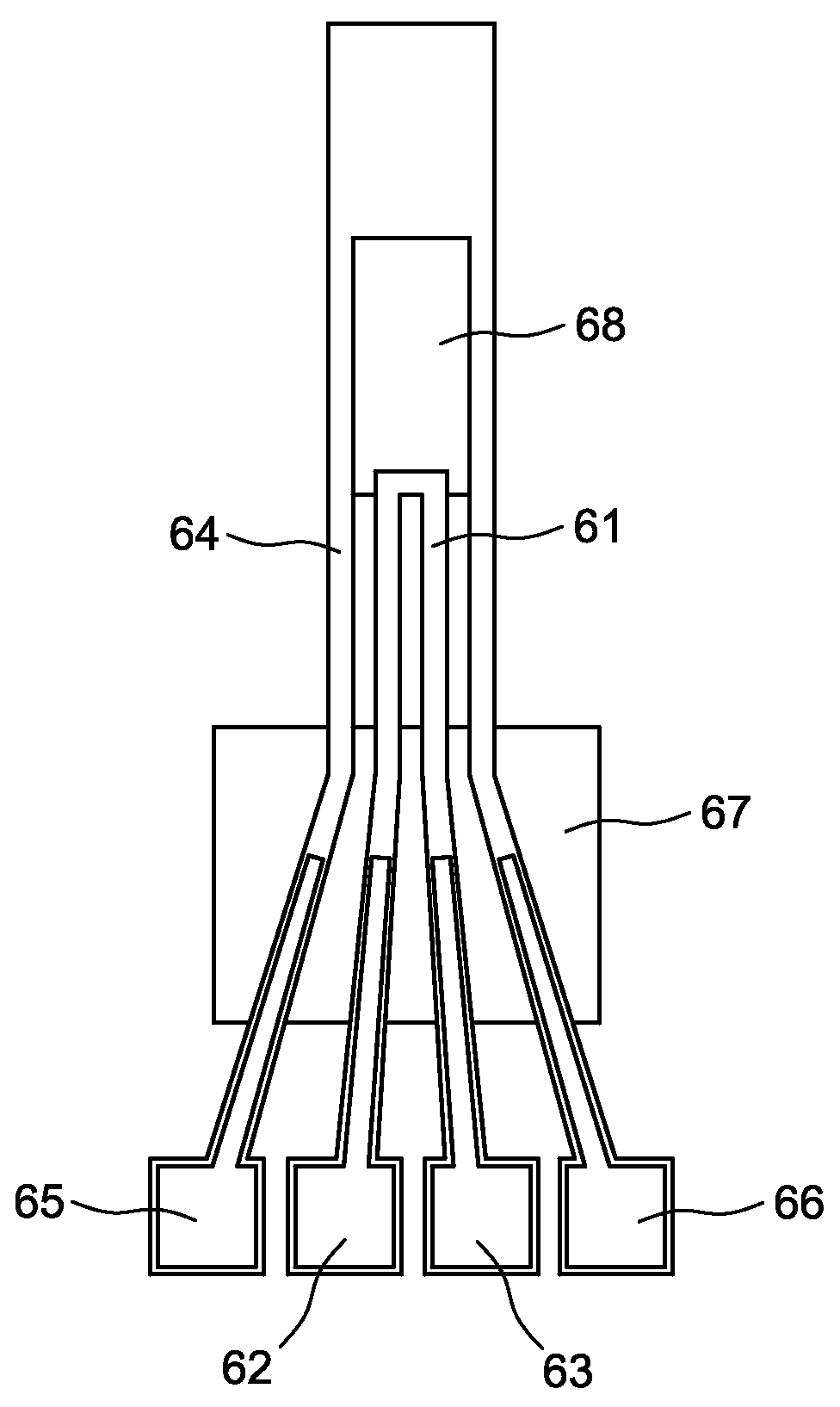

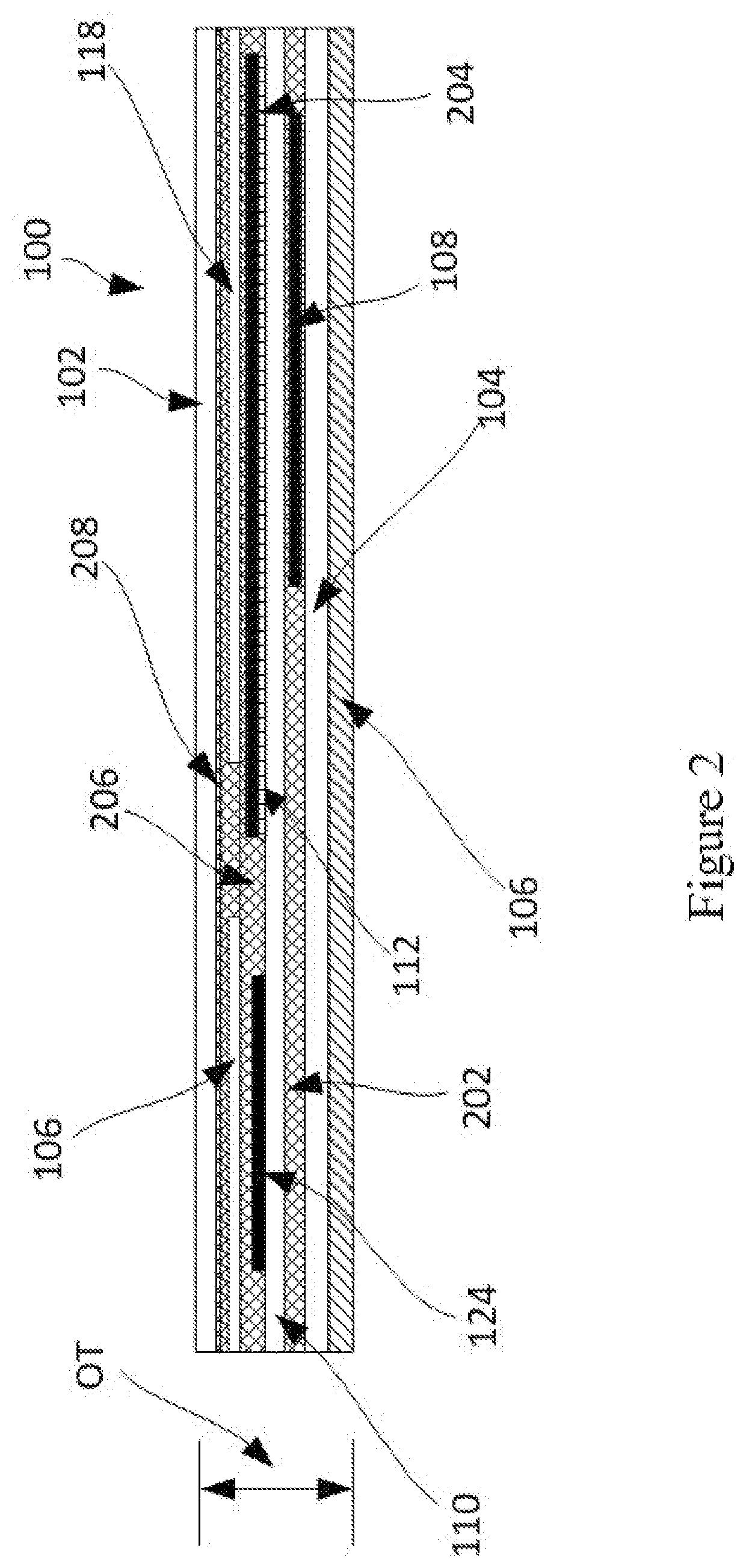

Method and apparatus for therapeutic apheresis

InactiveUS6849183B2Low mass densityIncrease mass densitySemi-permeable membranesSolvent extractionDiseaseBlood plasma

A method for carrying out therapeutic apheresis comprises separating plasma from whole blood in-vivo and removing selected disease-related components from the separated plasma. Apparatus for carrying out therapeutic apheresis includes a filter device for being implanted in a blood vessel for carrying out in-vivo plasma separation having one or more elongated hollow tubes and a plurality of elongated hollow microporous fibers capable of separating plasma from whole blood at pressure and blood flow within a patient's vein, a multiple lumen catheter secured to the proximal end of the filter device having one or more lumens in fluid communication with the interior of said one or more hollow tubes and a plasma return lumen, and therapeutic apheresis apparatus for removing and / or separating selected disease-related components from the separated plasma and means for directing plasma between said catheter and the selective component removal apparatus.

Owner:TRANSVIVO

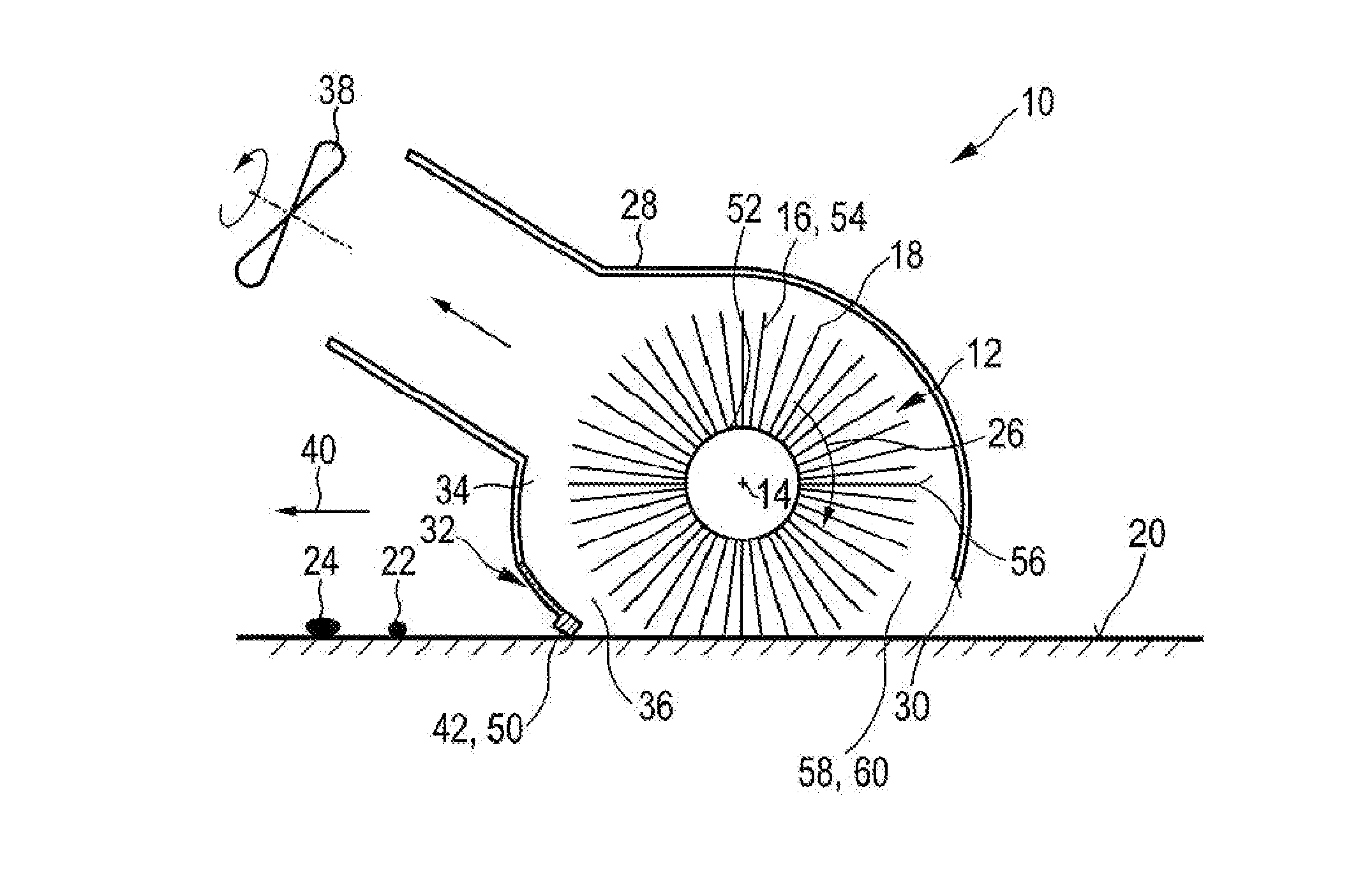

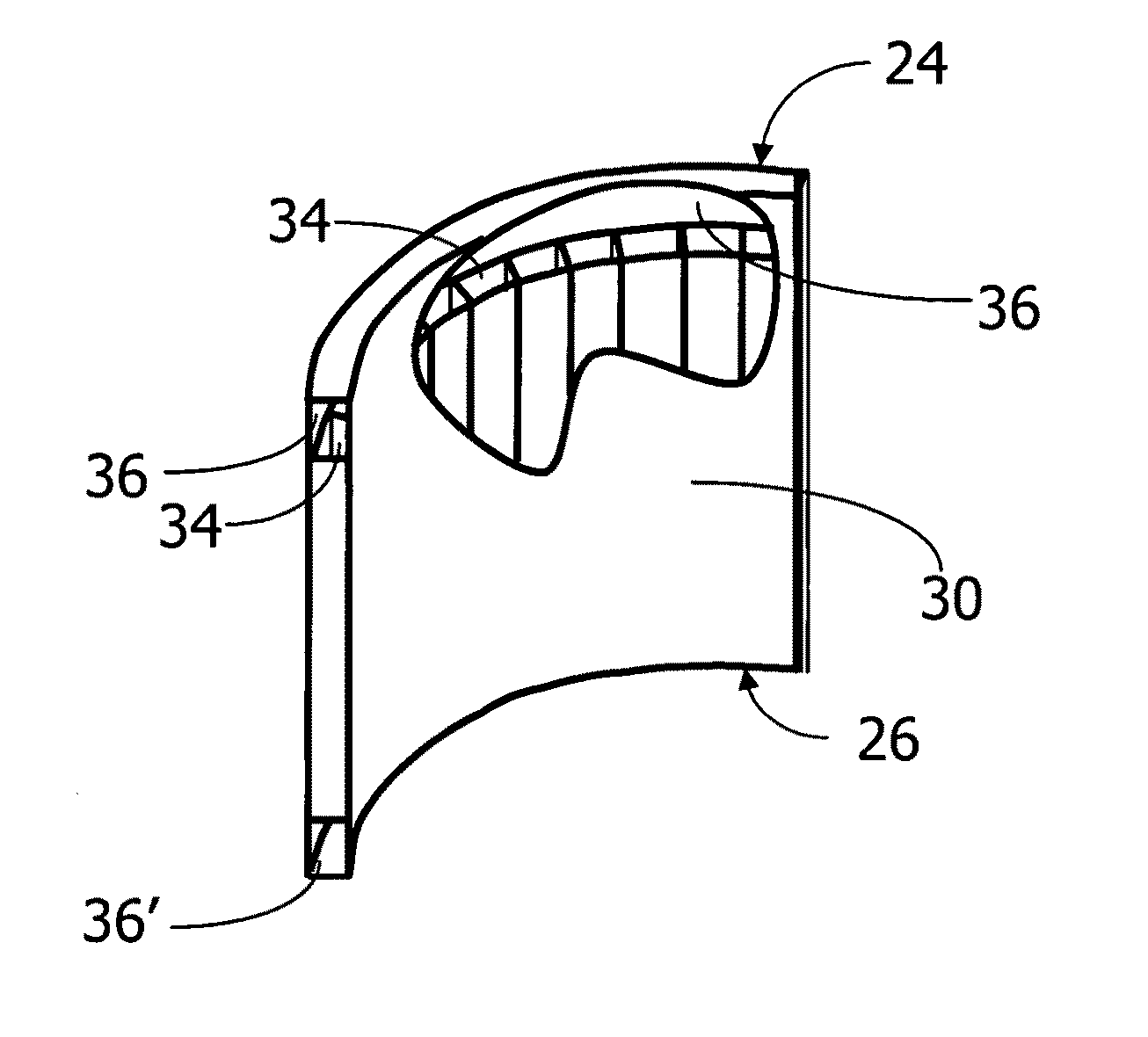

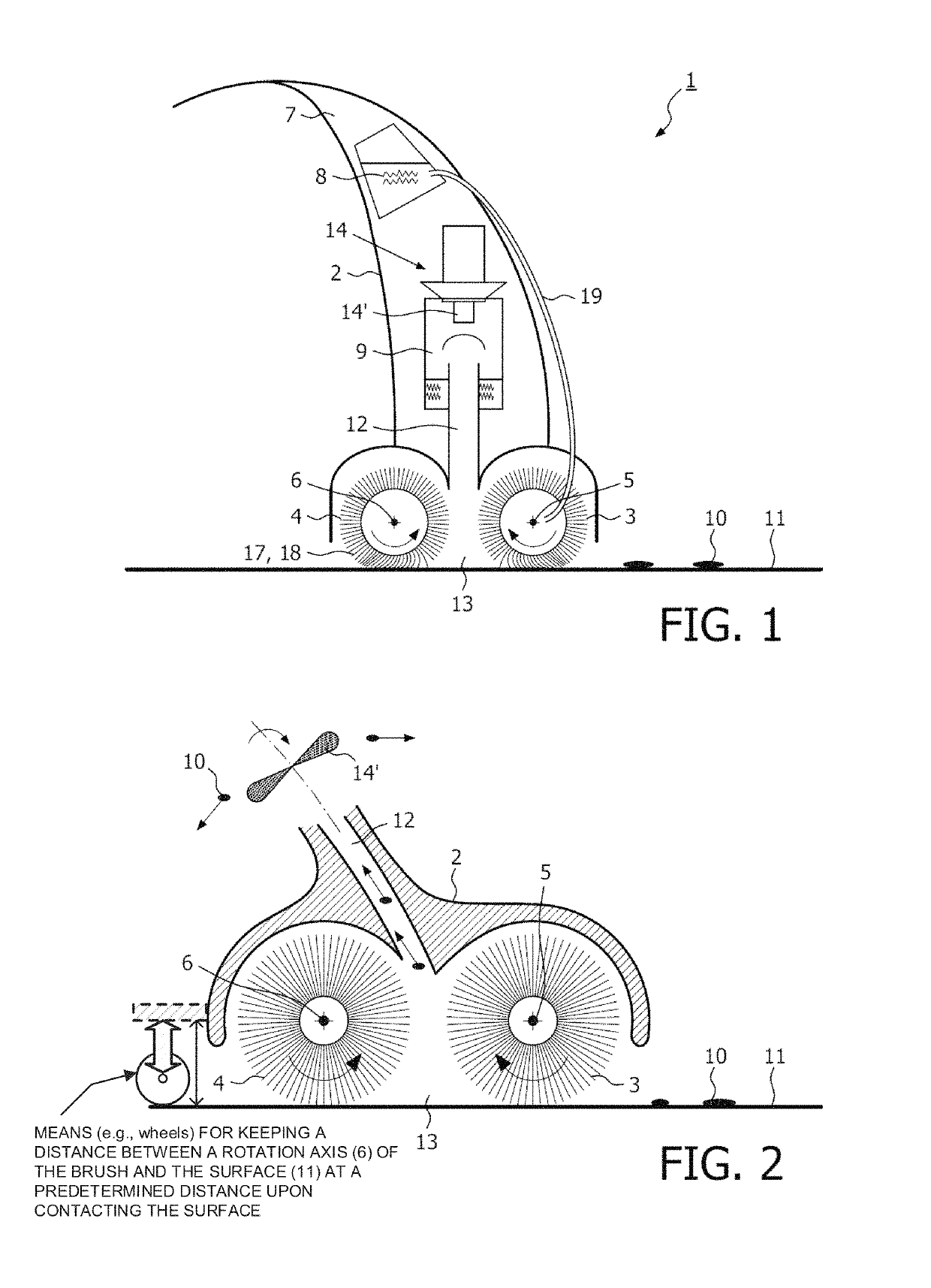

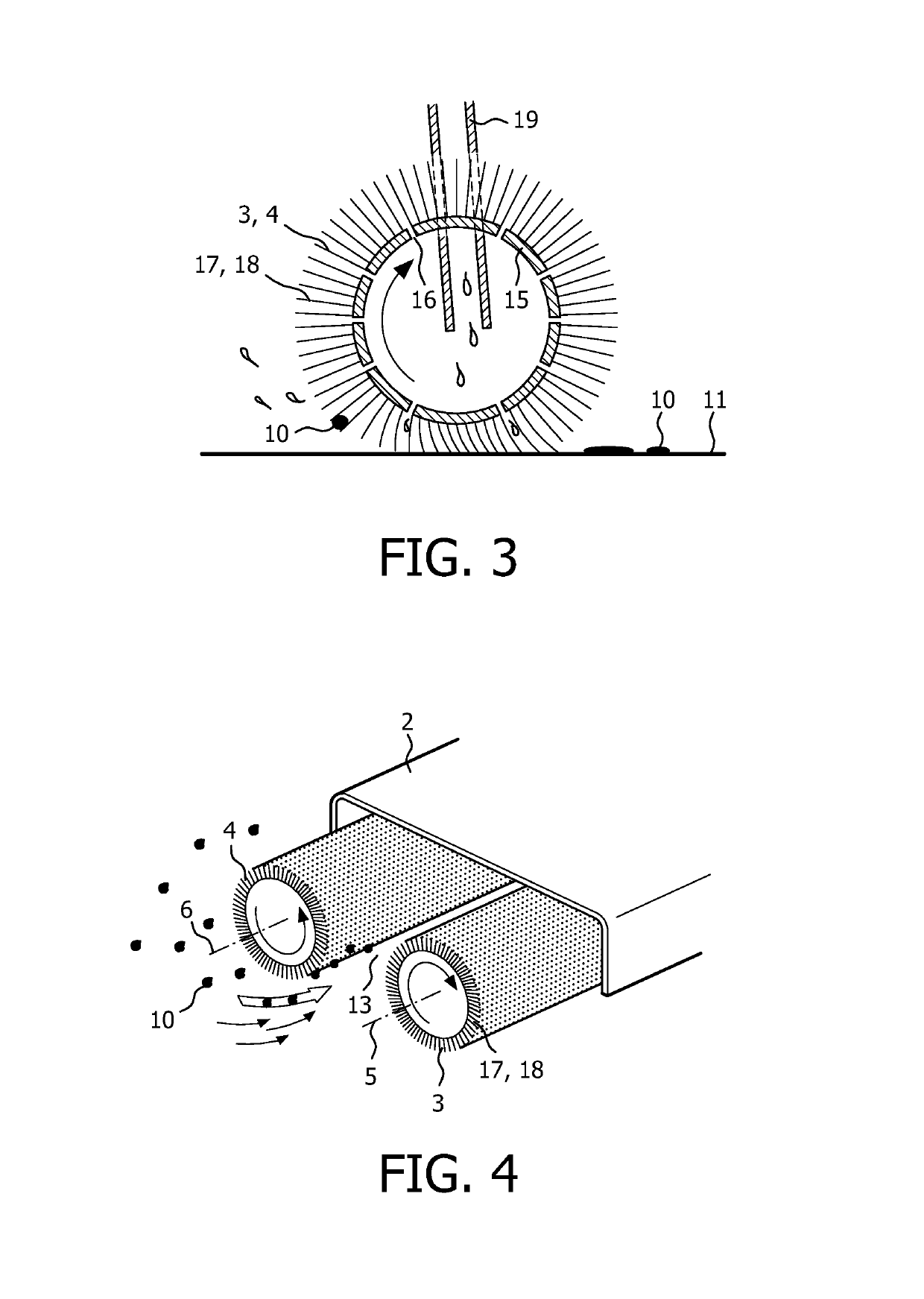

Cleaning device for cleaning a surface comprising a brush and a squeegee element

PendingUS20140182079A1Increase heightHigh strengthCarpet cleanersFloor cleanersEngineeringVolumetric Mass Density

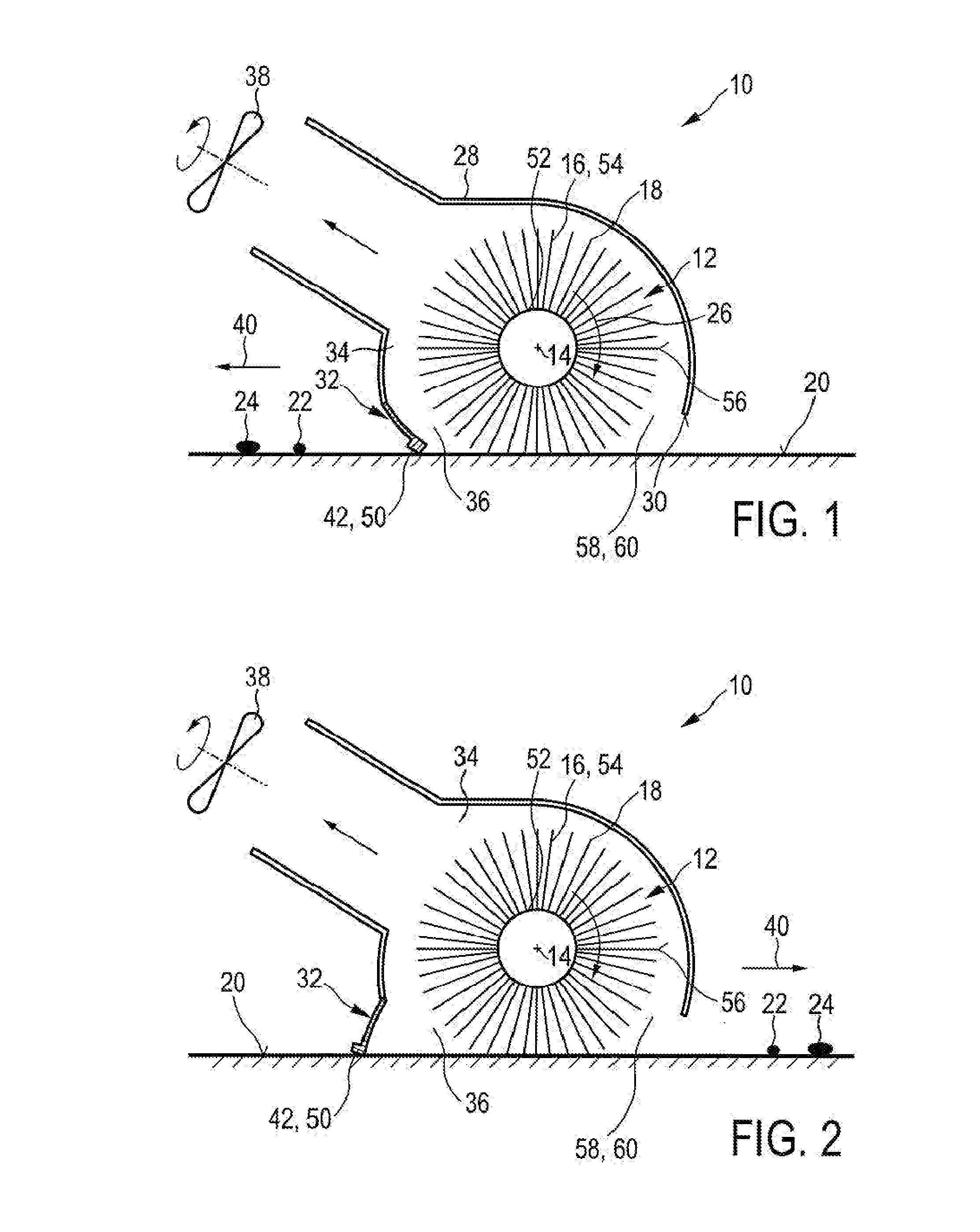

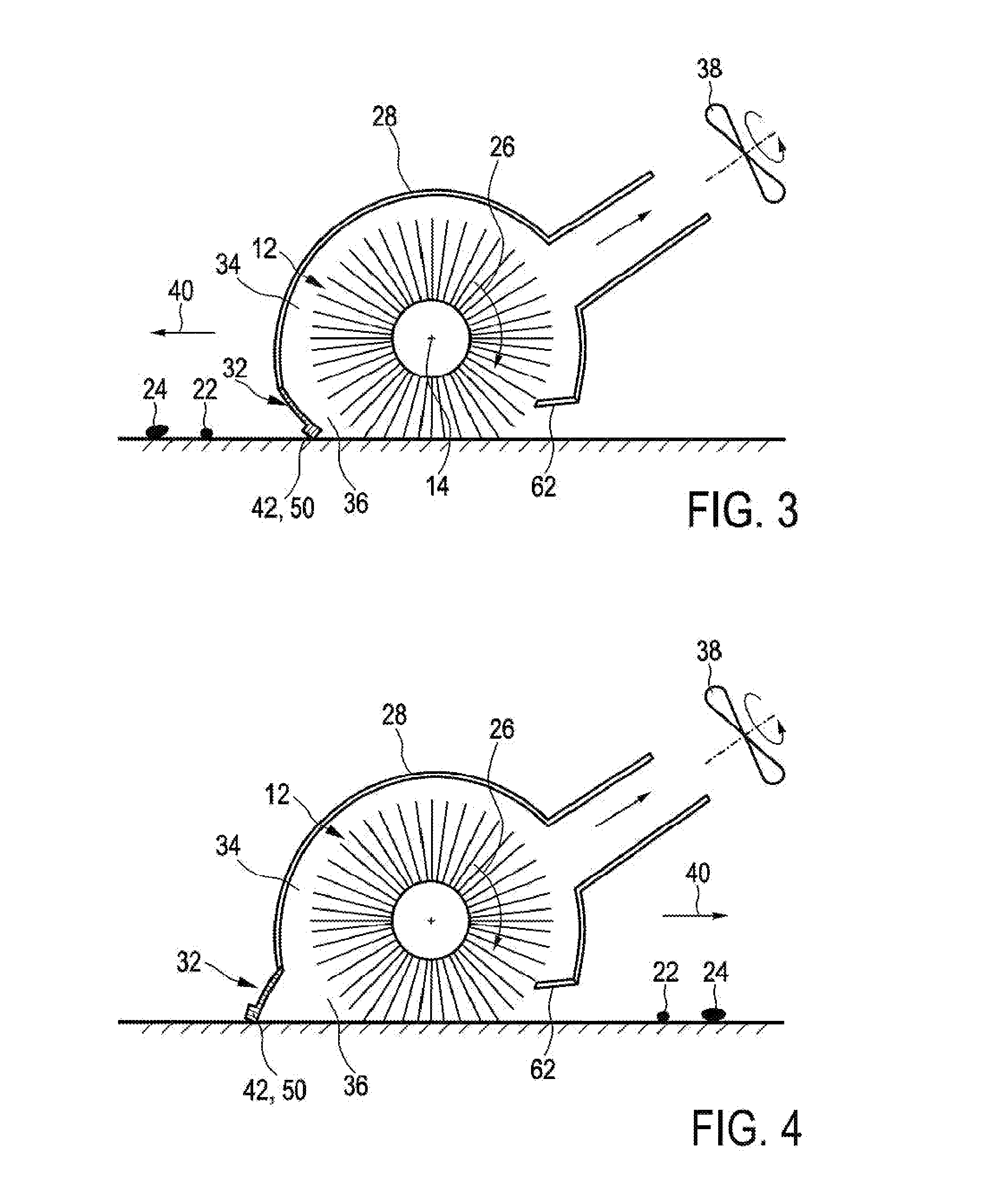

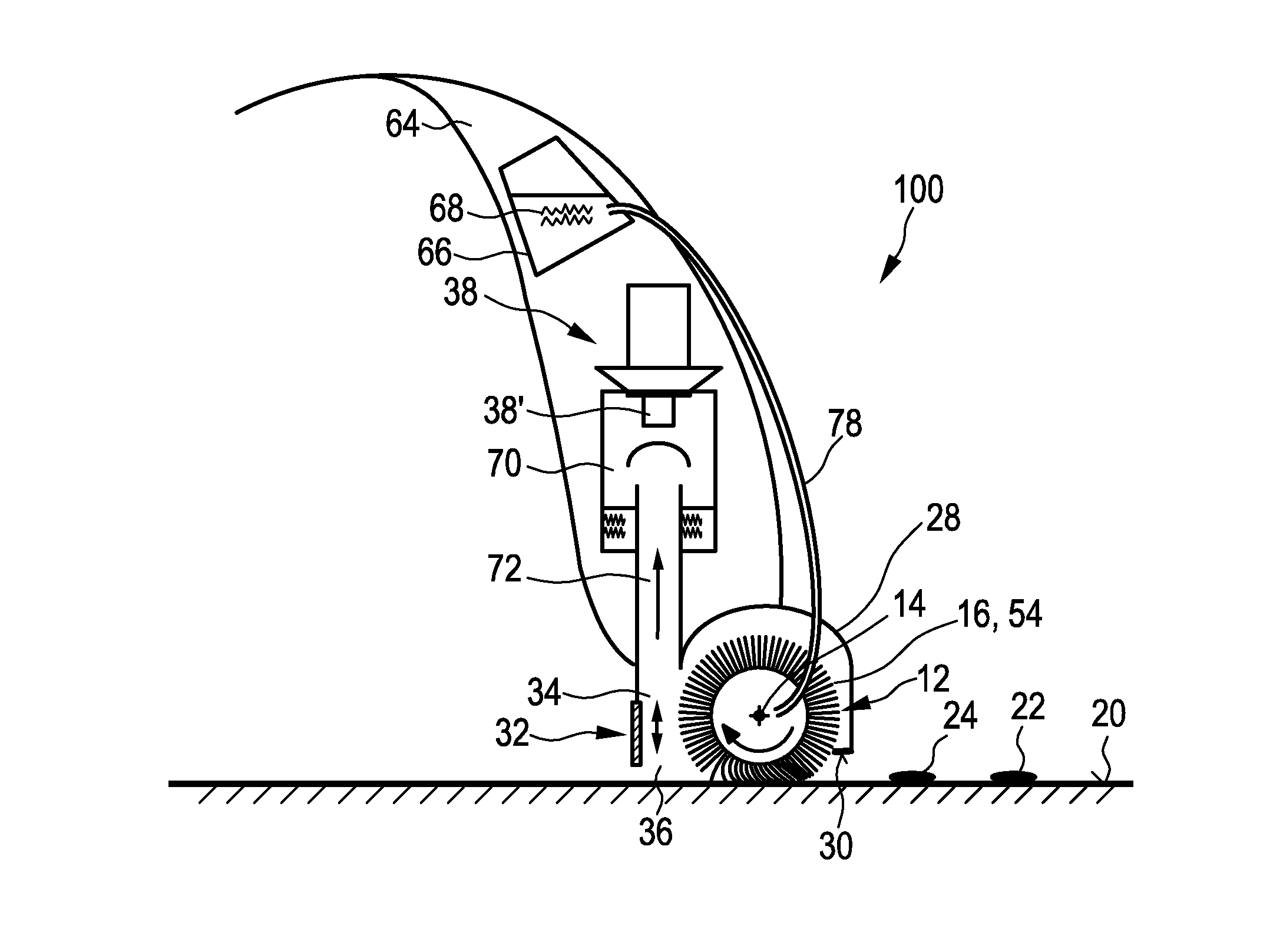

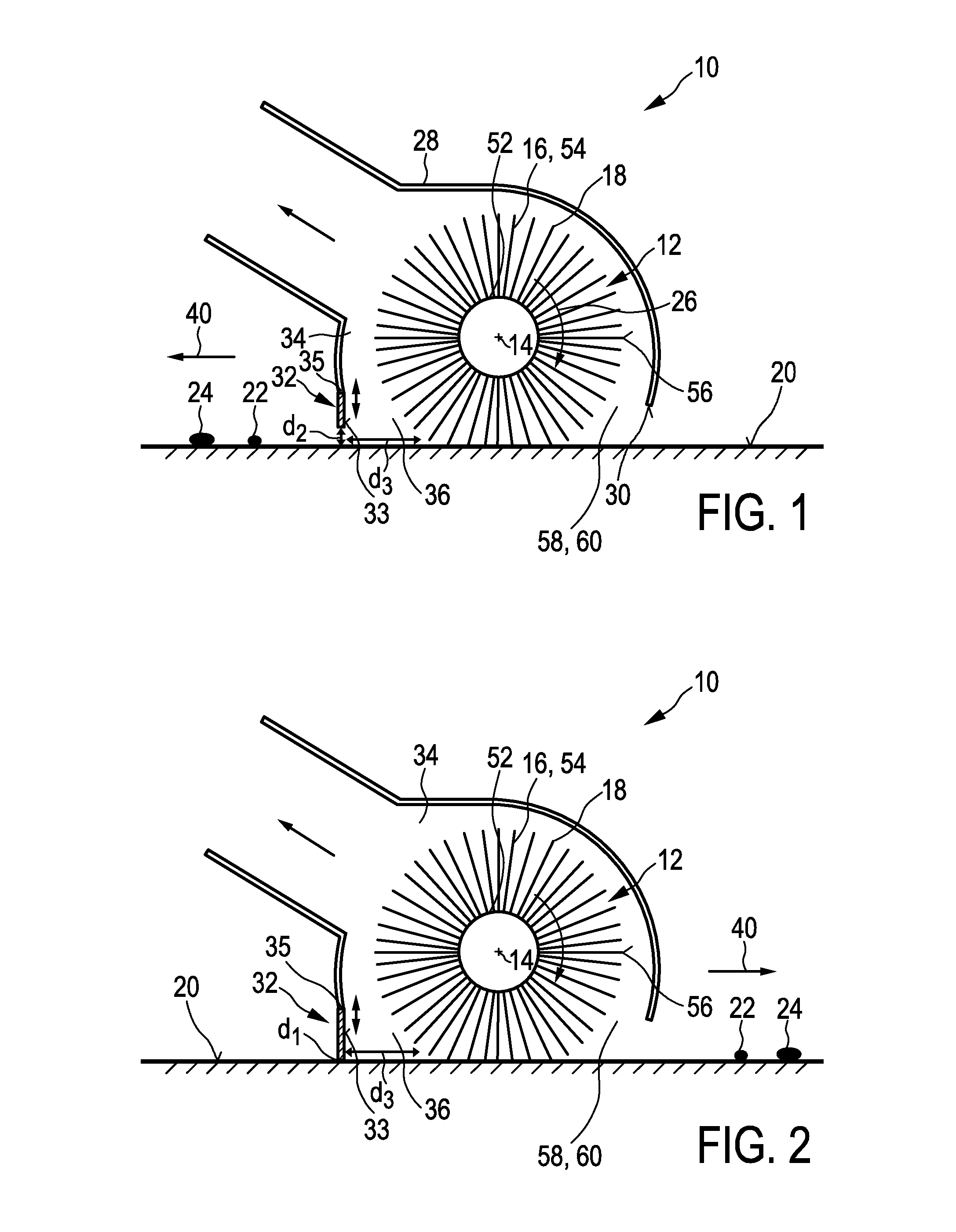

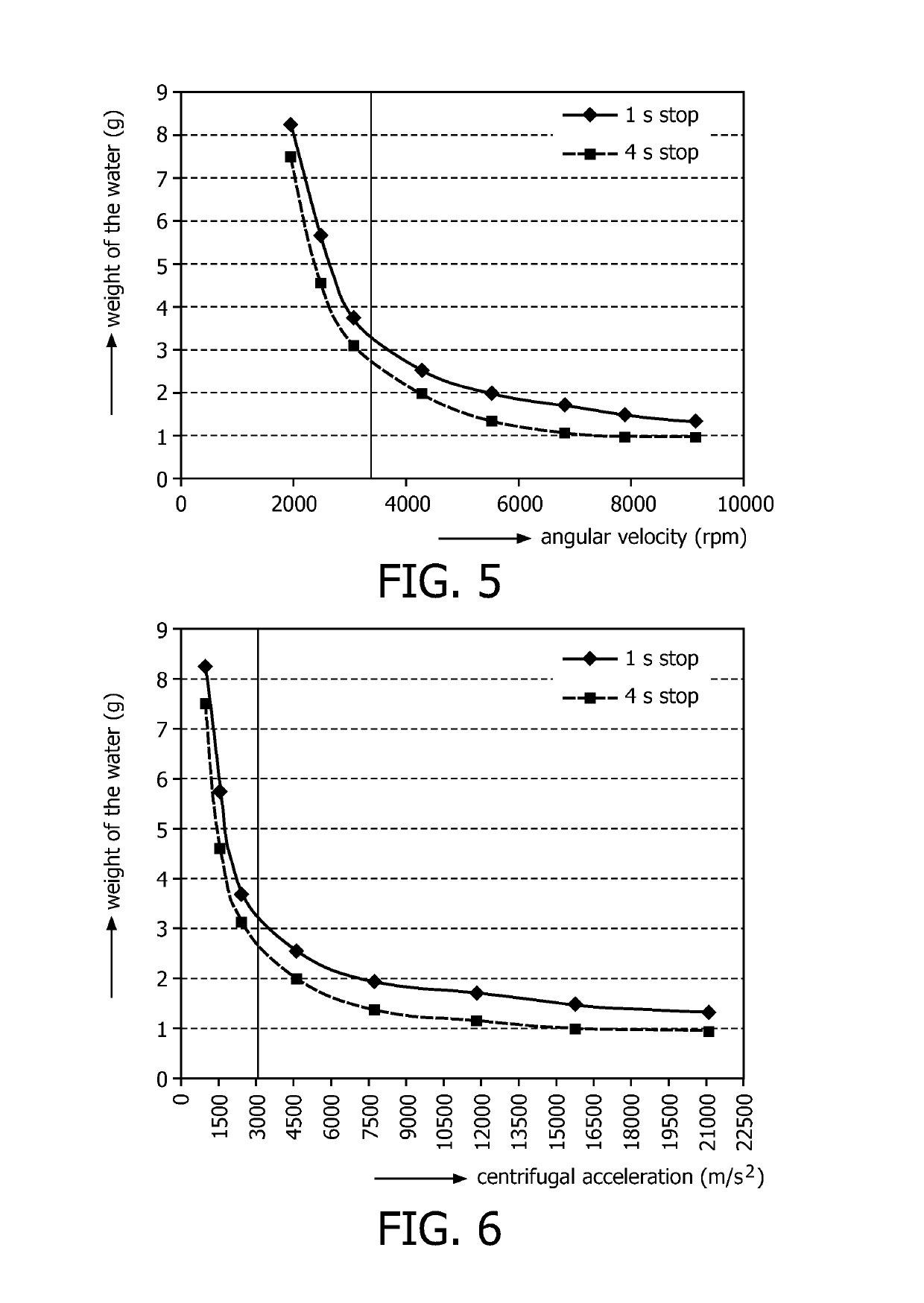

The present invention relates to a cleaning device for cleaning a surface (20), comprising: —a nozzle arrangement (10) that comprises i) a brush (12) rotatable about a brush axis (14), said brush (12) being provided with flexible brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and liquid (24) from the surface (20) during a pick-up period when the brush elements (16) contact the surface (20) during the rotation of the brush (12), wherein a linear mass density of a plurality of the brush elements (16) is, at least at the tip portions (18), lower than 150 g per 10 km, and ii) a single squeegee element (32) for pushing or wiping dirt particles (22) and liquid (24) across or off the surface to be cleaned (20) during movement of the cleaning device (100), said squeegee element (32) being spaced apart from the brush (12) and extending substantially along a longitudinal direction (48) being substantially parallel to the brush axis (14), wherein a suction area (34) is defined within the nozzle arrangement (10) between the squeegee element (32) and the brush (12), —a drive means for driving the brush (12) in rotation, wherein the drive means are adapted to realize a centrifugal acceleration at the tip portions (18) which is, in particular during a dirt release period when the brush elements (16) are free from contact to the surface (20) during rotation of the brush (12), at least 3,000 m / s 2, and —a vacuum aggregate (38) for generating an under-pressure in the suction area (34) for ingesting dirt particles (22) and liquid (24).

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Coated cbn

InactiveUS20100213247A1Reduced strengthHigh retention ratePigmenting treatmentOther chemical processesSecondary layerBoride

The invention relates to a coated boron or nitrogen containing superhard abrasive material selected from cBN, boron suboxide and boron carbide comprising: cBN, boron suboxide and / or boron carbide superhard abrasive material substrate; a primary layer of a carbide / nitride / boride forming metal, such metal preferably being Ti and preferably being substantially in the form of the carbide, nitride or boride; a secondary layer of a high melting point metal selected from W, Mo, Cr, Ni, Ta, Au, Pt, Pd and alloys thereof; and an overcoat of Ag, Ni, Cu, Au, Pd, Pt, Rh, Os, Ir, Re, combinations and alloys thereof such as bronze (Cu / Sn), silver / bronze and silver / tin, the metal of the secondary layer being different to the metal of the overcoat. The invention further relates to methods for the manufacture of such material, use of such materials in tools and tools including such material.

Owner:ELEMENT SIX LTD

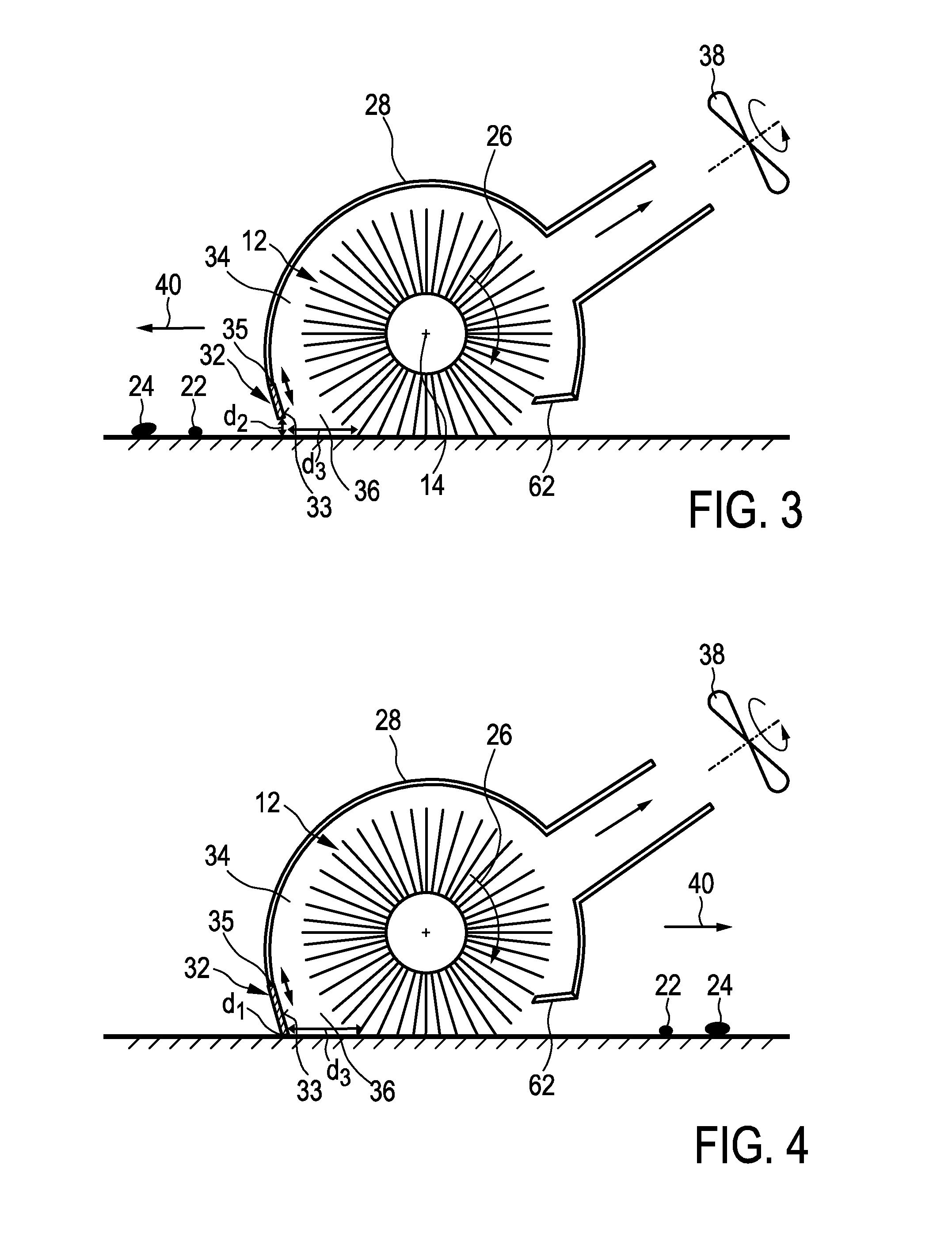

Floor nozzle for vacuum cleaner

The present invention relates to a cleaning device for cleaning a surface, with a nozzle arrangement (10) comprising: —a brush (12) rotatable about a brush axis (14), said brush (12) being provided with brush elements (16) having tip portions (18) for contacting the surface to be cleaned (20) and picking up dirt particles (22) and / or liquid (24) from the surface (20) during the rotation of the brush (12), —a drive means for driving the brush (12) in rotation, —a bouncing element (32) comprising a bouncing surface (33) that is configured to let the dirt particles (22) and / or liquid (24), that are released from the brush (12) during rotation, rebound to the brush (12), said bouncing surface (33) being spaced apart from the brush (12) and extending substantially parallel to the brush axis (14), and —an adjustment means (35) for adjusting the position of the bouncing element (32) relative to the surface (20) depending on a direction of movement (40) of the device, wherein the adjustment means (35) is adapted to arrange the bouncing element (32) in a first position in which the bouncing element (32) has a first distance d1 to the surface (20), when the cleaning device is moved in a forward direction, in which the bouncing element (32) is, seen in the direction of movement of the device (40), located behind the brush (12), and to arrange the bouncing element (32) in a second position in which the bouncing element (32) has a second distance d2 to the surface, when the cleaning device is moved in an opposite backward direction, wherein d2 is greater than d1 and equal to d3*tan(α), d3 being the distance between the bouncing surface (33) and the position of the brush (12) where the tip portions (18) lose contact from the surface to be cleaned (20) during the rotation of the brush (12), and α being an angle that is equal to or smaller than 20°.

Owner:VERSUNI HLDG BV

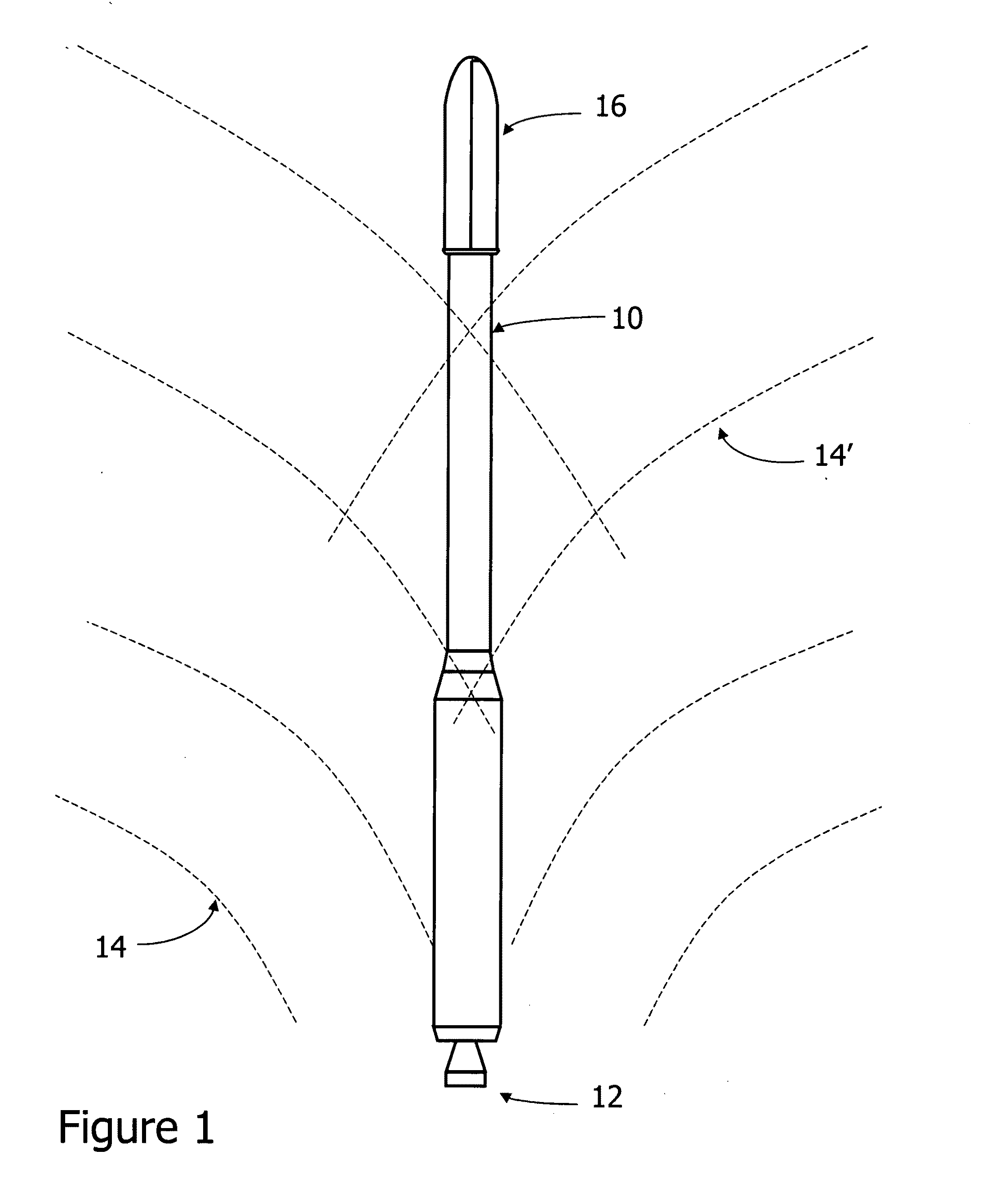

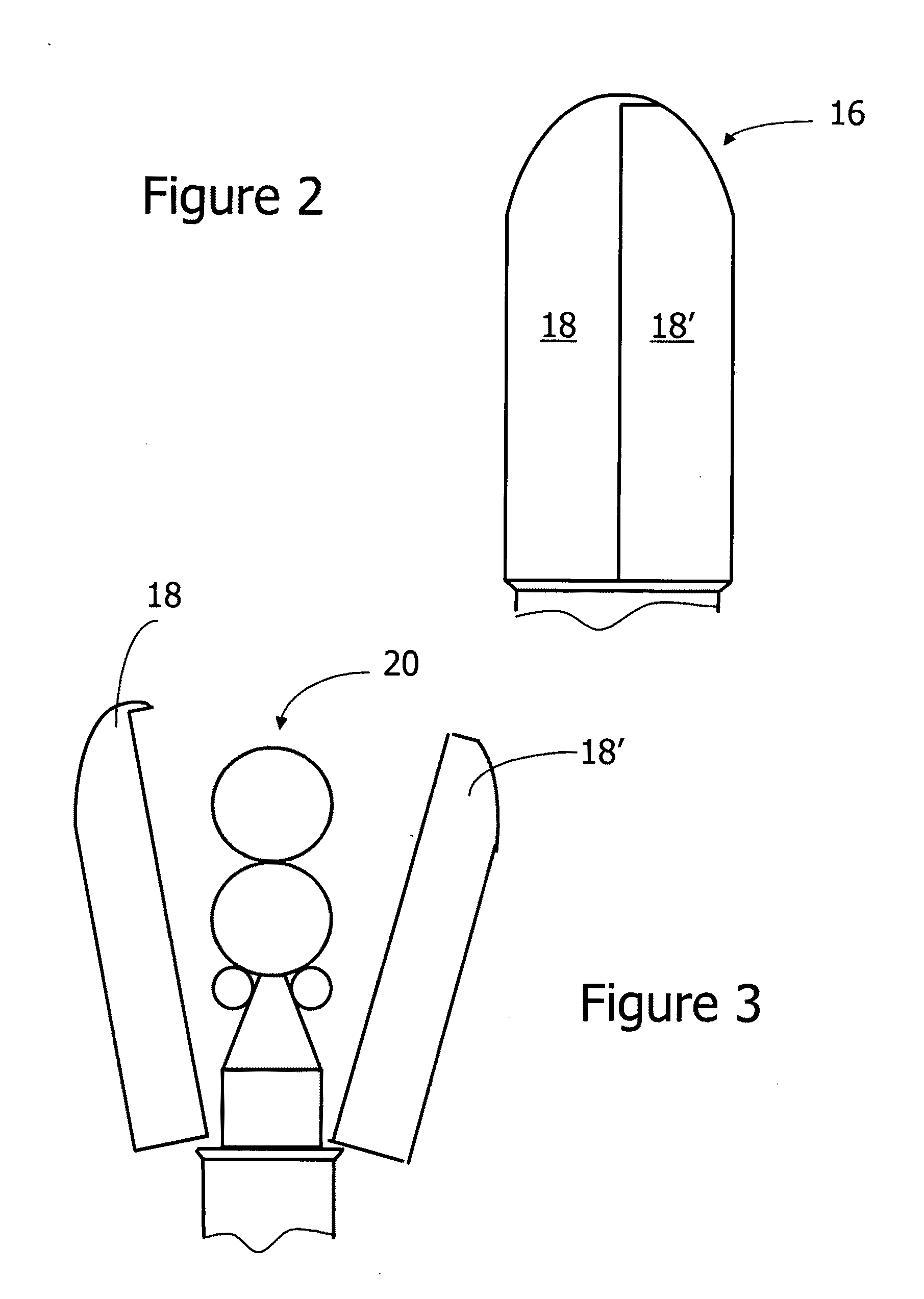

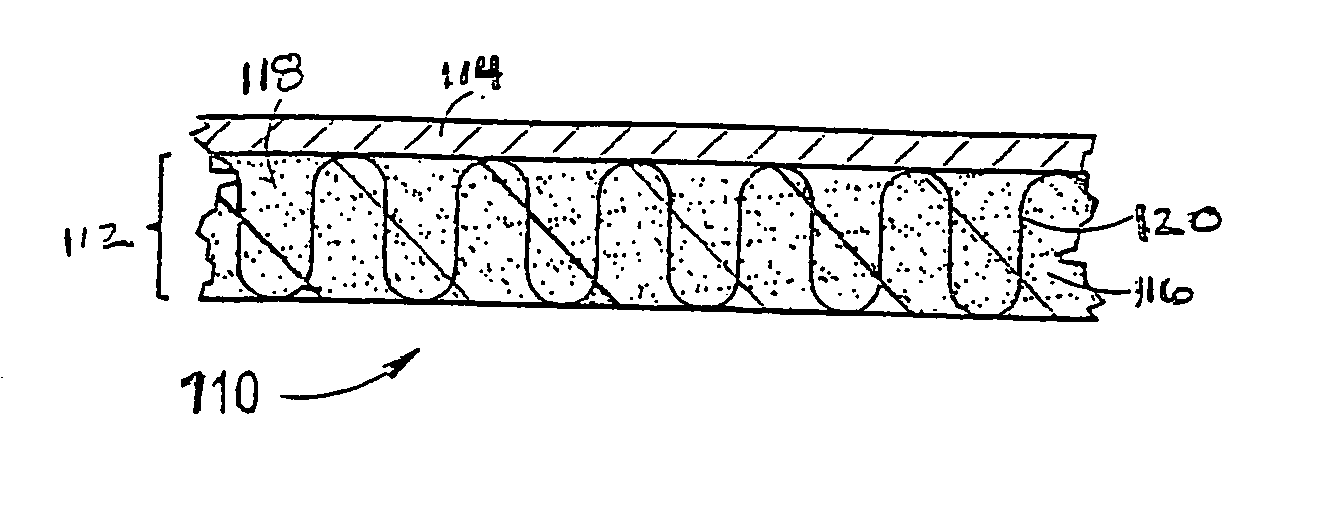

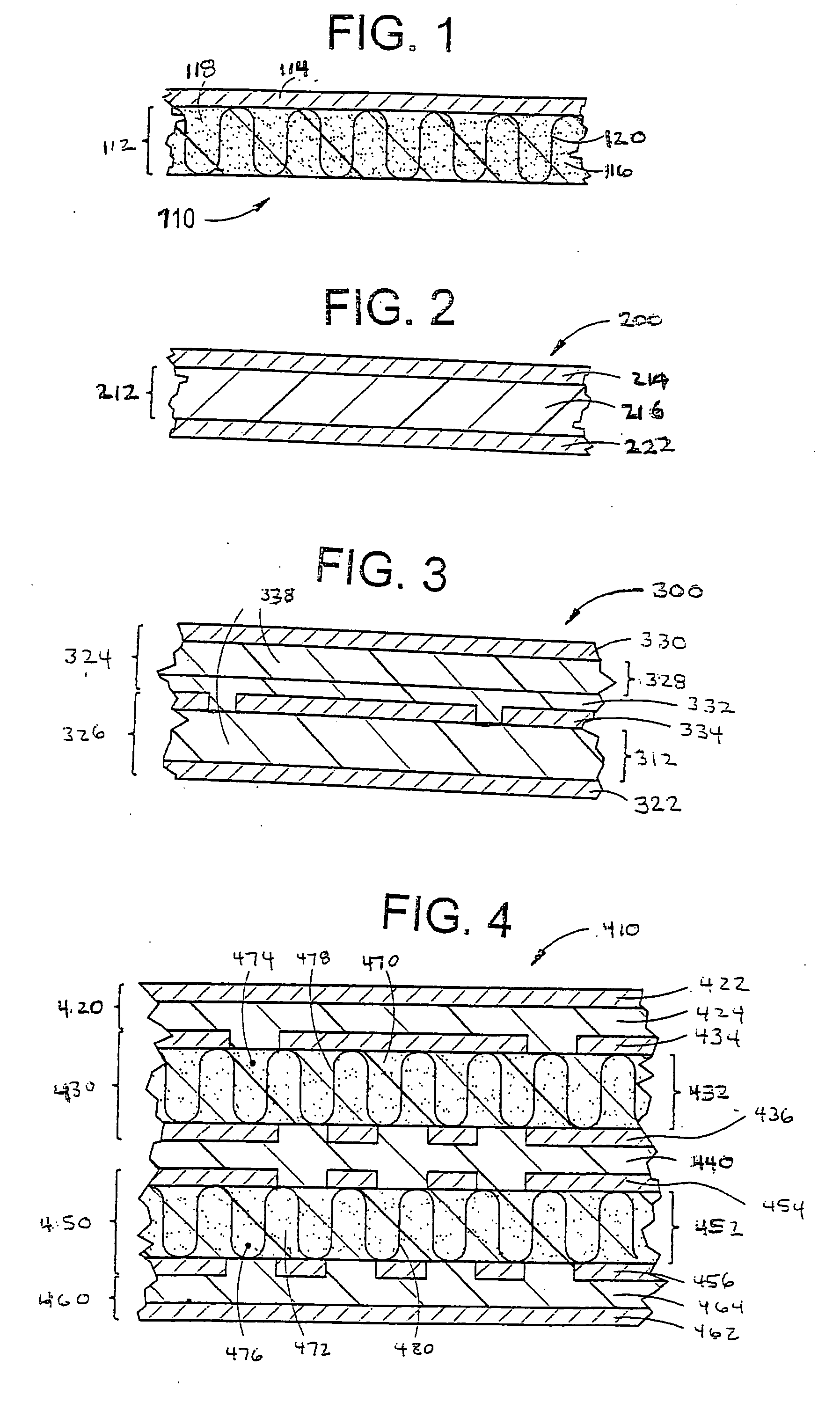

Launch vehicle fairing and construction

InactiveUS20110226897A1High strengthHigh stiffnessCosmonautic vehiclesFuselage insulationFiberEngineering

Light-weight acoustic dampening launch vehicle fairing structures having high strength and stiffness and capable of filling to provide high mass density and rapidly unloaded at a predetermined time following launch, and methods of making them are provided. The panels include a monolithic body comprised of fibrous reinforcement material in a polymeric binder and comprise longitudinal chambers extending from the length of body. Fluid passage means are provided at both the top and bottom of the monolithic body and interconnected by the longitudinal chambers for filling and emptying said chambers with a fluid.

Owner:DELTA VELOCITY CORP

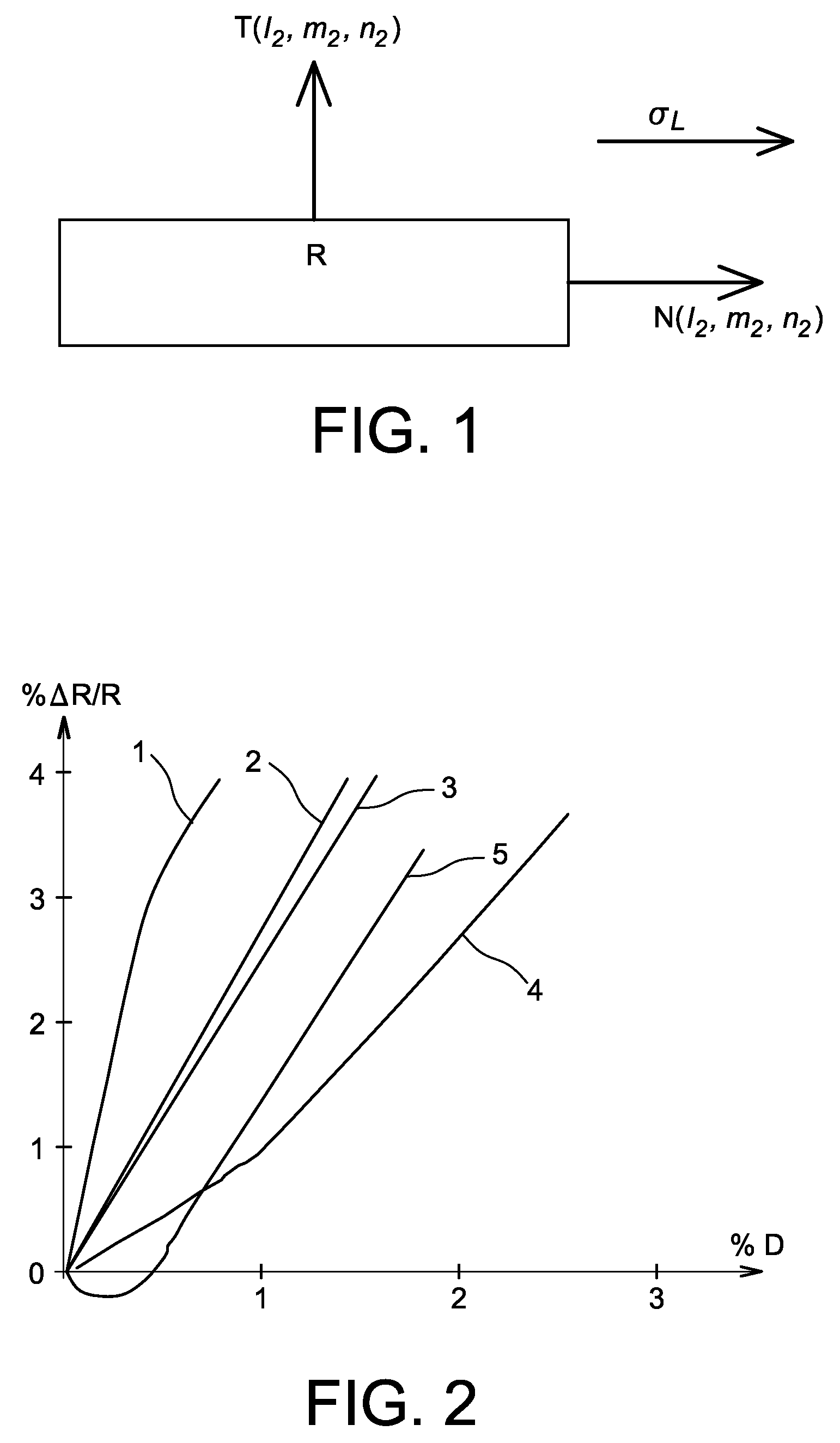

NEMS comprising alsi alloy based transduction means

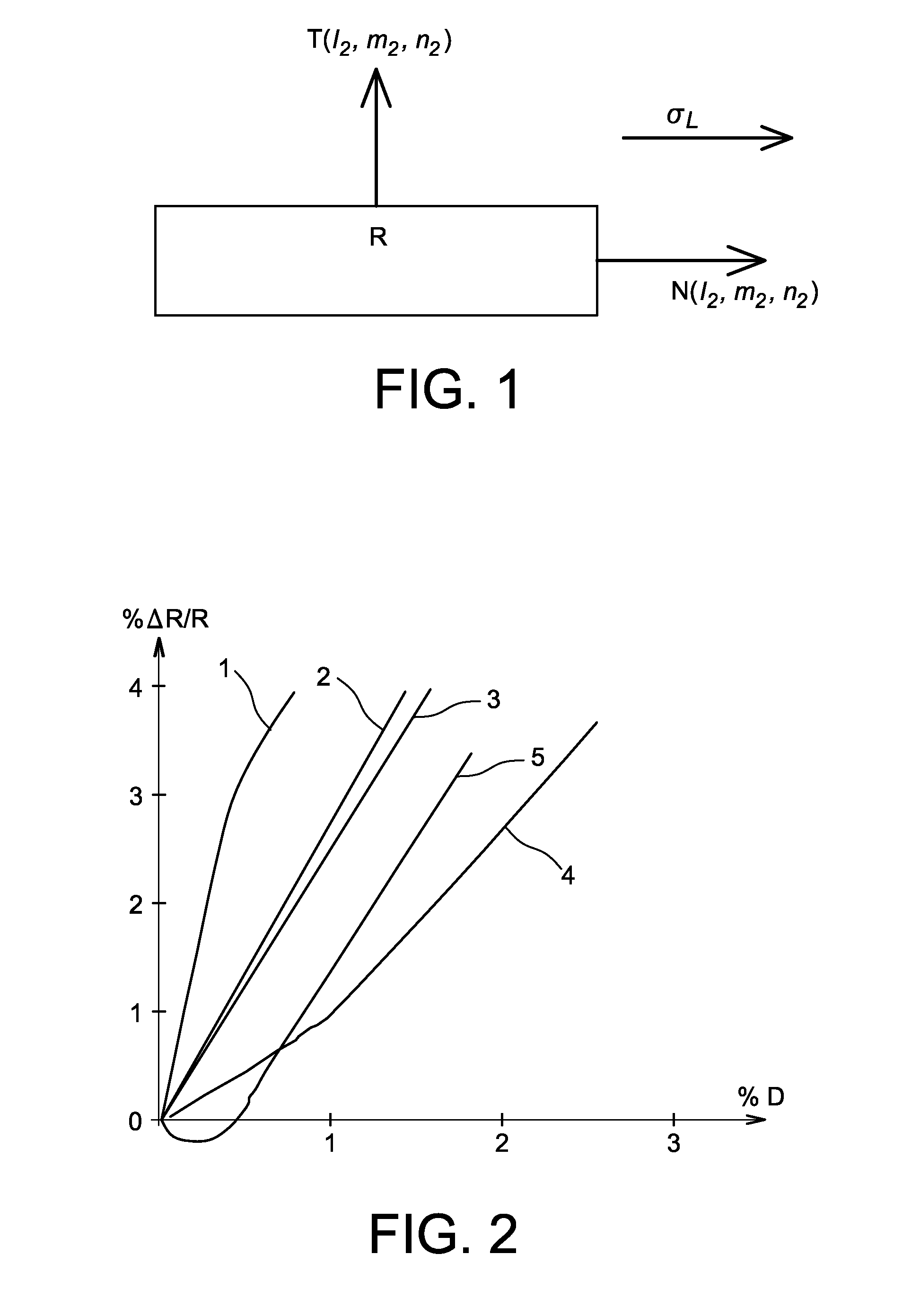

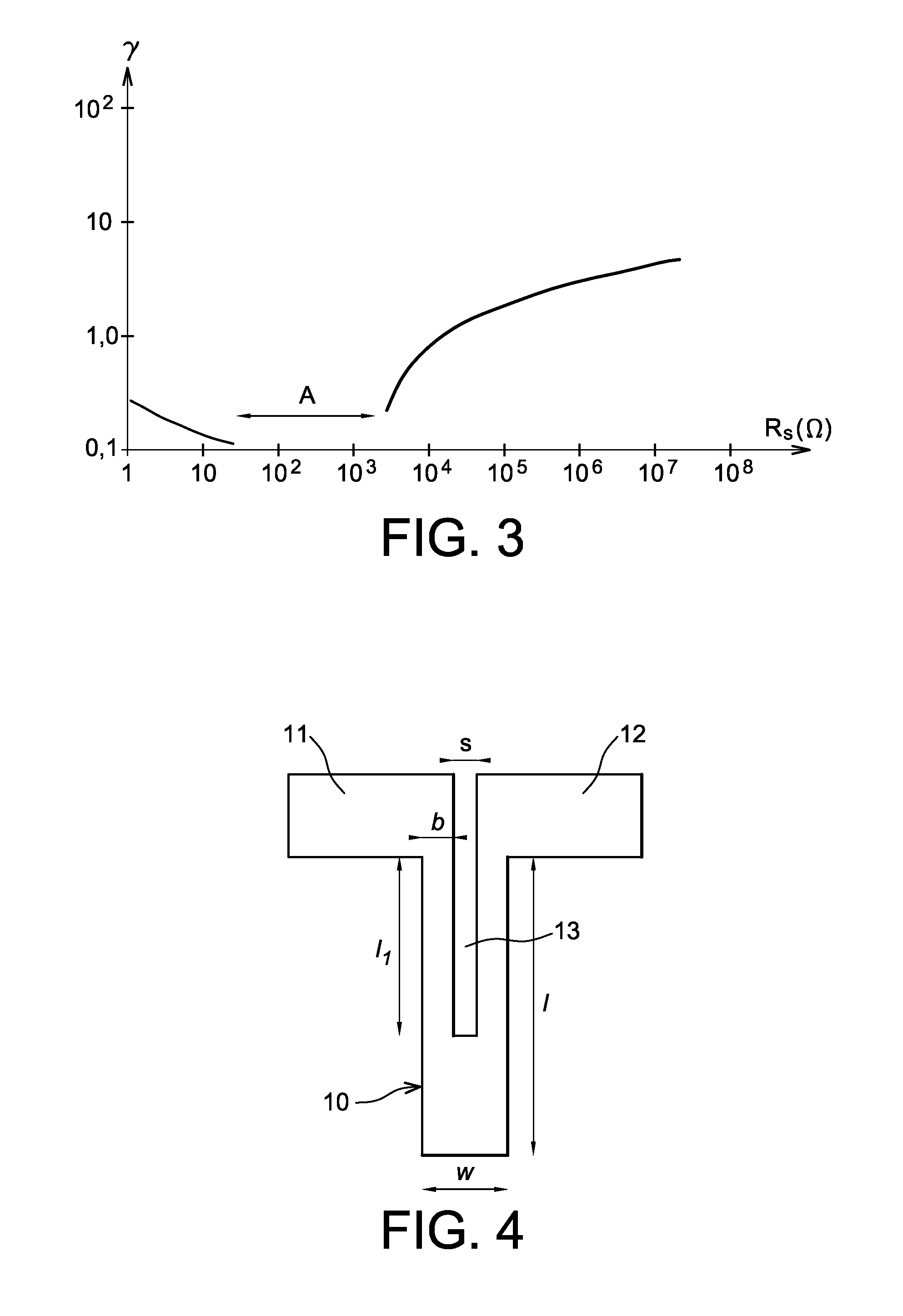

ActiveUS20120272742A1High sensitivityReduce sizeMaterial analysis using sonic/ultrasonic/infrasonic wavesAcceleration measurementAlloyEngineering

The invention relates to a nano electro- mechanical system (NEMS) formed on a substrate (21) and comprising at least one fixed part associated with the substrate and at least one movable part (23) in relation to the substrate, said system comprising transduction means (24) capable of exciting the movable part to confer on it a movement and / or to detect a movement of movable part, the transduction means comprising at least one electrically conductive material. The electrically conductive material is made of an AlSi alloy based deposition, said deposition being supported at least in part by the movable part of the system.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

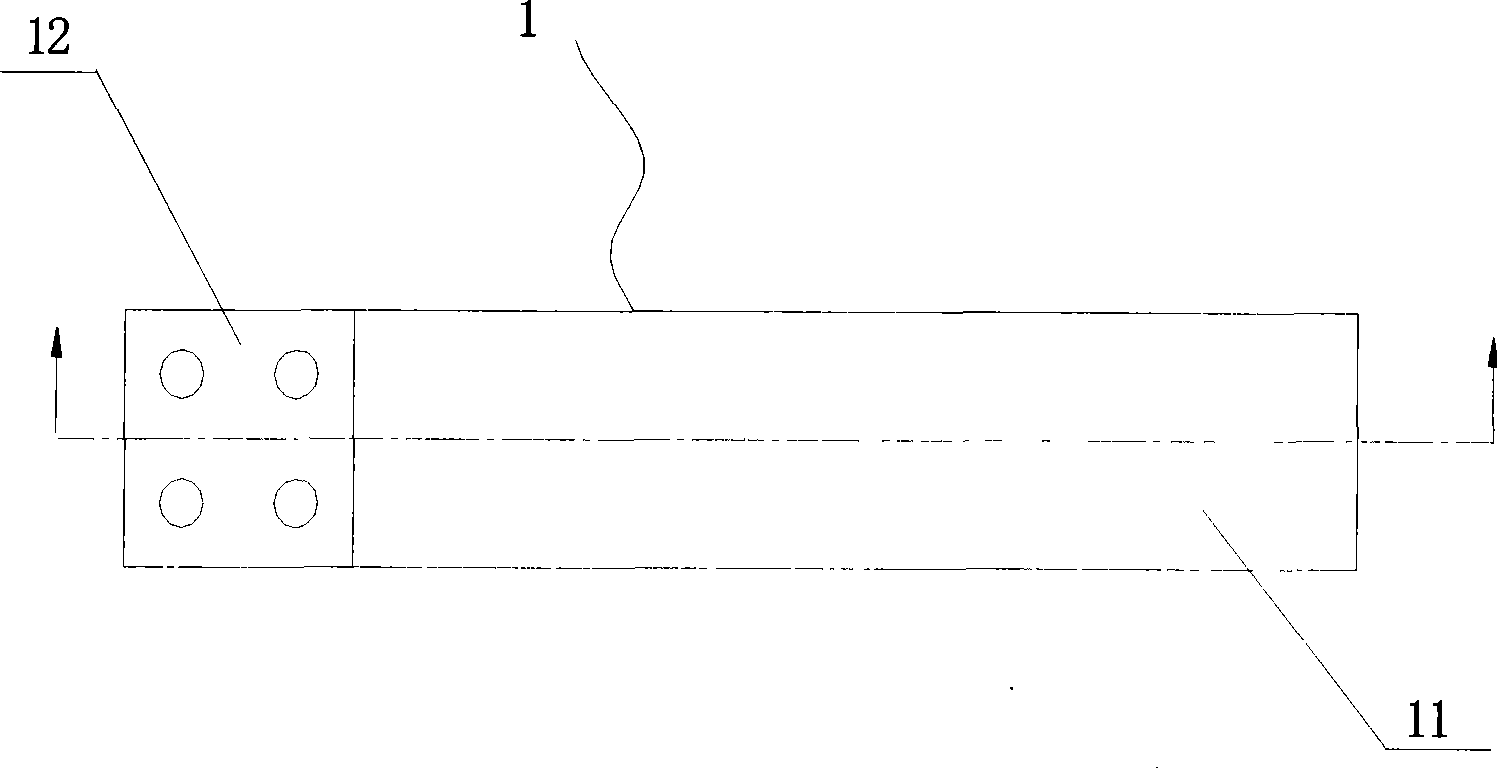

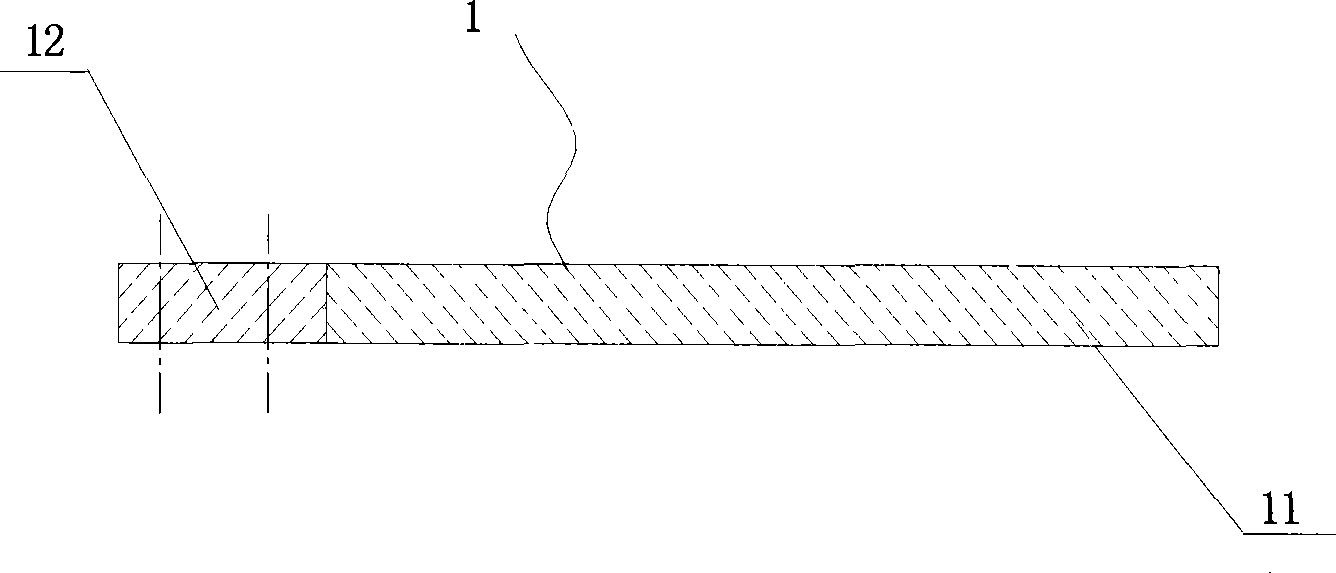

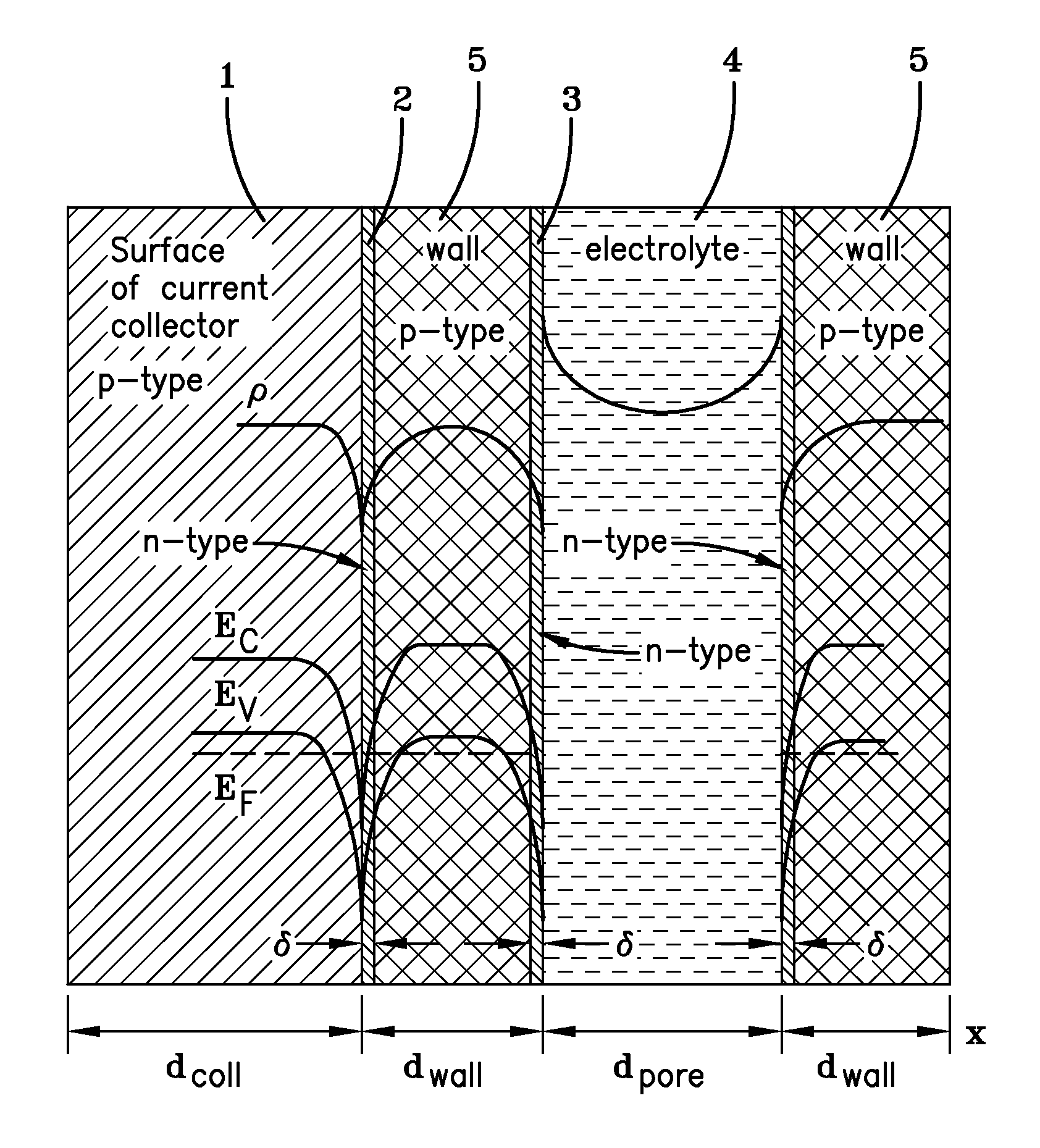

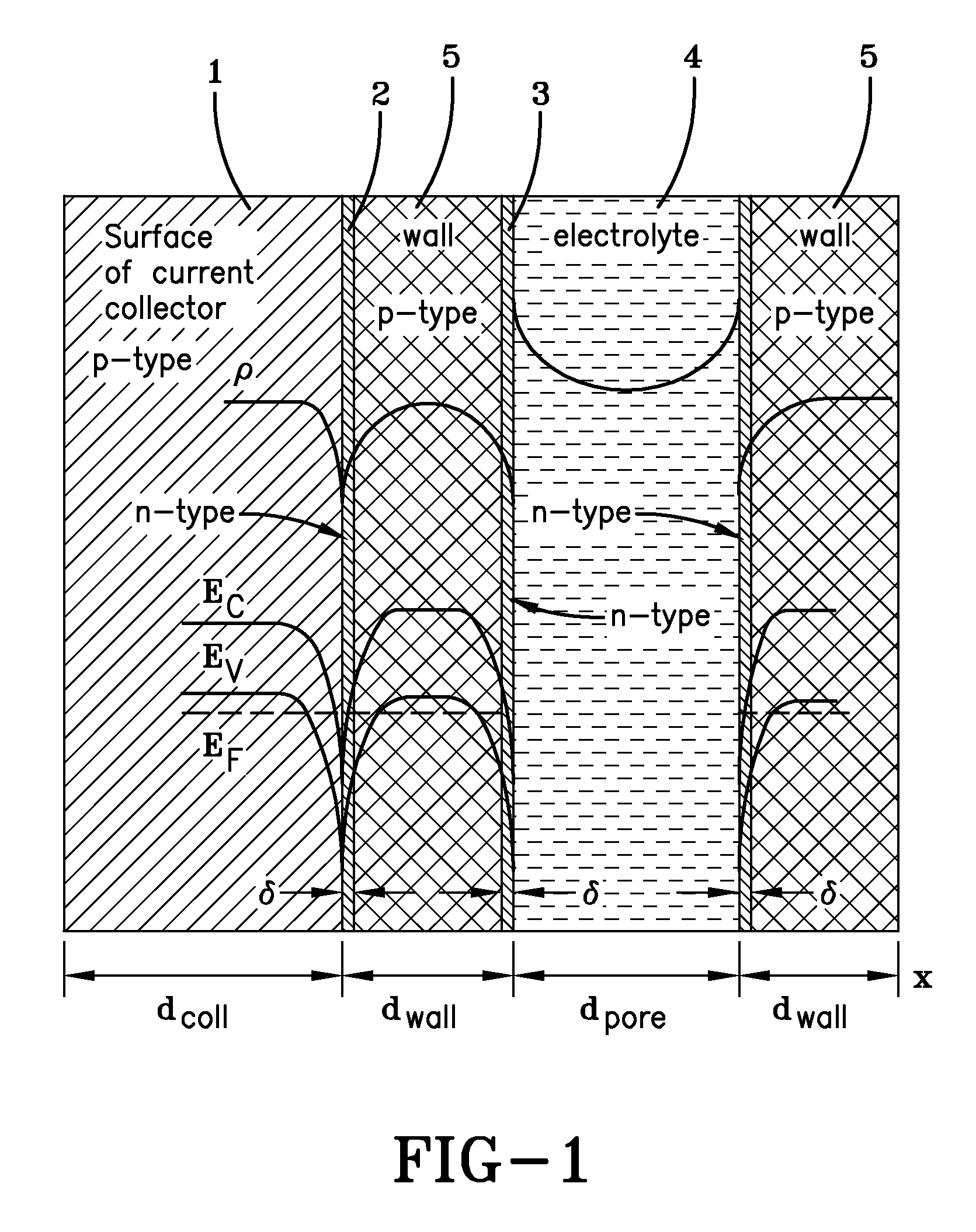

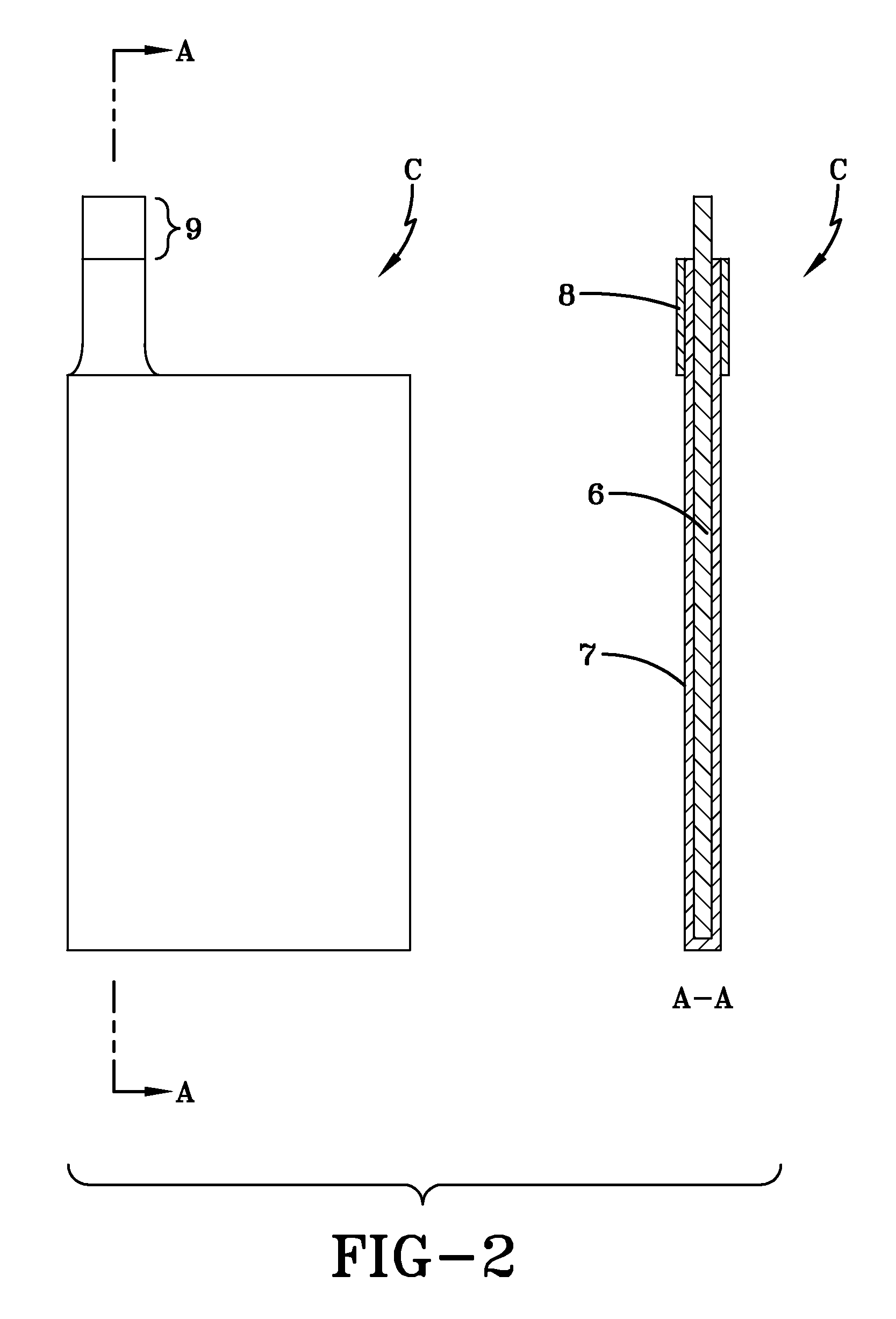

Current collector for lithium ion battery and preparation method of current collector

InactiveCN105762365ALow mass densityLow densityElectrode carriers/collectorsSecondary cellsCopper foilLithium-ion battery

The invention discloses a current collector for a lithium ion battery and a preparation method of the current collector.The current collector is composed of metal coatings and a microporous film layer.The microporous film layer is coated with the metal coatings in a double-face symmetry mode.The mass density of the current collector is only 1 / 3 to 1 / 2 that of conventional aluminum foil and copper foil metal, the mass of the lithium ion battery is obviously reduced, the energy density of the battery is improved, and the problem of short runtime of a power battery is solved.The surface roughness of the current collector is increased through the coatings, and the current collector can fully make contact with active matter; the capacity of the active matter is evenly released through the double-face symmetry coating structure, electrochemical polarization of the battery in the charge and discharge process is relieved, and the cycle performance of the battery is stable.

Owner:SHENZHEN LIWEI LI ENERGY TECH CO LTD

Circuits, multi-layer circuits, and methods of manufacture thereof

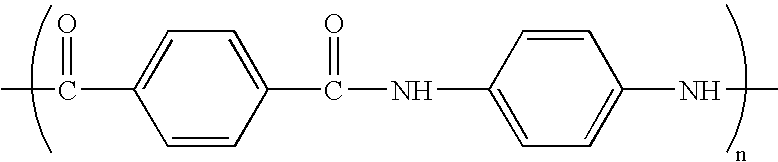

ActiveUS20040262739A1Low mass densityIncrease stiffnessSemiconductor/solid-state device detailsPrinted circuit aspectsLiquid crystallineSilsesquioxane

A dielectric material for use in a circuit material comprises a liquid crystalline polymer and a polyhedral oligomeric silsesquioxane (POSS) filler. Such dielectric materials may provide a variety of advantageous properties, especially in high frequency circuits.

Owner:WORLD PROPERTIES

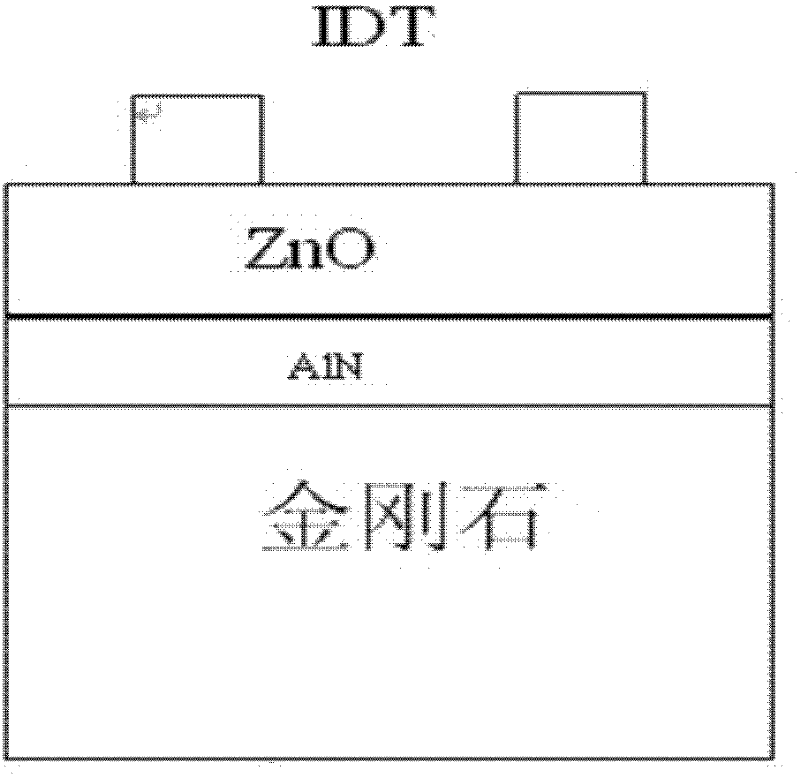

IDT/h-BN/c-BN/diamond multi-layer film structure surface acoustic wave device and its manufacture method

InactiveCN101060318ASmall difference in phase velocity VSmall velocity dispersionImpedence networksTemperature coefficientFilm structure

The disclosed IDT / h-BN / c-BN / diamond multilayer membrane structure SAW device comprises: from bottom to top, a nano-diamond membrane base prepared on mirror silicon, a nano c-BN membrane intermediate layer, a high-C-axis preferred orientated nano h-BN membrane, and an IDT. This invention can be used on condition of 2. 5GHz, high electromechanical coupling factor, smaller loss at 8w propagation, and low frequency temperature coefficient.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

NEMS comprising AlSi alloy based transducer

ActiveUS9016125B2High sensitivityReduce sizeVibration measurement in solidsAnalysing fluids using sonic/ultrasonic/infrasonic wavesTransducerConductive materials

A nano electro-mechanical system (NEMS) formed on a substrate is provided including at least one fixed part associated with the substrate and at least one movable part in relation to the substrate, the system including a transduction component configured to excite the movable part to confer on it a movement and / or to detect a movement of the movable part, the transduction component including at least one electrically conductive material. The electrically conductive material is made of an AlSi alloy based deposition, the deposition being supported at least in part by the movable part of the system.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

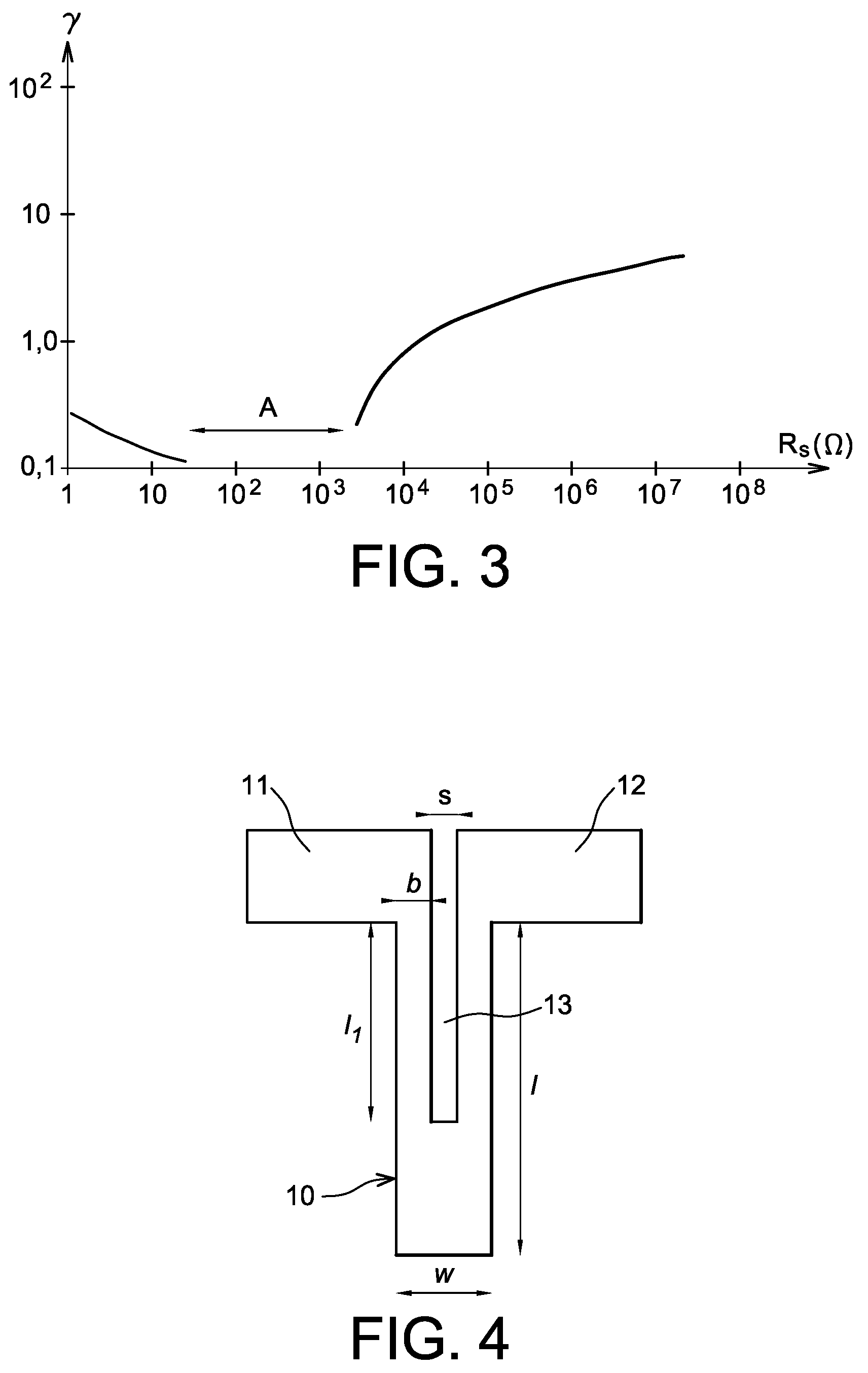

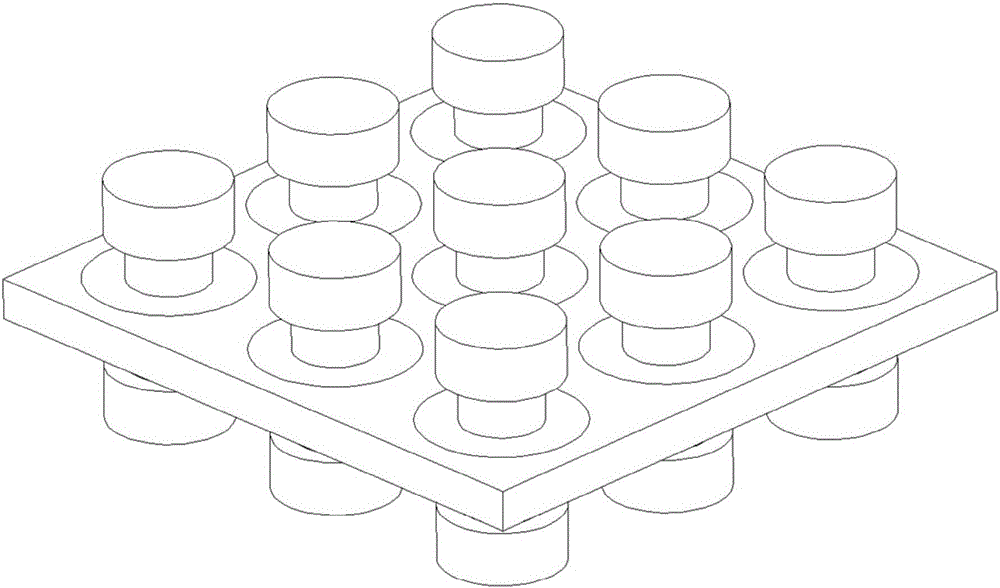

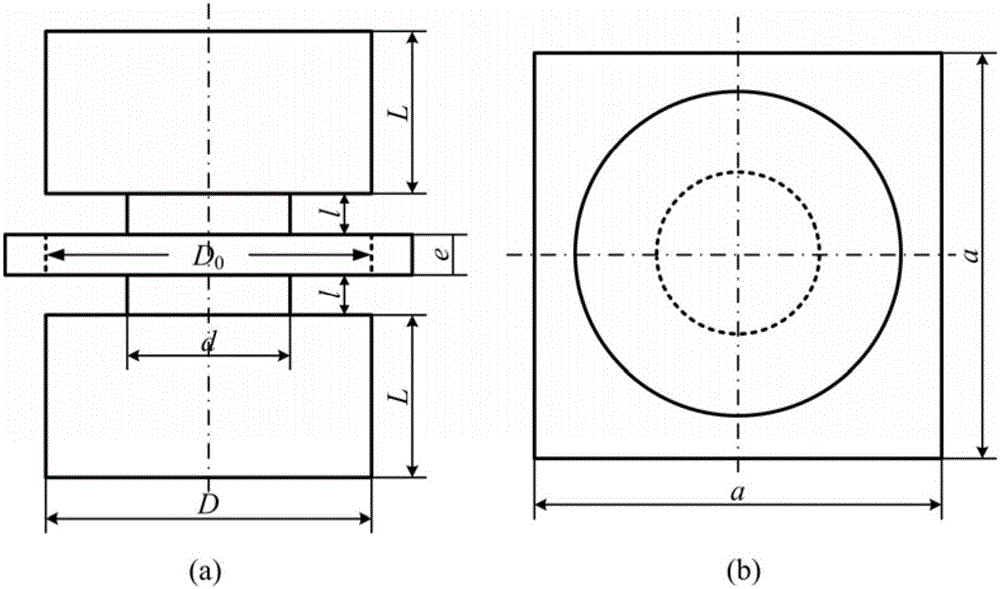

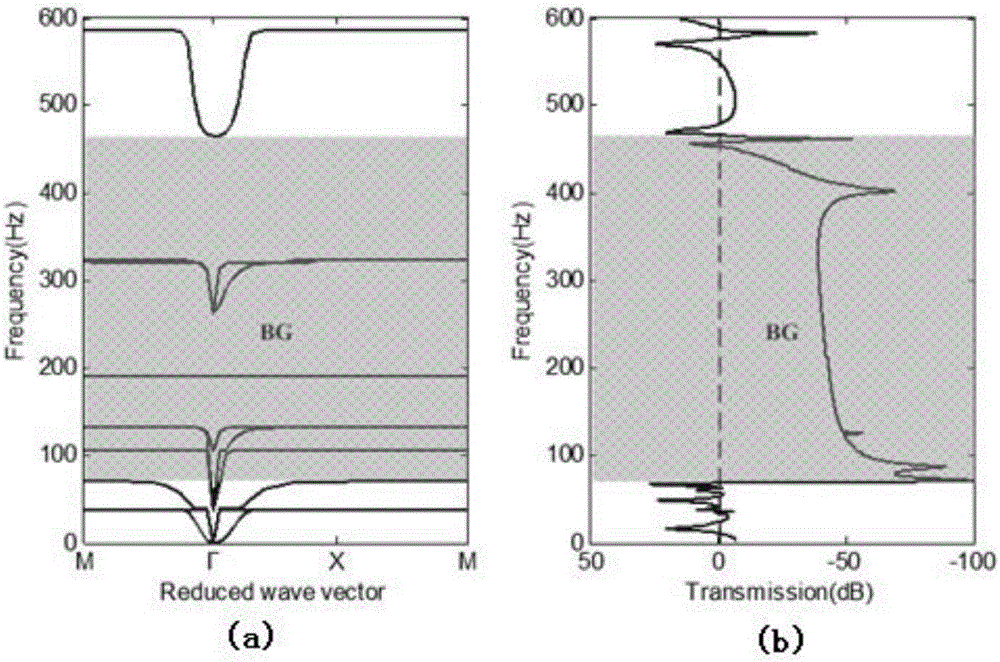

Metal-based foam-filling low-frequency broad-band-gap elastic metamaterial

InactiveCN106205586AAchieve low frequency bandgapGuaranteed StrengthSound producing devicesNoise controlMetallic materials

The invention relates to a metal-based foam-filling low-frequency broad-band-gap elastic metamaterial. The elastic metamaterial adopts a metal material as a matrix sheet material. Multiple round holes are arranged in the matrix sheet material in an array manner. Each round hole is filled with a foamed aluminium material to form a filling unit. Each filling unit is adhered to a local resonance unit. Each local resonance unit comprises two pairs of cylinders which are symmetrically arranged at two edges of the filling unit and are on the same straight line with the center of circle and the filling unit. The elastic metamaterial meets requirements for structural intensity and rigidity. A theoretical model of a prepared test piece has three complete band gaps in a low frequency range of below 500Hz and has a curved vibration band gap with the width of 400Hz. The lower boundary of the band gap is 66Hz. The metamaterial can be used for achieving low frequency broadband vibration noise control of a naval ship structure, and is significant for application of the elastic metamaterial in engineering vibration damping and noise reduction and naval ship acoustic stealth.

Owner:WUHAN UNIV OF TECH

Coated cBN

InactiveUS8308830B2Exceptional physical and chemical propertiesHigh hardnessPigmenting treatmentOther chemical processesBorideBoron carbide

The invention relates to a coated boron or nitrogen containing superhard abrasive material selected from cBN, boron suboxide and boron carbide comprising: cBN, boron suboxide and / or boron carbide superhard abrasive material substrate; a primary layer of a carbide / nitride / boride forming metal, such metal preferably being Ti and preferably being substantially in the form of the carbide, nitride or boride; a secondary layer of a high melting point metal selected from W, Mo, Cr, Ni, Ta, Au, Pt, Pd and alloys thereof; and an overcoat of Ag, Ni, Cu, Au, Pd, Pt, Rh, Os, Ir, Re, combinations and alloys thereof such as bronze (Cu / Sn), silver / bronze and silver / tin, the metal of the secondary layer being different to the metal of the overcoat. The invention further relates to methods for the manufacture of such material, use of such materials in tools and tools including such material.

Owner:ELEMENT SIX LTD

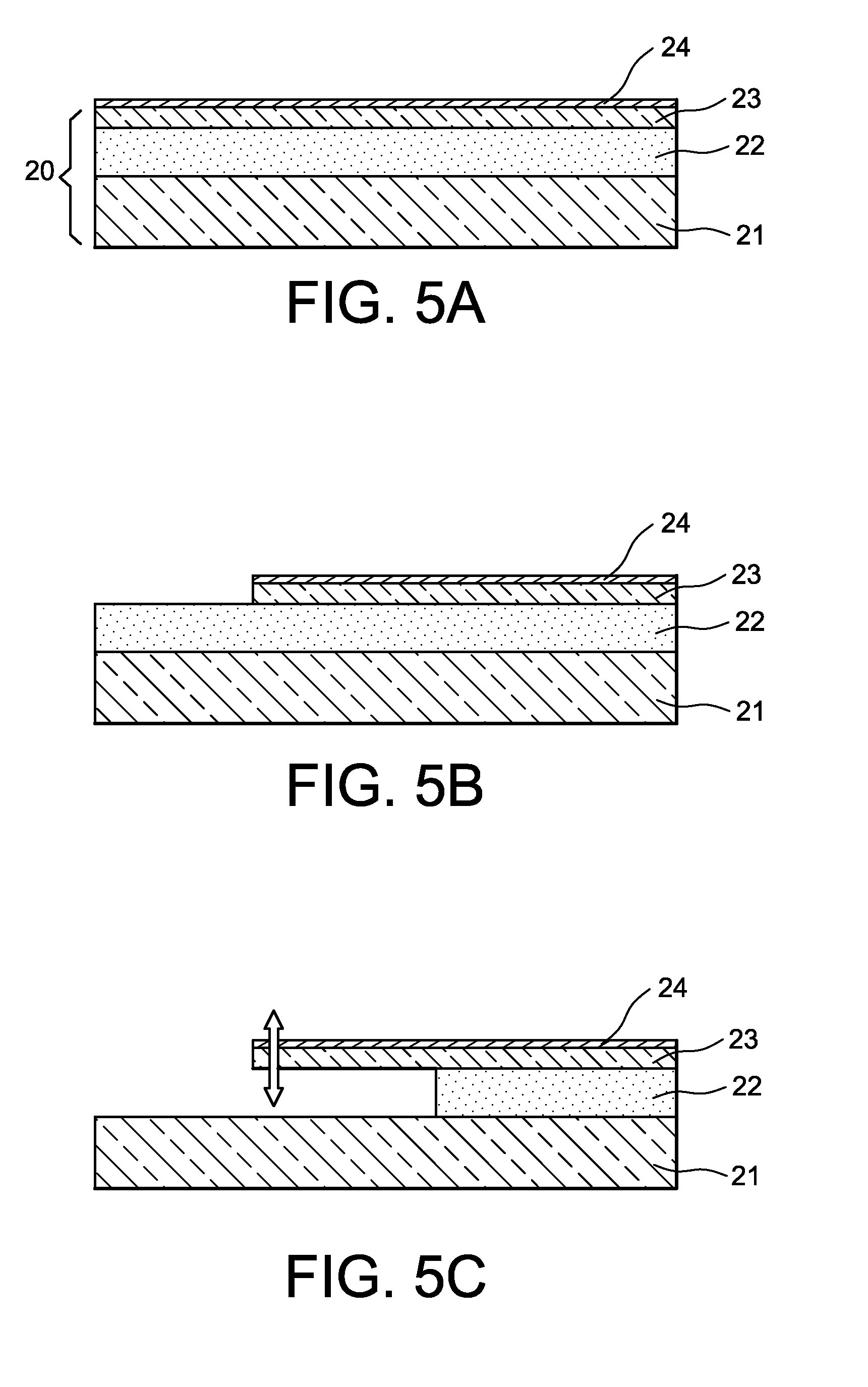

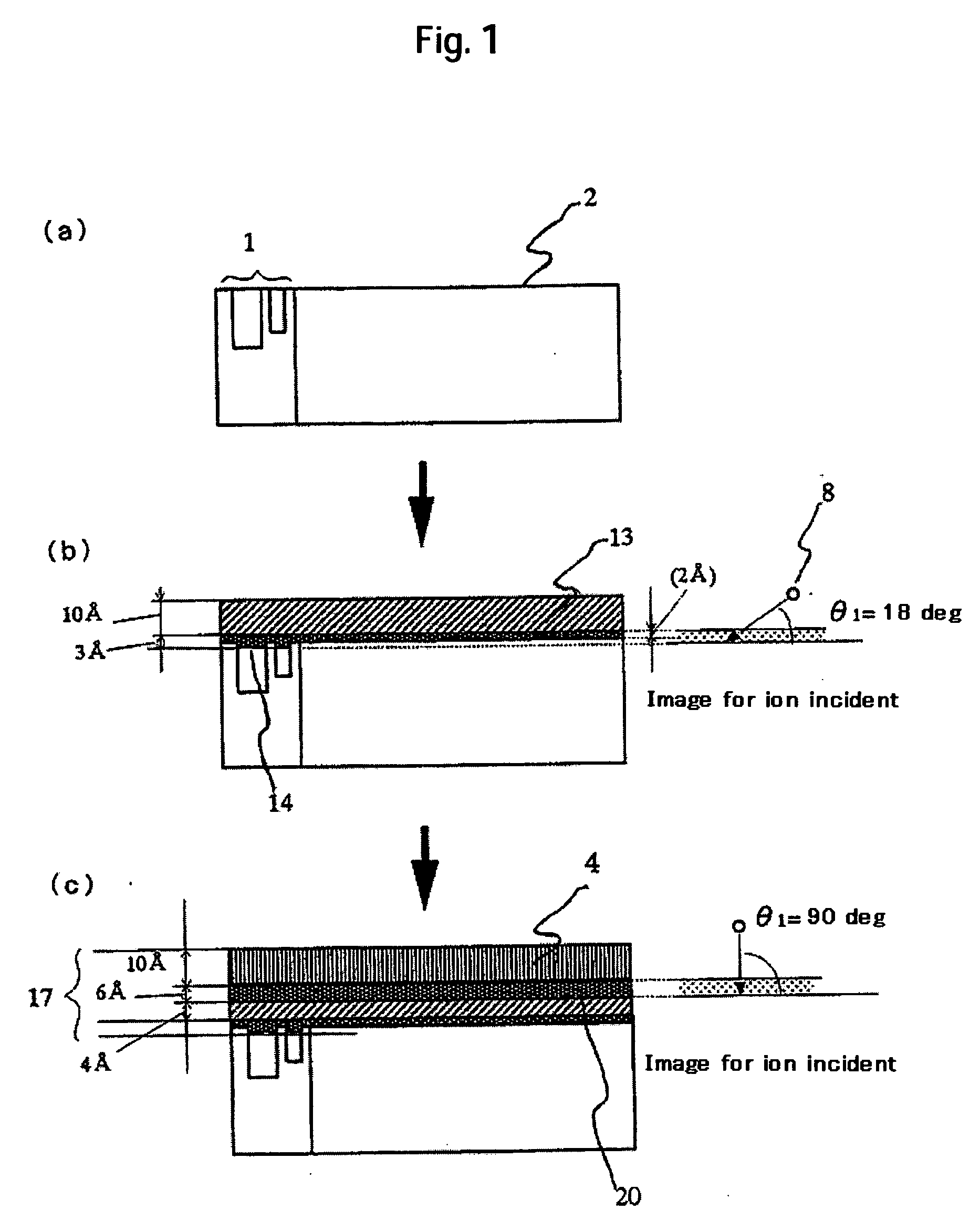

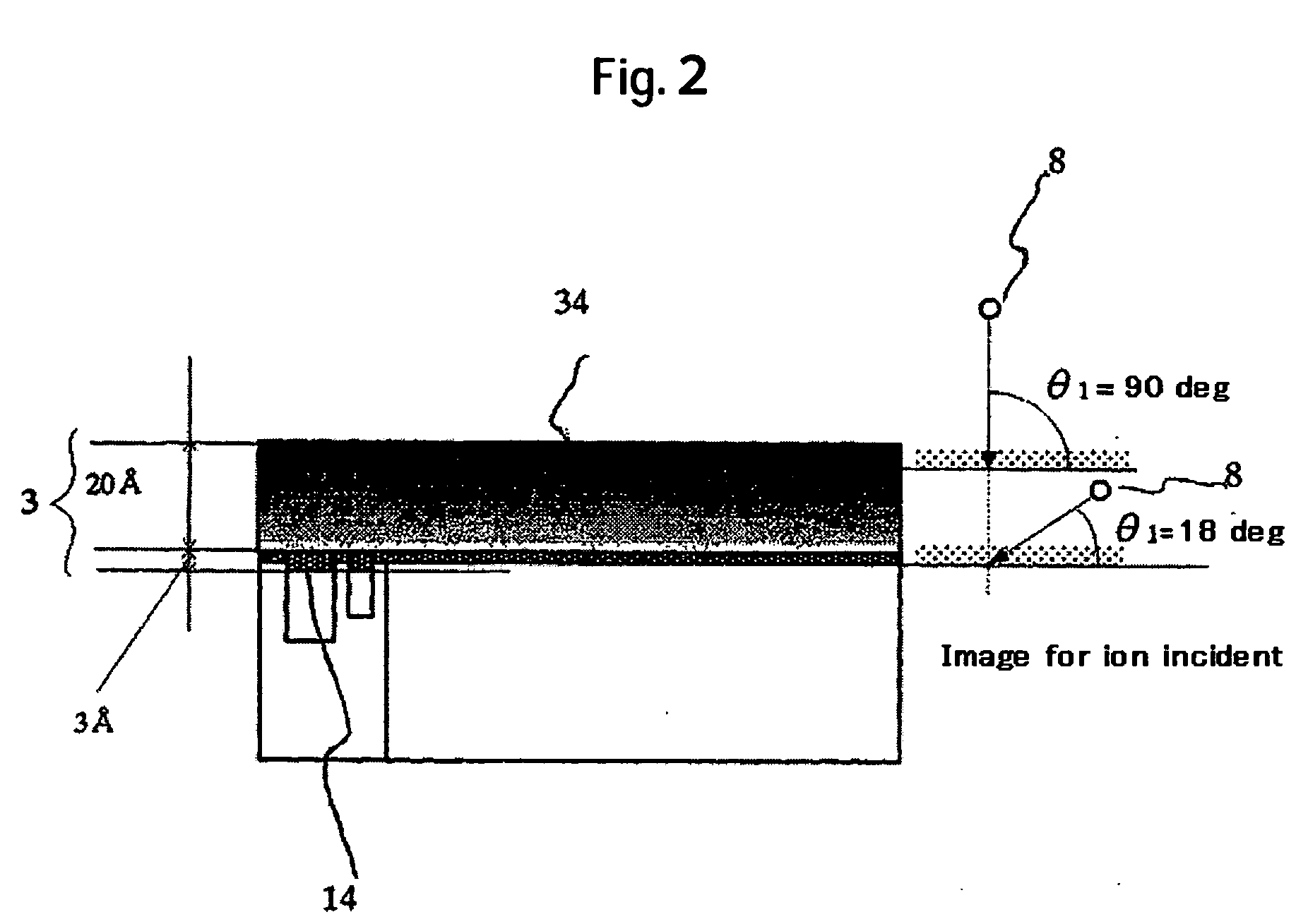

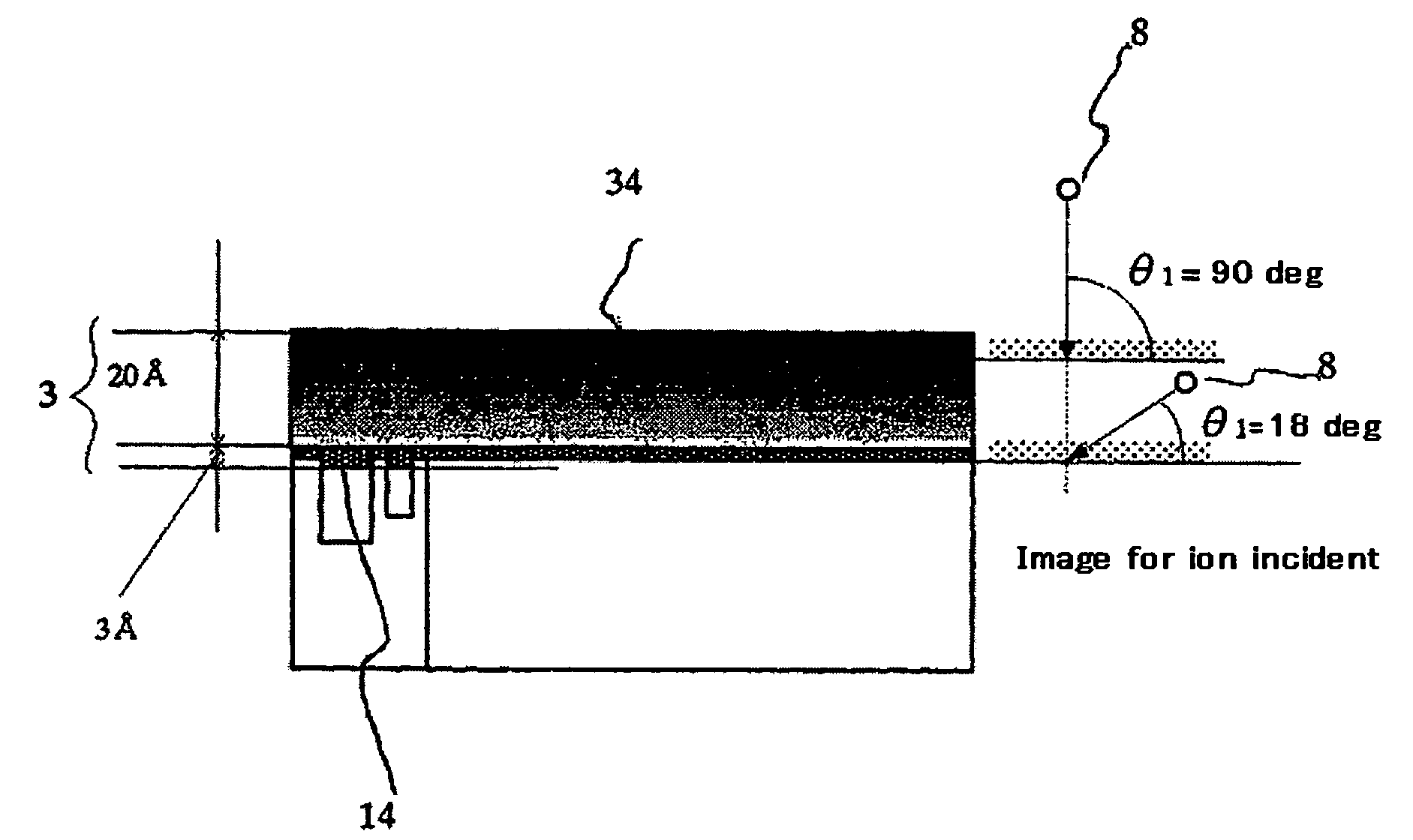

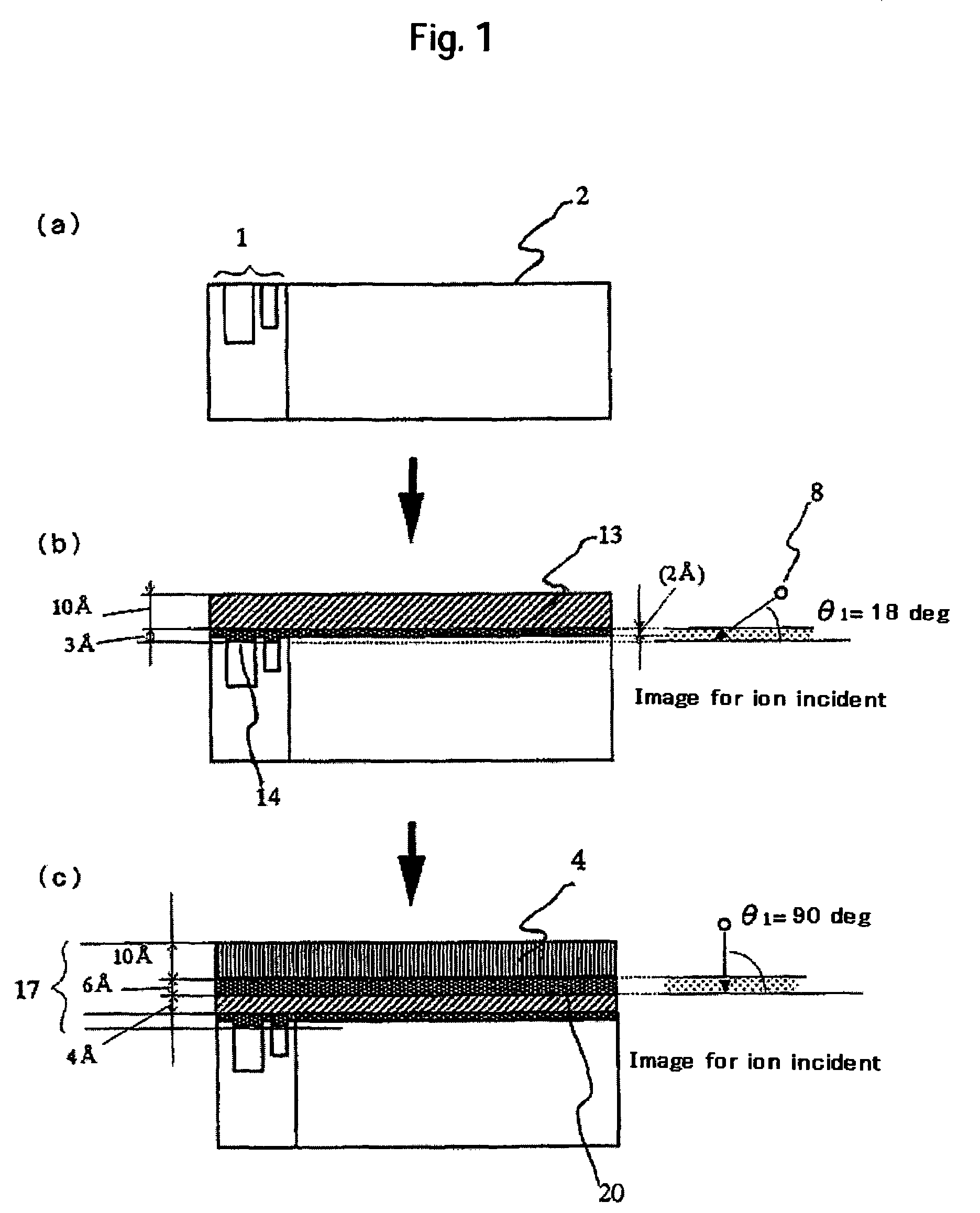

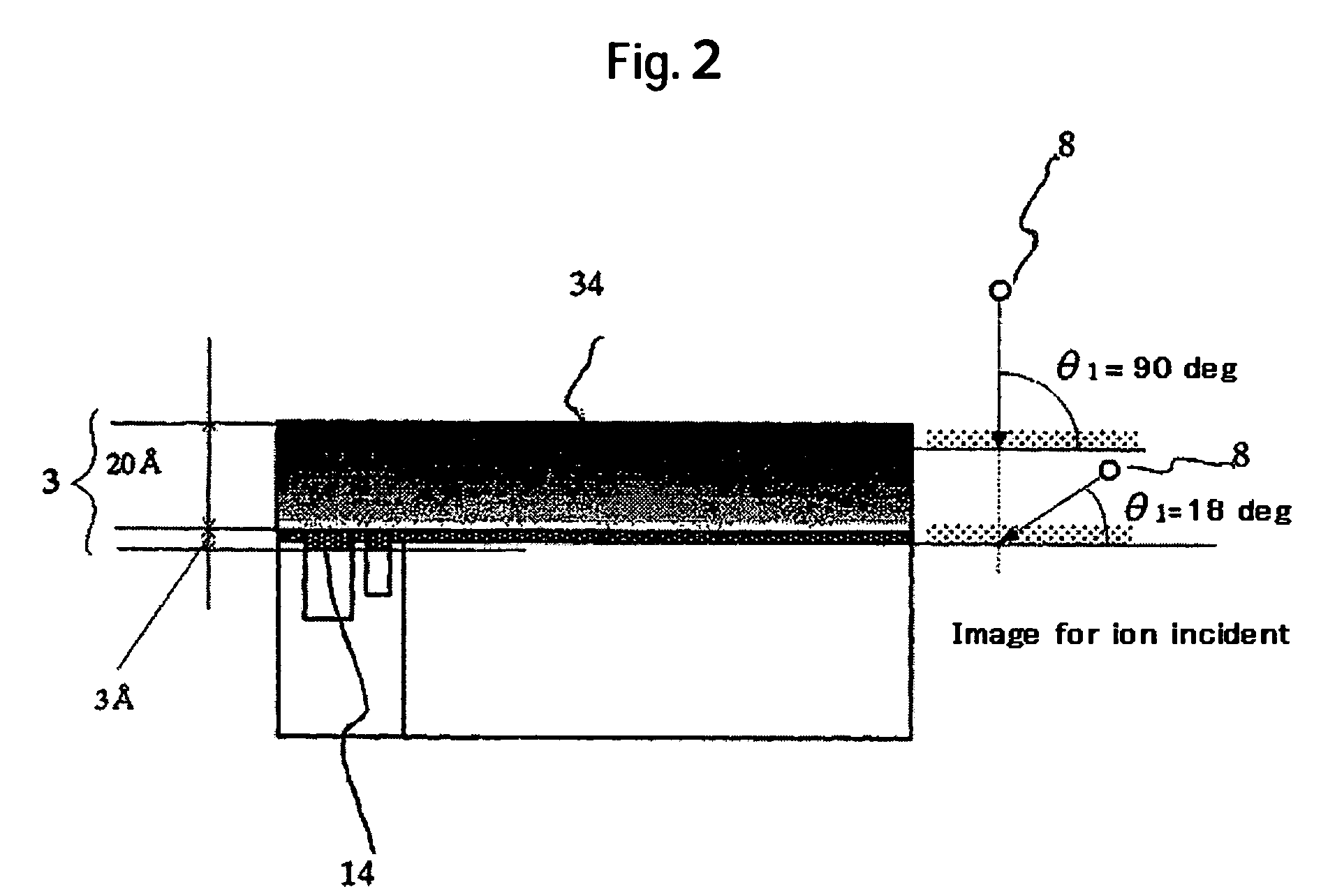

Magnetic head with air bearing surface protection film and manufacturing method thereof

InactiveUS20060072246A1Reduce thicknessReduce film thicknessManufacture head surfaceFluid-dynamic spacing of headsCarbon filmAir bearing

To promote reduction in thickness of an air bearing surface protective film of a magnetic head, a magnetic head having an air bearing surface protective film consisting only of a thin carbon film while excluding formation of a dead layer by ion incidence as less as possible to the read / write device, and a manufacturing method therefore, are provided. In an embodiment, an air bearing surface protective film of a magnetic head comprises a thin carbon film, in which the mass density a lowermost layer of the air bearing surface protective film on the side of a magnetic device is made lower compared with a thin carbon film constituting other adjacent layers. Further, the manufacturing method comprises deposition under the control of time for the incident angle of ion flow to a substrate to be processed and deposition under the control of time for the ion flow energy to a substrate to be processed

Owner:WESTERN DIGITAL TECH INC

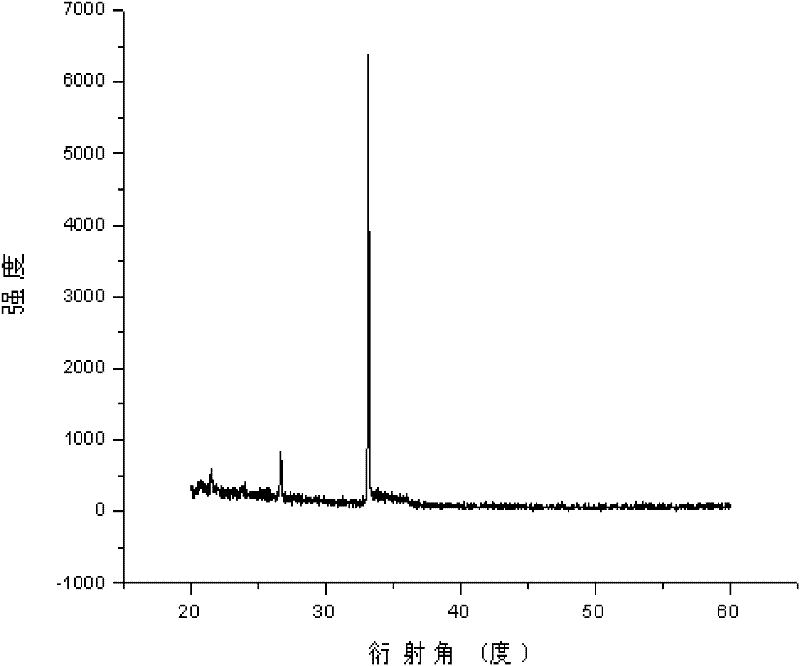

High frequency surface acoustic wave device with AlN (aluminum nitride) film as interlayer and preparation method thereof

InactiveCN102412803ASmall velocity dispersionHigh electromechanical coupling coefficientImpedence networksVacuum evaporation coatingFrequency dispersionChemical vapor deposition

The invention provides a high frequency surface acoustic wave device with an AlN (aluminum nitride) film as an interlayer. The device is characterized in that an a-axis preferred orientation AlN film is taken as a CVD (chemical vapor deposition) diamond substrate and a c-axis preferred orientation ZnO film is taken as an interlayer, the substrate and the interlayer are formed into an IDT(interdigital transducer) / ZnO / a-axis preferred orientation AlN / diamond multi-layered membrane structure and the structure is stacked with the IDT in sequence to form the high frequency surface acoustic wave device; the preparation method comprises the following steps of preparing an a-axis preferred oritention AlN film interlayer, and preparing a c-axis preferred oritentation ZnO film on the a-axis preferred orientation AlN film interlayer. The device and the preparation method provided by the invention have the following advantages that the sound velocity frequency dispersion caused by a large sound velocity gap between nanodiamond and ZnO can be solved, the application demand of the surface acoustic wave with high frequency above 4.8 GHz can be met, and moreover, the process is simple and easy to implement, and is beneficial for large-scale population and application.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Flexible low-resistance current collector and preparation method thereof

InactiveCN113725441AImprove flexibilityEasy to processElectrode carriers/collectorsSecondary cellsElectrical resistance and conductanceConductive coating

The invention belongs to the technical field of current collectors. The invention provides a flexible low-resistance current collector. The current collector comprises a non-conductive base material and conductive coatings; the two faces of the non-conductive base material are each provided with one conductive coating. The thickness of the non-conductive base material is 1-30 microns; and the thickness of a single surface of each conductive coating is 0.1-4 microns. The invention also provides a preparation method of the flexible low-resistance current collector. The current collector can better adapt to large size change of an electrode material in the working process, and the effective surface area of the current collector for conducting electrons is increased; the mass per unit area of the current collector is small, the mass of a whole electrode is greatly reduced, and the weight is lighter; and the specific surface area of the current collector is large, so that the contact performance of an electrode material and the current collector is effectively improved, the interface resistance between the current collector and the electrode material is reduced, and the rate capability is improved.

Owner:宁波铵特姆新能源科技有限公司

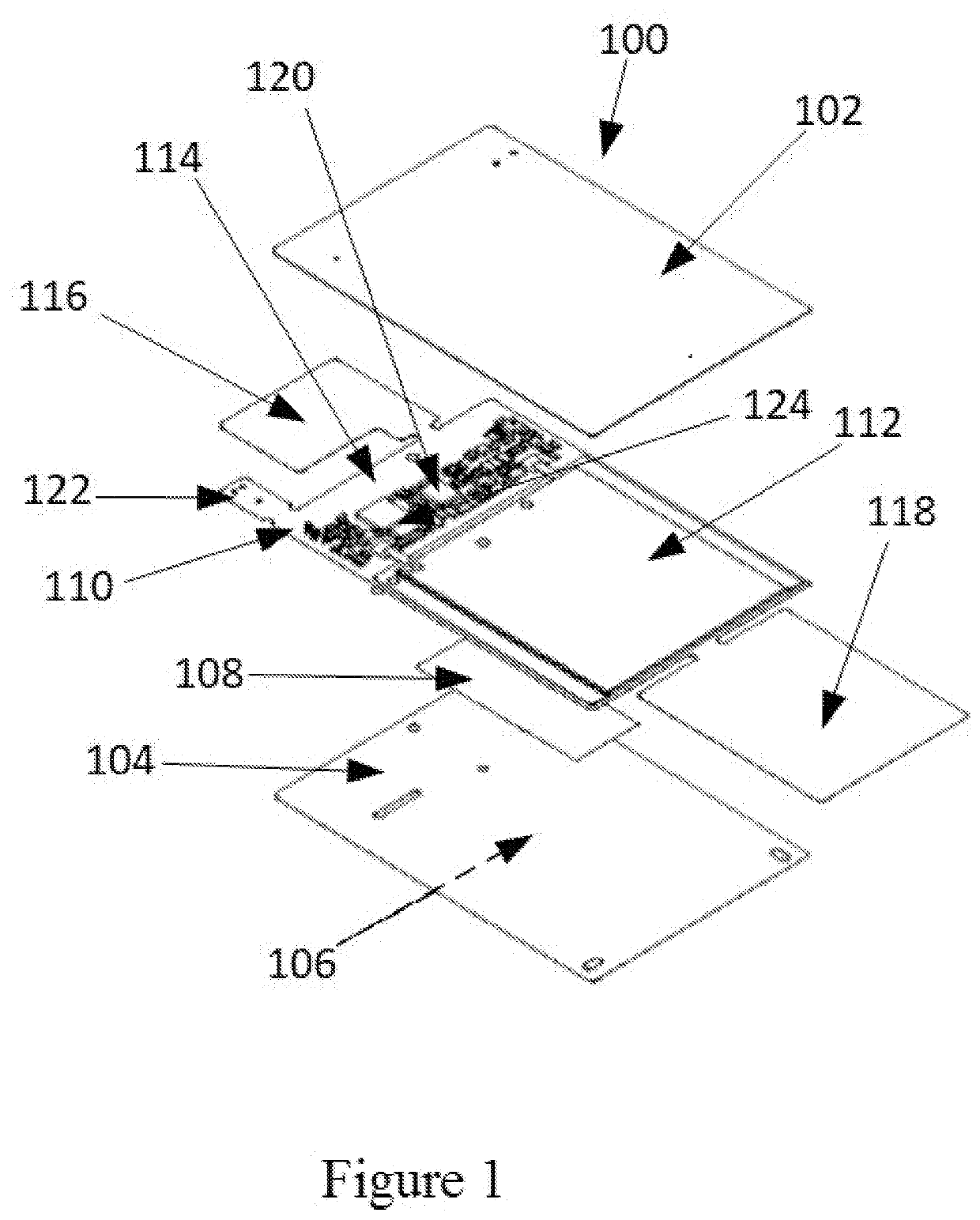

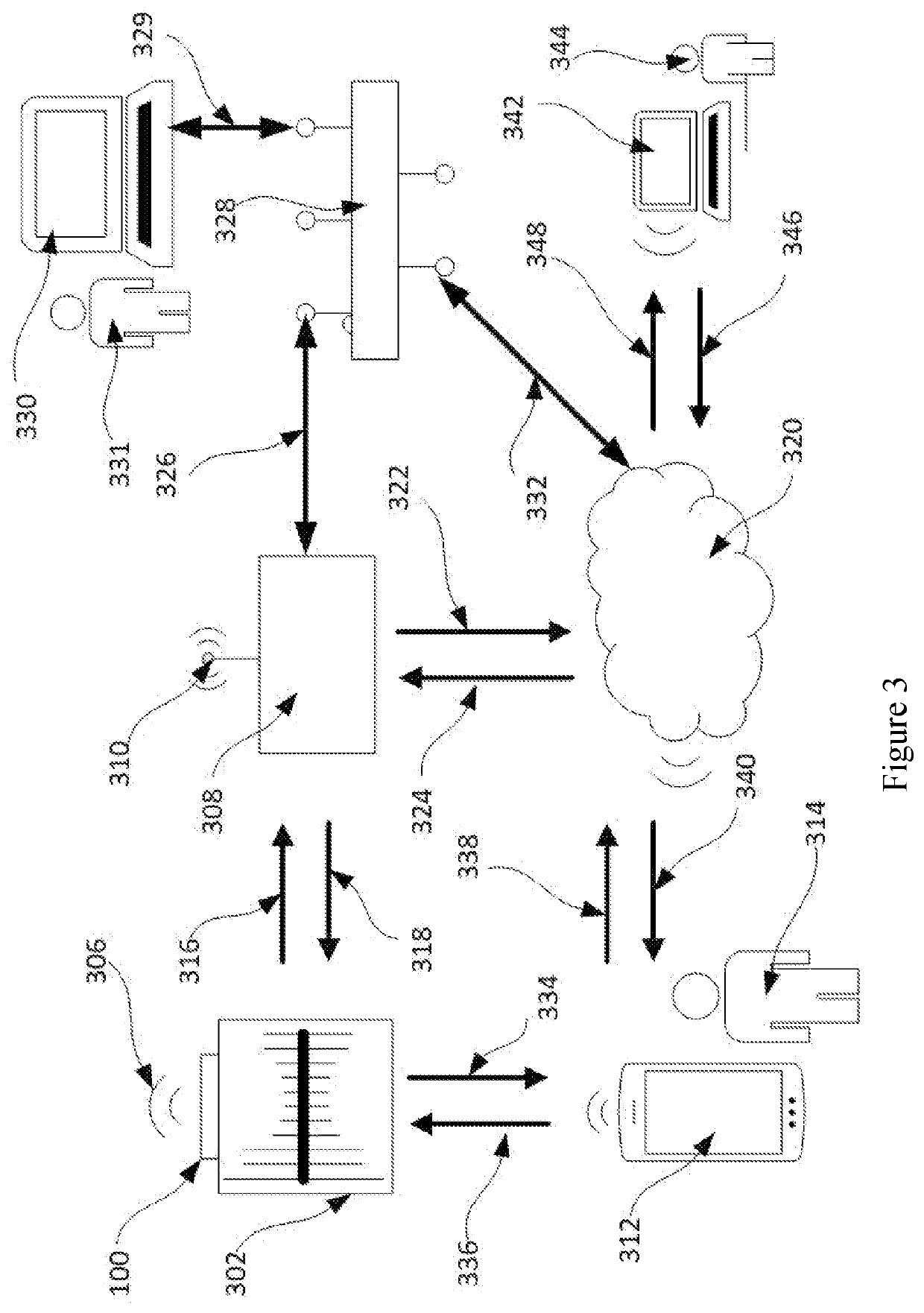

System and method for sensing vibrations in equipment

InactiveUS20210140815A1Provide useful informationLow profileAcceleration measurement using interia forcesSubsonic/sonic/ultrasonic wave measurementTelecommunications linkUser-defined codes

This invention provides a low-profile, highly-sensitive, high-frequency sensor that can be affixed to equipment. Low-profile electronics with the ability to capture and analyze specific signals of concern can be utilized as to remain unobtrusive. Vibration data can be captured and stored locally on the equipment where user-defined code can analyze data and pick specific parameters of concern to send via the wireless communications link to a receiver. The receiver is able to capture the data and monitor parameters of the equipment.

Owner:FUTURE TECH IN SPORT INC

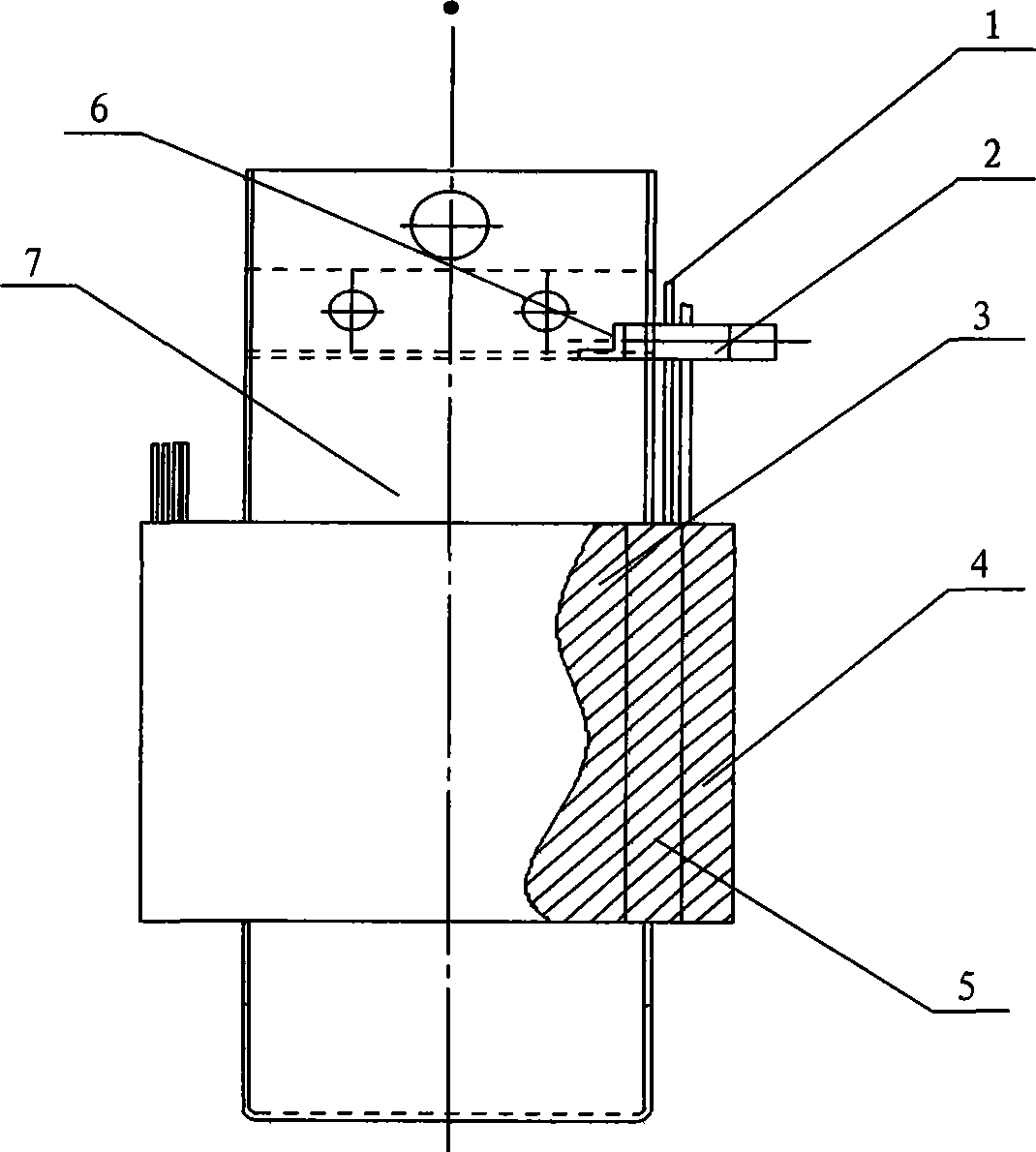

Amorphous alloy oil immersion type distribution transformer body structure and manufacturing method thereof

InactiveCN101471170ALow mass densityAbundant resourcesTransformers/inductances coils/windings/connectionsDistribution transformerType distribution

The invention relates to a manufacture method of amorphous alloy oil-immersed distribution transformer which comprises a low-tension line copper-aluminum transition terminal block, an iron core, a high and a low tension coils and a clipper, wherein both the high and the low tension coils have rectangular layered structures, and the conducting material of the high and the low tension coils is metal aluminum. The invention also comprises a rectangular insulating frame arranged in the low tension coil which directly coils surrounding the insulating frame. The manufacture method not only has the feature of low open circuit loss of common amorphous alloy oil-immersed distribution transformers but also is characterized by low material cost and light weight, which reduces effects caused by price rise of copper to cost of oil-immersed distribution transformers, and reduces consumption of copper which is short in supply.

Owner:SHANGHAI ZHIXIN ELECTRIC +2

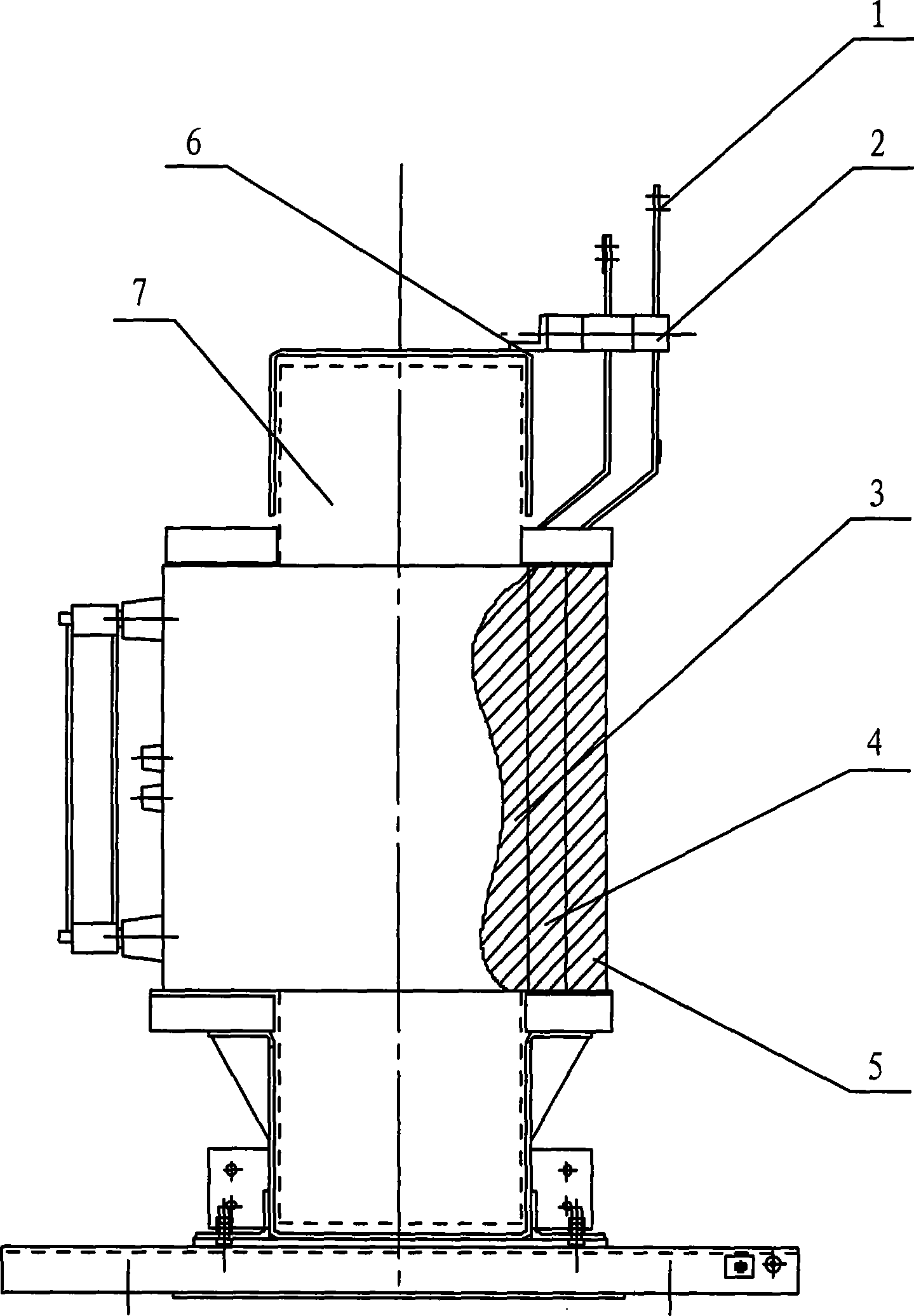

Amorphous alloy oil immersion type distribution transformer body structure and manufacturing method thereof

InactiveCN101471171ALow mass densityAbundant resourcesTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureAluminiumThree-phase

The invention relates to a structure and a manufacture method of amorphous alloy dry distribution transformer, wherein the structure comprises a three-phase iron core, a high and a low tension coils which are respectively winded into a whole structure and which case on the three-phase iron core, an insulating frame arranged in the low tension coil, upper and lower clippers arranged at the upper and the lower ends of the high and the low tension coils, and a plurality of aluminum-copper transition joints fixed on the upper clippers by insulating wire clamps or insulators. The high and the low tension coils all employ aluminum as conducting material, and the high tension coil cases around the high tension coil after being bound with aluminum wires and encapsulated by epoxy. The manufacture method of amorphous alloy dry distribution transformer replaces copper with aluminum, which not only has the feature of low open circuit loss of common amorphous alloy distribution transformers but also is characterized by low material cost and light weight, thereby reducing effects caused by price rise of copper to cost of distribution transformers, and reducing consumption of copper which is short in supply.

Owner:SHANGHAI ZHIXIN ELECTRIC +2

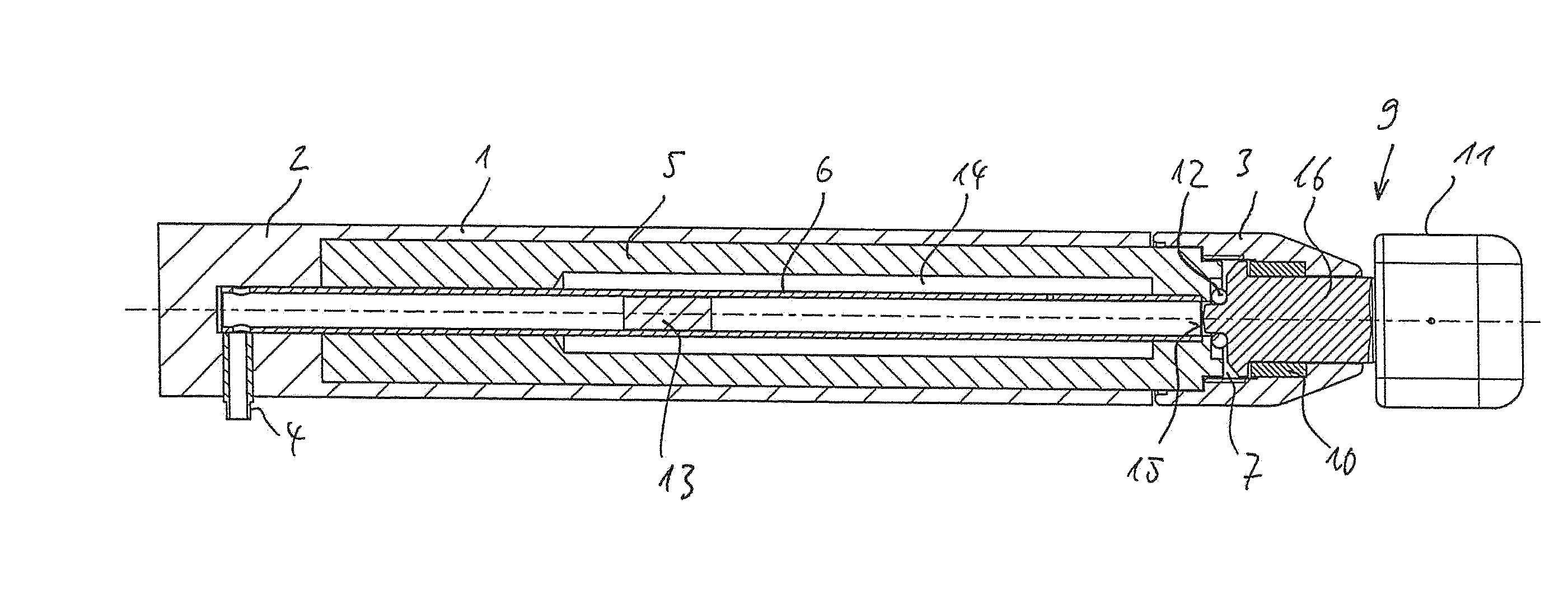

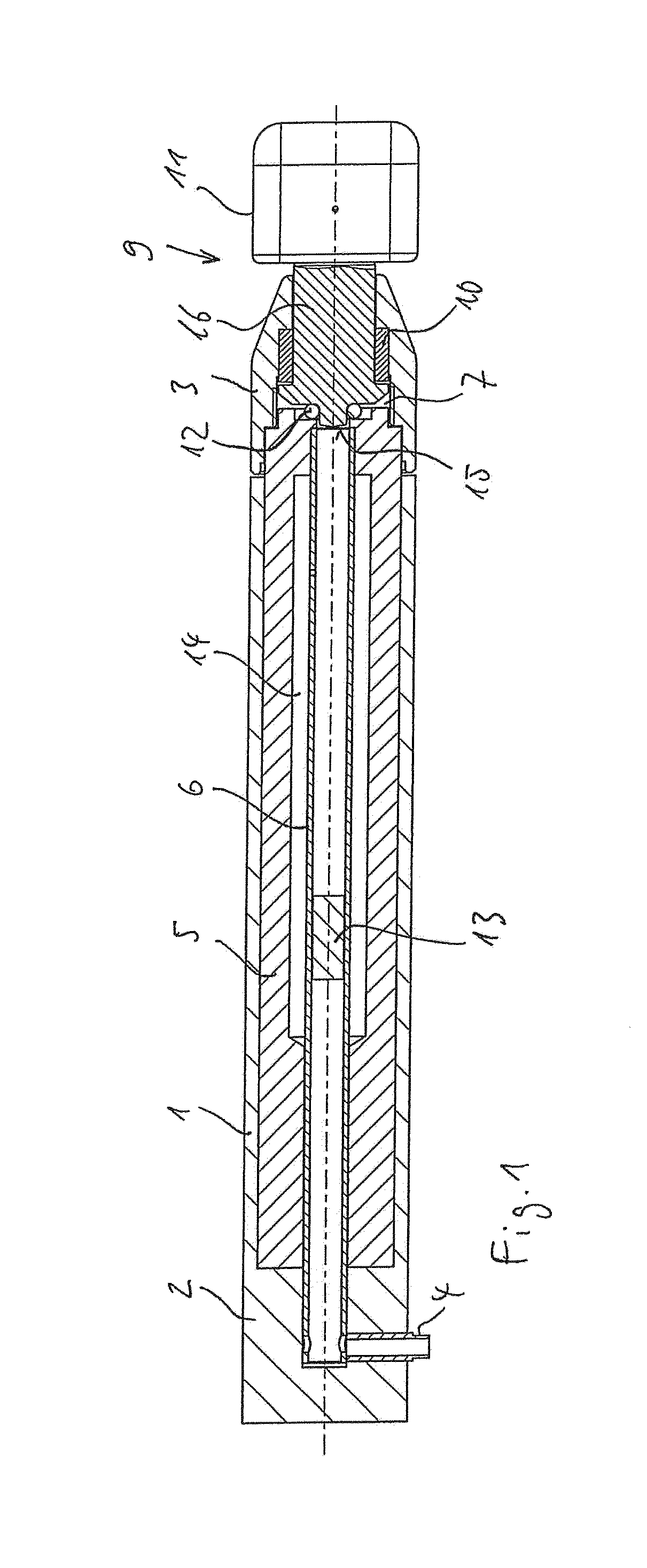

Apparatus for treating the human or animal body with mechanical strokes

ActiveUS20160089296A1Less careIncreased mechanical load capacitySurgeryVibration massageRisk strokeAnimal body

The invention relates to an apparatus for treating a human or animal body by mechanical strokes, wherein an applicator for being placed on the patient's body surface has a basically oblique front area portion in an angle between 30° and 60° to the stroke direction.

Owner:STORZ MEDICAL

Magnetic head with air bearing surface protection film and manufacturing method thereof

InactiveUS7551398B2Reduce thicknessLow mass densityManufacture head surfaceRecord information storageCarbon filmAir bearing

To promote reduction in thickness of an air bearing surface protective film of a magnetic head, a magnetic head having an air bearing surface protective film consisting only of a thin carbon film while excluding formation of a dead layer by ion incidence as less as possible to the read / write device, and a manufacturing method therefore, are provided. In an embodiment, an air bearing surface protective film of a magnetic head comprises a thin carbon film, in which the mass density a lowermost layer of the air bearing surface protective film on the side of a magnetic device is made lower compared with a thin carbon film constituting other adjacent layers. Further, the manufacturing method comprises deposition under the control of time for the incident angle of ion flow to a substrate to be processed and deposition under the control of time for the ion flow energy to a substrate to be processed.

Owner:WESTERN DIGITAL TECH INC

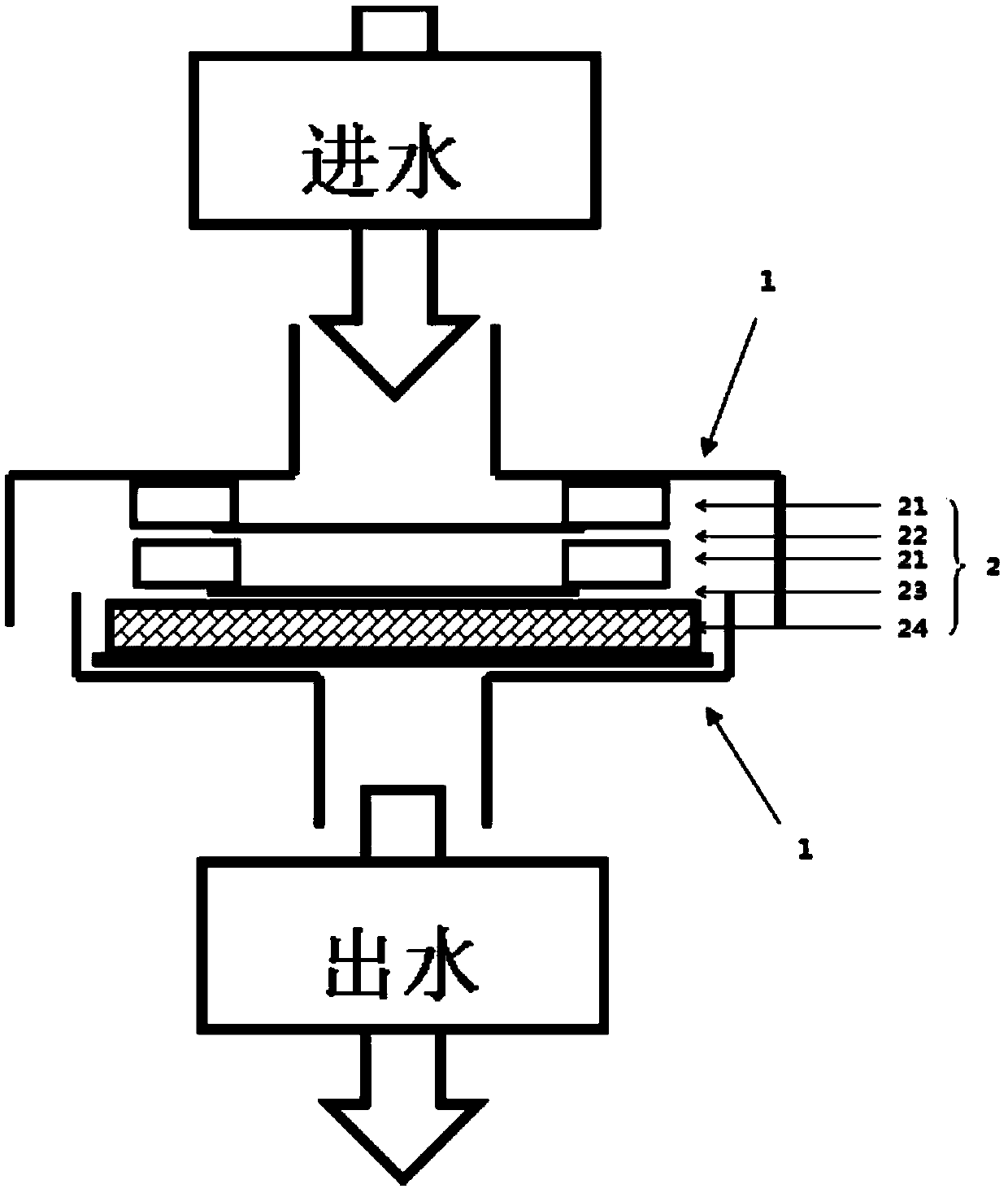

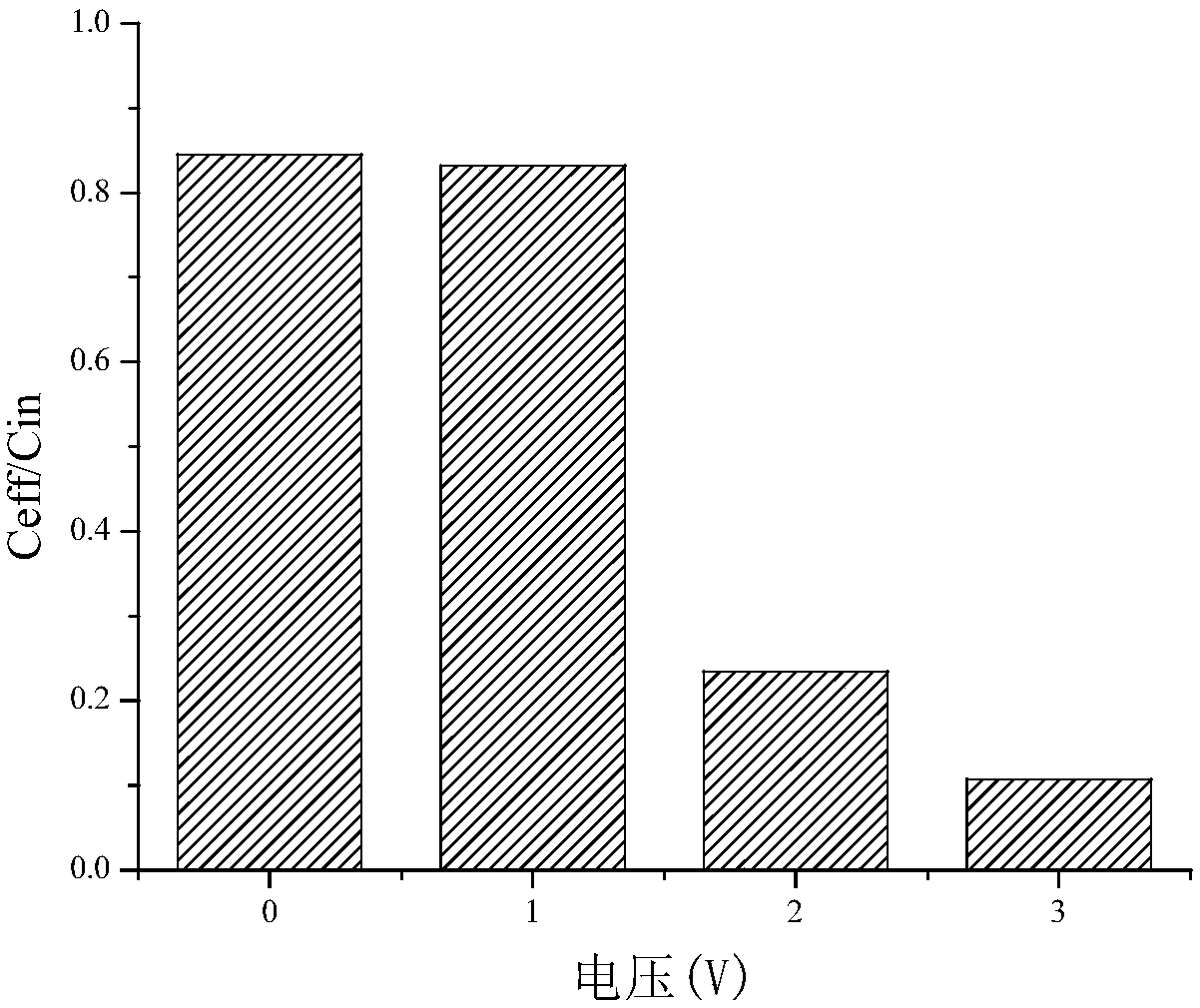

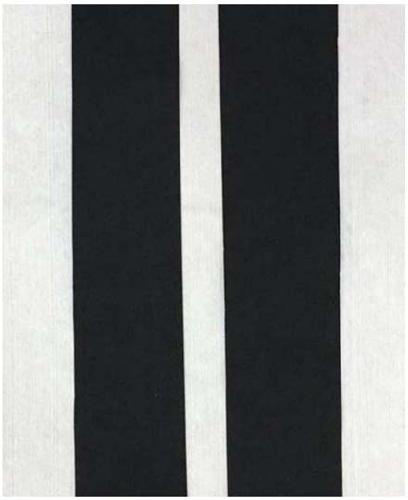

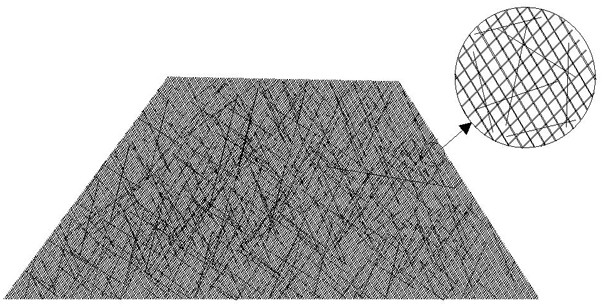

Filtering type electrochemical reactor and method for removing antibiotics from water mass

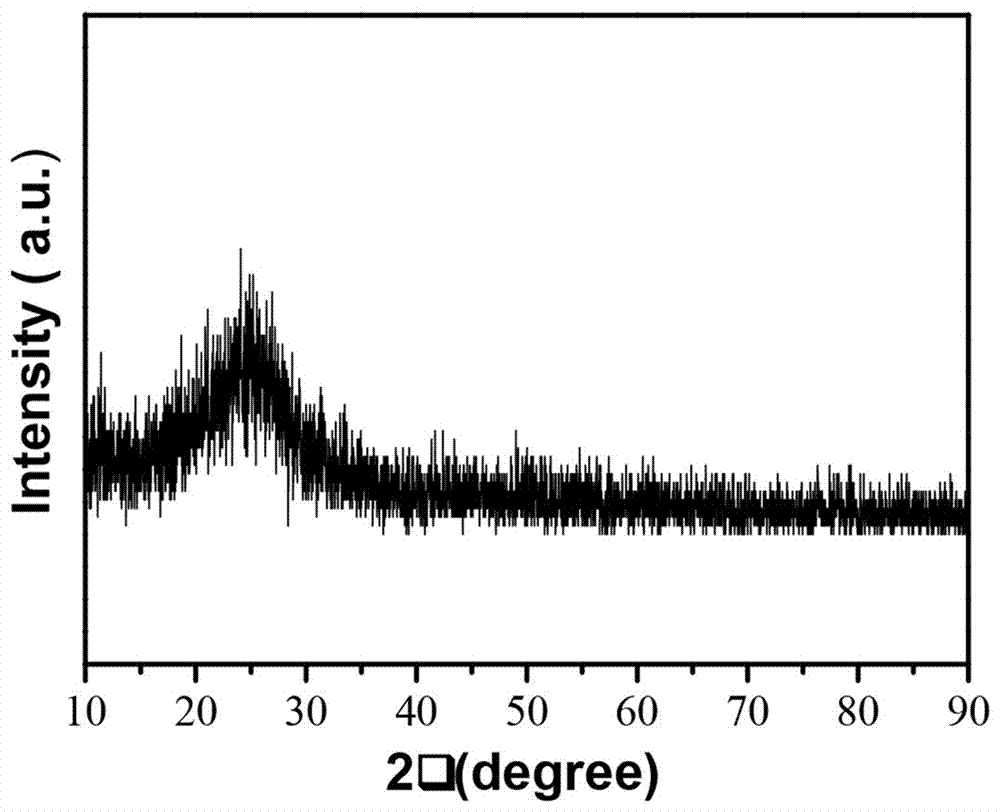

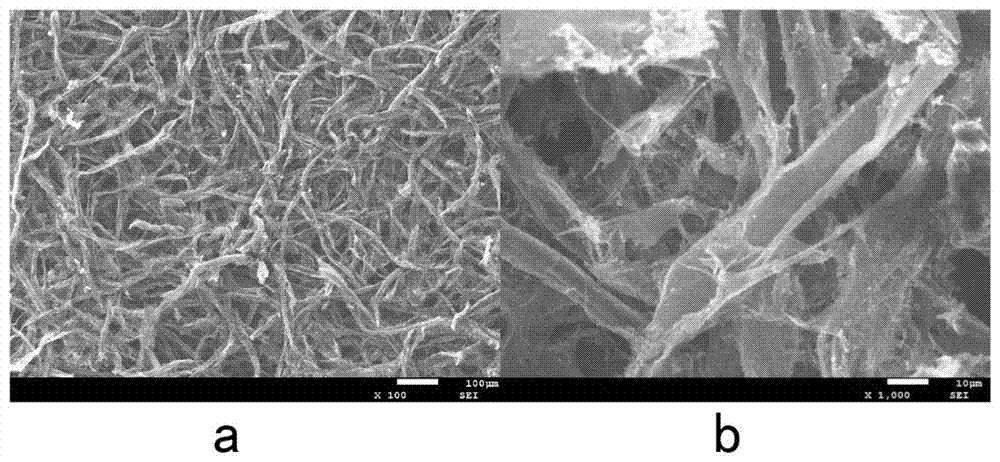

InactiveCN110723786ALarge specific surface areaLow mass densityCarbon compoundsWater contaminantsElectrochemical responsePollutant

The invention discloses a filtering type electrochemical reactor and a method for removing antibiotics from water mass. The filtering type electrochemical reactor comprises a tank body and a filteringdevice, wherein in the filtering device, a carbon nanotube membrane serves as an anode. The method for removing the antibiotics from the water mass comprises the step of performing treatment by usingthe filtering type electrochemical reactor. The filtering type electrochemical reactor disclosed by the invention has the advantages that the use is simple, the operation is convenient, the efficiency of mass transfer is high, the effect of removing pollutants is good, and the like, so that the filtering type electrochemical reactor can be extensively applied to removal of the pollutants from thewater mass and has very good use values and application prospects. According to the method for removing the antibiotics from the water mass, disclosed by the invention, the antibiotics can be removedthrough enabling the antibiotic water mass to pass through the reactor in the form of filtering, so that the method has the advantages of simplicity in operation, low cost, wide applicable range, high treatment efficiency, high removal rate, environment-friendliness and the like and thus can be extensively applied to the removal of the antibiotics from the water mass; and the method has a relatively good removal effect on the antibiotics of different types, thereby being an environment-friendly electrochemical method.

Owner:HUNAN UNIV

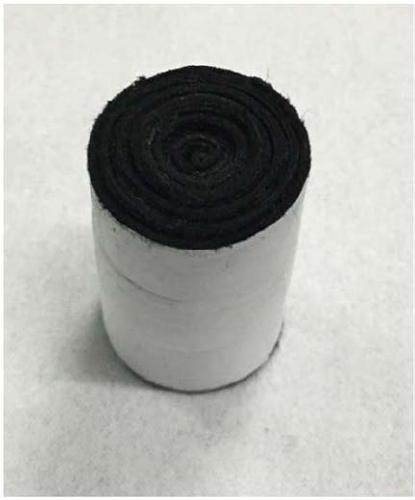

Energy-absorbing component manufactured by carbon nano-tube paper and manufacture method thereof

ActiveCN109017654AGood deformabilityStrong elastic deformationCarbon nanotubesBumpersHigh energyCarbon nanotube

The invention discloses an energy-absorbing component manufactured by carbon nano-tube paper, belonging to the field of manufacturing nano-materials and related devices. The energy absorbing member ismade of carbon nanotube paper. Wherein, the carbon nanotube paper adopts a carbon nanotube paper made of a vertical carbon nanotube array, a vertical carbon nanotube array / graphene three-dimensionalcomposite structure material, ultra-long perfect carbon nanotubes and / or agglomerated carbon nanotubes. The energy-absorbing components provided in this paper have excellent impact resistance, high energy-absorbing density and low mass density, and are easy to be manufactured in batches, which is very conducive to improving the impact resistance of vehicles and promoting the lightweight process ofautomobiles.

Owner:TSINGHUA UNIV

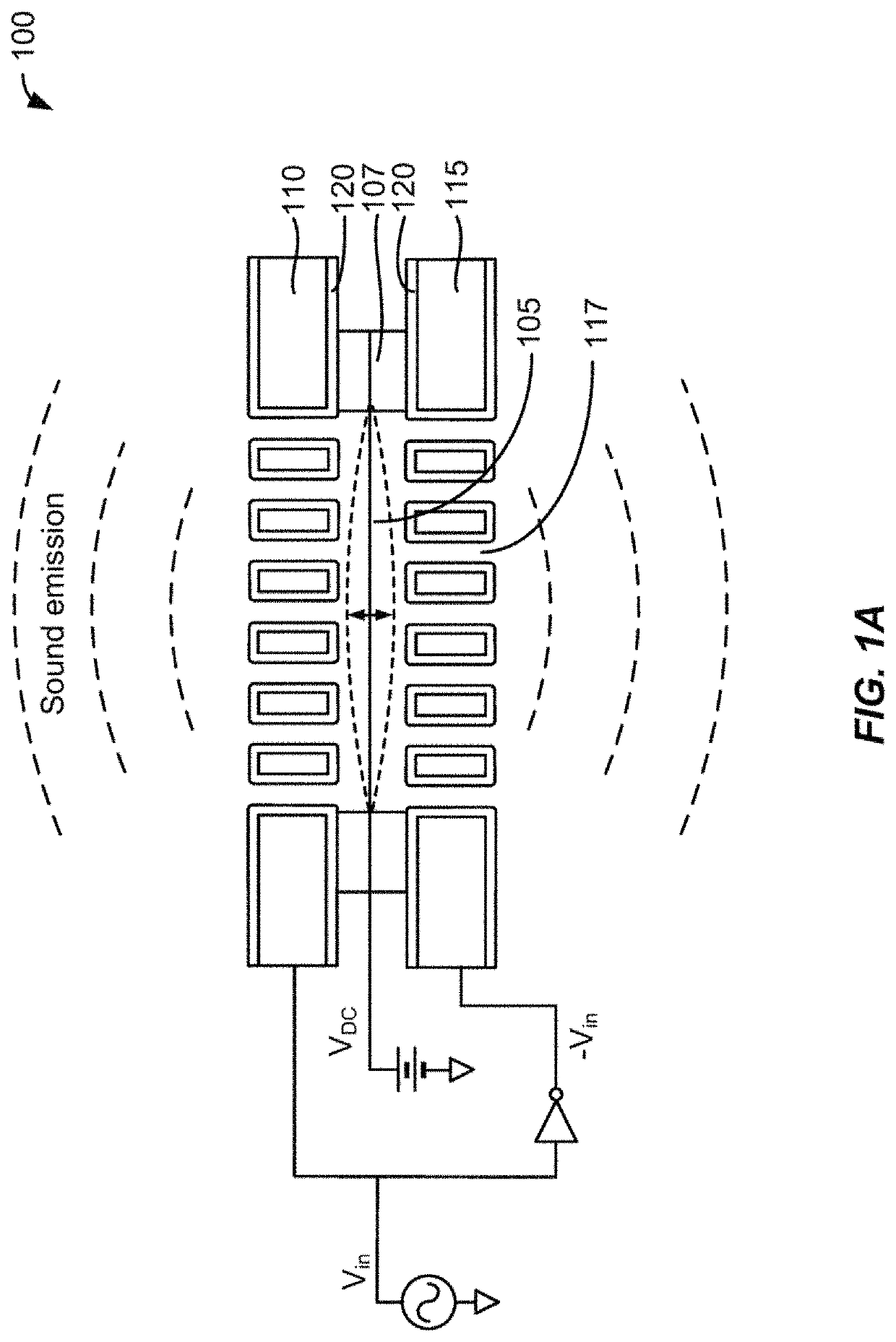

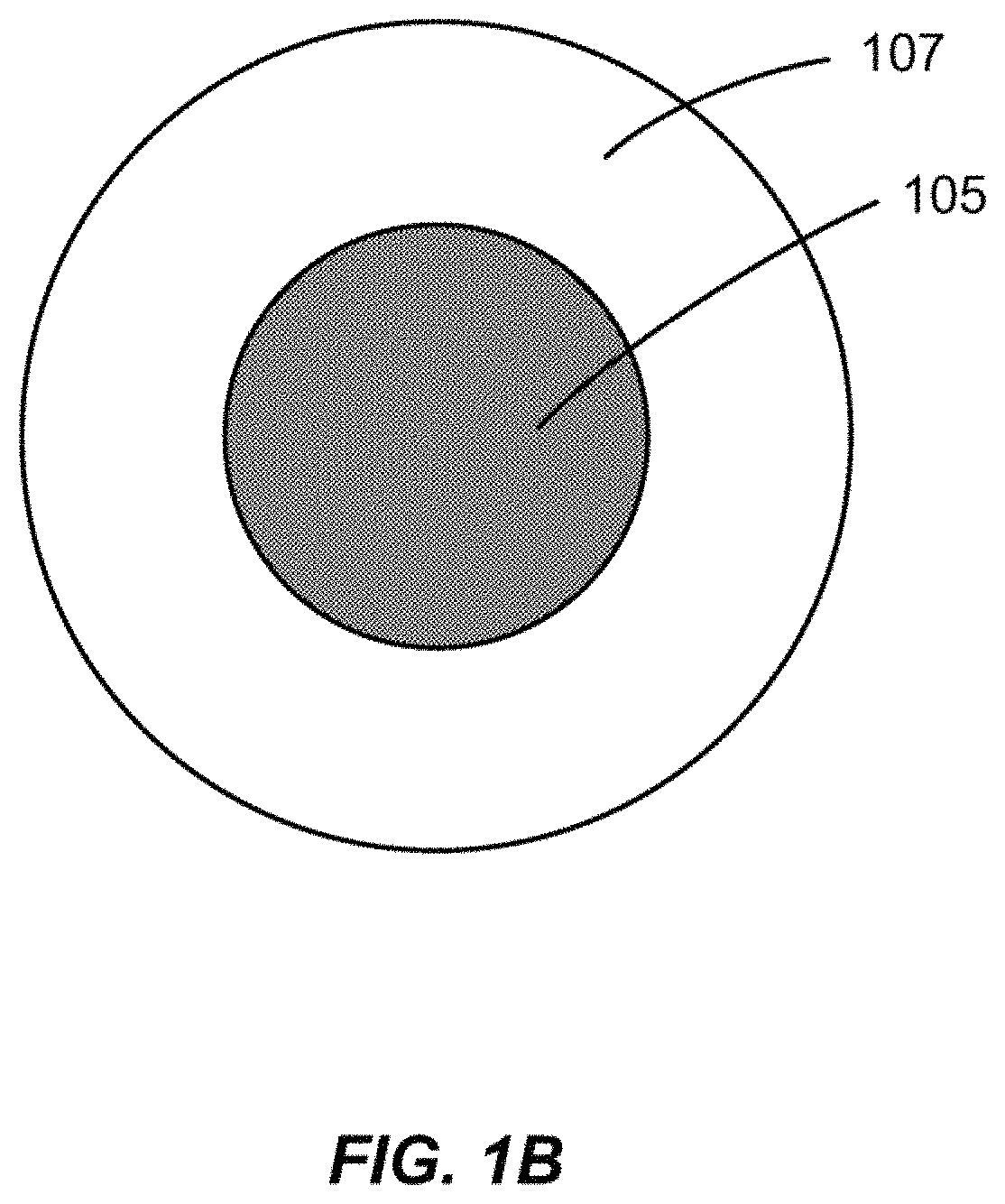

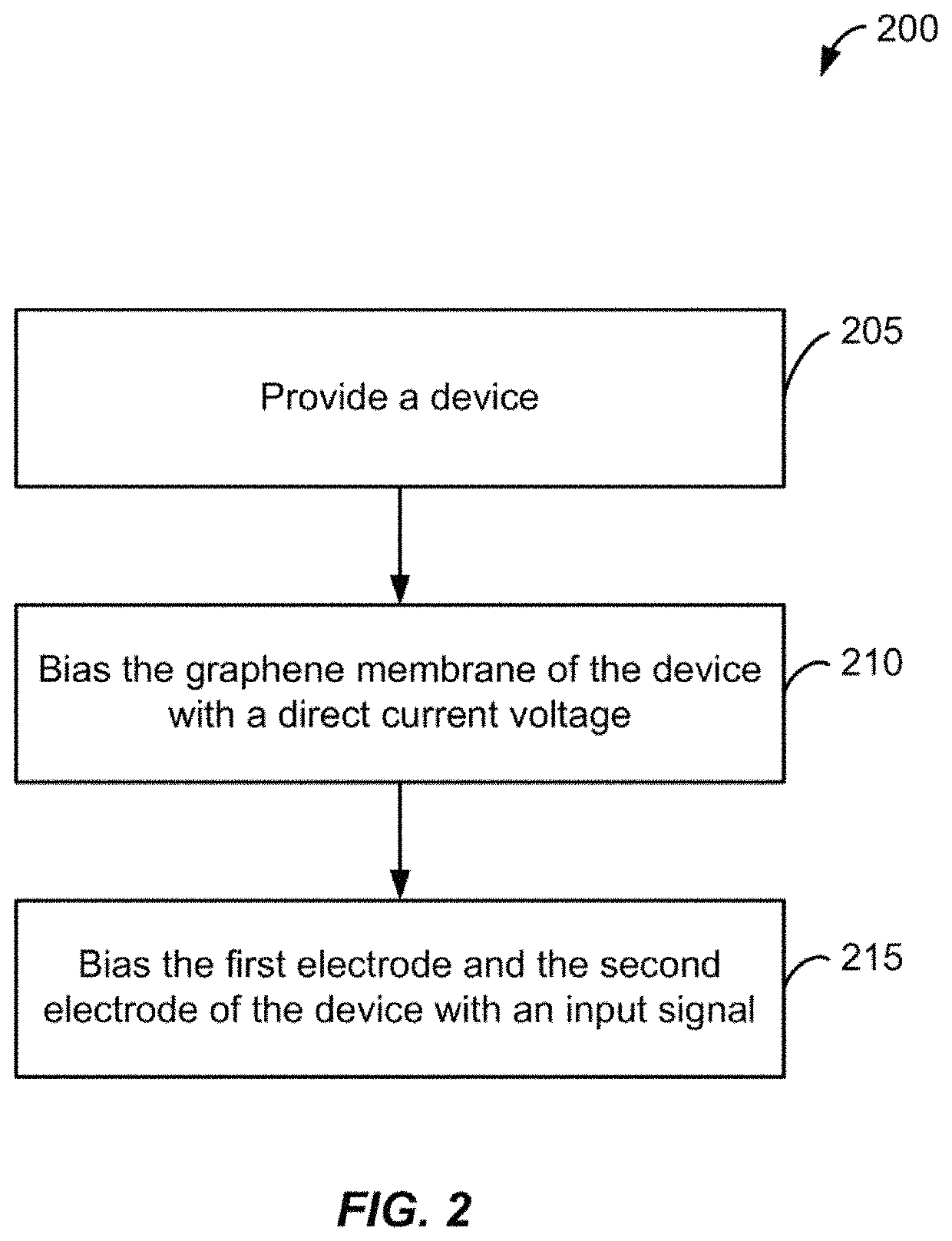

Electrostatic graphene speaker

ActiveUS10582305B2Low mass densityHigh mechanical strengthElectrothermic-effect transistorSemiconductor electrostatic transducersGraphiteMechanical engineering

This disclosure provides systems, methods, and apparatus associated with an electrostatically driven graphene speaker. In one aspect, a device includes a graphene membrane, a first frame on a first side of the graphene membrane, and a second frame on a second side of the graphene membrane. The first frame and the second frame both include substantially circular open regions that define a substantially circular portion of the graphene membrane. A first electrode is proximate the first side of the circular portion of the graphene membrane. A second electrode proximate the second side of the circular portion of the graphene membrane.

Owner:RGT UNIV OF CALIFORNIA

Ceramic foams, methods of making same, and uses thereof

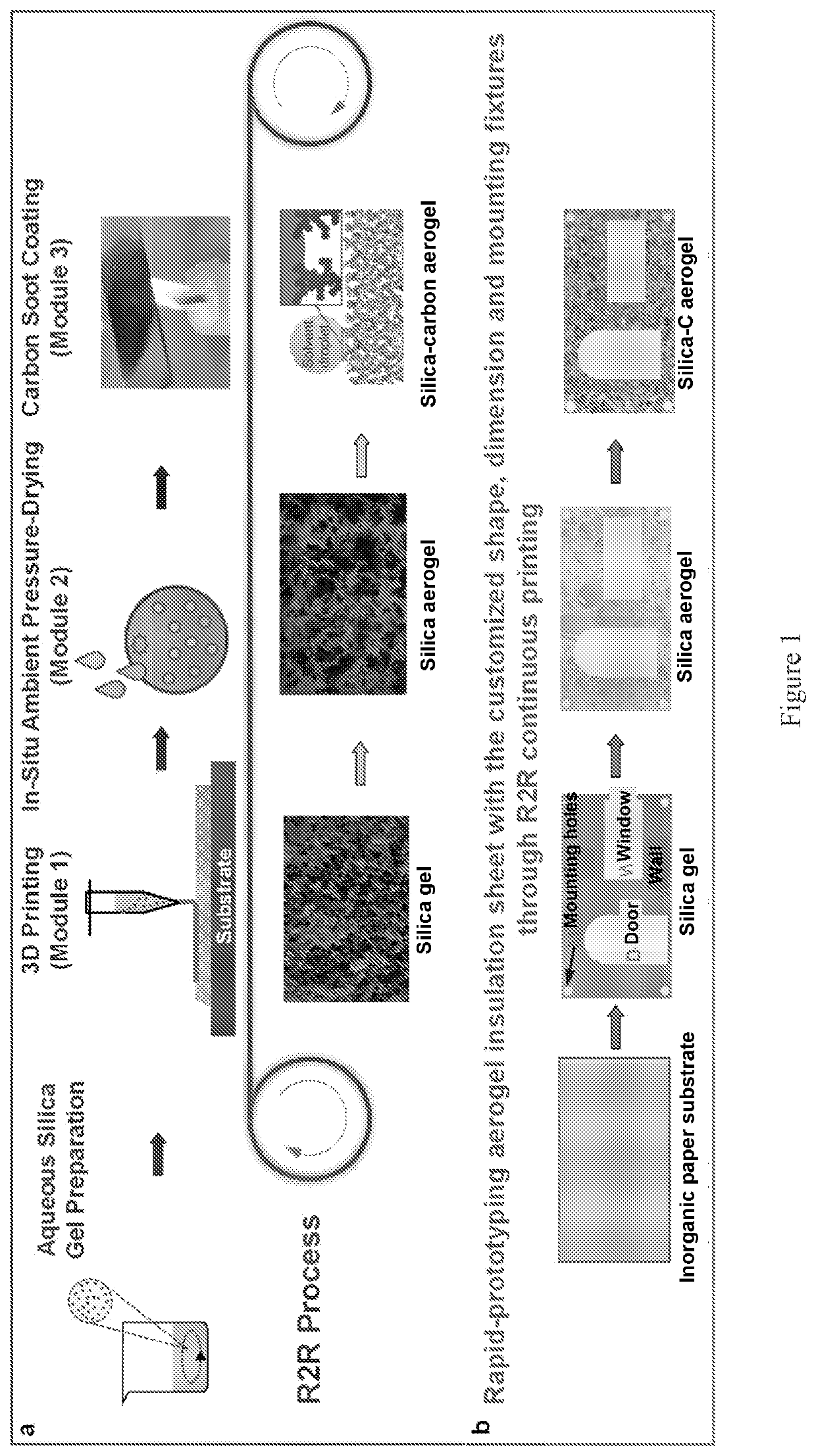

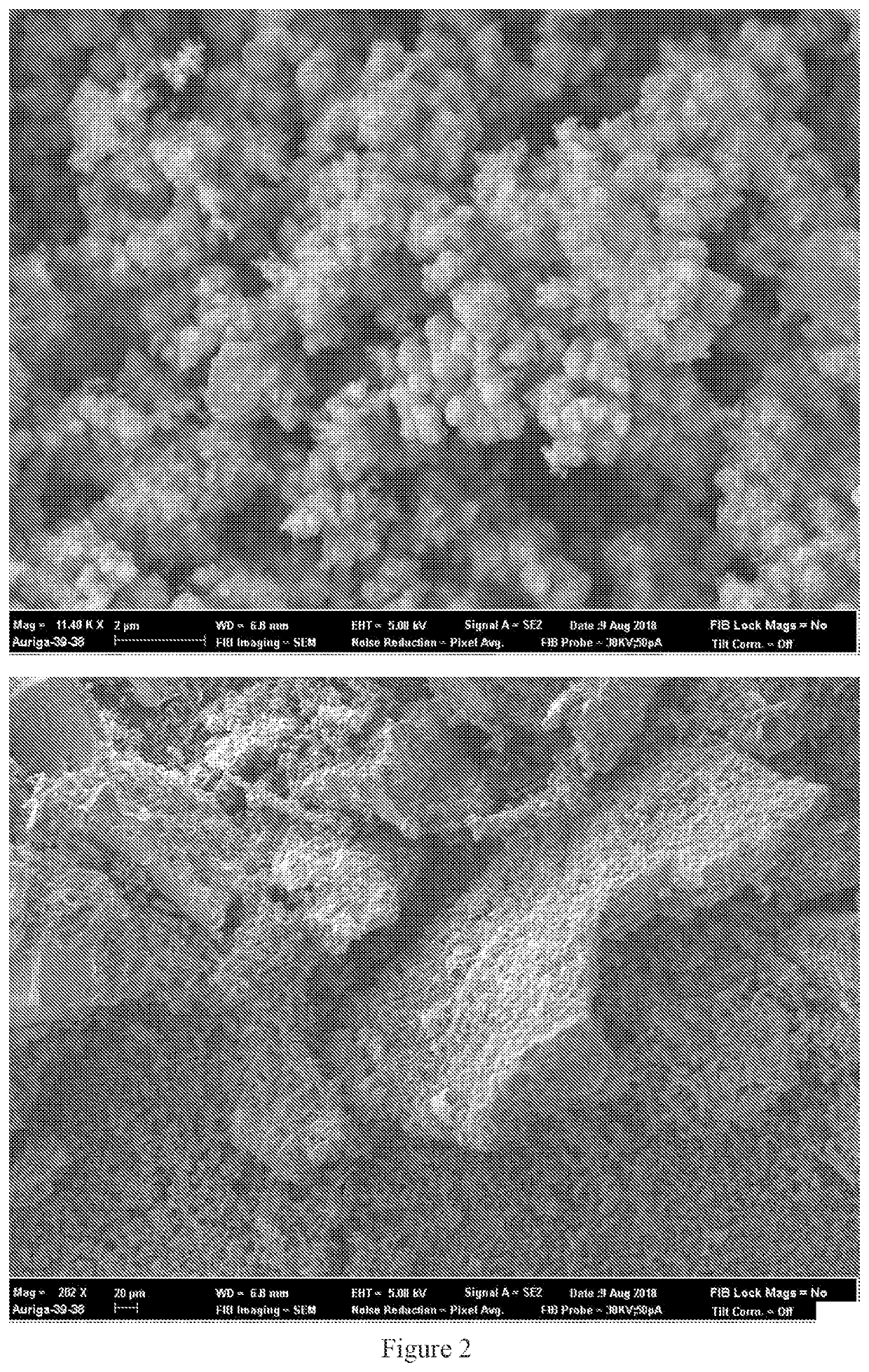

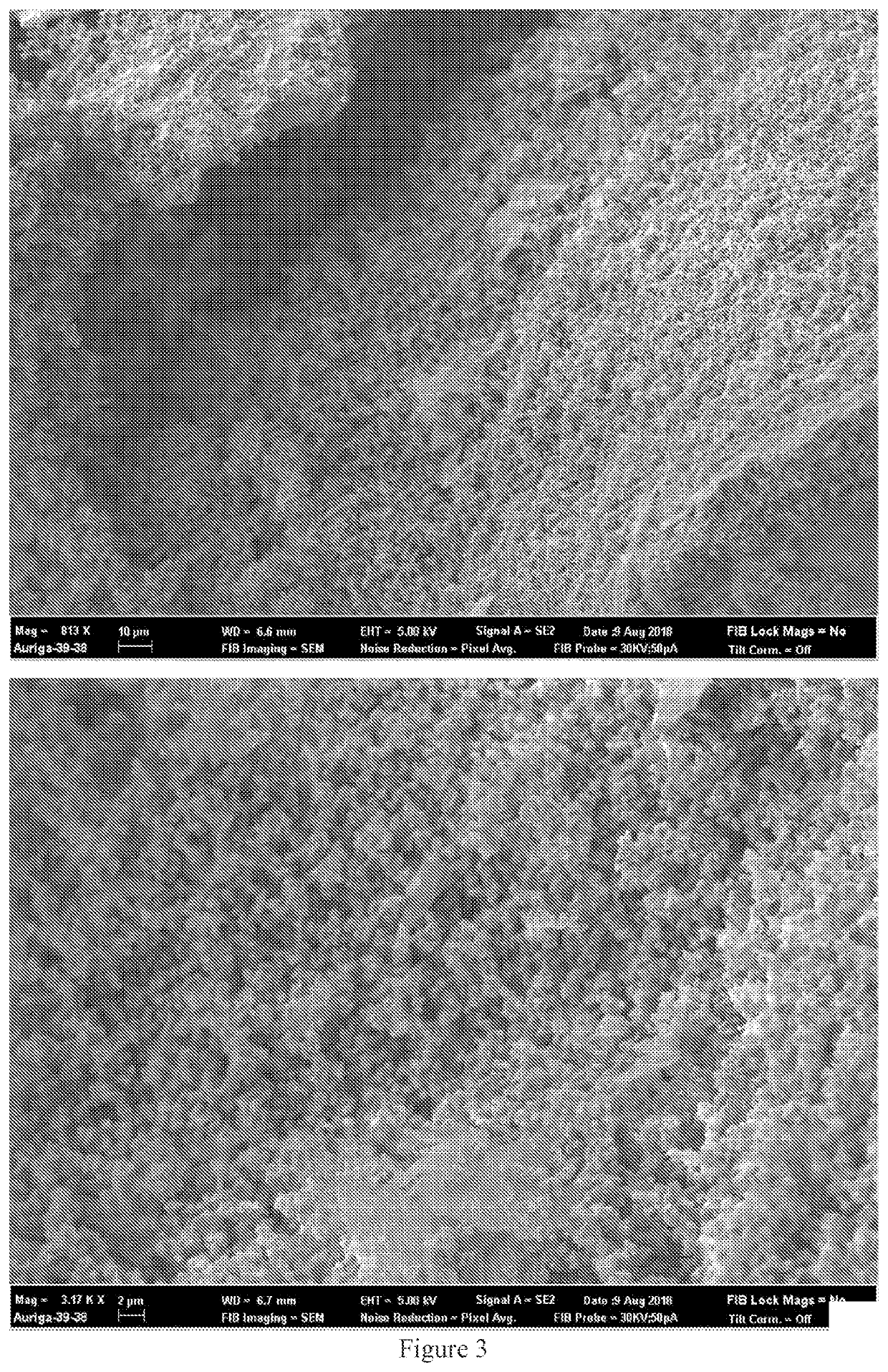

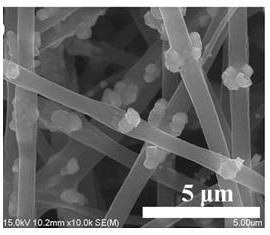

PendingUS20220089503A1Low cost manufacturingRobust mechanical stabilityAerogel preparationCeramicwareSilicon dioxideCeramic foam

Provided are ceramic foams. The ceramic foams may have a hierarchical pore gradient. The ceramic foams may be silica aerogels. The ceramic foams may be made by reaction of one or more precursors in the presence of an inert gas generated by a pore-forming gas-forming additive. The ceramic foams may be used as insulating materials.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

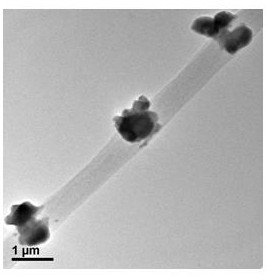

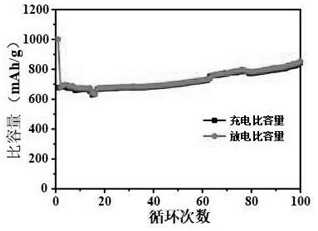

Flexible lithium/sodium ion battery negative electrode material and preparation method thereof

PendingCN113921807AImprove flexibilityImprove conductivityCell electrodesHeating/cooling textile fabricsMANGANESE ACETATECarbon fibers

The invention discloses a flexible lithium / sodium ion battery negative electrode material and a preparation method thereof, the flexible electrode material adopts an electrostatic spinning method, manganese oxide is uniformly distributed on one-dimensional carbon fiber to form a bamboo-like flexible electrode, and the diameter of the carbon fiber is about 700nm. The preparation method comprises the following steps of: stirring and dispersing zinc acetate, manganese acetate and polyacrylonitrile into a dimethylformamide solution to form a uniform spinning precursor; transferring the spinning precursor liquid into an injector, and adjusting proper spinning conditions to prepare a fiber membrane precursor; and then, utilizing a heat treatment method to carbonize the precursor fiber membrane to finally prepare the bamboo-like manganese oxide fiber membrane with controllable size and excellent flexibility. The process is simple, the cost is low, and the obtained bamboo-like manganese oxide fiber membrane has excellent electrochemical performance.

Owner:ZHONGBEI UNIV

Lightweight imitation ceramic composite material and preparation method thereof

The invention discloses a lightweight imitation ceramic composite material. The lightweight imitation ceramic composite material is composed of, by mass, 25% of polyamide, 60 to 75% of nanosized ceramic powder, 0.2 to 0.6% of a coupling agent, 0.5 to 1% of an anti-oxidant, 2 to 5% of zinc stearate, and 0.5 to 5% of aluminium powder. According to a preparation method, the raw materials above are subjected to mixing, fusion, extrusion, and granulation under certain conditions so as to obtain the lightweight imitation ceramic composite material. The lightweight imitation ceramic composite material is light, excellent in mechanical properties, thermal insulation performance and comprehensive properties, and low in heat conductivity coefficient.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Device for cleaning a surface, comprising at least one rotatable brush

ActiveUS10349796B2Reduce quality problemsIncrease flexibilityBowling gamesCarpet cleanersVolumetric Mass DensityEngineering

A device for cleaning a surface (11) comprises at least one rotatable brush (3,4) which is provided with flexible brush elements (18) for contacting the surface (11) and picking up dirt particles (10) and liquid which are present on the surface (11) during a dirt pick-up period of each revolution of the brush (3, 4), and means for driving the brush (3, 4). A linear mass density of the flexible brush elements (18) is chosen such as to be lower than 50 g per 10 km, at least at tip portions, and an acceleration at tips of the brush elements (18) is set such as to be at least 3,000 m / sec2, at least at some time during another period of each revolution of the brush (3, 4) than the dirt pick-up period, namely a period in which the brush elements (18) are free from contact to the surface (11).

Owner:VERSUNI HLDG BV

A kind of preparation method of nitrogen and phosphorus co-doped flexible carbon fiber membrane negative electrode material

ActiveCN106099055BIncrease energy densityImprove power densityElectrode carriers/collectorsSecondary cellsFiberCarbon fibers

The invention discloses a preparation method for an ultra-thin nitrogen-phosphorus co-doped flexible carbon fiber membrane used as a negative electrode material of a lithium / sodium ion battery, and belongs to the fields of electrochemistry and new energy materials. Filter paper and hydrazine hydrate are subjected to a hydrothermal reaction directly to obtain nitrogen-doped filter paper; the nitrogen-doped filter paper is mixed with urea, dried and put into an atmosphere tubular furnace to be calcined; the filter paper is carbonized into carbon fiber paper at a high temperature; the urea is decomposed at the high temperature to generate gas to enable the carbon fiber paper to be stripped into an ultra-thin carbon fiber membrane to obtain the nitrogen-phosphorus co-doped carbon fiber membrane. According to the nitrogen-phosphorus co-doped carbon fiber membrane, the shortcoming of the carbon fiber is overcome and the energy band structure is improved; the specific capacity of the material and the lithium ion diffusion rate are improved; a three-dimensional conductive network is formed in the carbon fiber material, so that the conductivity of the material is improved; the electrode material has good mechanical flexibility property, so that the electrode material is applicable to manufacturing of a flexible electrode; the electrode material has no additive; and when the electrode material is used as the negative electrode material of the lithium / sodium ion battery, ultrahigh specific capacity and excellent cycling stability are represented.

Owner:CHINA THREE GORGES UNIV

Negative electrode current collector for heterogeneous electrochemical capacitor and method of manufacture thereof

InactiveUS8472163B2Improve stabilityLower resistanceHybrid capacitor electrolytesHybrid capacitor electrodesGraphiteCapacitor

Owner:UNIVERSAL SUPERCAPACITORS LLC

Composite multi-layer stab-resistant bulletproof fabric piece and preparation method thereof

PendingCN113375504AImprove structural performanceLow mass densitySynthetic resin layered productsLaminationPolytetramethylene terephthalateElastomer

The invention discloses a composite multi-layer stab-resistant bulletproof fabric piece and a preparation method thereof. The stab-resistant bulletproof fabric piece is formed by weaving and compounding high-performance fibers such as ultra-high molecular weight polyethylene fibers, aramid fibers, carbon fibers and PBO fibers and a small amount of elastomer fibers; the elastomer fibers are polybutylene terephthalate fibers; and the preparation method comprises the following steps of uniformly blending the ultra-high molecular weight polyethylene fibers, the aramid fibers, the carbon fibers, the PBO fibers and a small amount of polybutylene terephthalate fibers, and then carrying out composite hot pressing. According to the composite multi-layer stab-resistant bulletproof fabric piece and the preparation method thereof, hot-pressing gluing is conducted after blending, structure increasing is facilitated, meanwhile, through uniform blending of different kinds of fiber filaments, the overall structural performance of the stab-resistant bulletproof fabric piece can be enhanced, the overall mass density of the stab-resistant bulletproof fabric piece can be reduced, the toughness, the shaping performance, the elasticity and other performance are improved, the wearing and using comfort and flexibility can be improved, and the composite multi-layer stab-resistant bulletproof fabric piece is suitable for use in security operations.

Owner:山东莱威新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com