Energy-absorbing component manufactured by carbon nano-tube paper and manufacture method thereof

A carbon nanotube paper, carbon nanotube technology, applied in the direction of carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve problems such as heat dissipation, safety, and smaller engine compartments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

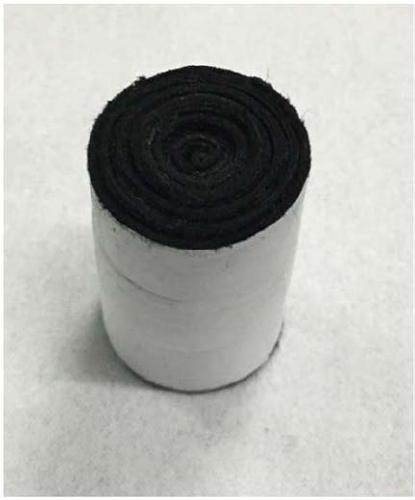

[0056] Automotive crash box made of carbon nanotube paper based on vertical carbon nanotube array

[0057] Firstly, vertical carbon nanotube arrays were prepared by CVD method, wherein the carbon nanotubes had a diameter of 10 nm and a length of about 80 μm, and the carbon nanotube paper was produced by papermaking method. Carry out front and rear rolling on the roller press each once, then dry in a blast oven at 80°C, the thickness of the obtained carbon nanotube paper is 1.5mm, take 0.200kg of this carbon nanotube paper, add 0.020kg of pitch, Put it in a rotary oven, heat it with a rotary solvent at 140°C, and then carbonize it at a high temperature of 1100°C to make a cylindrical material with a height of 112mm and a diameter of 50mm. Then it is packaged in an aluminum alloy pipe fitting with the same shape, a weight of 0.050kg, and a thickness of 2mm. It is installed between the bumper and the longitudinal beam of the car as a car energy-absorbing box. The energy-absorbing...

Embodiment 2

[0060] Automobile B-pillar based on vertical carbon nanotube array carbon nanotube paper

[0061] Firstly, vertical carbon nanotube arrays were prepared by CVD method, wherein the carbon nanotubes had a diameter of 20nm and a length of about 90μm, and the carbon nanotube paper was made by papermaking method. After rolling and drying, take 0.400kg of the carbon nanotube paper, add 0.030kg of maleimide, place it in a rotary oven, perform a rotary solvent heat treatment at 120°C, and then carbonize it at a high temperature of 1100°C , made into a block material with a length of 120mm, a width of 50mm, and a height of 33mm, and then encapsulated in an aluminum alloy pipe fitting with the same shape and capacity, a weight of 0.053kg, and a thickness of 2mm, installed on a car bumper with The energy-absorbing box between the longitudinal beams of the vehicle body can absorb about 21kJ of collision kinetic energy.

Embodiment 3

[0063] Automotive crash box made of carbon nanotube paper based on vertical carbon nanotube array / graphene composite

[0064]Firstly, using the combination of low temperature CVD and high temperature CVD, the vertical carbon nanotube arrays are prepared at low temperature (750°C), and then graphene intercalation is grown between the vertical carbon nanotube array layers at high temperature (950°C) to obtain a three-dimensional The three-dimensional vertical carbon nanotube array / graphene composite material (the carbon nanotube diameter is 10nm, the length is about 80μm), and the carbon nanotube paper is produced by the papermaking method. After rolling and drying, take 0.180kg of the carbon nanotube paper, add 0.010kg of maleimide, place it in a rotary oven, perform a rotary solvent heat treatment at 140°C, and then carbonize it at a high temperature of 1000°C , made into a block material with a height of 118mm, a length of 52mm, and a width of 30mm, and then encapsulated in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com