Conductive fabric and preparation method thereof

A technology of conductive fabrics and fabric substrates, applied in textiles and papermaking, etc., can solve the problems of poor fabric folding resistance, washing resistance and stretch resistance, and achieve the effects of protecting structural stability, enhancing washing resistance, and avoiding electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

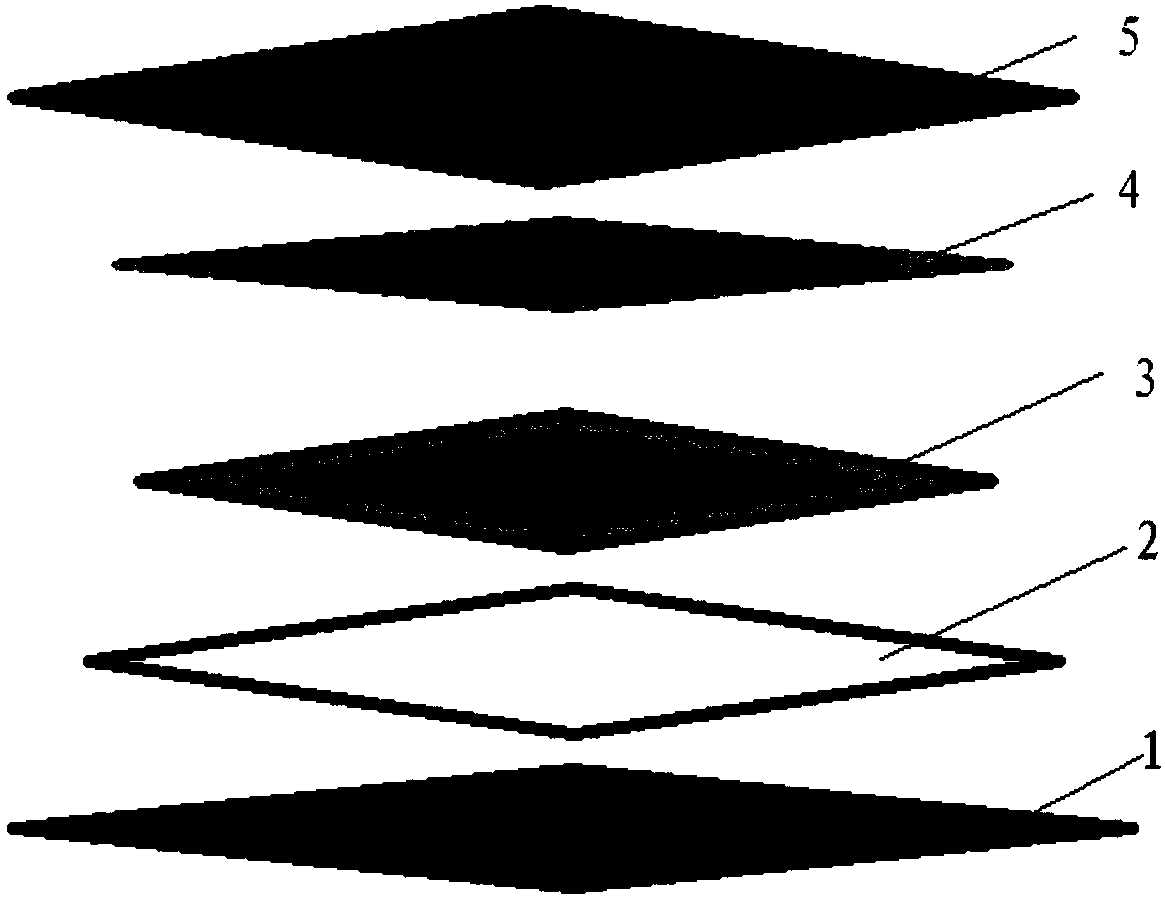

[0091] see figure 1 As shown, a conductive fabric includes: an adhesion improving layer 2, a liquid metal layer 3, an oxygen barrier protective layer 4 and an encapsulation protective layer 5 attached to the surface of the fabric base 1 in sequence from the inside to the outside;

[0092] The material of the fabric base 1 is polyester; the thickness of the fabric base 1 is 300 μm;

[0093] The material of the adhesion improving layer 2 is polyacrylic acid; the thickness of the adhesion improving layer 2 is 100 microns;

[0094] The liquid metal layer 3 has only one layer, the liquid metal in which is gallium-indium alloy, and the thickness of the liquid metal layer 3 is 49 μm;

[0095] The material of the oxygen barrier protective layer 4 is polyvinyl dichloride; the thickness of the oxygen barrier protective layer 4 is 50 μm;

[0096] The material of the encapsulation protection layer 5 is soft polyurethane; the thickness of the encapsulation protection layer 5 is 180 μm. ...

Embodiment 2

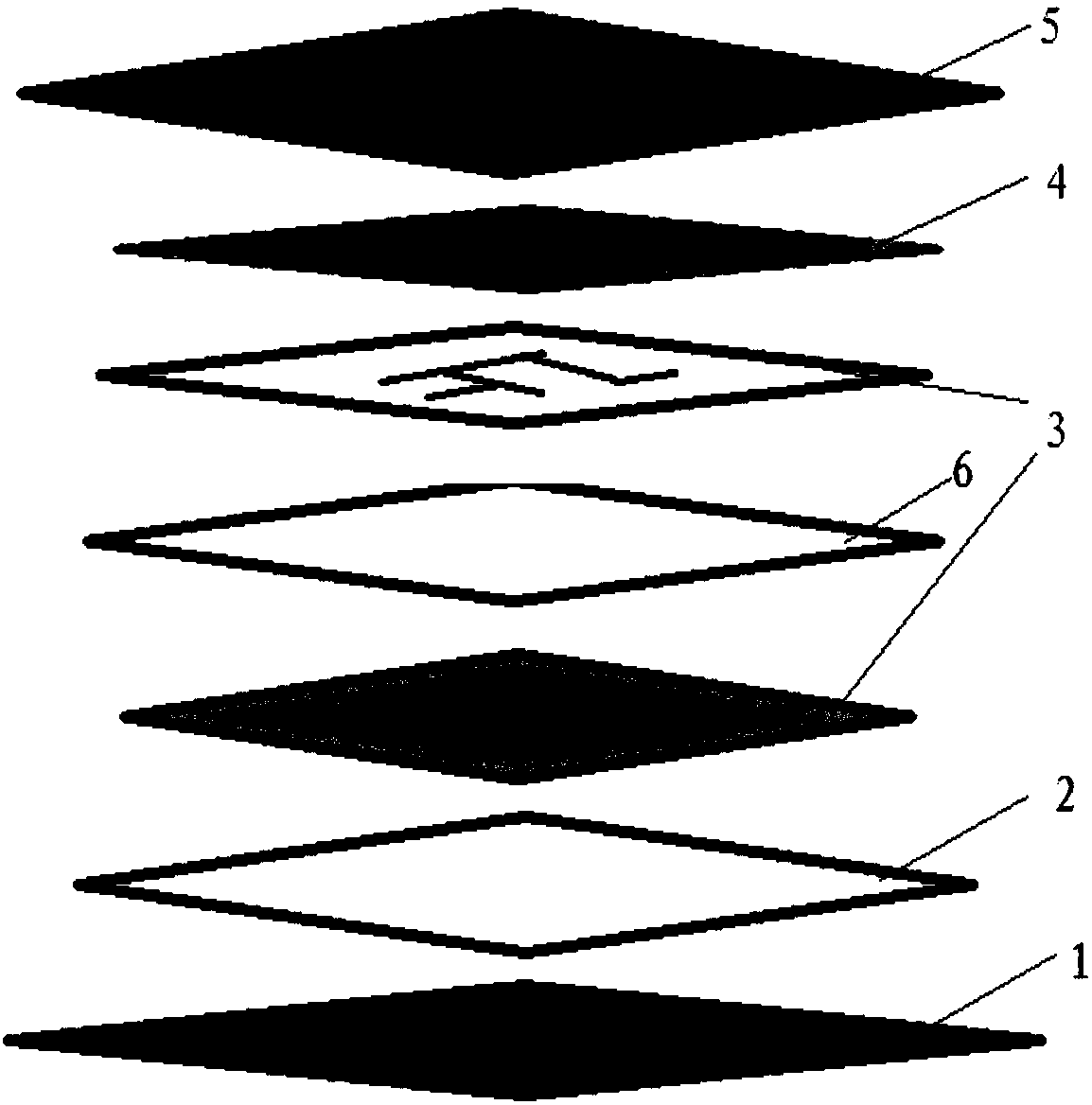

[0107] A conductive fabric, comprising: an adhesion improving layer 2, a liquid metal layer 3, an oxygen barrier protection layer 4 and an encapsulation protection layer 5, which are sequentially attached to the surface of a fabric base 1 from inside to outside;

[0108] The material of the fabric base 1 is cotton; the thickness of the fabric base 1 is 1500 μm;

[0109] The material of the adhesion improving layer 2 is polyurethane; the thickness of the adhesion improving layer 2 is 90 μm;

[0110] The liquid metal layer 3 comprises two liquid metal monolayers and an isolation layer 6 between the two liquid metal monolayers; the liquid metal in the first liquid metal monolayer is bismuth indium tin alloy, and the thickness of the first liquid metal monolayer 48 μm; the second liquid metal single layer is a functional circuit formed by gallium indium alloy, temperature measuring chip, 0 ohm resistor and LED lamp; the thickness of the second liquid metal single layer is 30 μm; ...

Embodiment 3

[0124] A conductive fabric, comprising: an adhesion improving layer 2, a liquid metal layer 3, an oxygen barrier protection layer 4 and an encapsulation protection layer 5 attached to the surface of a fabric base 1 sequentially from inside to outside;

[0125] The material of the fabric base 1 is Lycra; the thickness of the fabric base 1 is 800 μm;

[0126] The material of the adhesion improving layer 2 is epoxy resin; the thickness of the adhesion improving layer 2 is 90 μm;

[0127] The liquid metal layer 3 has only one layer, and the liquid metal therein is a bismuth-indium alloy, and the thickness of the liquid metal layer 3 is 51 μm;

[0128] The material of the oxygen barrier protection layer 4 is polyvinyl alcohol; the thickness is 50 μm.

[0129] The material of the encapsulation protection layer 5 is polydimethylsilane; the thickness of the encapsulation protection layer 5 is 180 μm.

[0130] Above-mentioned conductive fabric adopts following method to prepare:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com