Preparation method for shape thermo-sensitive hydro-gel material

A temperature-sensitive hydrogel and body-shaping technology, applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of changing fabrics, low moisture permeability, and non-existence, so as to increase air permeability, Reduces breathability for warmth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

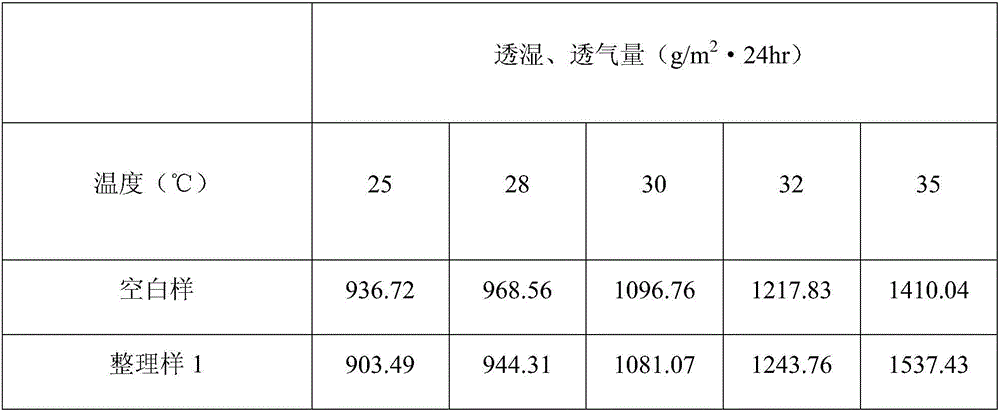

Embodiment 1

[0027] (1) Measure 17.7g of isopropylamine, 32.7g of triethylamine and 75ml of ethyl acetate into a 250ml four-neck flask, and mix 22.6g of acryloyl chloride and 25ml of ethyl acetate in a 50ml constant pressure dropper. Add dropwise the mixture of acryloyl chloride and ethyl acetate in a constant pressure dropper to the four-neck flask. Stir in an ice-water bath, keep the reaction temperature in the bottle below 5°C, and continue stirring for 6 hours. Then filtered, the precipitate was washed with ethyl acetate and discarded, and the filtrate was rotary evaporated to obtain a reddish-brown viscous liquid, namely the crude product of N-isopropylacrylamide. Recrystallize with petroleum ether, add a small amount of activated carbon, filter while hot, and place the filtrate at room temperature to obtain white needle-shaped crystal isopropylacrylamide NIPAM.

[0028] (2) Weigh 20g of PEG600, dry it in vacuum at 120°C for 2 hours, then cool down to 90°C, add maleic anhydride MA at...

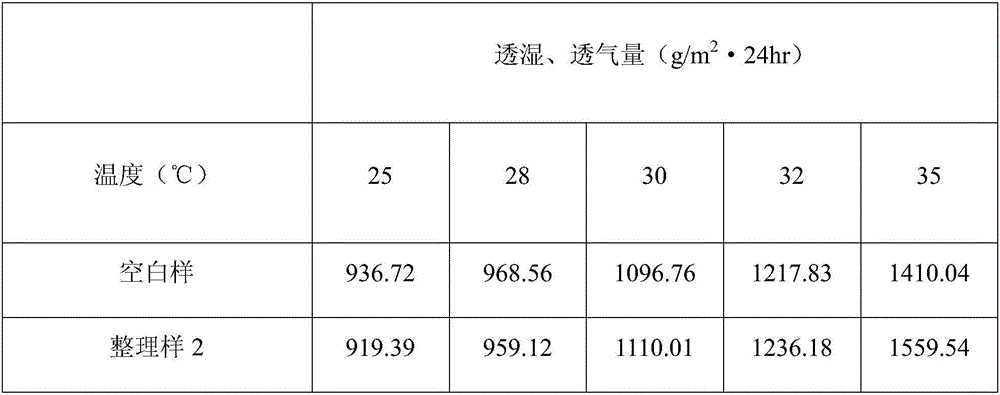

Embodiment 2

[0035] (1) Measure 17.7g of isopropylamine, 32.7g of triethylamine and 75ml of ethyl acetate into a 250ml four-neck flask, and mix 22.6g of acryloyl chloride and 25ml of ethyl acetate in a 50ml constant pressure dropper. Add dropwise the mixture of acryloyl chloride and ethyl acetate in a constant pressure dropper to the four-neck flask. Stir in an ice-water bath, keep the reaction temperature in the bottle below 5°C, and continue stirring for 6 hours. Then filtered, the precipitate was washed with ethyl acetate and discarded, and the filtrate was rotary evaporated to obtain a reddish-brown viscous liquid, namely the crude product of N-isopropylacrylamide. Recrystallize with petroleum ether, add a small amount of activated carbon, filter while hot, and place the filtrate at room temperature to obtain white needle-shaped crystal isopropylacrylamide NIPAM.

[0036] (2) Weigh 20g of PEG400, dry it in vacuum at 120°C for 2 hours, then lower the temperature to 90°C, add maleic anh...

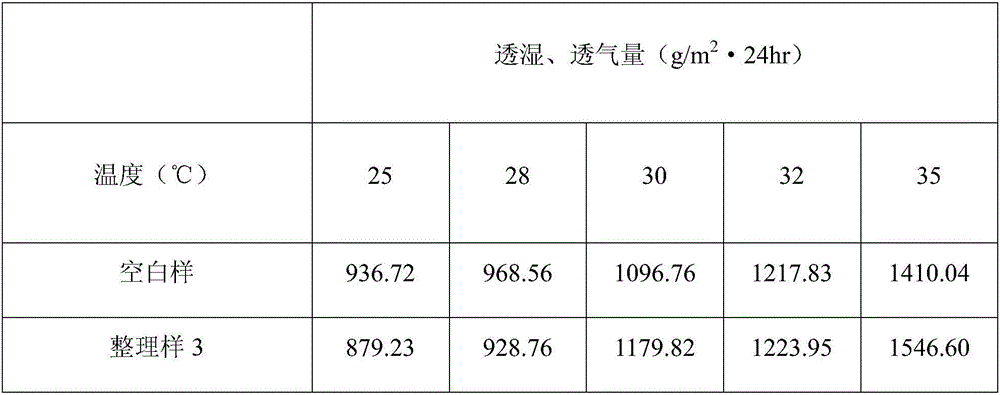

Embodiment 3

[0043] (1) Measure 17.7g of isopropylamine, 32.7g of triethylamine and 75ml of ethyl acetate into a 250ml four-neck flask, and mix 22.6g of acryloyl chloride and 25ml of ethyl acetate in a 50ml constant pressure dropper. Add dropwise the mixture of acryloyl chloride and ethyl acetate in a constant pressure dropper to the four-neck flask. Stir in an ice-water bath, keep the reaction temperature in the bottle below 5°C, and continue stirring for 6 hours. Then filtered, the precipitate was washed with ethyl acetate and discarded, and the filtrate was rotary evaporated to obtain a reddish-brown viscous liquid, namely the crude product of N-isopropylacrylamide. Recrystallize with petroleum ether, add a small amount of activated carbon, filter while hot, and place the filtrate at room temperature to obtain white needle-shaped crystal isopropylacrylamide NIPAM.

[0044] (2) Weigh 20g of PEG1000, dry in vacuum at 120°C for 2 hours, then cool down to 90°C, add maleic anhydride MA at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com