Patents

Literature

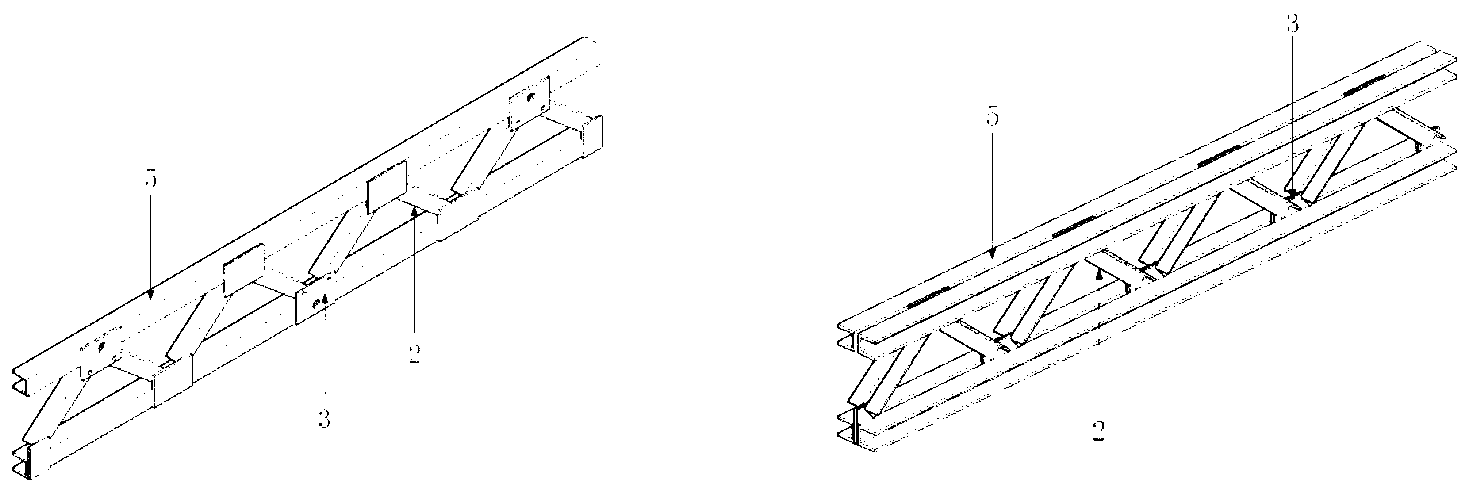

167results about How to "Increase net height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

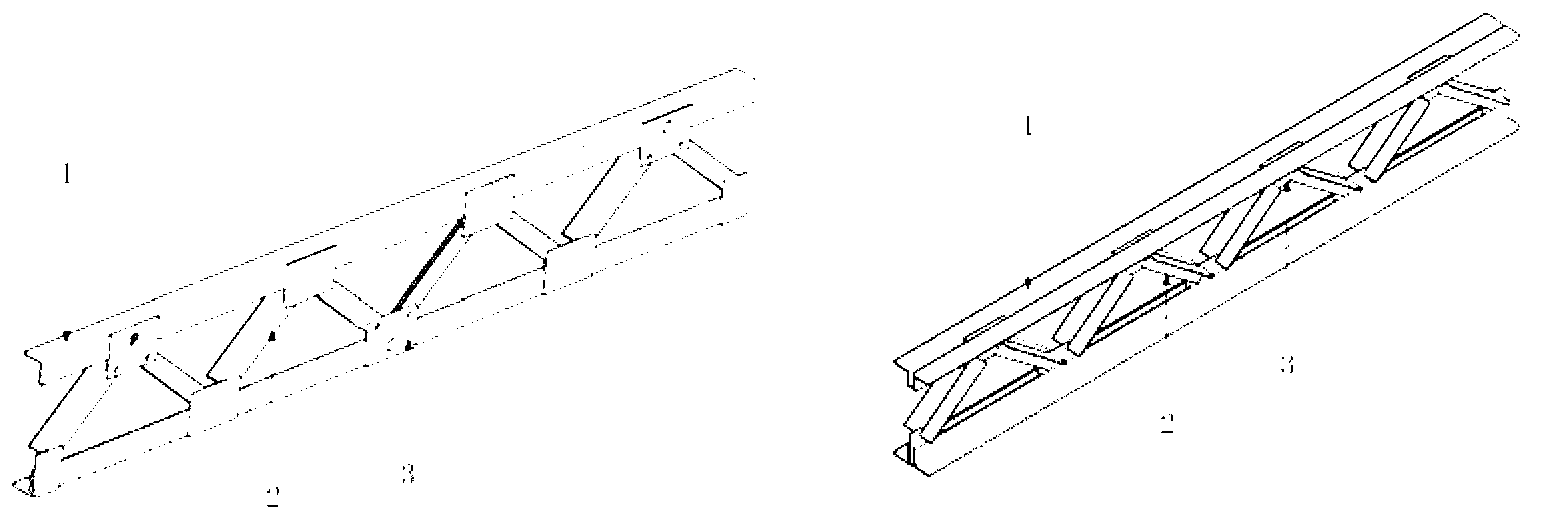

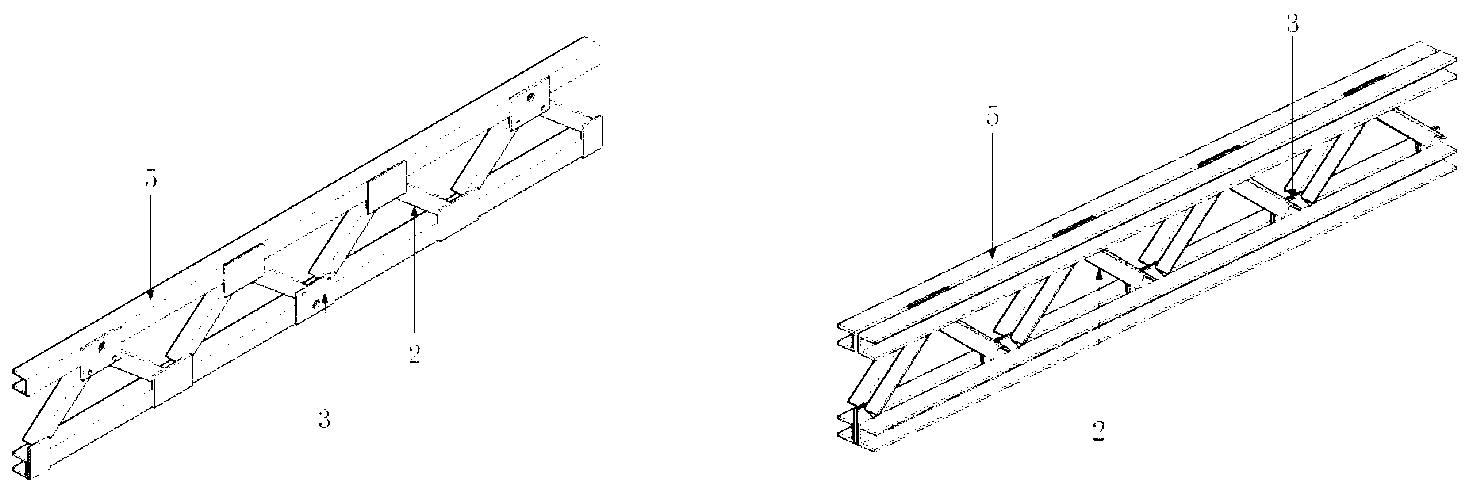

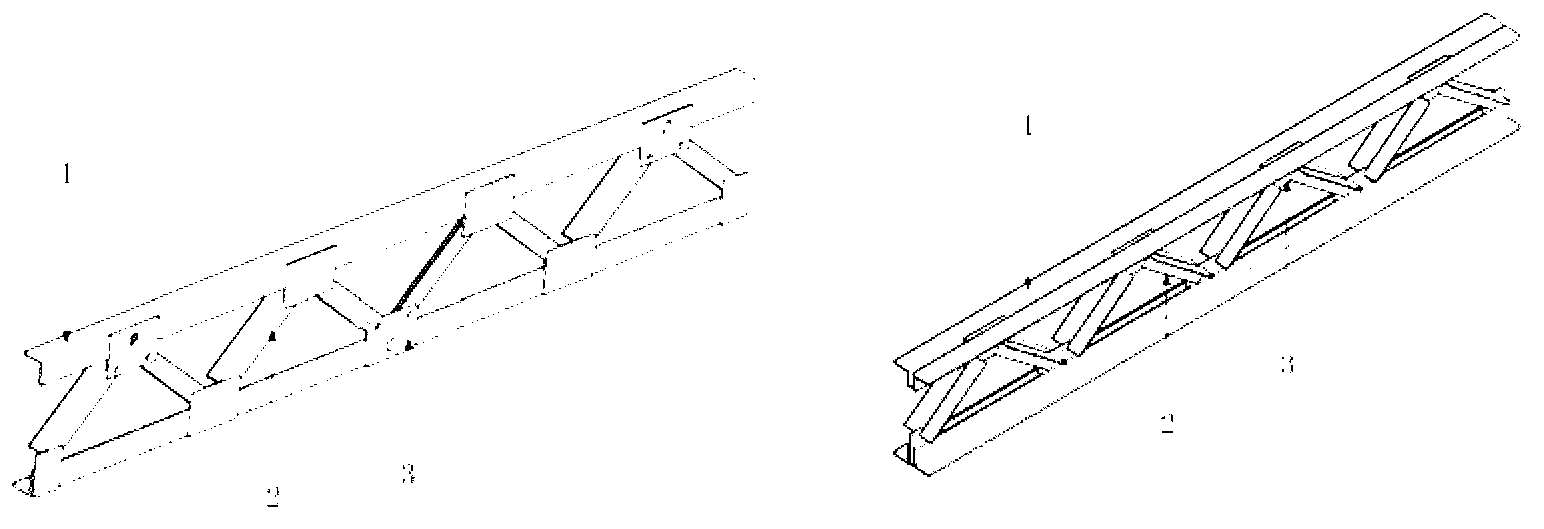

Industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system

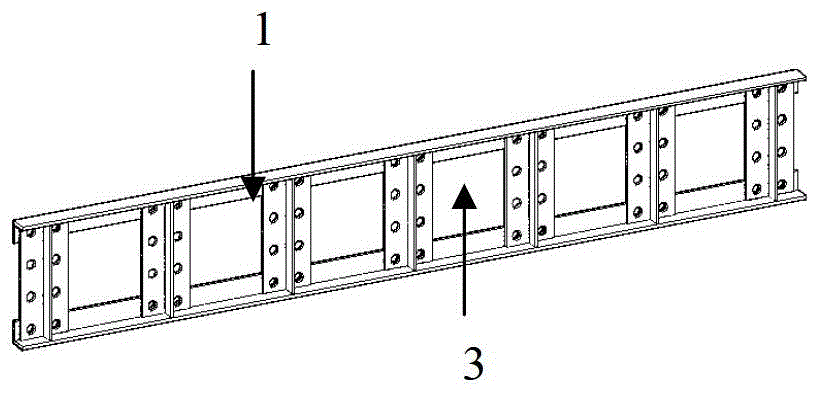

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled truss plates, assembled flange columns and eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

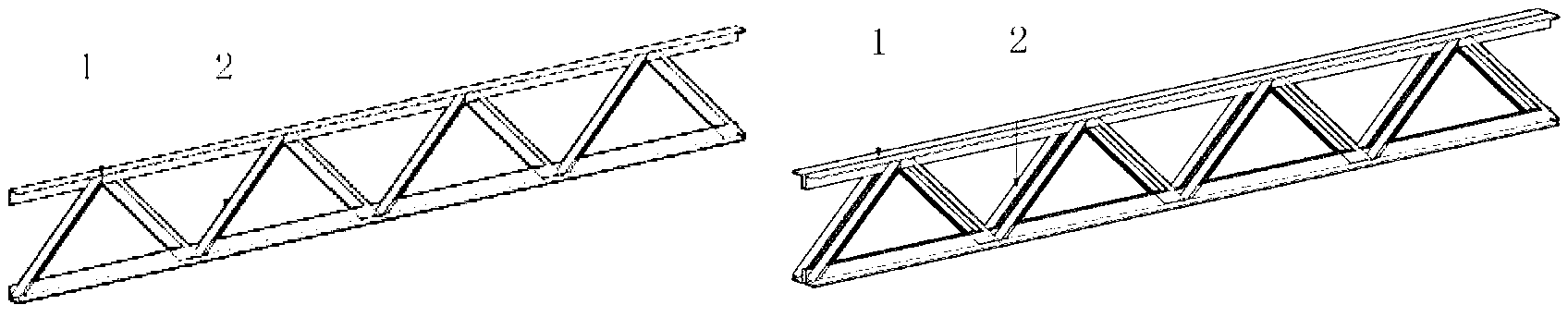

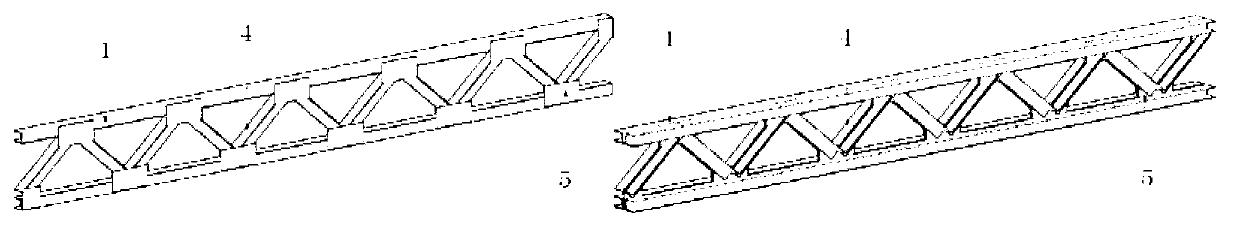

Multi-story high-rise assembled steel structure frame - prestressed centrally-braced system

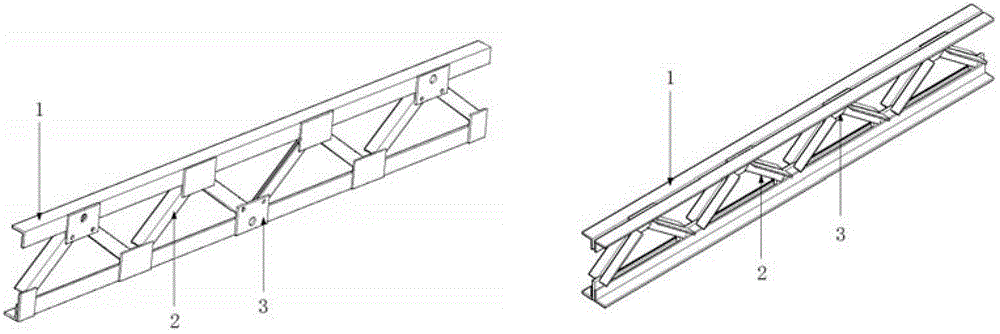

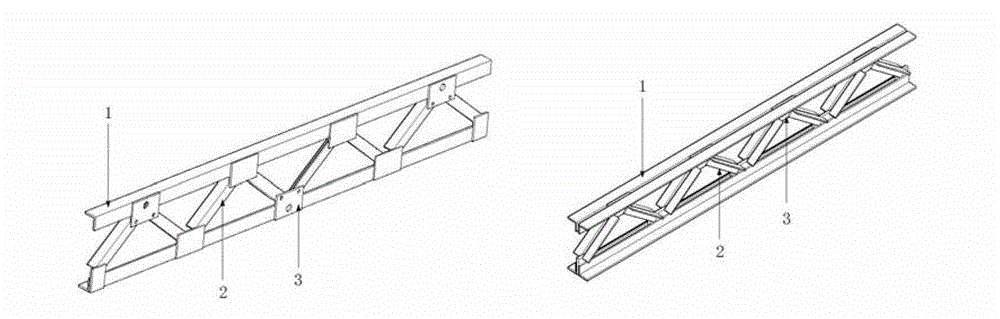

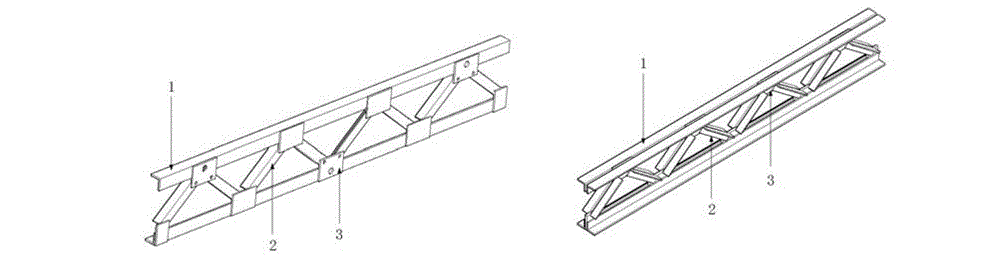

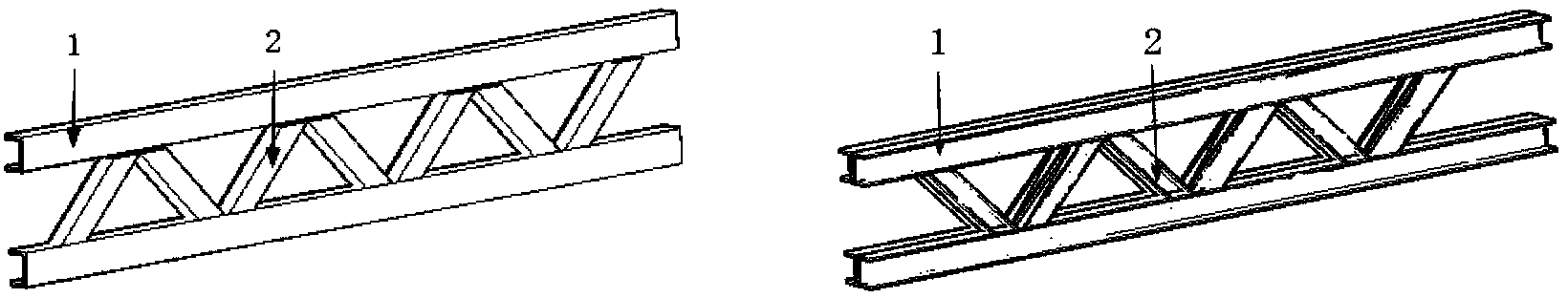

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed centrally-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed centrally-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed sway braces are arranged on the basis of the steel frame, so as to improve the lateral rigidness of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled truss plates, assembled flange columns and prestressed eccentric bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the prestressed eccentric bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

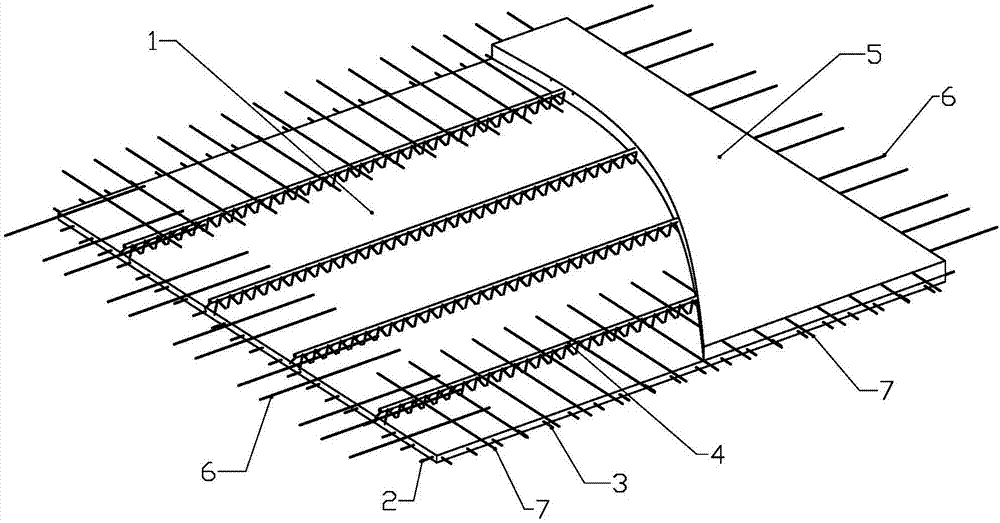

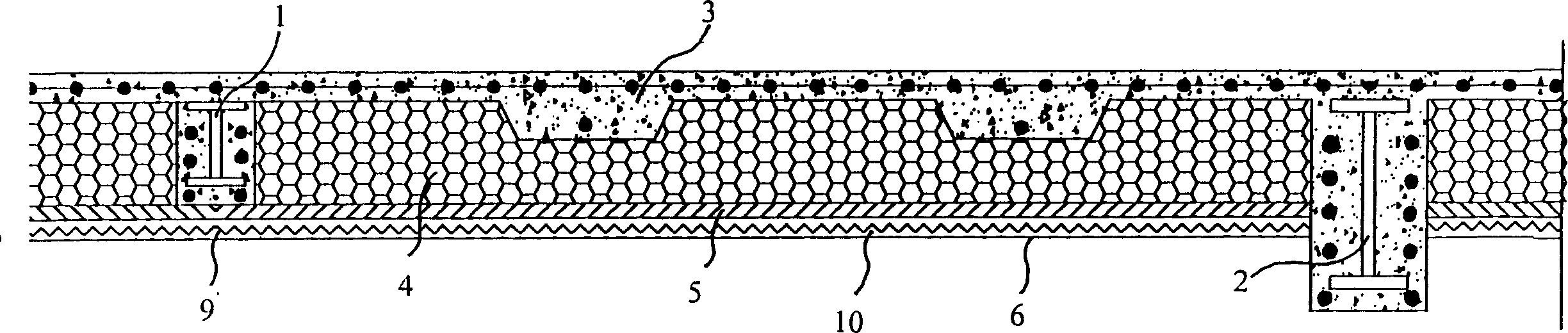

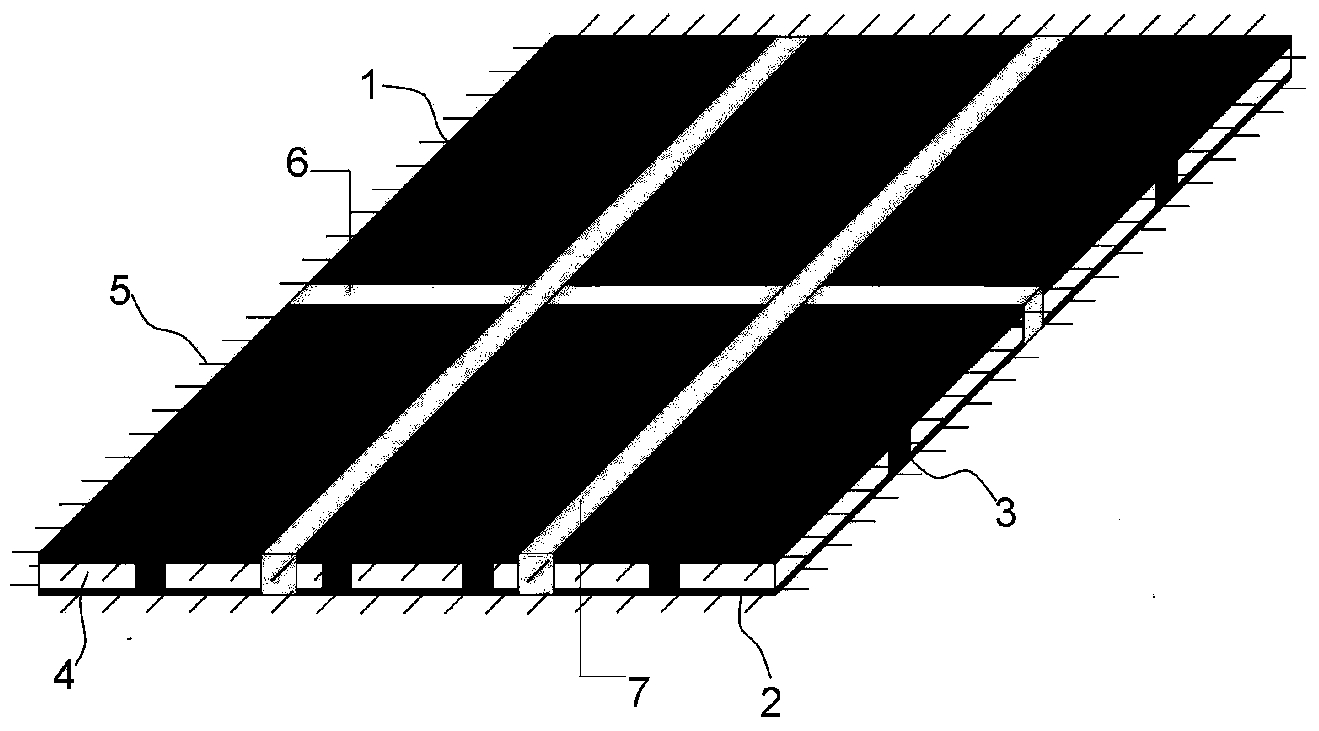

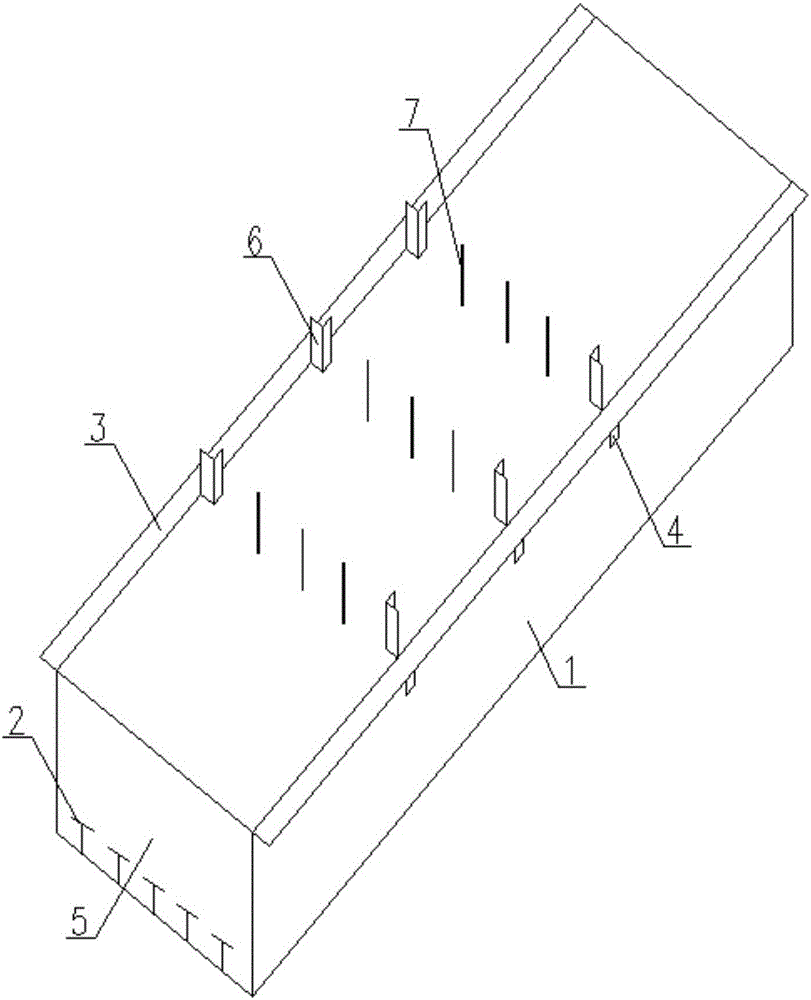

Prestressed concrete superimposed sheet with steel trusses and manufacturing method

InactiveCN106703269AIncreased out-of-plane stiffness and load carrying capacityApplicable span is largeFloorsBuilding material handlingRebarPre stress

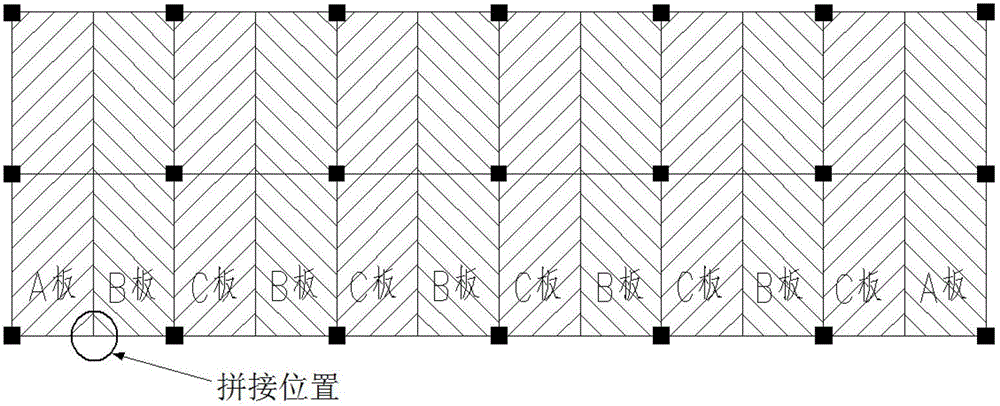

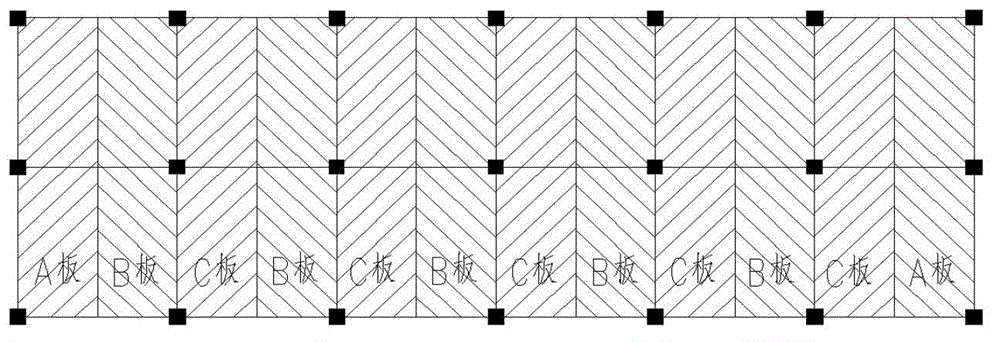

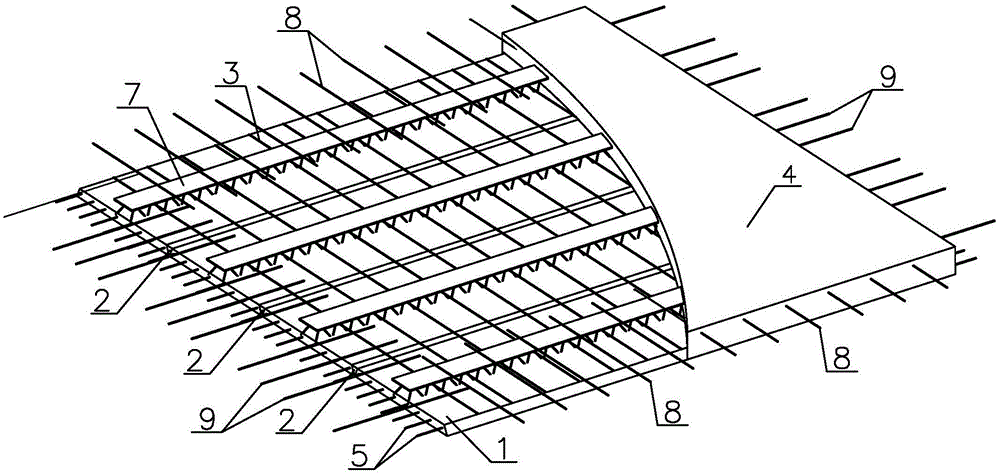

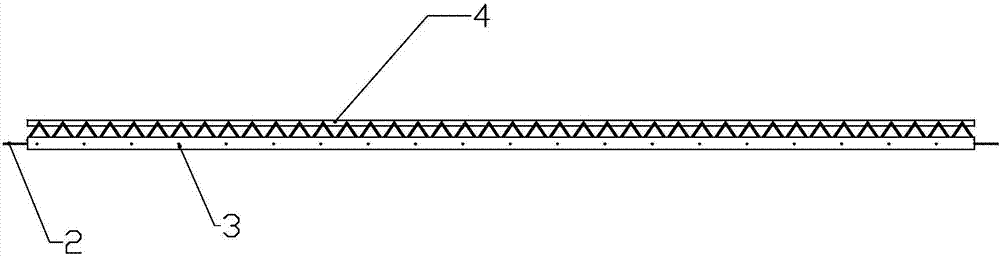

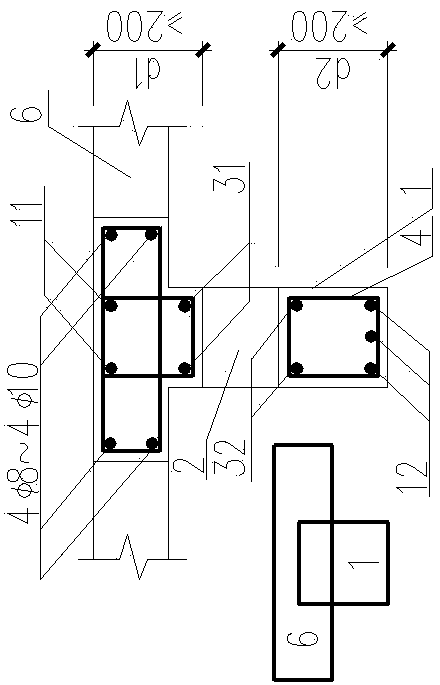

The invention discloses a prestressed concrete superimposed sheet with steel trusses and a manufacturing method, and belongs to the technical field of architectural engineering. The prestressed concrete superimposed sheet structurally comprises prefabricated bottom plates, transverse steel bars and a superimposed layer, two sides faces, in the length direction, of each prefabricated bottom plate are inclined faces, a wedge-shaped edge joint is formed between every two adjacent prefabricated bottom plates, the wedge-shaped edge joints are filled with high-strength grouting materials, longitudinal prestress steel bars are distributed in the prefabricated bottom plates in the length direction, and the transverse distribution steel bars are arranged in the width direction. The upper portion of each prefabricated bottom plate is provided with at least one steel truss in the length direction, the transverse steel bars are arranged below the steel trusses in the width direction of the prefabricated bottom plates in a penetrating mode, the prefabricated bottom plates can be connected together, the superimposed layer is poured to the prefabricated bottom plates, and superimposed layer transverse steel bars and superimposed layer longitudinal steel bars are arranged in the superimposed layer. The prestressed concrete superimposed sheet has the advantages of being good in overall stress performance, large in application span, excellent in fireproof effect and high in factory production efficiency, enabling site operation to be easy and convenient and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

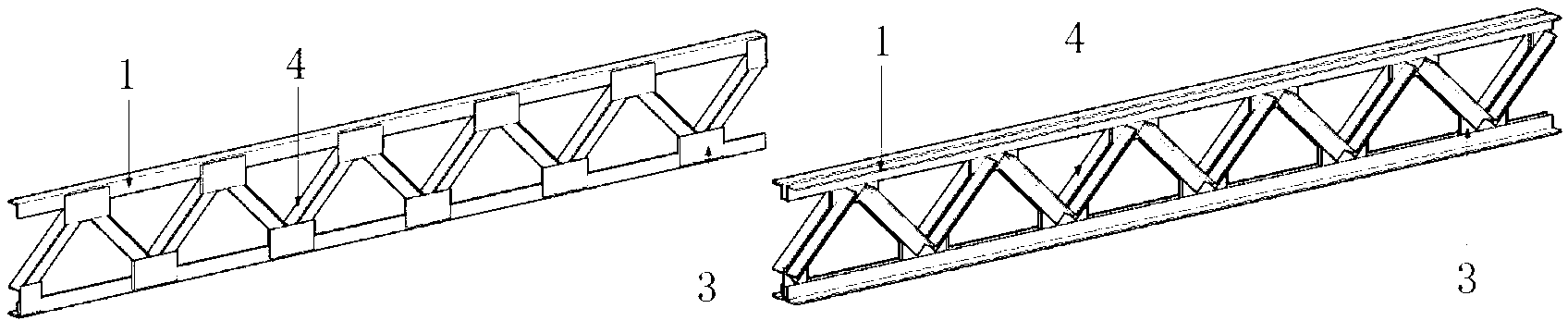

Industrialized multi-high-rise assembly type steel structure frame-pre-stressed center support system

ActiveCN102995744AEasy to pass throughIncrease net heightBuilding constructionsPre stressingEngineering

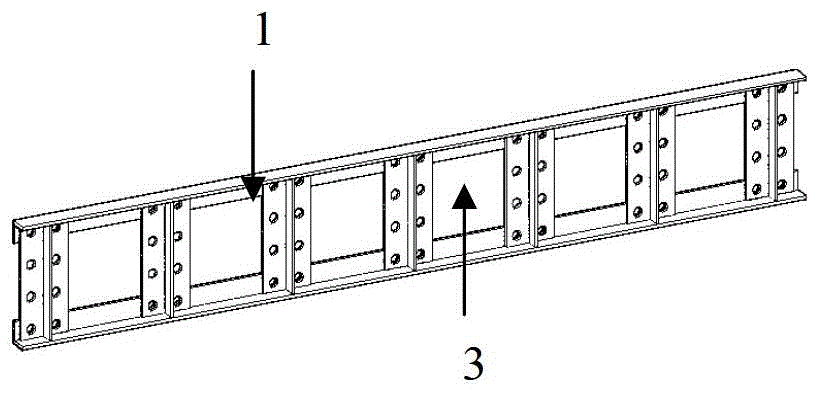

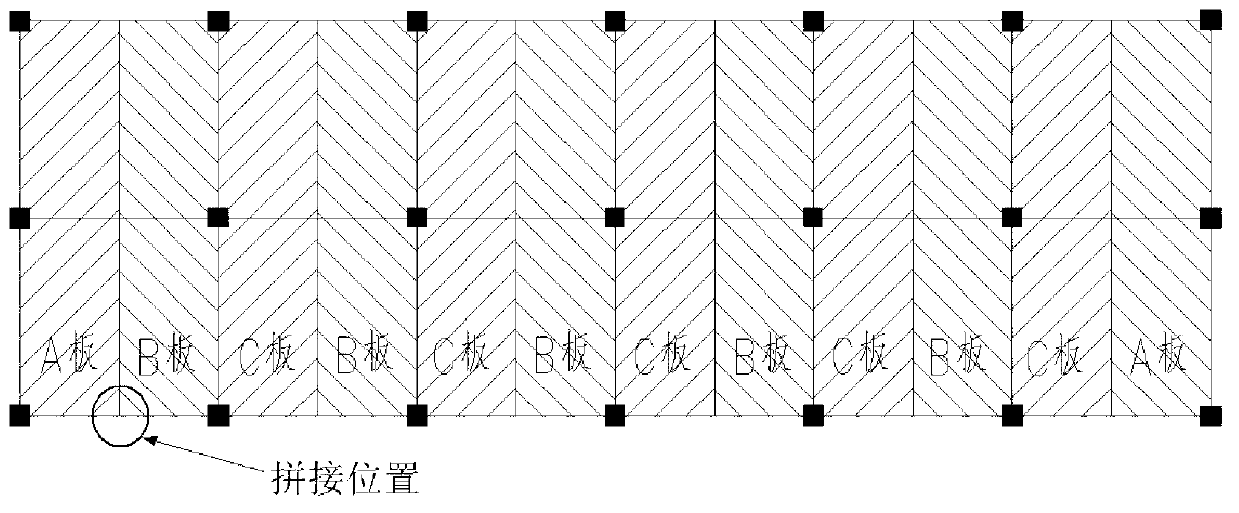

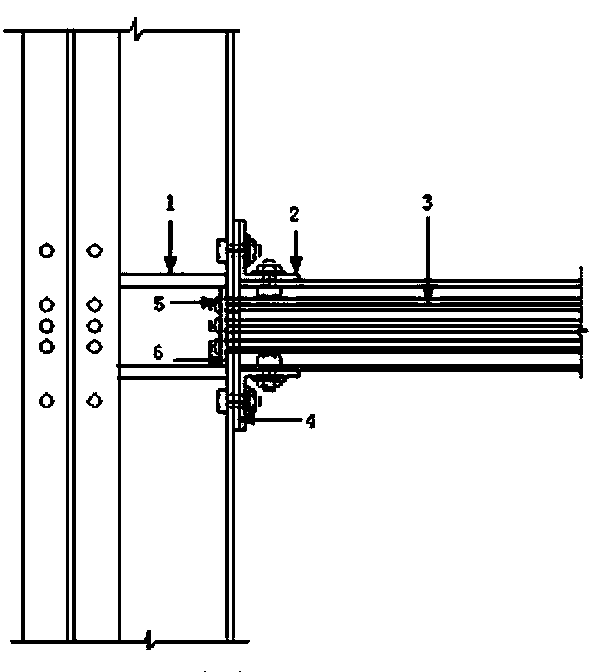

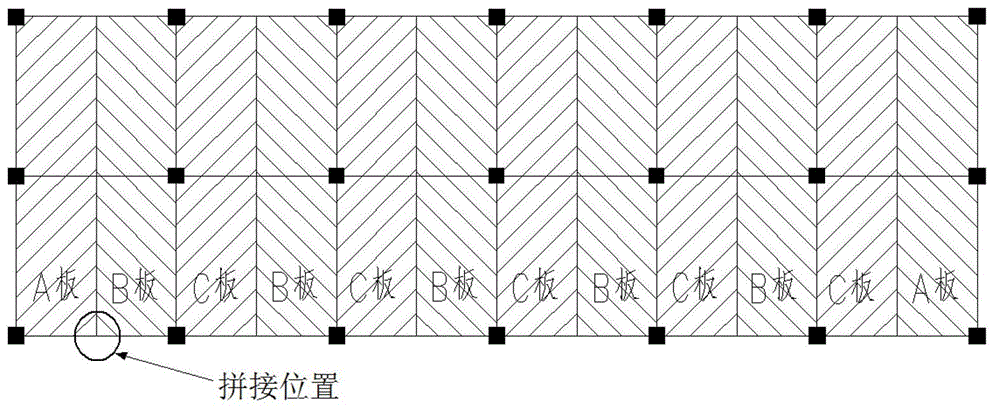

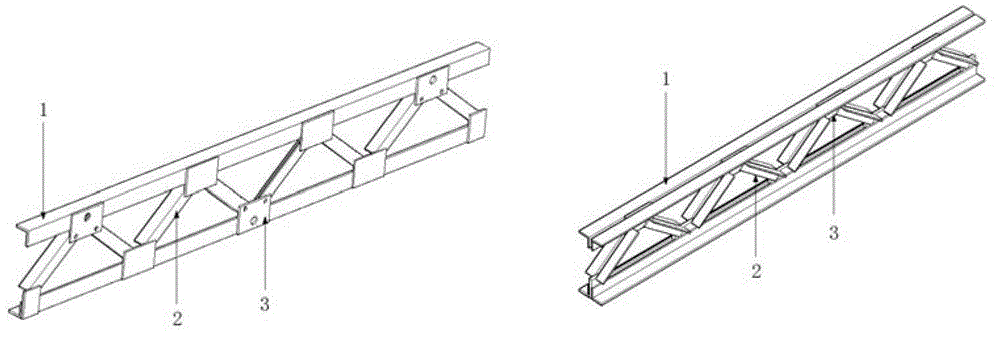

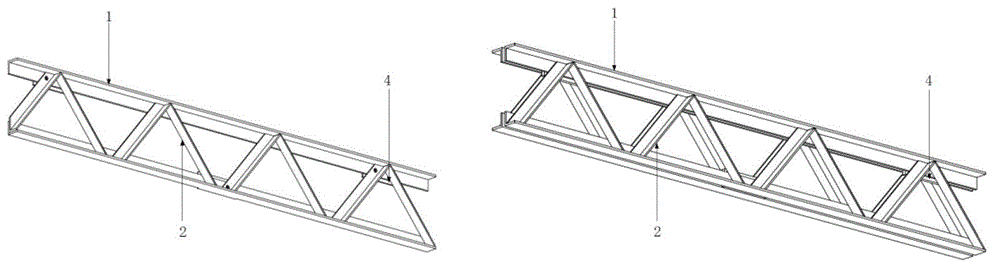

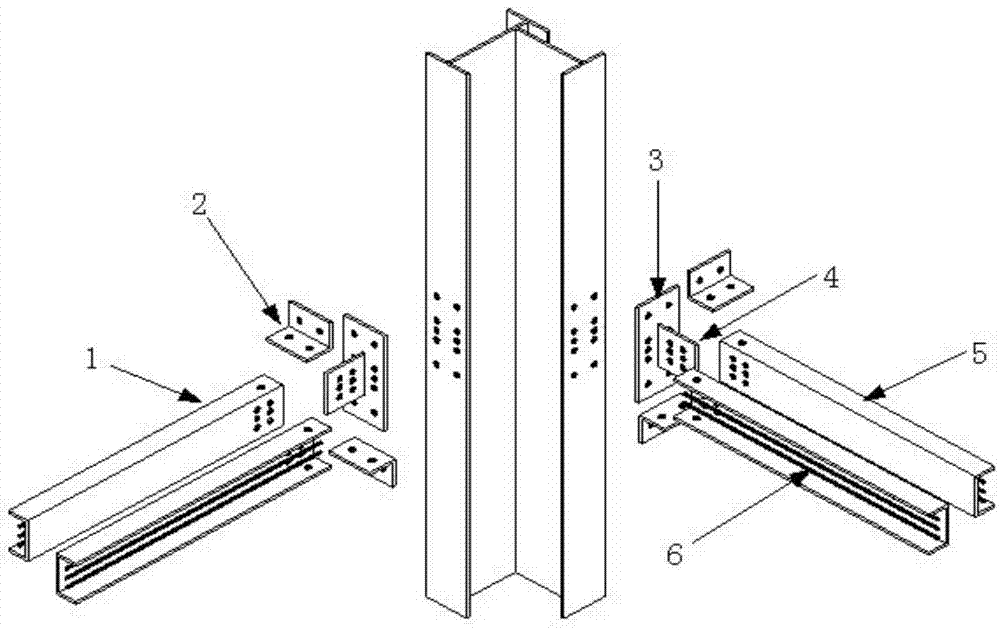

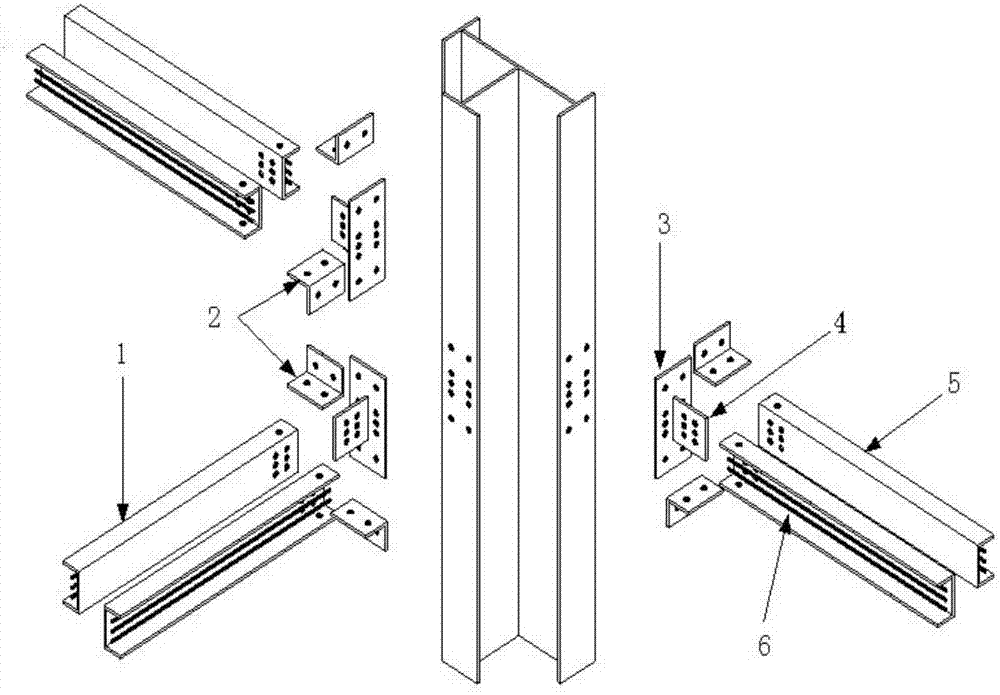

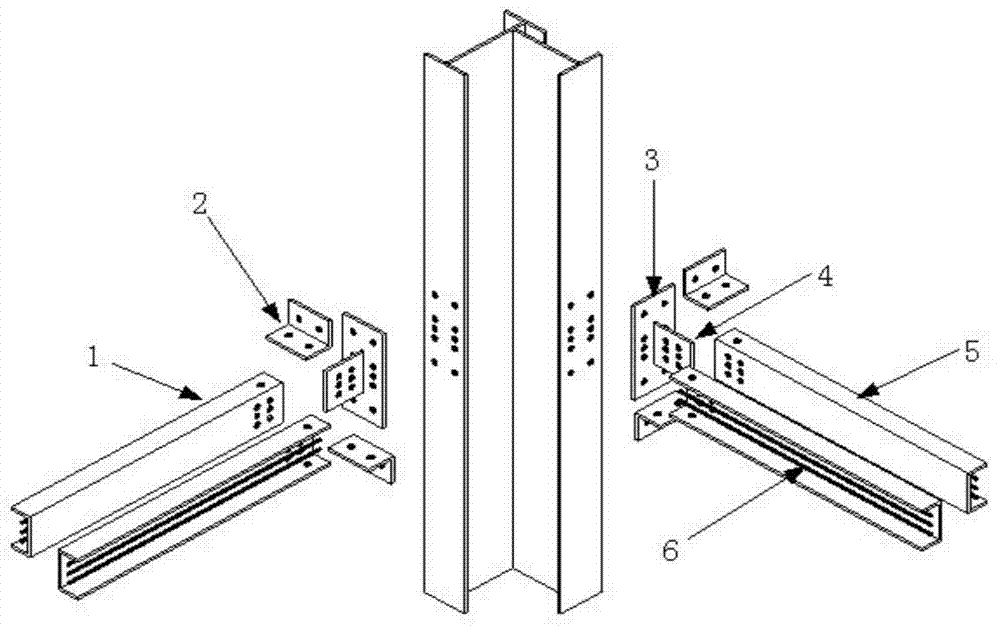

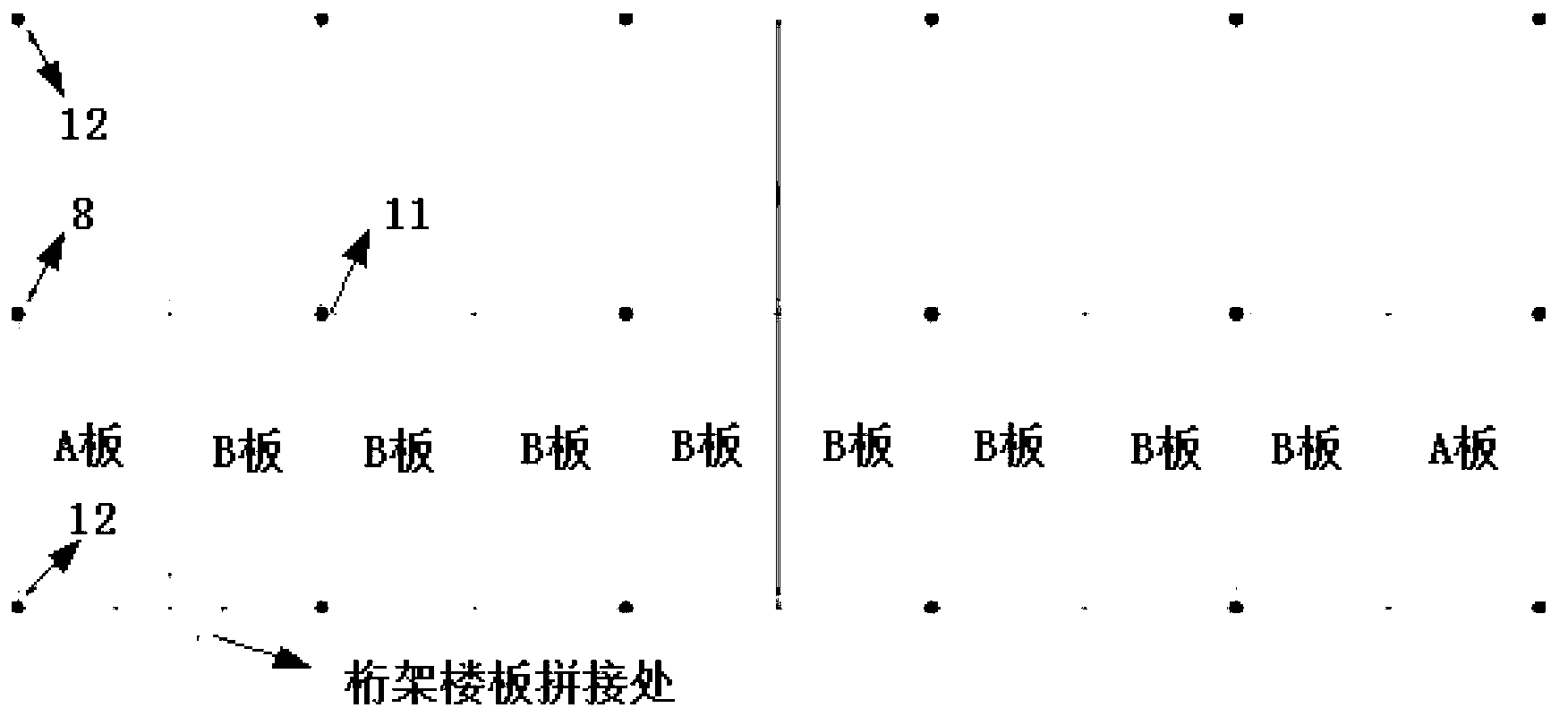

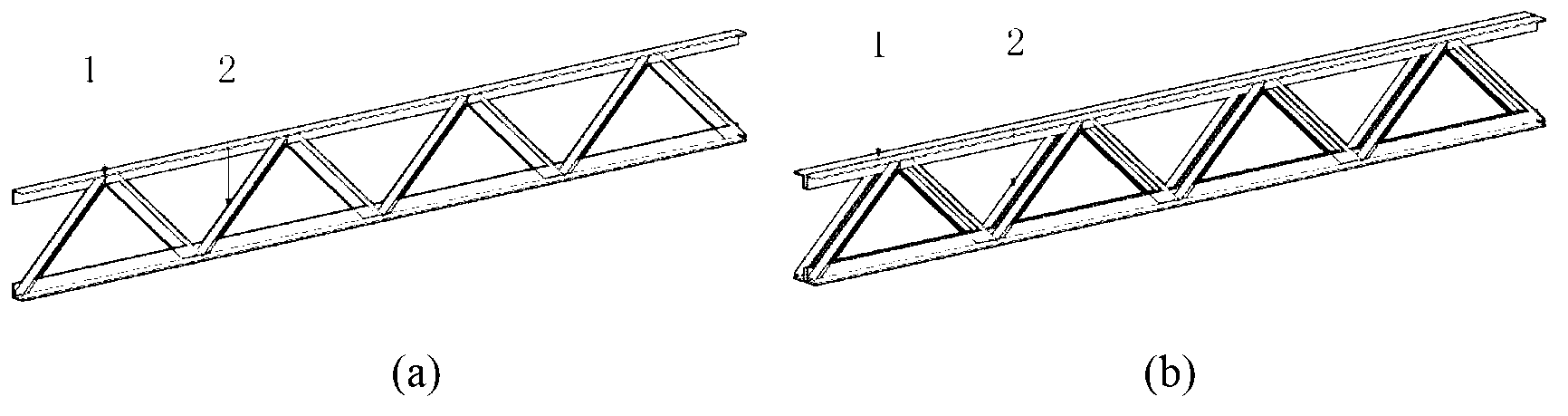

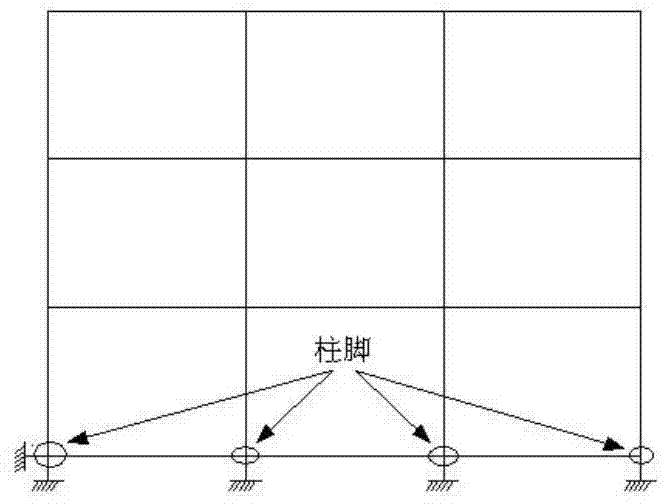

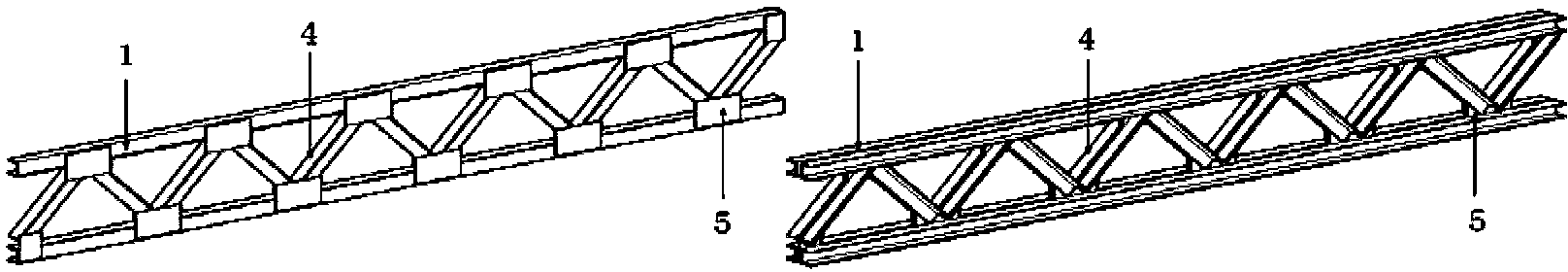

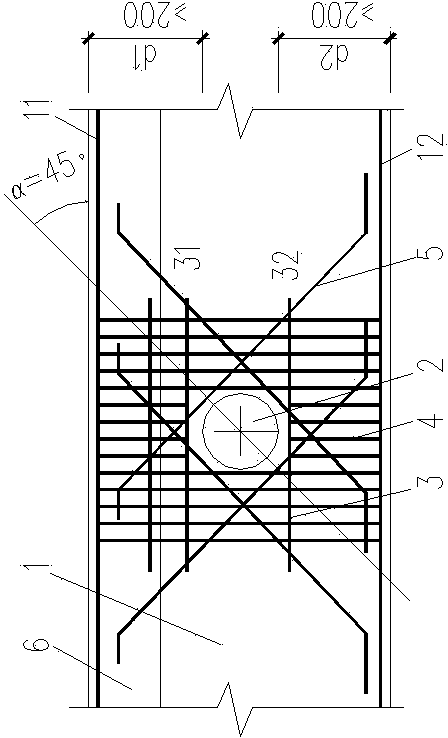

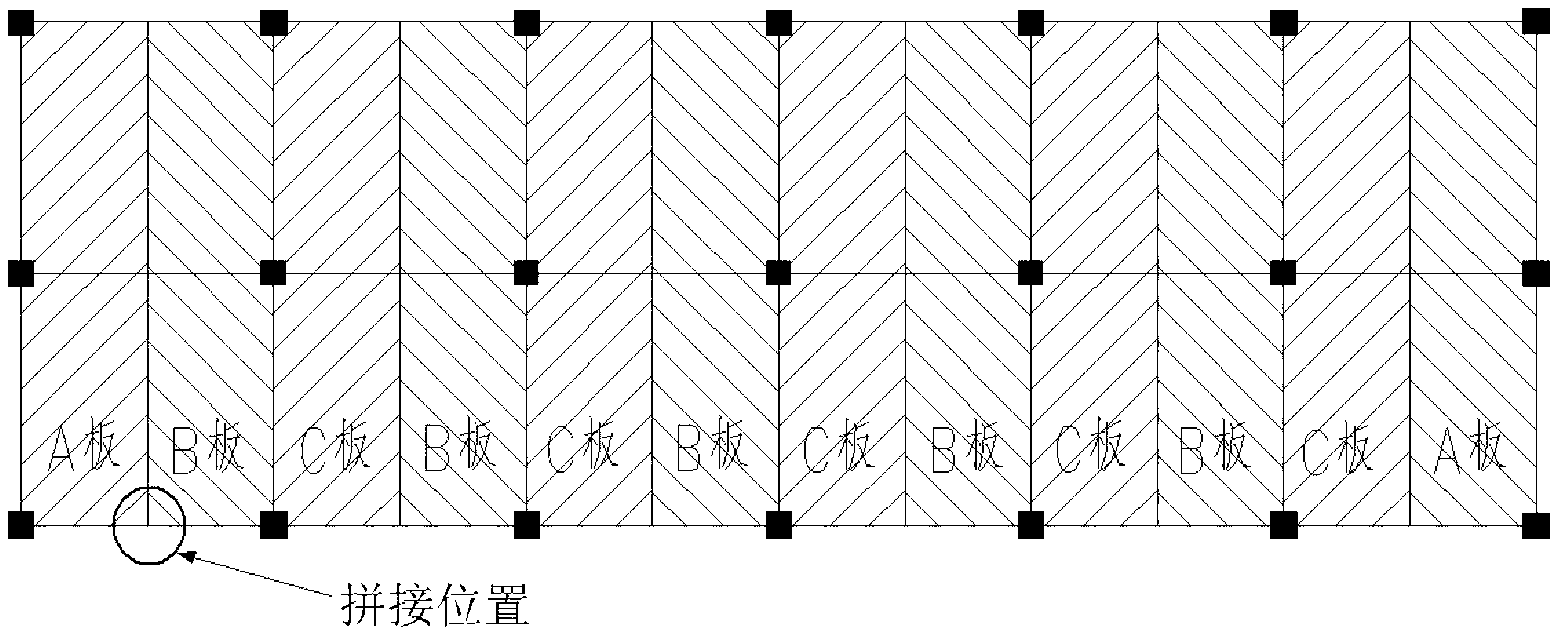

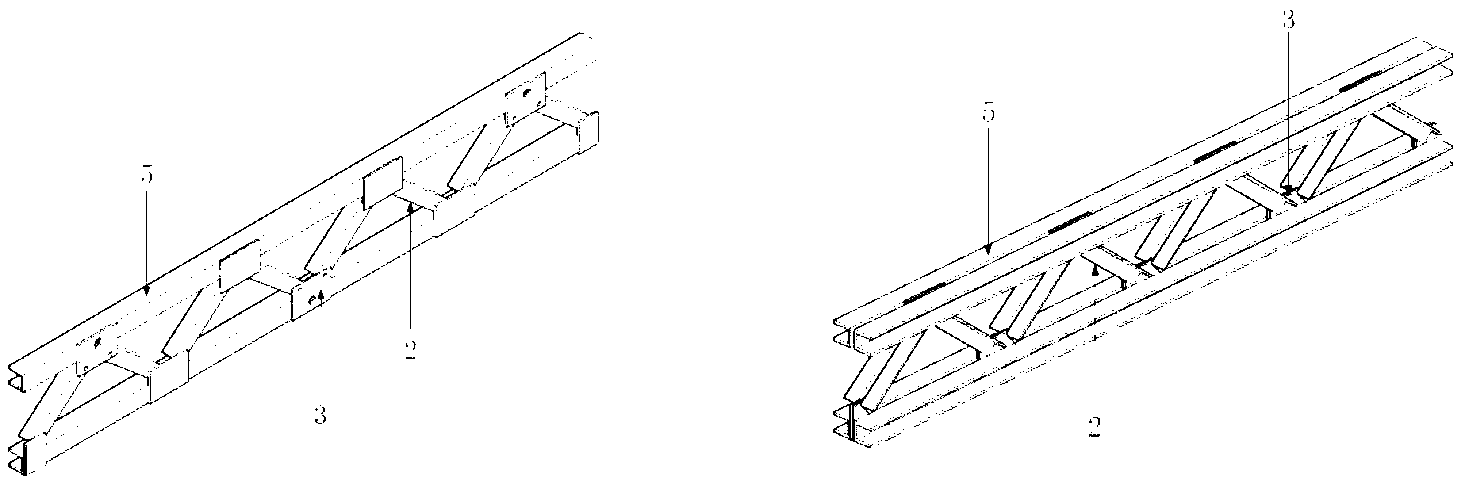

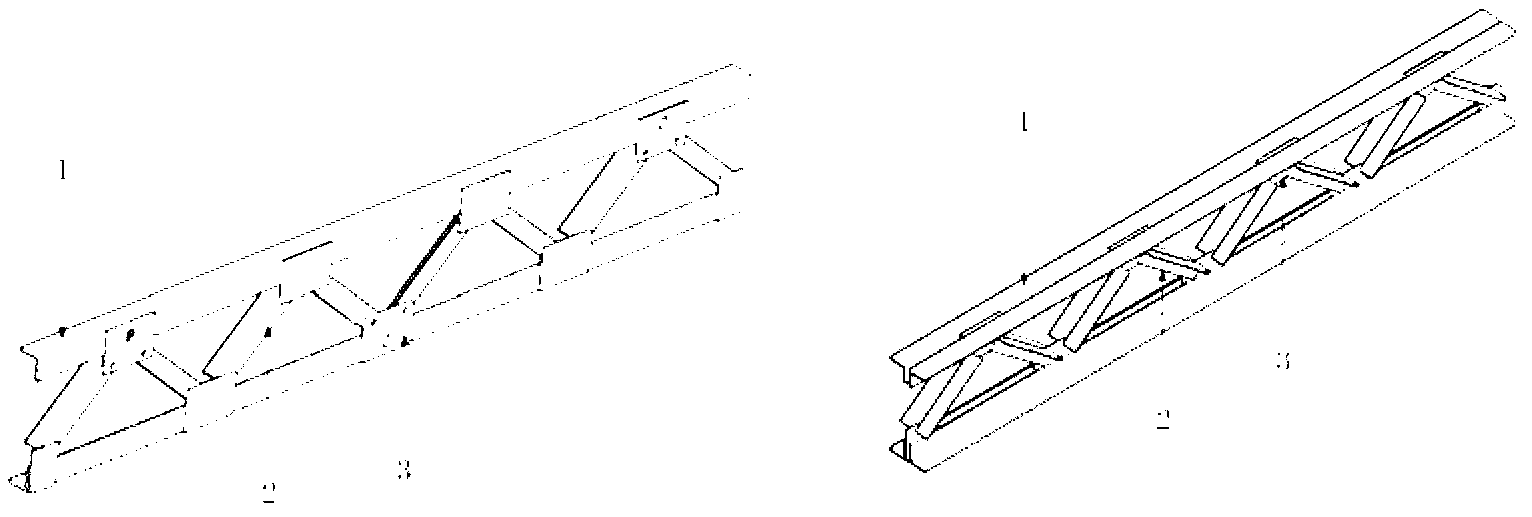

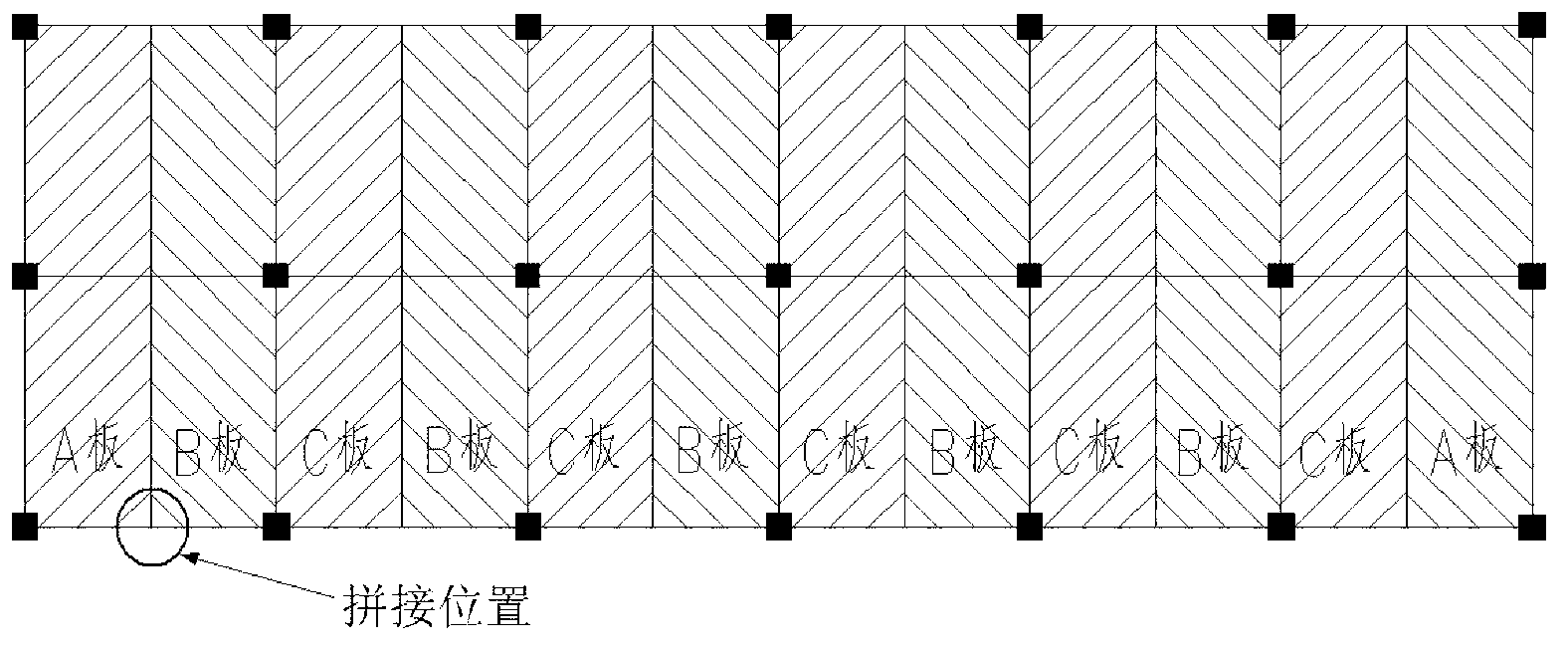

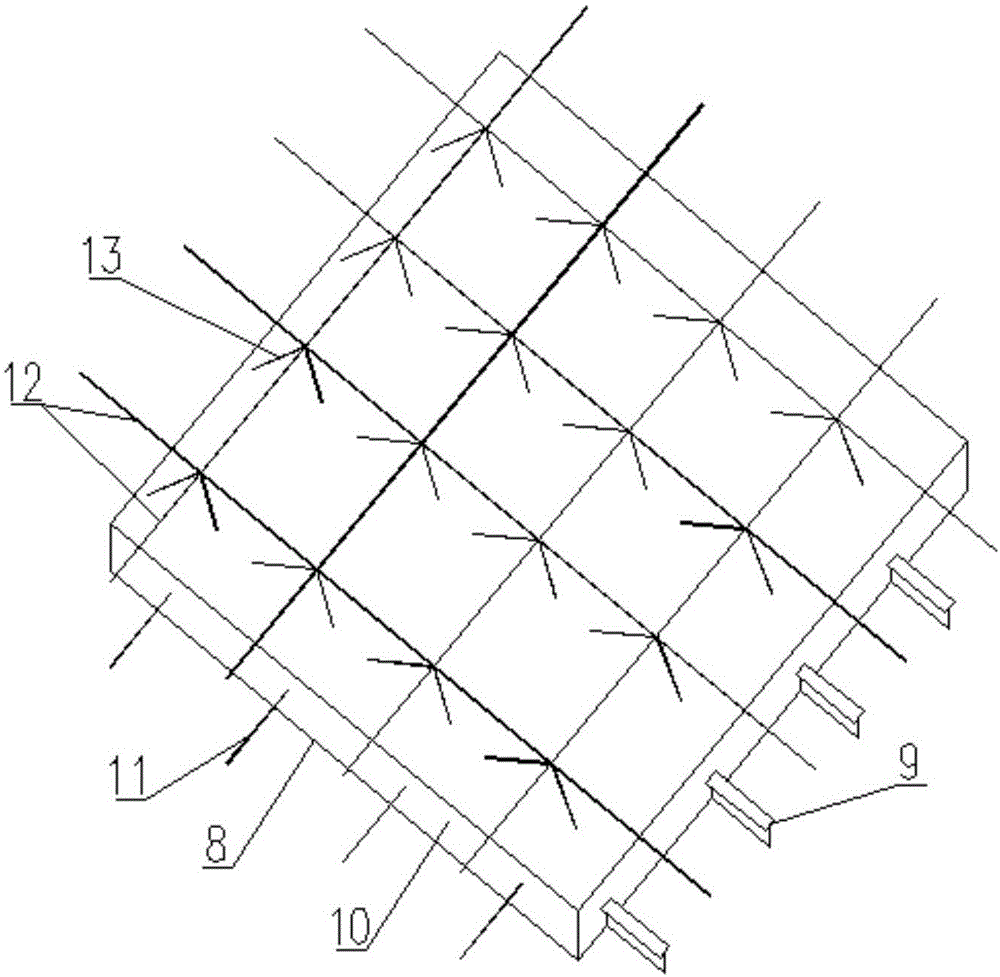

The invention discloses an industrialized multi-high-rise assembly type steel structure frame-pre-stressed center support system, belonging to the technical field of structural engineering, and comprising assembly type truss plates, assembly type flange posts and pre-stressed center support members, wherein the assembly type truss plates are prefabricated in a factory, and are mutually spliced through beam end sealing plates or post base nodes in a construction field to be used as frame structure beam and slab layers, the frame structure beam and slab layers are up and down connected through the assembly type flange posts to form a multi-layer steel frame structure; on the basis of the steel frame structure, the pre-stressed center support members are connected to the bottoms and the tops of posts or the truss beams in the frame structure beam and slab layers to be used as side force-resisting members; and the pre-stressed center support members are pre-fabricated in the factory, and are assembled by using bolts in the construction field. The invention integrates modularization, industrialization, standardization and assembly, realizes industrialized production and rapid field assembly, and has the advantages of increasing the construction speed, reducing the construction period and lowering the engineering cost under the premise of ensuring the construction quality.

Owner:CHINA RAILWAY CONSTR GROUP +1

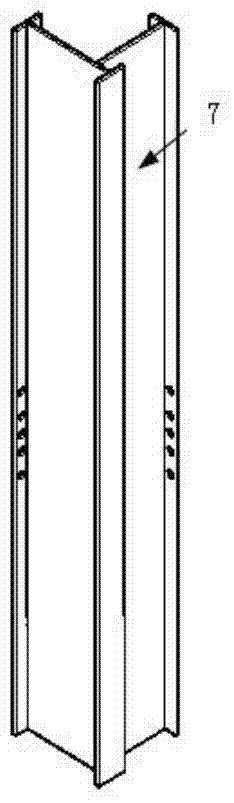

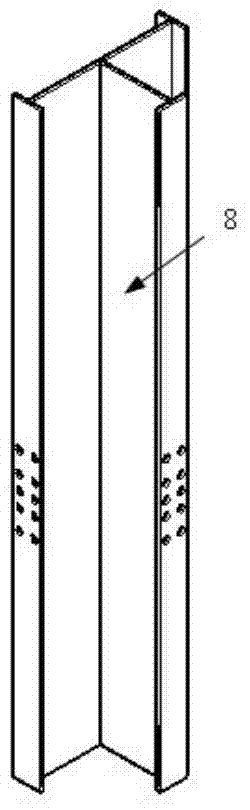

Fabricated multistory and high-rise prestressed steel frame-sway brace system provided with special-shaped columns

InactiveCN103410218AEasy to pass throughIncrease net heightBuilding constructionsFloor slabPre stress

The invention discloses a fabricated multistory and high-rise prestressed steel frame-sway brace system provided with special-shaped columns, and relates to the technical field of structural engineering. The fabricated multistory and high-rise prestressed steel frame-sway brace system comprises fabricated profile steel plates, fabricated special-shaped columns and eccentric supporting members, wherein the fabricated profile steel plates comprise profile steel beams consisting of steel channels and floor slabs; the fabricated profile steel plates are prefabricated in a factory; at the construction site, the fabricated profile steel plates are mutually spliced with flange plates of the fabricated special-shaped columns through beam-end blanking plates of the fabricated profile steel plates, steel angles with equal legs and steel tightwires, and layers of the fabricated special-shaped columns are spliced at the site by bolts, so that a multilayer profile steel plate steel-frame structure is formed; on the basis of the steel-frame structure, the eccentric supporting members are connected to profile steel beams or column bottoms in beam and slab layers of the frame structure and taken as lateral force resisting members; and the fabricated profile steel plates, the fabricated special-shaped columns and the eccentric supporting members are all prefabricated in the factory and assembled at the construction site by bolts.

Owner:BEIJING UNIV OF TECH

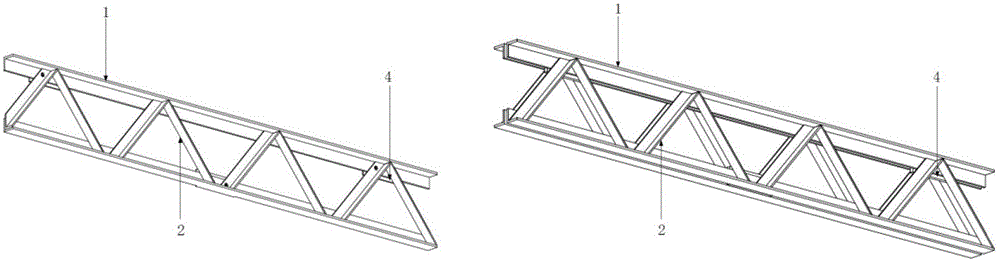

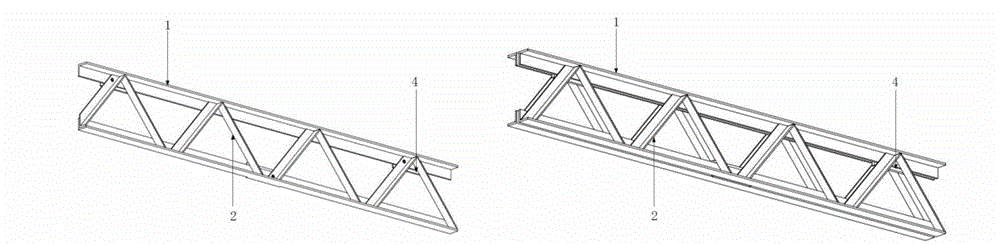

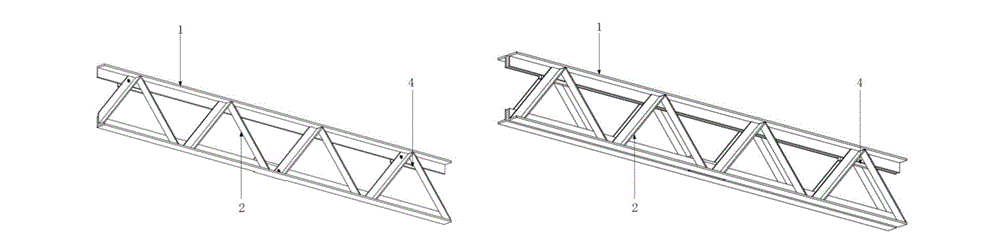

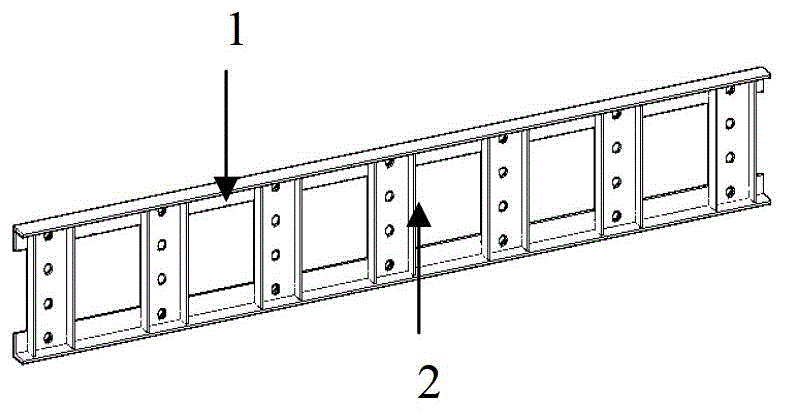

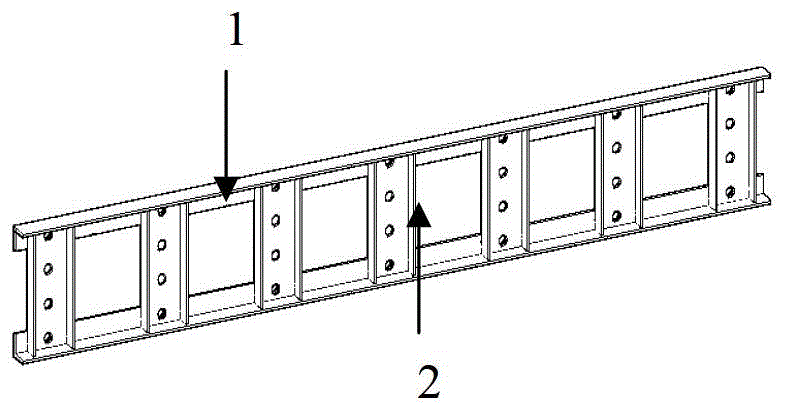

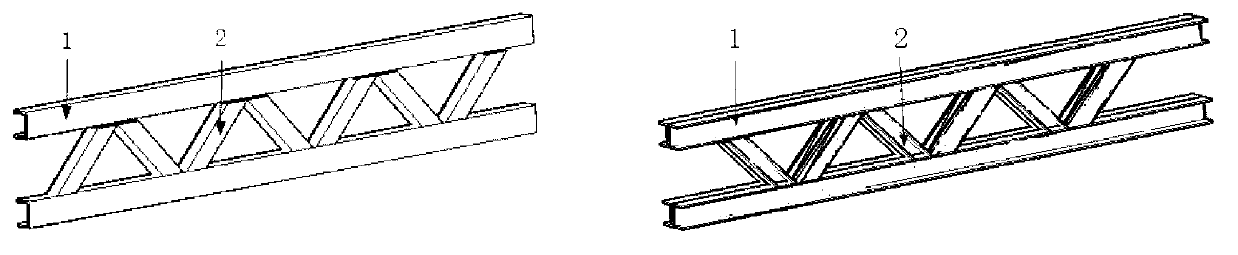

Industrialized multi-story high-rise assembled steel structure system

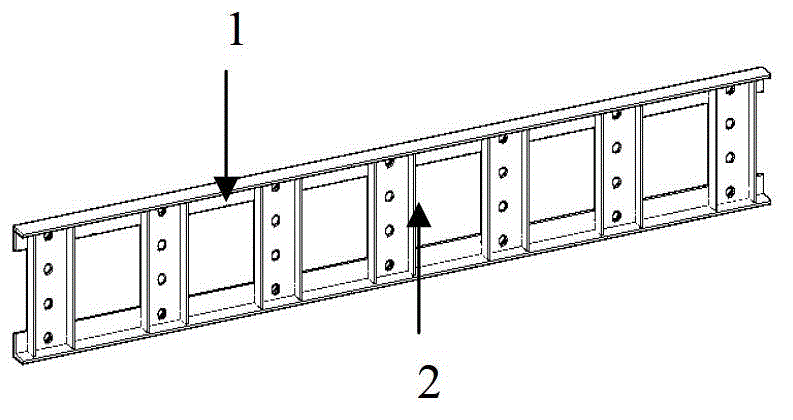

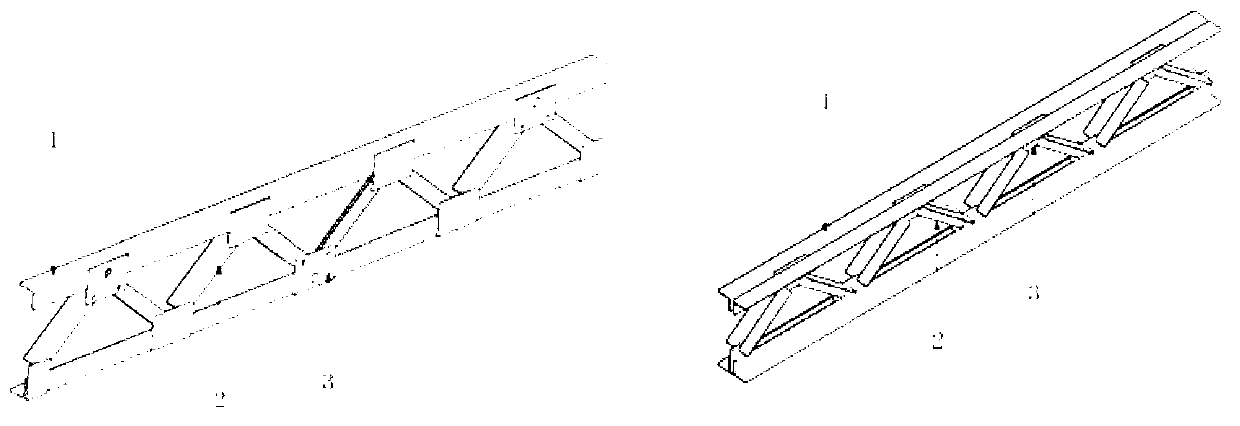

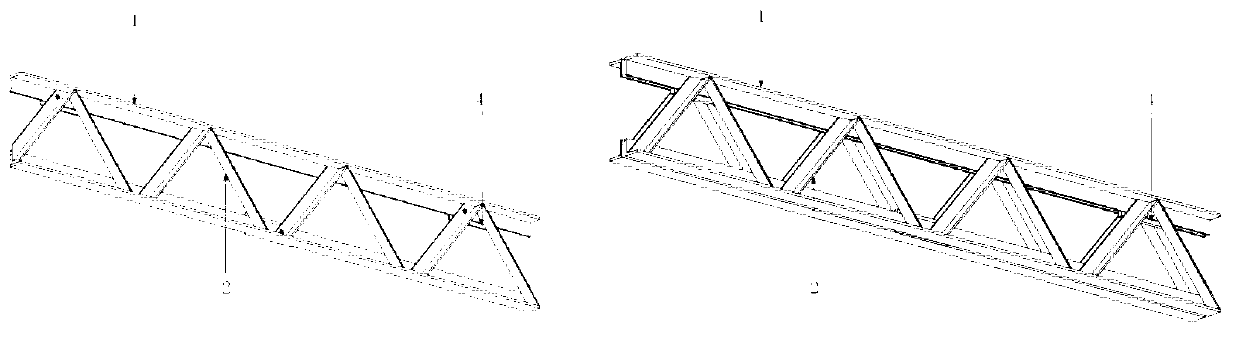

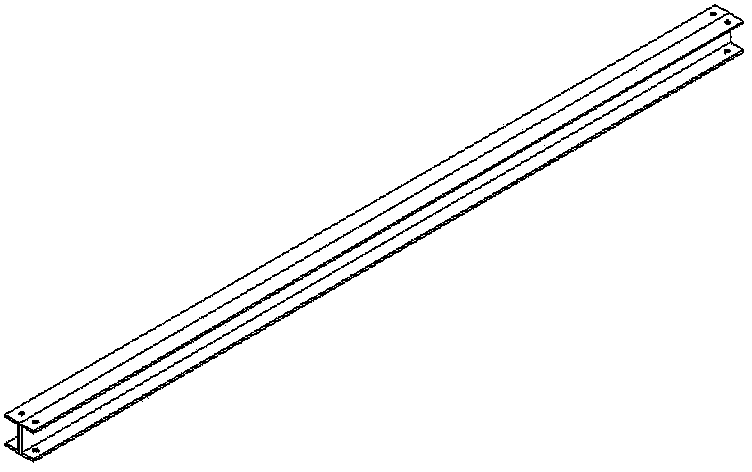

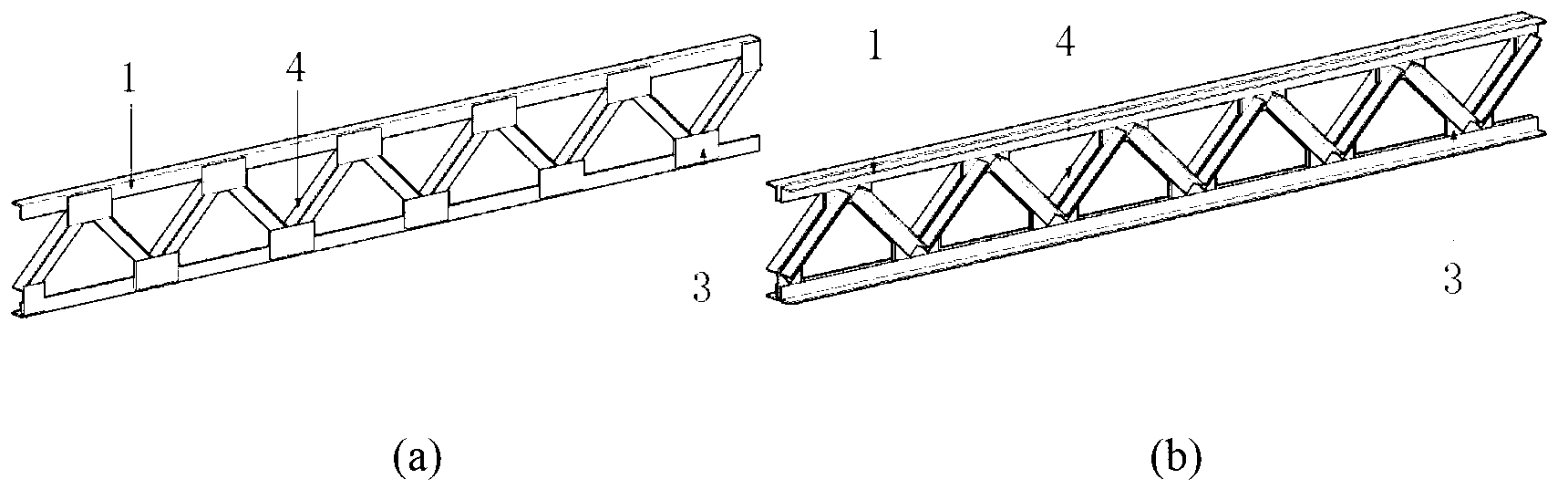

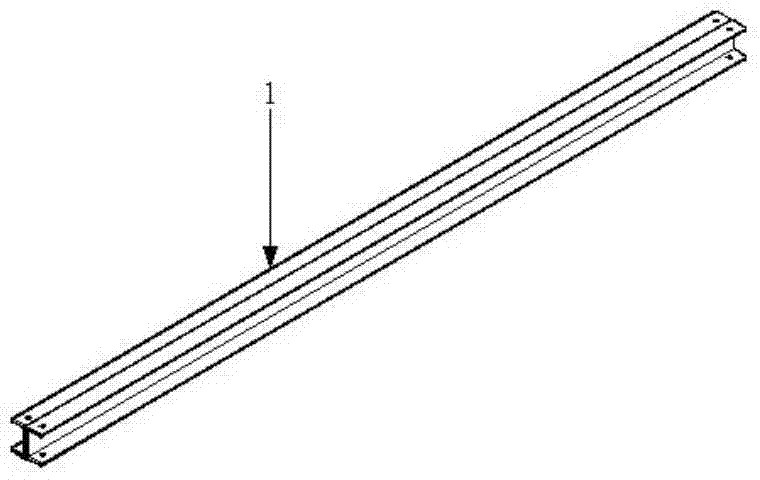

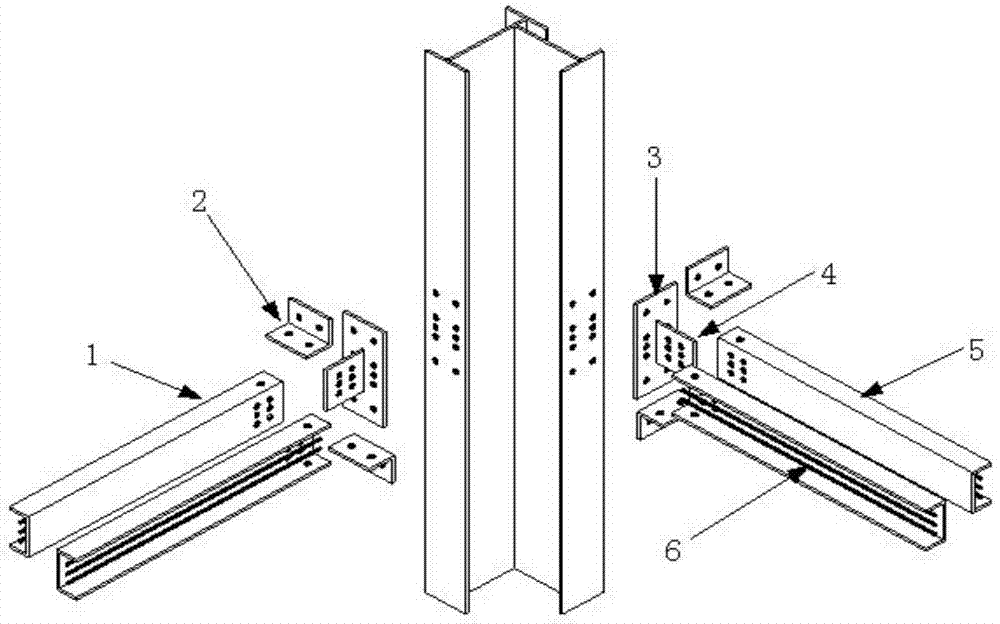

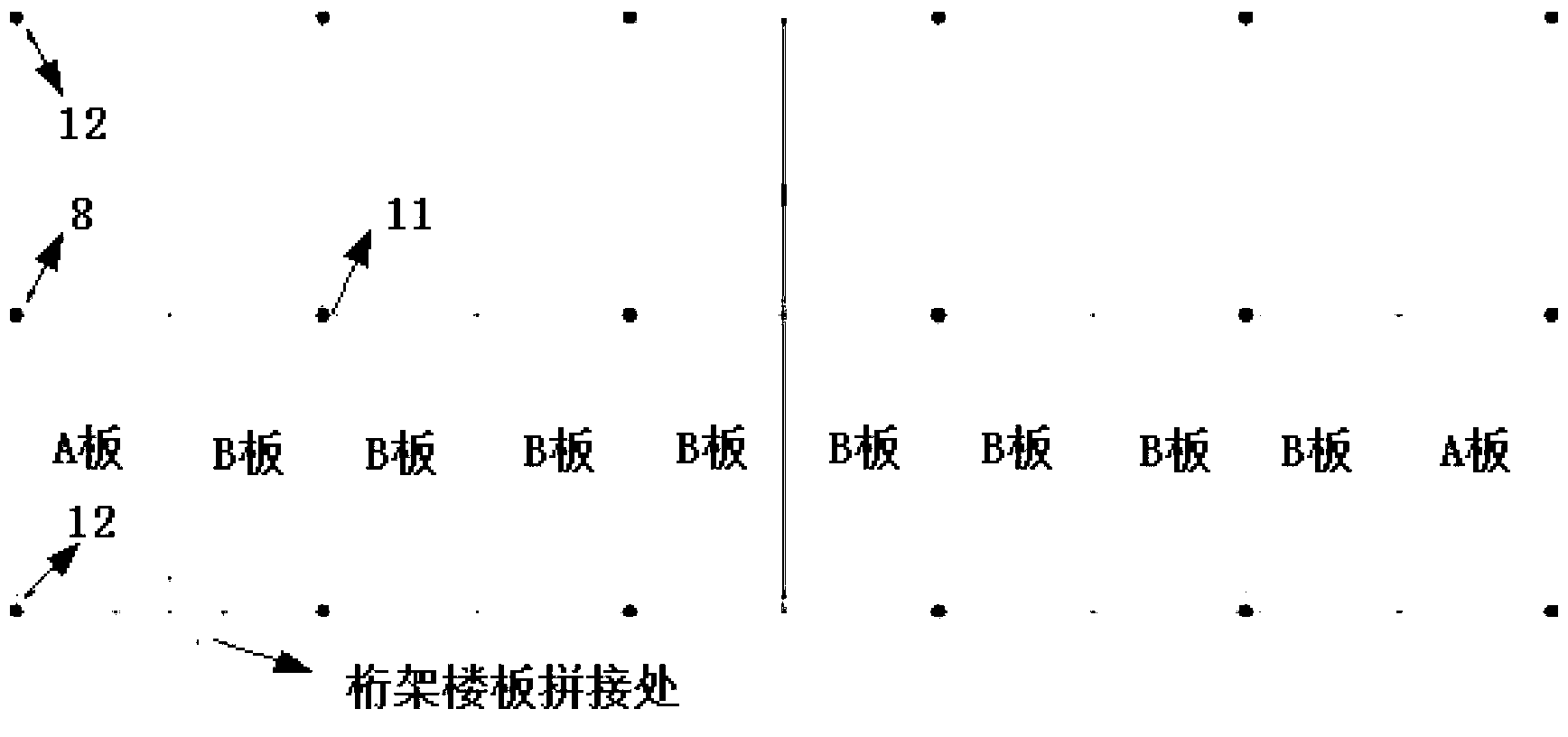

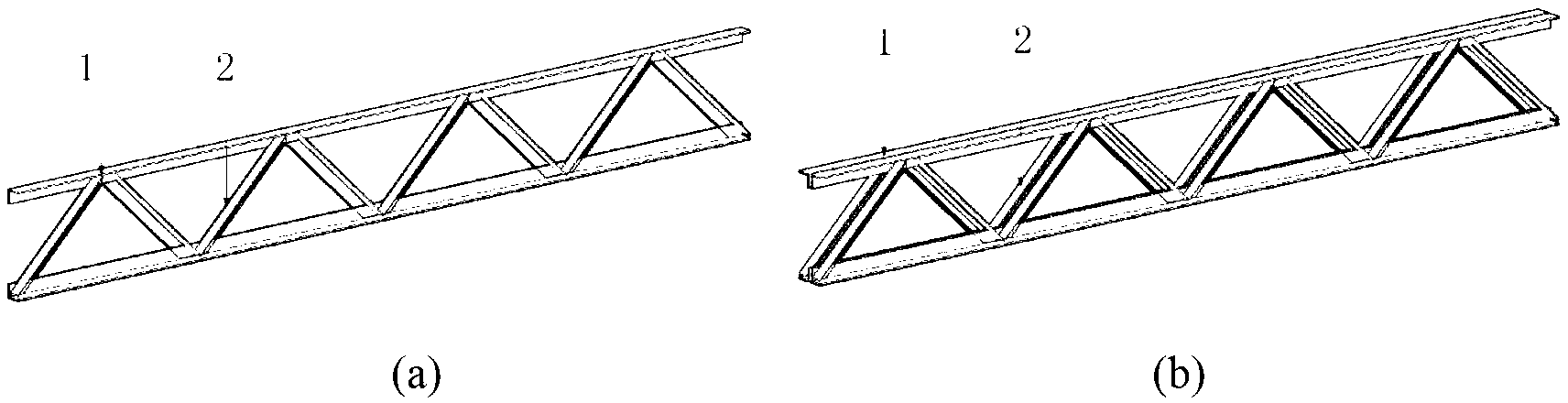

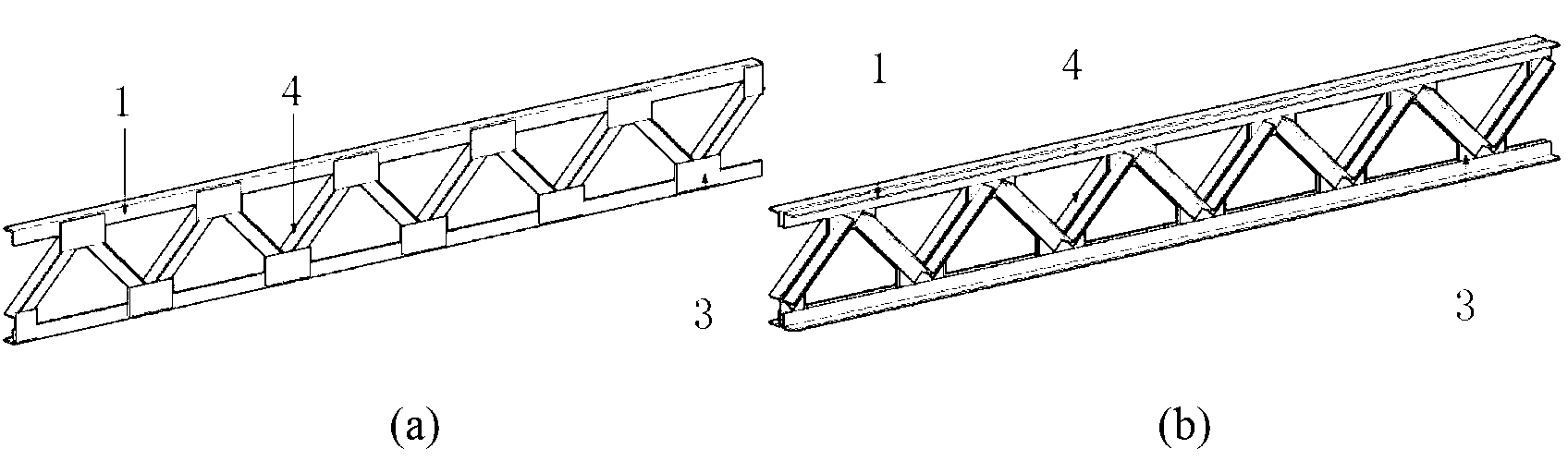

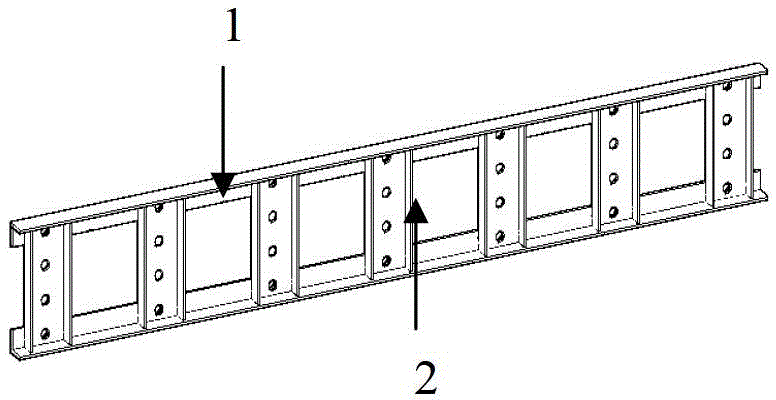

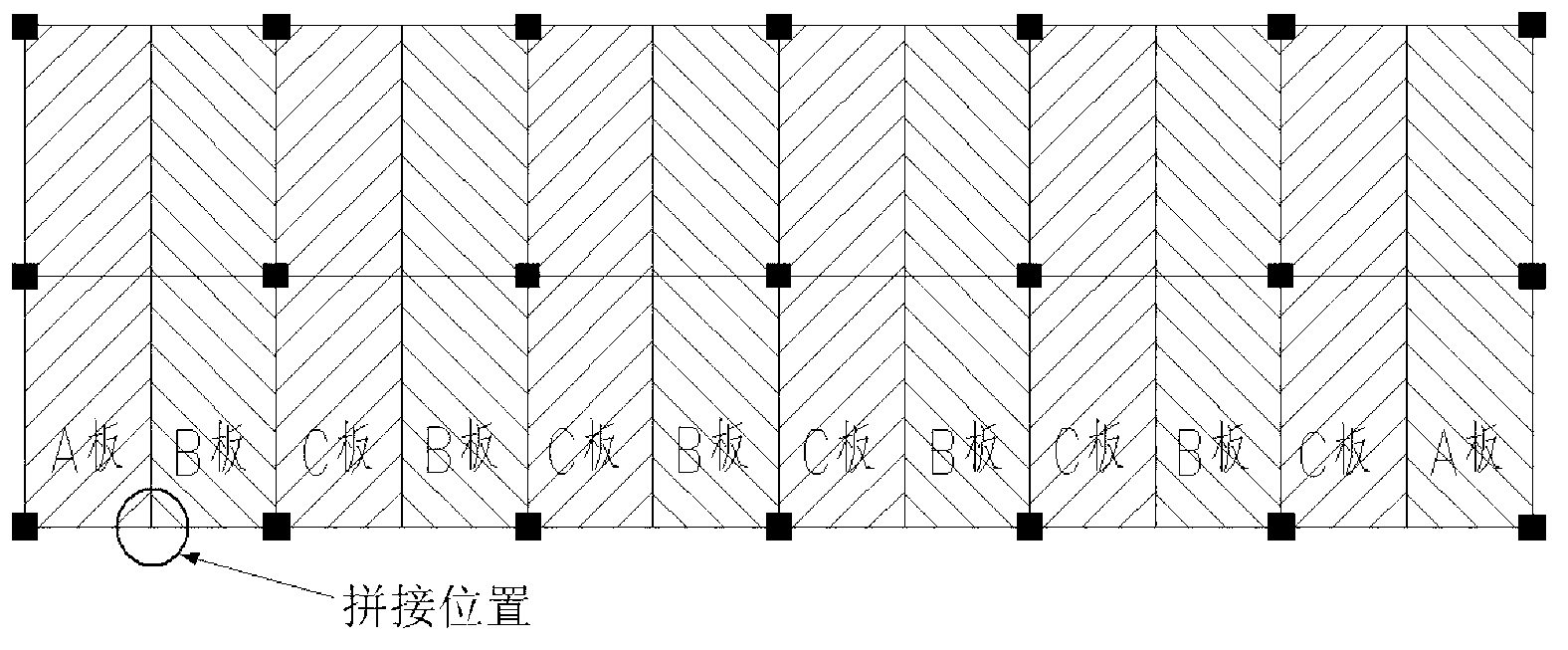

The invention relates to an industrialized multi-story high-rise assembled steel structure system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure system comprises assembled truss plates and assembled flange columns. The assembled truss plates comprise latticed truss beams with angle steel web members, column base joints and slabs. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or the column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure, and the assembled flange columns are arranged on the column base joints on the assembled truss plates; and the assembled truss plates and the assembled flange columns are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

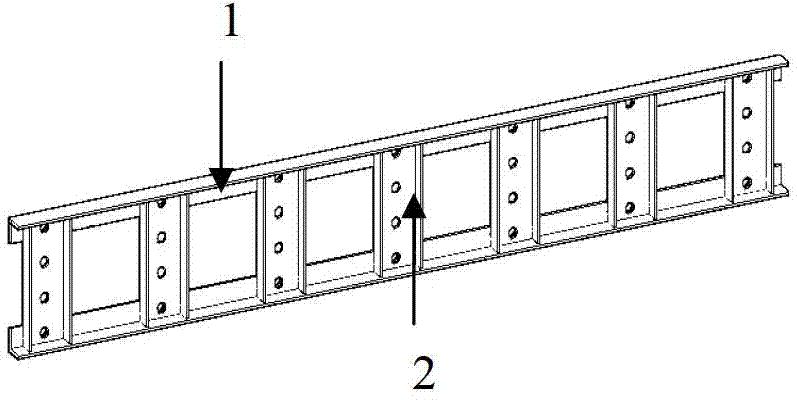

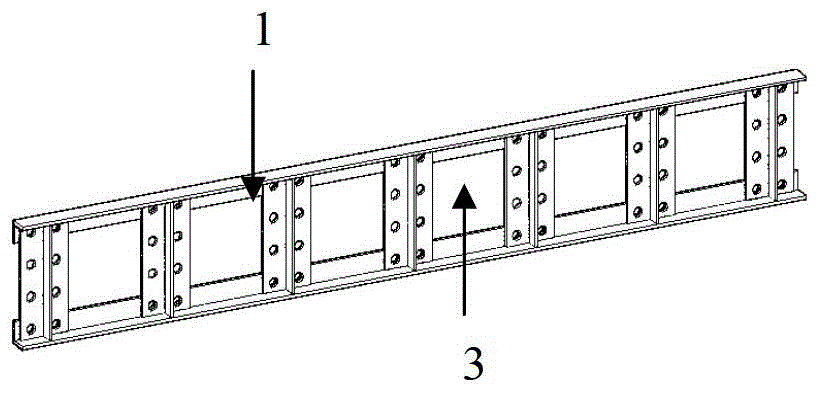

Assembled steel structure center support frame system

InactiveCN103290920AEasy to pass throughIncrease net heightBuilding constructionsBraced frameFloor slab

The invention relates to an assembled steel structure center support frame system and belongs to the technical field of structure engineering. The system comprises assembled truss plates, assembled uprights and center support members, wherein the assembled truss plates comprise lattice truss beams with steel angle web members, and floor plate, and are prefabricated in a factory; the assembled truss plates are spliced with beam column nodes of the assembled uprights by beam end sealing plates of the assembled truss plates at a construction site; the assembled uprights are spliced between layers by bolts on site to form a multilayer steel frame structure; based on the steel frame structure, the center support members serve as lateral force resisting members and are connected with the truss beams in the assembled truss plates and the bottoms or tops of the assembled uprights; the assembled truss plates, the assembled uprights and the center support members are prefabricated in the factory and assembled by the bolts at the construction site.

Owner:河南天蚕富煌钢结构有限公司

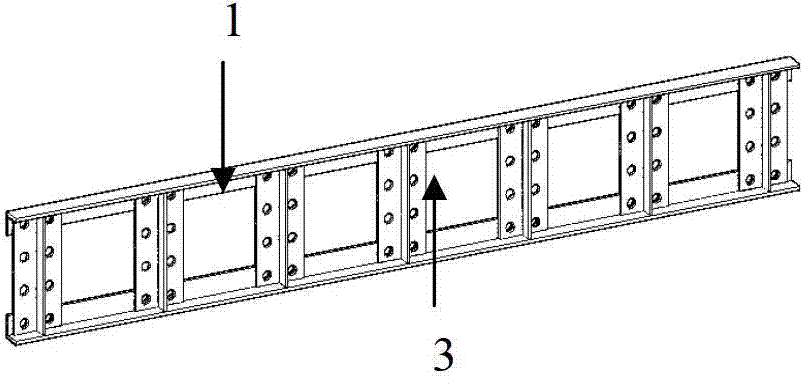

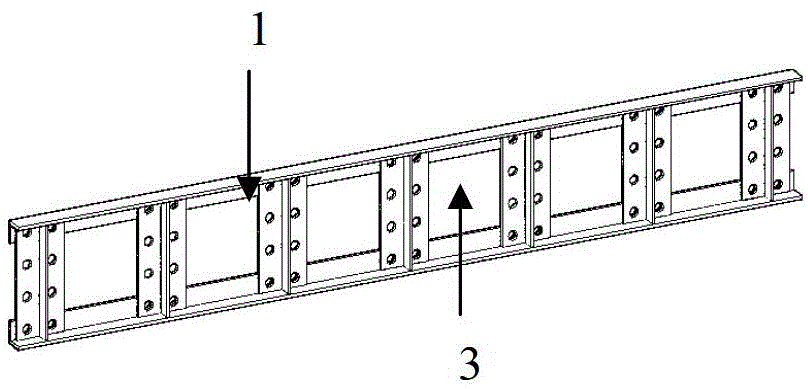

Industrialized multi-story high-rise assembled steel structure frame - centrally-braced system

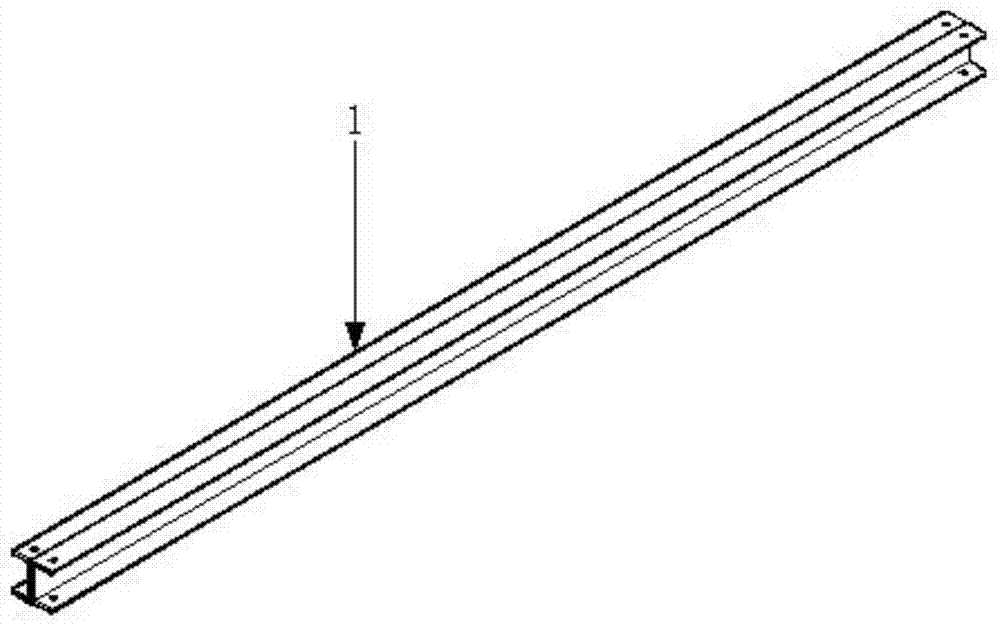

ActiveCN102979168AEasy to pass throughIncrease net heightBuilding constructionsModularitySteel frame

The invention relates to an industrialized multi-story high-rise assembled steel structure frame - centrally-braced system, belonging to the technical field of structure engineering. The industrialized multi-story high-rise assembled steel structure frame - centrally-braced system comprises assembled truss plates, assembled flange columns and central bracing members. The assembled truss plates are prefabricated in a factory. On a construction site, the assembled truss plates are spliced together through beam end closing plates or column base joints to form frame structure beam-slab layers; the frame structure beam-slab layers are vertically connected through the assembled flange columns to form a multilayer steel frame structure; on the basis of the steel frame structure, the central bracing members are connected to truss beams or column bottoms in the frame structure beam-slab layers and are used as lateral-force-resistant members; and all members are prefabricated in the factory and are assembled through bolts on the construction site. In combination with modularization, factory production, standardization and assembling, the industrialized multi-story high-rise assembled steel structure frame - centrally-braced system has the advantages that the factory production and the on-site rapid assembling are realized; and on the premise that the construction quality is guaranteed, the construction speed is improved, the construction period is shortened and the construction cost is decreased.

Owner:CHINA RAILWAY CONSTR GROUP +1

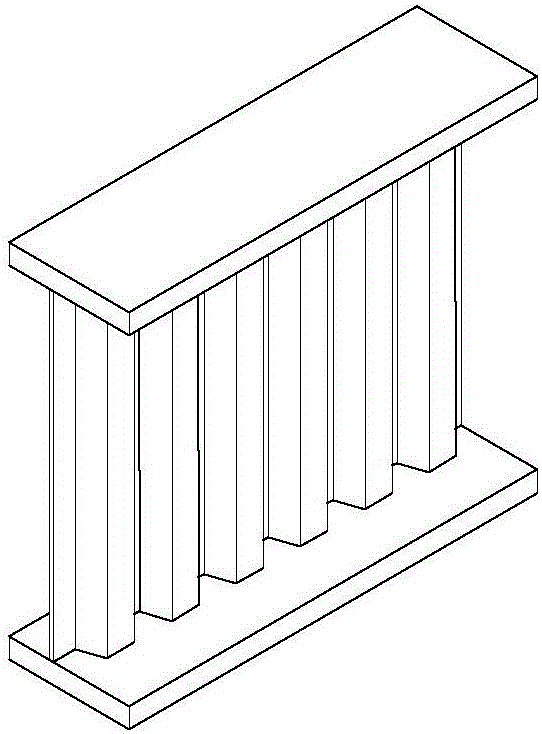

Multi-high-layer assembly type steel structure frame-center supporting system

ActiveCN103114648AEasy to pass throughIncrease net heightStrutsFloorsSupporting systemLateral stiffness

The invention provides a multi-high-layer assembly type steel structure frame-center supporting system, and belongs to the technical field of structural engineering. The system comprises assembly type beam-slabs, assembly type upright columns and profile steel inclined supports. Each assembly type beam-slab comprises a floor, a column joint and a hollow steel beam of a matched profile steel web member. The hollow steel beams are connected with the column joints, the floors are supported on the hollow steel beams, and each assembly type upright column is composed of a box-shaped column and a flange plate. During construction, the assembly beam-slabs and the assembly type upright columns are connected to form a frame structure, the profile steel inclined supports are arranged on the basis of the steel frame, and lateral stiffness of the structure is improved. All elements of the system are precast in factories and are rapidly assembled to form the structural system through bolts on construction sites. Concrete pouring and welding work are not needed, the defects that a traditional building is long in construction period, severe in material waste, severe in pollution during the construction process and the like are reduced, and factory integral production of the building can be achieved.

Owner:CHINA RAILWAY CONSTR GROUP +1

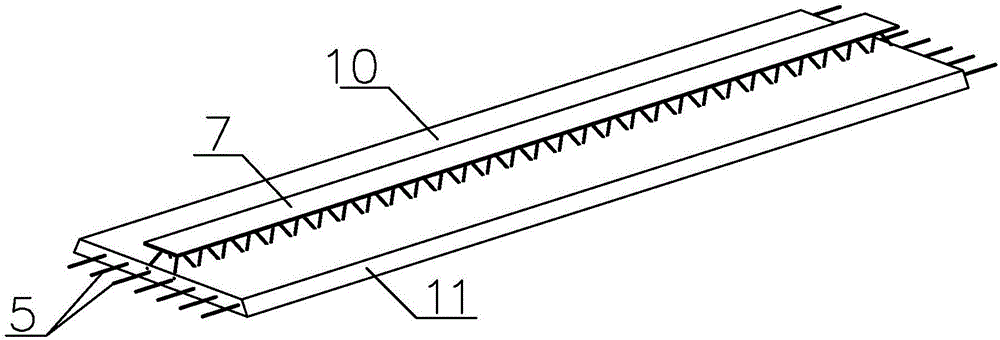

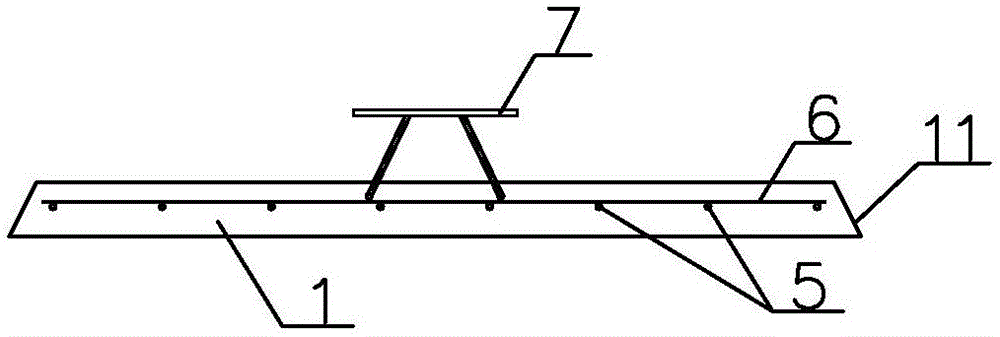

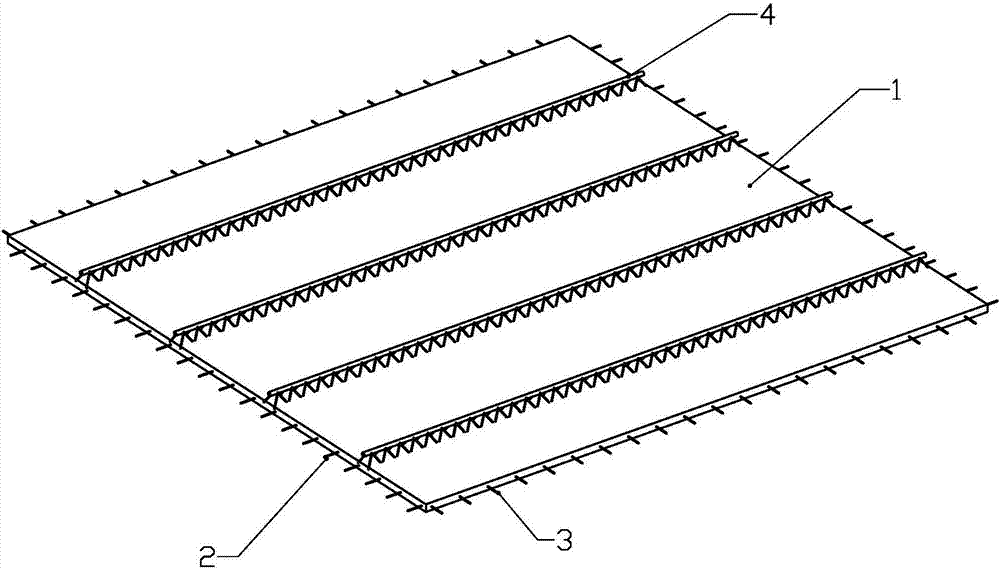

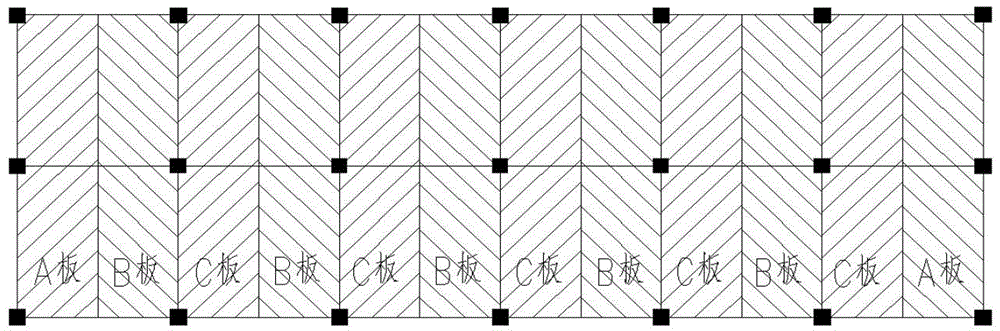

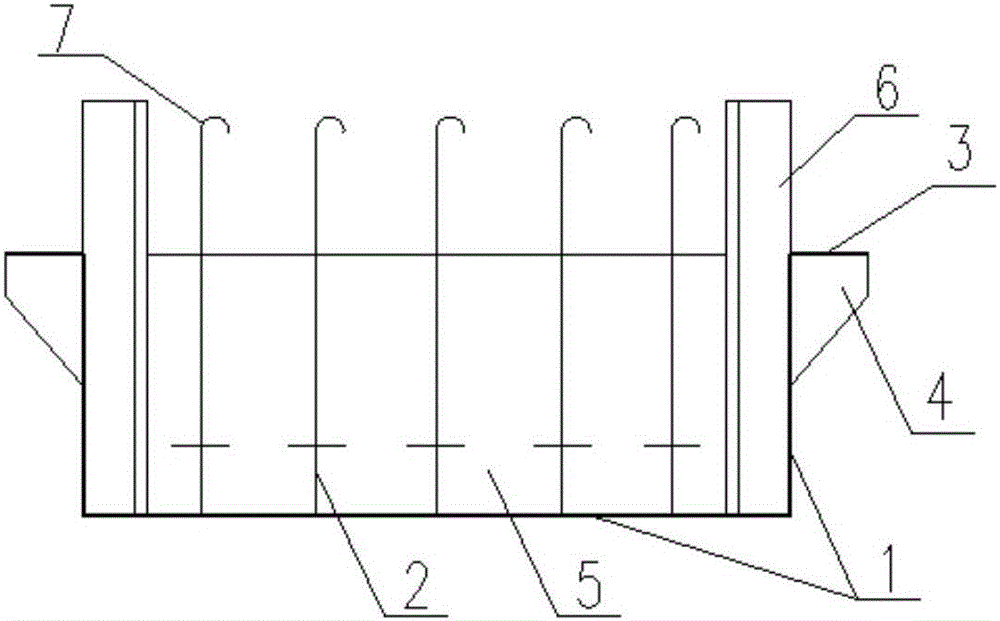

Prestressed concrete bidirectional laminated slab and manufacturing method

InactiveCN107542196AReduce support and formwork usageImprove construction efficiencyFloorsBuilding material handlingRebarPre stress

The invention discloses a prestressed concrete two-way laminated slab and a manufacturing method thereof, which belong to the technical field of construction engineering. Its structure includes a prefabricated bottom plate, a laminated layer and a steel truss. The trusses are connected, and the laminated layer transverse steel bars and laminated layer longitudinal steel bars are arranged inside the laminated layer. The laminated layer longitudinal steel bars are fixed on the upper surface of the steel truss. The transverse prestressed reinforcement is arranged at equal intervals, the longitudinal prestressed reinforcement is arranged at equal intervals along the length direction, the longitudinal prestressed reinforcement is located above the transverse prestressed reinforcement, and multiple steel trusses are arranged at equal intervals along the width direction on the upper part of the prefabricated floor. The invention also discloses a manufacturing method of the laminated board. The invention has the characteristics of high overall rigidity of the laminated slab, good force bearing performance, two-way force transmission mechanism, no joints on the prefabricated bottom plate, reduced on-site support and formwork consumption, and improved construction speed and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

Multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system

The invention relates to a multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - prestressed eccentrically-braced system comprises assembled beams and slabs, assembled stand columns and prestressed sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns consist of box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the prestressed eccentric sway braces are arranged on the basis of the steel frame to form energy-dissipating beam sections, so as to improve the lateral rigidness and the energy dissipation capacity of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

Special-shaped steel column frame structure joint easy to restore after earthquake

The invention discloses a special-shaped steel column frame structure joint easy to restore after an earthquake. According to the special-shaped steel column frame structure joint easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that the prestress self-reset joint easy to restore after the earthquake is formed. By the adoption of a prestress self-reset joint form, self-reset of the joint after the earthquake is achieved, and restoring cost after the earthquake is greatly reduced; the shock resistance of the joint is improved, and thus the shock resistance of a frame structure system is improved; compared with a traditional steel-structural construction joint, the special-shaped steel column frame structure joint easy to restore after the earthquake has the advantages that the safety performance is high, environmental pollution is light, the number of safety accidents is small, and construction cost is low.

Owner:南通新丰威机械科技有限公司

Novel special-shaped steel column frame-steel plate shear wall easy to restore after earthquake

ActiveCN103669650AImprove securitySmall residual deformation after earthquakeWallsPre stressShock resistance

The invention discloses a novel special-shaped steel column frame-steel plate shear wall easy to restore after an earthquake. According to the novel special-shaped steel column frame-steel plate shear wall easy to restore after the earthquake, a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better shock resistance of the structure is achieved due to the steel plate shear wall.

Owner:南通新丰威机械科技有限公司

Multi-story high-rise assembled steel structure frame - eccentrically-braced system

ActiveCN102979166AEasy to pass throughIncrease net heightBuilding constructionsFloor slabLateral stiffness

The invention relates to a multi-story high-rise assembled steel structure frame - eccentrically-braced system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame - eccentrically-braced system comprises assembled beams and slabs, assembled stand columns and section steel sway braces. The assembled beams and slabs in the system consist of slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns comprise box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure, and the section steel sway braces are arranged on the basis of the steel frame to form energy-dissipating beam sections, so as to improve the lateral stiffness and the plastic energy dissipation capacity of the structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:CHINA RAILWAY CONSTR GROUP +1

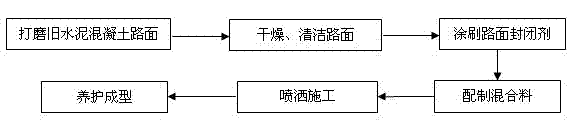

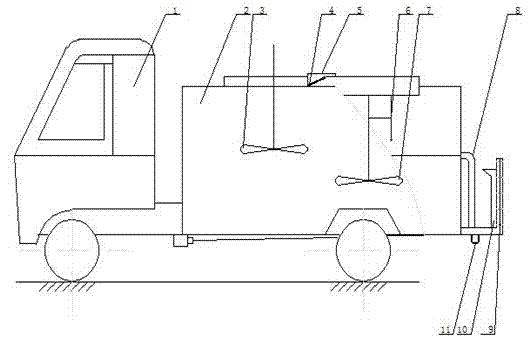

Method for micro-treatment of cement concrete road surface

The invention discloses a method for a micro-treatment of a cement concrete road surface, and belongs to the field of maintenance and repair of asphalt roads. The method comprises the following steps of a, polishing old cement concrete road surface, b, drying and cleaning the polished road surface, c, coating a road surface sealant, d, sprinkling a bonding material with aggregate by a bituminous distributor, and e, maintaining and molding Through the method, an old cement road surface can be repaired fast, and an anti-skidding capability and an appearance of a road can be improved.

Owner:CHONGQING SINCERE BOND PAVEMENT MATERIALS

Industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system

The invention discloses an industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system and belongs to the technical field of structure engineering. The industrialized assembling type special-shaped column steel structure-steel plate shear wall steel structure system comprises an assembling type truss plate, assembling type columns and a steel plate shear wall. The assembling type truss plate comprises a lattice truss beam provided with a web member and a floor plate. The assembling type truss plate is prefabricated in a plant and spliced with beam column joints of the assembling type columns through a beam end sealing plate of the assembling type truss plate at the construction site, and the assembling type columns are spliced to form a multiplayer truss plate steel framework structure among layers through bolts at site. On the basis of the steel framework structure, the steel plate shear wall is connected onto the truss beam in a framework structure beam plate layer or the column bottoms or the tops to serves as a lateral load resistance element. The assembling type truss plate, the assembling type special-shaped columns and the steel wall plate shear wall member are all fabricated in the plant and assembled at the construction site through bolts.

Owner:深圳市国富建筑有限公司

Special-shaped steel column-prestress central supporting frame easy to restore after earthquake

The invention discloses a special-shaped steel column-prestress central supporting frame easy to restore after an earthquake. The special-shaped steel column-prestress central supporting frame easy to restore after the earthquake is characterized in that a double-groove steel beam is connected with a special-shaped column through a beam-end sealing plate, so that a welding-line-free full-bolt connecting form is formed; a prestress steel cable is applied to a welding-line-free full-bolt joint, so that a prestress self-reset joint is formed; a self-reset column base and a prestress column base are used for optimizing the axial mechanical performance and the horizontal mechanical performance of the bottom of the column through a reinforcing plate, a bend-preventing steel plate is mainly used for dissipating energy of the earthquake, and a shear plate is used for preventing local deformation, caused by excessive shearing force, of the bottom of the column; the key component of the prestress column base is a prestress pull rod, the pull rod is used for providing precompression for the column so that the column can be tightly connected with the beam, as a result, approximate rigid connection can be achieved when the prestress column base bears small bending moment, and the self-reset capacity of the prestress column base after the earthquake is achieved; better lateral resistance of the structure is achieved through prestress central supporting.

Owner:南通新丰威机械科技有限公司

Industrialized assembling type special-shaped column steel structure prestress eccentric supporting system

ActiveCN103276806AIncrease lateral stiffnessGood deformabilityStrutsWallsSupporting systemBraced frame

The invention discloses an industrialized assembling type special-shaped column steel structure prestress eccentric supporting system and belongs to the technical field of structure engineering. The industrialized assembling type special-shaped column steel structure prestress eccentric supporting system comprises an assembling type truss plate, assembling type columns and a prestress eccentric supporting member. The assembling type truss plate comprises a lattice truss beam and a floor plate. The assembling type truss plate is prefabricated in a plant and spliced with beam column joints of the assembling type columns through a beam end sealing plate of the assembling type truss plate at the construction site, and the assembling type columns are spliced to form a multiplayer truss plate steel framework structure among layers through bolts at site. On the basis of the truss plate steel framework structure, the prestress eccentric supporting member serves as a lateral load resistance element to be connected with the bottoms or the tops of the truss beam in the assembling type truss plate and the assembling type columns. The assembling type truss plate, the assembling type columns and the prestress eccentric supporting member are all fabricated in the plant and assembled at the construction site through bolts.

Owner:RIZHAO WEIYE TOOL

Industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system

The invention provides an industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system, and relates to the technical field of structural engineering. The industrially assembled multiple high-rise steel special-shaped column frame-eccentric supporting system comprises assembled truss plates, assembled special-shaped columns and eccentric supporting components, wherein the assembled truss plates comprise structural truss beams and floor slabs, and the structural truss beams are provided with channel steel web members; the assembled truss plates are prefabricated in a factory, the assembled truss plates are mutually spliced with flange plates of the assembled special-shaped columns through beam-end blanking plates of the assembled truss plates at the construction site, and the assembled special-shaped columns are spliced on site through bolts in an interlayer to form a multi-layer truss plate steel frame structure; on the basis of the steel frame structure, the eccentric supporting components are connected to the truss beams in a beam plate layer of the frame structure or the bottoms of the columns to serve as lateral load resistance components; the assembled truss plates, the assembled special-shaped columns and the eccentric supporting components are all fabricated in the factory and assembled through the bolts on the construction site.

Owner:BEIJING UNIV OF TECH

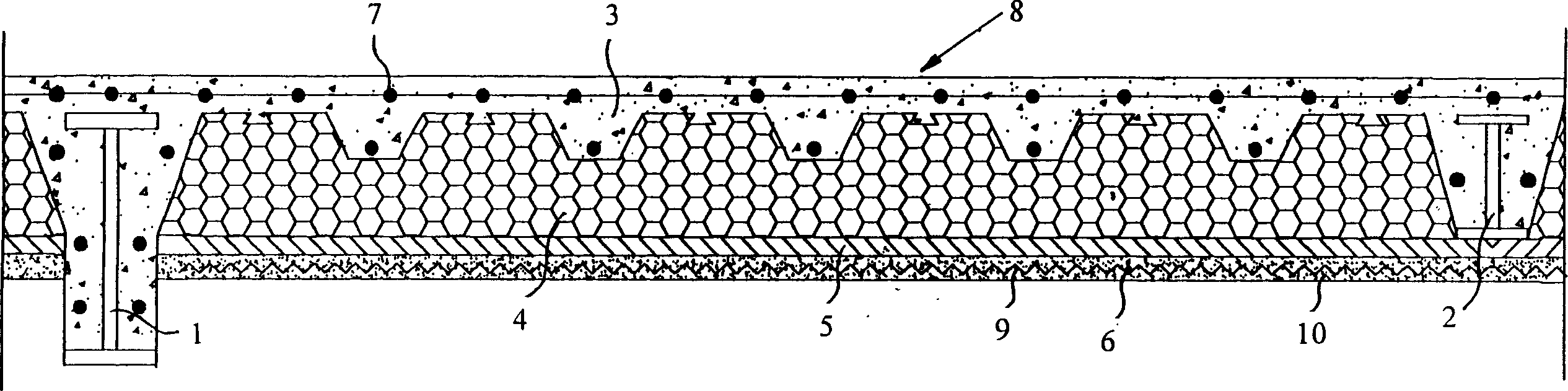

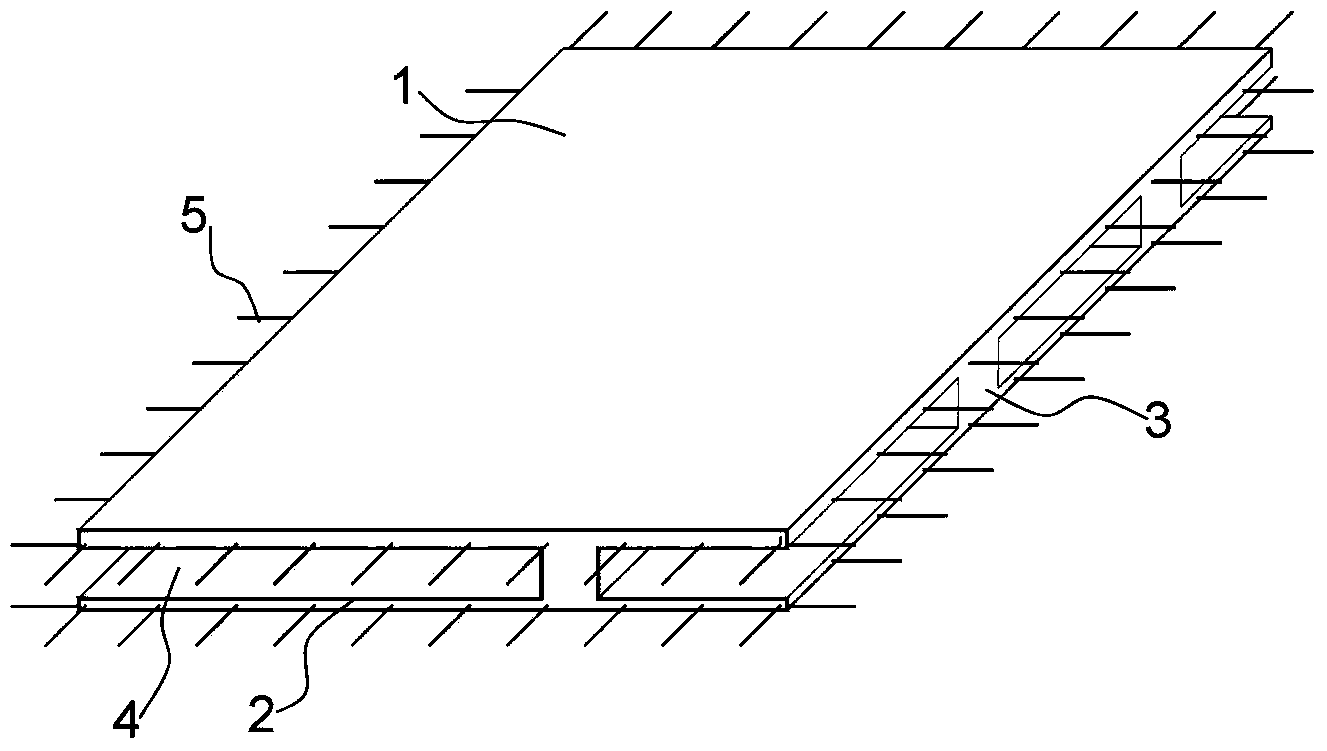

Assembled floor cover

A combined floor of building consists of several spaced bearing beams and composite plates. The composite plates include acoustic and thermal insulating parts with grooves on their top between the bearing beams, corrugated concrete cast in site and laid on them, fireproof and break resistant layers below the said acoustic and thermal insulating parts orderly. The floor can be cast with bearing beams uniformly in site reduce beam height so as to increase net height of room and acoustic and thermal insulating abilities, to enlarge effective space in use, to reduce sum of sub-beams and fireproof area of steel beams, with longer span length, no need of pressed steel plates and hanging roof so as to reduce cost with quality and high speed.

Owner:张英保

Multi-story high-rise assembled steel structure frame system

The invention relates to a multi-story high-rise assembled steel structure frame system, belonging to the technical field of structure engineering. The multi-story high-rise assembled steel structure frame system comprises assembled beams and slabs, and assembled stand columns. The assembled beams and slabs in the system comprise slabs, column base joints and open-web steel beams with section steel web members. The open-web steel beams are connected with the column base joints. The slabs are supported on the open-web steel beams. The assembled stand columns comprise box columns and flanges. During construction, the assembled beams and slabs and the assembled stand columns can be spliced to form a frame structure. All members of the structure system are prefabricated in factories and are rapidly assembled through bolts on the construction site to form the structure system. Concrete pouring and welding operation are avoided, the defects of long construction period, serious material wastage, great pollution during construction and the like existing the traditional buildings are overcome, and the factory integrated production of buildings can be realized.

Owner:GUANGDONG UNION STEEL MFG

Synthesized pipe rack with frame composite structure

ActiveCN105821903AAvoid lateral instabilityHigh strengthArtificial islandsUnderwater structuresWeb structureEngineering

The invention discloses a synthesized pipe rack with a frame composite structure. The synthesized pipe rack comprises unit plate pieces positioned on the upper and lower surfaces, and side unit plate pieces positioned on two side surfaces; the unit plate pieces and the side unit plate pieces are combined and spliced to form unit pipe sections; the unit pipe sections are axially spliced to form the synthesized pipe rack; the unit plate pieces consist of plates, hollow second pipes positioned at two ends, and hollow first pipes positioned at the other two ends; the side unit plate pieces consist of plates, and hollow second pipes positioned at two ends; the second pipes are axial splicing ends of the unit pipe sections; and in splicing of the synthesized pipe rack, the first pipes form longitudinal beams of the synthesized pipe rack, and the adjacent second pipes are connected with each other to form a skeleton structure of the synthesized pipe rack. The longitudinal beams and the skeleton structure of the pipe rack bear main loads; a bridge steel web structure is formed to enhance the shearing resistance of the pipe rack, and is skillfully used; based on dual enhanced structures, the bearing capacity is greatly improved; and under the same filling height, wall plates with the structures are thinner, and materials are saved.

Owner:NANJING LIANZHONG CONSTR ENG TECH

Assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system

The invention discloses an assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system, and relates to the technical field of structural engineering. The assembly-type multi-storey steel special-shaped column framework-steel plate shear wall structure system comprises an assembly-type truss plate, assembly-type special-shaped columns and a steel plate shear wall component. The assembly-type truss plate comprises a lattice truss girder provided with a steel channel web member, and a floor slab. The assembly-type truss plate is prefabricated in a plant. On a construction site, the assembly-type truss plate is spliced with a flange plate of the assembly-type special-shaped columns through a beam-end blanking plate of the assembly-type truss plate. The assembly-type special-shaped columns are spliced on site through bolts between storeys to form a multi-storey truss plate steel framework structure. One the basis of the steel framework structure, a steel plate shear wall is connected to the truss girder in a beam and slab layer of the steel framework structure or the bottom or the top of each column and used as a lateral load resistance component. The assembly-type truss plate, the assembly-type special-shaped columns and the steel plate shear wall component are all prefabricated in the plant and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

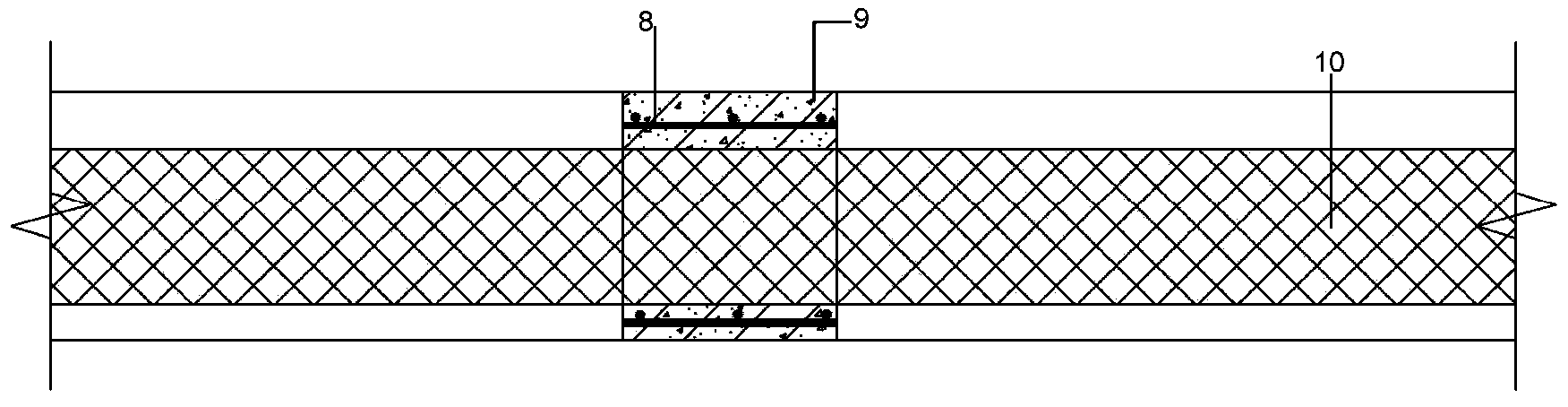

Opening structure of reinforced concrete beam

The invention discloses an opening structure of a reinforced concrete beam. The opening structure is characterized in that a position of an opening formed in the abdomen of the cast-in-place reinforced concrete beam is reserved, and reinforcing steel bars, confined stirrups and steel tie bars are configured at the opening; the reinforcing steel bars comprise opening upper-part reinforcing steel bars and opening lower-part reinforcing steel bars which are configured at the upper part and the lower part of the opening respectively; the opening upper-part reinforcing steel bars and beam upper-part reinforcing steel bars are wound with the confined stirrups, and the opening lower-part reinforcing steel bars and beam lower-part reinforcing steel bars are wound with the confined stirrups; and the steel tie bars are also configured nearby the opening of the beam, pulled from the lower part of a side wall of one side of the beam to the upper part of a side wall of the other side of the beam and extend into a beam plate. The reinforcing steel bars, the confined stirrups and the steel tie bars are configured nearby the opening of the beam, and by means of characteristics and performance of region constraints, the intensity and ductility reduction which is caused by opening of the beam abdomen is effectively reduced, the anti-bending and shear-resisting capacity of the reinforced concrete beam is guaranteed, the phenomenon of stress concentration of the periphery of the opening is relieved, and the reliability of the structure is improved.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

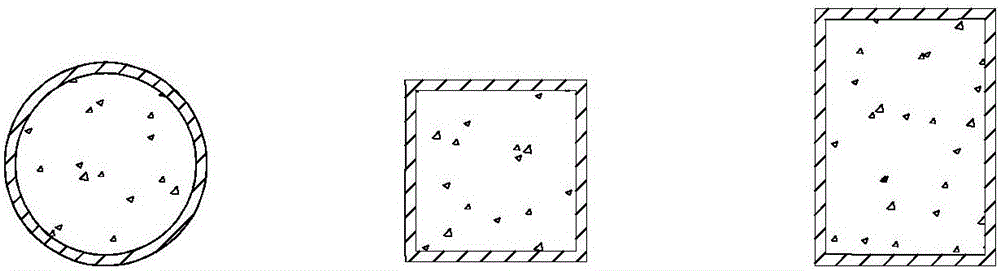

Hollow irregular column multi-layer high-rise assembling steel frame-central support system

A hollow irregular column multi-layer high-rise assembling steel frame-central support system relates to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-central support system comprises assembling truss plates, assembling flange columns and central support members. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, the central support members are connected with the bottoms and tops of the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and the central support members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

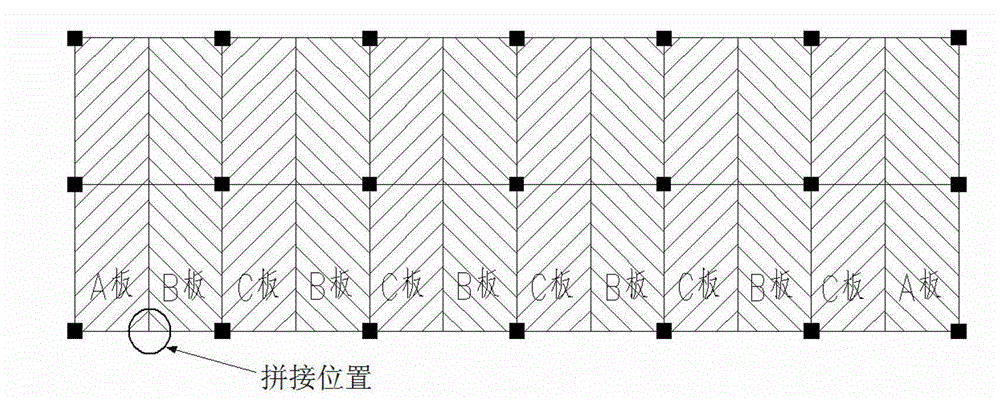

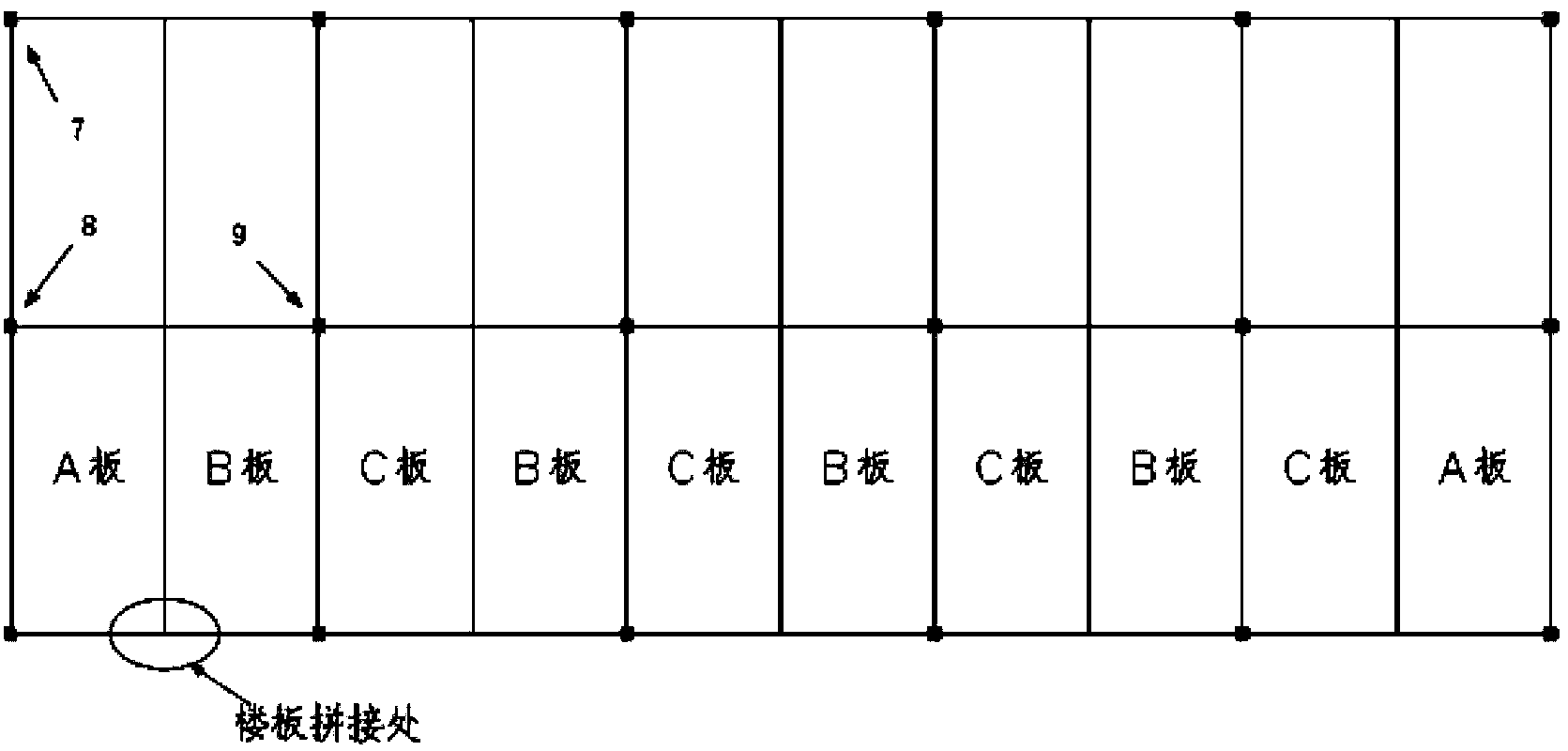

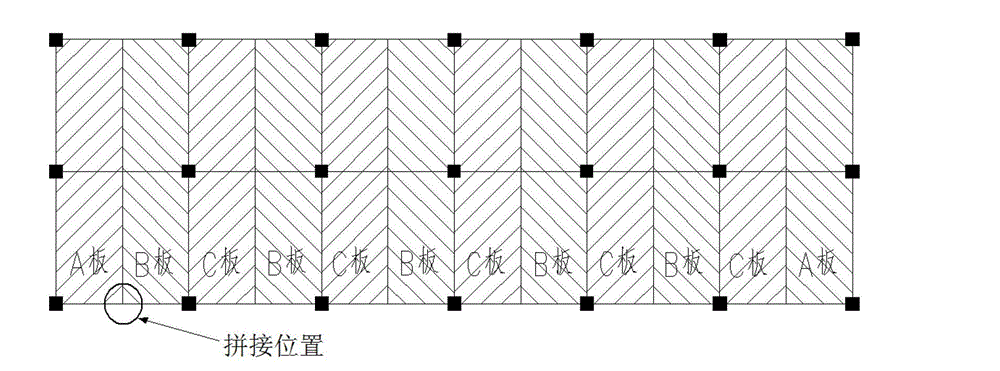

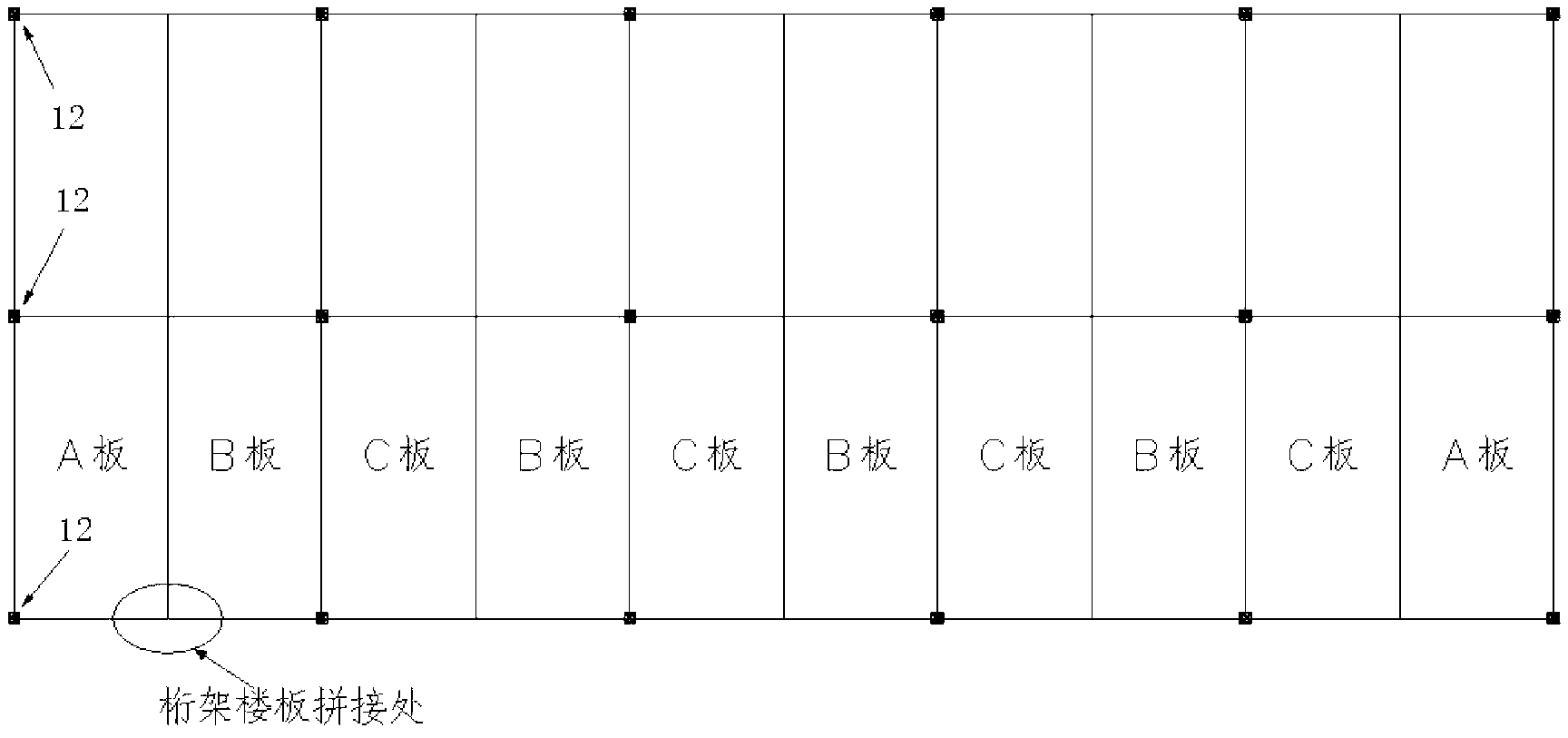

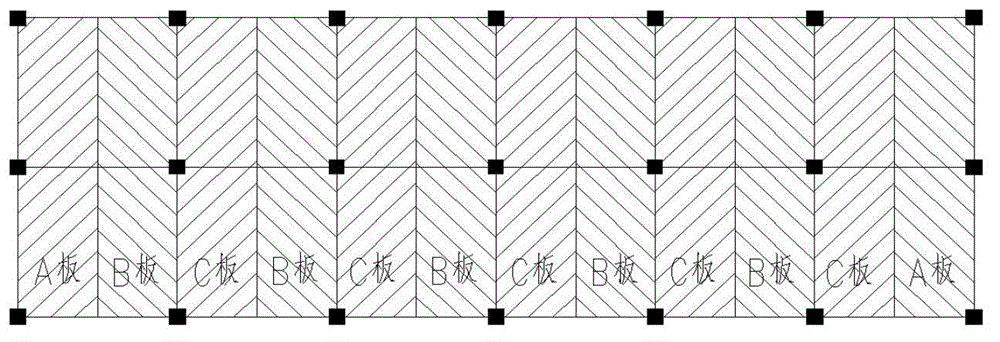

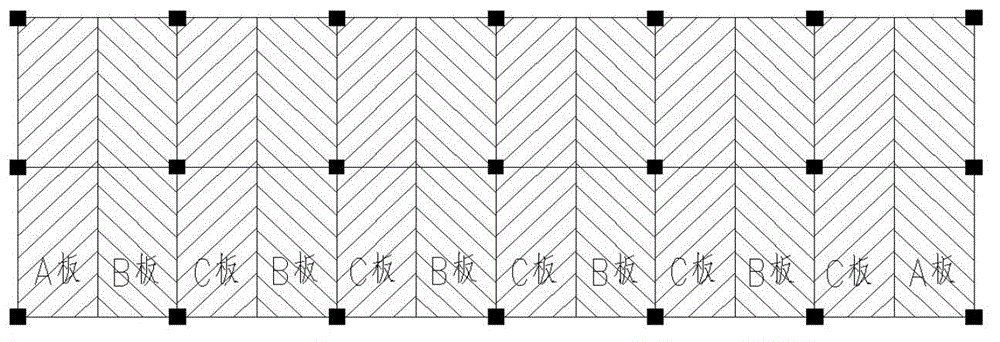

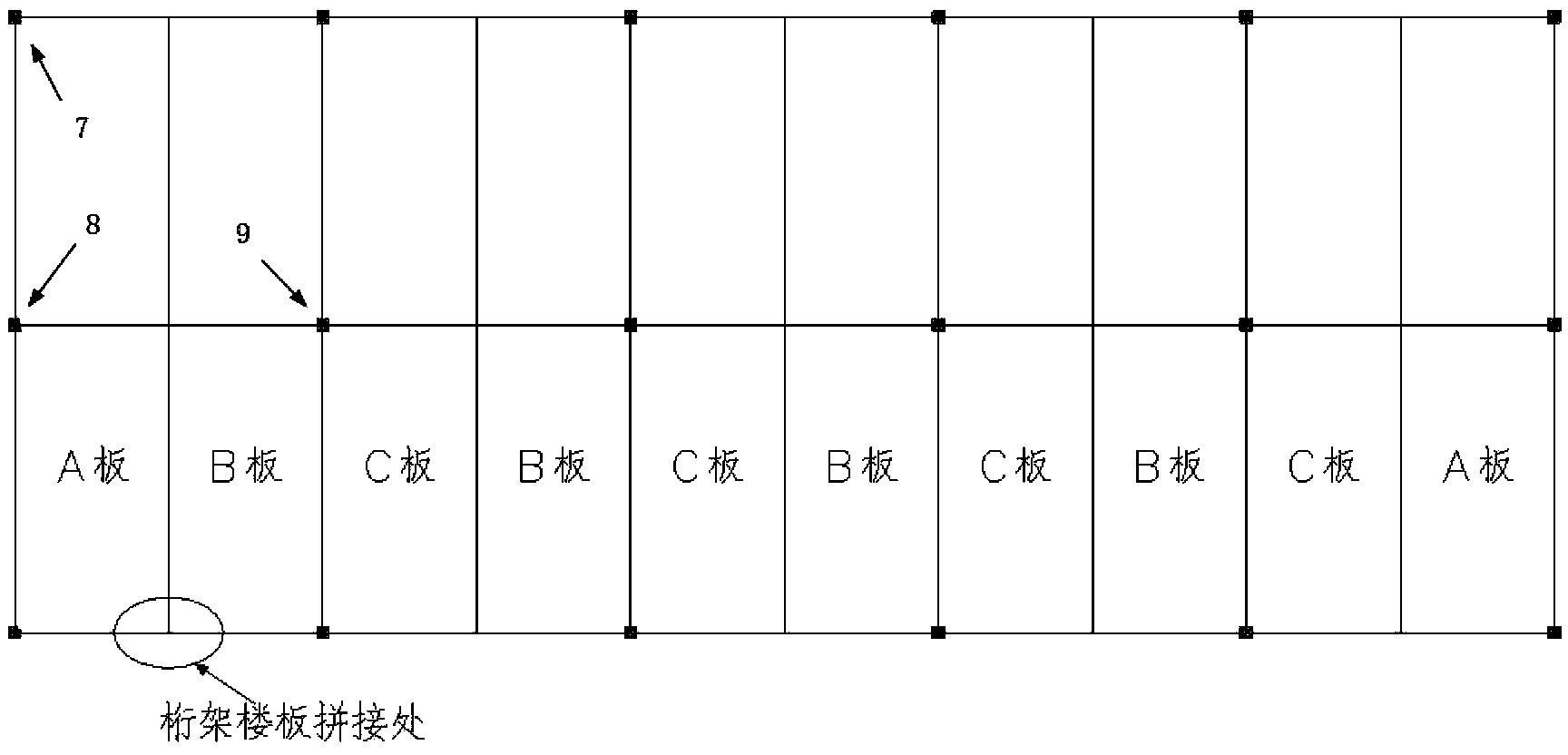

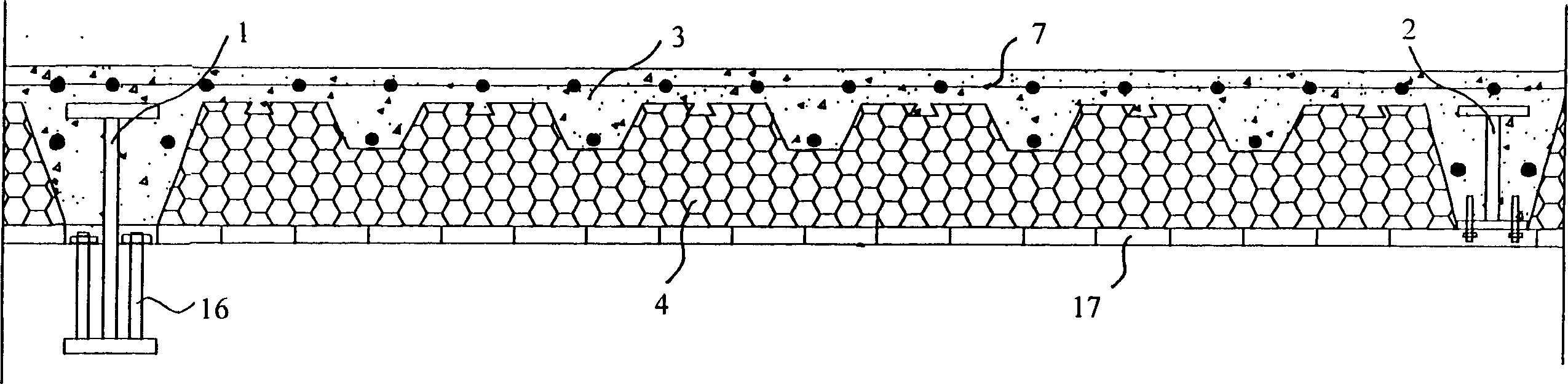

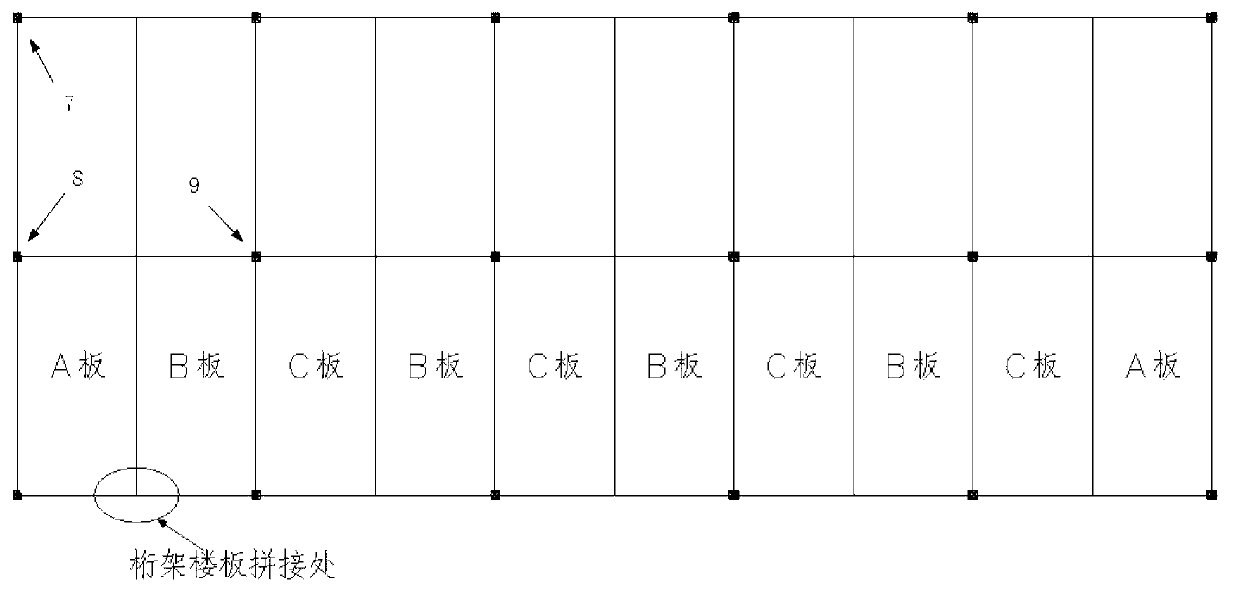

Novel large-span assembly type hollow groined floor system

The invention discloses a novel large-span assembly type hollow groined floor system which is composed of a plurality of blocks of prefabricated floors capable of being spliced and concrete post-cast strips located between adjacent prefabricated floors. Each prefabricated floor comprises a top plate, a base plate, longitudinal ribbed beams and transverse ribbed beams, wherein the longitudinal ribbed beams and the transverse ribbed beams are arranged between the top plate and the base plate. The top plates and the base plates are parallel surface plates. The novel large-span assembly type hollow groined floor system effectively solves the problem of the traditional assembly type integrated floors of small span, poor rigidity and large concrete consumption. The concrete consumption at the connection positions of all the prefabricated floors is small, template consumption is small, and the prefabricated floors are few in shapes, convenient to construct, economical and practical. The integral floor system formed by assembling all the prefabricated floors is of a hollow groined structure and has the advantages of bidirectional force transfer, large rigidity, good shock resistance and small self weight and thickness. Light thermal insulation materials are filled in the hollow positions of the floor system so that the heat retaining property of the floor system is improved. Pipes can be arranged in the floor system in a penetrating mode without additional equipment layers, and therefore space is saved and storey clear height is increased.

Owner:SOUTHEAST UNIV

Hollow irregular column multi-layer high-rise assembling steel structure system

ActiveCN103276803AEasy to pass throughIncrease net heightBuilding constructionsFloor slabSteel frame

A hollow irregular column multi-layer high-rise assembling steel structure system relates to the technical field of engineering and comprises assembling truss plates and assembling flange columns. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. The assembling truss plates and the assembling flange columns are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:镇江电力设计院有限公司

Hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system

The invention relates to a hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system and belongs to the technical field of structural engineering. The hollow irregular column multi-layer high-rise assembling steel frame-steel plate shear wall system comprises assembling truss plates, assembling flange columns and steel plate shear walls. Each assembling truss plate comprises a lattice truss beam with an angle steel web member, a column base node and a floor slab. The assembling truss plates are prefabricated in a factory and spliced with one another through beam end sealing plates or the column base nodes on a construction site to form frame structure beam plate layers. The frame structure beam plate layers are connected vertically through the assembling flange columns to form a multi-layer steel frame structure, and the assembling flange columns are arranged on the column base nodes of the assembling truss plates. On the basis of the steel frame structure, steel plate shear wall members are connected with the truss beams or the columns in the frame structure beam plate layers to be used as lateral load resistance members. The assembling truss plates, the assembling flange columns and steel plate shear wall members are all prefabricated in the factory and assembled through bolts on the construction site.

Owner:BEIJING UNIV OF TECH

Steel plate and concrete composite beam and slab structure system

PendingCN105822000AImprove mechanical performanceNode connection is simpleFloorsEarthquake resistanceArchitectural engineering

The invention discloses a steel plate and concrete composite beam and slab structure system. The system comprises concrete brackets, a steel plate and concrete precast beam, steel plate and concrete precast plates, and a beam and slab concrete composite layer. The steel plate and concrete precast beam and the precast plates are precast in a factory; a concrete of the composite layer is poured after the precast beam and the precast plates are lift on site. The steel plate and concrete precast beam comprises a beam bottom, and steel plates at two sides, T-shaped steel at the bottom of the beam, angle steel and lifting lugs at the side of the beam, longitudinal steel bars on the top of the beam, and tie bars in the middle of the beam. Each steel plate and concrete precast plate comprises a steel plate at the bottom of the plate, T-shaped steel, unidirectional steel bars on the bottom of the plate, bidirectional steel bars at the top of the plate and diagonal steel bars in the plate. When the beam and slab structure system is under construction, the steel plate and concrete precast beam is fixedly mounted on bracket supports firstly, then the steel plate and the concrete precast plates are mounted on the lifting lugs of the precast beam, and finally, the concrete composite layer is poured on the precast beam and the precast plates. The steel plate and concrete composition beam and slab structure system has favorable integrity, and has the anti-seismic property which is coincident with that of a cast-in on-site structure; a composite part is low in sectional height and is capable of increasing a net height of a storey.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com