Patents

Literature

33results about How to "Avoid lateral instability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

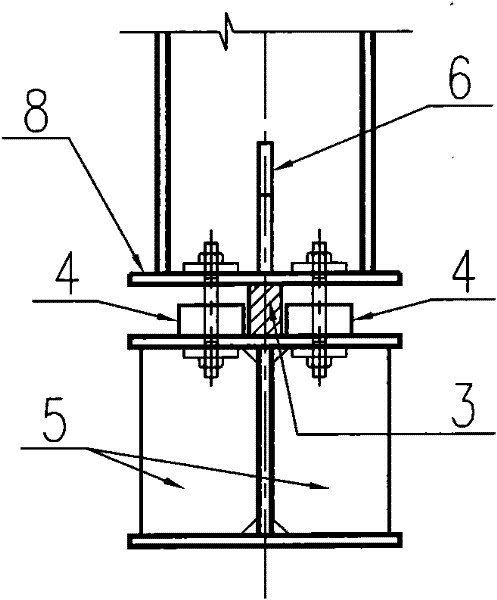

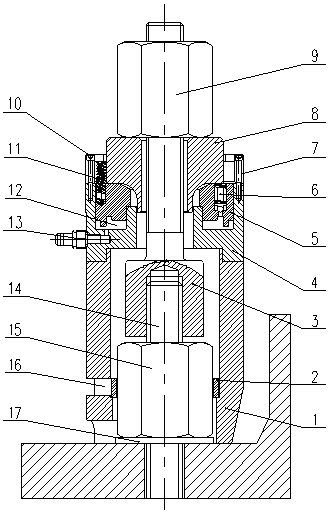

Method for performing expansion test of combined loads on solid expansion pipe

InactiveCN102023118AAvoid lateral instabilityMeasure displacement in real timeMaterial strength using tensile/compressive forcesMechanical stretchingEngineering

The invention relates to a method for performing an expansion test of combined loads on a solid expansion pipe, which comprises the following steps of: 1) preparing a sample and an expansion cone; 2) expanding an end part; 3) preparing an expansion test; 4) performing the expansion test, wherein the expansion test can be any one of the following tests: a, a mechanical stretching expansion test; b, a hydraulic expansion test; and c, a mechanical hydraulic combined expansion test; and 5) performing data acquisition and data analysis. In the method, the mechanical stretching expansion test or the hydraulic expansion test or the combined expansion test of mechanical stretching and hydraulic pressure is realized, and the displacement, speed, stretching loads and hydraulic pressure of the expansion cone and the radial deformation data of the solid expansion pipe in the process of the expansion test can be measured in real time by using axial controlled mechanical stretching loads and the hydraulic pressure and matching the corresponding expansion conical head. The invention provides a method for the expansion test for simulating actual working conditions in laboratories effectively for the detection of expansion performance and study evaluation of the solid expansion pipe and the study and improvement of a connecting structure of the expansion pipe.

Owner:XIAN SANHUAN TECH DEV GENERAL

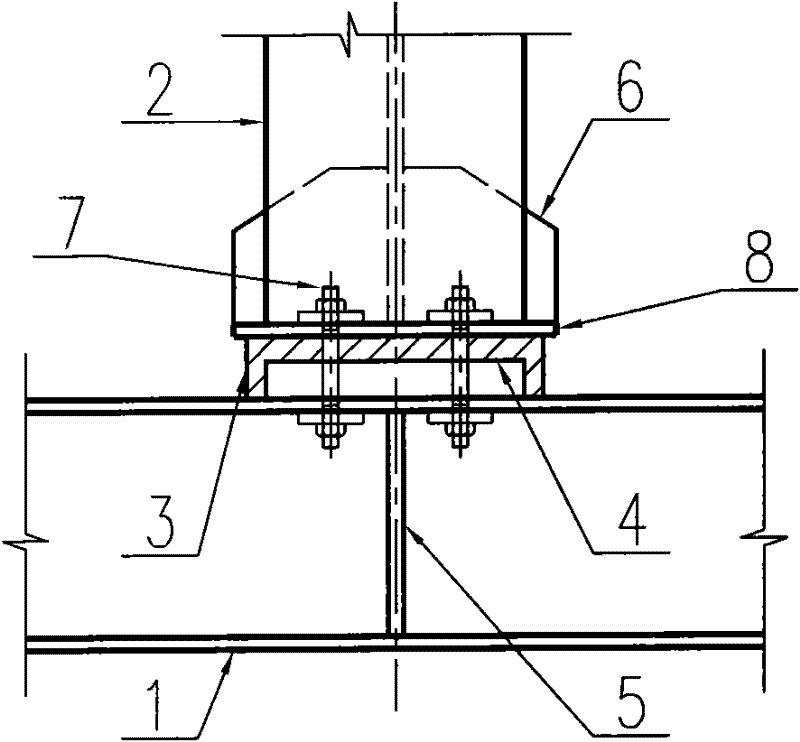

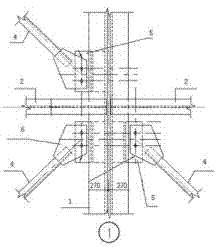

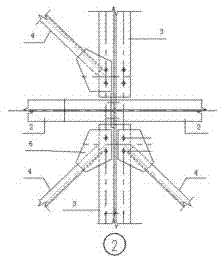

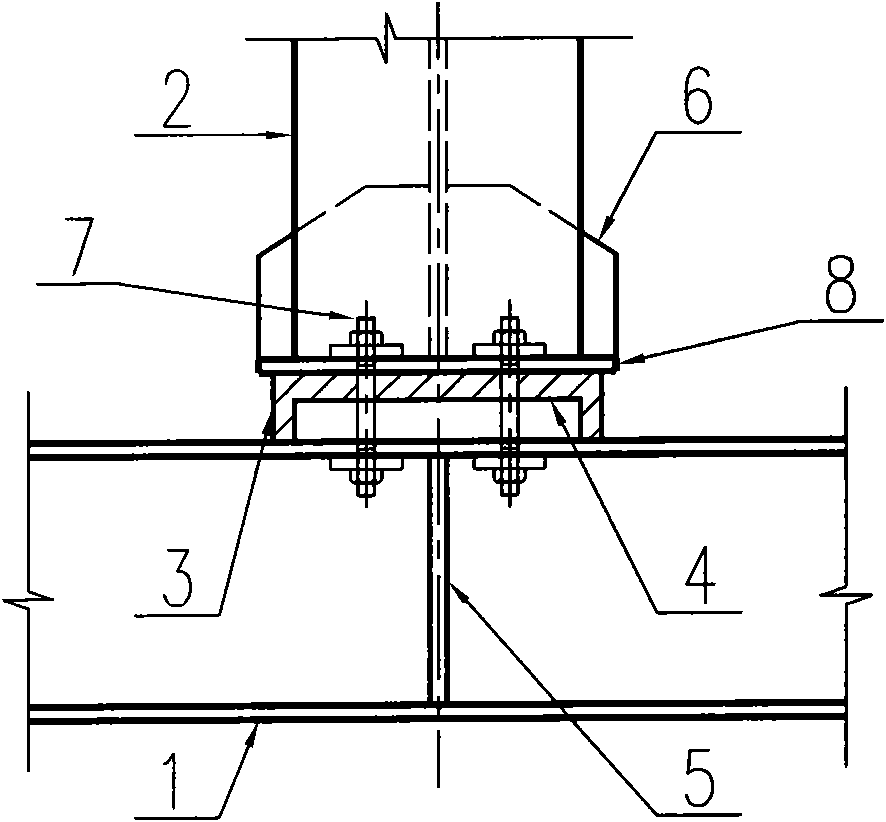

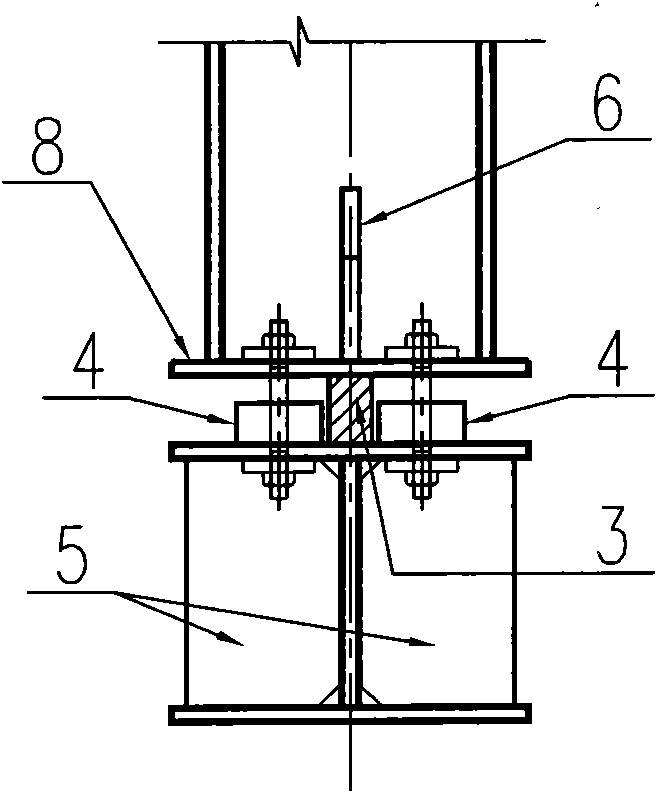

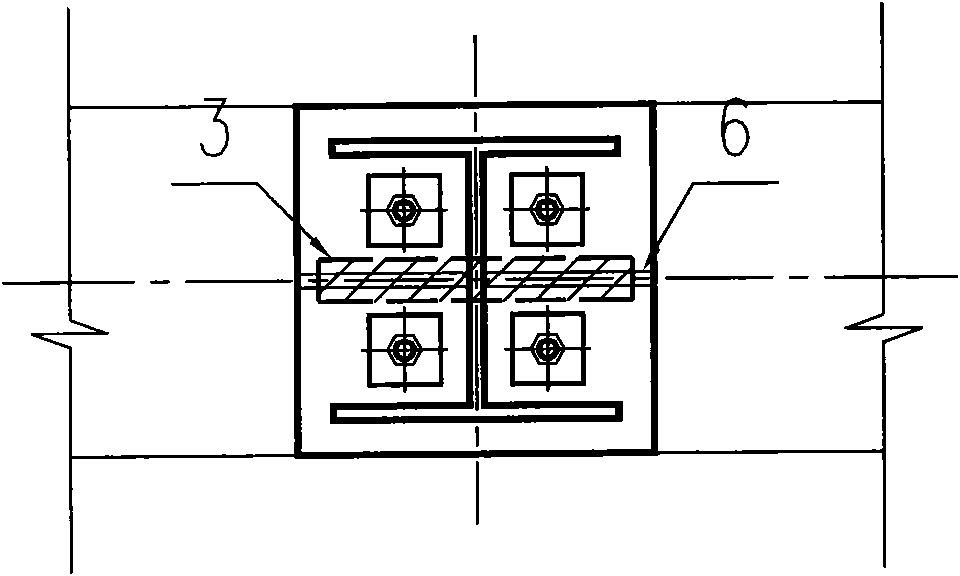

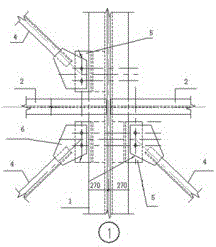

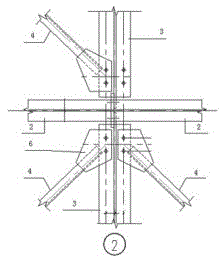

Hinge connection structure and method for supporting steel columns on steel beams

InactiveCN102220786ASimple structureImprove stabilityBuilding constructionsSteel columnsMaterials science

The invention relates to a connection structure, in particular to a hinge connection structure and method for supporting steel columns on steel beams. The structure comprises the steel beams, the steel columns arranged above the steel beams and a connection plate arranged between the steel beams and the steel columns. The structure and the method have the following advantages and effects: the counter force at the bottoms of the steel columns is transferred to the direction of the strong axes of the steel beams by arranging the thickening connection plate with the same direction as a web of the strong axes of the steel beams and additionally arranging steel base plates avoiding lateral unstability of the connection plate; the node construction is simple and practical; the force is reliably transferred; the steel beams are reasonably stressed; the stability of the nodes are enhanced; waste of the beam sections is avoided; the investment is reduced; convenience is provided for construction; and the requirements of connection are well met.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

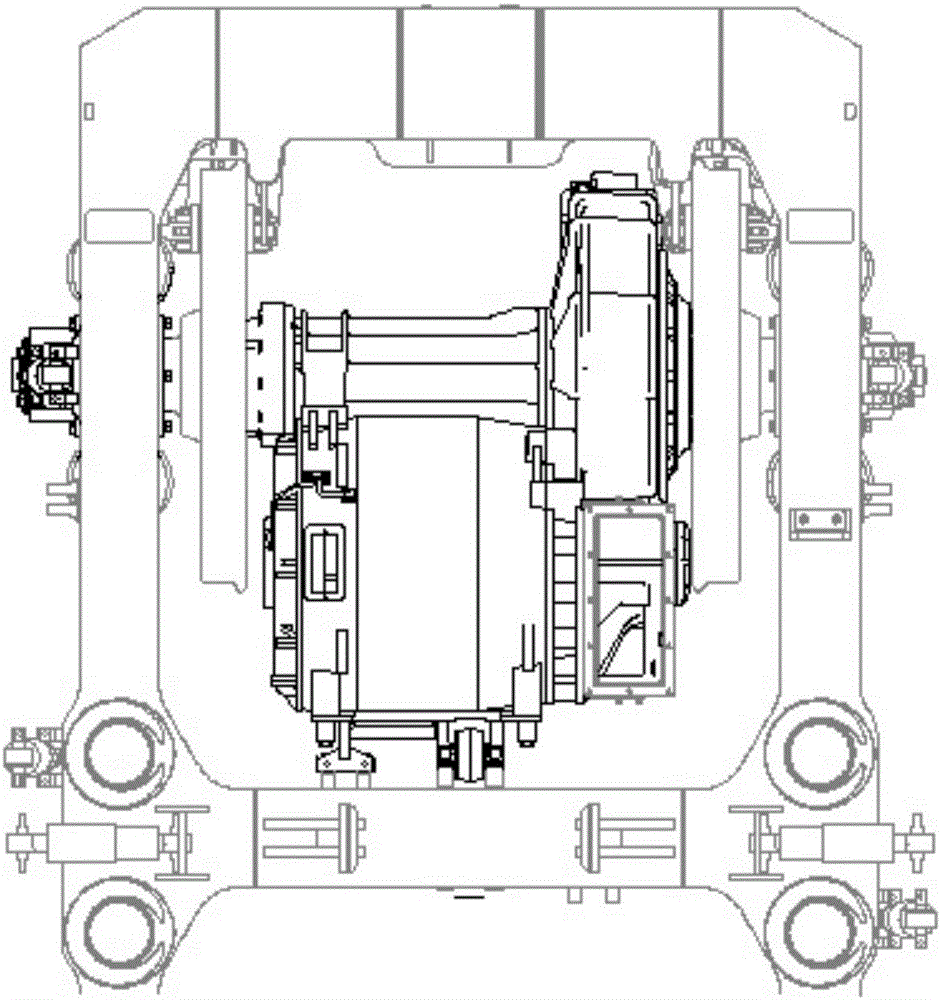

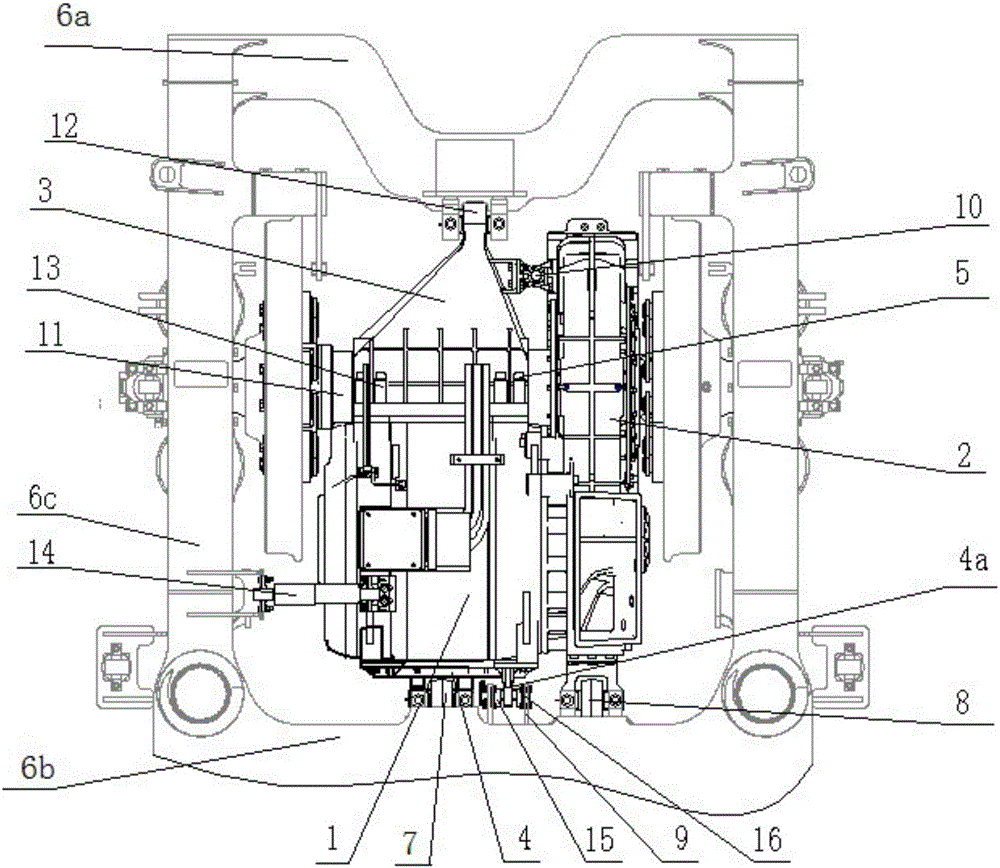

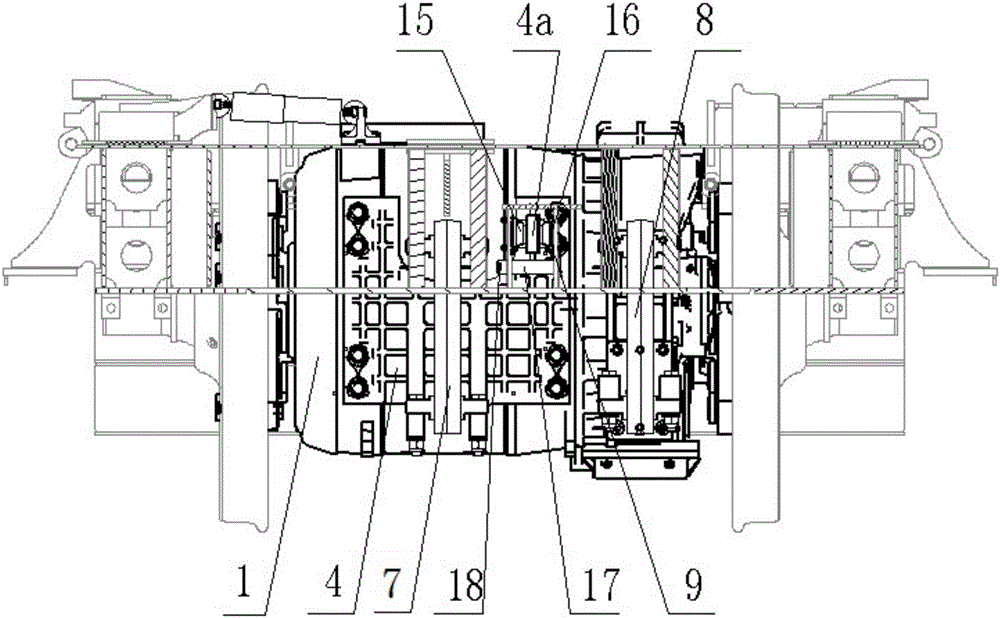

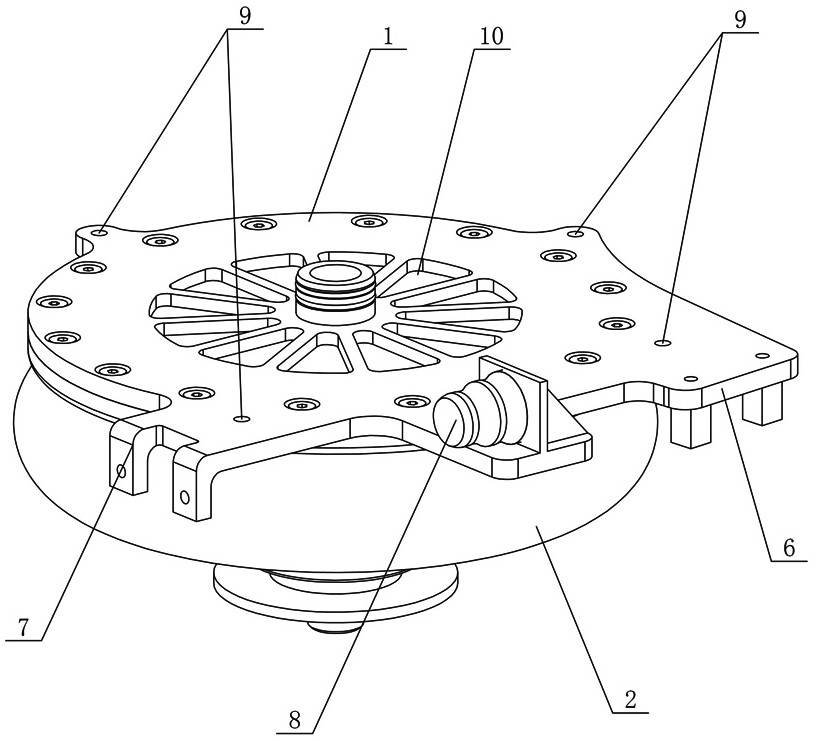

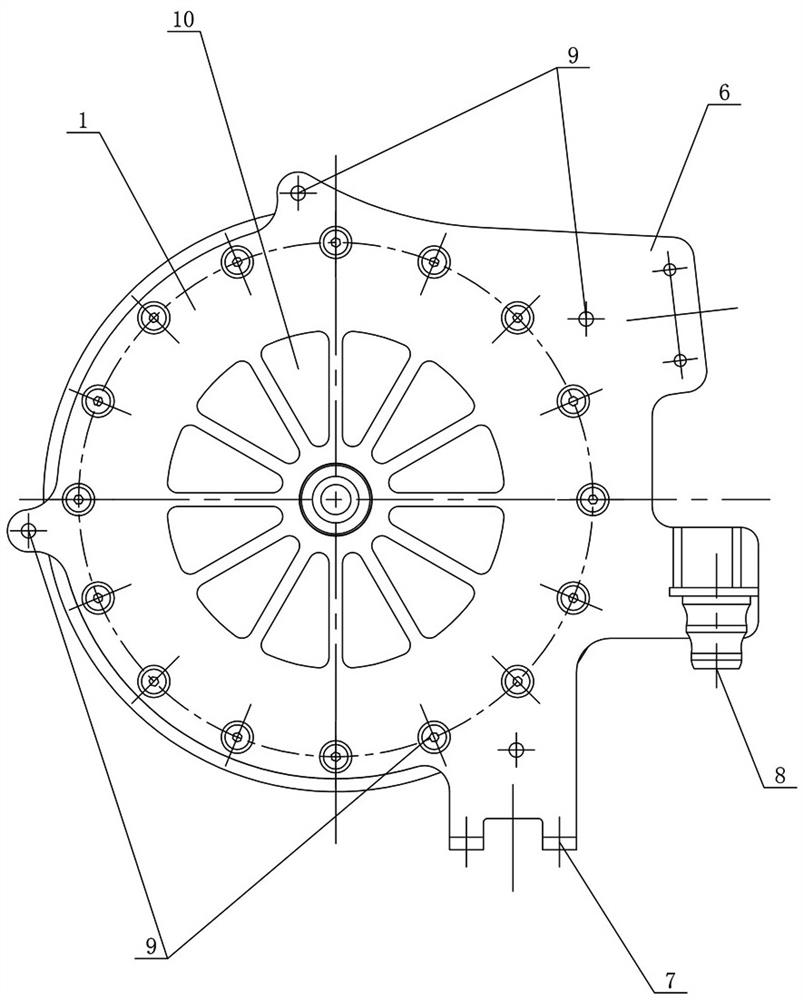

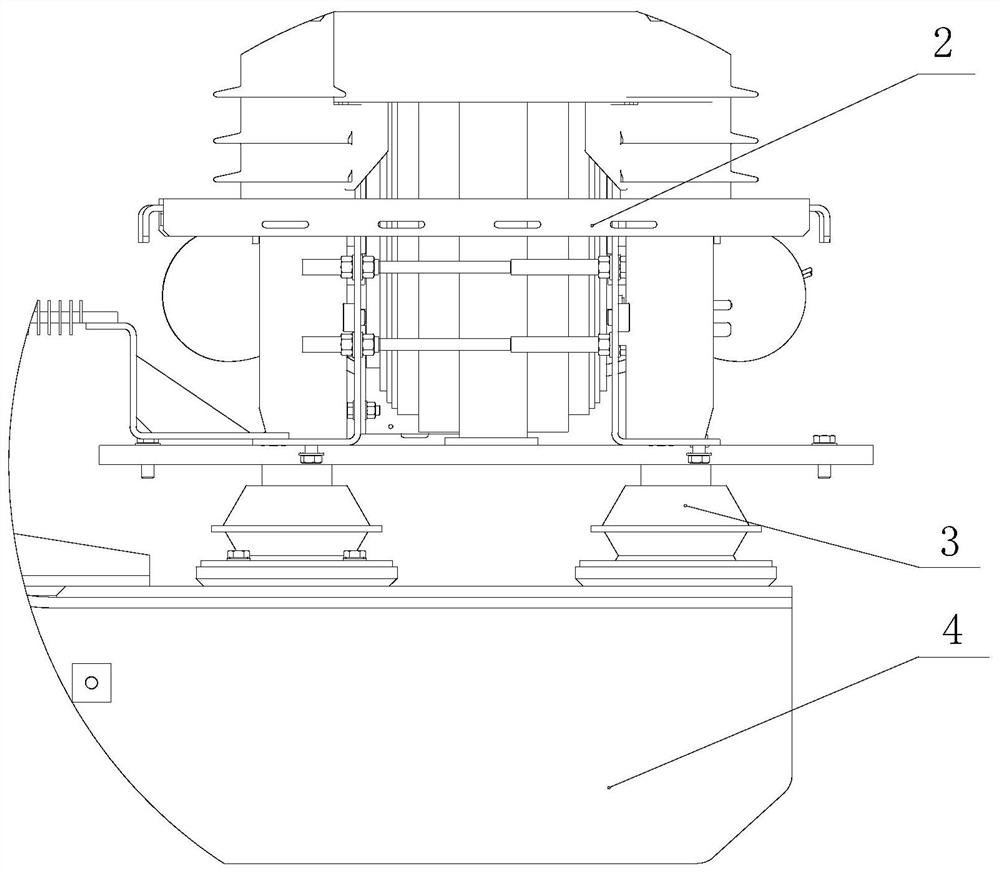

High-speed locomotive motor suspension device

InactiveCN106274919AImprove dynamic performanceReduce wheel-rail action forceElectric locomotivesElectric motor propulsion transmissionCarrying capacityBack support

Provided is a high-speed locomotive motor suspension device. A motor 1 is in rigid connection with a gear case 2 and is connected with a front supporting base 3 through a bolt casing pipe 13 and an inside hexagonal bolt 5, hung on a framework front end beam 6a through the front supporting base 3 and connected with a motor hanging rod 7 through a back supporting base 4 to be hung on a framework cross beam 6b, the gear case 2 is hung on the framework cross beam 6b through a gear case hanging rod 8, a baffle 4a of the back supporting base 4 is clamped between transverse stopping bases 9 arranged on the framework cross beam 6b, and a certain clearance is kept. According to the high-speed locomotive motor suspension device, an elastic frame suspension mode is adopted in motor suspension, and therefore it is guaranteed that a locomotive has the good dynamics performance and the low wheeltrack dynamic acting force; by combining the transverse stopping function, low transverse vibration and the good transverse dynamics performance are guaranteed. The high-speed locomotive motor suspension device is simple in structure and reasonable in design and has the high carrying capacity and safety coefficient.

Owner:CRRC DALIAN CO LTD

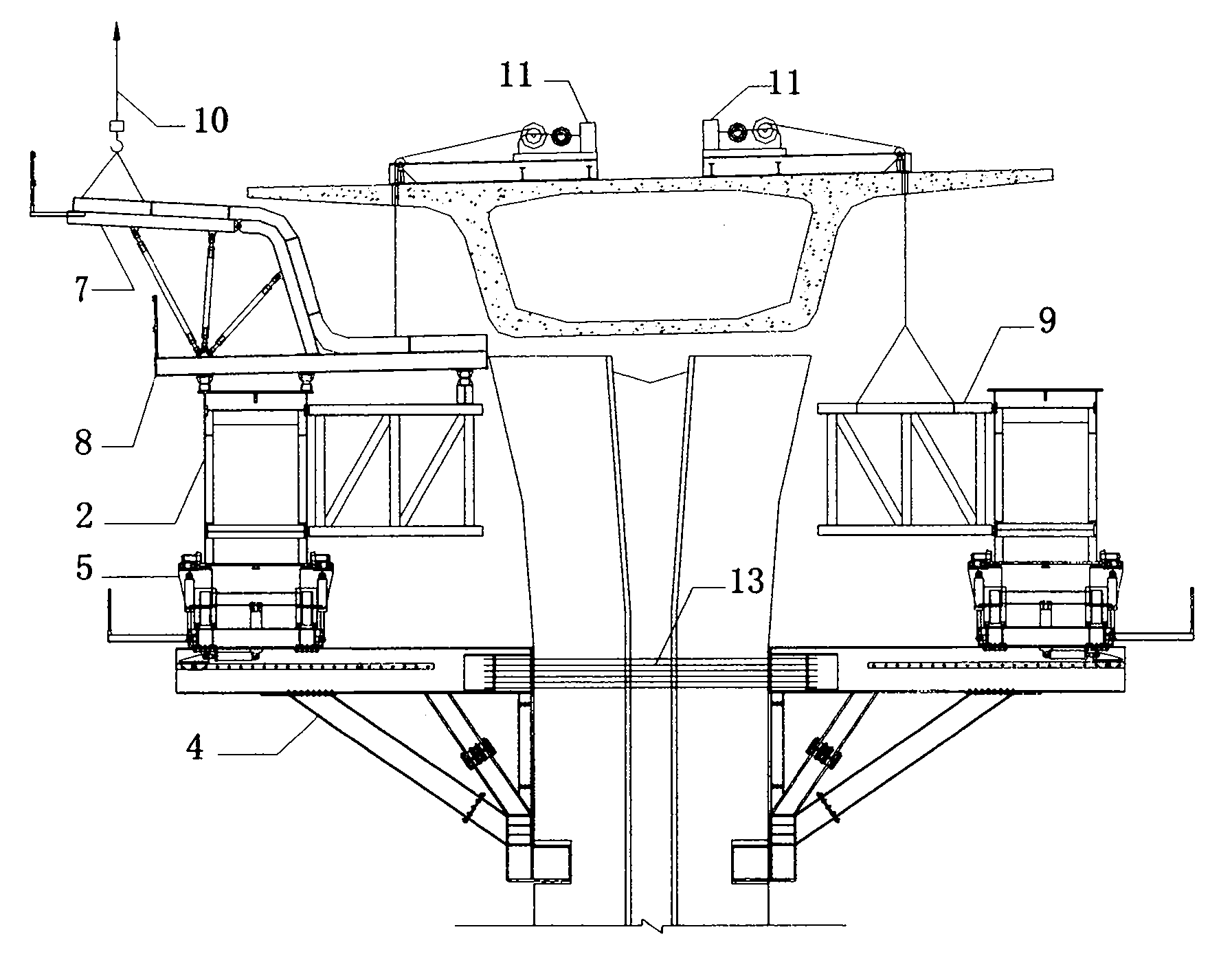

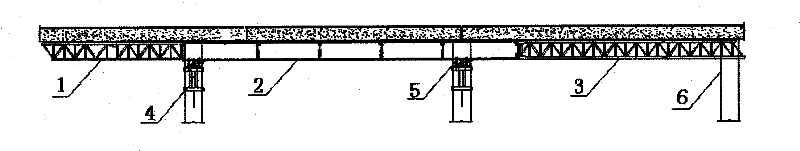

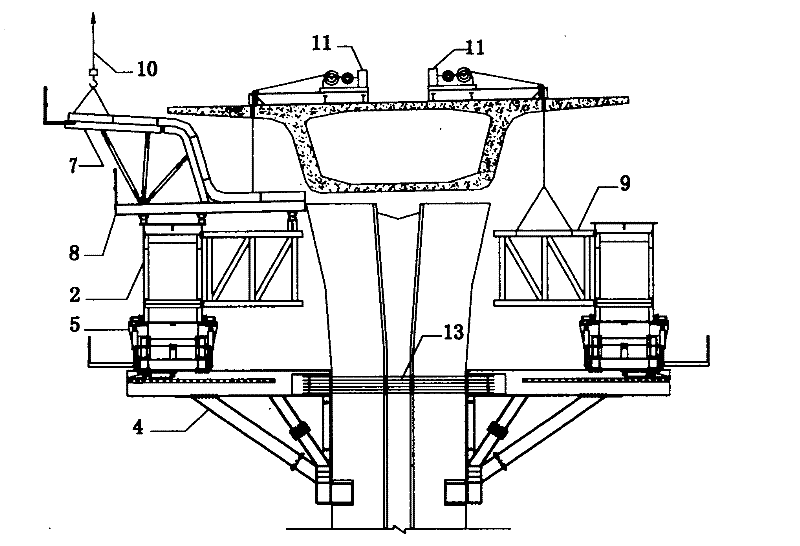

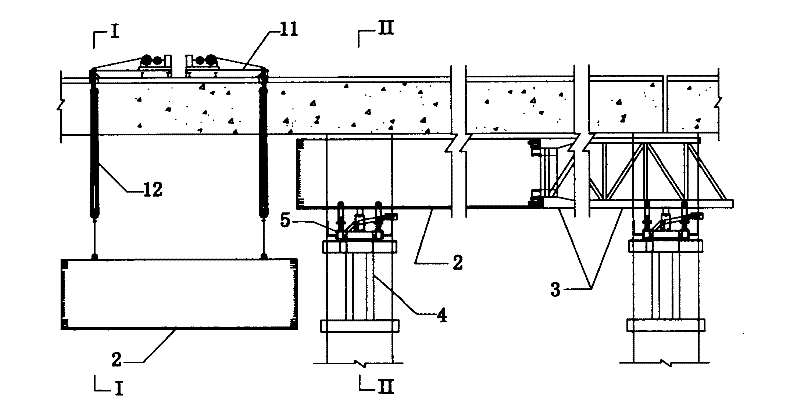

Construction process for overhead back-up movement and dismantlement of movable shuttering form

InactiveCN101818479AAvoid lateral instabilityShorter dismantling timeBridge erection/assemblyForm treatmentStructural engineeringTruck

The invention belongs to the field of bridge construction processes, is applied in the construction of a movable shuttering form for a cast-in-place box girder, and particularly relates to a construction process for the overhead back-up movement and dismantlement of a movable shuttering form after a cast-in-place box girder is completely constructed by the movable shuttering form. The process is characterized in that: a back guide girder, a main beam, a front guide girder, a bracket, a cart, an external mould plate, a mould plate beam, a middle beam and bracket tensioning fining twisted steel on both sides of the bride need to be removed; the cart transversely moves on the bracket to open the movable shuttering form, a winder is arranged on a concrete box girder, the external mould plate is removed by the winder and by the drawing and hoisting operation of a truck crane, the mould plate beam and the middle beam are removed from the top to the bottom in sequence, only the back guide girder, the main beam and the front guide girder remain, the main beam of the movable shuttering form is removed, and finally the last section of main beam and the front guide girder are moved. The process has the advantages of speeding up the construction, reducing construction equipment, guaranteeing the construction safety and lowering construction cost.

Owner:CCCC SHEC SECOND ENG

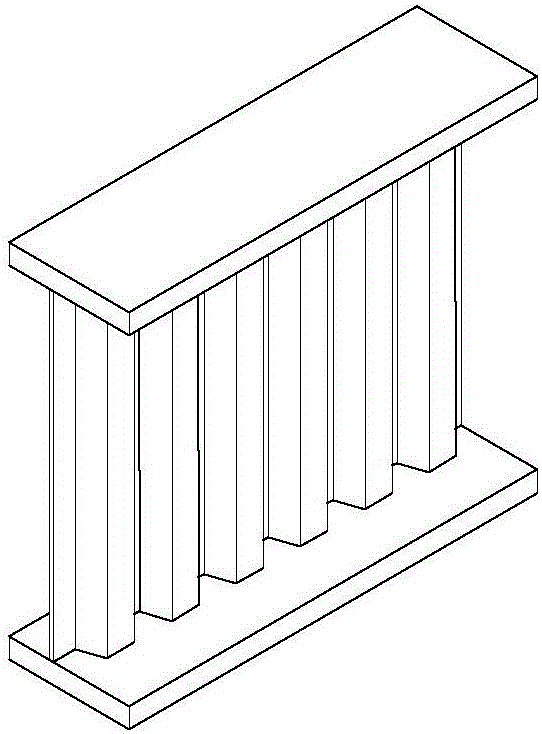

Synthesized pipe rack with frame composite structure

ActiveCN105821903AAvoid lateral instabilityHigh strengthArtificial islandsUnderwater structuresWeb structureEngineering

The invention discloses a synthesized pipe rack with a frame composite structure. The synthesized pipe rack comprises unit plate pieces positioned on the upper and lower surfaces, and side unit plate pieces positioned on two side surfaces; the unit plate pieces and the side unit plate pieces are combined and spliced to form unit pipe sections; the unit pipe sections are axially spliced to form the synthesized pipe rack; the unit plate pieces consist of plates, hollow second pipes positioned at two ends, and hollow first pipes positioned at the other two ends; the side unit plate pieces consist of plates, and hollow second pipes positioned at two ends; the second pipes are axial splicing ends of the unit pipe sections; and in splicing of the synthesized pipe rack, the first pipes form longitudinal beams of the synthesized pipe rack, and the adjacent second pipes are connected with each other to form a skeleton structure of the synthesized pipe rack. The longitudinal beams and the skeleton structure of the pipe rack bear main loads; a bridge steel web structure is formed to enhance the shearing resistance of the pipe rack, and is skillfully used; based on dual enhanced structures, the bearing capacity is greatly improved; and under the same filling height, wall plates with the structures are thinner, and materials are saved.

Owner:NANJING LIANZHONG CONSTR ENG TECH

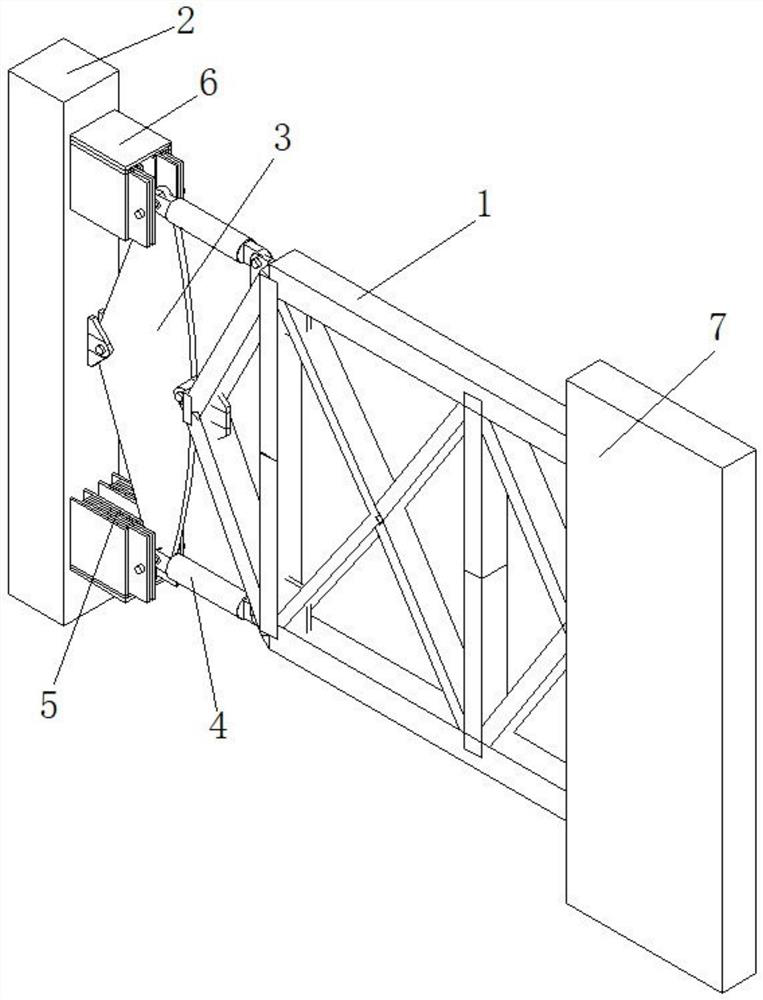

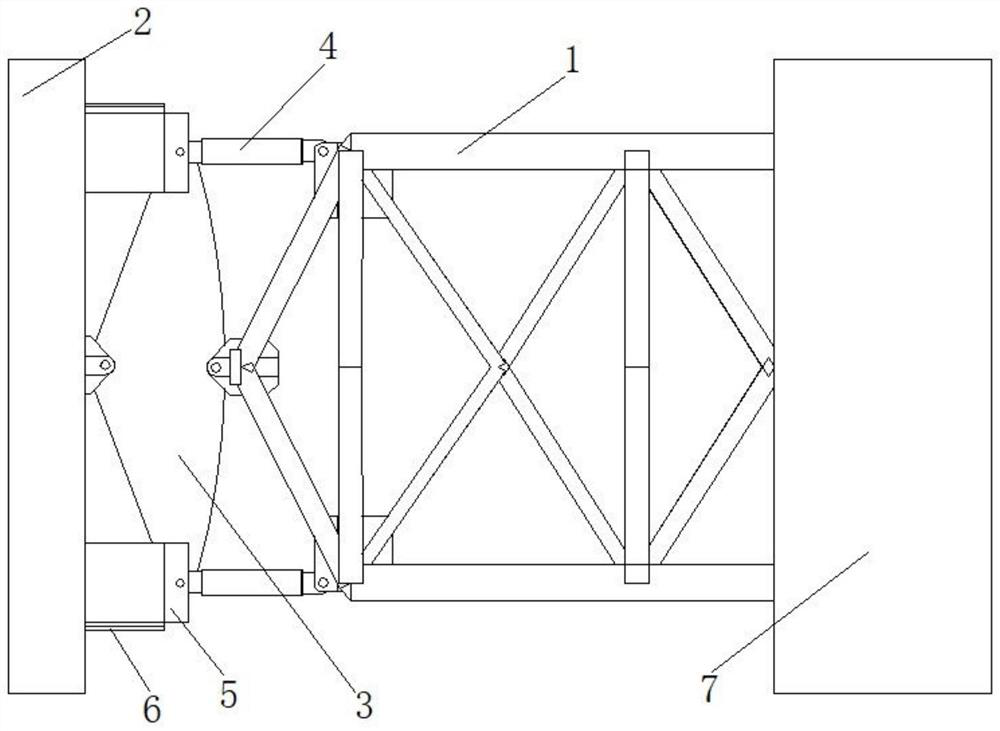

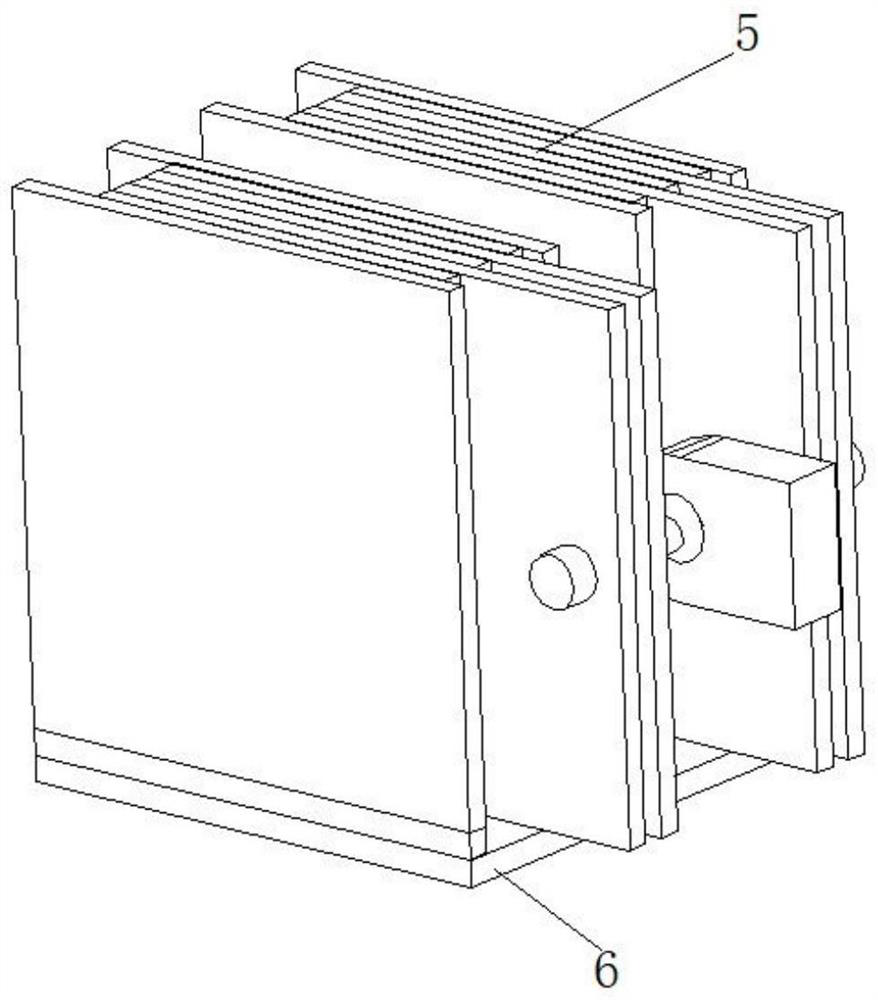

Seesaw type amplification type energy dissipation extending arm capable of preventing out-of-plane instability

PendingCN113374109AEffectively dissipateReduced seismic responseProtective buildings/sheltersShock proofingEngineeringShock absorber

The invention discloses a seesaw type amplification type energy dissipation extending arm capable of preventing out-of-plane instability. The extending arm comprises an extending arm truss, an outer frame column, a seesaw type amplification device, a viscous fluid damper, a viscoelastic damper and out-of-plane instability preventing connecting steel plates. The seesaw type amplification device is hinged to the outer frame column through a left hinge point, and the seesaw type amplification device is hinged to the extending arm truss through a right hinge point; the seesaw type amplification device is respectively hinged with one end of the viscous fluid damper through the upper hinge point and the lower hinge point, and the other end of the viscous fluid damper is hinged with the extending arm truss; and the out-of-plane instability preventing connecting steel plates are fixed to the upper end and the lower end of the outer frame column and fixedly connected with the viscoelastic damper, and the viscoelastic damper is fixedly connected with a pin shaft of the upper hinge point or the lower hinge point. The energy dissipation extending arm is high in feasibility, the key technical problem of an existing energy dissipation extending arm with an amplifying device is solved, and the energy dissipation and shock absorption effects and the capacity of coordinating deformation of an inner cylinder and an outer frame are superior to those of an existing technical scheme.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

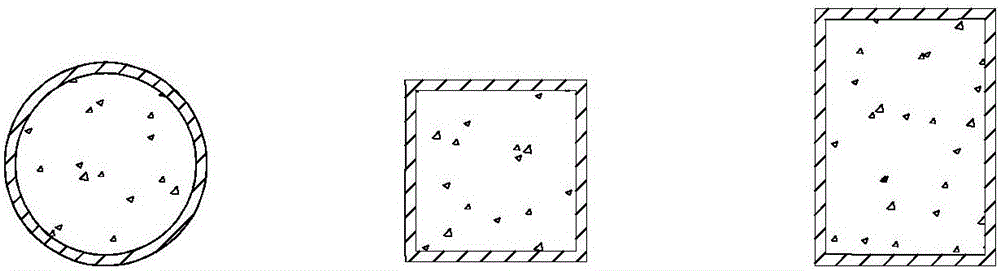

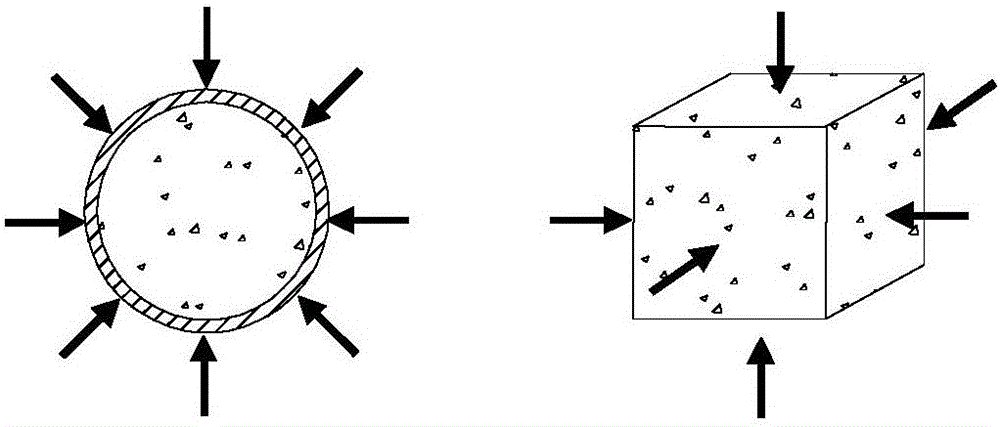

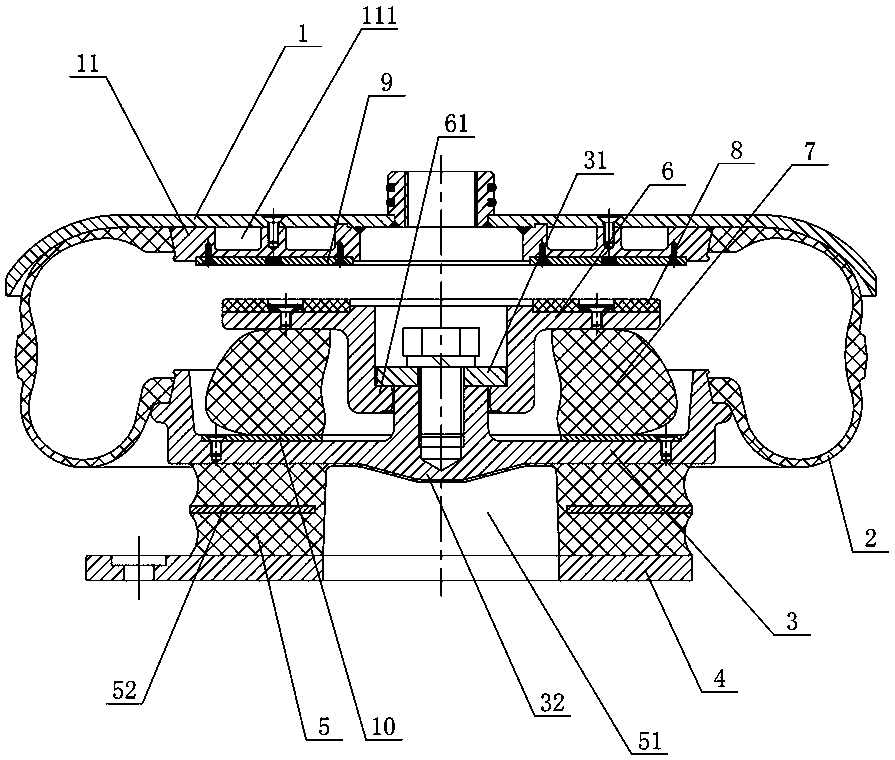

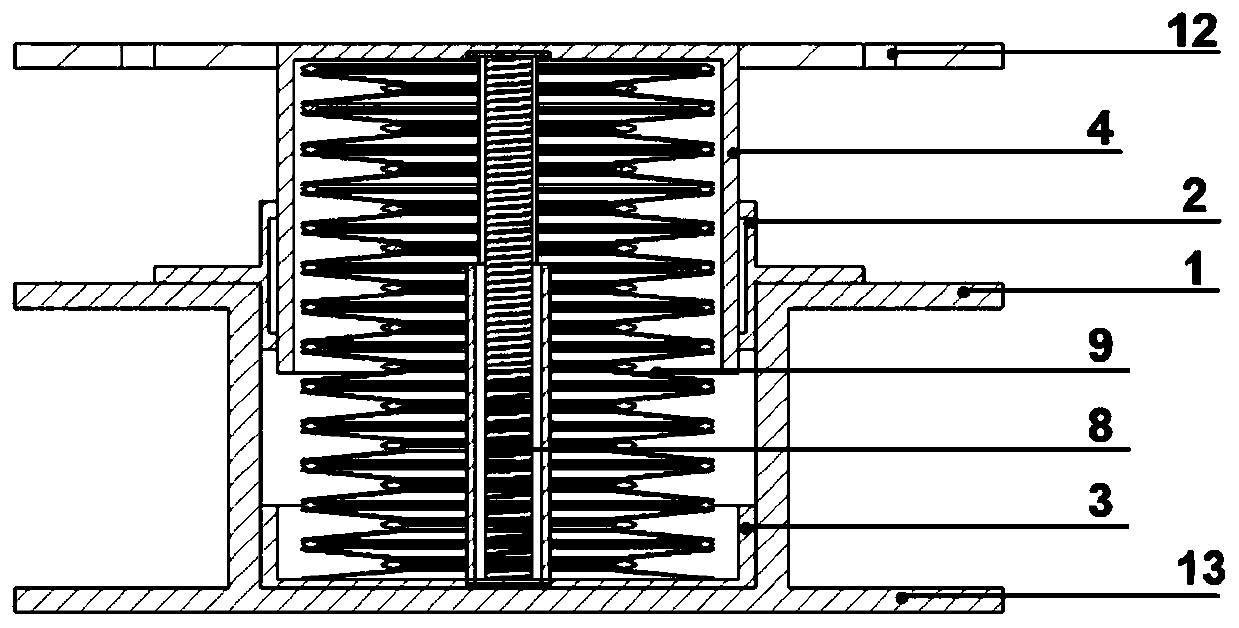

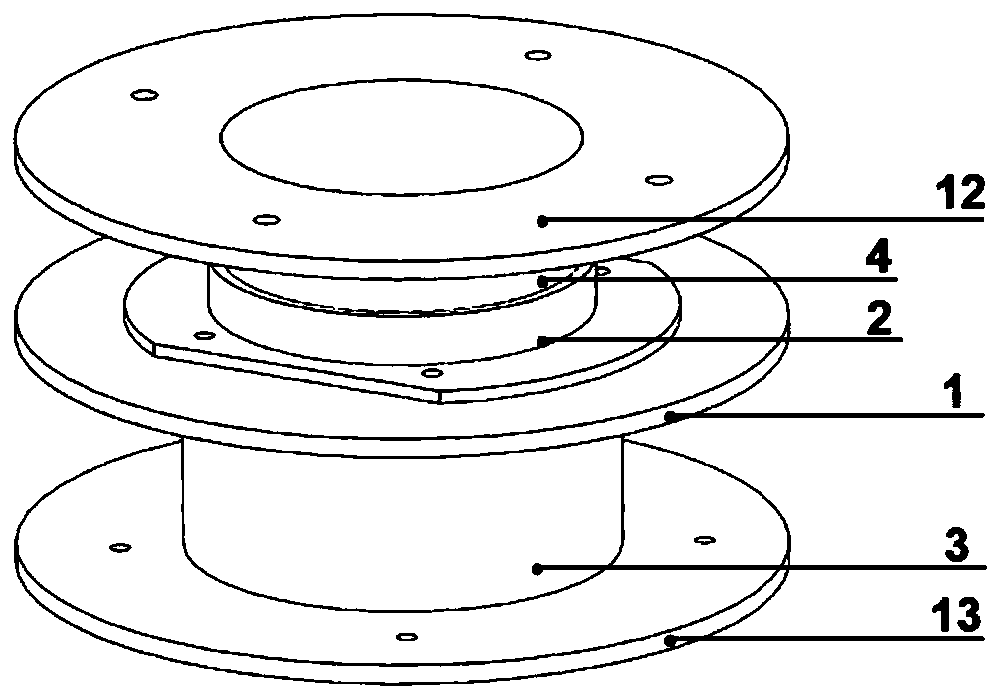

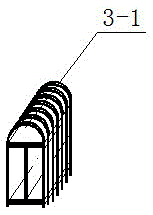

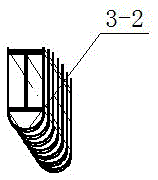

Pre-compaction type air spring system

ActiveCN108105324AWon't breakAvoid destructionSpringsSprings/dampers functional characteristicsElastomerAir spring

The invention discloses a pre-compaction type air spring system. The pre-compaction type air spring system comprises an upper cover plate, a gasbag, an upper end plate and a lower end plate, wherein the periphery of the upper cover plate is connected with the periphery of the upper end plate through the gasbag; a lower elastomer is connected between the upper end plate and the lower end plate; a pre-compaction plate is arranged on the top of the upper end plate; a higher ring-shaped elastomer is arranged between the pre-compaction plate and the upper end plate; and a first stop part which is positioned in the higher ring-shaped elastomer is arranged on the middle position of the pre-compaction plate. The air spring system has the advantages of being simple in structure, convenient to mount, low in gas-leakage heavy-load perpendicular rigidity and high in comfort and stability.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

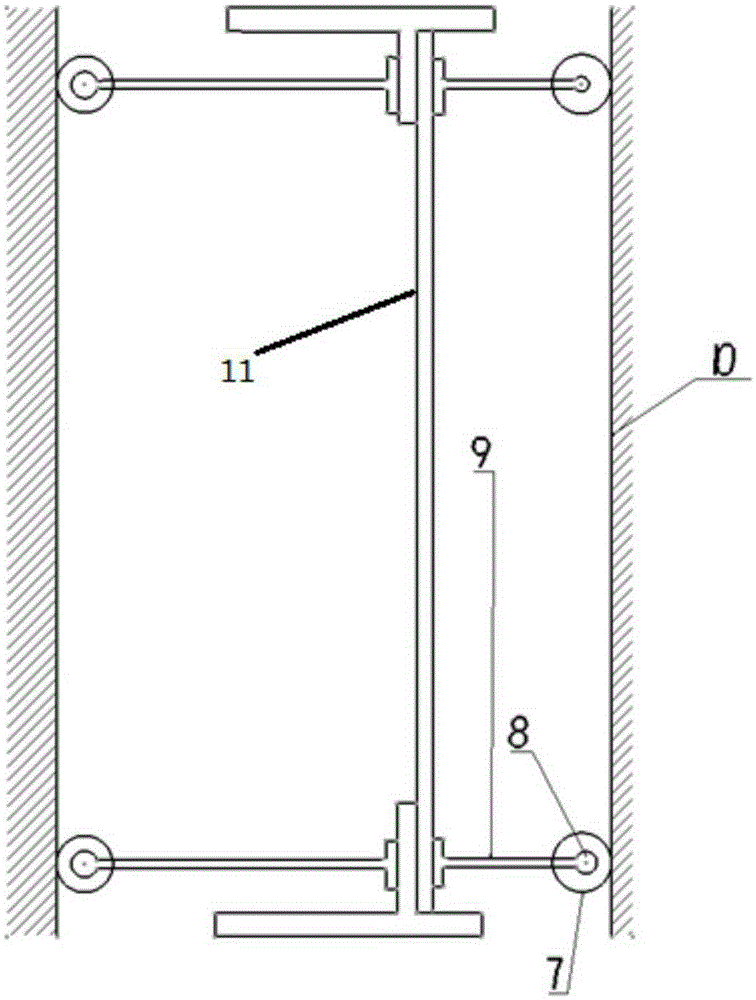

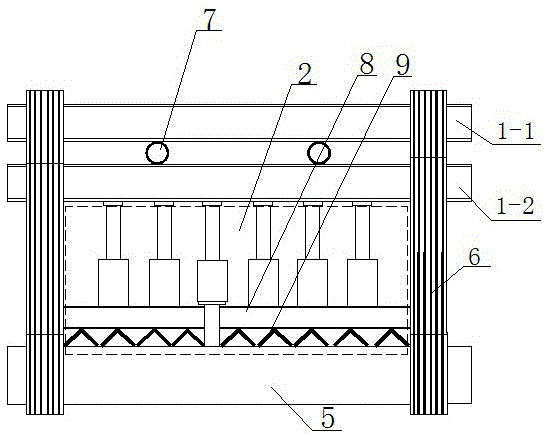

Web beam structure anti-destabilization clamper under fatigue shear load effect

InactiveCN106404520AReduce the influence of human factorsPrevent twistingStrength propertiesEngineeringShear load

The present invention belongs to the field of tooling design, and particularly relates to a web beam structure anti-destabilization clamper under a fatigue shear load effect. The web beam structure anti-destabilization clamper comprises a bracket 9, rollers 7 and clamping plates 10, wherein one end of the bracket 9 is the clamping end and the other end is the sliding end, the sliding end is connected to the rollers 7 through ball hinges 8, the clamping ends are fixedly connected to a web beam structure 11 from both sides, and the clamping plates are tightly matched with the rollers 7 from both sides, such that the clamping effect is provided for the whole clamper.

Owner:HARBIN

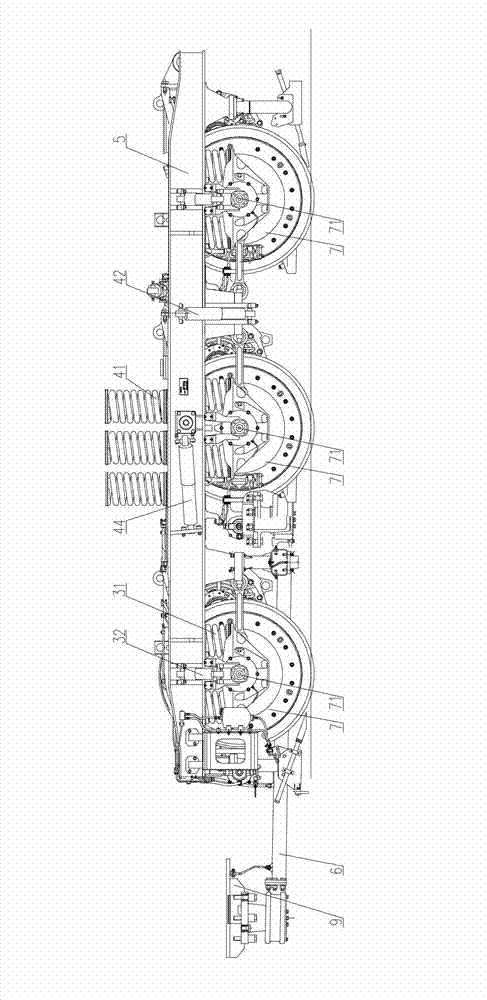

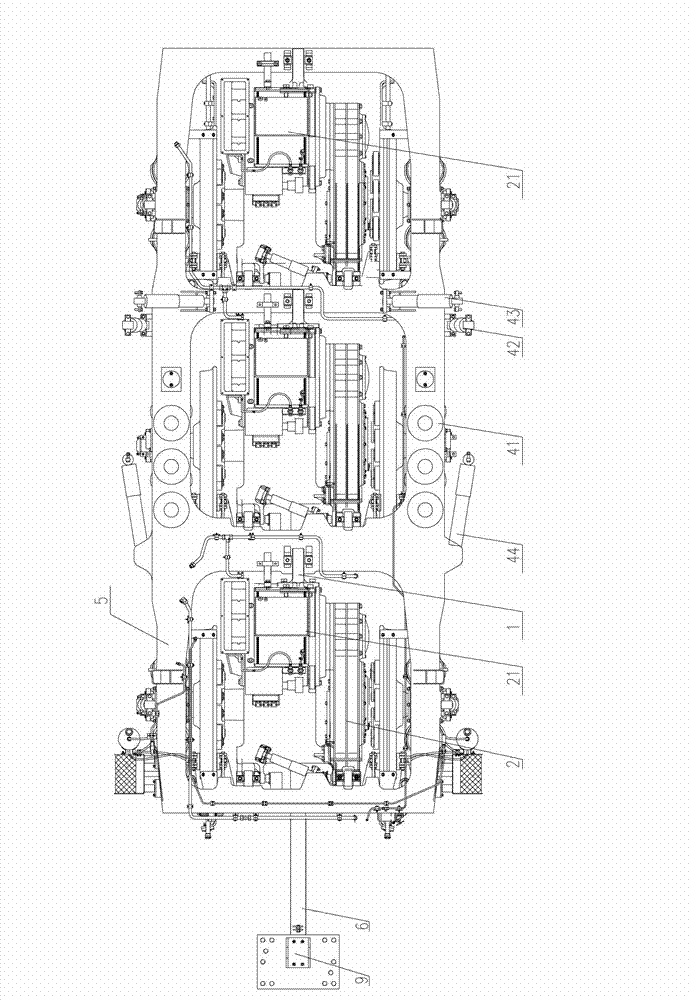

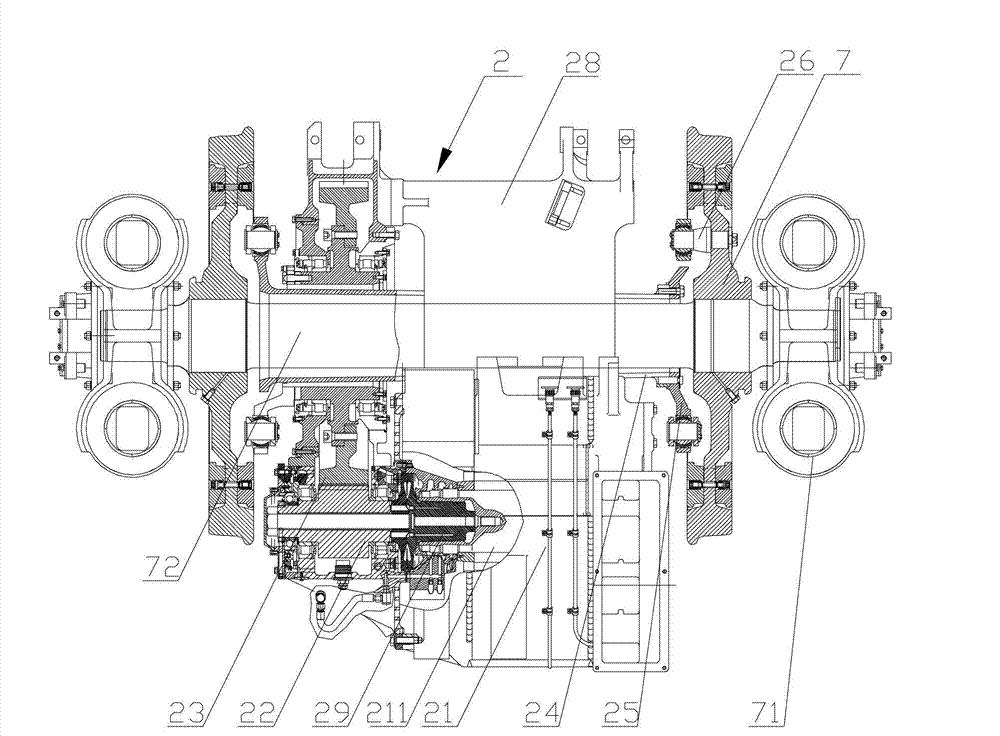

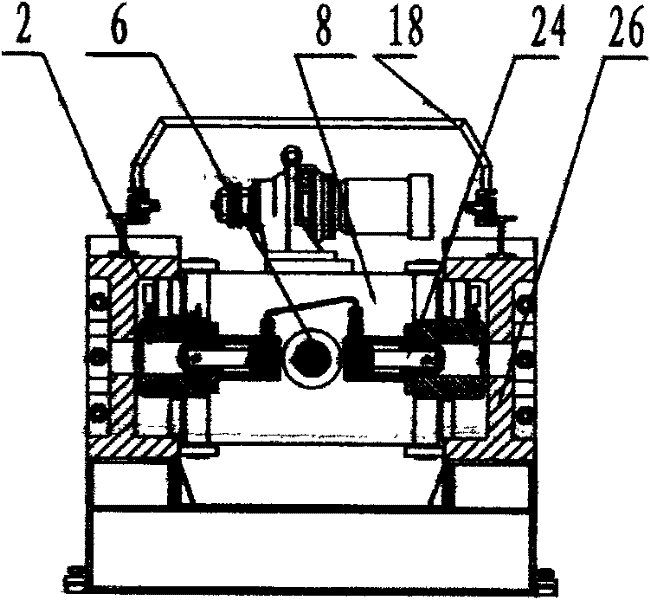

Three-axle bogie

InactiveCN102963380AImprove lateral dynamicsAvoid lateral instabilityBogiesBogie-underframe connectionsBogieDrive shaft

The invention discloses a three-axle bogie. A driving device of the bogie comprises a motor, wherein a transmission shaft of the motor is connected with a pinion through a coupler; the exterior of the pinion is meshed with a gearwheel that is mounted on a hollow shaft; the hollow shaft is rotatably mounted at the outer part of the axle of the bogie in a sleeving way; the exterior of the hollow shaft is connected with a driving disc; the driving disc is connected with wheel pairs through force transmission pins; and a driving device is elastically suspended on the frame of the bogie through a motor suspension device. The driving device with the structure can simply and reliably drive the wheel pairs. The structure further facilitates the elastic suspension structure between the motor and the frame, enables most of the transverse inertia and the shaking inertia of the driving device to be decoupled with the whole frame, is beneficial to improve the transverse dynamics performance of the bogie, and avoids a transverse unstable phenomenon of the bogie.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

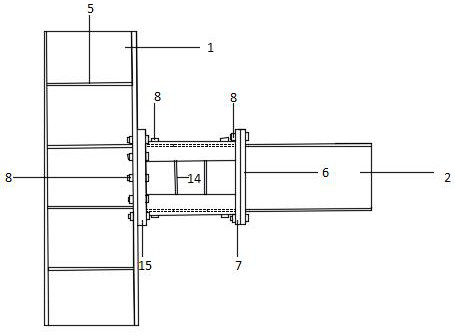

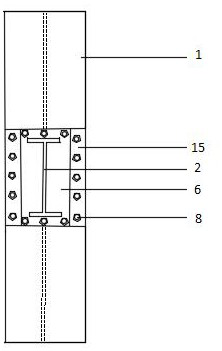

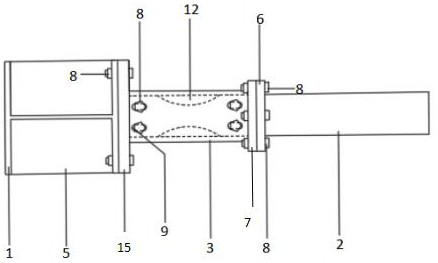

Buckling-restrained steel frame beam column connecting structure

PendingCN112900623AAvoid lateral instabilitySave materialProtective buildings/sheltersShock proofingEngineeringSteel frame

The invention discloses a buckling-restrained steel frame beam column connecting structure, and belongs to the technical field of building structures. The structure comprises an I-shaped steel column, an I-shaped steel beam and a buckling-restrained connecting part; the I-shaped steel column and the I-shaped steel beam are connected through the buckling-restrained connecting part; the buckling-restrained connecting part comprises buckling-restrained channel steel, side buckling-restrained channel steel and an energy dissipater; arc-shaped groove openings are formed in the side edges of an upper flange plate and a lower flange plate of energy dissipater I-shaped steel respectively; the buckling-restrained channel steel is arranged on the upper side and the lower side of the energy dissipater I-shaped steel respectively; the buckling-restrained channel steel is arranged on the two sides of a middle web of the energy dissipater I-shaped steel respectively; and arc-shaped base plates matched with the arc-shaped groove openings are arranged at the arc-shaped groove openings. According to the buckling-restrained steel frame beam column connecting structure, lateral instability of a steel beam is avoided, the seismic energy dissipation property of a joint is improved, and the seismic capacity is greatly improved.

Owner:UNIV OF SCI & TECH LIAONING +1

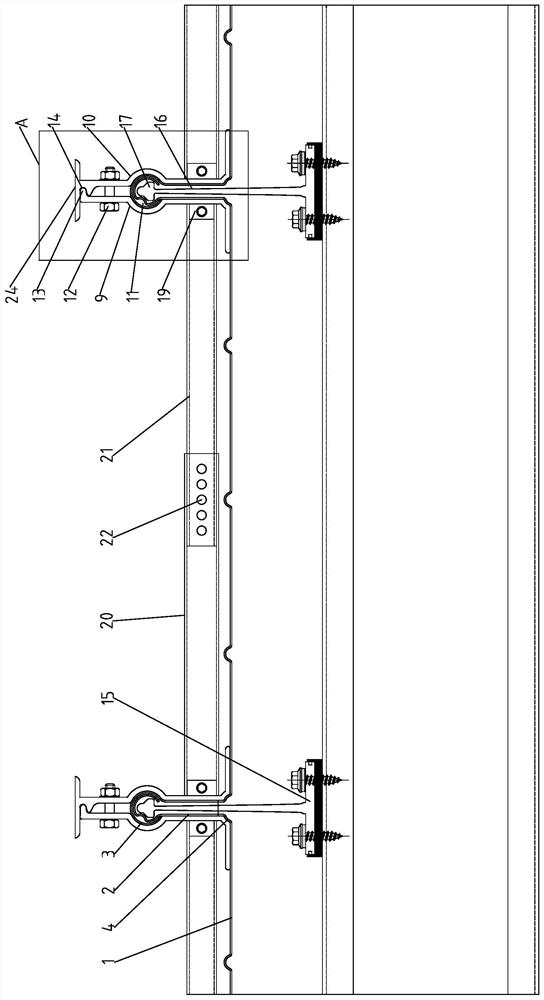

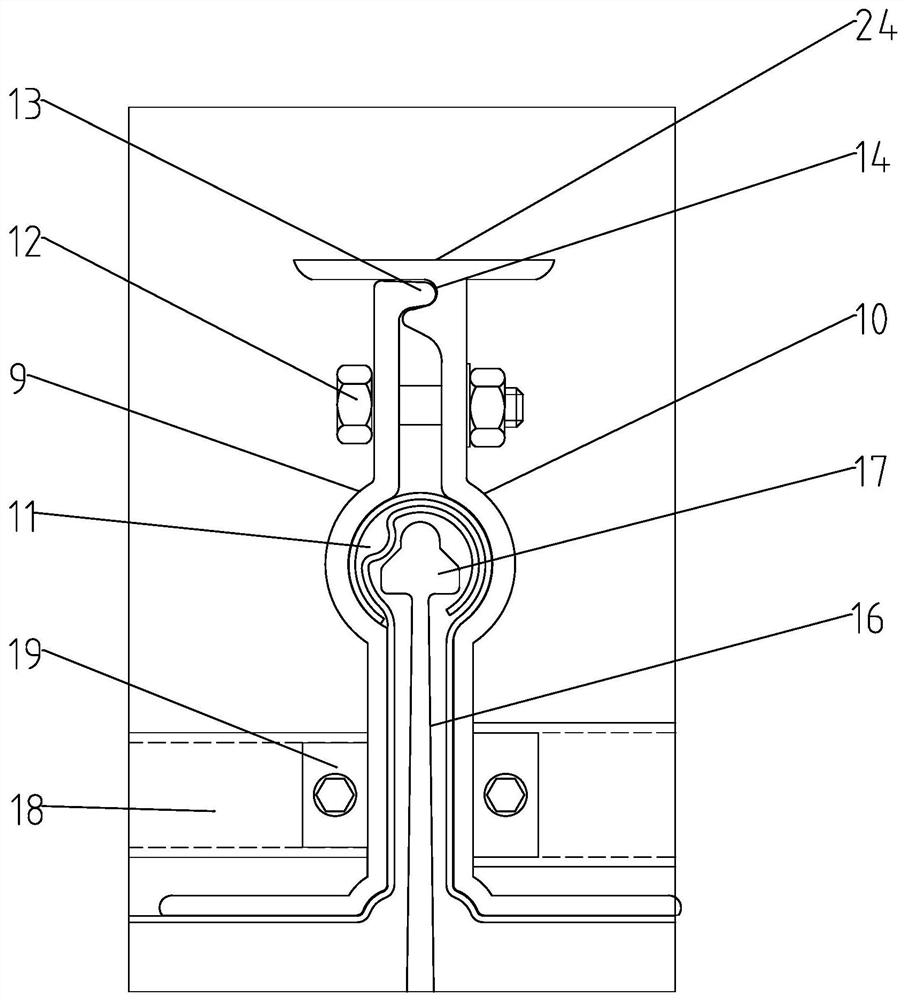

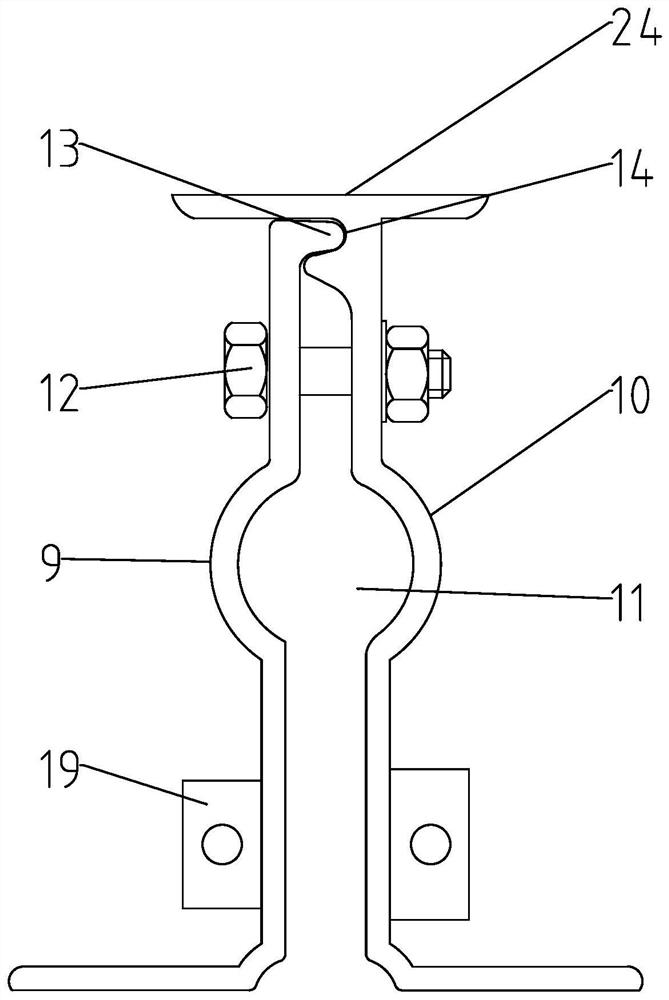

Metal roof wind-resistant clamping piece, clamp, system and composite roof wind-resistant system

PendingCN111706010AAvoid deformationPrevent trippingRoof covering using slabs/sheetsIndustrial engineeringMetal roof

The invention discloses a metal roof wind-resistant clamping piece. The metal roof wind-resistant clamping piece comprises a clamping piece body, an anti-disengagement part is arranged in the middle of the clamping piece body, and an anti-deformation part is arranged at the bottom of the clamping piece body. The invention further discloses a metal roof wind-resistant clamp, the wind-resistant clamp comprises two wind-resistant clamping pieces which are oppositely arranged, the two wind-resistant clamping pieces are oppositely arranged, and the anti-deformation parts of the two wind-resistant clamping pieces are located on the opposite sides of the two wind-resistant clamping pieces respectively; an anti-disengagement area matched with a lock catch is formed between the anti-disengagement parts of the two wind-resistant clamping pieces, the two wind-resistant clamping pieces are connected and fixed through bolts, and the bolts are located above the anti-disengagement area. The inventionfurther discloses a metal roof wind-resistant system and a composite roof system. The metal roof wind-resistant clamping piece, clamp and system disclosed by the invention have the advantages that the tripping problem and the fulcrum lateral instability problem caused by deformation of the metal roof can be effectively prevented; the temperature stress (thermal expansion and cold contraction) inthe length direction of the plate surface can be effectively released; and the stress conduction of the fulcrum can be effectively increased when the roof system is composited, and the fulcrum lateralinstability is prevented.

Owner:CHONGQING UNIV

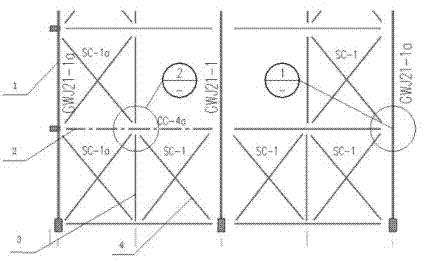

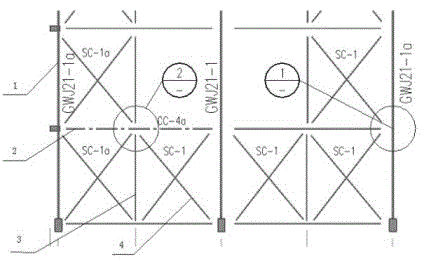

Built-up connection structure and built-up connection method for roof support and I-steel purlins

The invention relates to the technical field of arrangement of steel structure roof support, and discloses a built-up connection structure and a built-up connection method for roof support and I-steel purlins. The built-up connection structure is provided with a plurality of steel roof truss structures and a plurality of roof support structures which are connected into a net-shaped connection structure. Each steel roof truss structure comprises a steel roof truss upper chord and a purlin which are perpendicularly connected in a cross mode. Four corners of the panel point where each purlin is connected with each steel roof truss upper chord are connected with a roof support rod in an inclined mode through a structural steel piece and a connecting plate. Each roof support structure comprises a connecting beam and a purlin which are perpendicularly connected in an overlapped mode. Four corners of the panel point where each purlin is connected with each connecting beam are connected with the roof support structure in an inclined mode through a connecting plate. According to the built-up connection structure and the built-up connection method for the roof support and the I-steel purlins, the purlins can concurrently serve as pressure levers so as to prevent the roof upper chords from being unstable along the side direction. Meanwhile, the purlins and the connecting beams can further and concurrently serve as tie bars of the roof support. The area of the roof support is divided into sizes with good economical efficiency and applicability. The built-up connection structure is convenient to arrange, simple in structure, easy to machine and low in manufacture and machining cost.

Owner:芜湖金康建设工程有限公司

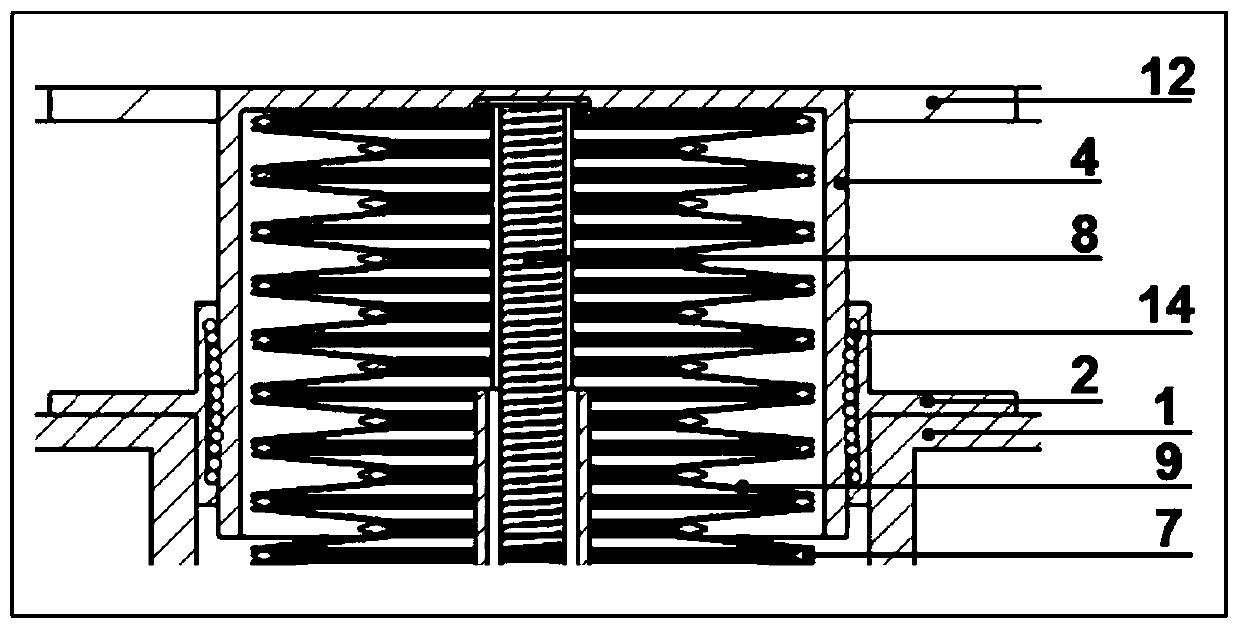

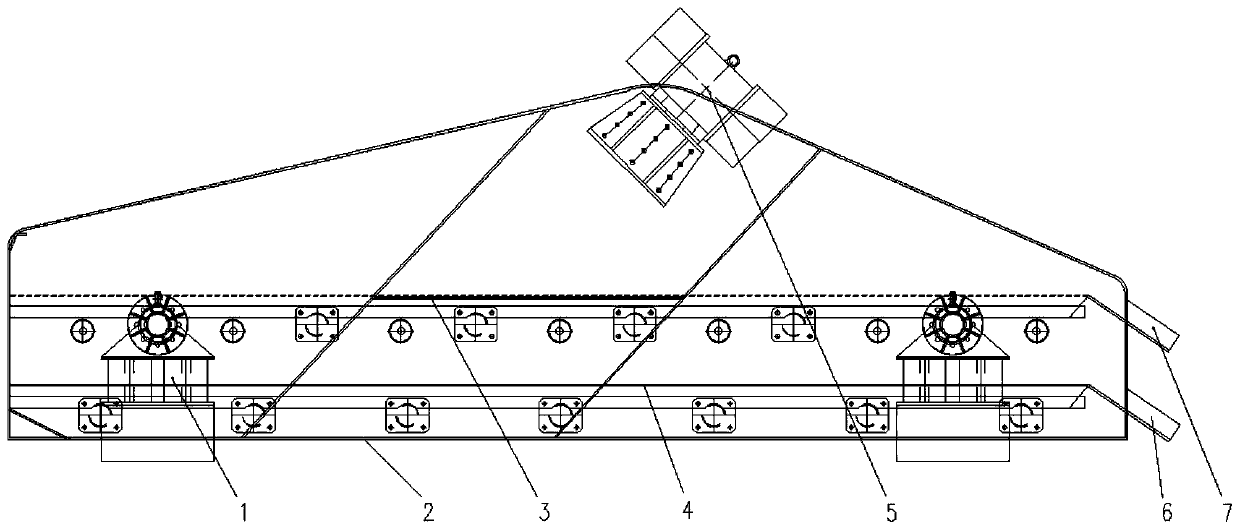

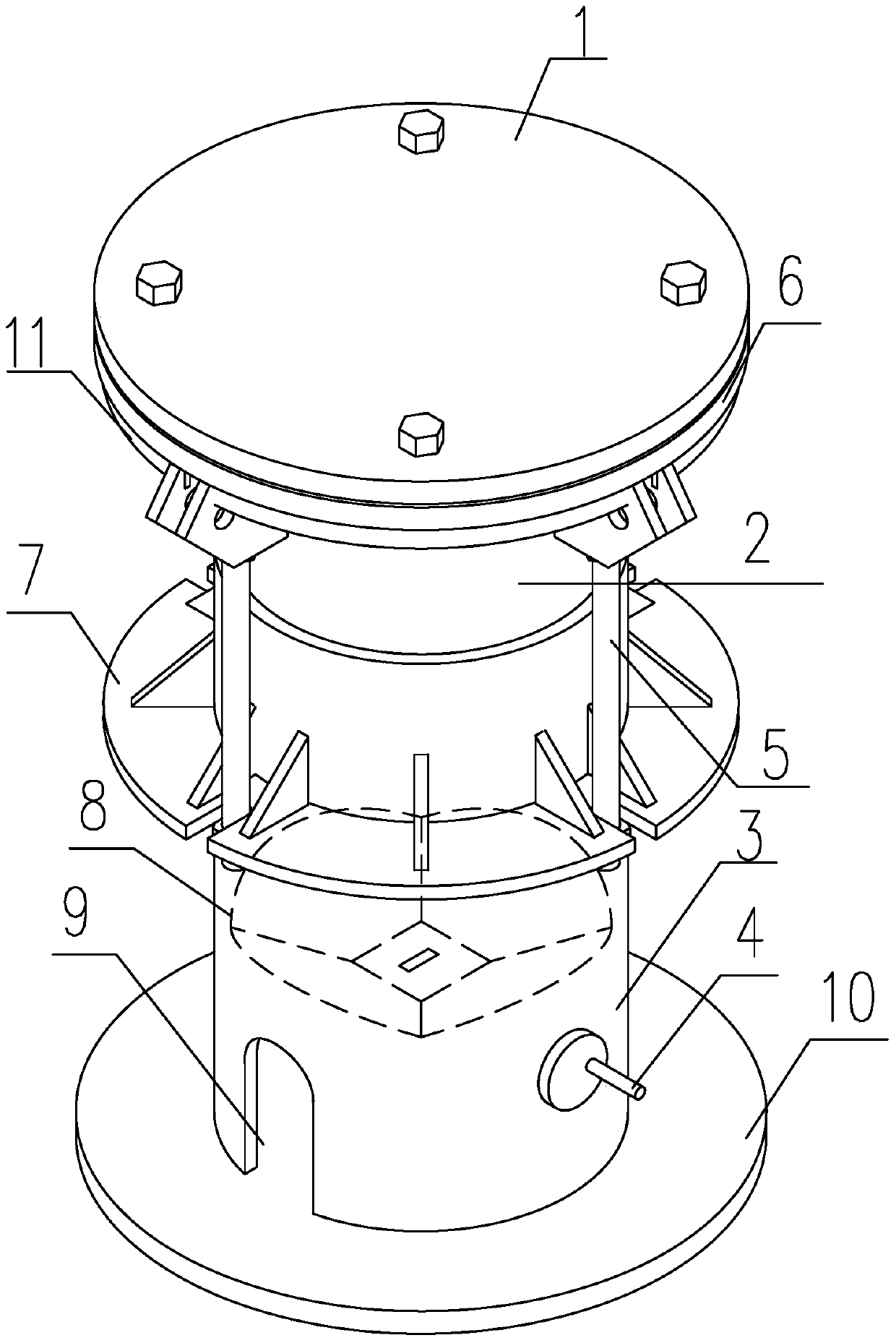

Bearing type motion decoupling vertical vibration isolation device

PendingCN111005963AGood effectAvoid lateral instabilityLinear bearingsMultiple spring combinationsVertical motionEngineering

The invention discloses a bearing type motion decoupling vertical vibration isolation device, which is characterized by comprising a vertical vibration isolation mechanism, a connecting and fixing mechanism, an anti-instability mechanism, a positioning mechanism and a motion decoupling mechanism, wherein the vertical vibration isolation mechanism is a core mechanism, located in the center of the whole device and responsible for providing vertical self-adaptive rigidity characteristics needed by vibration isolation; the whole device plays a role in connection and bearing through the connectingand fixing mechanism, the top and the bottom of the connecting and fixing mechanism are fixed to the structure, and meanwhile, the top, the bottom and the vertical vibration isolation mechanism located in the middle realize the transmission and bearing of a vertical force; the anti-instability mechanism and the positioning mechanism are arranged around an elastic element in the vertical vibrationisolation mechanism and are matched with each other to guarantee the stability of the performance of the vertical vibration isolation mechanism; the motion decoupling mechanism is arranged on the waist portion of the whole device and matched with the connecting and fixing mechanism to achieve decoupling of vertical motion and horizontal motion. The problems of instability and eccentricity of a vertical vibration isolation system are comprehensively solved.

Owner:TONGJI UNIV

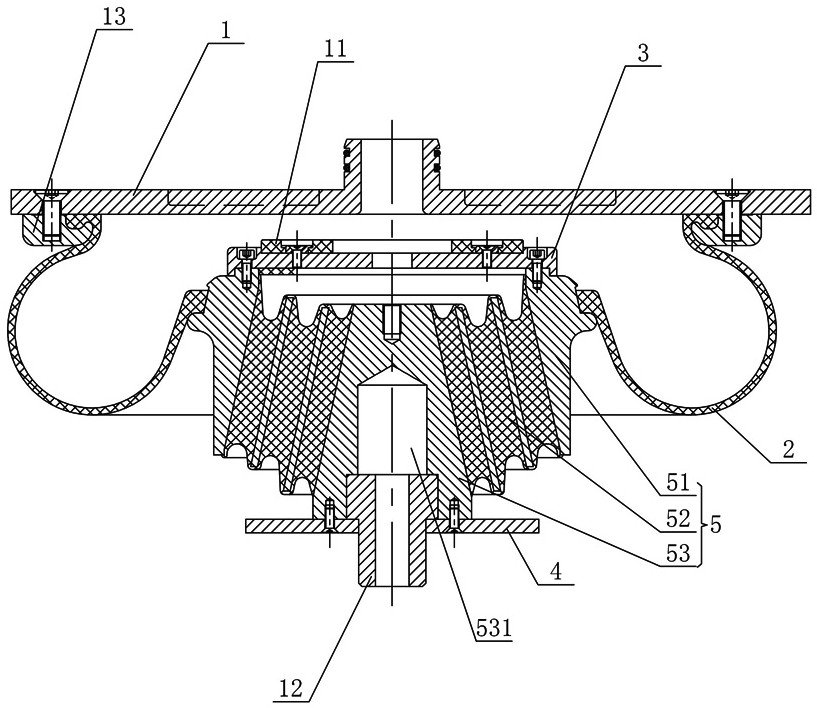

A hydraulic single cylinder tensioner

ActiveCN106284344BAvoid lateral instabilityReduce tension requirementsBulkheads/pilesAnchoring boltsCylinder blockFlange

The invention discloses a hydraulic single-cylinder tension device. The hydraulic single-cylinder tension device comprises a base, a connecting rod, a cylinder body, a piston, a support base, a top screw nut, a bottom screw nut and an anchor rod, wherein the base penetrates through the anchor rod and is arranged on surrounding rock; the upper end of the base is provided with a flange; the bottom part of the cylinder body is connected with the base through the flange in a matching way; the piston is arranged in the cylinder body; a cavity is formed between the piston and the cylinder body; the cylinder body is provided with an oil inlet, the piston is provided with an oil outlet, and the oil inlet and the oil outlet are respectively communicated with the cavity; the bottom screw nut is arranged on the anchor rod, the tail part of the anchor rod is fixedly connected with one end of the connecting rod, the other end of the connecting rod is fixedly connected with the support base, and the support base is positioned at the upper end of the piston; the connecting rod is tightened by the top screw nut. The hydraulic single-cylinder tension device has the advantages that the tension device is suitable for the quick tension of the anchor rods with different exposing lengths in the narrow operation space, the working efficiency is improved, the tension requirement of the anchor rod is decreased, and the transverse instability of the hydraulic double-cylinder tension device is avoided.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD +1

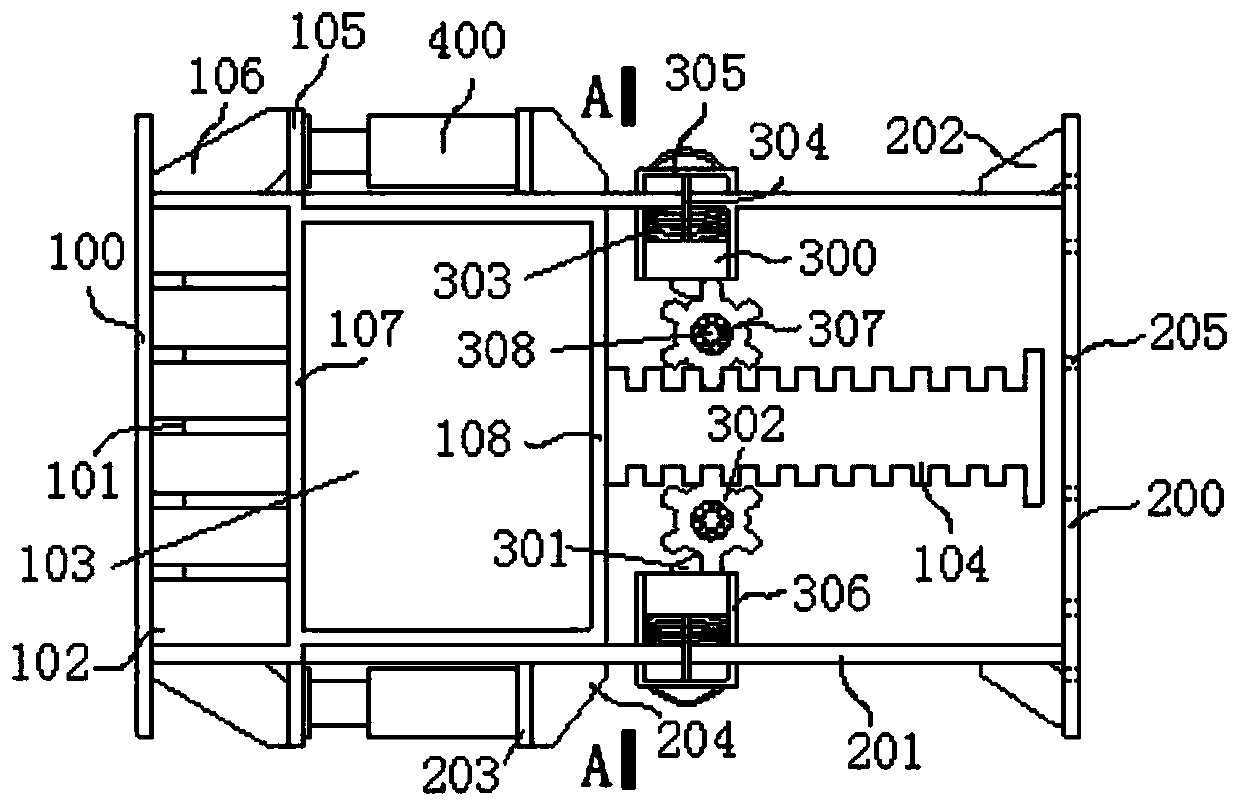

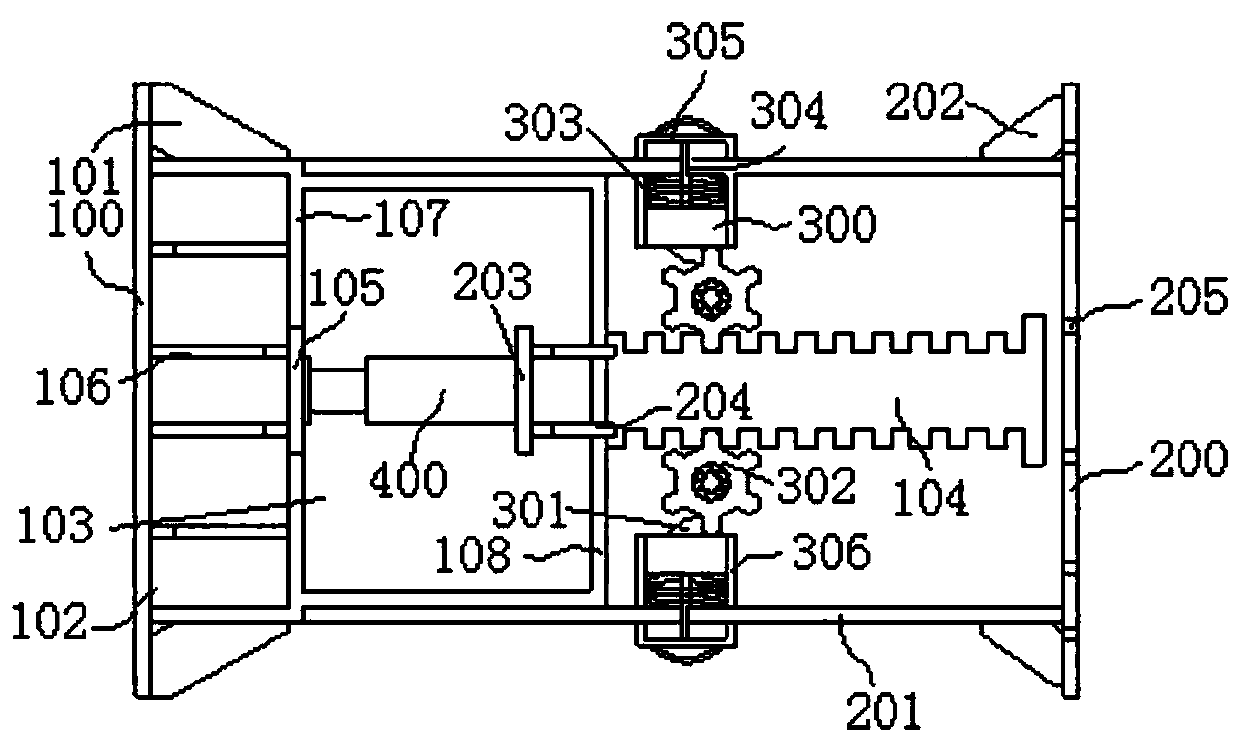

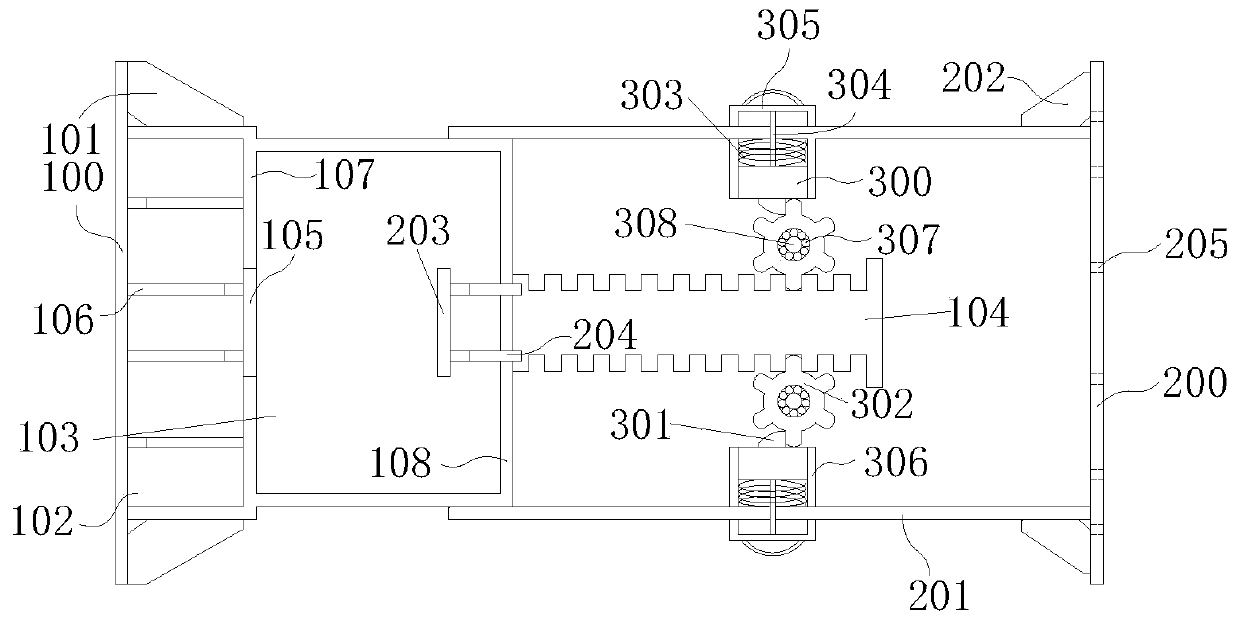

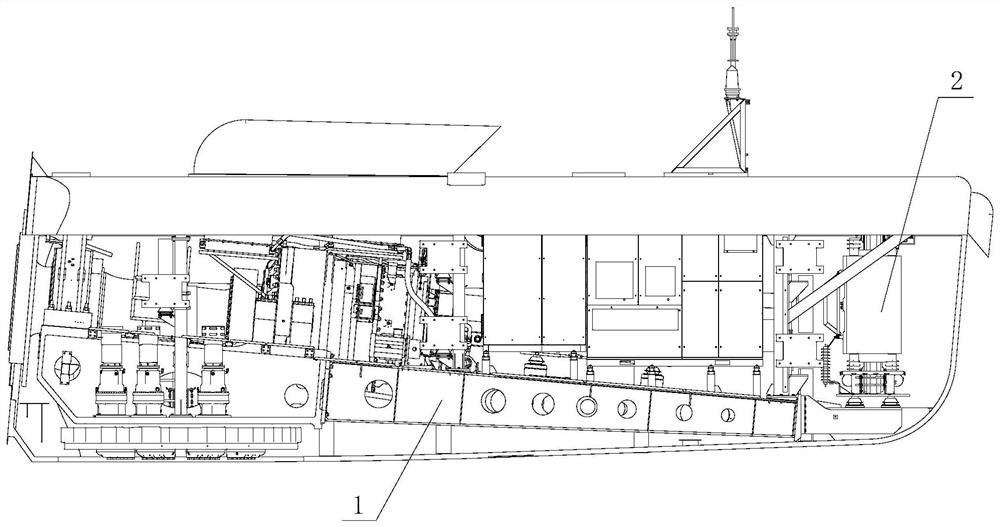

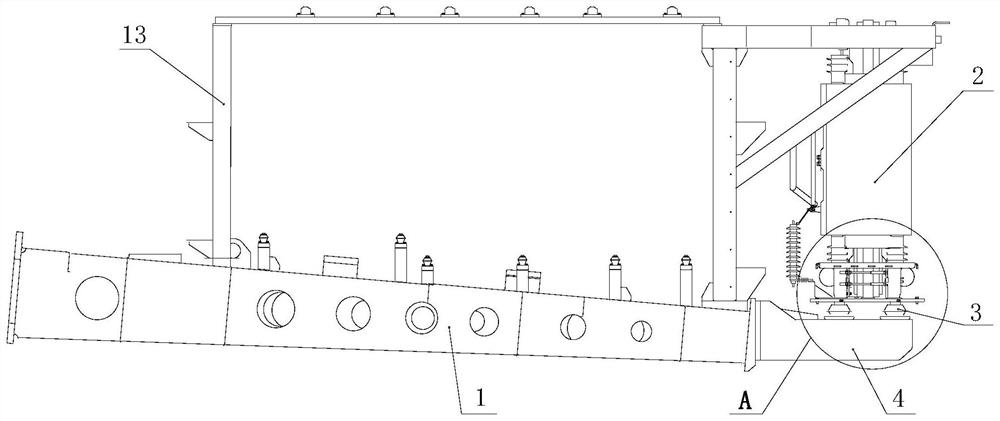

Amplitude-adjustable screening equipment for shield construction muck treatment

InactiveCN111420873AChange the vibration amplitudeAmplitude adjustmentSievingScreeningVibration amplitudeClassical mechanics

The invention belongs to the technical field of shield construction muck treatment, and particularly relates to amplitude-adjustable screening equipment for shield construction muck treatment. The problem that the treatment capacity and adaptability of a vibration screening device can be reduced when the vibration screening device adopts the same amplitude in the prior art is solved. According tothe technical scheme of the invention, the amplitude-adjustable screening equipment for shield construction muck treatment comprises a screening equipment box body (2), wherein a screen mesh (3), a spring assembly (1) and a vibrating device (5) are arranged in the vibrating screening equipment box body (2), and an amplitude adjusting device is arranged in the spring assembly (1). According to theamplitude-adjustable screening equipment for shield construction muck treatment, the vibration amplitude of the spring assembly can be changed, so that the vibration amplitude of the screening equipment can be adjusted, the screening equipment can work under different vibration amplitudes, the treatment capacity and the adaptability of the screening equipment are improved, and the screening equipment is suitable for treating shield construction muck.

Owner:CHINA RAILWEY ENG SERVICE CO LTD

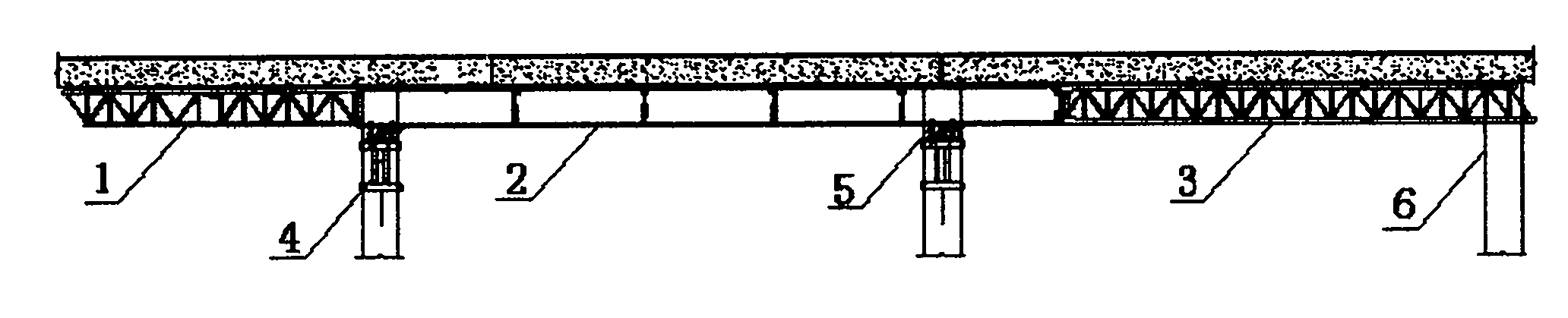

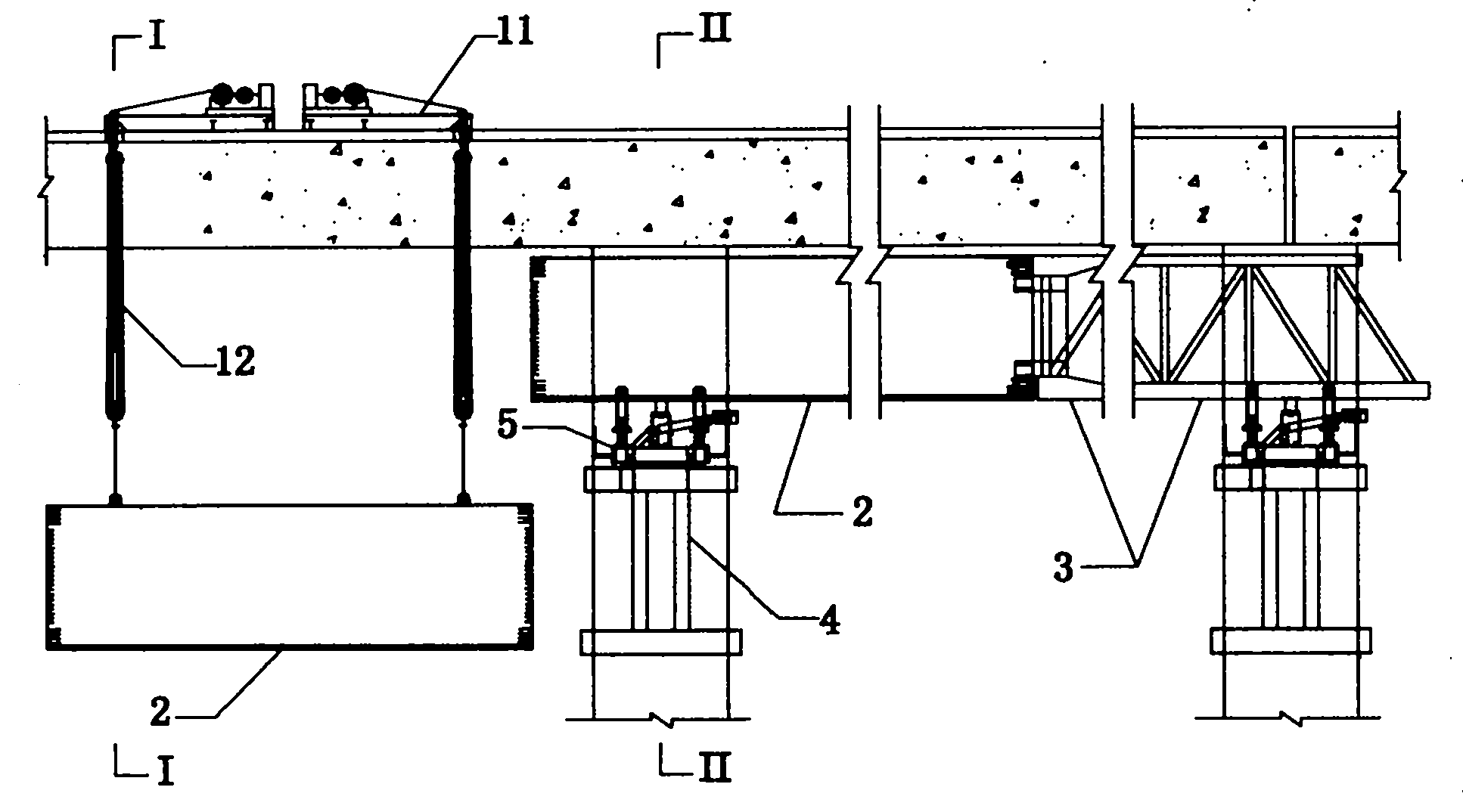

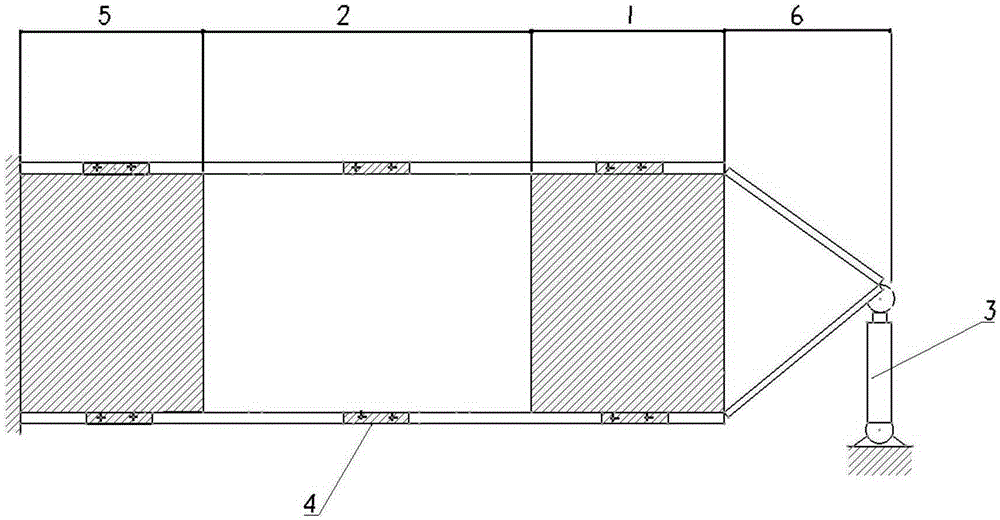

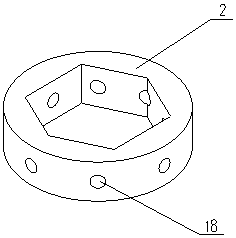

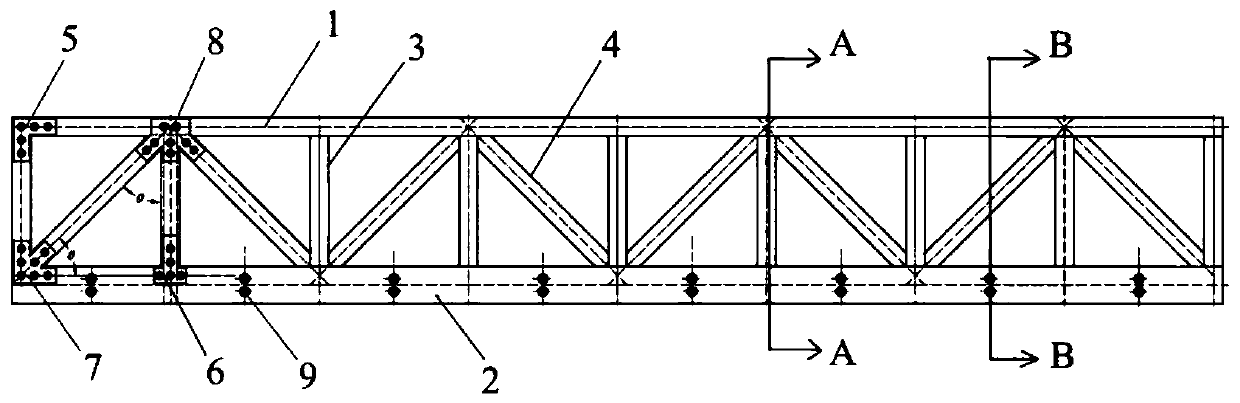

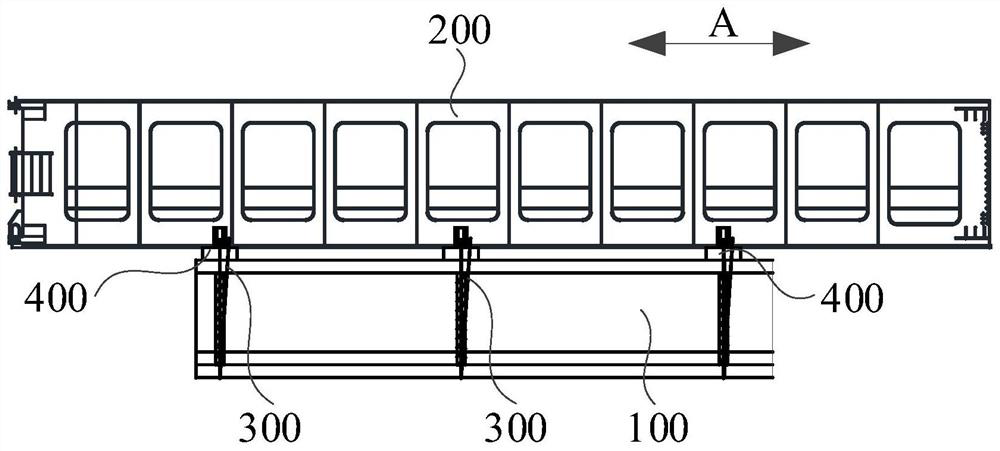

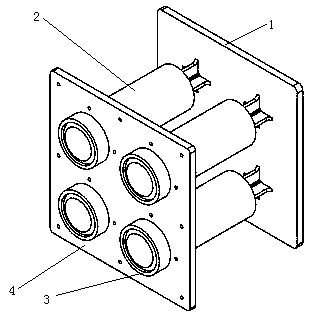

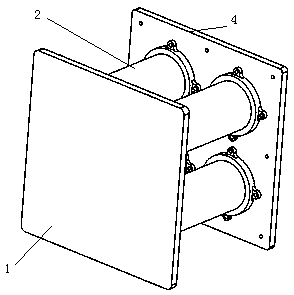

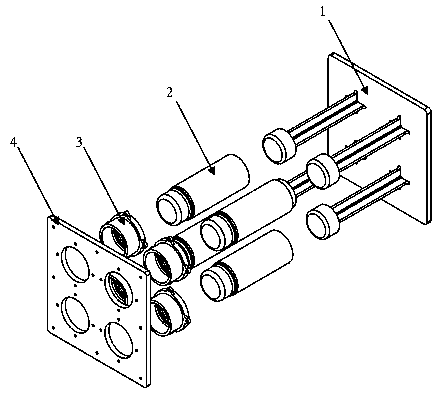

On-site load simulation experiment detection device and detection method for large continuous beam structure

ActiveCN102589968BAvoid lateral instabilitySimple structureStrength propertiesClassical mechanicsContinuous beam

The invention discloses a large-scale (continuous) beam-type structure on-site load simulation experiment detection device and detection method. The detection device includes a structural beam arranged parallel to the detection engineering beam. There is a force transmission and detection device between the structural beam and the detection engineering beam. Both ends of the structural beam and the detection engineering beam are connected by wire ropes. The structural beam, detection engineering beam, force transmission, detection device and steel wire rope are composed to realize the simulated load. structural system. After adopting such a mechanism, it is possible to carry out on-site load experiment, detection and inspection of large-scale beam structure engineering. The pulley fixing devices at both ends can meet the requirements of carrying large loads and super large loads. The uniform force and concentrated force can be correctly simulated by adding pad beams and small pads. Lateral instability, the overall equipment structure is simple, which can meet the design and use requirements.

Owner:关喜才

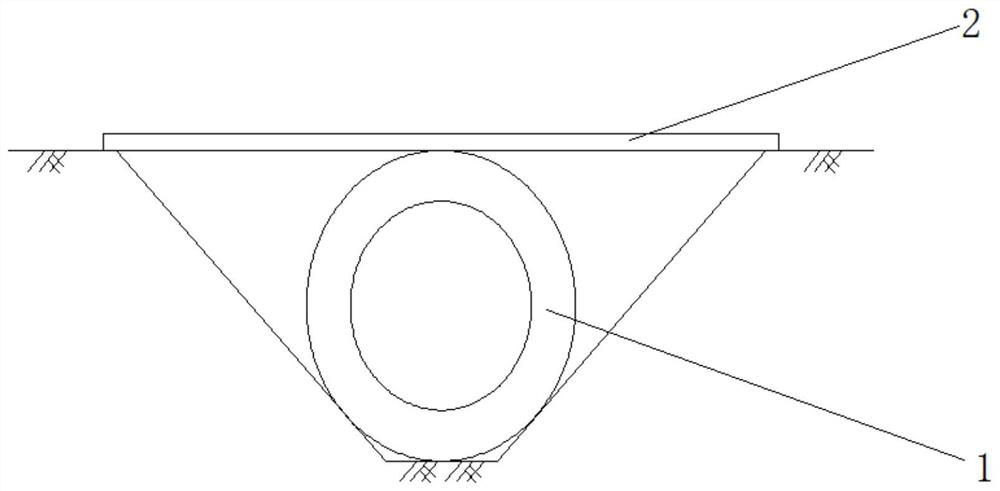

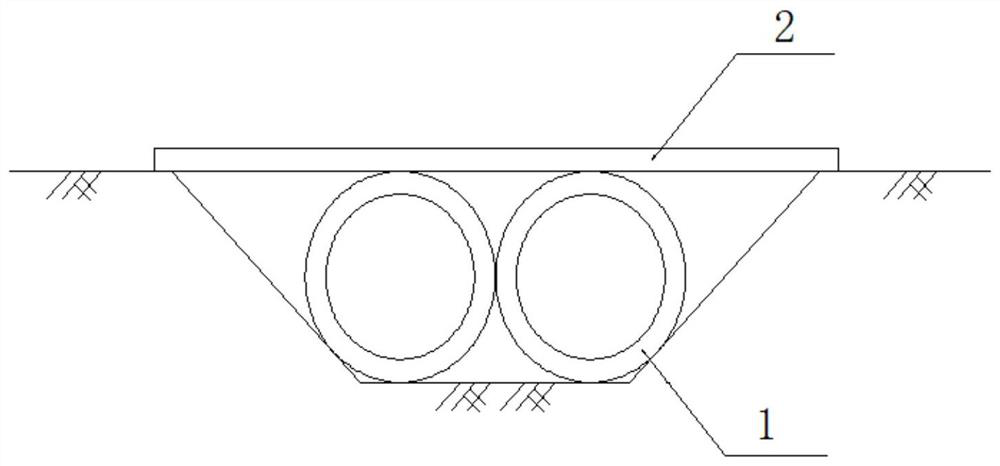

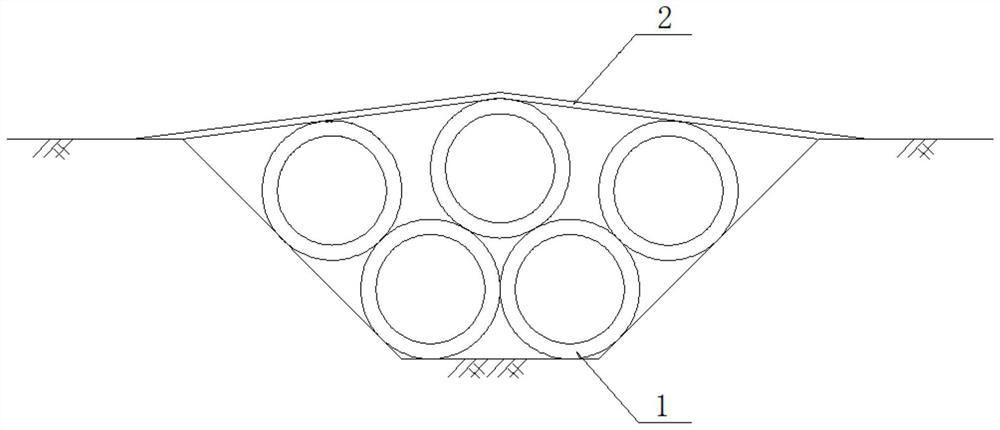

Inflatable bridge capable of being erected quickly

PendingCN112502019AQuick assemblyLight in massPortable bridgeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses an inflatable bridge capable of being erected quickly. The inflatable bridge comprises an inflatable ring assembly and a bridge deck bearing plate. The inflation ring assemblyis arranged in a valley to serve as a vertical support. The bridge deck bearing plate is installed on the inflation ring assembly in the valley span direction, and the inflation ring assembly, the inflation ring assembly and valleys on the two sides form a filling interlocking relation. According to the invention, quick assembly and quick erection can be realized.

Owner:NO 63921 UNIT OF PLA

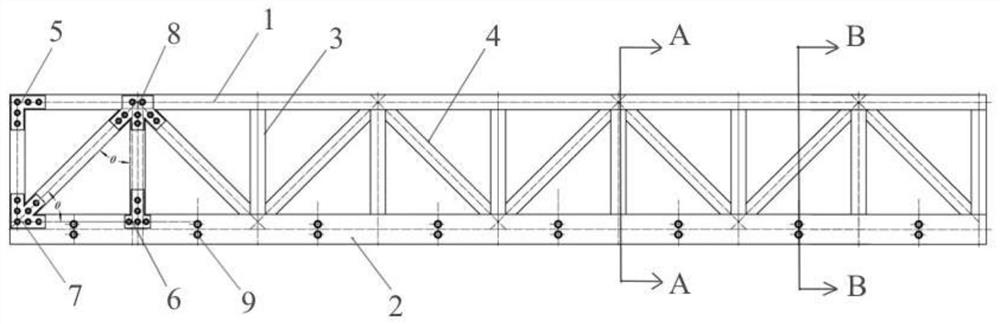

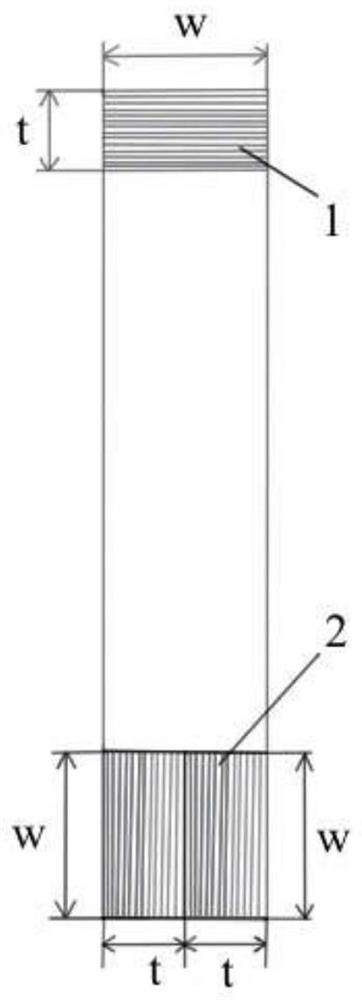

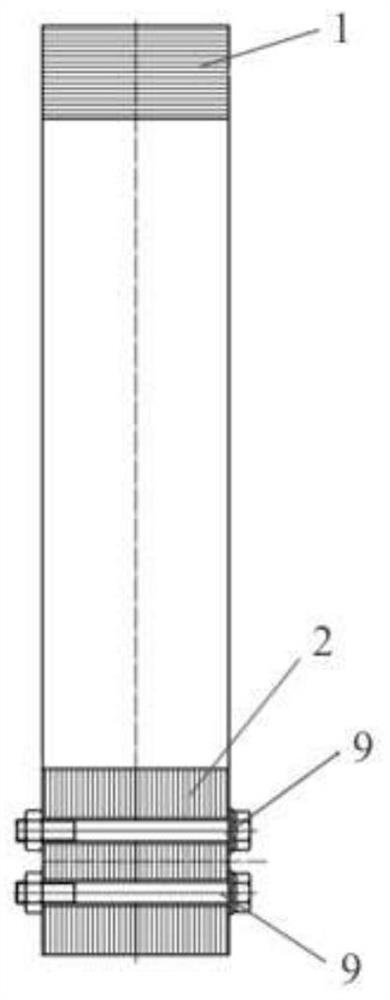

Parallel chord wood truss and manufacturing method thereof

ActiveCN111485672AMeet the stiffness requirementsGuaranteed vibration frequencyGirdersJoistsFloor slabAgricultural engineering

The invention discloses a parallel chord wood truss and a manufacturing method thereof. The parallel chord wood truss comprises an upper chord, a lower chord parallel to the upper chord, straight webmembers perpendicular to the upper chord and oblique web members which have preset included angles with the straight web member, wherein the upper chord comprises a single laminated veneer lumber, thewidth of the single laminated veneer lumber is twice of the thickness of the single laminated veneer lumber, and the thickness direction of the single laminated veneer lumber is parallel to the height direction of the upper chord; the lower chord comprises two laminated veneer lumbers, and the thickness direction of the two laminated veneer lumbers is perpendicular to the height direction of theupper chord; the two ends of each straight web member are respectively connected with the upper chord and the lower chord; and the two ends of each oblique web member are respectively connected with the upper chord and the lower chord. The parallel chord wood truss can meet the rigidity requirement, ensure that the deflection and vibration frequency of a floor slab with the parallel chord wood truss are in a vibration insensitive area, and solve the problem of poor vibration comfort of the floor slab.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

A function integrated air spring

The invention discloses a function integrated air spring which comprises an upper cover plate, an air bag, an upper end plate and a lower end plate. An auxiliary spring is connected between the upperend plate and the lower end plate, the periphery of the upper cover plate is connected with the outer periphery of the upper end plate or the outer periphery of the auxiliary spring through the air bag, and a vertical oil pressure shock absorber mounting base, a transverse oil pressure shock absorber mounting base and a transverse rubber soft stop plate are integrally arranged on the peripheral edge of the upper cover plate; a plurality of mounting holes for fixing a vehicle body are further formed in the top surface of the upper cover plate. The air spring has the advantages that the rigidityis adjustable, the application range is wide, and the overall structure and layout are optimized.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Direction-adjustable ratchet wheel type self-locking movable joint

The invention discloses a direction-adjustable ratchet wheel type self-locking movable joint which comprises a movable end, a fixed end and a direction-adjustable ratchet wheel mechanism. The movableend mainly comprises a movable end flange, a movable end rib plate, a movable end steel pipe, a movable end embedded steel pipe, movable end wing plates and a rack. The movable end rib plate is arranged between the movable end flange and the movable end steel pipe, and the movable end wing plates are symmetrically arranged on the two sides of the movable end steel pipe. One side of the fixed end steel pipe is provided with an opening, the movable end embedded steel pipe is embedded in the side, and the other side is coaxially connected with the fixed end flange. Fixed end wing plates are symmetrically arranged on the two sides of the opening end of the fixed end steel pipe and correspond to the movable end wing plates. The ratchet wheel is engaged with the rack, and movement of the rack can drive the ratchet wheel to rotate. A direction-adjusting handle is arranged outside the fixed end steel pipe, and a connecting rod penetrates through the fixed end steel pipe and a spring in the fixed end steel pipe to connect the ratchet and the direction-adjusting handle. The movable joint is simple and convenient in structure, free of redundant accessories, capable of being self-locked, convenient to erect and disassemble and capable of bearing pressure and tension at the same time.

Owner:BEIJING UNIV OF TECH

Parallel chord timber truss and method of making the same

ActiveCN111485672BMeet the stiffness requirementsGuaranteed vibration frequencyGirdersJoistsFloor slabEngineering

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

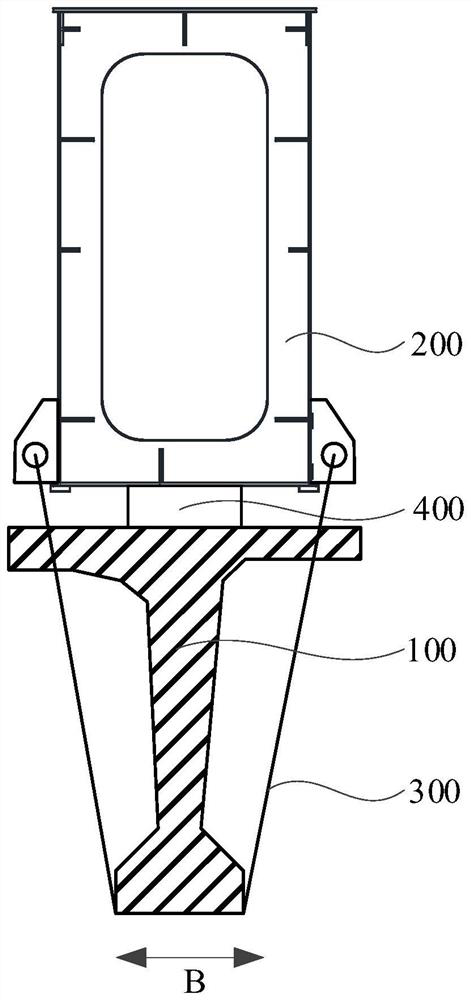

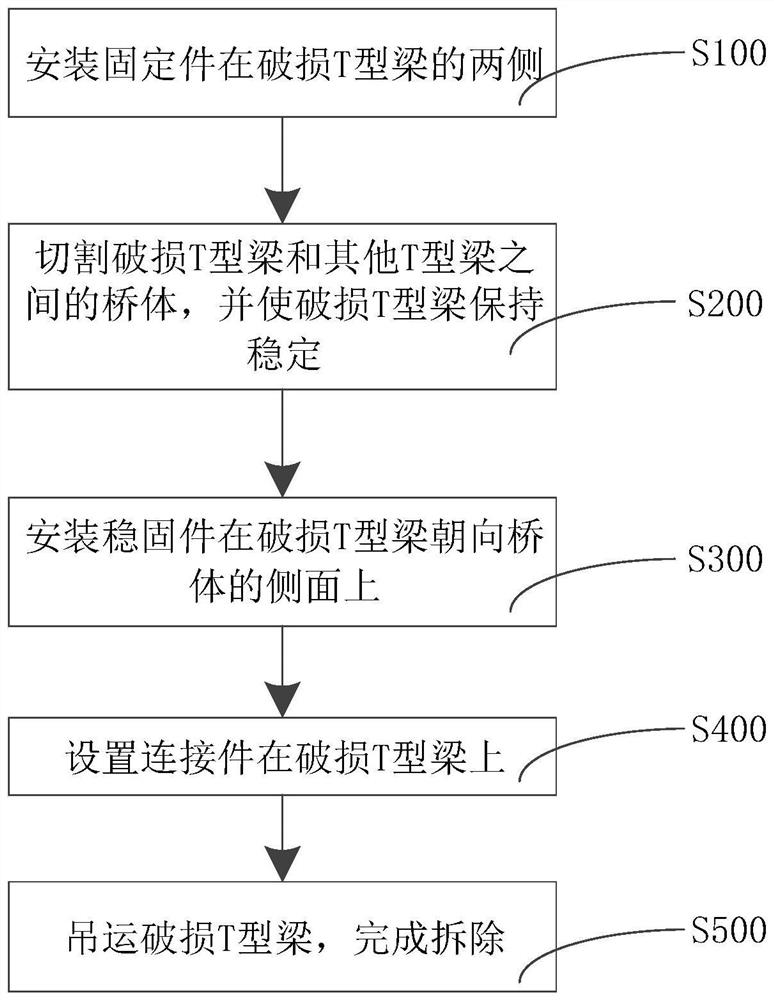

T-shaped beam dismantling method

PendingCN114032797AImprove structural stabilityImprove stabilityBuilding repairsBridge strengtheningShaped beamClassical mechanics

The invention relates to a T-shaped beam dismantling method. Fixing pieces are installed on the two sides of a damaged T-shaped beam; a bridge body between the damaged T-shaped beam and other T-shaped beams is cut, and the damaged T-shaped beam is kept stable; a stabilizing piece is installed on the side face, facing the bridge body, of the damaged T-shaped beam, the length direction of the stabilizing piece is consistent with that of the damaged T-shaped beam, and the length of the stabilizing piece is larger than or equal to that of the damaged T-shaped beam; a connecting piece is arranged on the damaged T-shaped beam, the two ends of the connecting piece are connected to the two opposite side faces of the stabilizing piece respectively, and the connecting piece abuts against the side face, opposite to the stabilizing piece, of the damaged T-shaped beam; and the damaged T-shaped beam is hoisted, and dismantling is completed. The structure stability of the damaged T-shaped beam is guaranteed, stress between the stabilizing piece and the damaged T-shaped beam can be stable and uniform in the hoisting process, lateral instability or further damage in the hoisting process is avoided, and the stability and safety of the T-shaped beam dismantling method are improved.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

Construction process for overhead back-up movement and dismantlement of movable shuttering form

InactiveCN101818479BAvoid lateral instabilityShorter dismantling timeBridge erection/assemblyForm treatmentEngineeringTruck

The invention belongs to the field of bridge construction processes, is applied in the construction of a movable shuttering form for a cast-in-place box girder, and particularly relates to a construction process for the overhead back-up movement and dismantlement of a movable shuttering form after a cast-in-place box girder is completely constructed by the movable shuttering form. The process is characterized in that: a back guide girder, a main beam, a front guide girder, a bracket, a cart, an external mould plate, a mould plate beam, a middle beam and bracket tensioning fining twisted steelon both sides of the bride need to be removed; the cart transversely moves on the bracket to open the movable shuttering form, a winder is arranged on a concrete box girder, the external mould plate is removed by the winder and by the drawing and hoisting operation of a truck crane, the mould plate beam and the middle beam are removed from the top to the bottom in sequence, only the back guide girder, the main beam and the front guide girder remain, the main beam of the movable shuttering form is removed, and finally the last section of main beam and the front guide girder are moved. The process has the advantages of speeding up the construction, reducing construction equipment, guaranteeing the construction safety and lowering construction cost.

Owner:CCCC SHEC SECOND ENG

An energy-absorbing device based on necking plastic deformation

ActiveCN107336721BStable tensile plastic deformationStretch-Plastic Deformation OrderRailway wheel guards/bumpersEnergy absorptionAbsorbed energy

Owner:CENT SOUTH UNIV

Early warning system for out-of-plane instability in sliding construction of inverted triangular truss type roof

ActiveCN112878696AAvoid lateral instabilityGuarantee smooth implementationBuilding material handlingEarly warning systemControl engineering

The invention relates to the field of installation or transportation of large-scale buildings, in particular to an early warning system for out-of-plane instability in sliding construction of an inverted triangular truss type roof. The early warning system is characterized by comprising a load adjustment subsystem (1), a slip unit lateral instability identification and stabilization subsystem (2) and a computer acquisition control subsystem (3). According to the early warning system, through the combined action of the load adjusting subsystem (1), the sliding unit lateral instability identification and stabilization subsystem (2) and the computer acquisition control subsystem (3), lateral instability of a sliding unit in the sliding process is effectively avoided, synchronous deviation correction in the sliding process is achieved, and smooth implementation of a sliding construction scheme is guaranteed; and the system has the biggest characteristic that the problem of lateral instability in the sliding process of the large-span inverted triangular truss type roof sliding unit is solved on the premise that the structural form of the sliding unit is not specially treated.

Owner:中冶(上海)钢结构科技有限公司

A funnel type sand box unloading device and method

ActiveCN105672669BImprove bearing capacityEasy to operateBuilding material handlingSlide plateSupport point

The invention belongs to the technical field of steel structure buildings, and particularly relates to a funnel type sand box unloading device and method which are used for unloading temporary supporting frames of bearing steel components. Four bolts in a horizontal release part need to be unscrewed before unloading is started, and horizontal displacement of the steel components in the unloading process is effectively released through sliding between a stainless steel plate and a slide plate. The unloading device is novel in concept, can conveniently unload the temporary supporting frames of the steel structure, and has the advantages of being good in sealing performance, capable of releasing horizontal displacement of supporting points, convenient to operate, high in safety, and the like.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Connecting structure of wind turbine generator cabin and dry-type transformer

PendingCN114278524ALow operating and maintenance costsImprove adaptabilityTransformers/reacts mounting/support/suspensionMachines/enginesEngineeringStructural engineering

The invention discloses a connecting structure of a wind turbine generator cabin and a dry-type transformer. The connecting structure comprises a cabin base, the dry-type transformer, a first elastic supporting piece, a box transformer substation base and a cable-stayed assembly. The bottom of the dry-type transformer is connected with a cabin base through a first elastic supporting piece and a box transformer substation base, a support is arranged on the cabin base, the top of the dry-type transformer is connected with the top of the support through a cable-stayed assembly, and installation of the dry-type transformer in a wind turbine generator cabin is completed. According to the connecting structure of the wind turbine generator cabin and the dry-type transformer, the top and the bottom of the dry-type transformer are both flexibly connected with the cabin through the elastic supporting pieces and the cable-stayed assemblies, connection and fixation of the dry-type transformer and the cabin are achieved, and a certain flexible adjusting space can be provided for the dry-type transformer; therefore, the dry-type transformer can work safely, reliably and stably in a dynamic environment of a cabin.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Hinge connection structure and method for supporting steel columns on steel beams

InactiveCN102220786BAvoid lateral instabilitySimple structureBuilding constructionsSteel columnsMaterials science

The invention relates to a connection structure, in particular to a hinge connection structure and method for supporting steel columns on steel beams. The structure comprises the steel beams, the steel columns arranged above the steel beams and a connection plate arranged between the steel beams and the steel columns. The structure and the method have the following advantages and effects: the counter force at the bottoms of the steel columns is transferred to the direction of the strong axes of the steel beams by arranging the thickening connection plate with the same direction as a web of the strong axes of the steel beams and additionally arranging steel base plates avoiding lateral unstability of the connection plate; the node construction is simple and practical; the force is reliablytransferred; the steel beams are reasonably stressed; the stability of the nodes are enhanced; waste of the beam sections is avoided; the investment is reduced; convenience is provided for construction; and the requirements of connection are well met.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

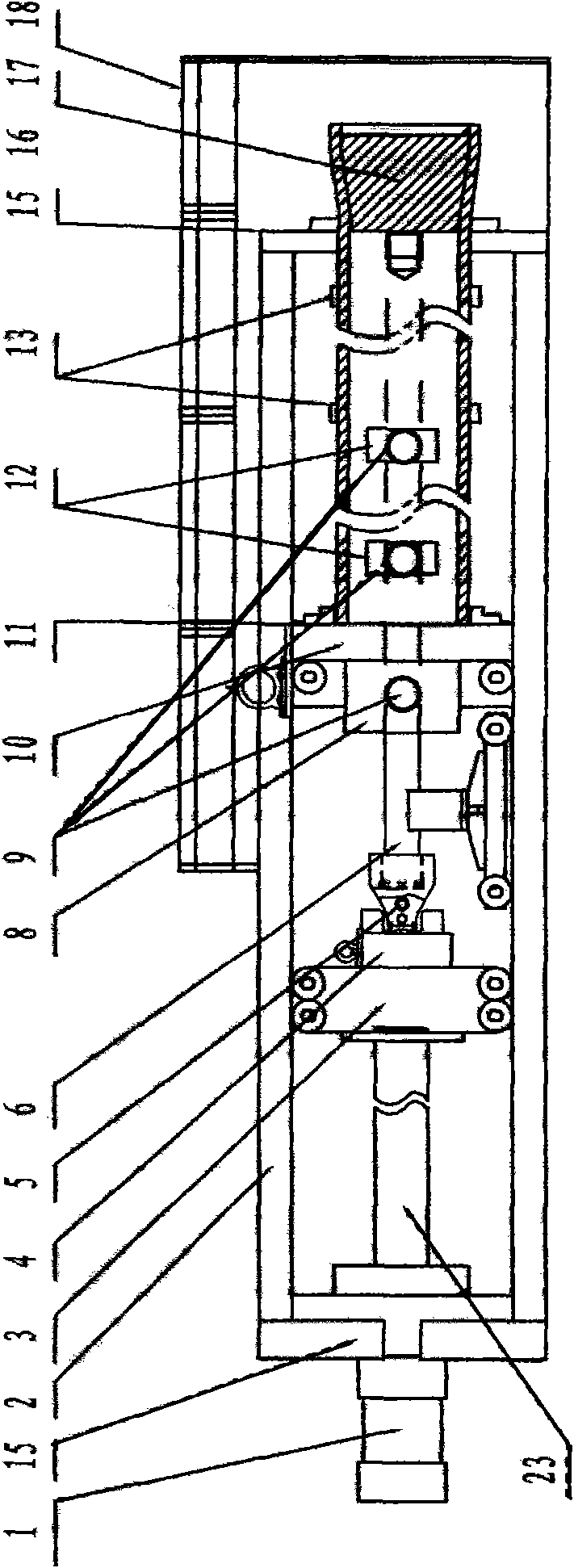

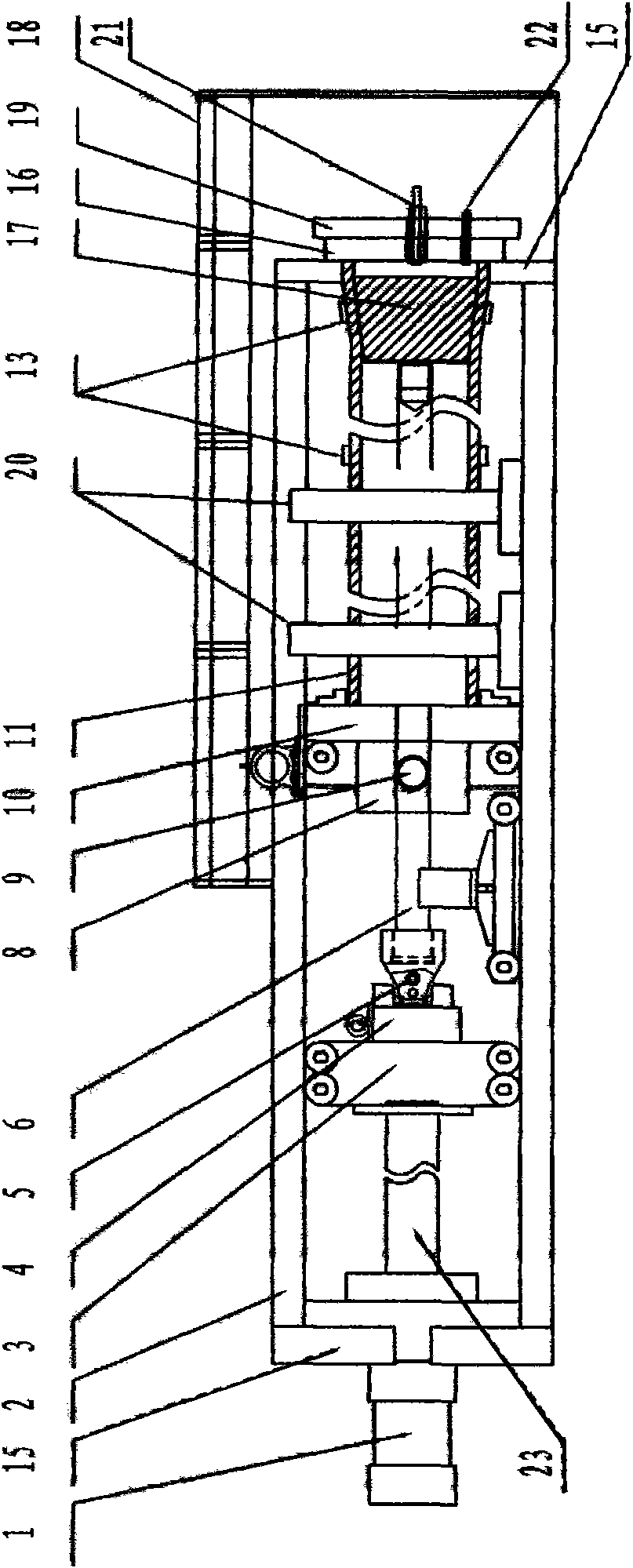

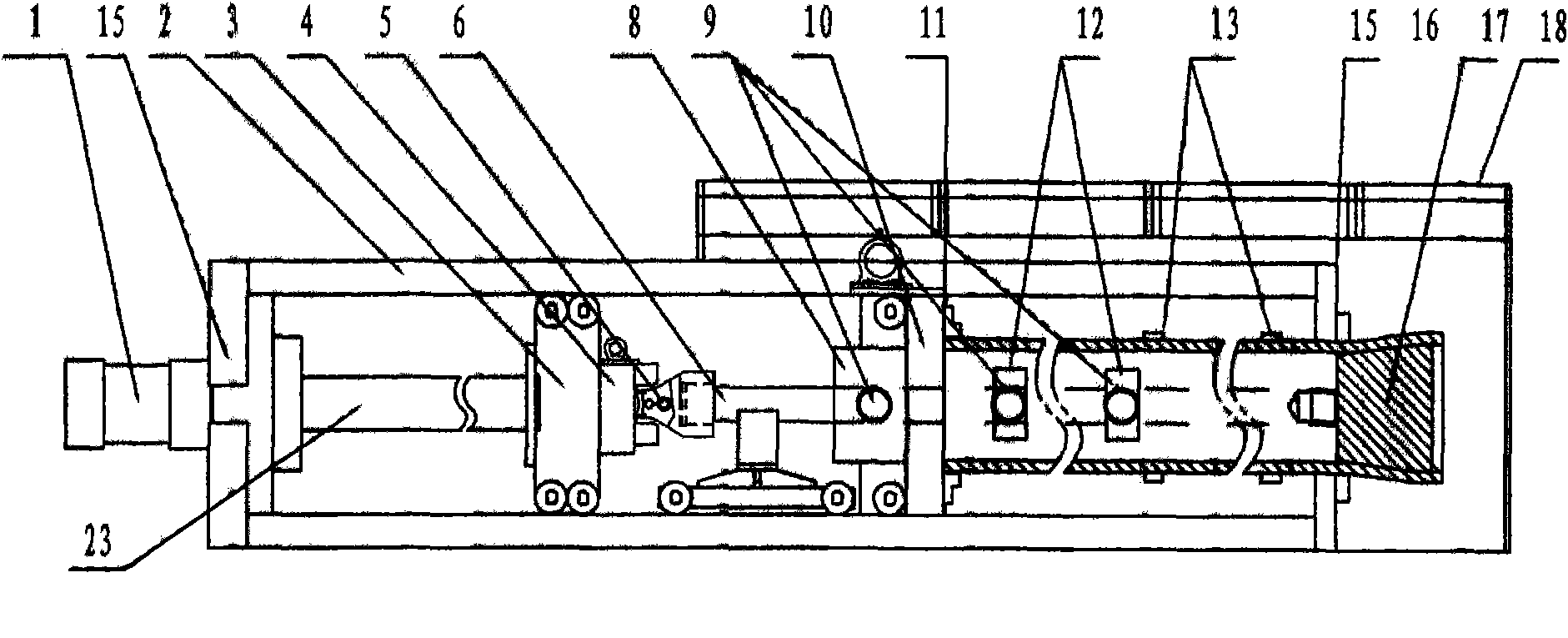

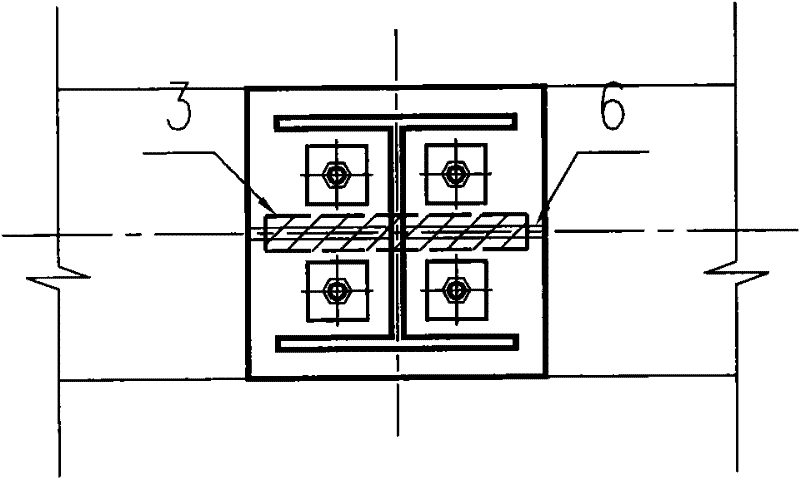

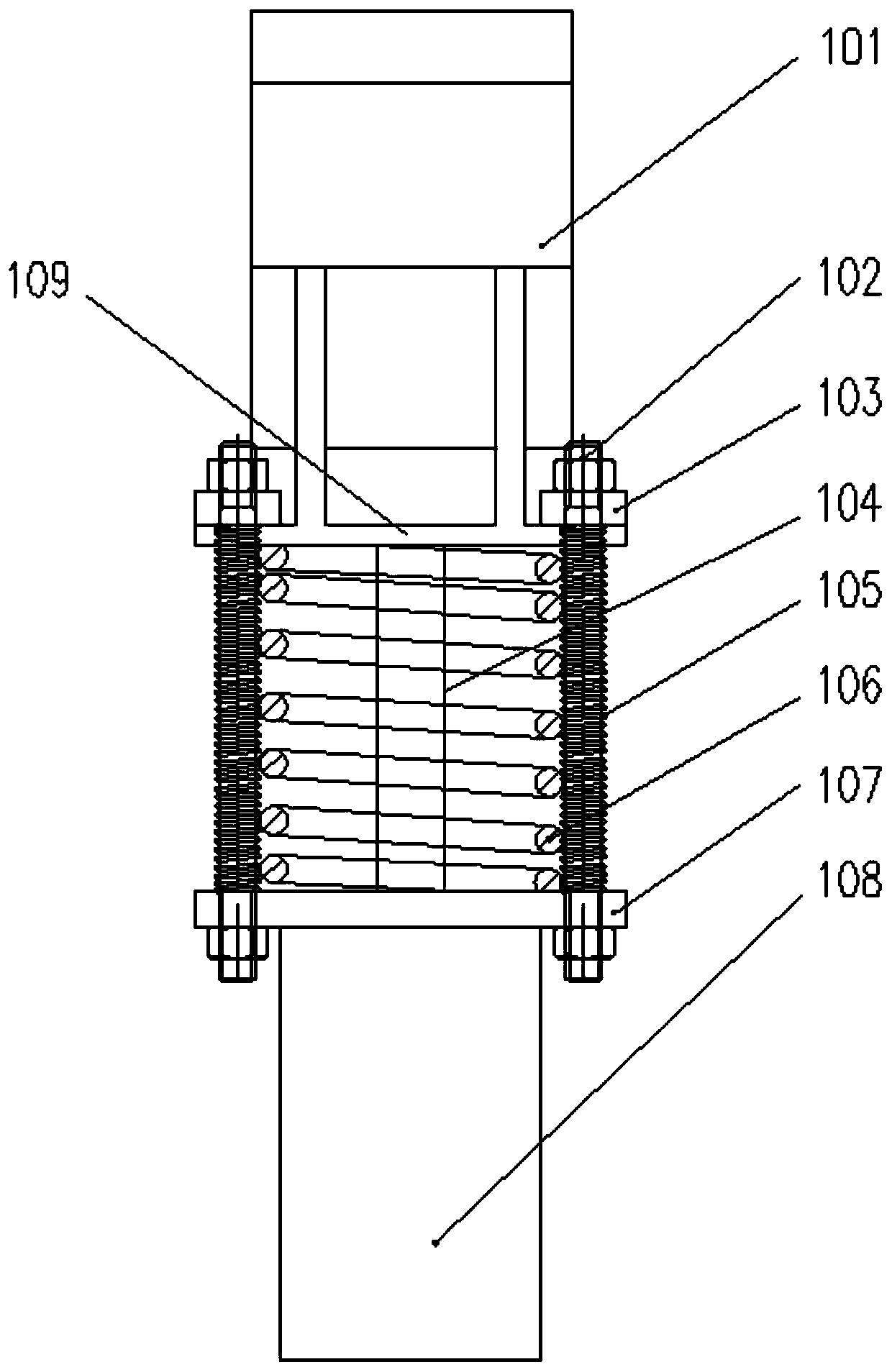

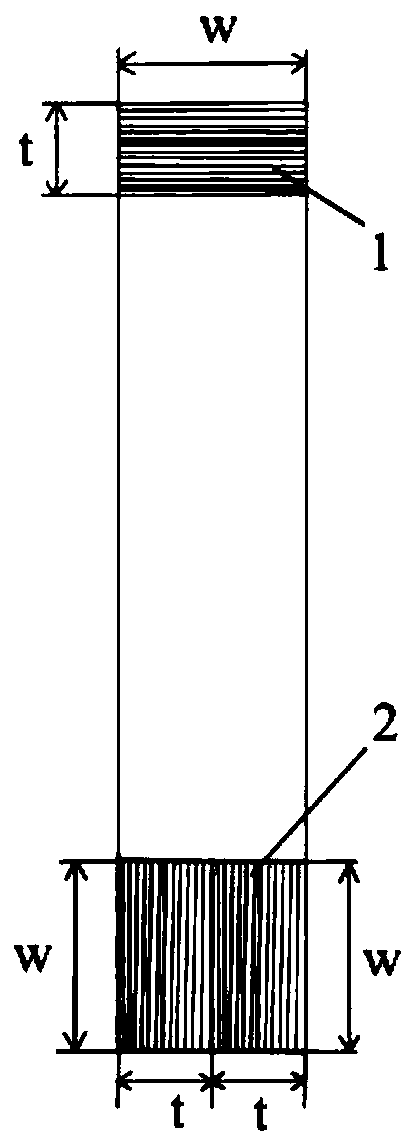

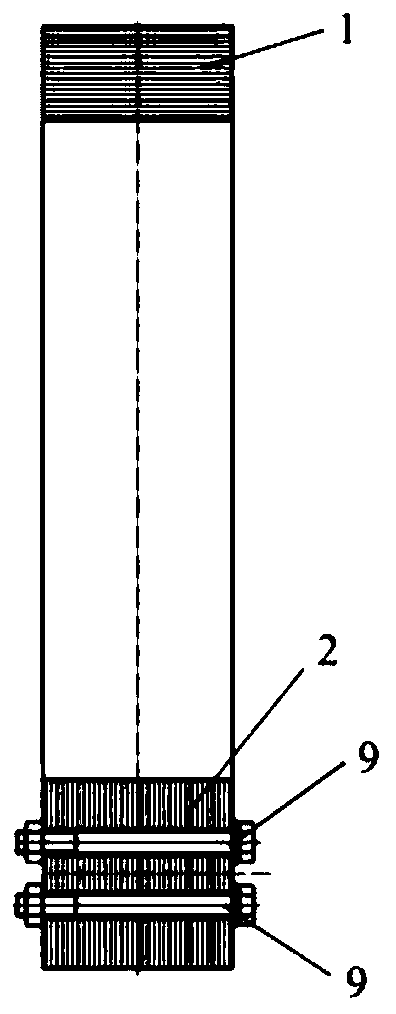

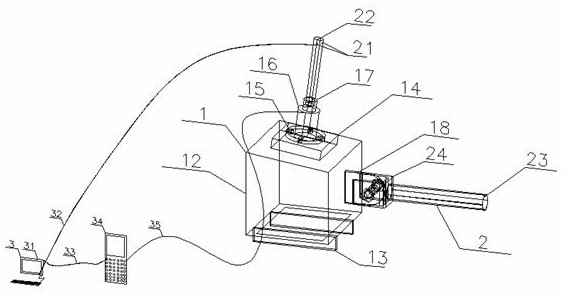

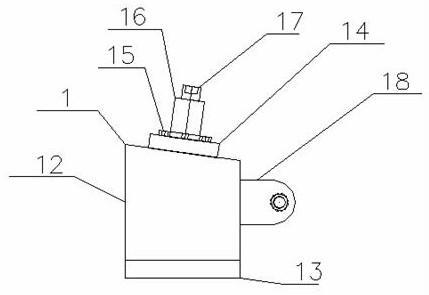

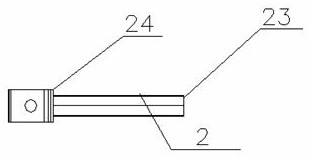

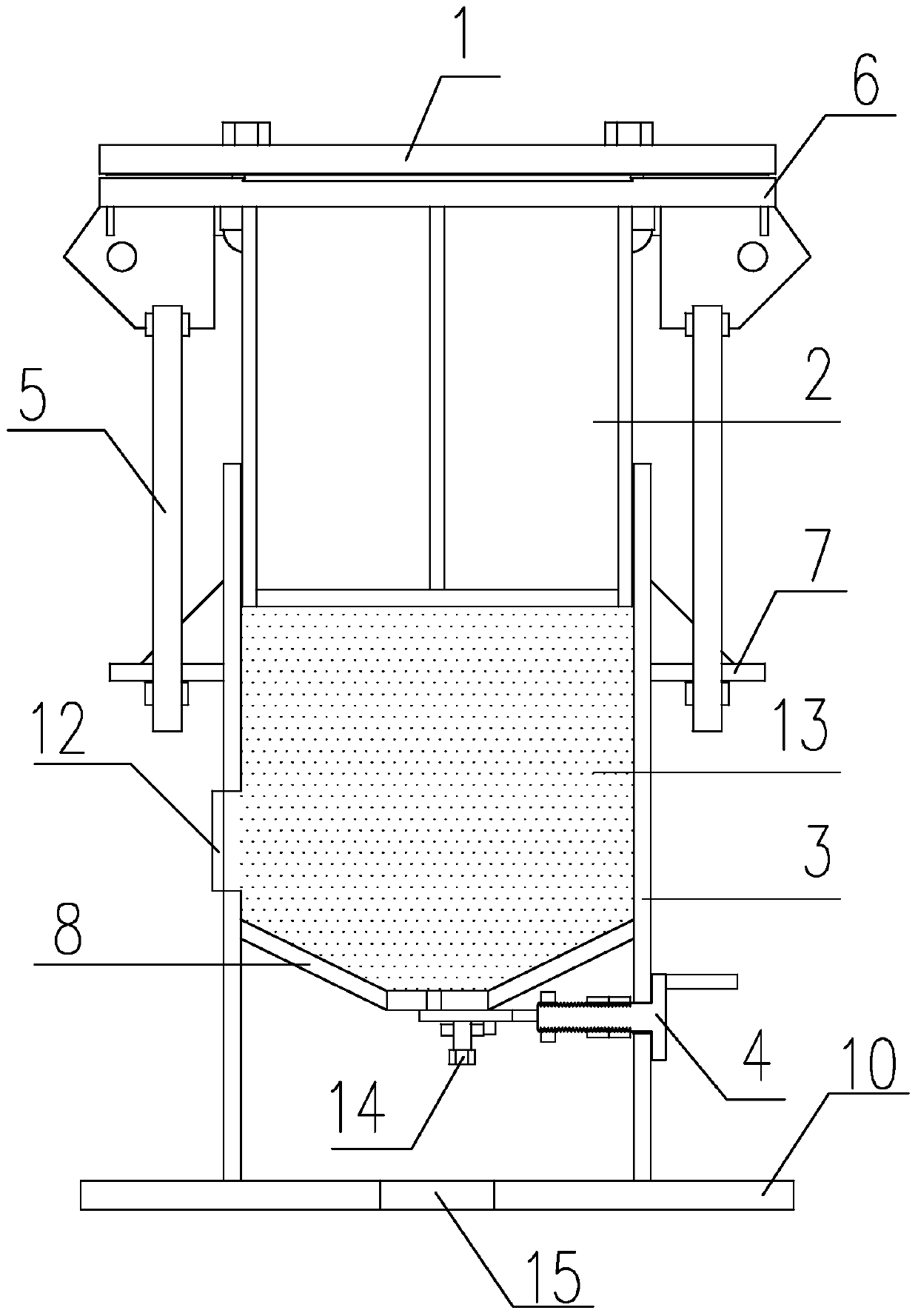

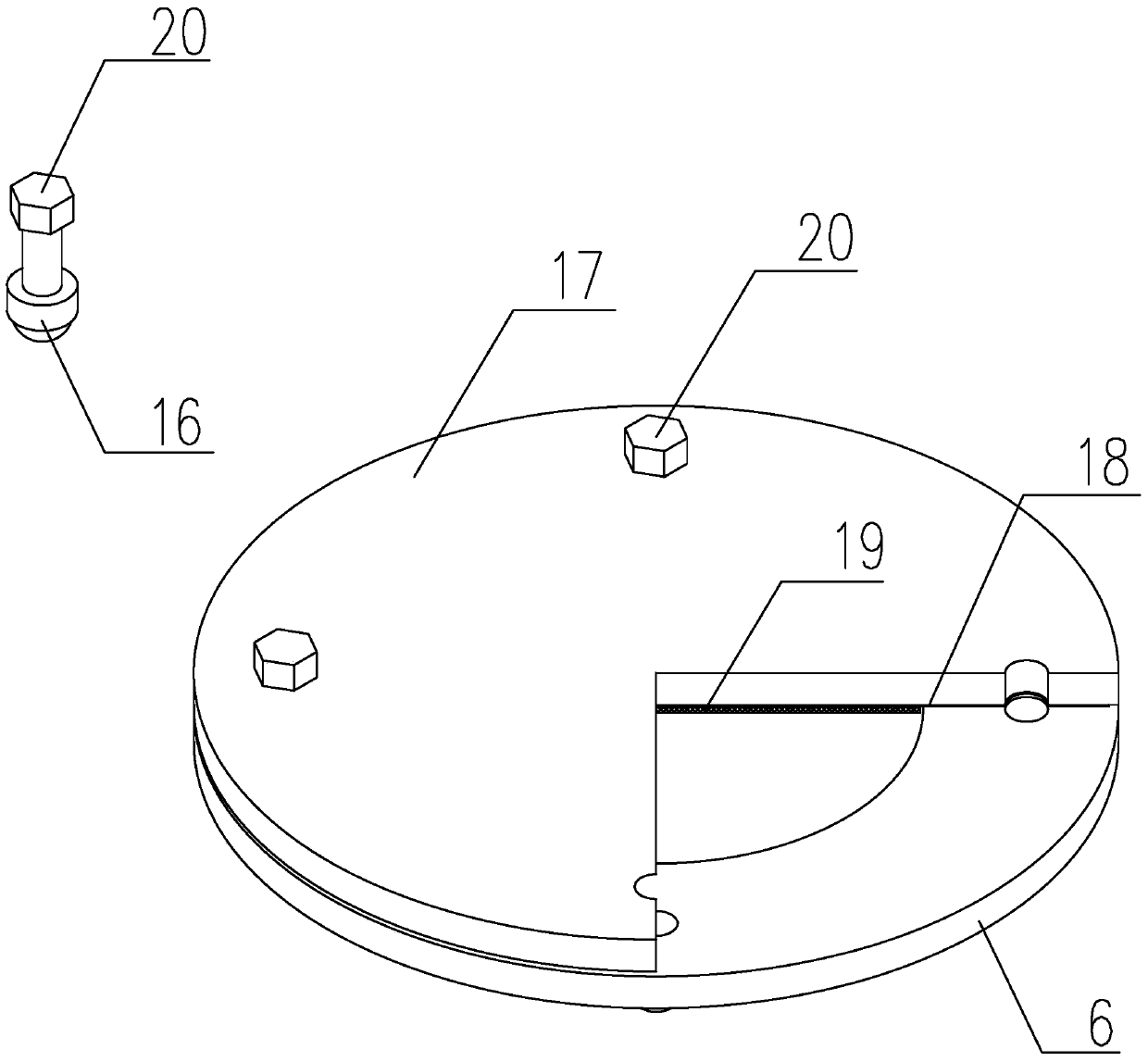

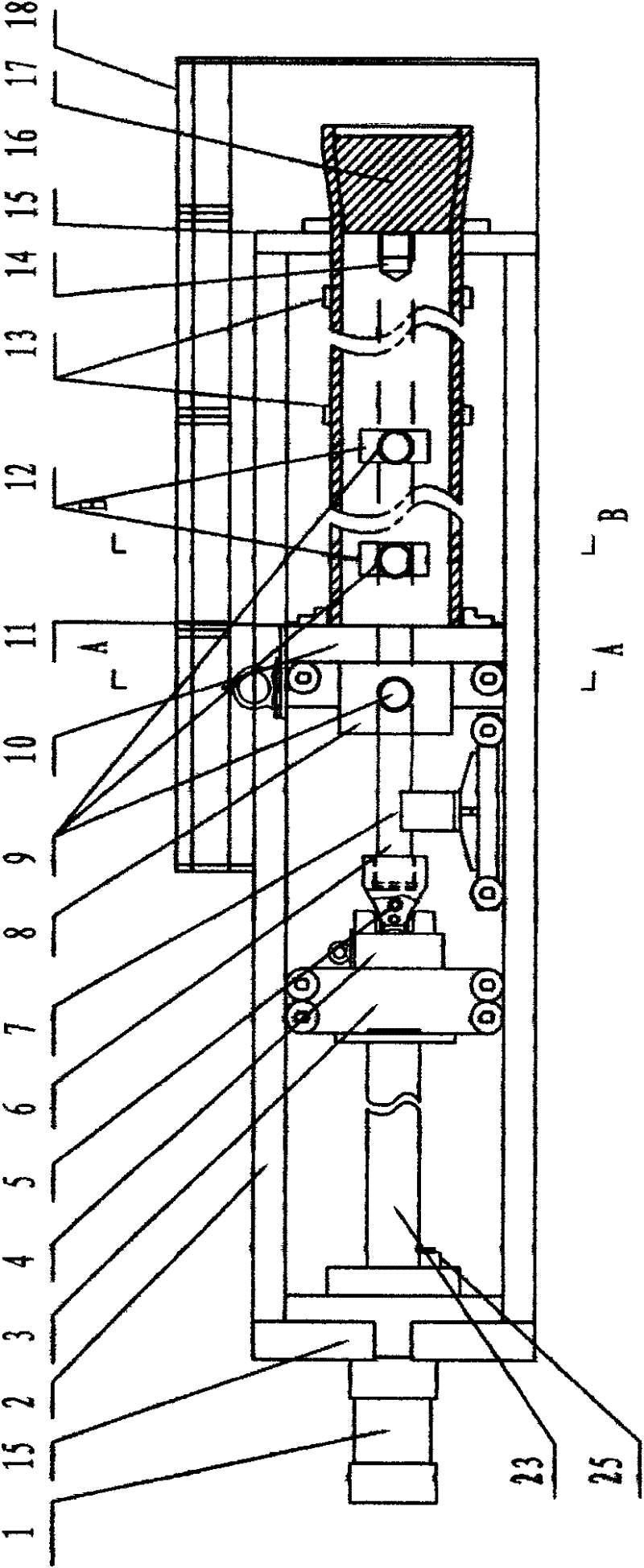

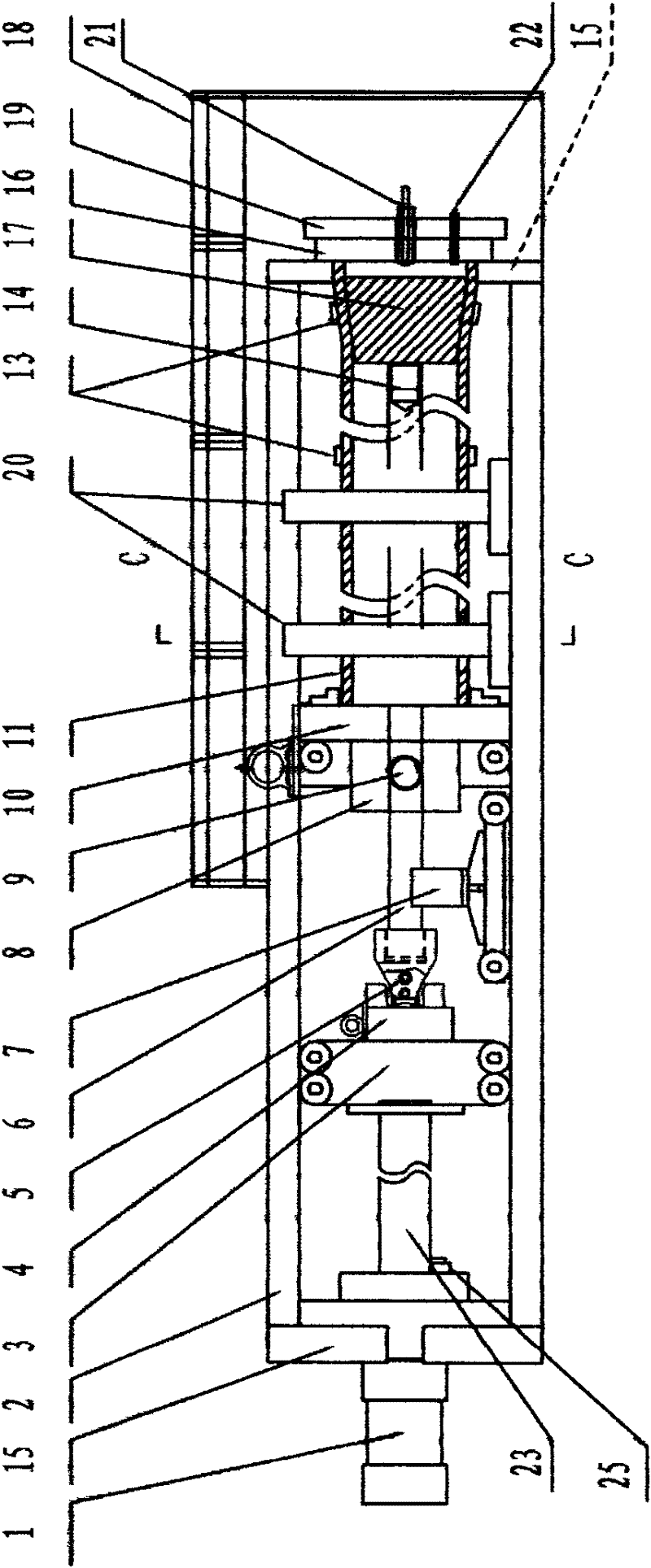

Combined loading expansion test device for entity expansion pipe

InactiveCN101957293BThe overall structure is simple and reliableMeasure displacement in real timeMaterial strength using tensile/compressive forcesEngineeringSensor system

The invention relates to a combined loading expansion test device for an entity expansion pipe, comprising a loading frame, an expansion test system, an expansion clamping system and a sensor system, wherein the expansion test system is fixed on the loading frame, and one side of the loading frame is provided with the expansion clamping system. The invention has simple and reliable structure, cansupply axial controllable mechanical tensile load of 0-2000kN and hydraulic pressure of 0-80Mpa, can realize the mechanical tensile expansion or hydraulic expansion or mechanical tensile and hydraulic pressure composite expansion test for the entity expansion whole pipe, can measure the displacement, the tensile load and the hydraulic pressure in an expansion test process and the radial deformation data of the entity expansion pipe in real time, can satisfy the expansion test of various sizes of entity expansion whole pipes or entity expansion pipe connecting structures, effectively avoids horizontal destabilization in a test process and provides an effective test device for detecting expansion performance, evaluating a research, improving the whole pipe structure and optimizing an expansion technology for the entity expansion pipe.

Owner:XIAN SANHUAN TECH DEV GENERAL

A combined connection structure and combined connection method of roof support and I-shaped steel purlin

The invention relates to the technical field of arrangement of steel structure roof support, and discloses a built-up connection structure and a built-up connection method for roof support and I-steel purlins. The built-up connection structure is provided with a plurality of steel roof truss structures and a plurality of roof support structures which are connected into a net-shaped connection structure. Each steel roof truss structure comprises a steel roof truss upper chord and a purlin which are perpendicularly connected in a cross mode. Four corners of the panel point where each purlin is connected with each steel roof truss upper chord are connected with a roof support rod in an inclined mode through a structural steel piece and a connecting plate. Each roof support structure comprises a connecting beam and a purlin which are perpendicularly connected in an overlapped mode. Four corners of the panel point where each purlin is connected with each connecting beam are connected with the roof support structure in an inclined mode through a connecting plate. According to the built-up connection structure and the built-up connection method for the roof support and the I-steel purlins, the purlins can concurrently serve as pressure levers so as to prevent the roof upper chords from being unstable along the side direction. Meanwhile, the purlins and the connecting beams can further and concurrently serve as tie bars of the roof support. The area of the roof support is divided into sizes with good economical efficiency and applicability. The built-up connection structure is convenient to arrange, simple in structure, easy to machine and low in manufacture and machining cost.

Owner:芜湖金康建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com