Method for performing expansion test of combined loads on solid expansion pipe

A technology of expansion test and composite load, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve the unfavorable quality control of physical expansion tubes, the lack of expansion performance test evaluation, and the inability to ensure the safety and reliability of expansion tubes, etc. problems, to achieve the effect of avoiding instability in the lateral direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

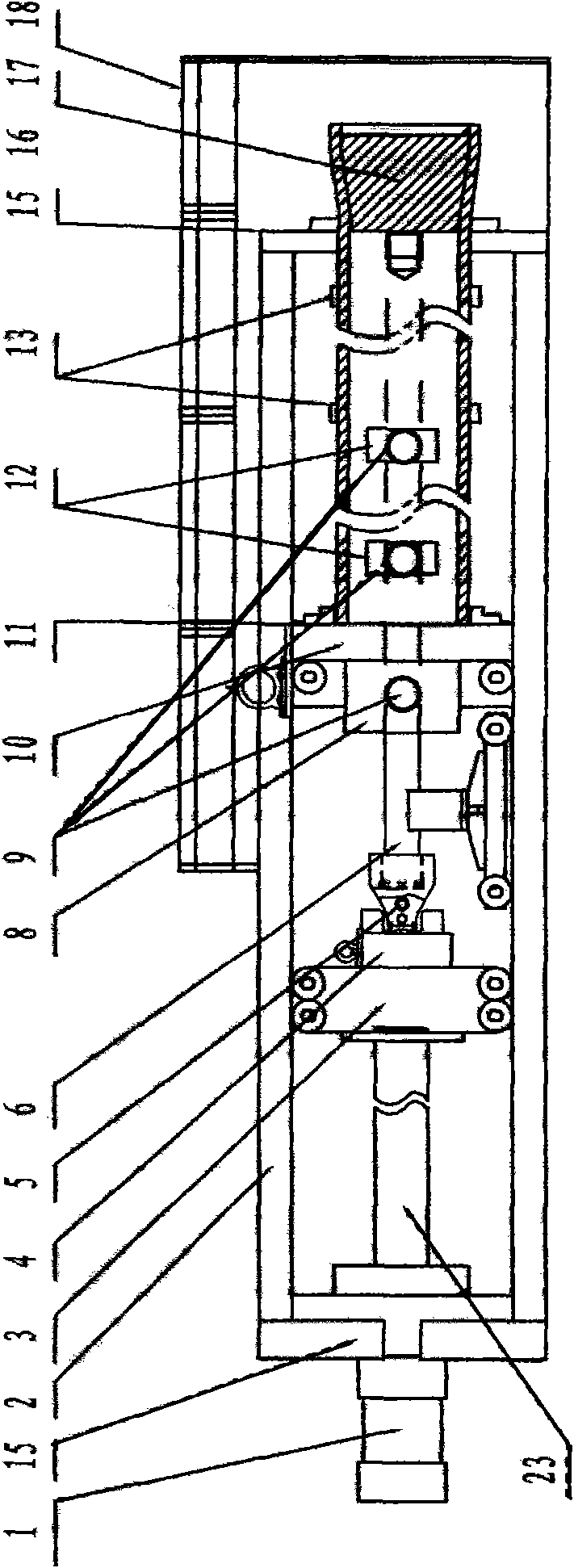

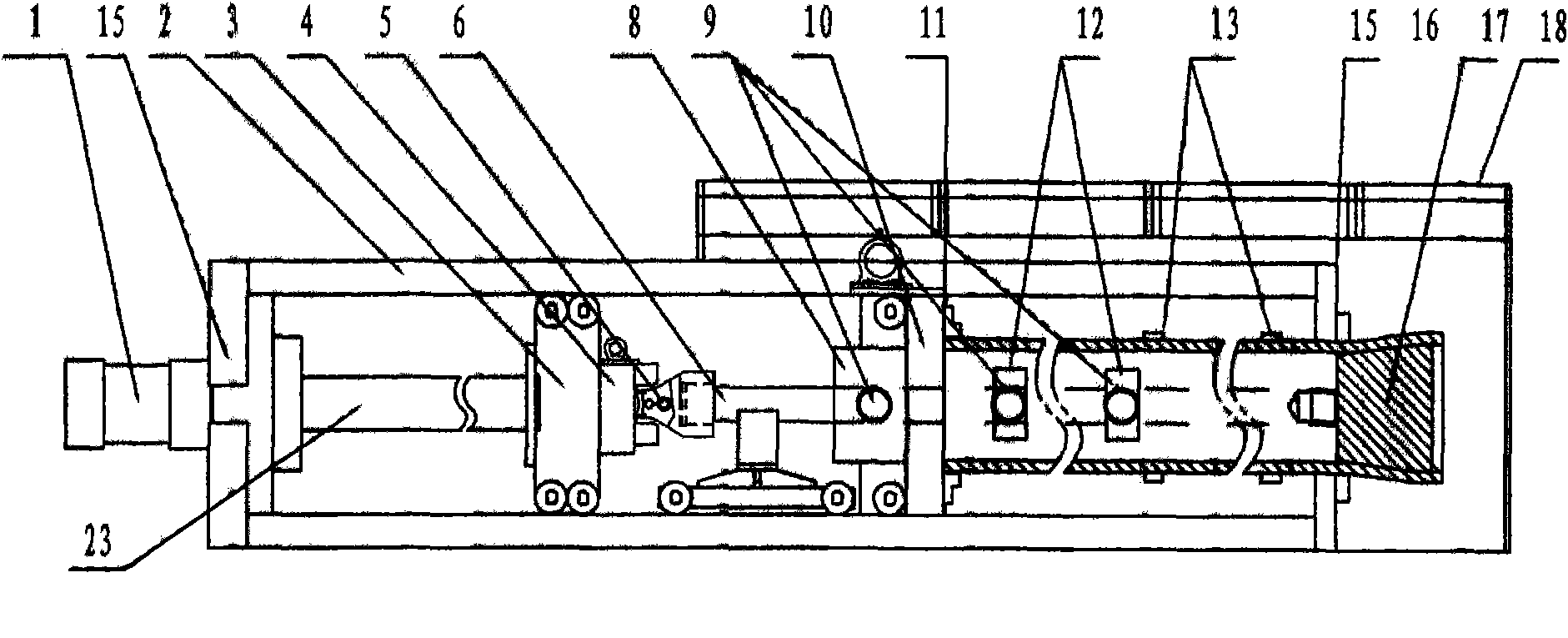

Embodiment 1

[0021] 1), sample and expansion cone preparation. Prepare a J55 steel grade solid expansion tube 11Φ139.7mm×7.72mm×10000mm. After inspection, there is no surface defect. The cross-section at both ends of the sample 11 is perpendicular to the axis of the tube body. The outer diameter is 143 mm, the outer diameter of the expansion cone is the same as the inner diameter after expansion of the solid expansion tube 11 sample, and the expansion cone angle is 8 degrees. Calculate the expansion range of the expansion cone:

[0022] The expansion range of the expansion cone = (the outer diameter of the expansion cone - the inner diameter of the solid expansion tube sample) / the inner diameter of the solid expansion tube sample

[0023] The expansion cone expansion range is 15%.

[0024]2), the end swelling. Put the sample 11 through the pull rod 6 and put it into the expansion test device, control the three-grip chuck 10 and the positioning flange 16 to fix the expansion tube sample...

Embodiment 2

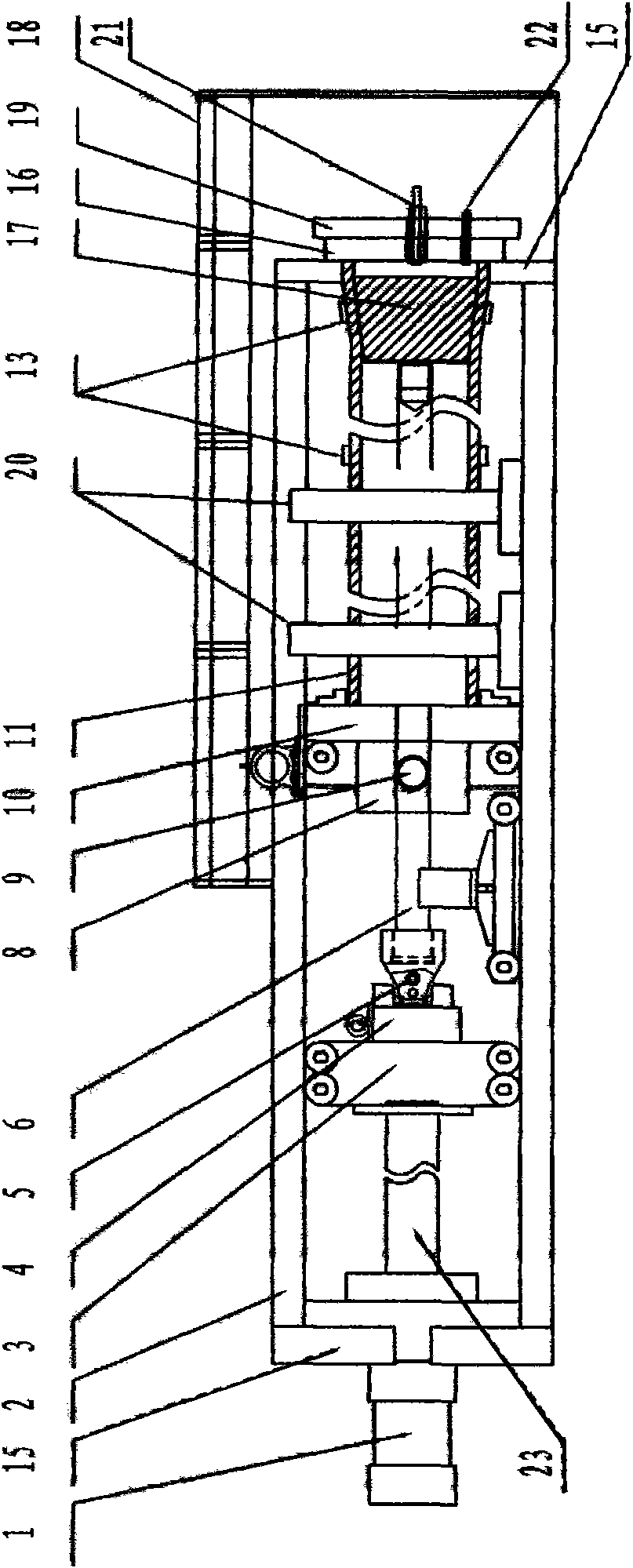

[0029] 1), sample and expansion cone preparation. Prepare two samples of L80 steel grade solid expansion pipe Φ177.8mm×9.19mm×5000mm, one of which has a direct-connection male thread and one with a direct-connection female thread, and the two sample threads are tightened to form a test Using expansion tube sample 11, no surface defects were found after inspection, and the outer diameter of the expansion cone was selected to be 180.3 mm, the expansion cone angle was 8 degrees, and the expansion range of the expansion cone was 13.1%.

[0030] 2), the end swelling. Open the protective cover 18, put the solid expansion tube sample 11 into the pull rod 6 and hang it into the right side of the expansion test device together, control the three-grip chuck 10 and the positioning flange 16 to fix the expansion tube sample, and ensure that the center of the sample is the same as the pull rod 6. The center of the piston rod 23 is coaxial, adjust the position of the middle beam so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com