A funnel type sand box unloading device and method

An unloading device and funnel-type technology, applied in construction, building structure, construction material processing, etc., can solve problems such as increasing the difficulty of on-site control, low sand box height, affecting unloading operations, etc., and achieve intuitive operation and data reading. , The effect of simple processing and production process and low processing and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing.

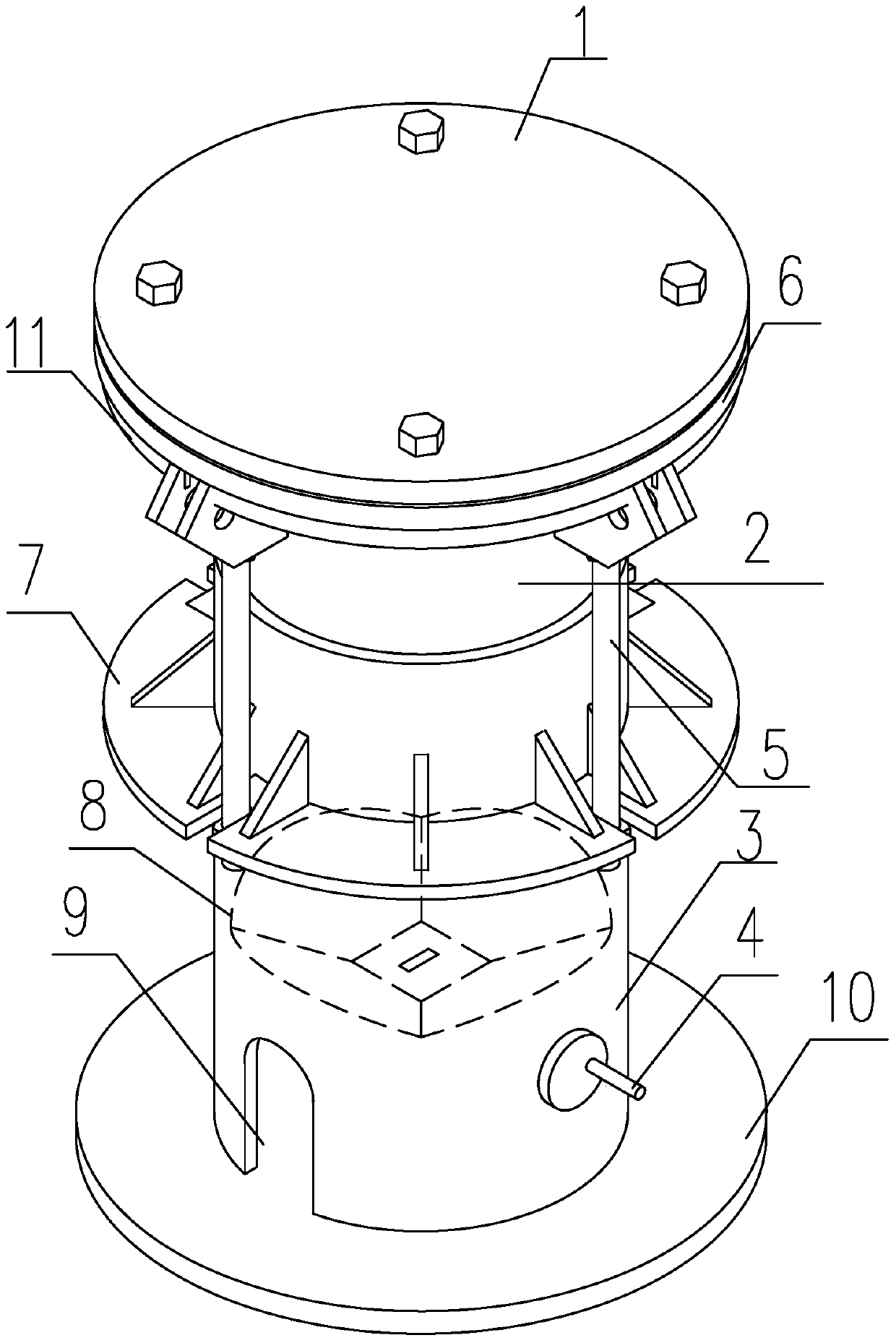

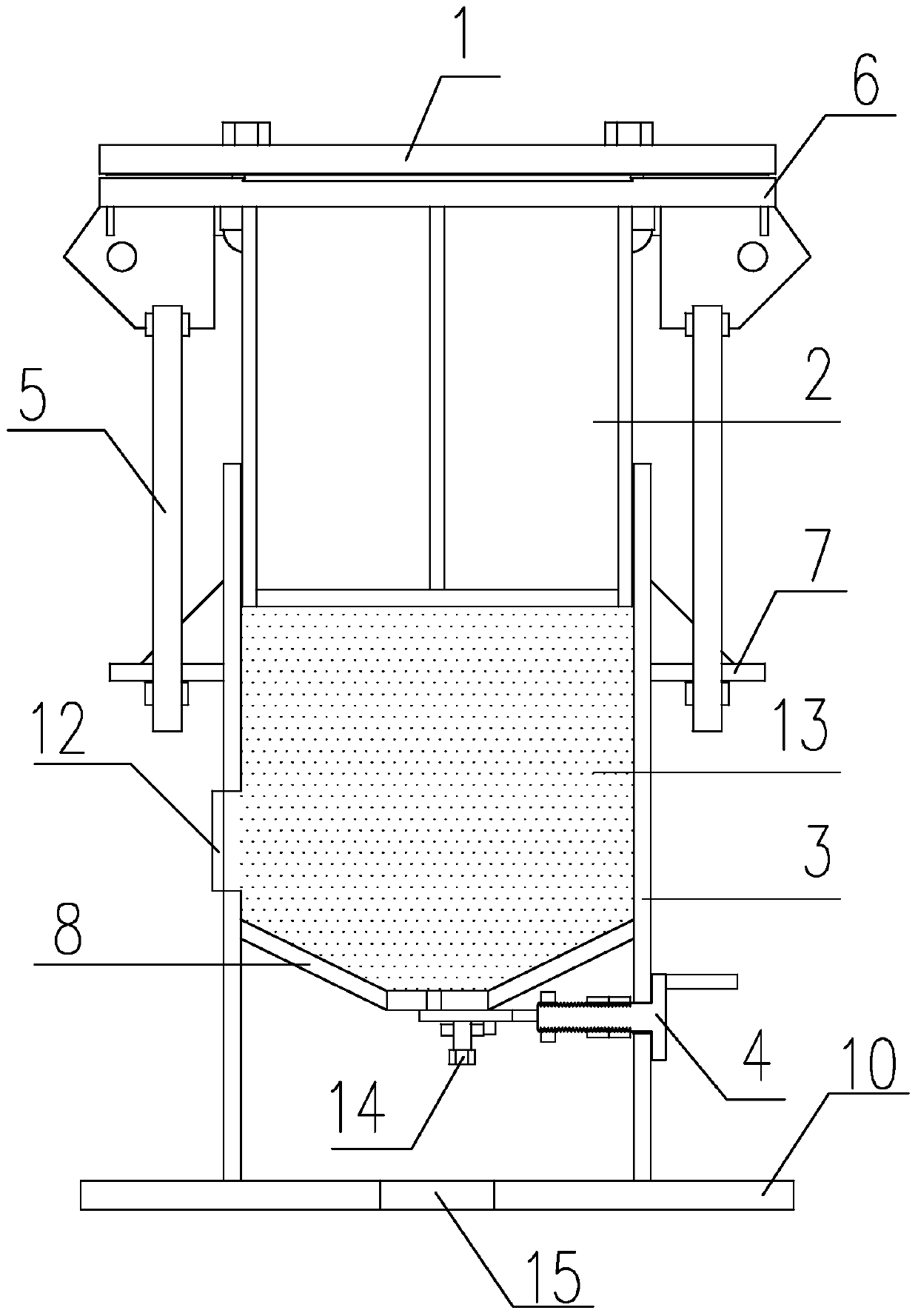

[0041] The invention provides a funnel-type sand box unloading device, which can be well applied to the unloading of support frames in steel structure engineering, such as Figure 1~2 As shown, the sand box device mainly includes:

[0042] Horizontal displacement release part 1, inner cylinder 2, outer cylinder 3, dry sand 13, plug-in sand discharge valve 4 and temporary connecting rod 5;

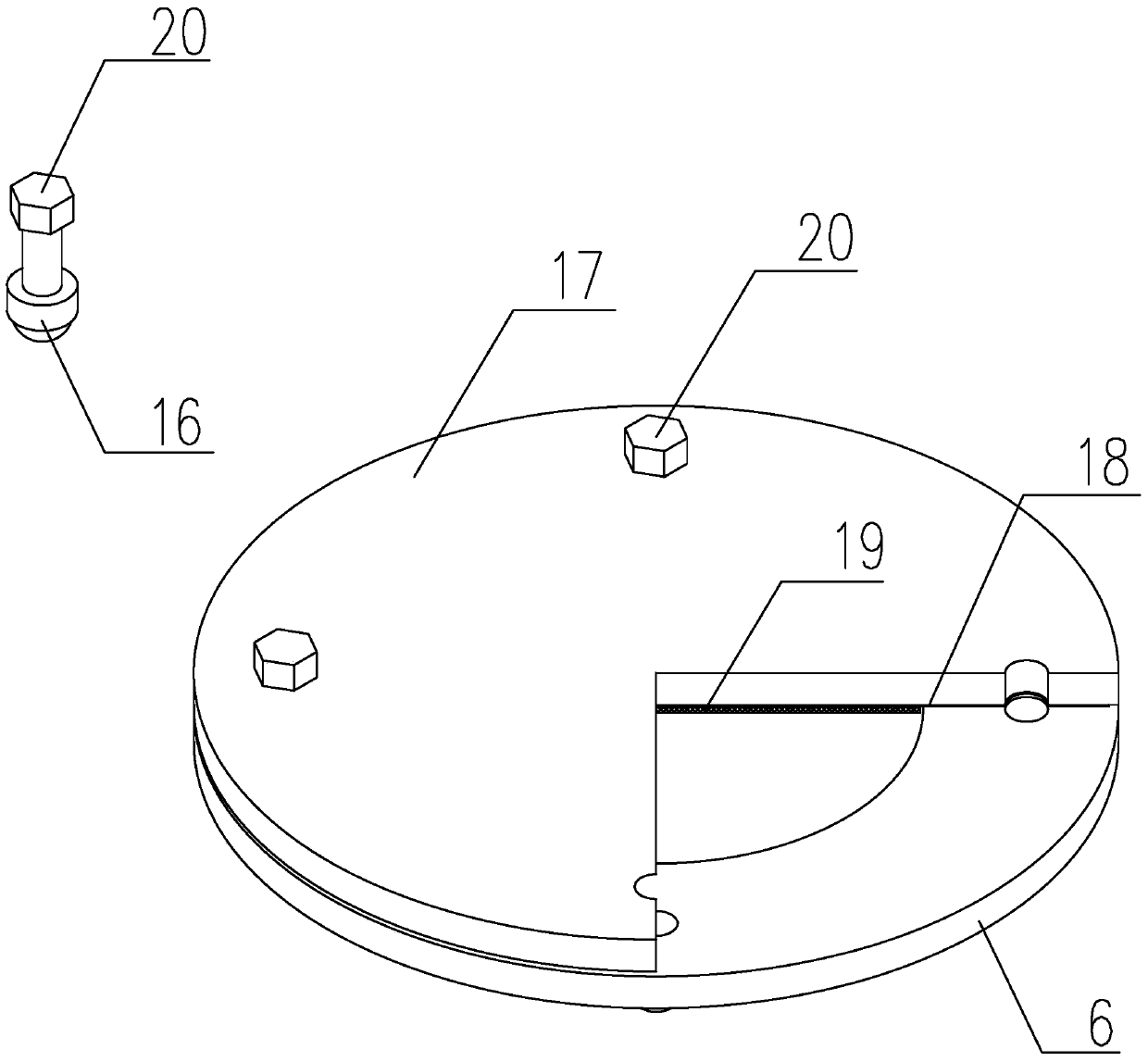

[0043] The horizontal displacement release part 1 is fixed on the top plate 6 of the inner cylinder; the inner cylinder 2 and the outer cylinder 3 are both made of seamless round tubes, and the contact surfaces of the outer cylinder 3 and the inner cylinder 2 are closely matched by machining, and both The gap between them is controlled at 1mm~2mm; a drip line 11 is set at the edge of the inner cylinder top plate 6; the outer cylinder 2 is equipped with a funnel-shaped sand guide groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com