Combined loading expansion test device for entity expansion pipe

A technology of expansion test and composite loading, which is applied in the direction of measuring device, using stable tension/pressure testing material strength, instruments, etc., can solve the problem of unfavorable expansion tube quality control, lack of expansion performance test device, and inability to ensure expansion tube In order to achieve the effect of simple and reliable structure and avoid lateral instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

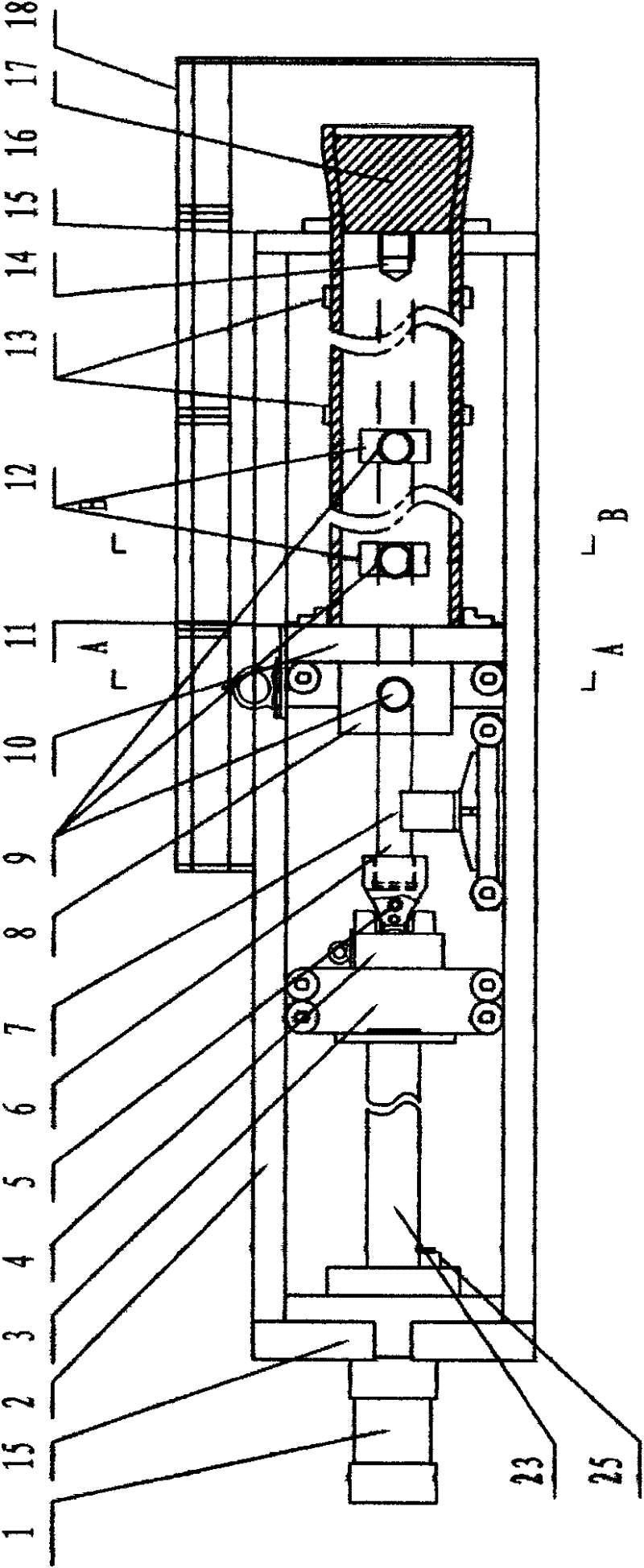

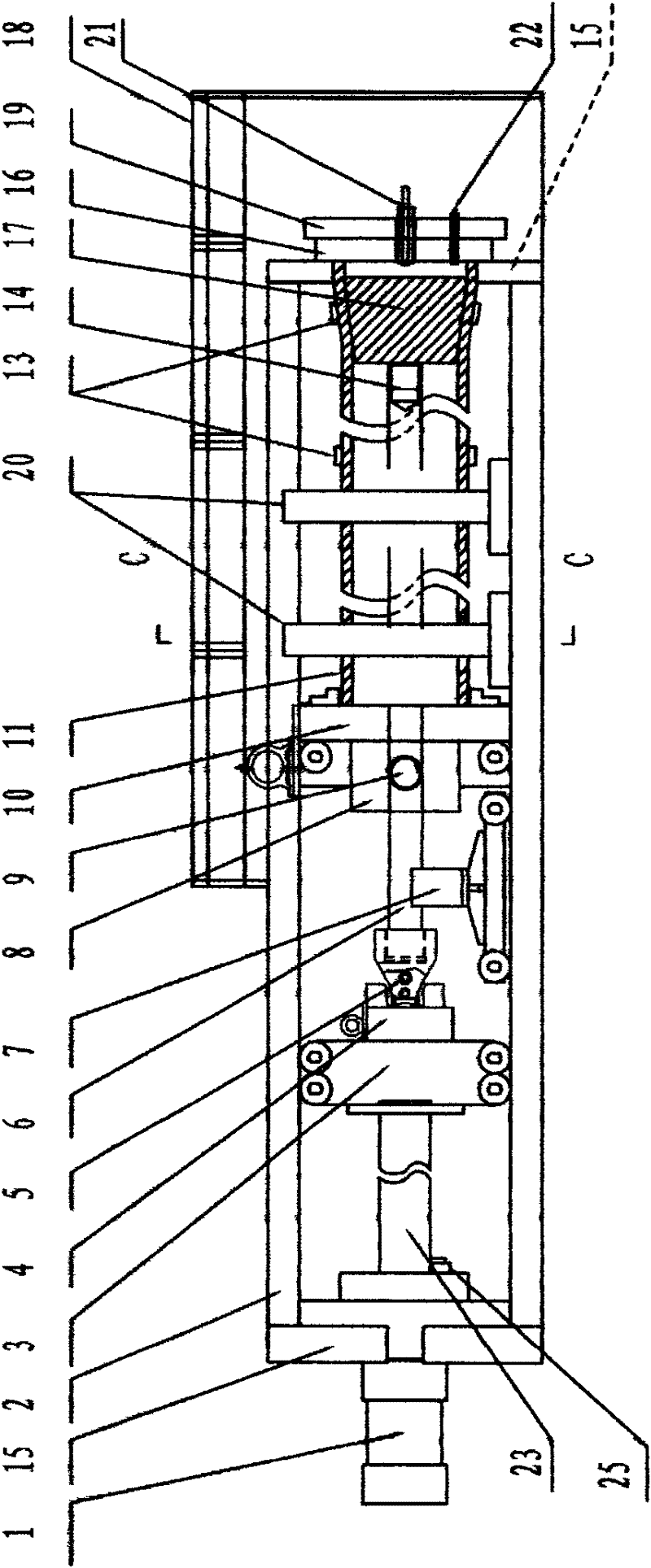

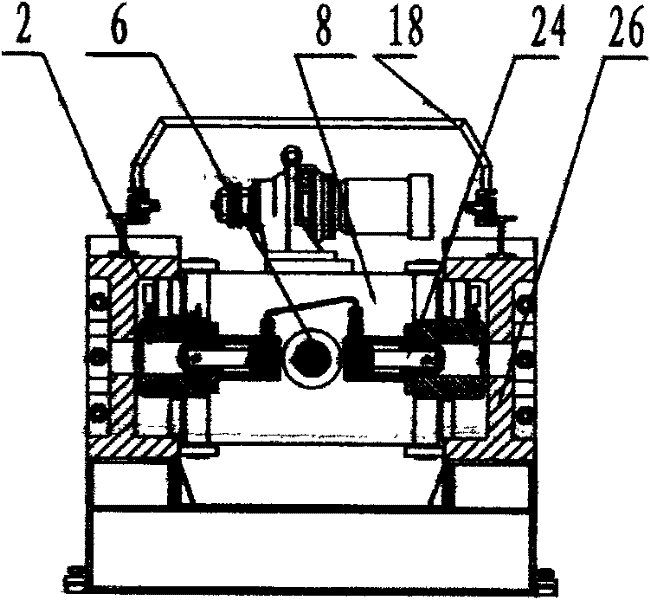

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0015] The invention consists of a loading frame, an expansion test system, an expansion clamping system and a sensor system. The loading frame is composed of end beam 15, guide rail 2, guide beam 3, middle beam 8, and frame side wall 26. The guide beam 3 and middle beam 8 can move axially along the guide rail 2, and the middle beam 8 is provided with hydraulic pins laterally 24. It can be connected with the pin hole 9 on the side wall 26 of the frame to fix the middle beam 8. The expansion test system includes a hydraulic cylinder 1, a piston rod 23, a pull rod 6, an expansion cone 17, a positioning flange 16 and a high-pressure water injection mechanism 21. The hydraulic cylinder 1, the piston rod 23, the pull rod 5, and the expansion cone 17 are sequentially connected to form a mechanical stretching and expansion test device. The positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com