Connecting structure of wind turbine generator cabin and dry-type transformer

A technology for dry-type transformers and wind turbines, which is applied in wind turbine combinations, wind power generation, transformer/reactor installation/support/suspension, etc., can solve the problems of rising land acquisition costs, difficulty in twisting and unwinding cables, and large electrical losses. Achieve the effect of reducing operation and maintenance costs and improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

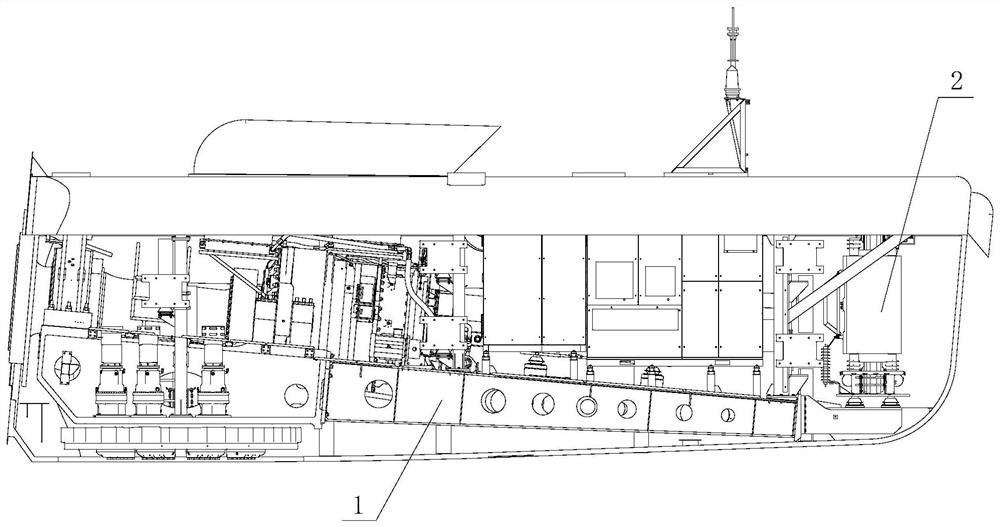

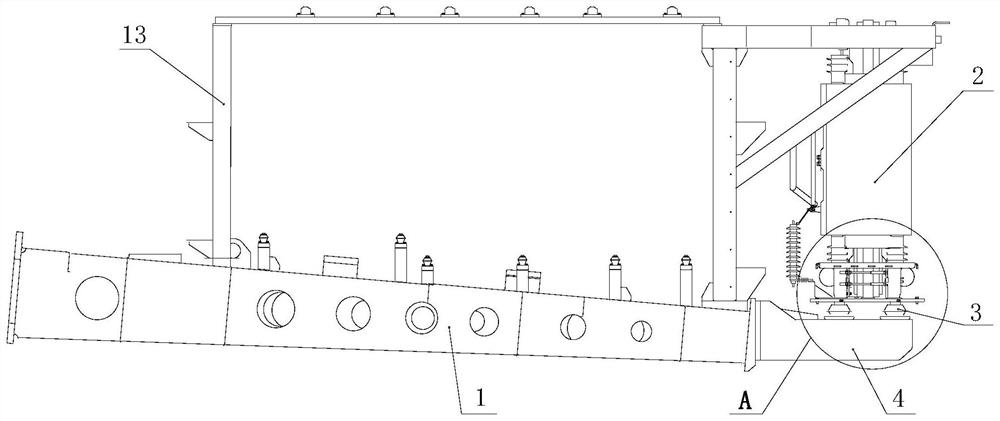

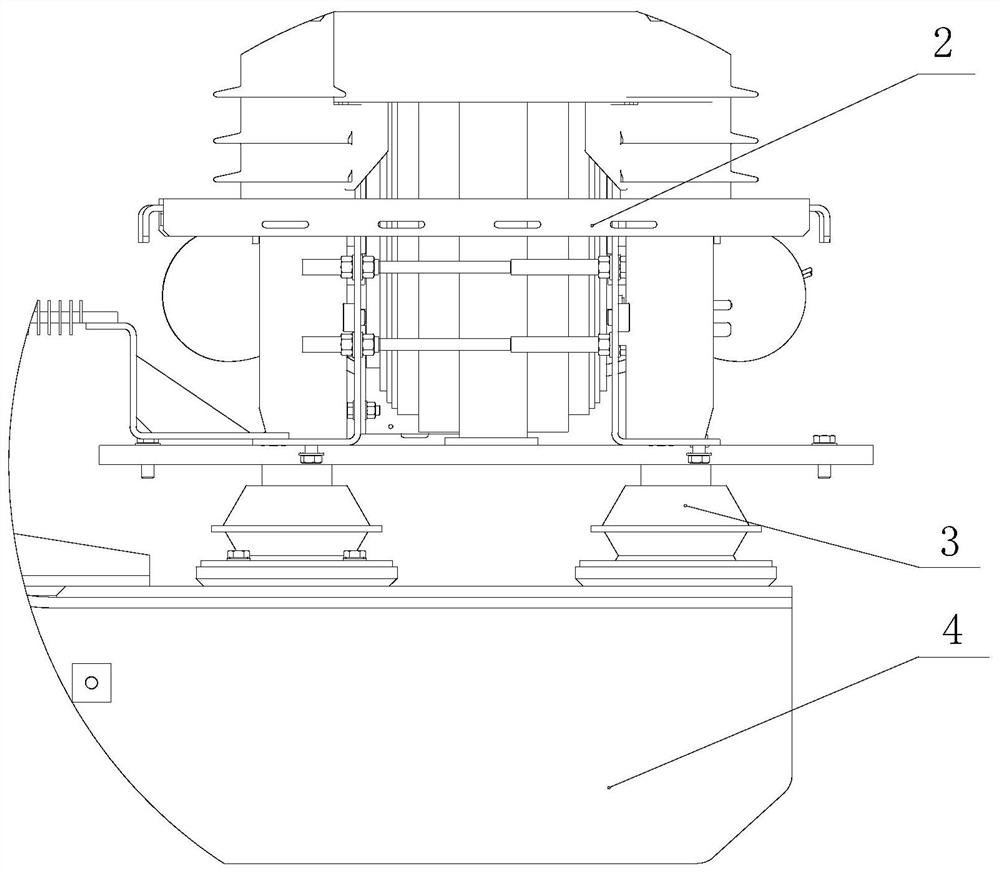

[0039] like Figure 1 to Figure 11 As shown, the connection structure between the wind turbine nacelle and the dry-type transformer of the present invention includes: a nacelle base 1, a dry-type transformer 2, a first elastic support member 3, a box transformer base 4 and a cable-stayed assembly 9; The bottom is connected with the nacelle base 1 through the first elastic support 3 and the box transformer base 4, and a bracket is provided on the nacelle base 1, and the top of the dry-type transformer 2 is connected with the top of the bracket through a cable-stayed assembly 9, and the Installation of the dry-type transformer 2 in the nacelle of the wind turbine.

[0040] In this embodiment, the top and bottom of the dry-type transformer 2 are flexibly connected to the engine room through the elastic support and the cable-stayed assembly 9, which not only realizes the connection and fixation of the dry-type transformer 2 and the engine room, but also can provide a solid foundatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com