Synthesized pipe rack with frame composite structure

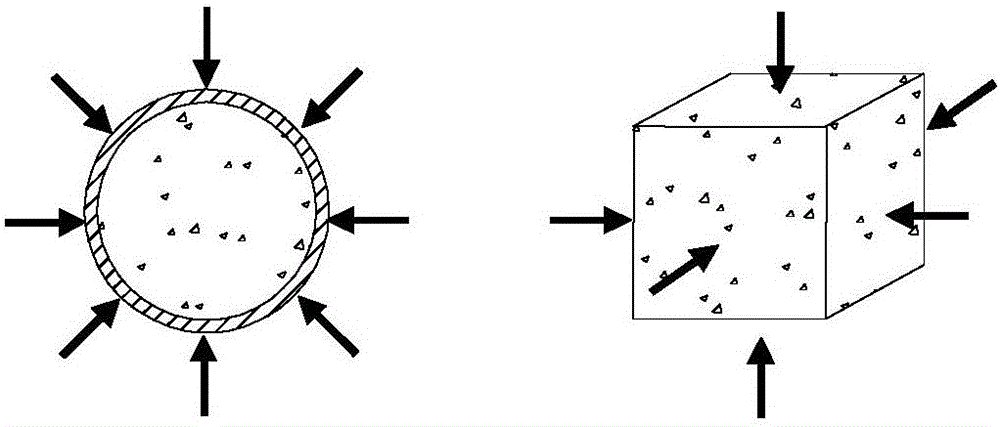

A technology of integrated pipe gallery and combined structure, applied in underwater structures, infrastructure engineering, hydraulic engineering and other directions, can solve the problems of limited bearing capacity, plate radian deformation, high processing cost, and achieve torsional stiffness and anti-distortion. Reduced stiffness, increased torsional and anti-distortion stiffness, small effects of torsional and anti-distortion stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

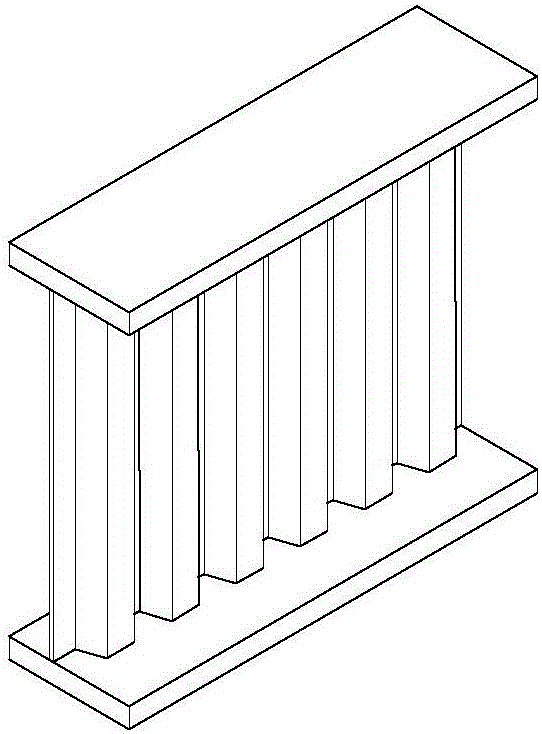

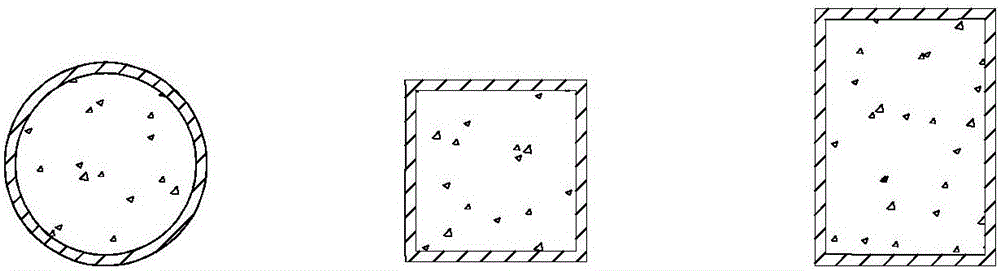

[0065] Such as Figure 15 As shown, the first frame-type composite structure integrated pipe gallery 100 disclosed in the present invention includes unit pipe joints 103 formed by combining unit plates 101 located on the upper and lower sides and side unit plates 102 located on both sides. The plates in the plate are all straight, such as Figure 13 , Figure 14 shown. Wherein, the plates in the unit plates can be arc-shaped or straight plates with small curvature, wherein the arc-shaped plates make the torsional rigidity of the unit plates higher, and the ability to resist vertical instability is stronger. Improve weld quality to a certain extent and reduce stress concentration. When the plate of the lower unit plate is straight, it can be used without paving, and its internal pipeline layout is more convenient, and it can be directly use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com