Patents

Literature

226results about How to "High structural efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

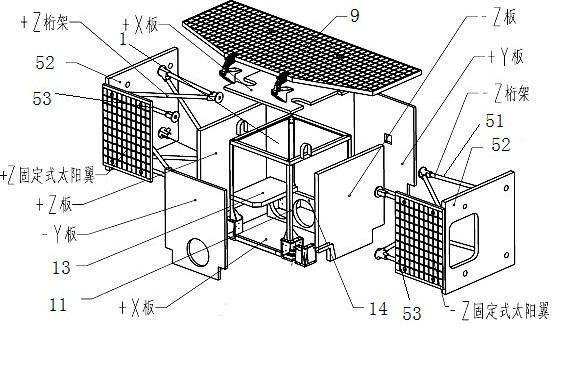

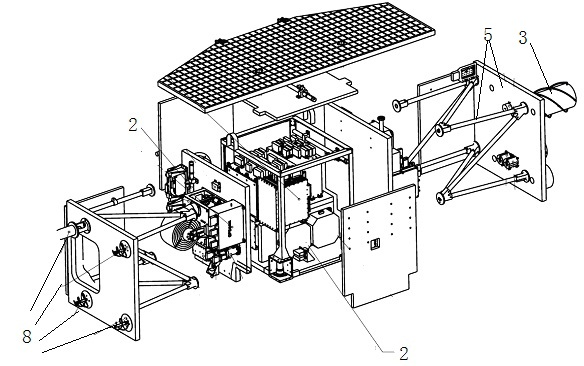

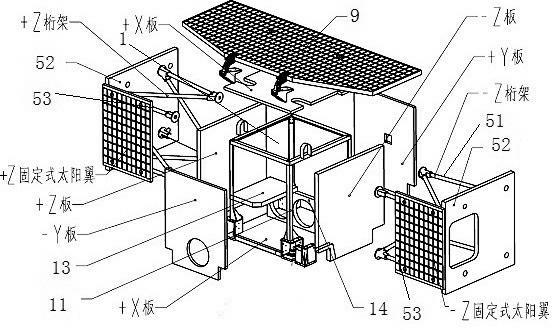

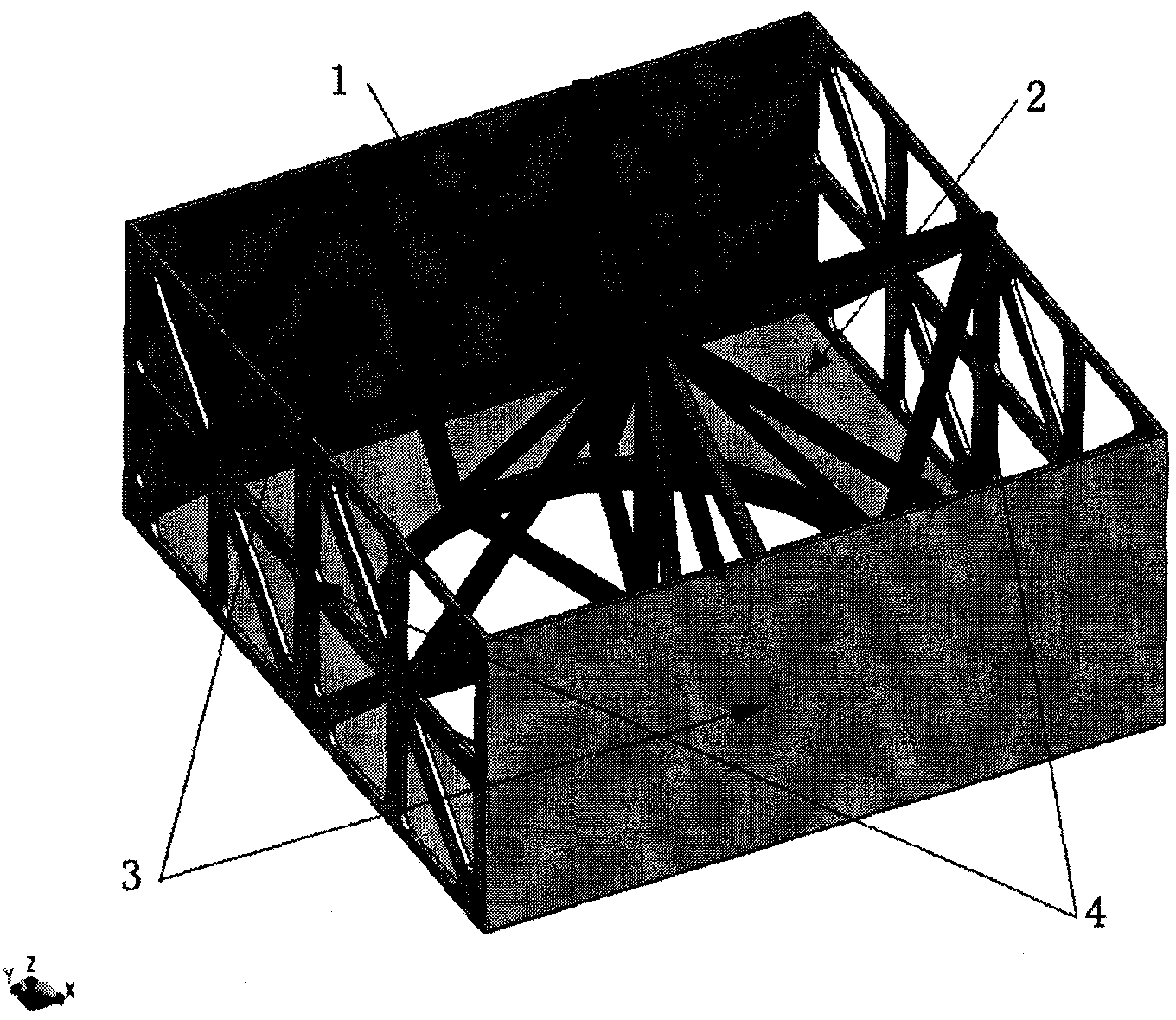

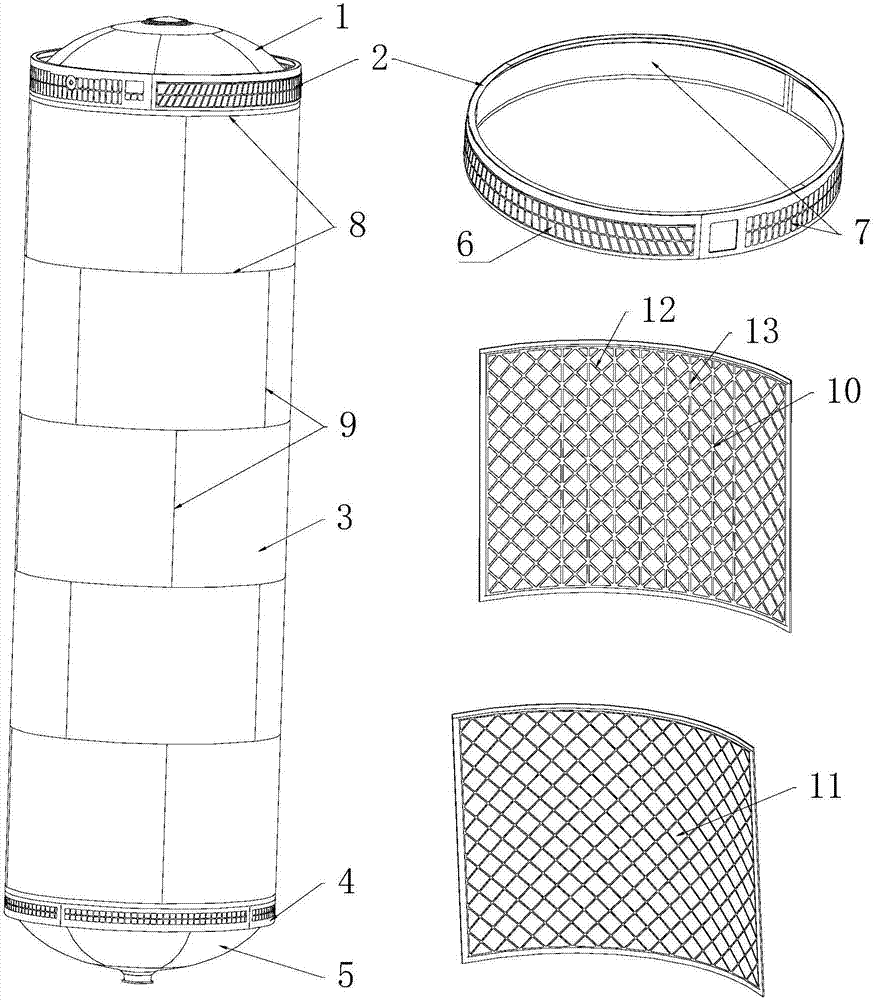

Truss-type satellite structure with central capsule

ActiveCN102616385AHigh structural efficiencyImprove space efficiencyArtificial satellitesSatellitePayload

The invention relates to a truss-type satellite structure with a central capsule, which comprises the central capsule, a satellite platform device, a payload device and a truss element. The satellite platform device is disposed on the central capsule and the truss element is disposed outside the central capsule. The central capsule is connected with the payload device through the truss element. The truss element comprises a truss and a truss plate which is connected with the truss. The wall of the central capsule is made of plates or shells. Due to the fact that interior of the capsule is used for installation of the satellite platform device and outside of the capsule is used for installation of the payload device, structure efficiency and spatial efficiency of the satellite are high, the structure efficiency can reach 19%, and the spatial efficiency can reach 400 kg per m3.

Owner:AEROSPACE DONGFANGHONG DEV LTD

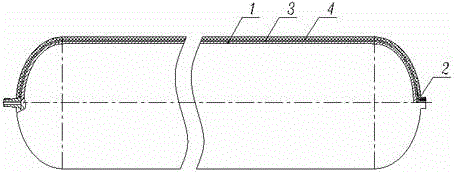

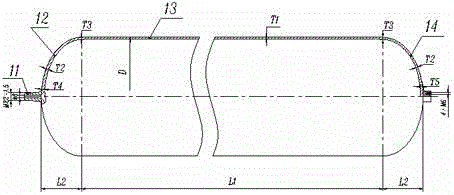

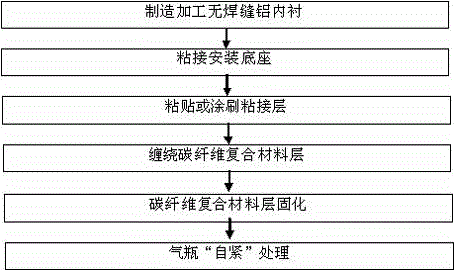

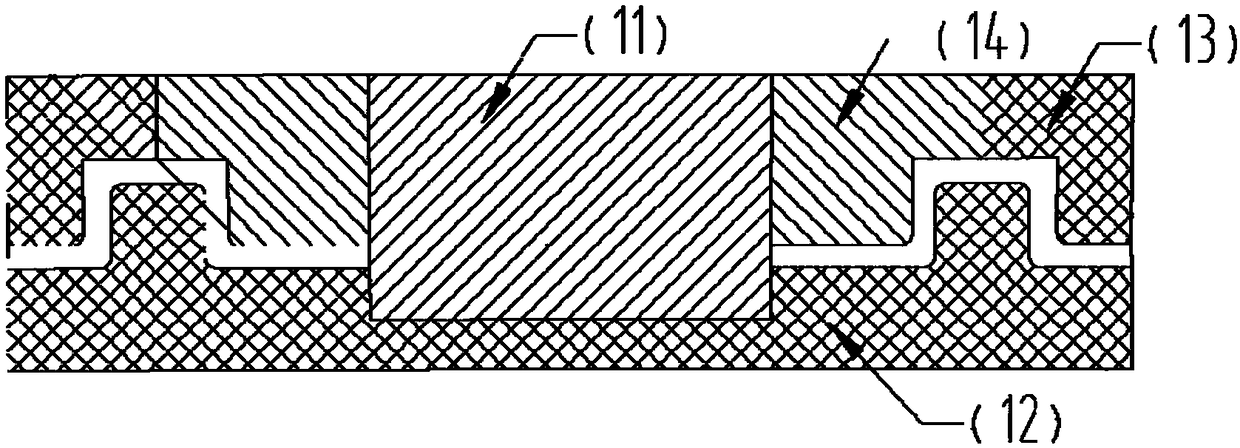

100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

The present invention provides a 100 L carbon fiber wrapped aluminum-lined composite cylinder, including a weldless aluminum liner, a mounting base, an adhesive layer and a carbon fiber composite layer. The mounting base and the weldless aluminum liner form a smooth flattening winding mandrel; the external part of the mandrel is wound by the carbon fiber composite layer; and the adhesive layer is arranged between the mandrel and the carbon fiber composite layer and is used for firmly connecting the weldless aluminum liner and the carbon fiber composite layer. The composite cylinder has the advantages of large volume, high pressure resistance, high efficiency, light weight, high security, low cost and short manufacturing cycle. The present invention also provides a manufacture method of the carbon fiber wrapped aluminum-lined composite cylinder.

Owner:SHANGHAI INST OF SPACE PROPULSION

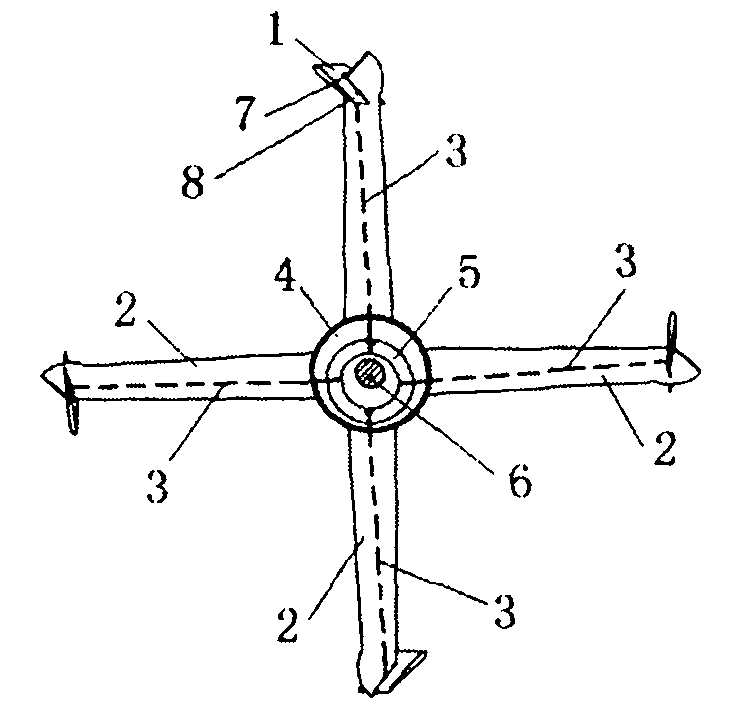

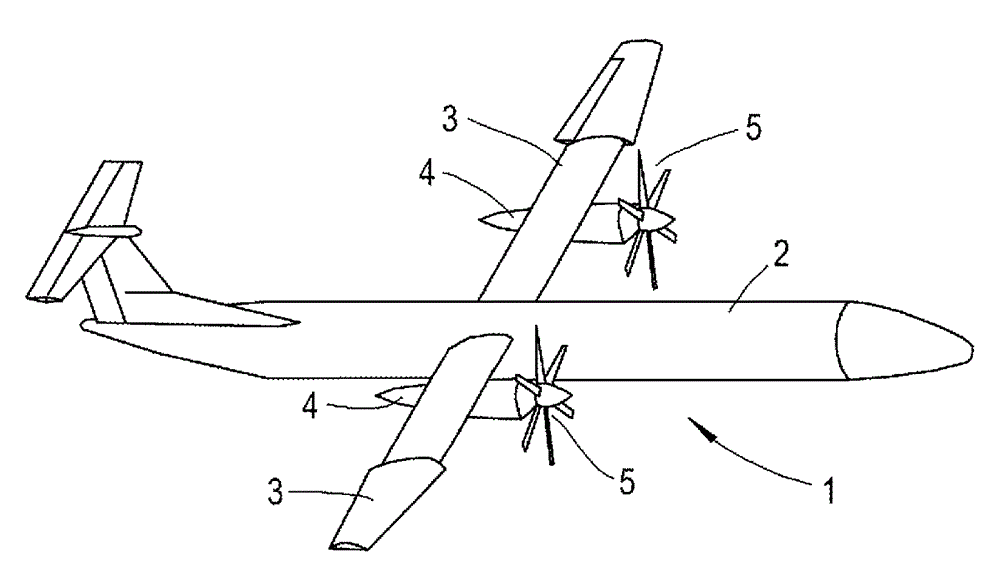

Omnidirectional vectored thrust cycloidal propeller

InactiveCN101863306AWith omnidirectional vector thrustImprove aerodynamic efficiencyPropulsive elements of rotary typePropellerFront edge

The invention discloses an omnidirectional vectored thrust cycloidal propeller, which comprises a propeller, a cycloidal oar and a cycloidal oar eccentric circle positioning mechanism, wherein the cycloidal oar comprises cycloidal oar blades in the same number as propeller blades, control pull rods, an operating rock arm and a cycloidal oar blade spherical hinge; each cycloidal oar blade is hinged with a propeller blade at rear grazing point of the front edge of the propeller blade; the airfoil surface of each cycloidal oar blade is vertical to that of a propeller blade; an eccentric circular ring of the cycloidal oar eccentric circle positioning mechanism is sleeved on a propeller shaft; the connecting rod of the spherical head of each spherical hinge is connected with the eccentric circular ring respectively; each control pull rod is connected with a cycloidal oar blade; the operating rock arm is positioned in a spanwise symmetrical surface of the cycloidal oar blades; the cycloidal oar blade spherical hinge at one end of the operating rock arm is connected with one end of the control pull rods; and the other end of the operating rock arm is fixedly connected to a cycloidal oar blade tubular beam. The omnidirectional vectored thrust cycloidal propeller of the invention combines the advantages of the cycloidal oar and the conventional propeller and has an omnidirectional vectored thrust while improving aerodynamic efficiency of the conventional propeller.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

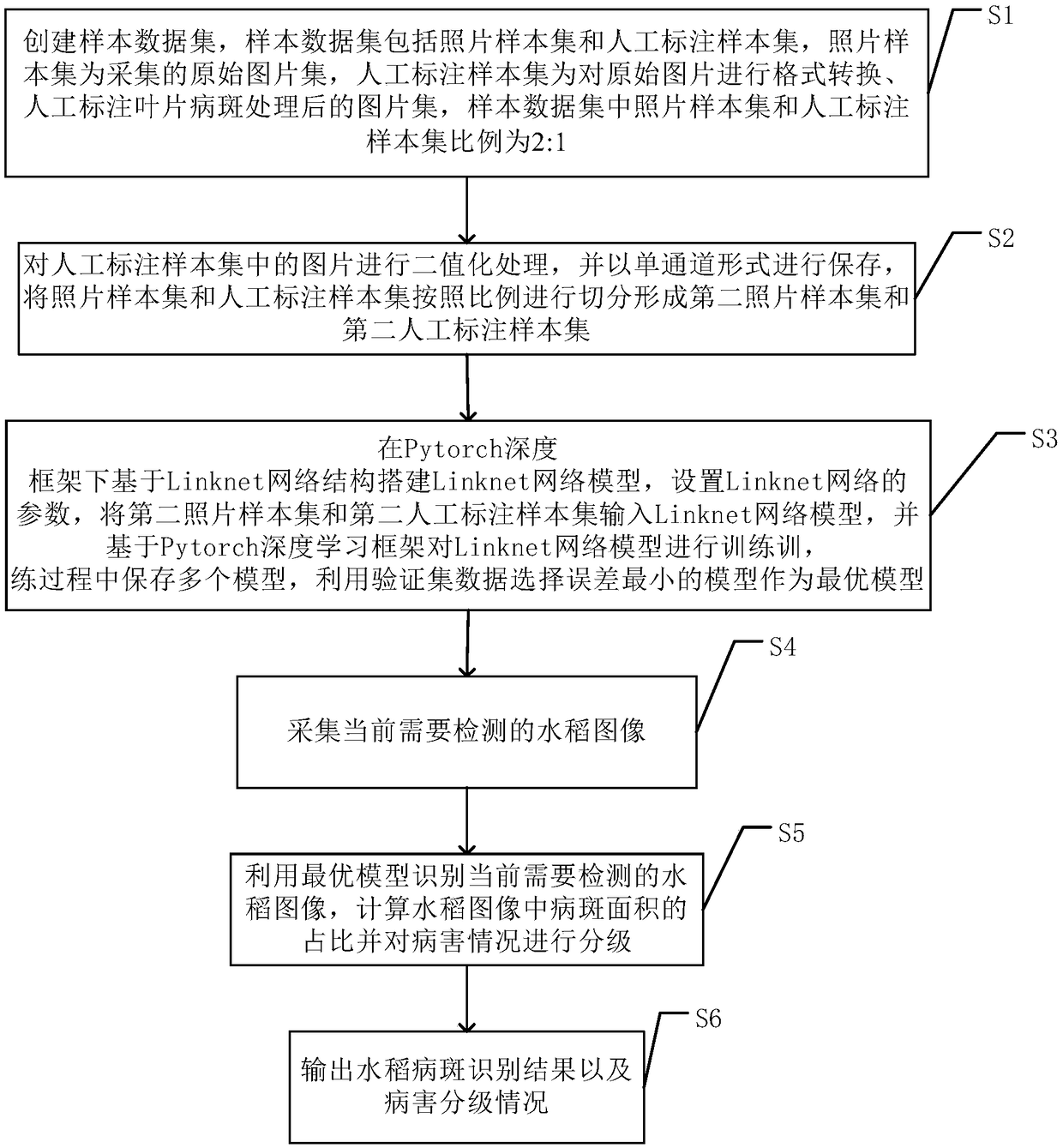

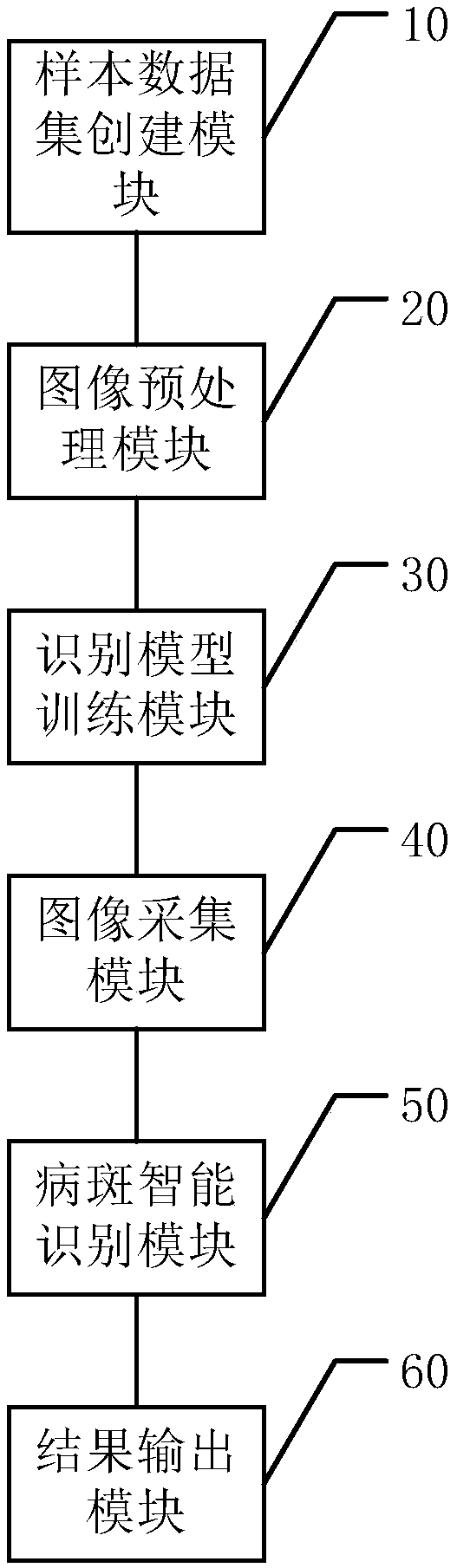

Rice lesion detection method and system based on deep learning

ActiveCN109165623AImprove generalization abilityImprove practicalityCharacter and pattern recognitionPattern recognitionImaging processing

The invention discloses a rice lesion detection method and system based on deep learning, belonging to the image processing field, the method comprising: providing a photo sample set and a manual labeling sample set, and cutting the photo sample set and the manual labeling sample set according to a proportion to form a second photo sample set and a second manual labeling sample set; inputting thesecond photo sample set and the second label sample set into the Linknet network model, and obtaining the optimal model by training the Linknet network model based on the Pytorch deep learning framework; using the optimal model to identify the rice lesion images needed to be detected at present, and calculating the proportion of rice lesion area and classifying the disease status. Through the Linknet network model of Pytorch deep learning framework, the generalization ability and field practicability of rice leaf lesion identification can be improved, and the utilization rate of information can be improved, which is conducive to the subsequent quantitative application of pesticides and reduce environmental pollution.

Owner:北京麦飞科技有限公司

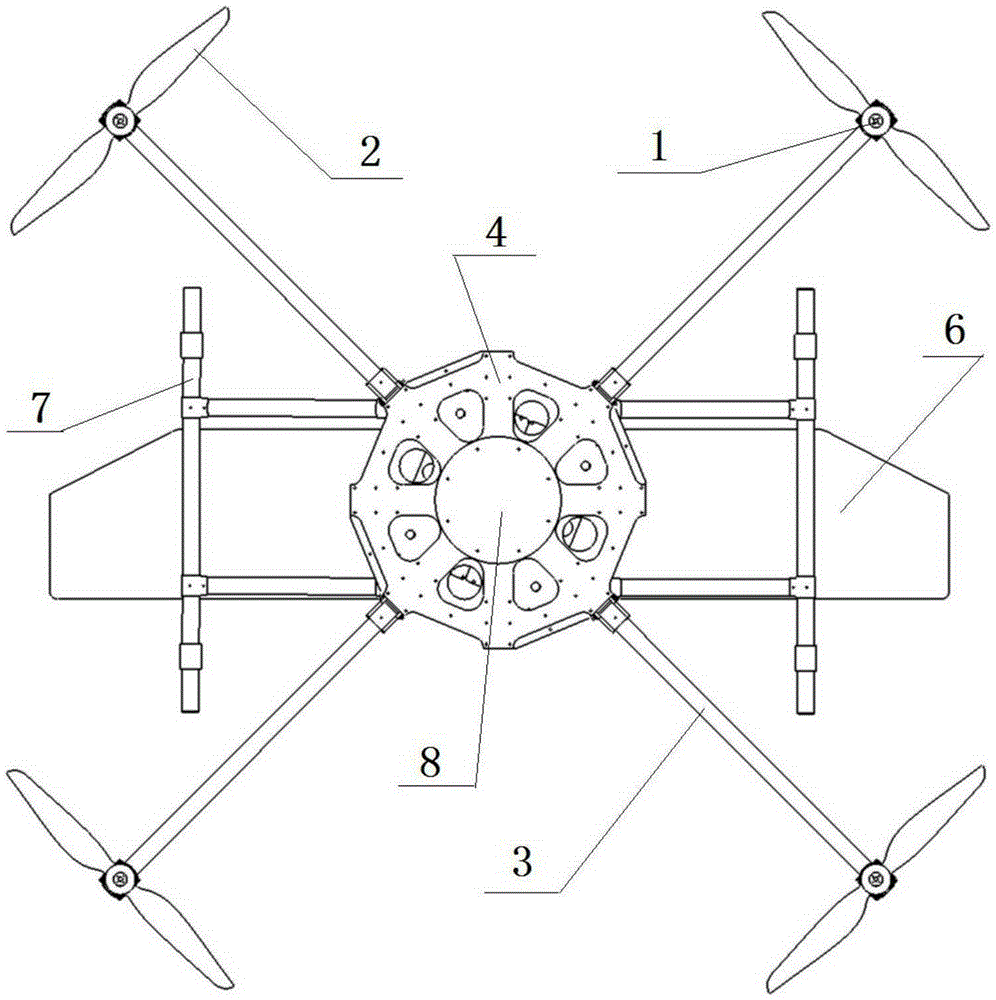

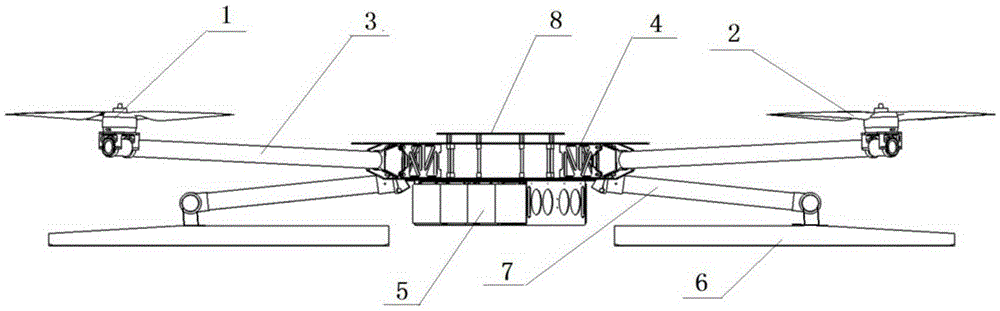

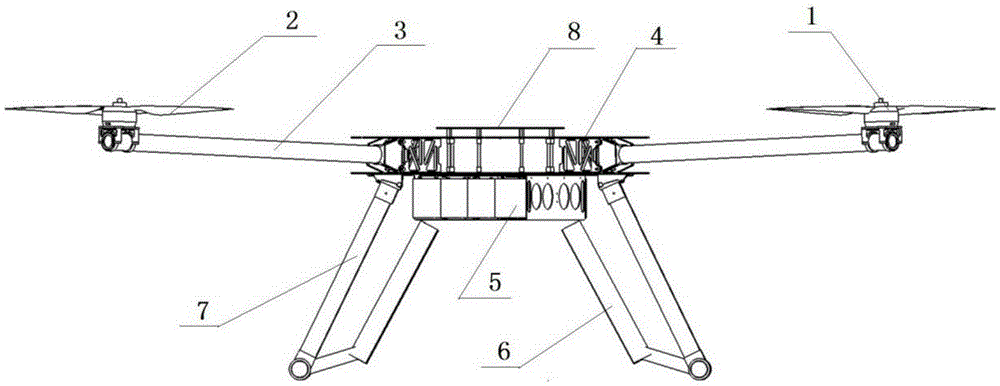

Hybrid multi-rotor aircraft with retractable wings

The invention relates to a hybrid multi-rotor aircraft with retractable wings, and mainly solves the problems in the prior art that the time of endurance is short and the load capacity is limited due to causes of structure. The hybrid multi-rotor aircraft with retractable wings mainly comprises motors, propellers, rocker arms, an aircraft body, a lithium battery pack, the retractable wings, retractable undercarriages and a flight control system; the assembly scheme of all the parts lies in that the propellers are mounted on the motors; the motors are fixed at one ends of the rocker arms through installation parts, and the other ends of the rocker arms are fixed in the middle of the aircraft body; the flight control system is mounted at the central position right above the aircraft body; the lithium battery pack is mounted at the central position under the aircraft body; the retractable undercarriages are symmetrically mounted at positions, close to the two sides, below the aircraft body; the retractable wings are fixed on the retractable undercarriages through installation parts. After the aircraft takes off, the undercarriages can be retracted, and at the same time the wings stretch towards outer sides, therefore the lift force of the multi-rotor aircraft is greatly increased, the time of endurance is prolonged, and the load capacity is further improved.

Owner:LIAONING GENERAL AVIATION ACAD

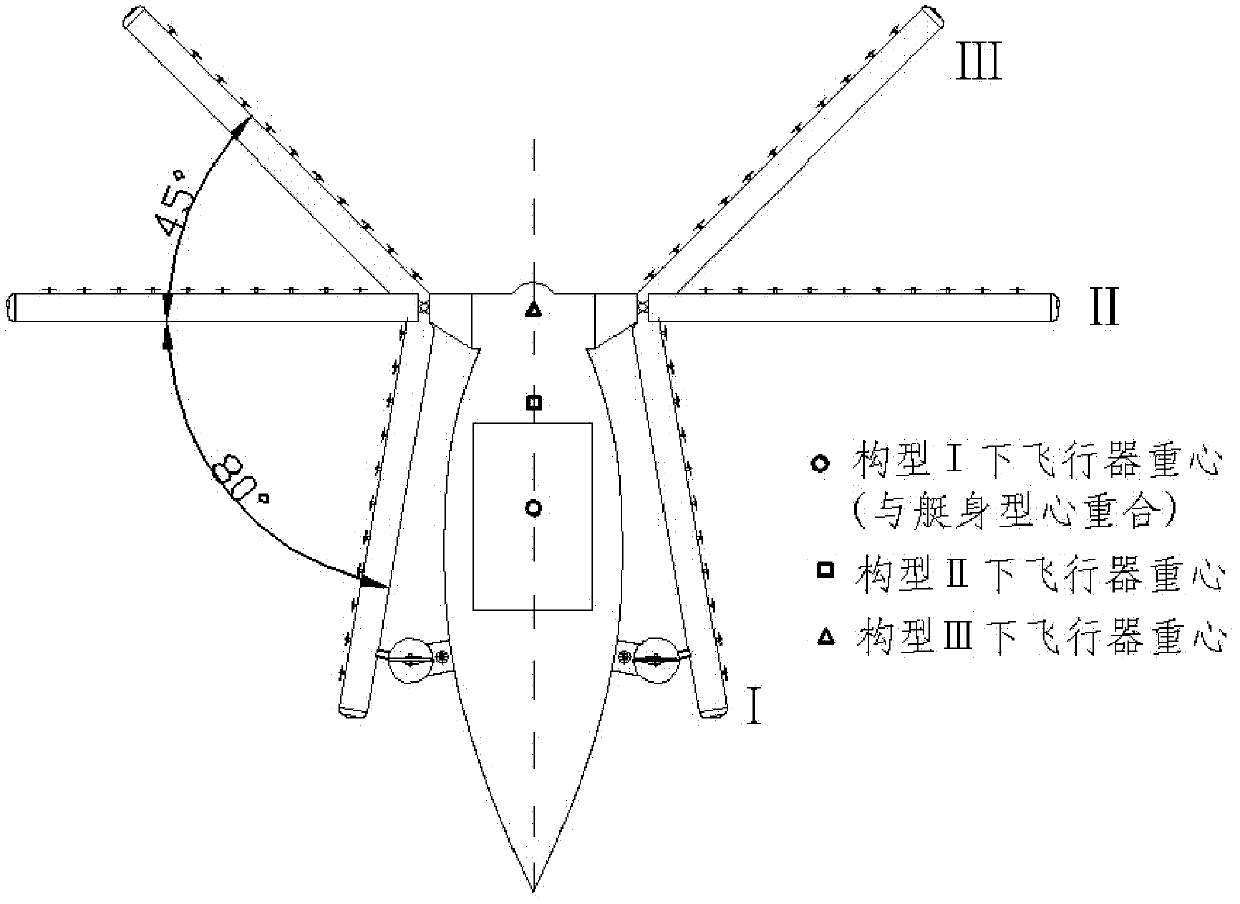

Near-space unmanned aircraft

The invention discloses a near-space unmanned aircraft. Helium gas is inflated into an inflatable aircraft, solar wings are mounted at the front end of the inflatable aircraft, can rotate around flatter positions of rotary shafts at the roots of the wings by an angle ranging from -45 degrees to 80 degrees and can be locked at the three positions of a -45-degree angle, a 0-degree angle and a 80-degree angle. A plurality of propellers are mounted on the solar wings, two slantingly-rotatable trust propellers and two directional-trust auxiliary propellers are mounted on the inflatable aircraft, and solar cell panels are distributed on the surface of the solar wings and the inflatable aircraft. The inflatable aircraft is divided into a front section, a middle section and a rear section, wherein the rear section has a soft structure, a middle section has a semi-hard structure, and the front section is a task loading cabin. The near-space unmanned aircraft can overcome the defects of high requirements to taking-off and landing fields, insufficiency in effective load, poor safety in low-altitude flying and the like of an existing unmanned aircraft, and meanwhile, higher flight altitude can be realized, hovering posture and flight path control performances of the near-space unmanned aircraft are improved, absorption and storage of solar energy are improved and time for staying in space is guaranteed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

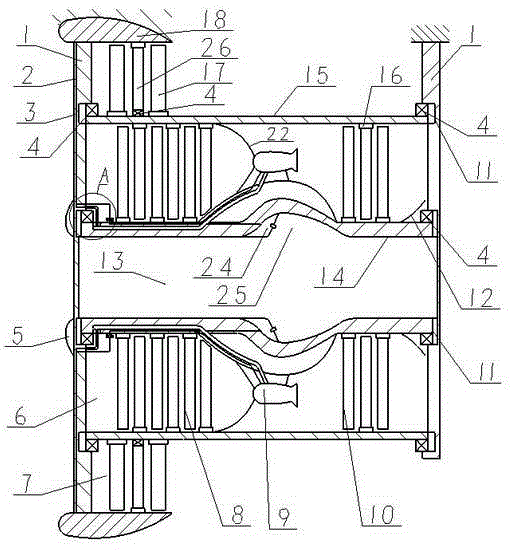

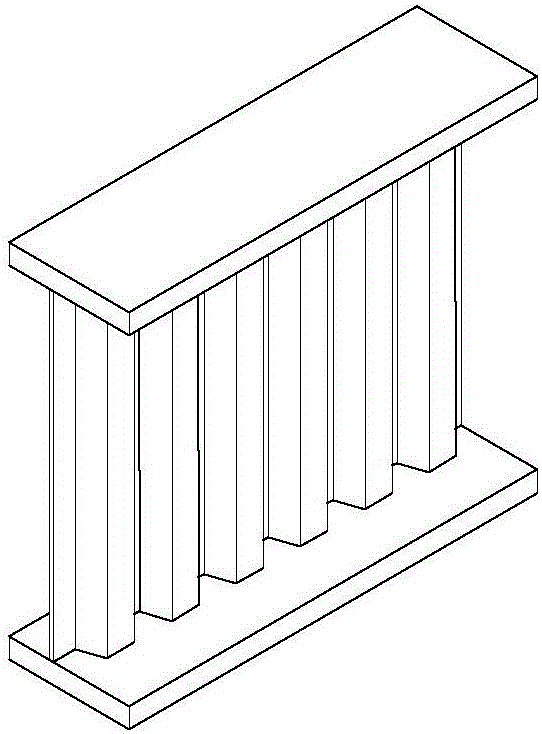

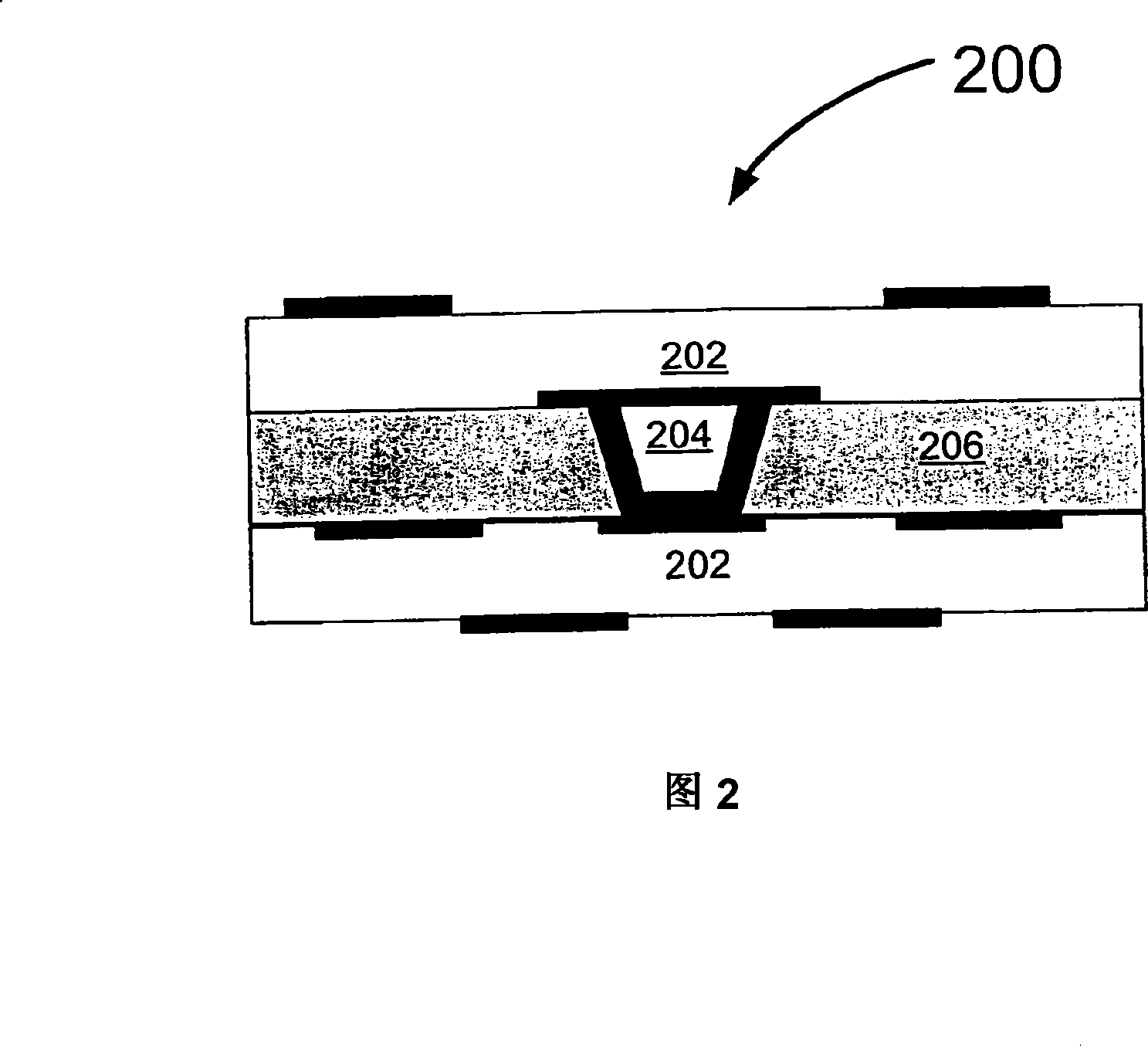

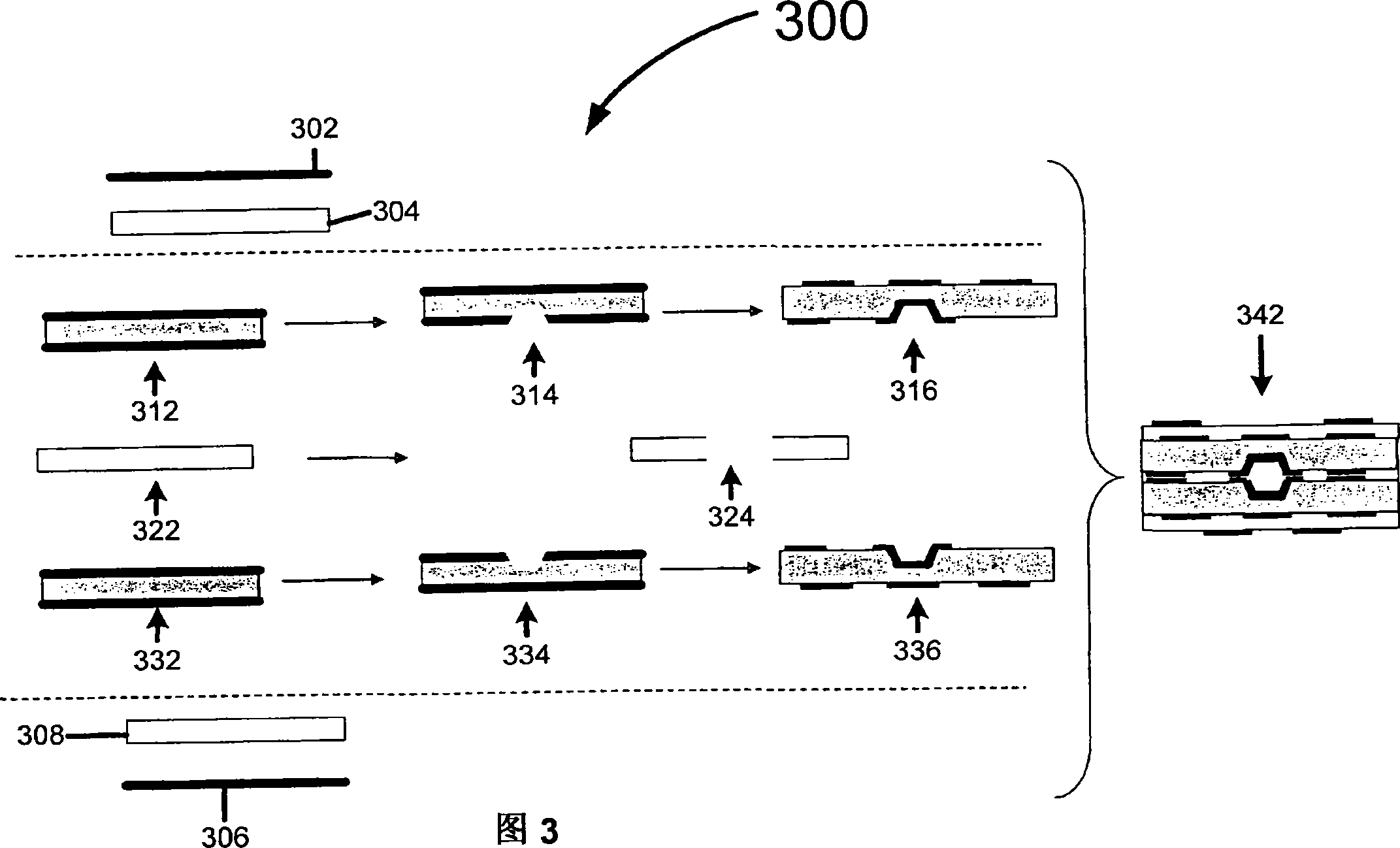

Composite material casing containing inward-flanging windows, forming die and forming method

ActiveCN108501398AGood for weight lossHigh structural efficiencyDomestic articlesMicrowaveEngineering

The invention relates to a composite material casing containing inward-flanging windows, a forming die and a forming method. The whole casing is of a cylindrical or conical rib-skin structure, and ischaracterized in that the skins at the upper side and lower side of the structure are flanged inwards along the radial direction to form an upper end framework and a lower end framework of the casing;the side surface of the structure is provided with an even number of windows towards the interior of the cylinder, and the inner walls of windows are in a step shape; every two windows are symmetrically distributed along the center of circle at the circumference; the casing is of an integrated forming structure. The composite material casing has the advantages that the inward-flanging windows andthe composite material casing with the rib-skin structure are integrally formed, so that the weight of the composite material member is reduced, and the structure efficiency is improved; the composite material casing is suitable for manufacturing the composite material member of the rib-skin structure containing the inward-flanging windows; by adopting the integrated structure, the weight is light, the strength is high, and a microwave absorbing and transmitting unit can be formed after a functional material is introduced into the integrated window; by adopting the structure type, the wide application prospect in the fields of anti-counterfeiting, hiding and the like of aircrafts is realized.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

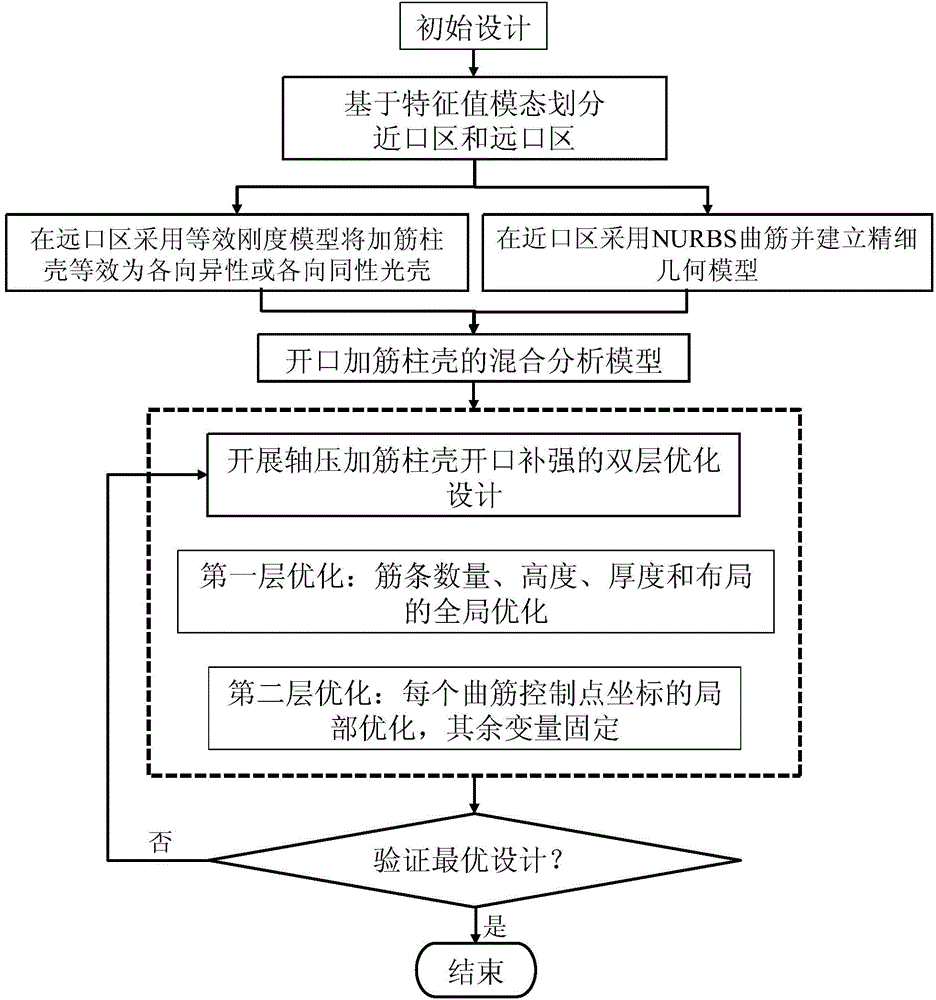

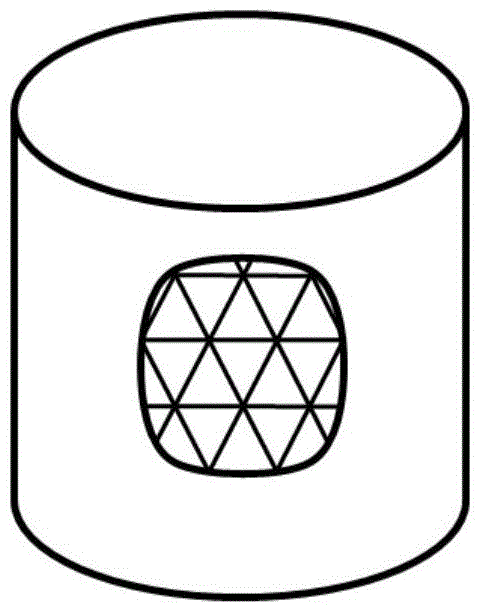

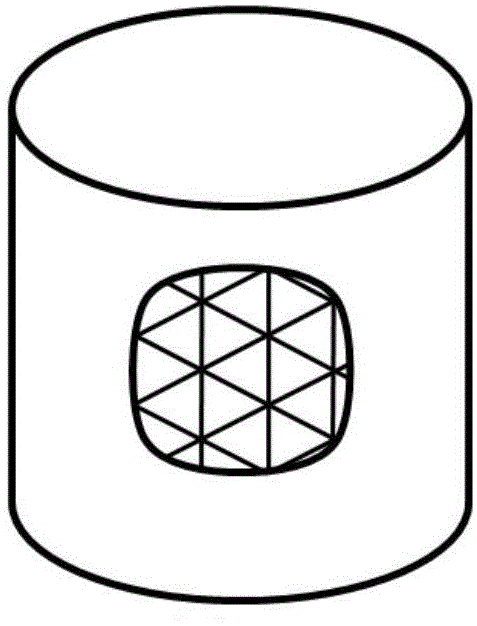

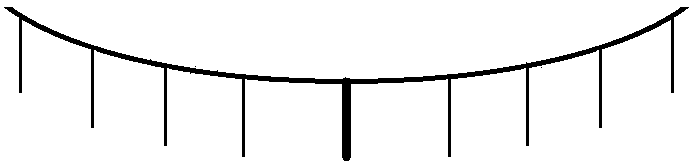

Opening reinforcement method of shaft pressing reinforced cylindrical shell

ActiveCN104866673AHigh structural efficiencyRational determinationSpecial data processing applicationsEquivalent stiffnessMechanical engineering

The invention relates to the field of aerospace structure main load-bearing member design, and provides an opening reinforcement method of a shaft pressing reinforced cylindrical shell. The opening reinforcement method of the shaft pressing reinforced cylindrical shell comprises the following steps: step 100, dividing the shaft pressing reinforced cylindrical shell with an opening into a distal opening area and a proximal opening area; step 200, establishing an equivalent stiffness model in the distal opening area, establishing a fine geometric model in the proximal opening area, and obtaining a hybrid analysis model of the shaft pressing reinforced cylindrical shell; step 300, peforming opening reinforcement and optimization on the shaft pressing rinforced cylindrical shell, and verifying an optimal result. According to the opening reinforcement method of the shaft pressing rinforced cylindrical shell, the opening reinforcing efficiency of the shaft pressing rinforced cylindrical shell can be improved, and the computing cost is reduced.

Owner:DALIAN UNIV OF TECH

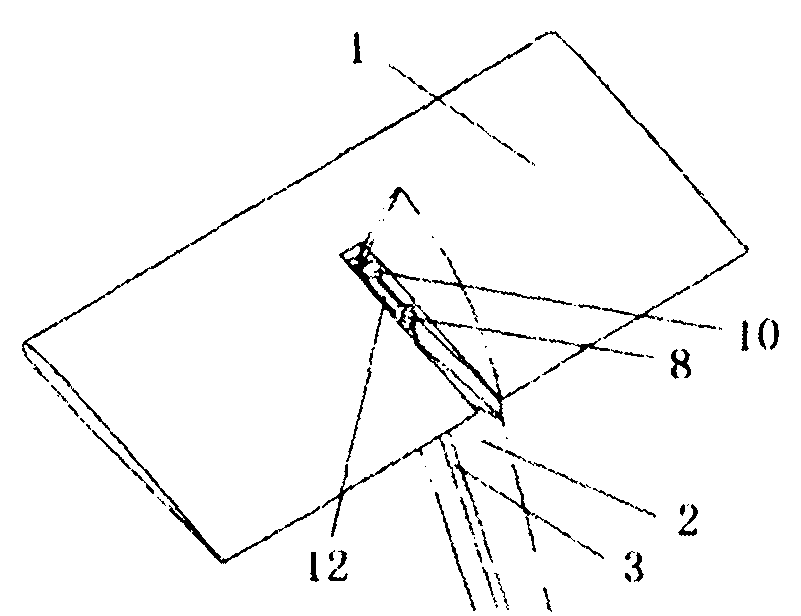

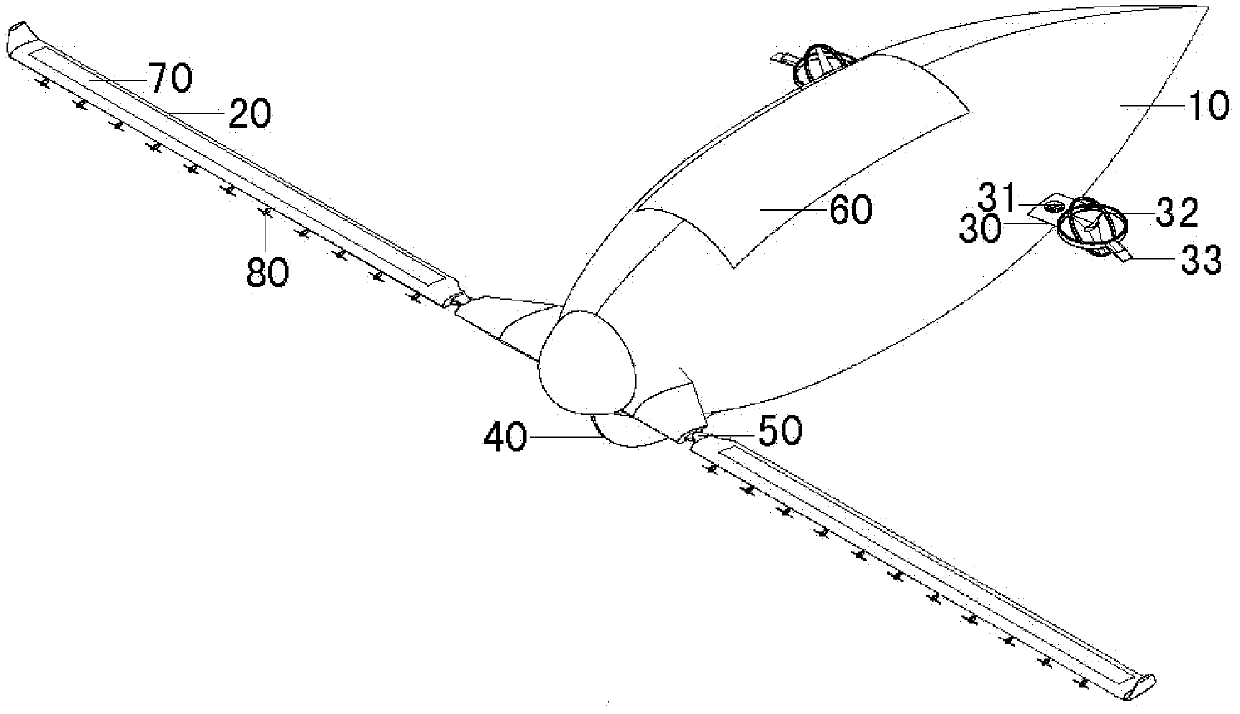

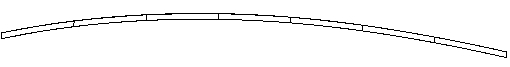

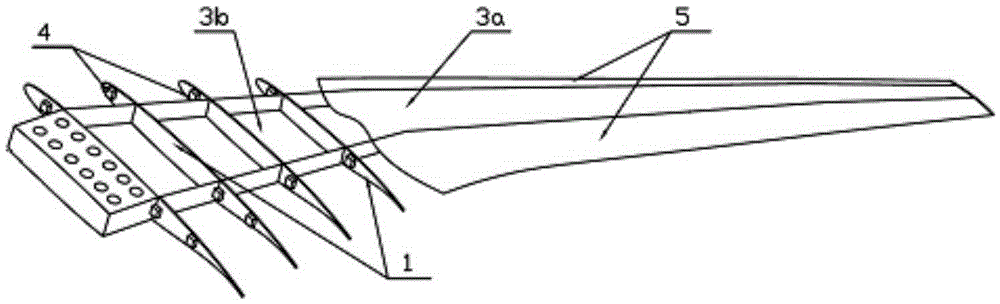

Manufacturing method of light aerofoil with super-high aspect ratio and high lift-drag ratio and aerofoil manufactured thereby

The invention discloses a manufacturing method of a light aerofoil with super-high aspect ratio and high lift-drag ratio and an aerofoil manufactured thereby. At present, some used optimized design methods for improving the strength and the rigidity of the aerofoil with the high aspect ratio have the limited improvement space; and if a method for increasing geometrical characteristic parameters of the sections of the plasmodium is adopted, the structure weight of the aerofoil needs to be increased and the effect is poor. By the manufacturing method adopted by the invention, these problems are solved. According to the overall configuration of an aircraft, the aerofoil is divided into a plurality of sections; tensile wires are arranged according to a certain mode section by section. The research result shows that the original bending function of the aerofoil is replaced by the tension of the tensile wires and the impaction of the aerofoil, and under the premise that the structure weight is basically not increased, the rigidity and the strength of the aerofoil with the high aspect ratio are greatly improved, and the pneumatic elastic deformation is reduced to be within 10 percent of the traditional aerofoil. The manufacturing method is very important for the practical application of the aerofoil with super-high aspect ratio, the cruising efficiency of the aircraft can be greatly improved, and the fuel consumption and the cost are reduced.

Owner:AERODYNAMICS NAT KEY LAB

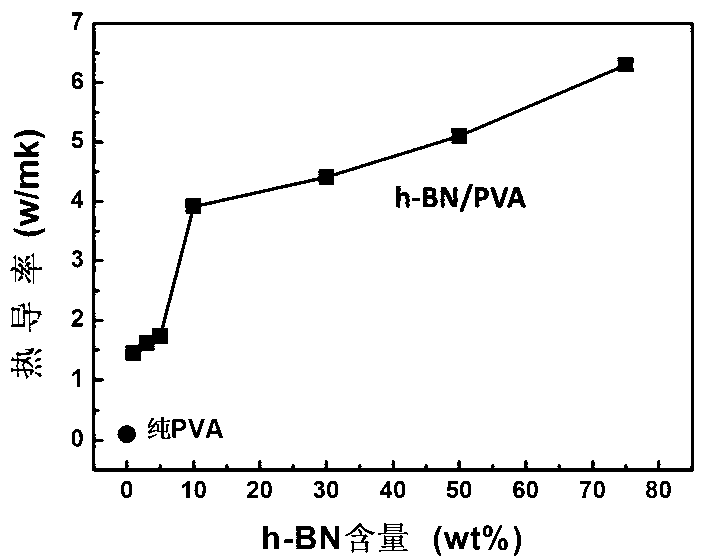

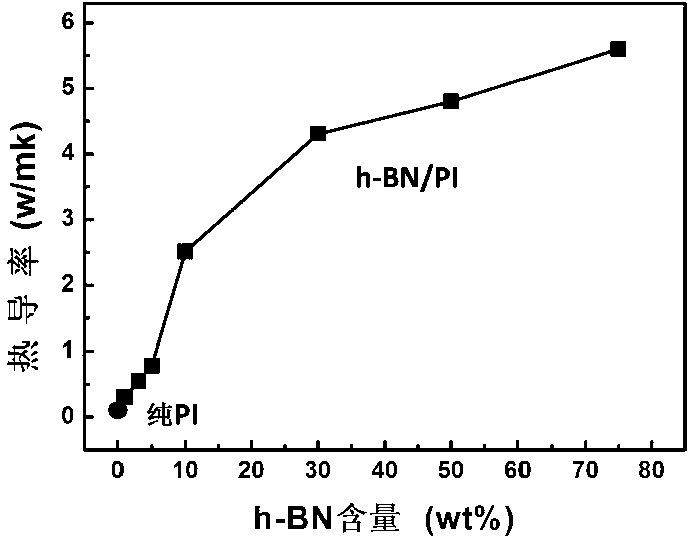

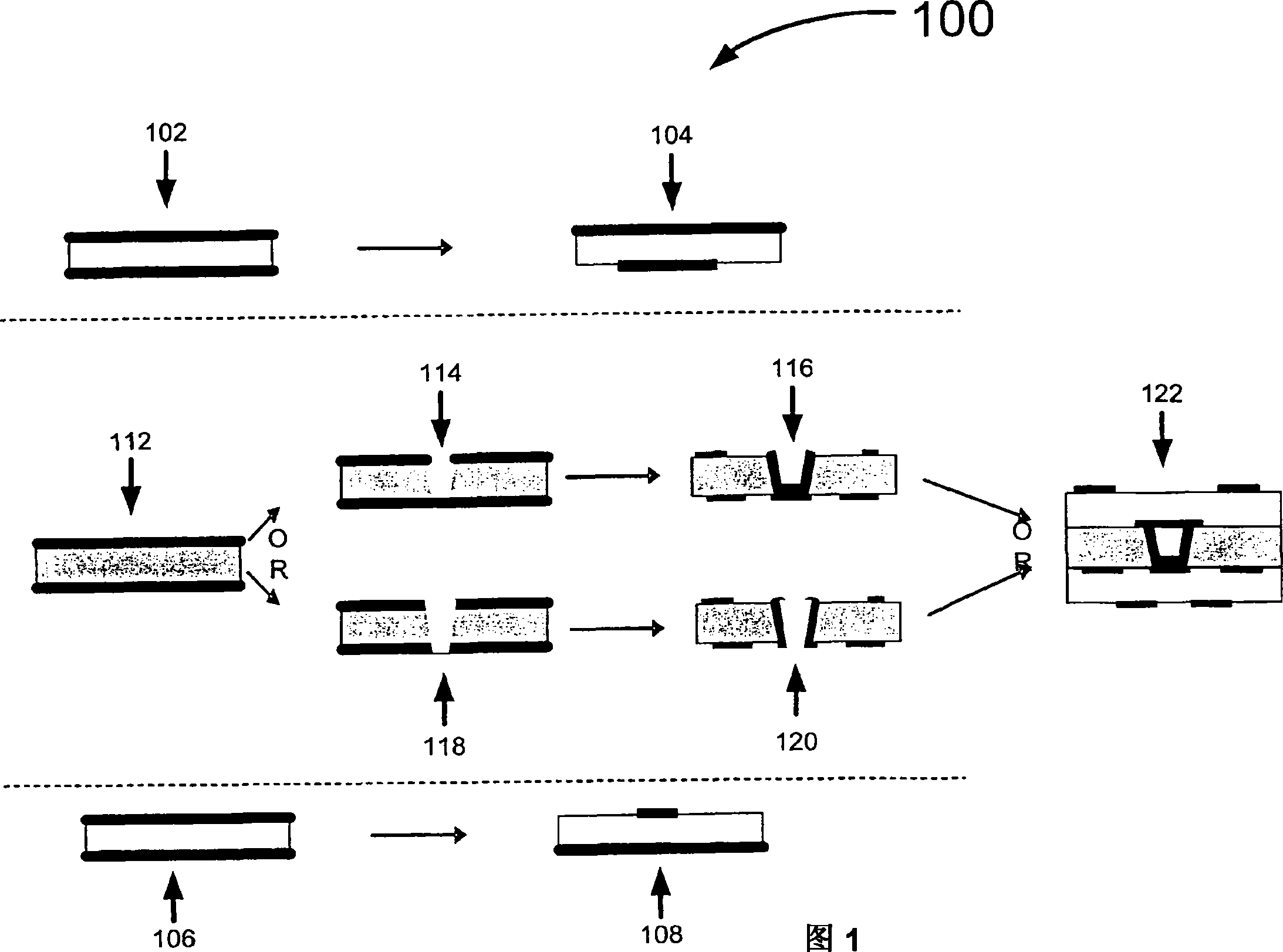

Filler-textured polymer matrix composite material with high thermal conductivity and preparation method thereof

InactiveCN103224638AIncrease optionalitySimple methodHeat-exchange elementsMicro nanoPolymer science

The invention relates to a filler-textured polymer matrix composite material with high thermal conductivity and a preparation method thereof. The preparation method comprises the following steps: 1, a mixing process: uniformly dispersing a micro-nano inorganic filler powdered raw material with anisotropy and two-dimensional geometrical morphology into a solution of a thermoplastic resin polymer raw material or uniformly dispersing the inorganic filler powered raw material into a polymer's performed polymer / monomer raw material solution which can be used to synthesize the polymer by in situ polymerization, and forming a mixture slurry; and 2, a molding process: making the mixed slurry to be molded through a molding method for providing directional acting force to make the filler to be textured.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

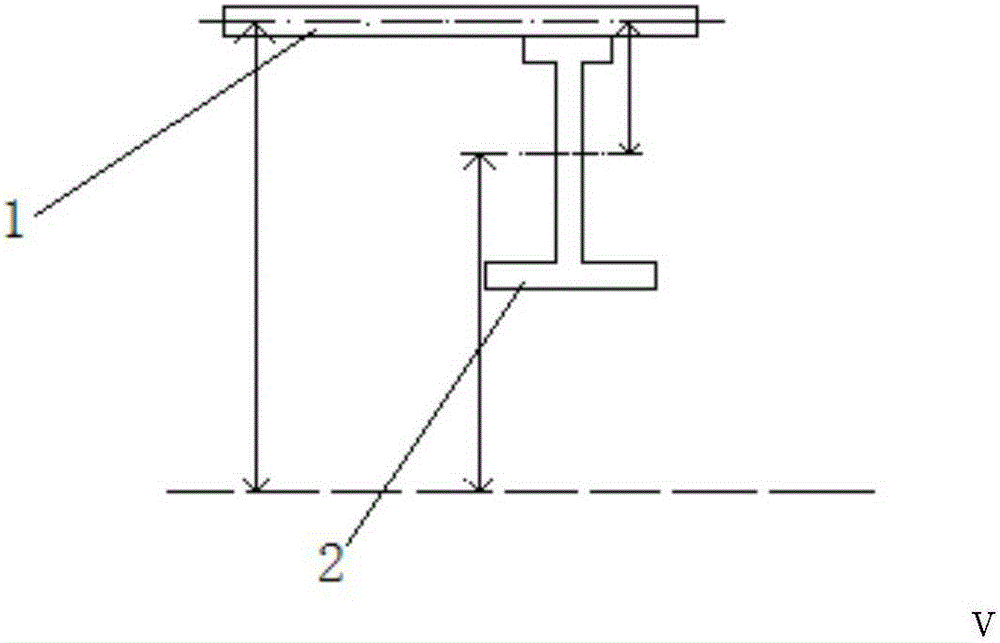

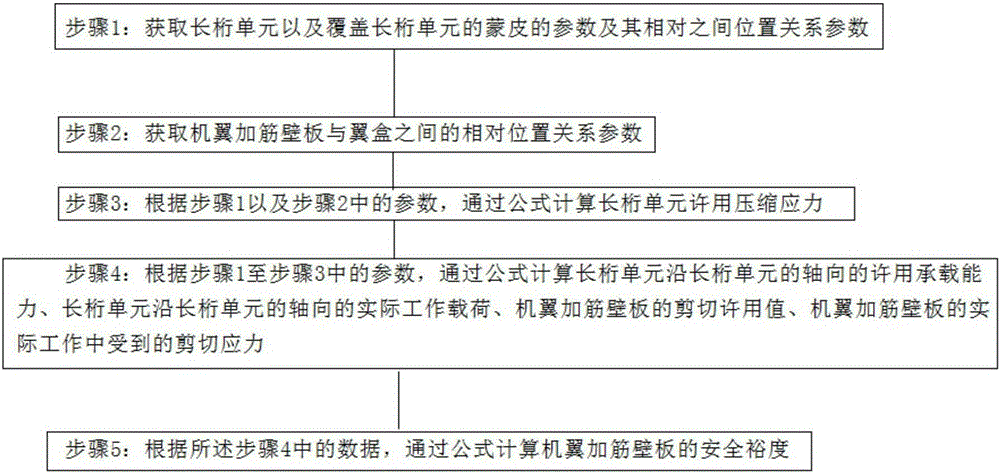

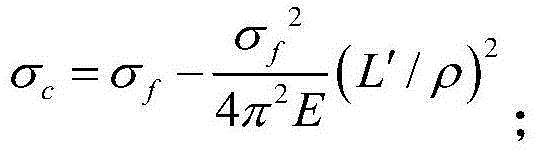

Safety margin calculation method of wing reinforced wallboard

ActiveCN105197253AHigh structural efficiencyShorten the design cycleGround installationsCarrying capacityShear stress

The invention discloses a safety margin calculation method of a wing reinforced wallboard. The safety margin calculation method of the wing reinforced wallboard comprises the following steps: step 1: acquiring parameters of a long truss unit and a skin covering the long truss unit, and relative position relation parameters between the long truss unit and the skin; step 2: acquiring relative position relation parameters between the wing reinforced wallboard and a wing box; step 3: calculating allowable compression stress of the long truss unit through a formula; step 4: calculating an allowable carrying capacity of the long truss unit, an actual working load of the long truss unit, a shearing allowable value of the wing reinforced wallboard and actual shearing stress on the wing reinforced wallboard in actual work through formulas; and step 5: calculating a safety margin of the wing reinforced wallboard through a formula. According to the safety margin calculation method of the wing reinforced wallboard, disclosed by the invention, the strength of the wing reinforced wallboard is metered in a manner of solving the safety margin of the wing reinforced wallboard; and the method is verified by a test, the structure efficiency can be improved and the design period is shortened.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

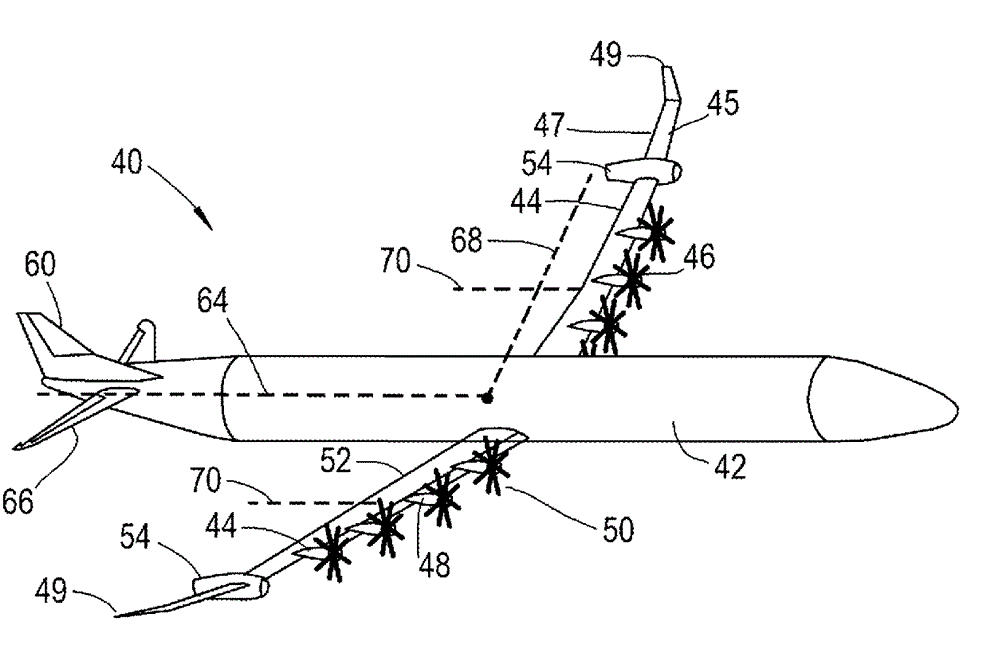

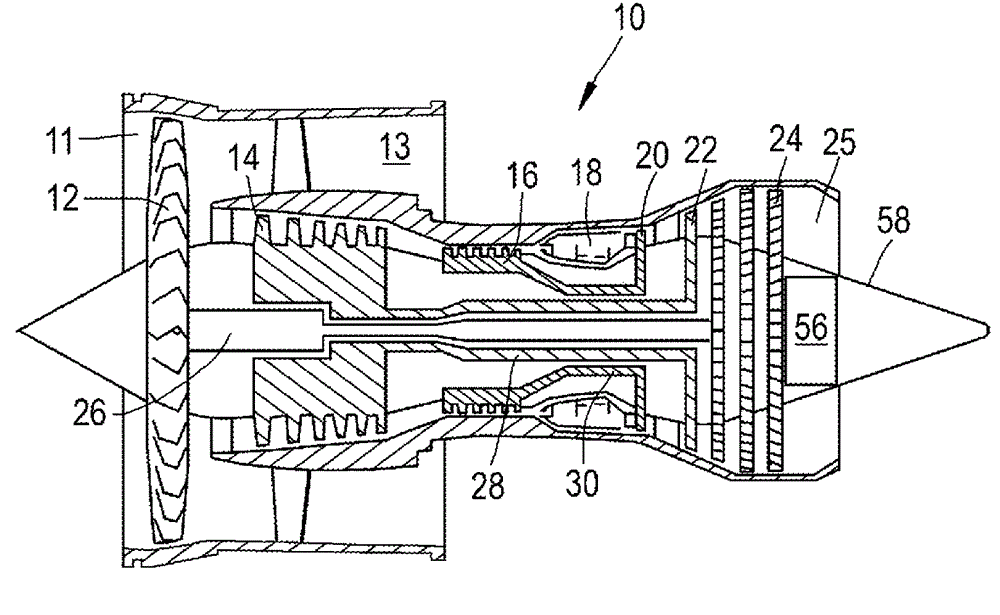

Aircraft

ActiveCN104670503AReduce loadImprove structural efficiencyPropellersGas turbine type power plantsLeading edgeCombustion

An aircraft (40). The aircraft (40) comprises a propulsion system comprising a pair of internal combustion engines (10) each driving an electrical power generator (56), each electrical power generator (56) being electrically coupled to a plurality of electrically driven propulsors (46). The propulsors (46) are located forward of a leading edge (45) of the wings (44) such that an airstream generated by the propulsors flows over the wings (44) in use. Each internal combustion engine (10) and electrical generator (56) is mounted on a respective wing (44) outboard of a centre of thrust (70) of the propulsors (46) on that wing (44).

Owner:ROLLS ROYCE PLC

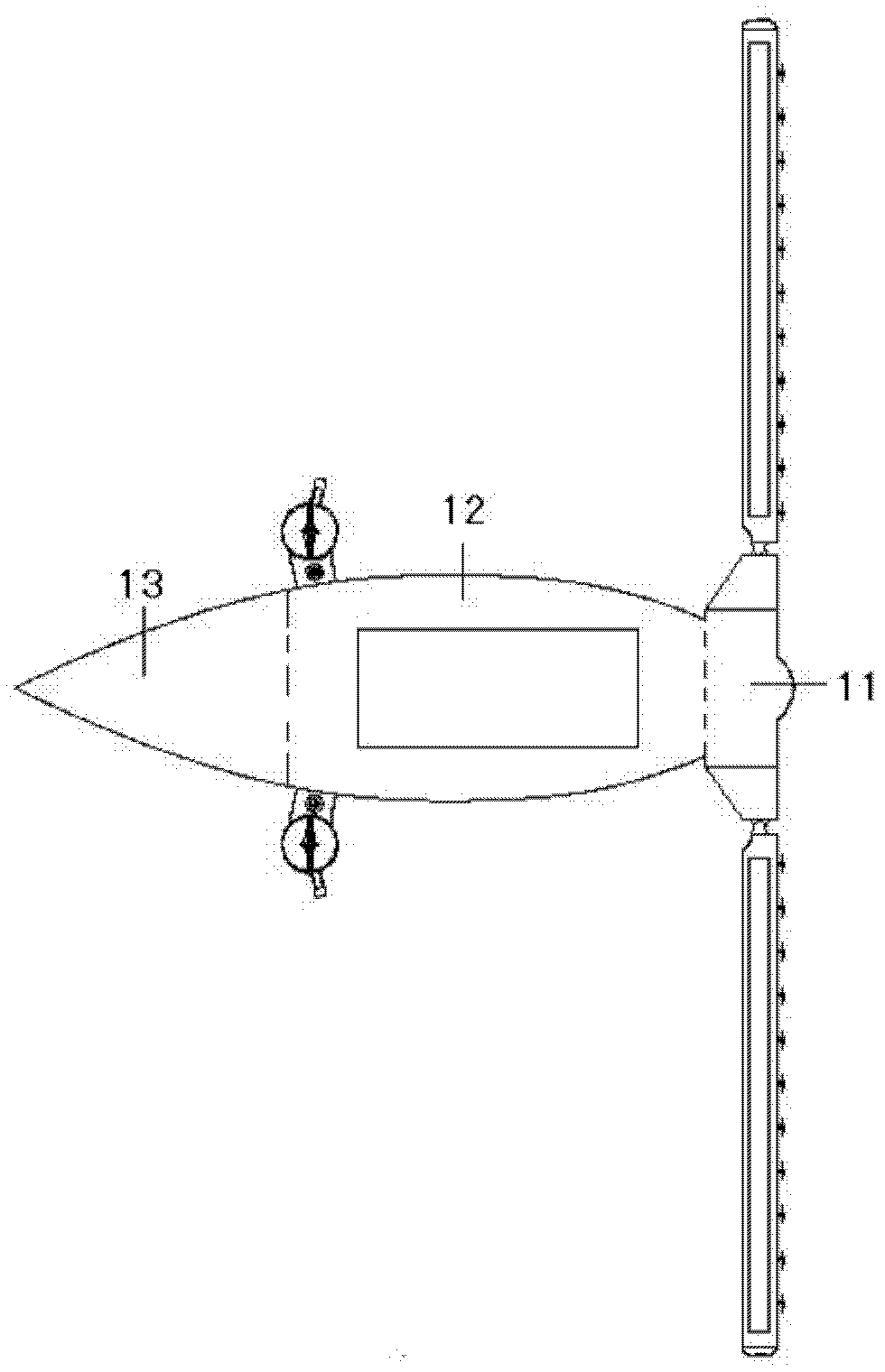

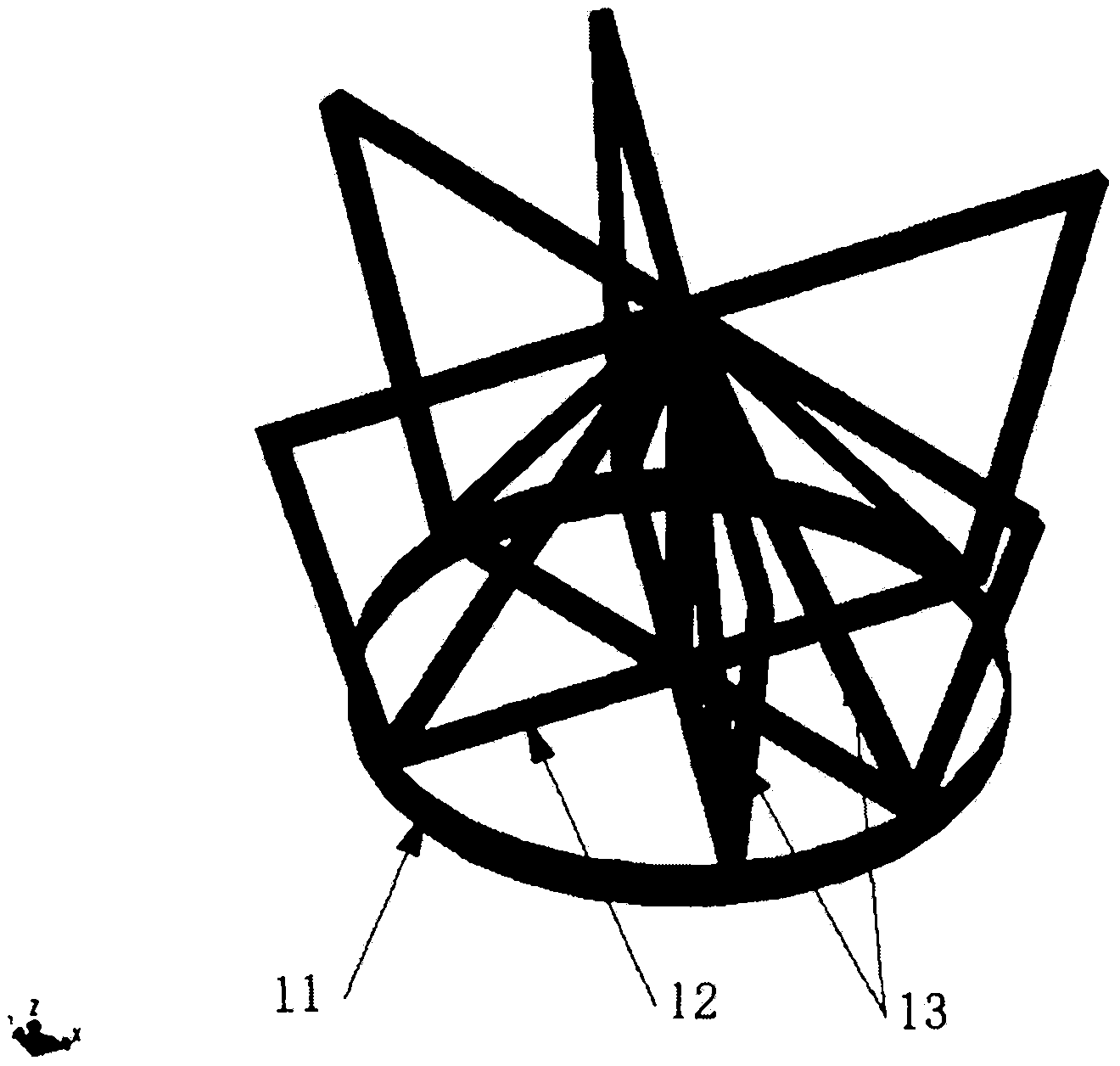

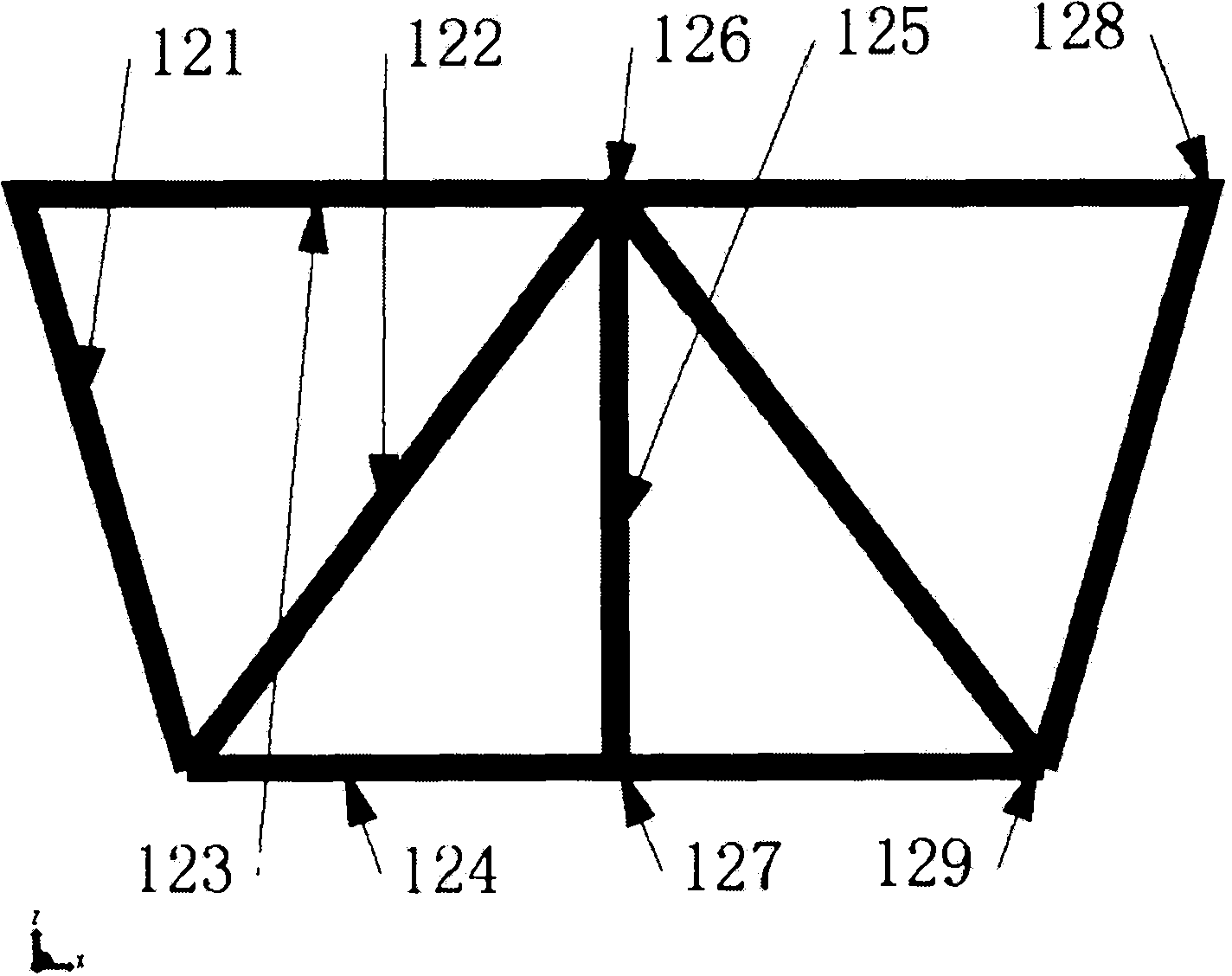

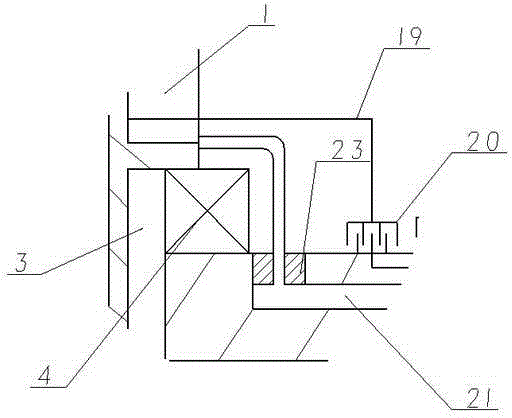

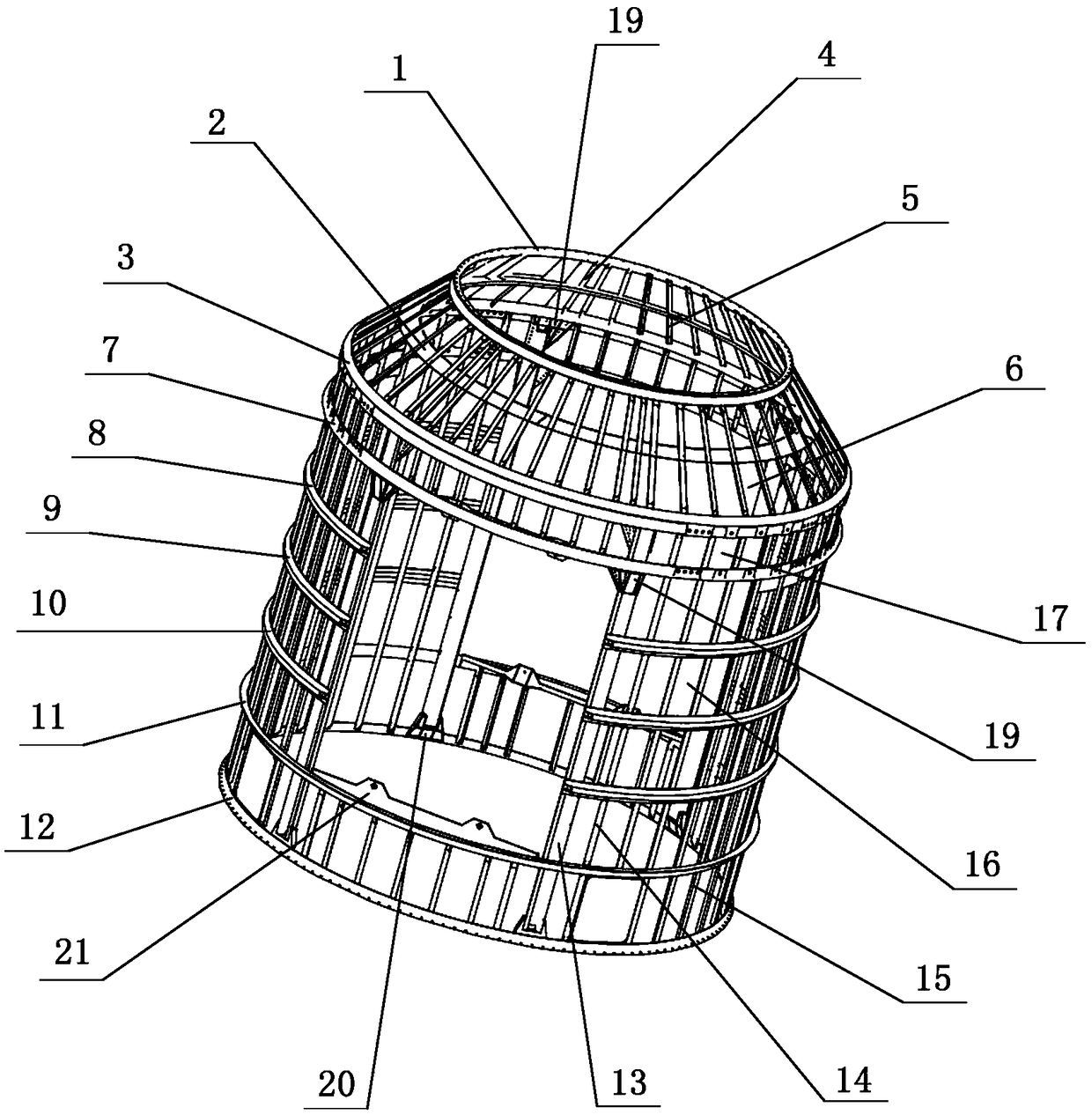

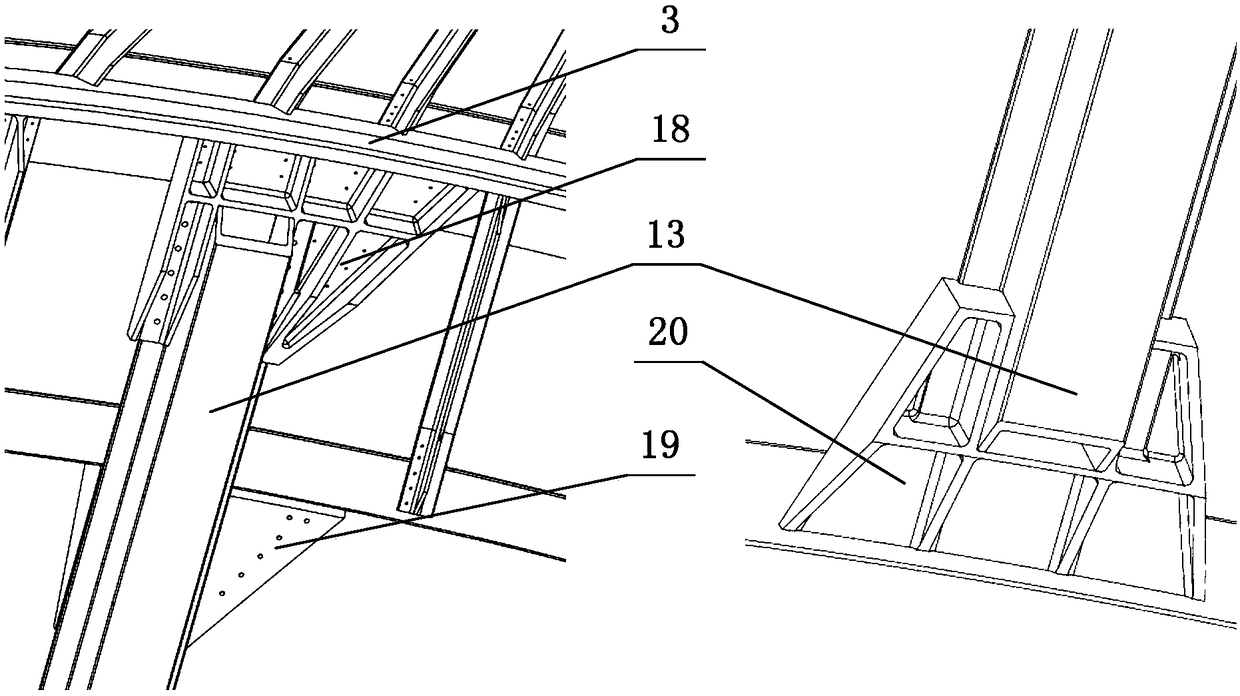

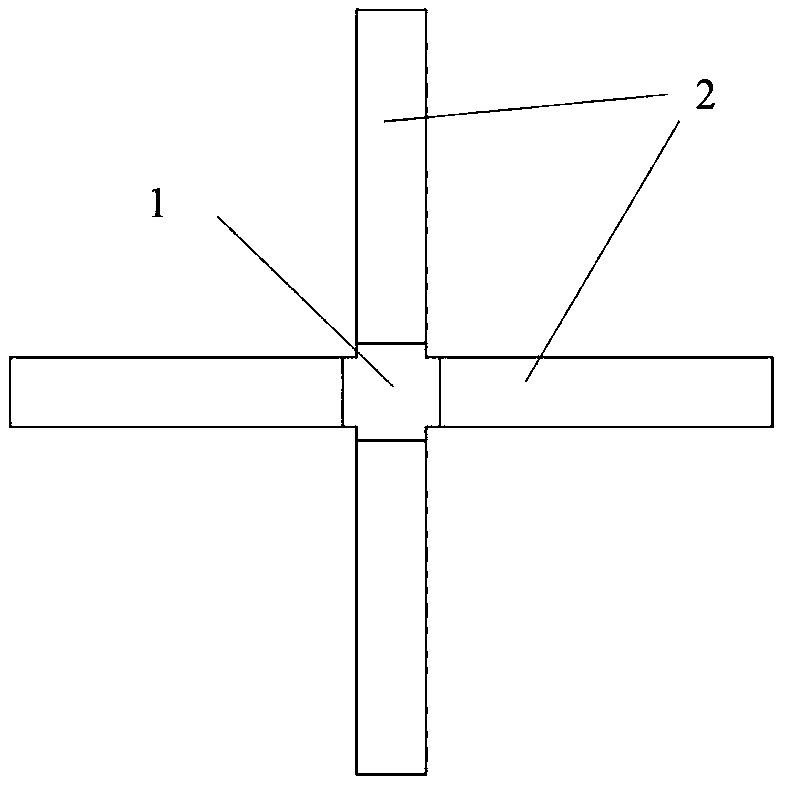

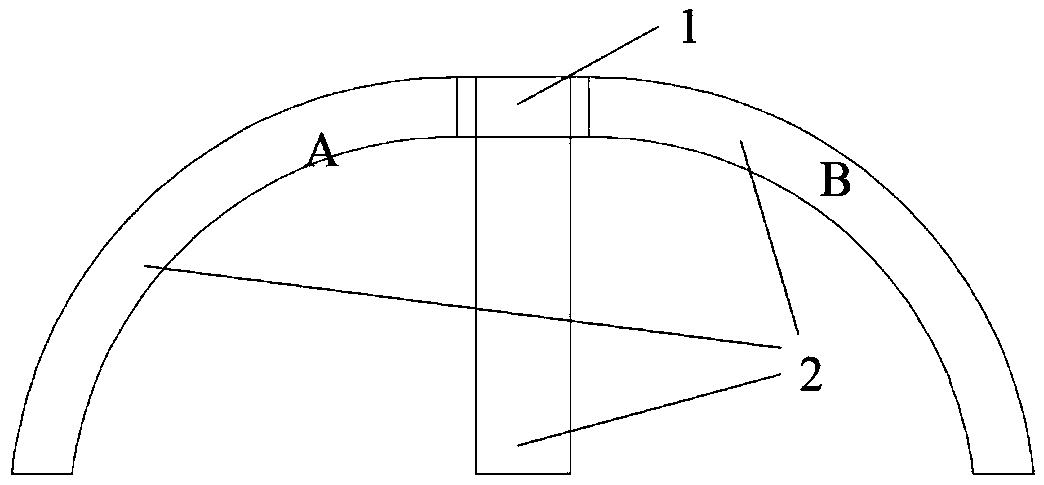

Truss type satellite main structure public platform

ActiveCN105659738BReduce the overall heightCompact structureCosmonautic vehiclesCosmonautic partsBe starComputer module

The invention discloses a new truss-type satellite main structure public platform, which consists of a star-shaped central load-bearing frame (1), a bottom plate (2), a pair of ±Y-directed side plates (3) parallel to each other, and a pair of ±X-directed The side plate (4) is composed of; the star-shaped central bearing frame (1) includes the star-arrow docking ring (11), one X-direction W-shaped plane truss (12) and two symmetrically distributed Y-direction W-shaped plane trusses (13 ); 3 W-shaped plane trusses are star-shaped, i.e. distributed in a * shape, connected as a whole and connected to the side plates respectively; 3 W-shaped plane trusses are connected to the star arrow docking ring (11) through the bottom outer joint (129); The bottom plate (2) is connected with the star arrow docking ring (11) at the position of the opening in the middle. The platform of the present invention meets the satellite layout requirements while ensuring a reasonable force transmission path, can carry various types of payload compartments (or modules), and is suitable for use when the weight of the entire satellite exceeds 6 tons and the diameter of the storage tank is greater than 1 meter.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

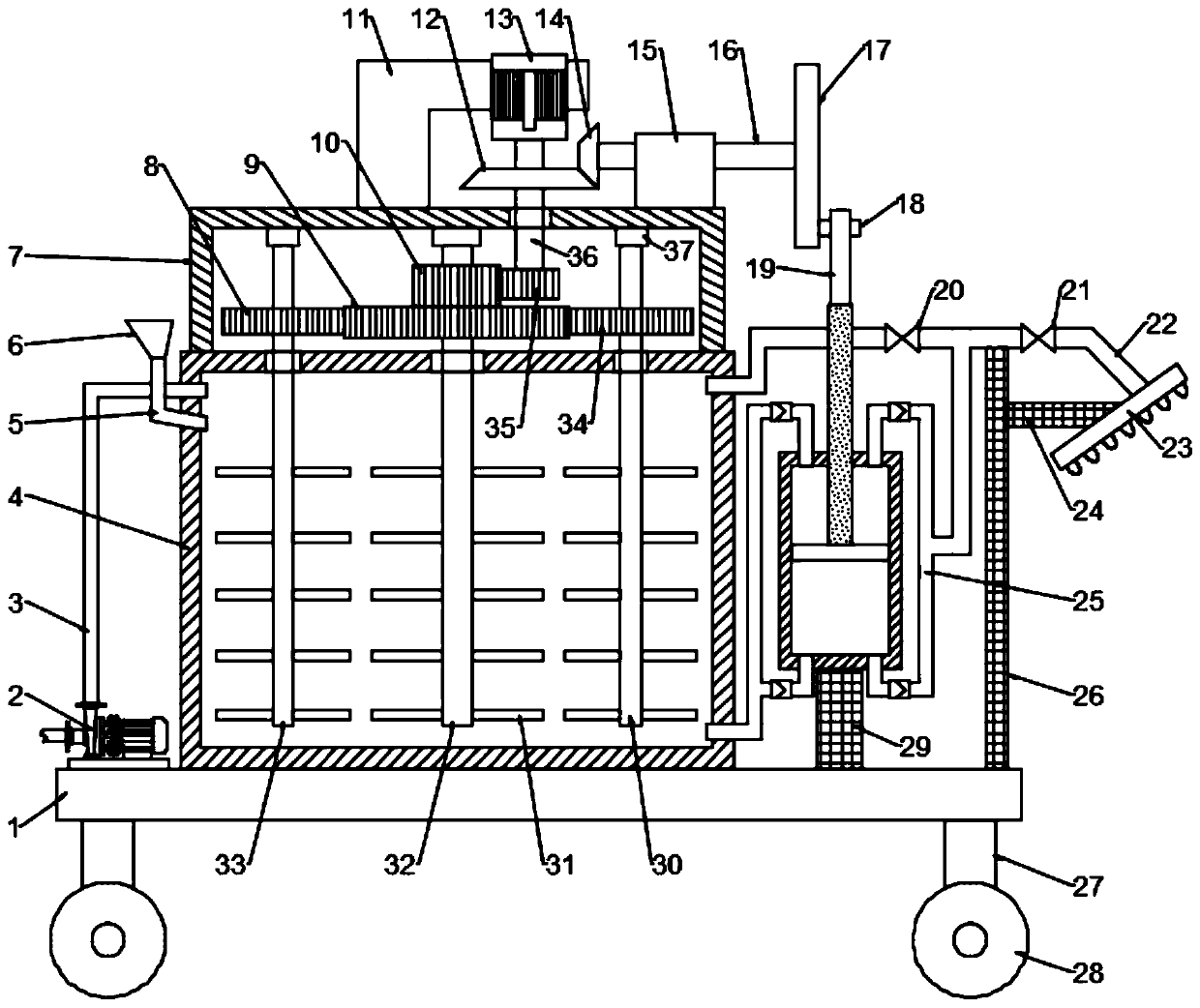

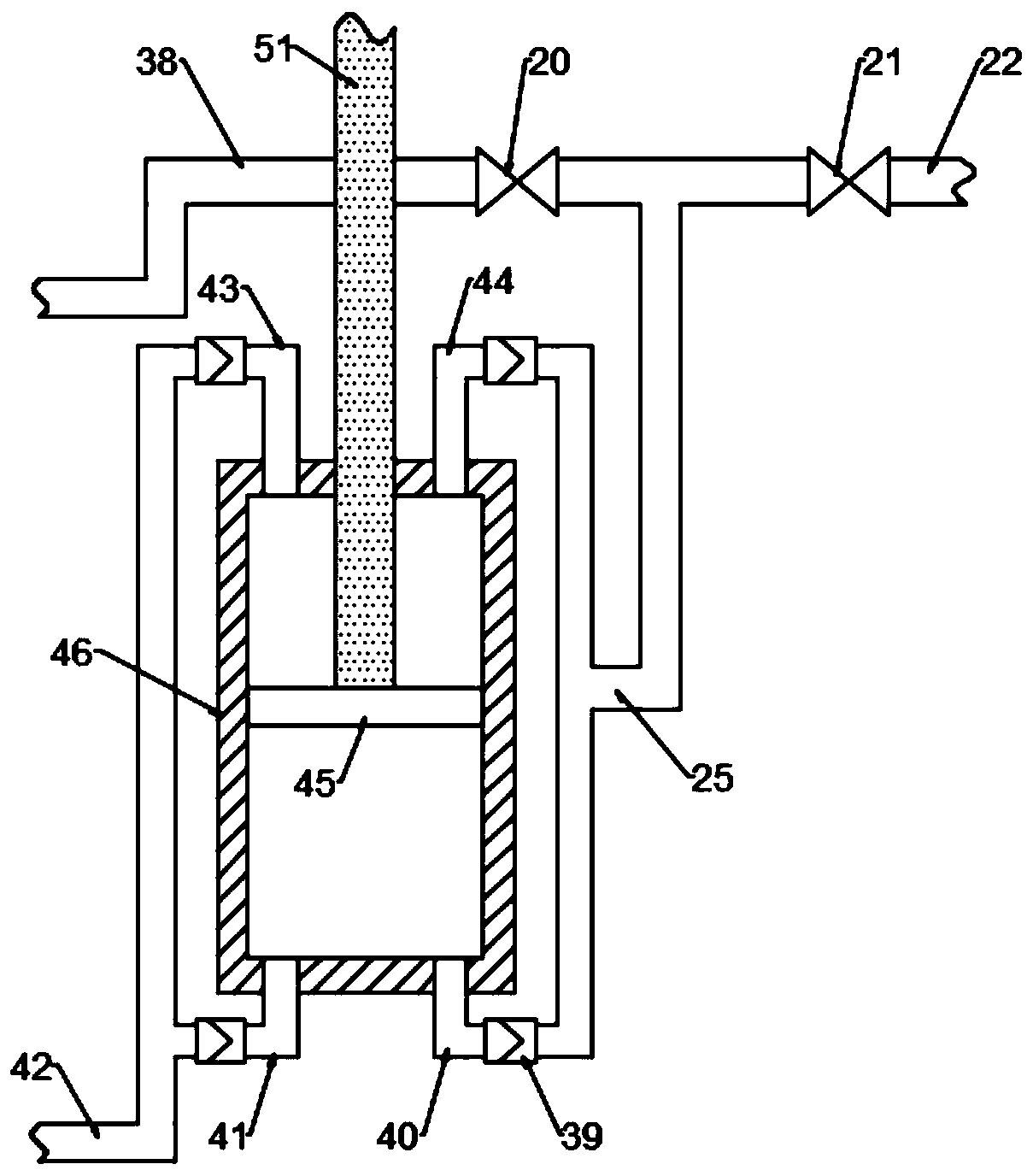

Irrigation device for water conservancy project

InactiveCN110226582AWell mixedHigh structural efficiencyFlow mixersRotary stirring mixersPipingSpray nozzle

The invention relates to the technical field of a water conservancy project, in particular to an irrigation device for the water conservancy project. The irrigation device comprises a bottom plate andspray nozzles, wherein a water suction pump and a mixing box are arranged on the bottom plate, an outlet of the water suction pump is connected with a water delivery pipe, and one end, away from thewater suction pump, of the water delivery pipe is connected to the top of the mixing box; an agent liquid pipe is arranged at the top of the mixing box, an agent adding hopper is arranged at the top end of the agent liquid pipe, and a mixing mechanism for mixing an agent liquid and water is arranged on the mixing box; the irrigation device for the water conservancy project further comprises an extraction mechanism used for extracting a mixed liquid and conveying the mixed liquid to the spray nozzles. According to the irrigation device for the water conservancy project, a motor drives a first rotating shaft, a second rotating shaft and a third rotating shaft to rotate, stirring blades also rotate accordingly, the agent liquid and water in the mixing box can be stirred and mixed, furthermore, the rotating directions of the first rotating shaft and the second rotating shaft are opposite, and the rotating directions of the third rotating shaft and the second rotating shaft are opposite, sothat the mixing is more sufficient.

Owner:焦新建

Contra-rotating outer framework water-air dual-purpose engine

InactiveCN104481696AReduce the size of the axial structureIncrease thrust-to-weight ratioGas turbine plantsReactive propulsion thrust deviceAbsolute rotationCombustion chamber

The invention discloses a contra-rotating outer framework water-air dual-purpose engine. The engine mainly structurally comprises a supporting frame, an oil electric pipeline, a front thrust bearing, a peripheral bearing, a radome, an inner duct, an outer duct, a gas compressor, a ring-shaped combustion chamber, a worm wheel, a rear thrust bearing, a convergent tail spray tube, a central duct, an inner rotor, an outer rotor, a blade tongue-and-groove, a fan, an engine cover, a power transmission circuit, a conductive slide ring, an oil conveying pipeline, a convergent channel, a rotary joint, a metal fuel cavity, a metal-water reaction combustion chamber and a fan stator blade. The gas compressor and the worm wheel of the engine are not provided with a stator blade, and an outer frame rotor and an inner rotor are in counter rotating in an air working state, so that the gas compressor and the worm wheel can realize counter rotating, the absolute rotation speed of the rotor is lowered when the engine efficiency is improved, the axial dimension of the engine is shortened and the structure weight is reduced. When the engine works in water, the ring-shaped combustion chamber does not work, the inner and outer rotors are static, and power is produced by the metal-water reaction combustion chamber, so that water-spraying propulsion is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

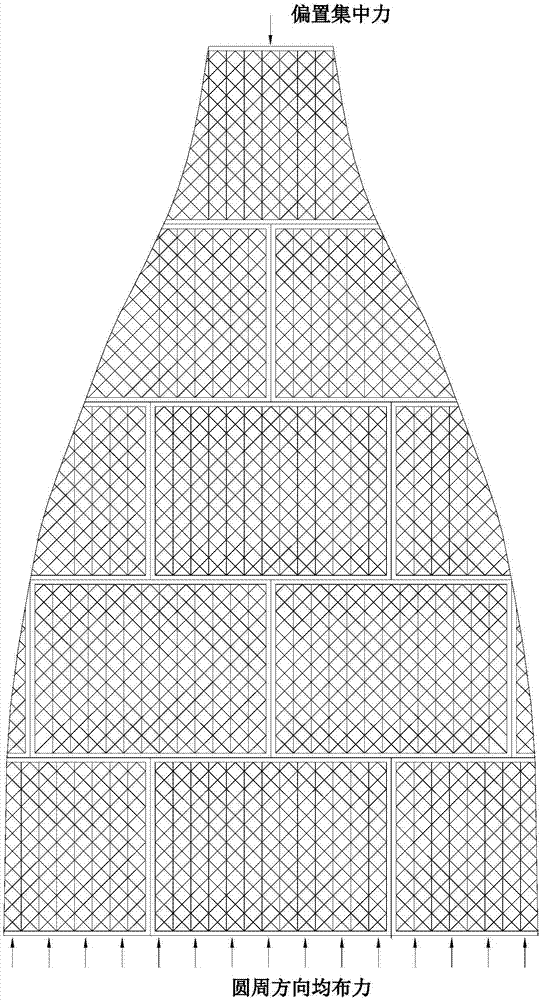

Carrier rocket booster tank structure for biased concentrated force

InactiveCN107063007AStrong carrying capacityHigh structural efficiencySelf-propelled projectilesWeld seamDiffusion function

The invention provides a carrier rocket booster tank structure for biased concentrated force. The structure comprises a front short shell, a front tank bottom, a cylinder segment, a rear tank bottom and a rear short shell, wherein the five parts form the whole tank structure through circumferential welded seams and form a sealed container which can store a propellant and bear various loads; the front short shell is welded into a whole by a radial outer reinforced wall plate and two positive outer reinforced wall plates, and the cylinder segment is composed of a mixed inner reinforced wall plate with a concentrated force diffusion function and an oblique inner reinforced wall plate. The carrier rocket booster tank structure solves the bearing and diffusion problem of the biased concentrated force, the biased concentrated force is diffused through the tank structure to become uniformly distributed force, and a good mechanical environment is provided for a cabin behind a tank. The tank structure has the characteristics of high bearing capacity, high structure efficiency, good concentrated force diffusion effect, etc.

Owner:SHANGHAI AEROSPACE SYST ENG INST

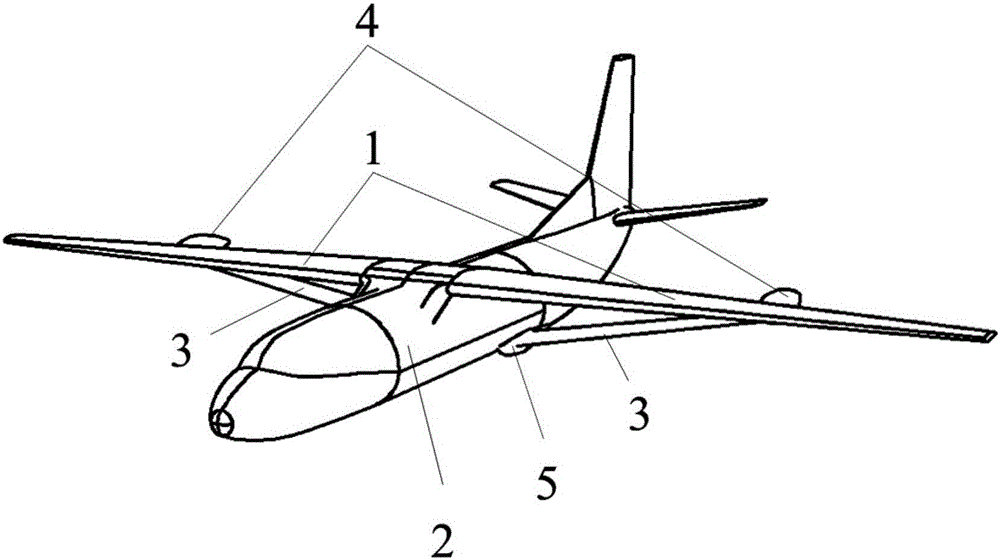

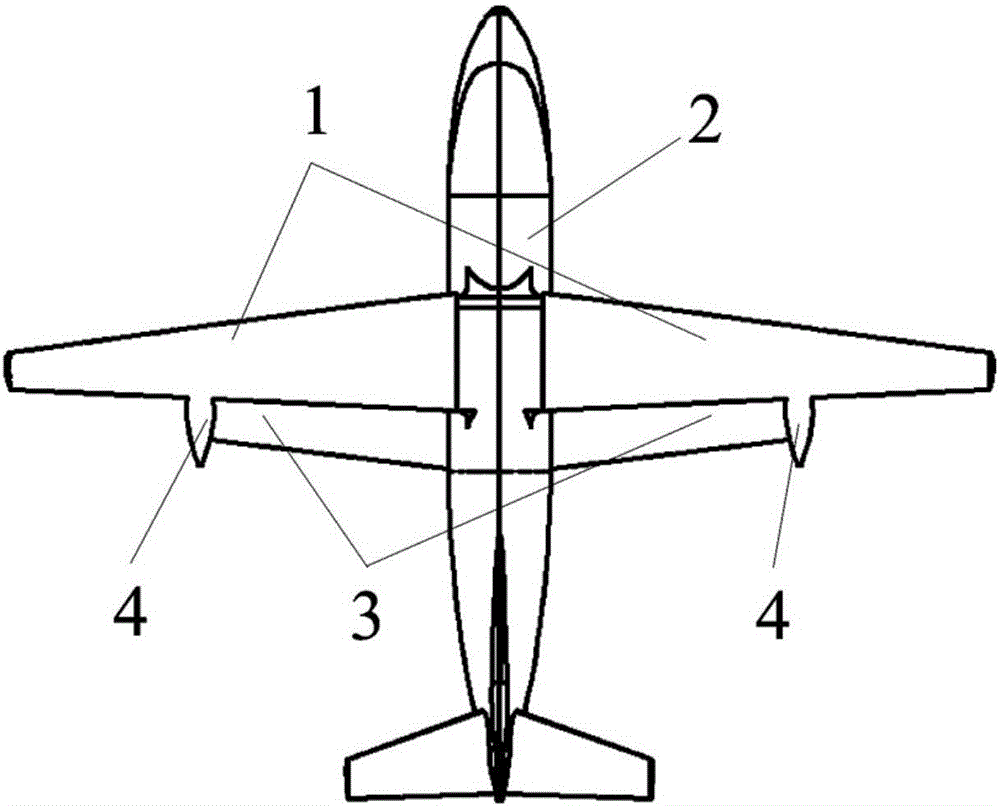

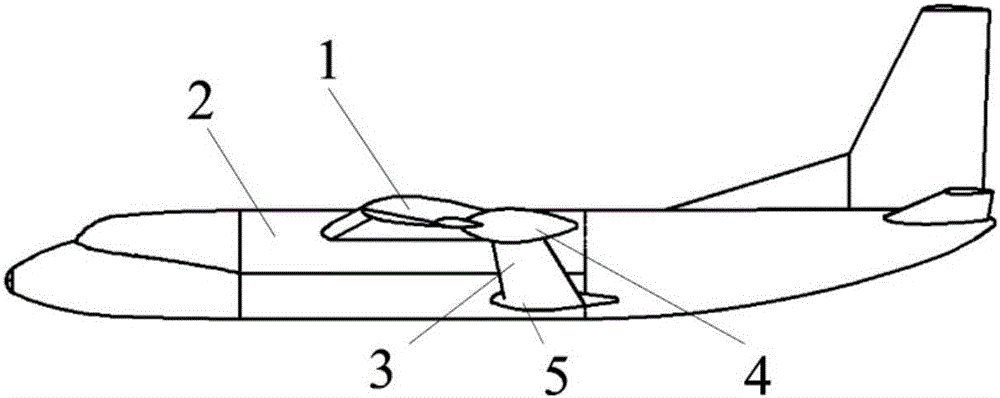

Air vehicle aerodynamic configuration with trailing edge supporting wing

ActiveCN105905277AImprove effectivenessHigh structural efficiencyAircraft stabilisationHeat reducing structuresVertical planeFlight vehicle

The invention discloses an air vehicle aerodynamic configuration with two trailing edge supporting wings. The supporting wings are installed below trailing edges of main wings at the two sides of a fuselage of an air vehicle. Wingtips of the supporting wings are connected to the middle parts of the trailing edges of the wings through connection sections. Wing roots of the supporting wings are connected to the fuselage through connection sections. The relative positions of the supporting wings and the main wings are reasonably designed. In a main wing cross section and a supporting wing cross section which are truncated by air flowing to a vertical plane in wingspans of the support wings upwardly during the flying process, the vertical distance between the centroids is a% of the chord length of the cross section of the main wing, wherein a is a constant value from 10 to 40; and meanwhile, the overlapping length of projections of the chord lines of the main wing cross section and the supporting wing cross section on a horizontal plane is b% of the chord length of the cross section of the main wing, wherein b is a constant value from 0 to 15. The aerodynamic configuration increases the total lift-drag ratio and achieves better aerodynamic performances, and also improves the rigidity of large-span-chord ratio wings and improves the total structural efficiency of the air vehicle.

Owner:BEIHANG UNIV

T-shaped connection structure of composite material laminboard

The invention provides a T-shaped connection structure of a composite material laminboard, comprising a connecting bottom plate, a honeycomb laminboard and a T-shaped reinforcing block, wherein the honeycomb laminboard is provided with a groove the shape of which is same with the shape of the upper end of a web of the T-shaped reinforcing block; the upper end of the web of the T-shaped reinforcing block is inserted into the groove; and a wing rafter of the T-shaped reinforcing block is in glue joint with the connecting bottom plate. The T-shaped connection structure also comprises two waveform connecting pieces, wherein the two waveform connecting pieces are positioned on two sides of the honeycomb laminboard; the waveform connecting pieces, the T-shaped reinforcing block and the honeycomb laminboard are fastened and connected by bolts; and the waveform connecting pieces and the connecting bottom pate are connected by glue and bolts in a mixing mode. The T-shaped connection structure has the advantages that the flexural rigidity is high; a bigger space is formed between the two waveform plates to bring convenience for overlaying a number of pipelines and subsequently maintaining; stress concentration on a joint can be effectively alleviated; the structural efficiency is improved; the bearing capability is enhanced, and the like. The T-shaped connection structure disclosed by the invention is suitable for mechanical connection between the composite material laminboard in a large-sized structure and other structures.

Owner:HARBIN ENG UNIV

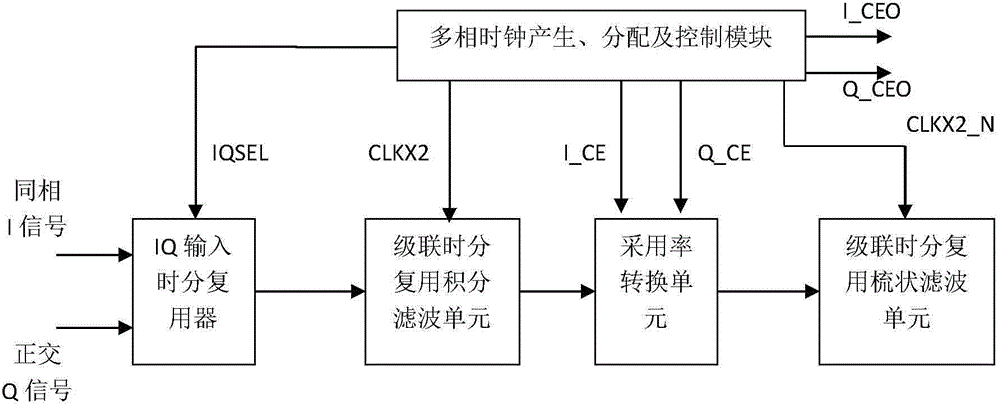

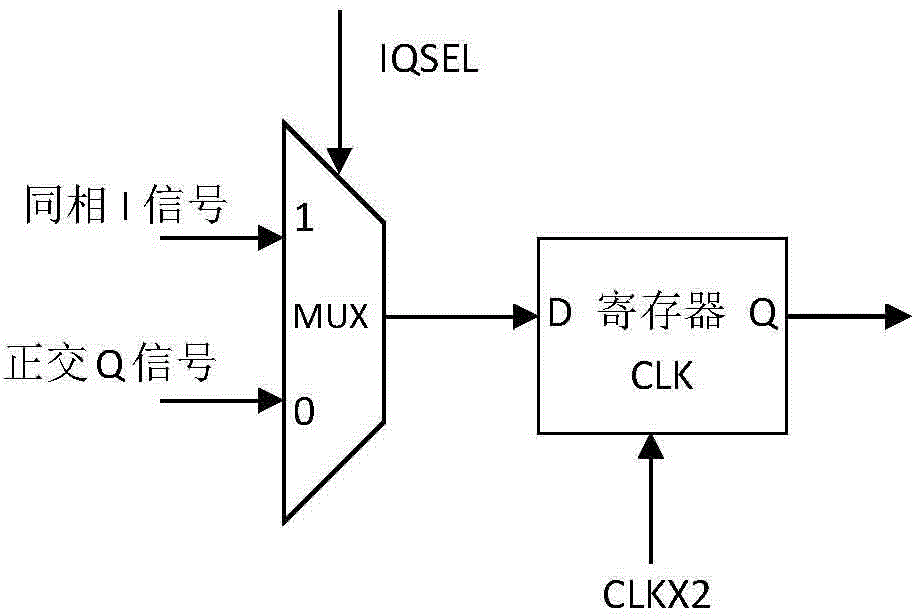

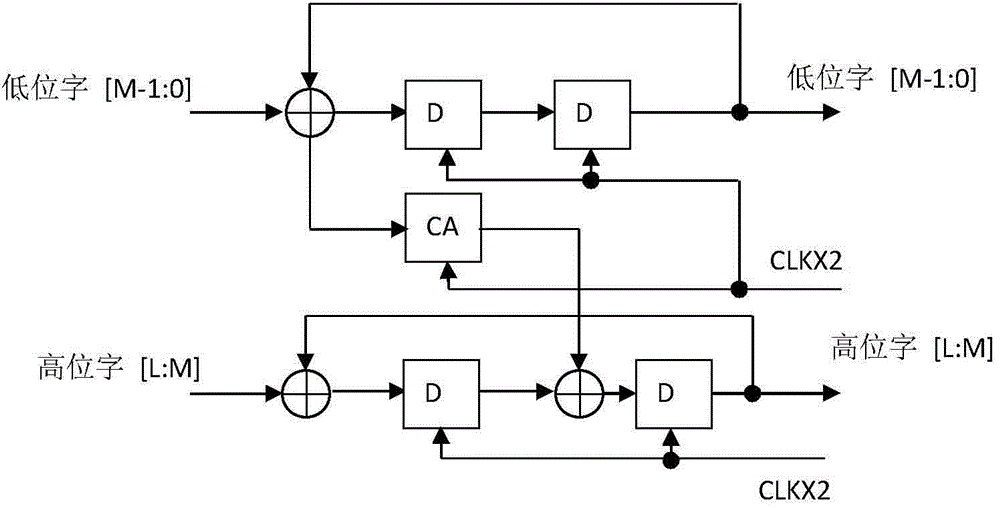

FPGA-based time division multiplexing cascaded integrator-comb decimation filter and realization method thereof

ActiveCN104393854AReduce occupancyFast operationDigital technique networkIntegratorCommunications system

The invention discloses a time division multiplexing cascaded integrator-comb decimation filter, comprising a multi-phase clock generation, distribution and control module, a cascaded integrator filter using a time division multiplexing and pipeline accumulator, a sampling rate conversion module, a time division multiplexing and cascade comb filter module and an in-phase and quadrature (IQ) input signal multiplexing module. Compared with the traditional cascaded integrator-comb (CIC) filter structure, the FPGA-based time division multiplexing cascaded integrator-comb decimation filter takes full use of the features of the FPGA (Field Programmable Gate Array) structure; while the occupation of the internal hardware resource of the FPGA chip is reduced, the computing speed of a circuit can be maintained or even improved, so that the efficiency of the cascaded integrator-comb (CIC) filter structure widely applied to digital communication systems and realized on the basis of the FPGA is improved.

Owner:HUAQIAO UNIVERSITY

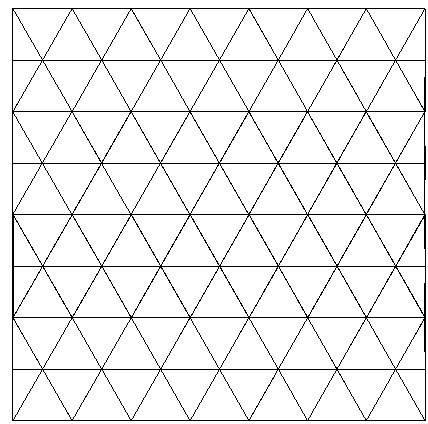

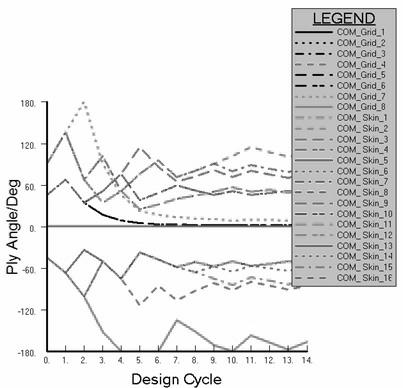

Aircraft wing box using grid structure and design method

InactiveCN102514709AImprove carrying capacityImprove fatigue lifeWingsSpecial data processing applicationsStress concentrationStress distribution

The invention relates to an aircraft wing part and especially to an aircraft wing box using a grid structure and a design method thereof. The aircraft wing box comprises grid ribs and skin panels; the skin panels wrap the outer sides of the grid ribs so as to form the aircraft wing box; and the aircraft wing box is characterized in that the grid ribs and a plurality of reinforcing ribs mutually intersect and form grid configuration, the grid ribs and the skin panels are both made of a plurality of layers of fiber reinforced composite laminates, the skin panels are fixed at the outer sides of the grid ribs and the grid ribs are made of eight layers of fiber reinforced composites laid at different angles. According to the invention, the grid ribs and the skin panels in a shape of an equilateral triangle are used, and compared to traditional wing boxes, the aircraft wing box provided in the invention has the following advantages: more superior stress distribution under the action of external load can be obtained, higher specific strength, specific rigidity and structural efficiency are obtained, the phenomenon of local stress concentration is reduced, weight of the structure is decreased, dangerous point stress which easily causes a composite material to lose efficacy is reduced, and bearing capacity and the fatigue life of the structure are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Synthesized pipe rack with frame composite structure

ActiveCN105821903AAvoid lateral instabilityHigh strengthArtificial islandsUnderwater structuresWeb structureEngineering

The invention discloses a synthesized pipe rack with a frame composite structure. The synthesized pipe rack comprises unit plate pieces positioned on the upper and lower surfaces, and side unit plate pieces positioned on two side surfaces; the unit plate pieces and the side unit plate pieces are combined and spliced to form unit pipe sections; the unit pipe sections are axially spliced to form the synthesized pipe rack; the unit plate pieces consist of plates, hollow second pipes positioned at two ends, and hollow first pipes positioned at the other two ends; the side unit plate pieces consist of plates, and hollow second pipes positioned at two ends; the second pipes are axial splicing ends of the unit pipe sections; and in splicing of the synthesized pipe rack, the first pipes form longitudinal beams of the synthesized pipe rack, and the adjacent second pipes are connected with each other to form a skeleton structure of the synthesized pipe rack. The longitudinal beams and the skeleton structure of the pipe rack bear main loads; a bridge steel web structure is formed to enhance the shearing resistance of the pipe rack, and is skillfully used; based on dual enhanced structures, the bearing capacity is greatly improved; and under the same filling height, wall plates with the structures are thinner, and materials are saved.

Owner:NANJING LIANZHONG CONSTR ENG TECH

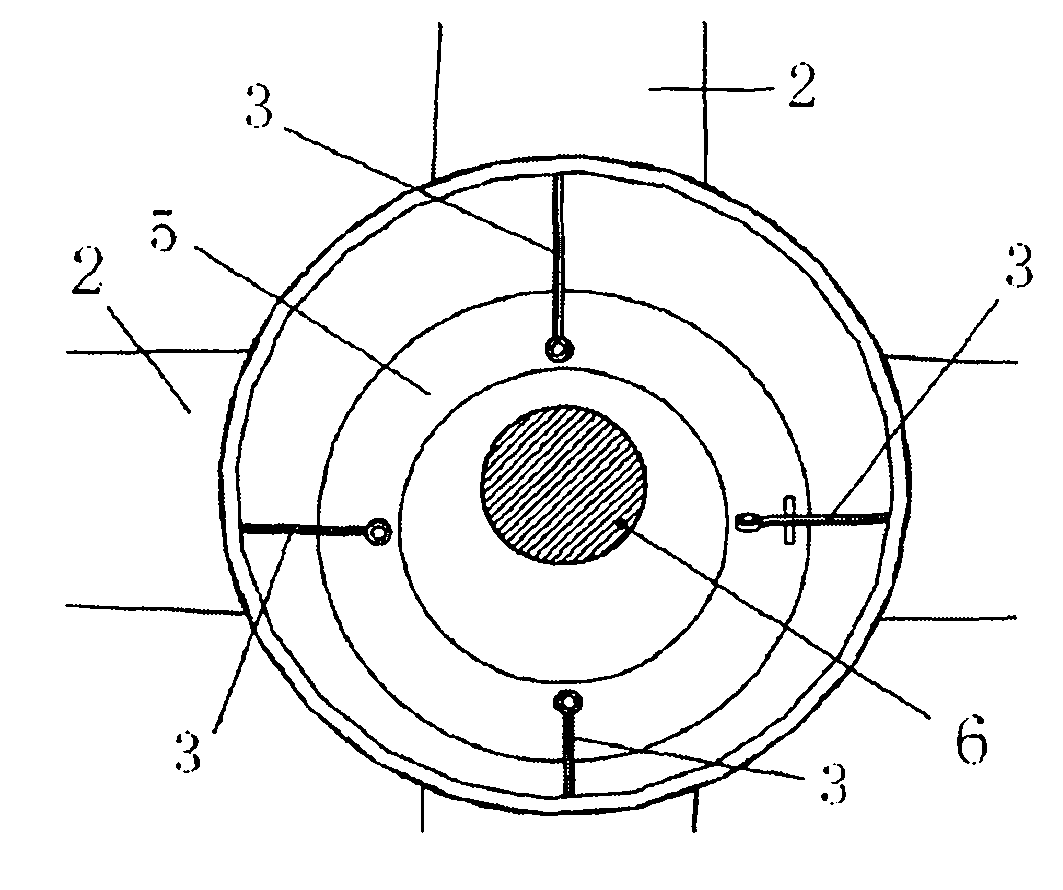

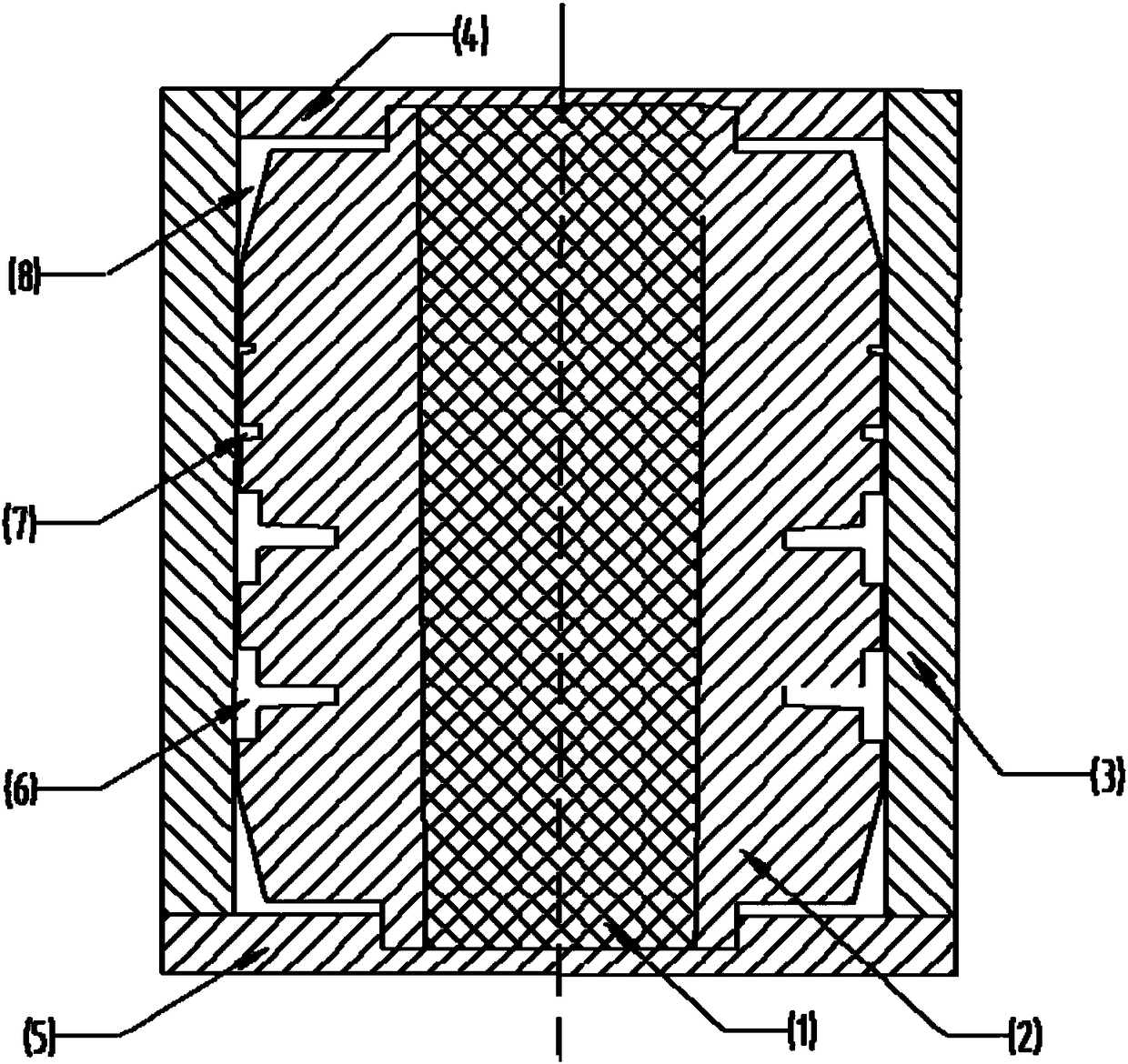

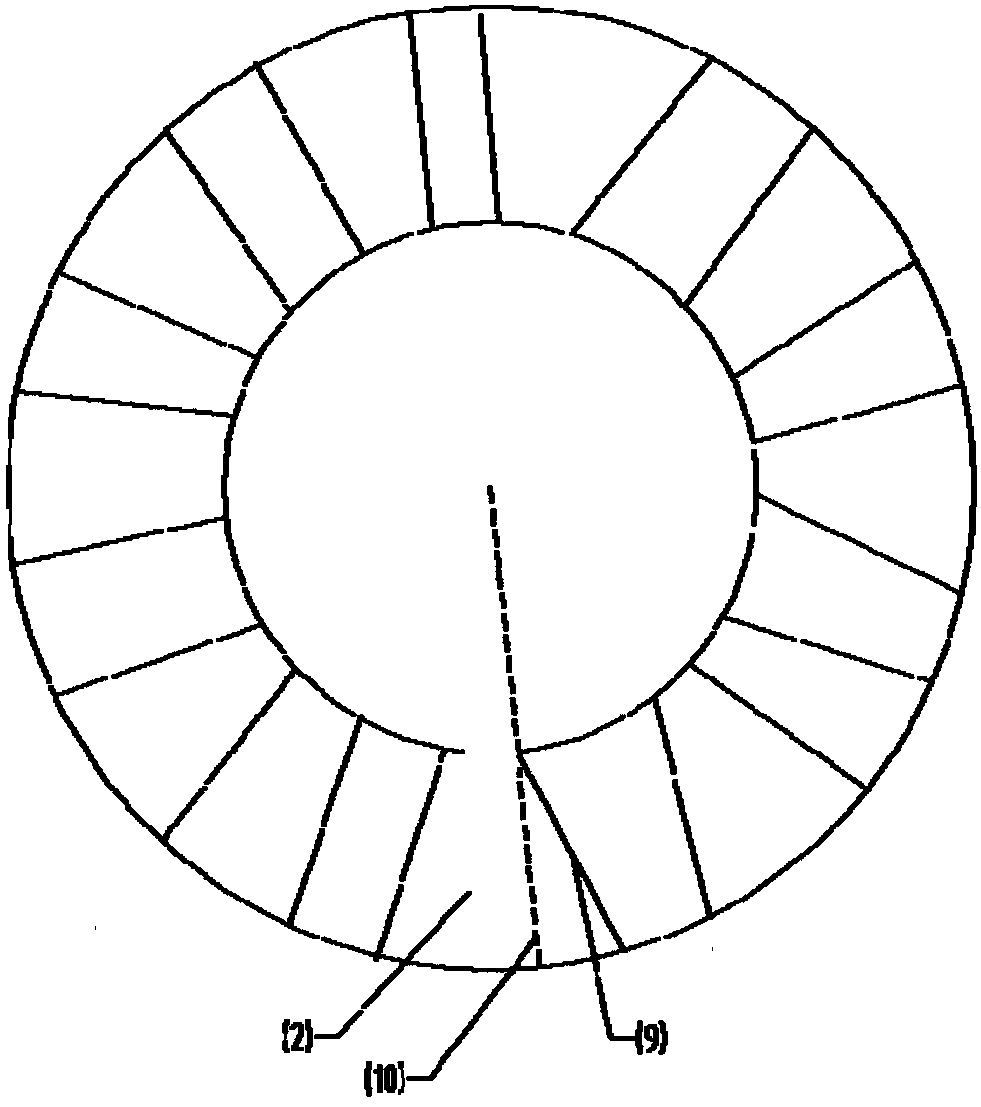

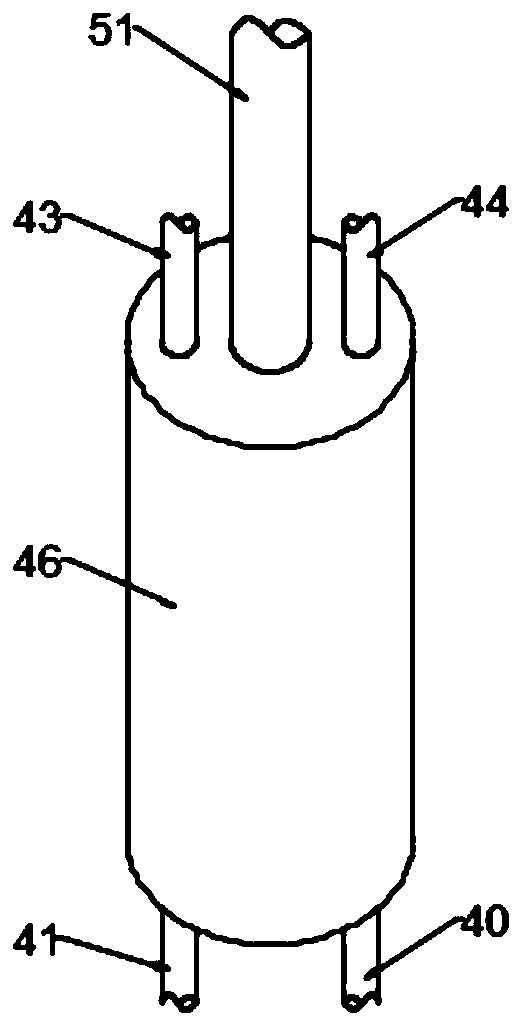

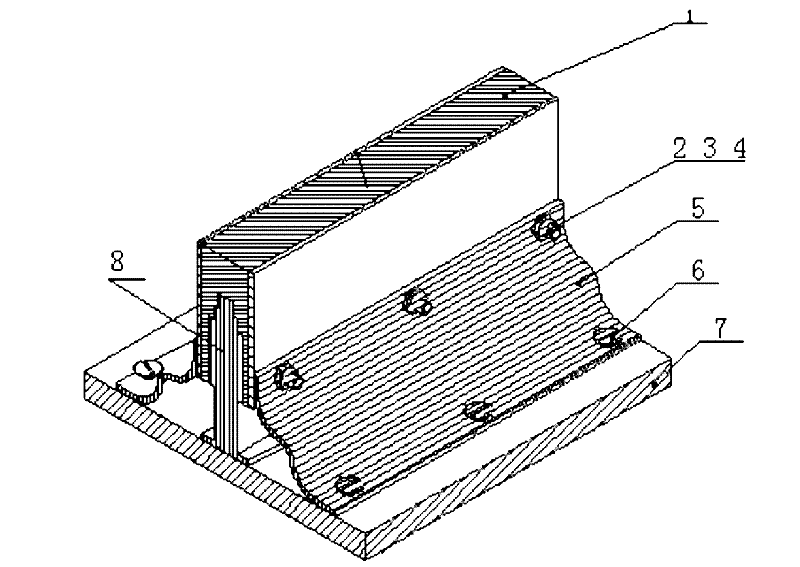

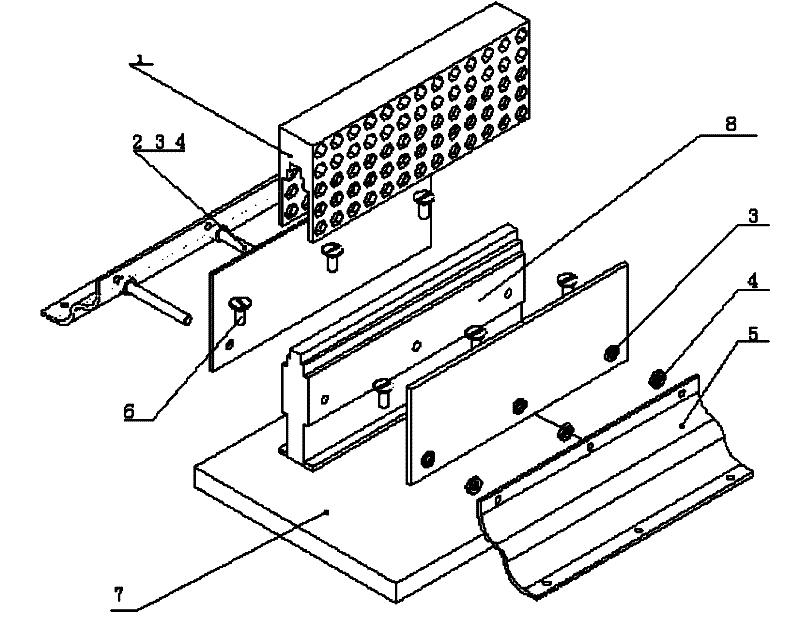

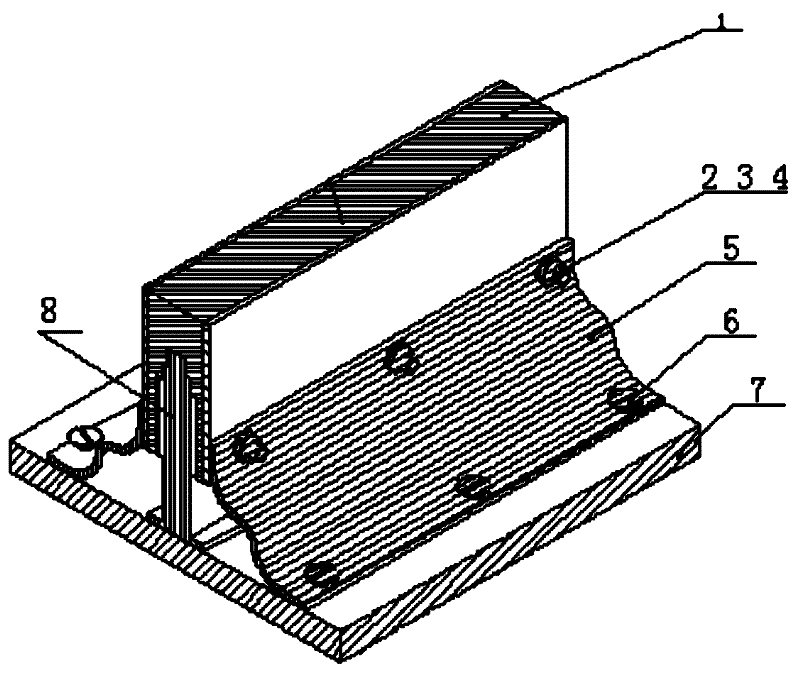

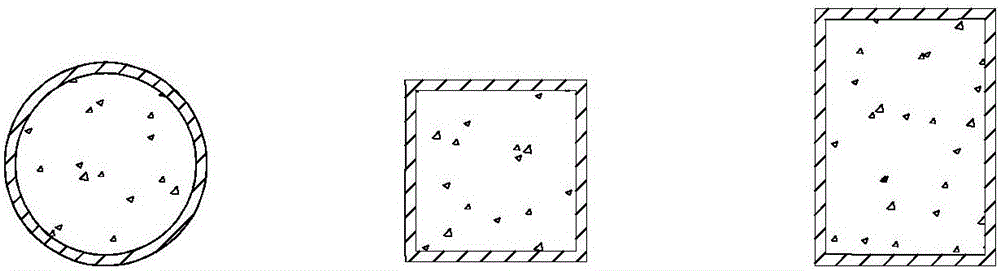

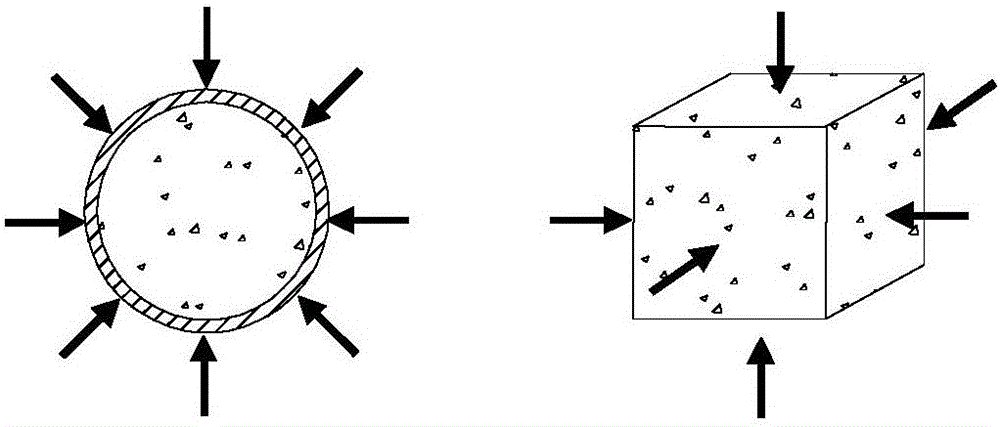

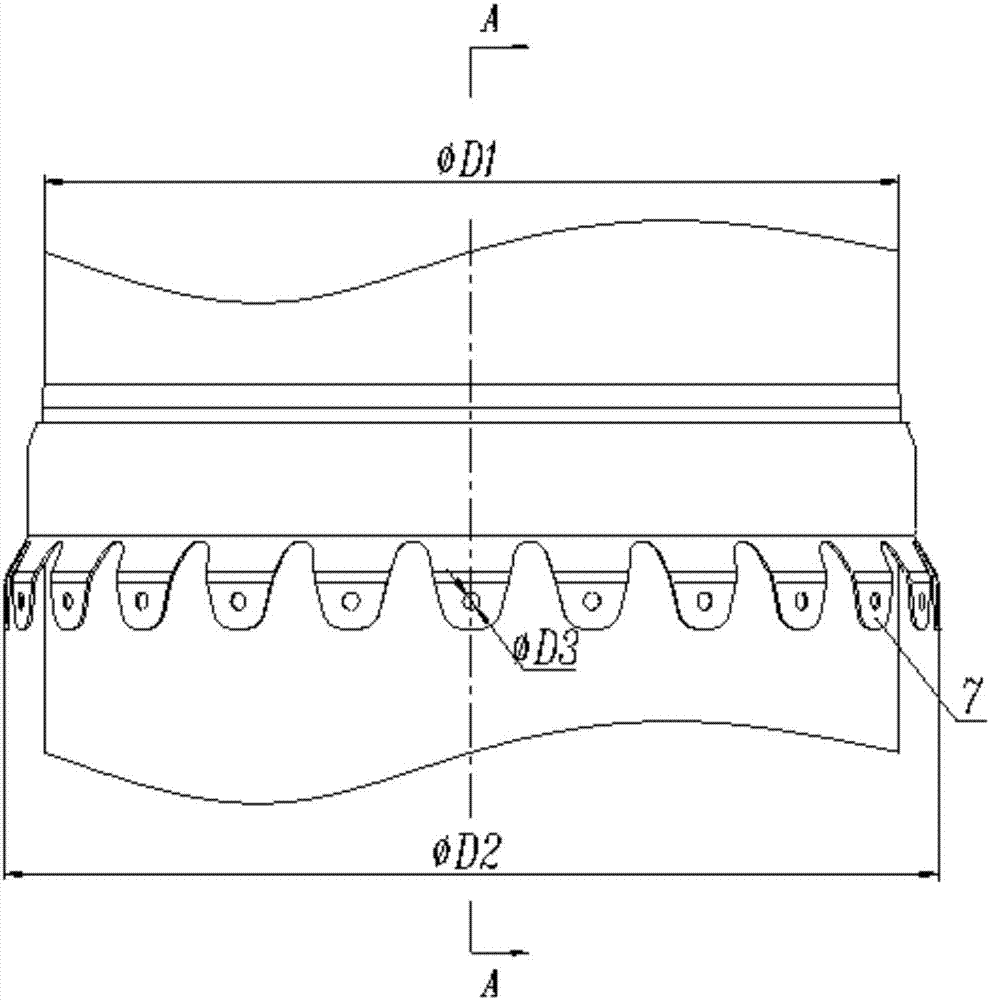

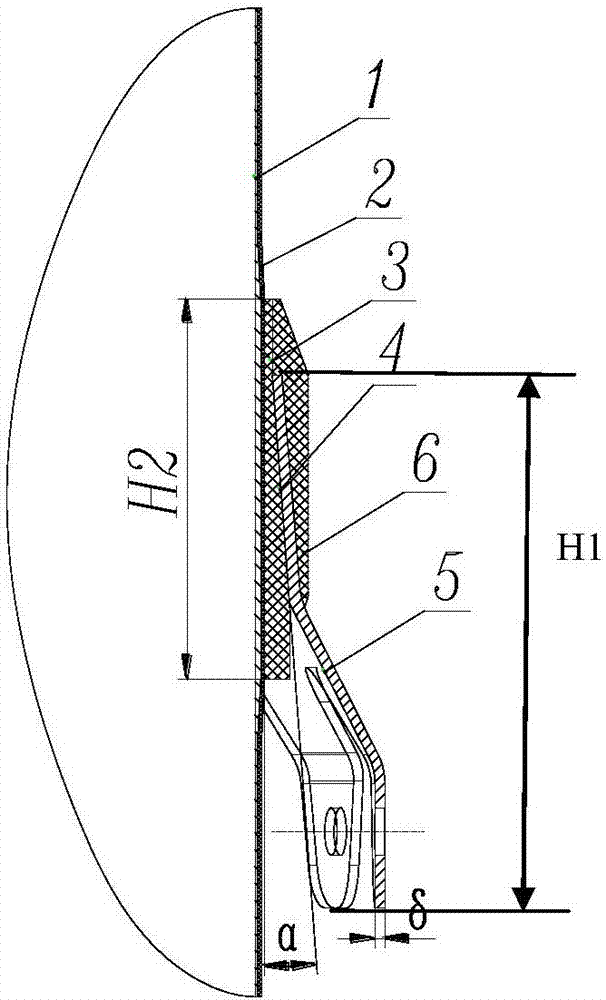

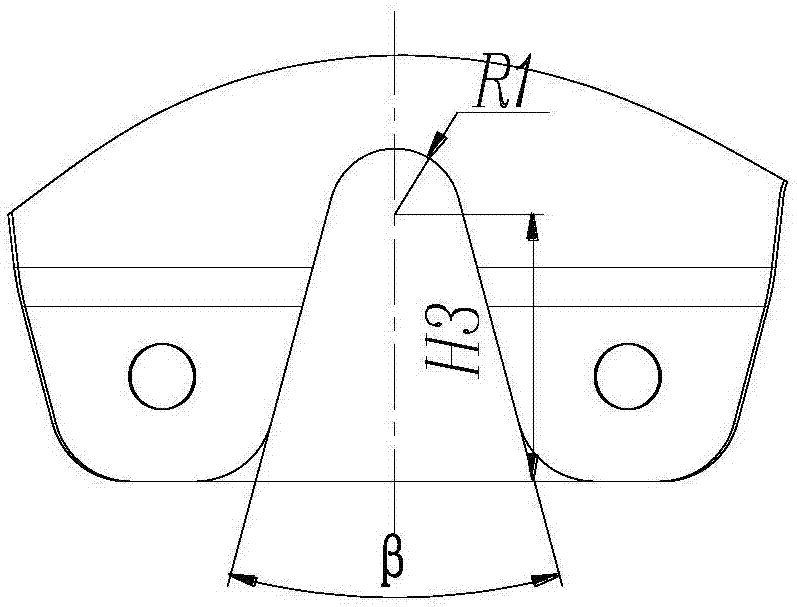

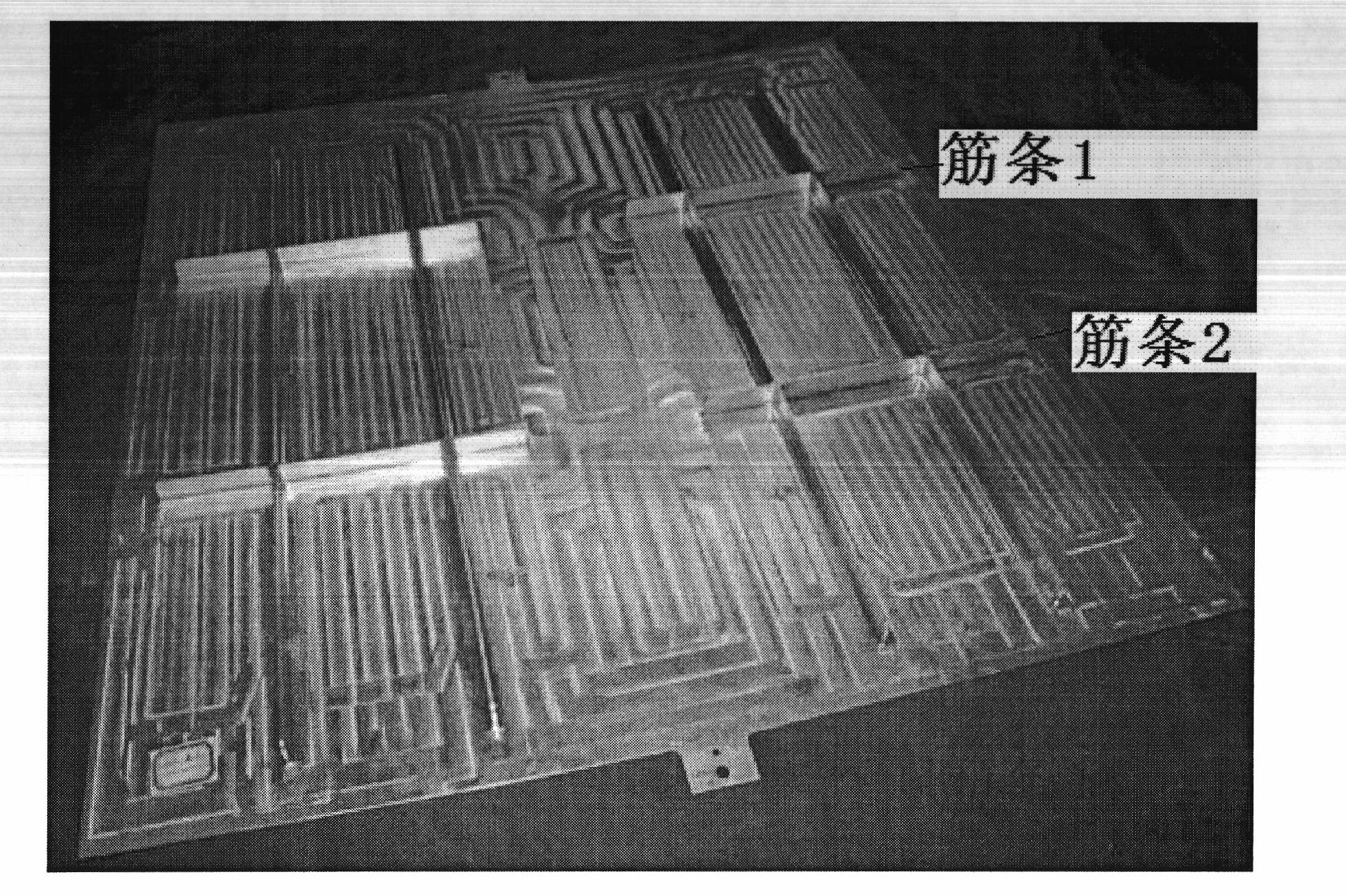

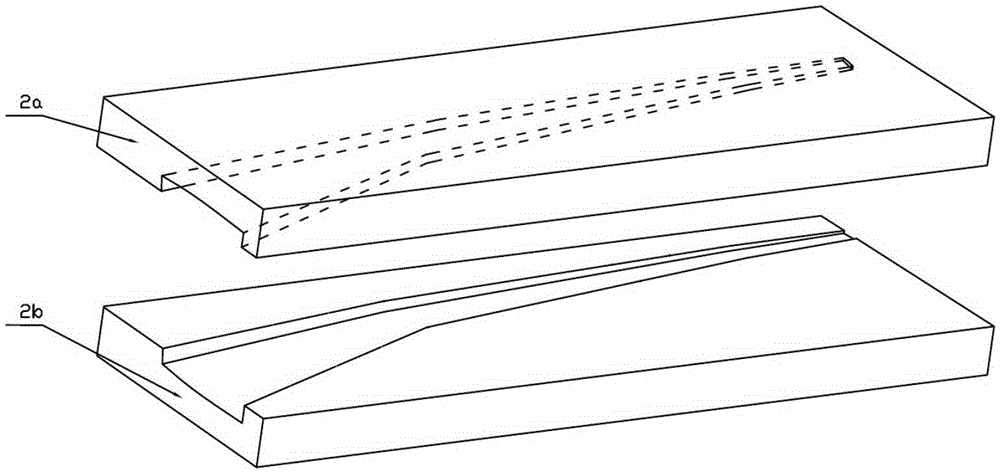

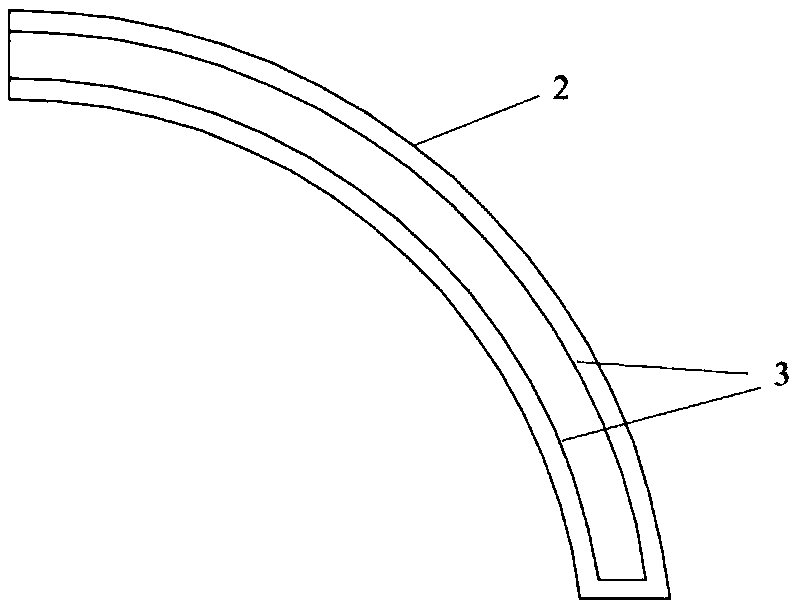

Propellant storage tank skirt mounting structure and manufacturing method thereof

ActiveCN107310821AImproving the overall structural efficiency and mechanical environment adaptability of the storage tankSolve the problem of single installation structureContainer/bottle contructionRigid containersAerospace engineeringMetal

The invention provides a propellant storage tank skirt mounting structure and a manufacturing method thereof. The propellant storage tank skirt mounting structure comprise a metal liner (1), a first composite layer (2) wound around the metal liner (1), a second composite layer (3) wound around the first composite layer (2), epoxy resin glue (4) spayed onto the second composite layer (3), a storage tank skirt (5) being in glue joint with the epoxy resin glue (4), and a third composite layer (6) wound around the storage tank skirt (5). According to the propellant storage tank skirt mounting structure, a storage tank is mounted on a final assembly structure through the storage tank skirt; the storage tank skirt (5) is made of an aluminum alloy or a composite and fixed on a storage tank shell in a glue-joint or winding manner; and accordingly, the propellant storage tank skirt mounting structure is capable of bearing the axial overload, the transverse overload and other mechanical environments. By adoption of the propellant storage tank skirt mounting structure, the problem that a conventional large-volume composite-wound storage tank shell mounting structure is difficult to design and manufacture, low in mechanical environment resistance, and the like can be solved, as well as the whole structure efficiency of the storage tank and the mechanical environment applicability can be improved.

Owner:SHANGHAI INST OF SPACE PROPULSION

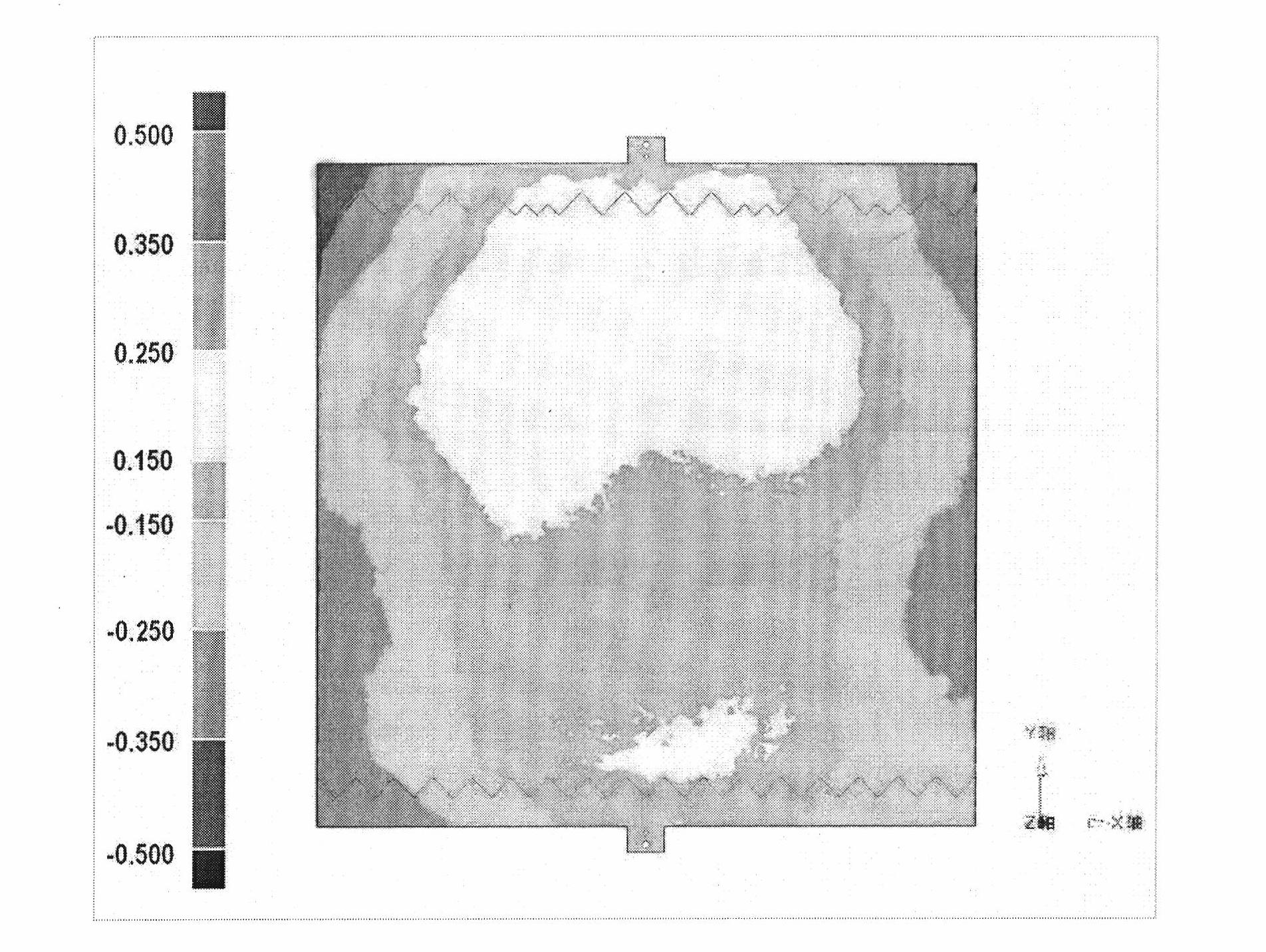

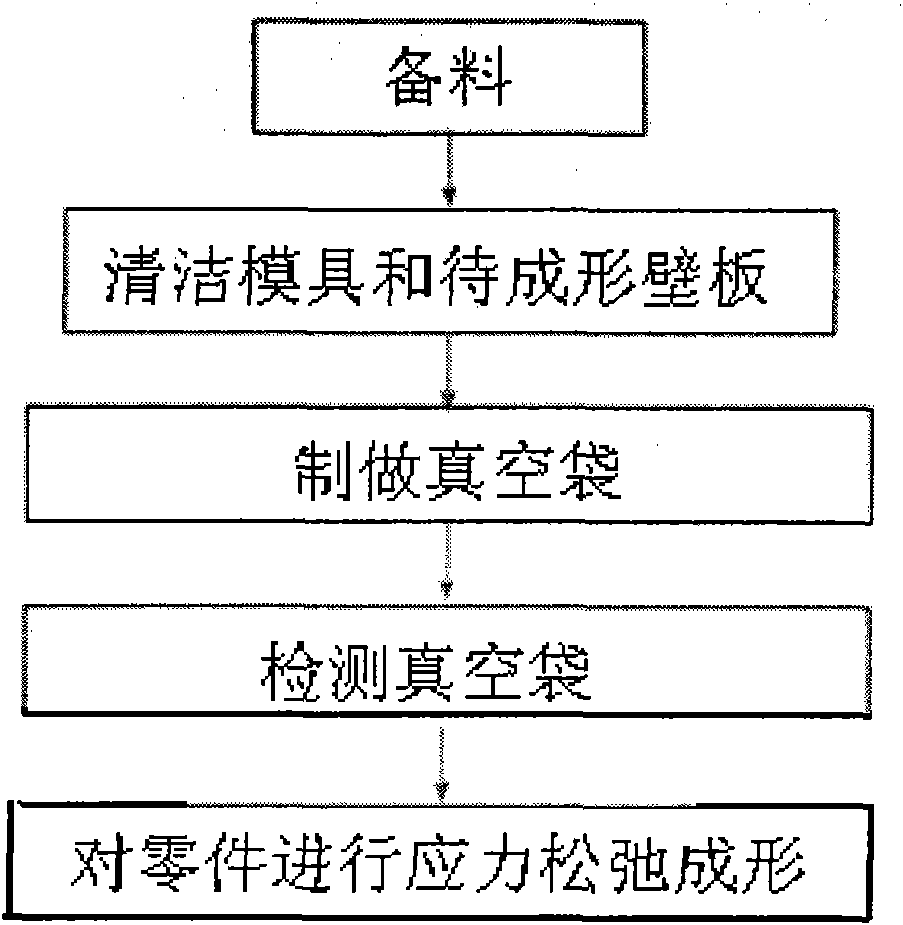

Stress-relaxation shaping method for complicated irregular-shaped integrated wallboard

InactiveCN102191444AHigh structural efficiencyShorten the production cycleFurnace typesHeat treatment furnacesFast releaseEngineering

The invention relates to a stress-relaxation shaping method for a complicated irregular-shaped integrated wallboard, which is characterized by the steps of: positioning wallboard parts above a mold in a sealed space formed by a vacuum bag and a bottom plate of the mold, vacuumizing, and increasing the pressure of an autoclave to form a pressure difference between the inside and outside of the sealed space, so that the parts are abutted against the mold due to the external pressure so as to form the shape of mold surface. High temperature is beneficial to rapid release of the internal stress of the deformed parts so as to transform elastic deformation into plastic deformation, thus realizing stress-relaxation shaping. The invention has a simple shaping process, is convenient to operate, and overcomes the defects of high processing cost and long production period of parts such as wallboards of airplane because of the difficulty in manufacturing a high-rib complicated irregular-shaped integrated wallboard.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Manufacturing method for low-speed wing flutter wind tunnel model

ActiveCN105354348AGeometry simulation is accurateGuaranteed accuracySpecial data processing applicationsLow speedManufacturing technology

The invention belongs to the technical field of design and manufacturing of composite material structures and aircraft wind tunnel aeroelastic test models, and relates to a manufacturing method for a low-speed wing flutter wind tunnel model. The invention provides the manufacturing method for the low-speed wing flutter wind tunnel model, which is a novel manufacturing method for a wing flutter model, and can effectively improve structural efficiency, reduce structural weight of the model, ensure accuracy of geometric precision, model rigidity and quality characteristics of a model shape and more effectively simulate flutter characteristics of a composite wing. Key points and protective points of the invention are that wing box skin, wing ribs and front and rear webs are all made from composite materials, and a flutter model structure form of bearing force mainly by the skin is adopted; a manufacturing process for a composite flutter model wing box is provided; and a material selection and manufacturing process for a counterweight of the flutter model is provided.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

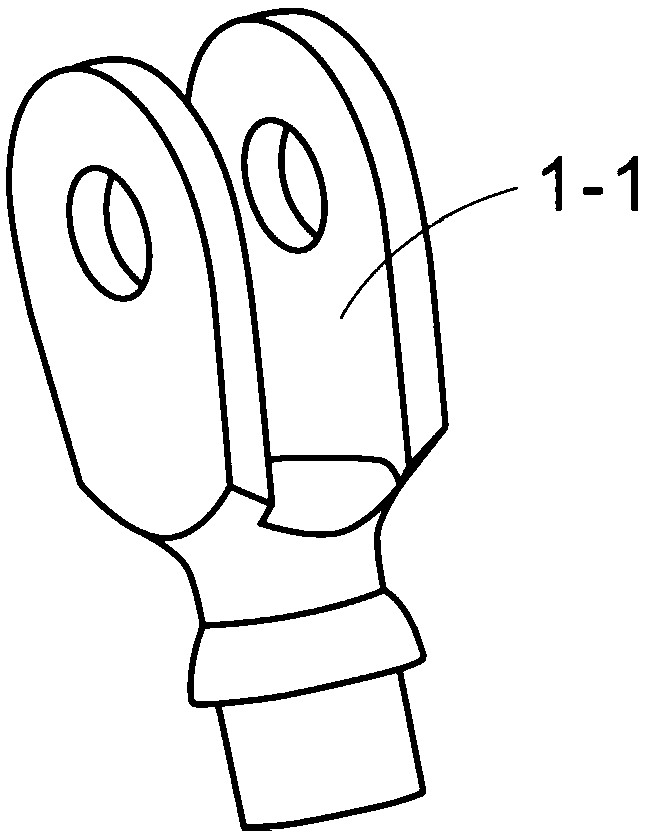

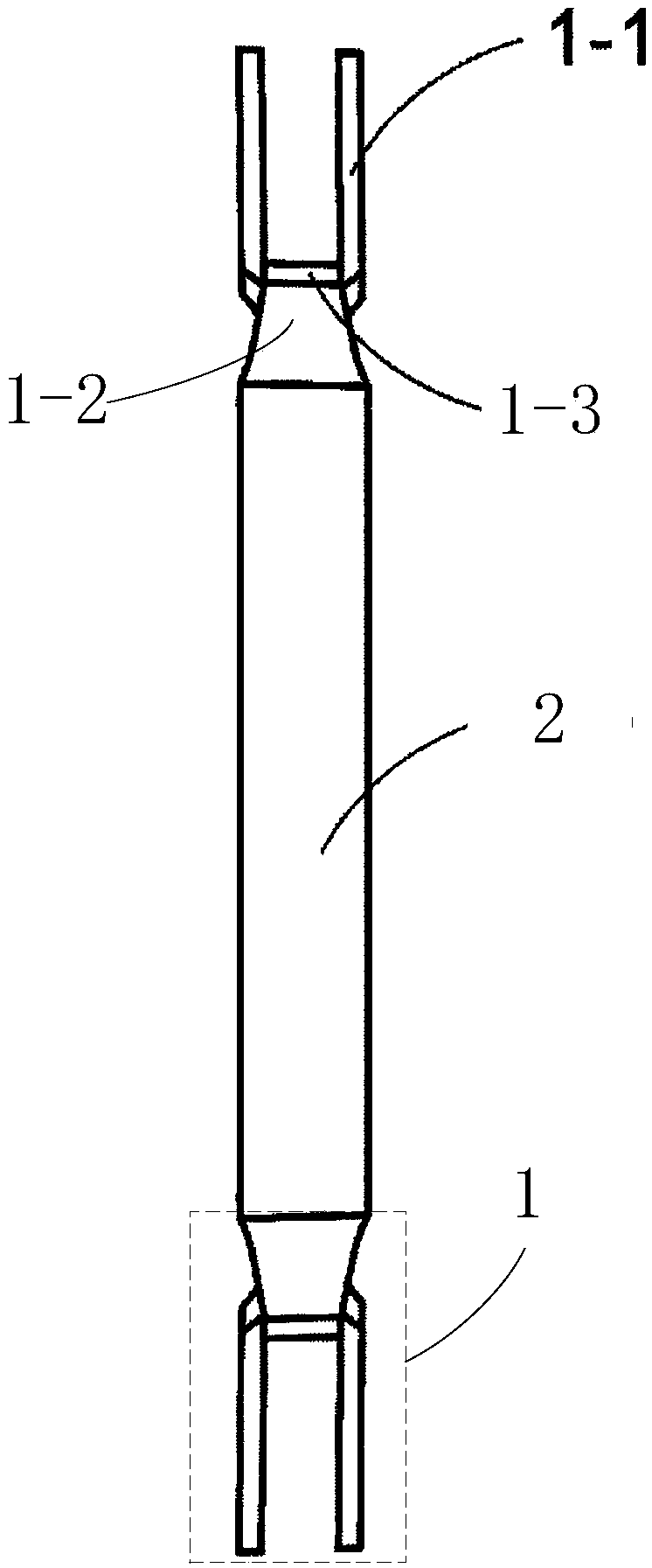

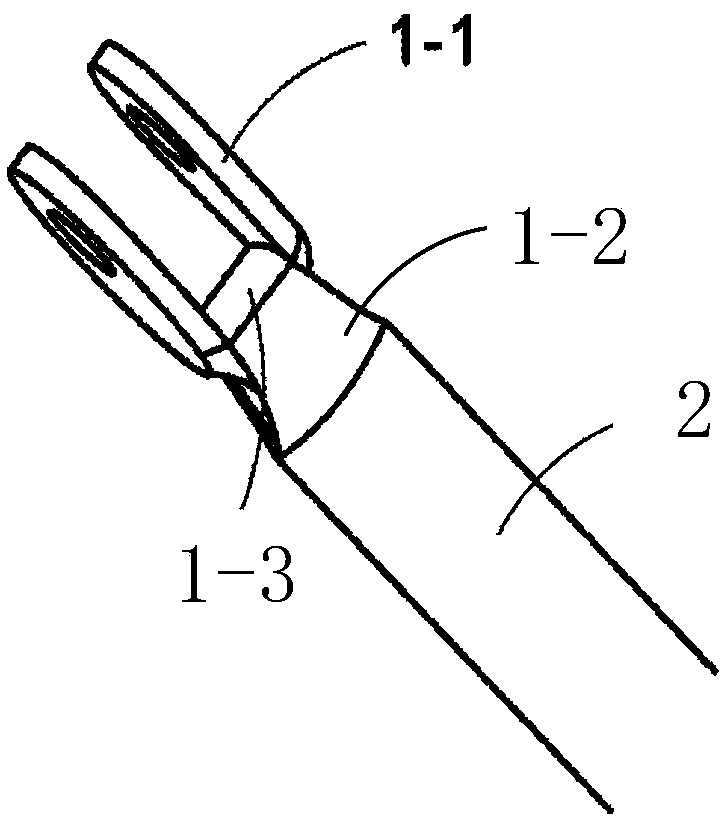

Connecting rod structure for combining composite material with metal

In view of a problem of poor durability of a barrel body and a metal connector of an existing composite connecting rod, the invention provides a connecting rod structure for combining a composite material with metal, and belongs to the technical field of aircraft weight reduction. The connecting rod structure provided by the invention comprises two metal connectors and a composite barrel body, wherein the two metal connectors are respectively connected with two ends of the composite barrel body; each metal connector comprises two metal lugs and one metal connecting structure; the two metal lugs are arranged at a first end of the metal connecting structure; the two metal lugs and the metal connecting structure form an integrated structure; the composite barrel body is an inner-outer double-cylinder structure; a tail end of the metal connecting structure of the two metal connectors is respectively connected with two end parts of an inner cylinder of the composite cylinder body; in an axial direction of the connecting rod, the metal connecting structure of the two metal connectors and the inner cylinder of the composite cylinder body are wound together by a composite material; and anouter cylinder of the composite cylinder body is formed on outer surfaces of the inner cylinder and the metal connecting structure.

Owner:HARBIN INST OF TECH

Embedded waveguide printed circuit board structure

InactiveCN101128088ALow costHigh structural efficiencyHigh frequency circuit adaptationsPrinted circuit aspectsPrinted circuit boardEngineering

In some embodiments a channel is formed in printed circuit board material, the formed channel is plated to form at least two side walls of an embedded waveguide, and printed circuit board material is laminated to the plated channel. Other embodiments are described and claimed.

Owner:INTEL CORP

An aircraft cabin structure with large openings

The invention discloses an aircraft cabin structure with a large opening, which is a conical-cylindrical riveted structure, the upper part is a conical section, the lower part is a cylindrical section, and the opening is located in the cylindrical section; The structure comprises a skin, a plurality of frame rings arranged horizontally and a plurality of stringers arranged vertically, the plurality of frame rings sequentially comprise a conical segment front end frame from the top to the bottom, The middle frame of the cone section, the connecting frame of the cylinder cone, several middle frames of the cylinder section, and the rear end frame of the cylinder section are respectively provided with a cone section reinforcing stringer, a front joint, a beam of the cylinder section, and a rear joint on each side of the left and right sides of the opening from the top to the bottom. The middle frames of the cylinder section on the upper and lower sides of the opening are respectively arranged as the middle frame I of the cylinder section and the middle frame V of the cylinder section. Various reinforcing structures are arranged around the large-scale opening of the cabin body to realize the transmission and diffusion of concentrated forces on both sides of the opening.

Owner:SHANGHAI AEROSPACE SYST ENG INST

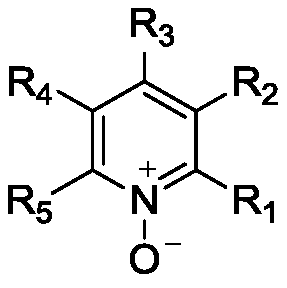

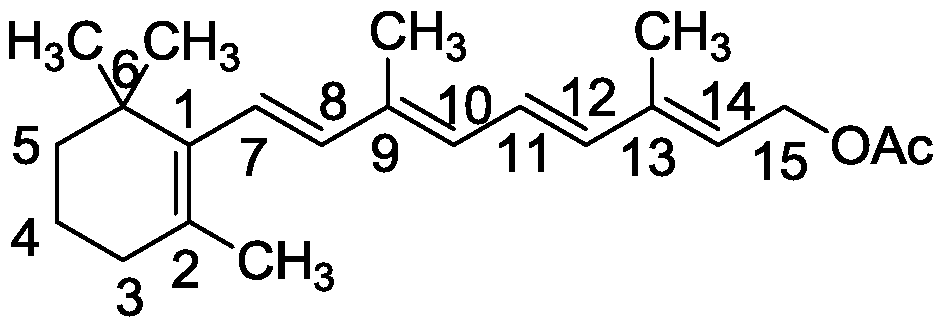

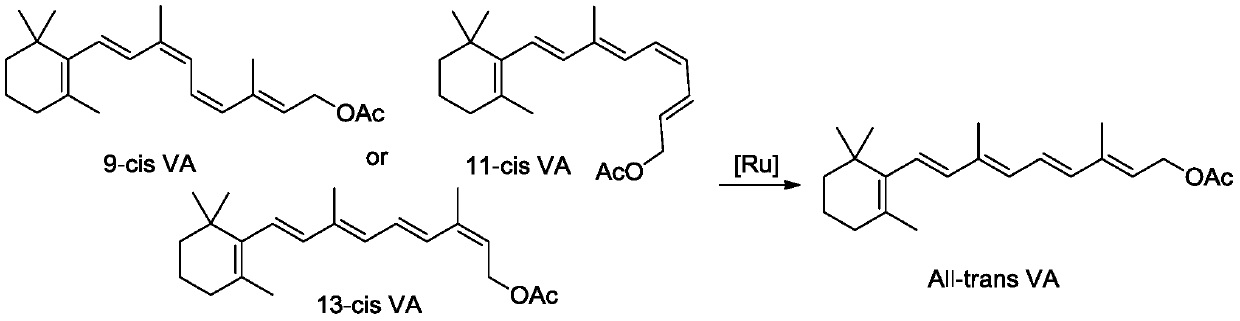

Method for catalyzing vitamin A isomerization with ruthenium catalyst

ActiveCN111004163AReduce dosageLower reaction costOrganic chemistry methodsRuthenium CompoundsCombinatorial chemistry

The invention provides a method for catalyzing vitamin A isomer conversion with a ruthenium catalyst. According to the method, a ruthenium compound is used as a catalyst, various vitamin A cis-isomerswith low biological activity can be converted into all-trans-isomers with high biological activity in a high proportion in the presence of an auxiliary agent, and the cis-isomers comprise 9-cis-isomers, 11-cis-isomers and 13-cis-isomers. The method has the characteristics of cheap and easily available catalyst, less catalyst dosage, mild reaction conditions, low reaction cost, high isomerizationefficiency and the like.

Owner:WANHUA CHEM GRP CO LTD

Temperature-driven 4D printing robot

InactiveCN110587619AHigh structural efficiencySimple structureProgramme-controlled manipulatorLaser beam welding apparatusTemperature controlLiquid medium

The invention belongs to the field of robots, and discloses a temperature-driven 4D printing robot. The robot comprises a robot body and driving feet arranged at the periphery of the robot body, wherein the center of each driving foot is provided with a liquid medium pipeline in a penetrating mode; liquid media are filled in the pipelines, and the robot body is internally provided with a temperature control unit; the temperature control unit is used for regulating the temperature of the liquid media in the pipelines in real time; the driving feet are made from shape memory alloy materials; when the temperature of the liquid media is changed, the driving feet are deformed according to the temperature change, so that the form of the driving feet is changed; and thus, the robot body is moved.Through the 4D printing robot, under the condition of no external forces utilized, the leftward or rightward walking of the robot can be achieved according to the requirements; and the 4D printing robot has the characteristics of the simple structure, higher efficiency of a crawling mechanism, applicability to intelligent control and multi-degree-of-freedom walking and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

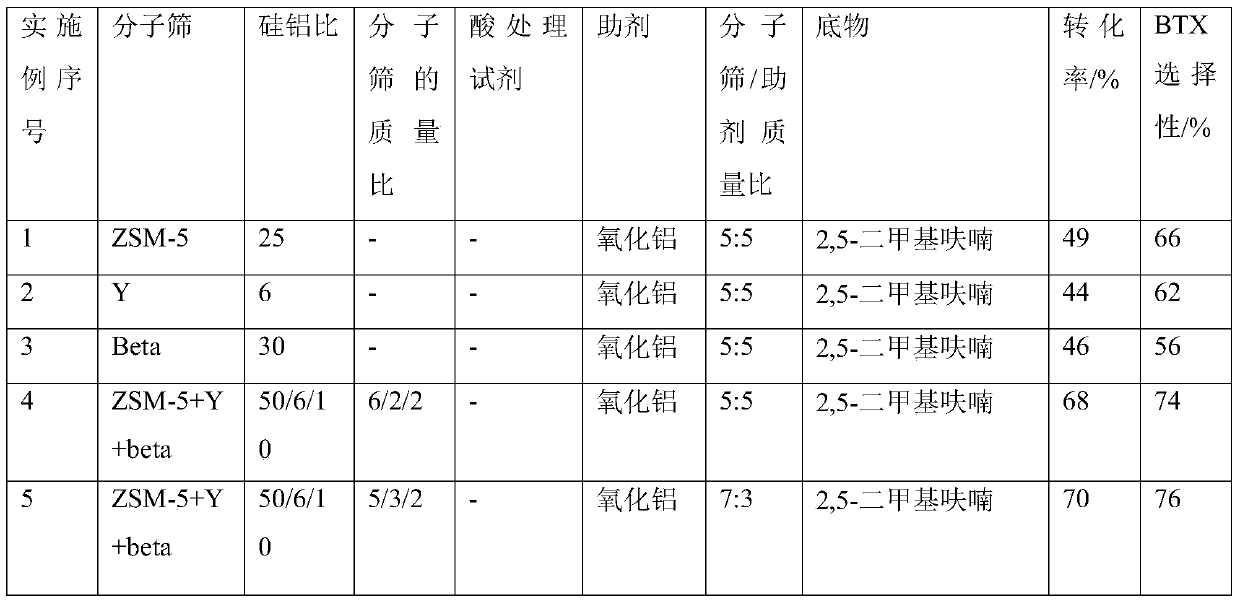

Method for efficient preparation of biomass based aromatic hydrocarbon

ActiveCN105498827AHigh structural efficiencyLow costMolecular sieve catalystsHydrocarbon from oxygen organic compoundsFuranMolecular sieve

The invention relates to a method for efficient preparation of biomass based aromatic hydrocarbon, and mainly solves the problem of low aromatization efficiency in the process of preparing aromatic hydrocarbon from biomass based furan derivatives. According to a technical scheme, a multicomponent composite molecular sieve with synergistic effect is employed for aromatization of a furan compound, the reaction temperature is 300-800DEG C, the hydrogen pressure is 0.1-5MPa, and the weight space velocity is 0.3-10h<-1>. Catalytic aromatization is carried out on the furan compound to perform high selectivity preparation of benzene, toluene, xylene and other aromatic compounds, the raw material conversion rate and the selectivity of benzene, toluene and xylene all reach more than 80%. Through the synergistic effect of the molecular sieve in the catalyst, the method improves the aromatization efficiency of the furan compound, well solves the problem of low efficiency in preparation of benzene, toluene and xylene from biomass based furan compounds, and can be used for the field of preparation of aromatic hydrocarbon from non-fossil resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com