Omnidirectional vectored thrust cycloidal propeller

A vector thrust and cycloidal propeller technology, applied in the field of omnidirectional vector thrust cycloidal propellers, can solve the problems of large aerodynamic resistance, heavy structure, single thrust direction, etc., achieve high structural efficiency, reduce induced loss, area and span smaller than the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

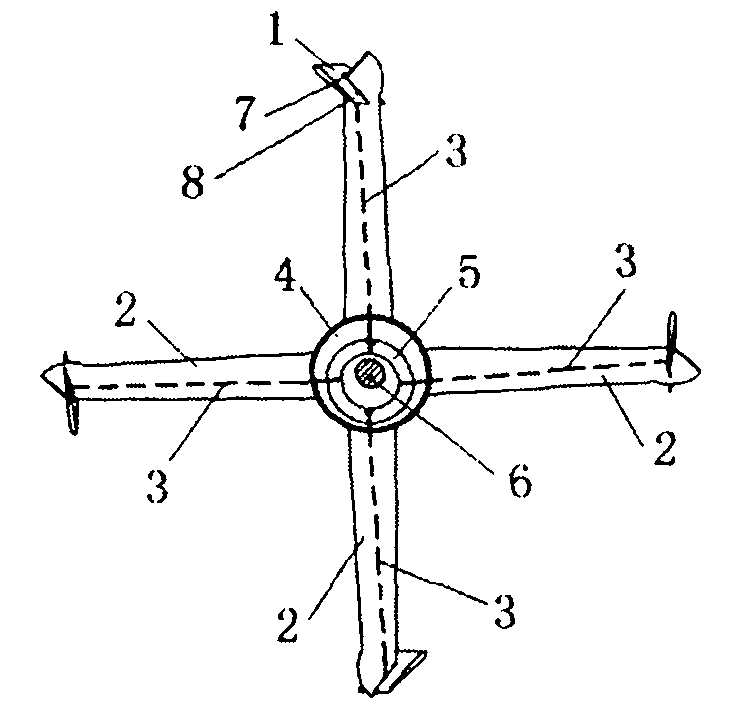

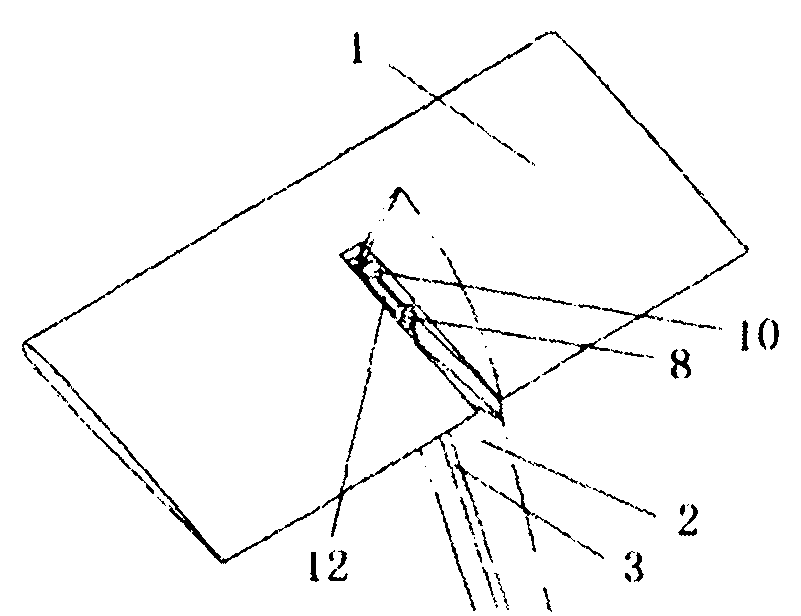

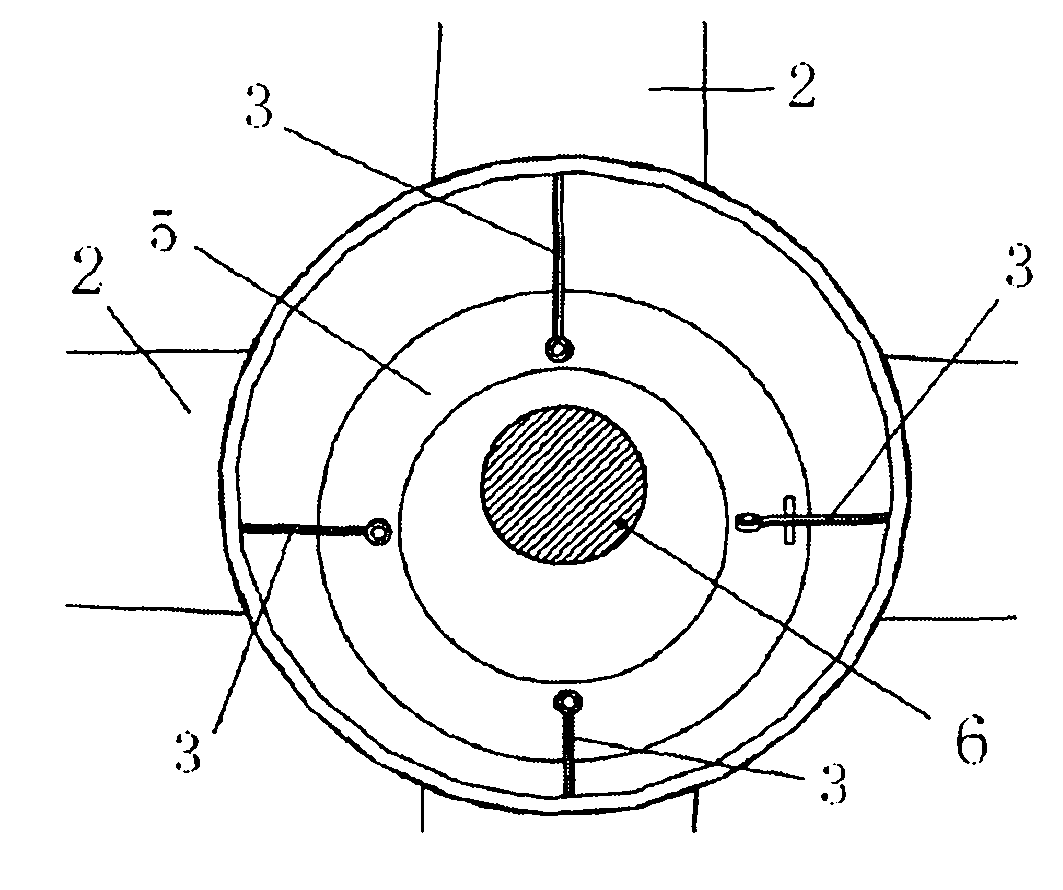

[0057] This embodiment is a cycloidal propeller for an aircraft, including a propeller and a cycloidal propeller. The propeller includes a propeller blade 2, a propeller shaft 6 and a propeller hub 4; the cycloidal propeller includes a cycloidal propeller blade 1, a control rod 3, an operating rocker arm 12, a spherical hinge 8 and an eccentric ring positioning mechanism 17.

[0058] The propeller blade 2 adopts a single-beam structure made of carbon fiber composite material, and the airfoil used is a Clark-Y airfoil with relatively large thickness and good lift-drag characteristics. The propeller blade 2 has an aspect ratio of 8 and a chord length of 10 cm. The paddle hub 4 is hollow and has a diameter of 32cm. The diameter of propeller rotating shaft 6 is 8cm. The inside of the propeller blade 2 is equipped with a control rod 3 (such as Image 6 Section A-A shown). The leading edge of the propeller blade 2 is swept back by 45 degrees at the blade tip, and the cycloidal b...

Embodiment 2

[0069] This embodiment is a cycloidal propeller for an aircraft, including a propeller and a cycloidal propeller. The propeller includes a propeller blade 2, a propeller shaft 6 and a propeller hub 4; the cycloidal propeller includes a cycloidal propeller blade 1, a control rod 3, an operating rocker arm 12, a spherical hinge 8 and an eccentric ring positioning mechanism 17. There are 3 propeller blades and cycloidal blades in this embodiment.

[0070] The propeller blade 2 adopts a single beam structure made of carbon fiber composite material, and the airfoil used is the HS1-404 airfoil commonly used by propellers. The propeller blade 2 has an aspect ratio of 7 and a chord length of 5 cm. The paddle hub 4 is hollow and has a diameter of 16cm. The diameter of propeller rotating shaft 6 is 4cm. The inside of the propeller blade 2 is equipped with a control rod 3 (such as Image 6 Section A-A shown). The leading edge of the propeller blade 2 is swept back by 45 degrees at t...

Embodiment 3

[0078] This embodiment is a cycloidal propeller for an aircraft, including a propeller and a cycloidal propeller. The propeller includes a propeller blade 2, a propeller shaft 6 and a propeller hub 4; the cycloidal propeller includes a cycloidal propeller blade 1, a control rod 3, an operating rocker arm 12, a spherical hinge 8 and an eccentric ring positioning mechanism 17. There are 6 propeller blades and cycloidal blades in this embodiment.

[0079] The propeller blade 2 adopts a single beam structure made of carbon fiber composite material, and the airfoil used is the E197 airfoil. The aspect ratio of the propeller blade 2 is 7.5, and the chord length is 20cm. The paddle hub 4 is hollow and has a diameter of 60cm. The diameter of propeller rotating shaft 6 is 20cm. The inside of the propeller blade 2 is equipped with a control rod 3 (such as Image 6 Section A-A shown). The leading edge of the propeller blade 2 is swept back by 45 degrees at the blade tip, and the cyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com