Minitype ornithopter wing driving mechanism with changeable wing area

A technology of a flapping-wing aircraft and a driving mechanism, which is applied in the field of micro flapping-wing aircraft, can solve the problem that the wing area of the micro- flapping-wing aircraft is difficult to change greatly, and achieve the effects of simple structure, high flight efficiency and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

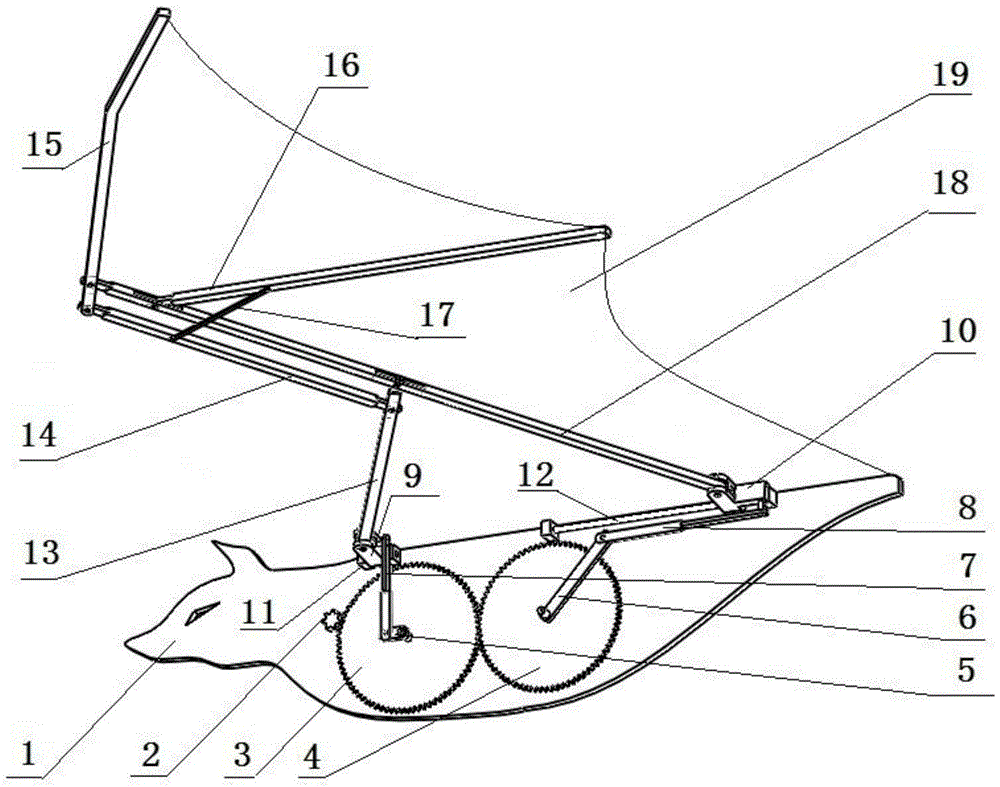

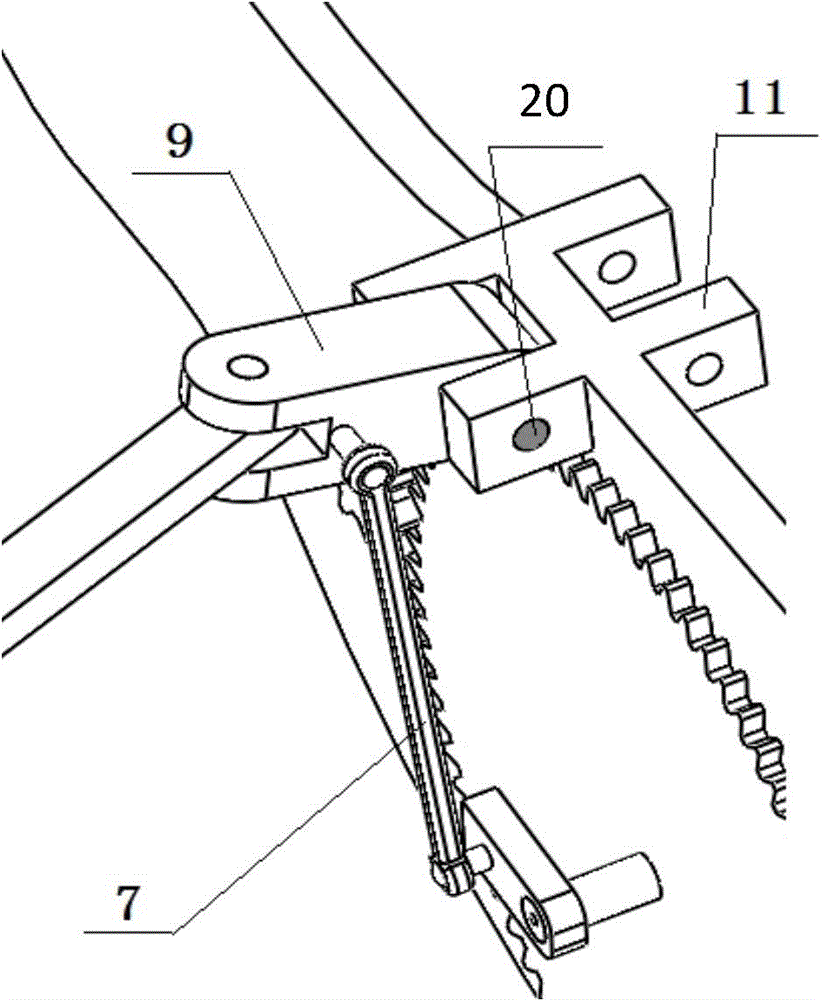

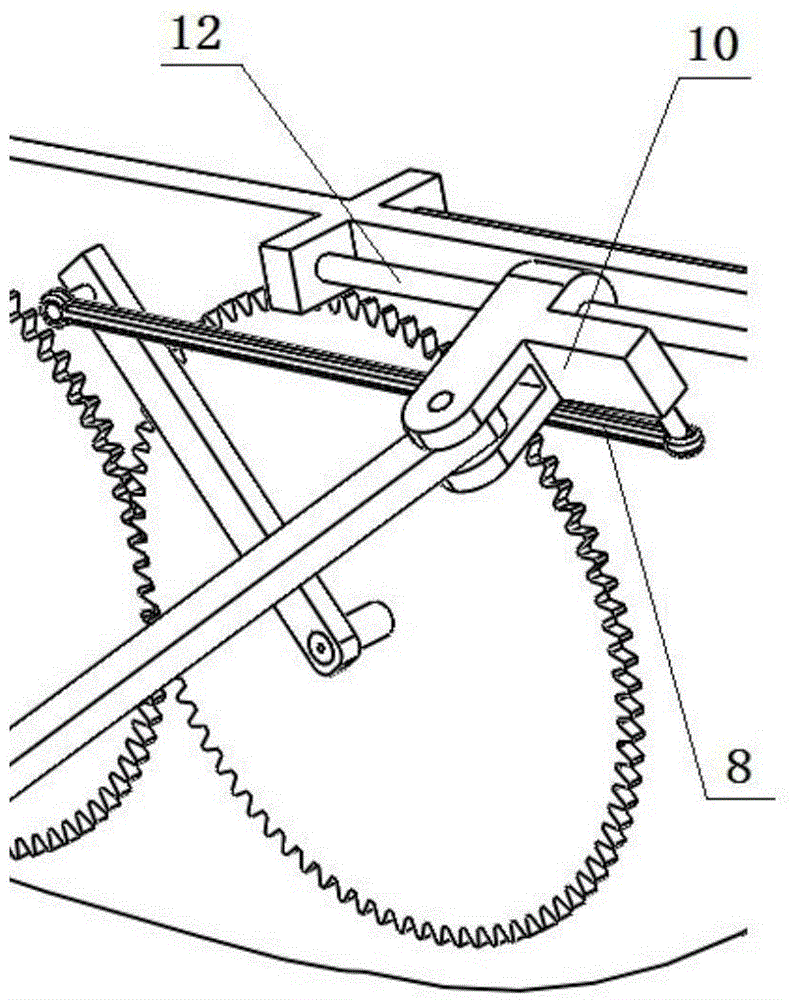

[0027] This embodiment is a set of micro-flapping-wing aircraft wing drive mechanisms that can change the wing area, such as figure 1 , including body frame 1, driving motor 2, follower gear 3, synchronous gear 4, front crank 5, rear crank 6, front connecting rod 7, rear connecting rod 8, fixed rocker arm 9, slider rocker arm 10, fixed shaft Seat 11, sliding shaft seat 12, humerus 13, ulna 14, middle phalanx 15, little phalanx 16, ulnar tendon 17, radius 18 and wing membrane 19. All parts of this mechanism are two sets except body frame 1, driving motor 2, follower gear 3, synchronous gear 4, fixed shaft seat 11, sliding shaft seat 12 and wing film 19, symmetrical to body frame 1 assembly. In the present embodiment, the body frame 1 is processed by carbon fiber plate; Figure 5 , the body frame 1 is fixedly connected with a fixed shaft seat 11 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com