Patents

Literature

360results about How to "With high pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High energy density lithium ion battery oxide positive electrode material and preparation method thereof

ActiveCN103515606AThickness is easy to controlImprove protectionSecondary cellsPositive electrodesElectrical batteryHigh energy

The present invention relates to a high energy density lithium ion battery oxide positive electrode material and a preparation method thereof. The positive electrode comprises a positive electrode material main body and a coating layer positioned on the surface of the positive electrode material main body, wherein the coating layer material is one or a combination selected from Al2O3, ZrO2, MgO, SiO2, ZnO2, TiO2 and LiAlO2, the positive electrode material main body comprises a shell layer and a core positioned inside the shell layer, the core material is Li1+x[Ni1-y-zCoyMnz]O2, the shell layer material is Li1+a[Co1-bXb]O2, or the positive electrode material main body is a mixture of Li1+x[Ni1-y-zCoyMnz]O2 and LiCoO2, and x, y, z, a and b are defined in the instruction. The positive electrode material has advantages of high capacity, good cycle performance, low surface activity, high voltage resistance, good safety and the like. The preparation method has a characteristic of simple preparation process, and is suitable for mass production application.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

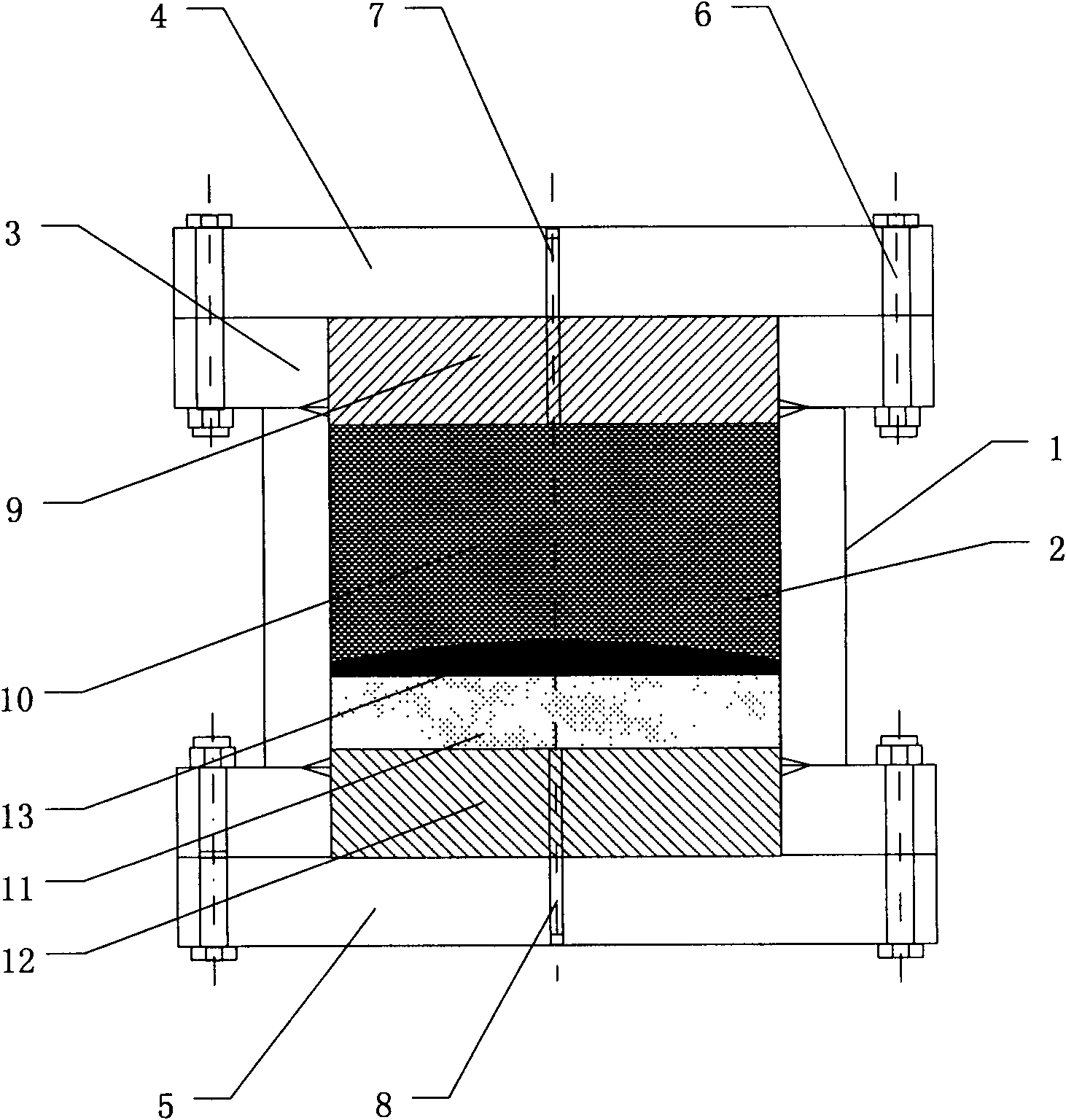

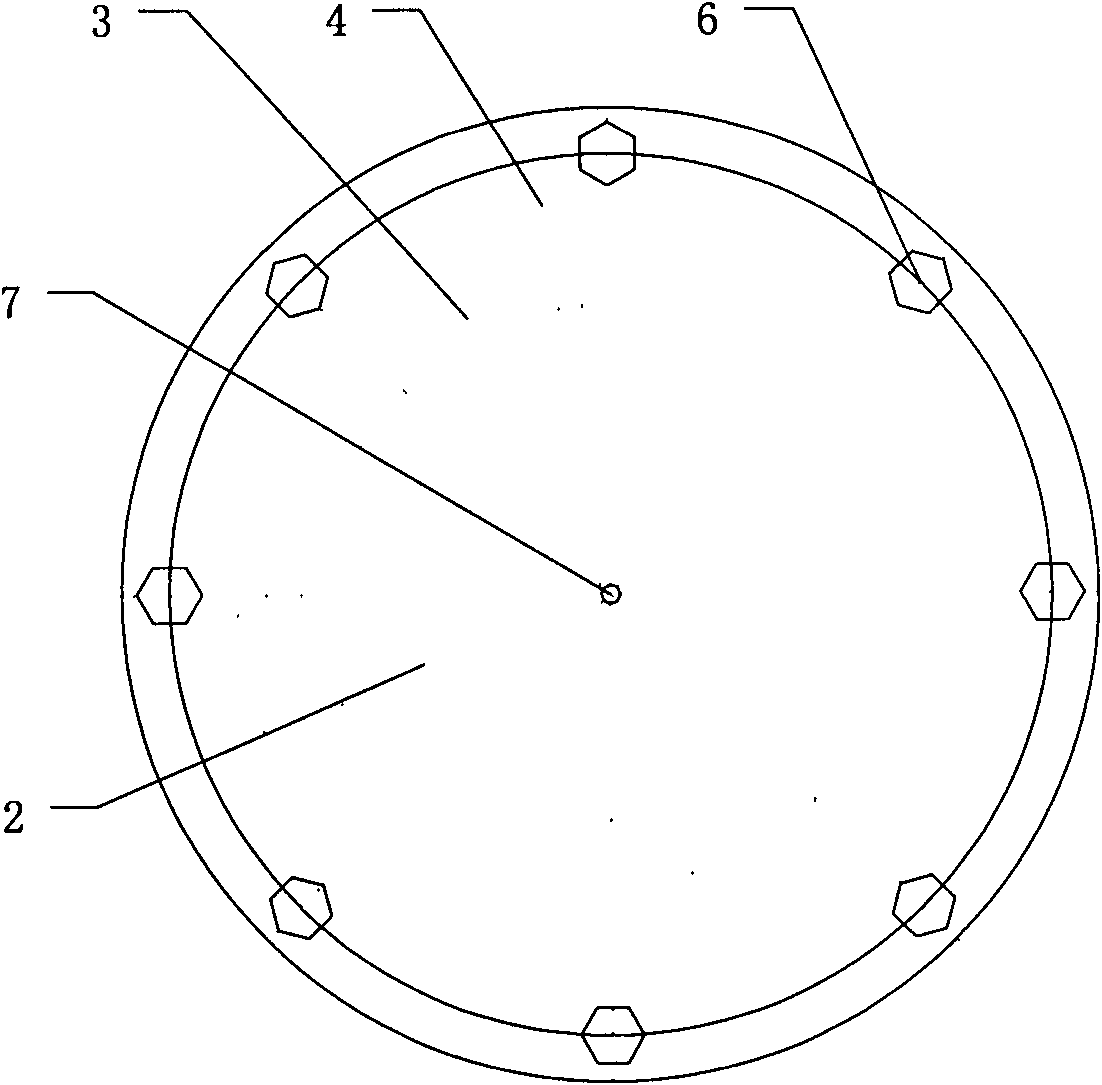

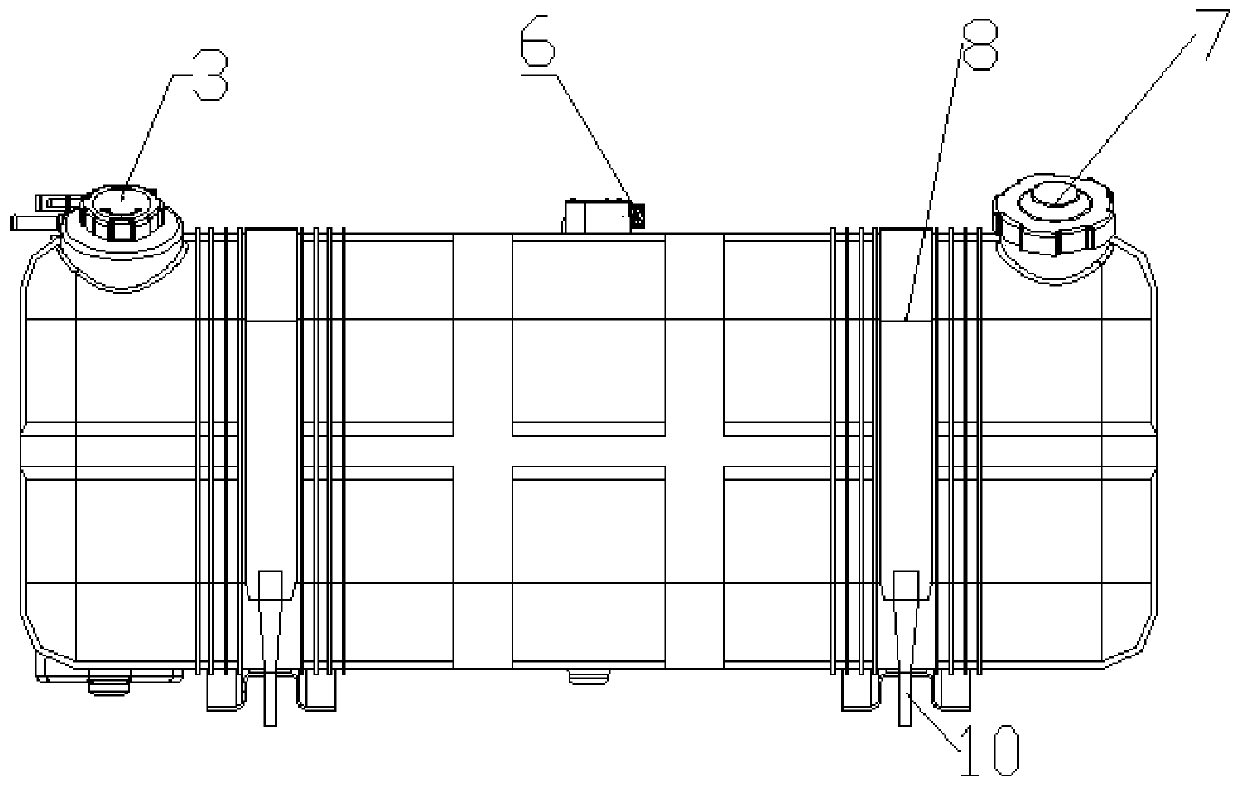

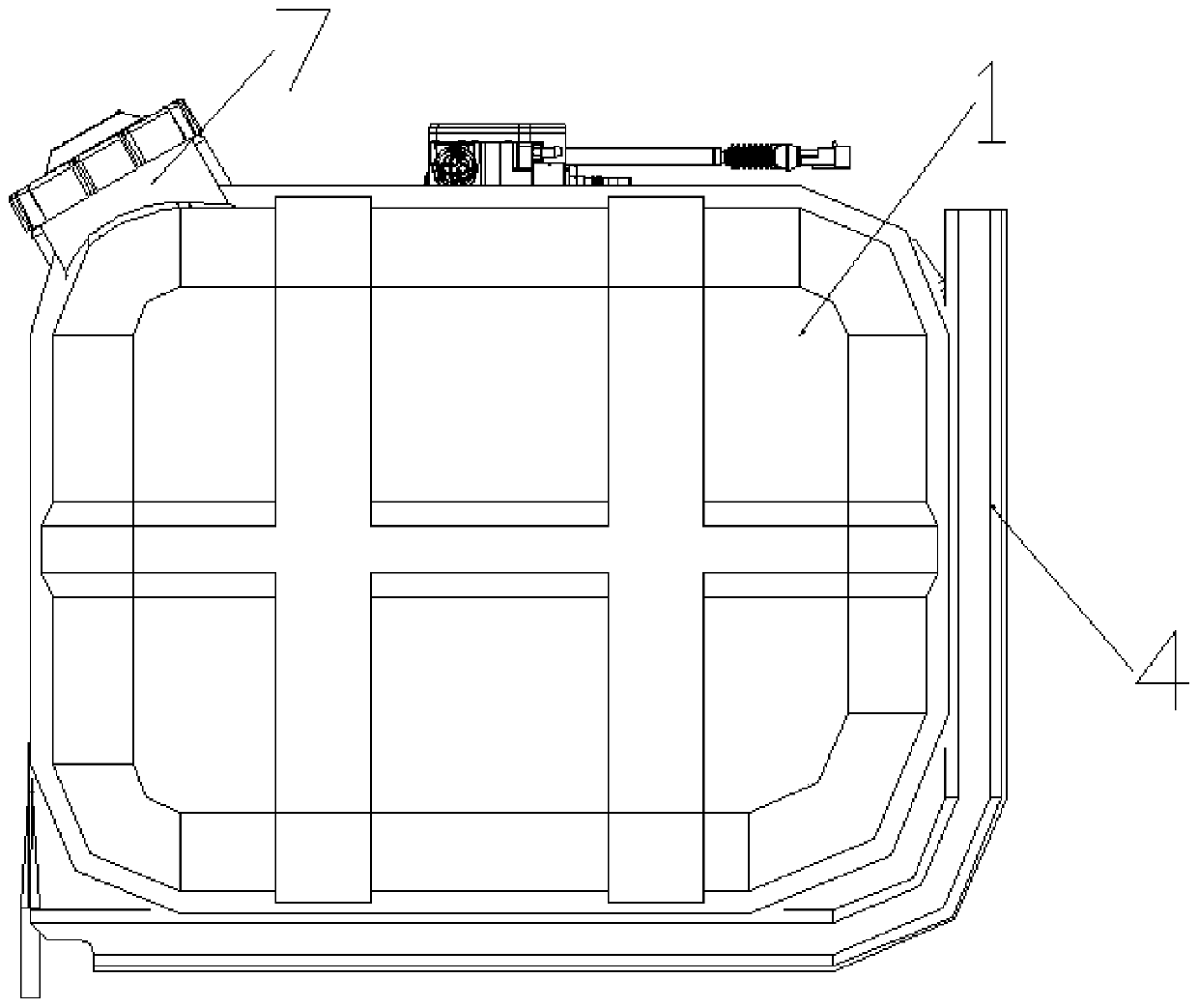

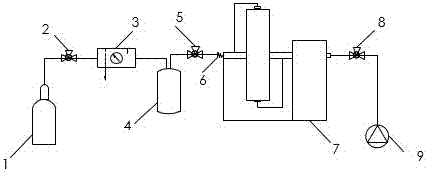

Simulation experimental device for natural hydrate geological stratification

ActiveCN101963057AWith high pressureHigh temperature resistanceBorehole/well accessoriesTemperature resistanceThree dimensional model

The invention discloses a simulation experimental device for natural hydrate geological stratification. The device comprises a three-dimensional model, wherein the three-dimensional model is a stainless steel reaction kettle which has the pressure resistance of between 5 and 40Mpa, and the cavity volume of between 50 and 500L; the three-dimensional model comprises a barrel, and an upper flange and a lower flange respectively arranged above and below the barrel; a seal cavity among the barrel, the upper flange and the lower flange forms a closed simulation cavity; and the upper flange and the barrel as well as the lower flange and the barrel are connected and fixed through a plurality of bolts respectively. A semipermeable clapboard layer adopted by the device has the characteristics of high pressure resistance, corrosion resistance, high-temperature resistance and the like; the simulation cavity in the high-pressure three-dimensional model can be assembled and disassembled freely; specific numbers, sizes and the like can be selected flexibly; and the semipermeable clapboard layer having corresponding characteristics can be adopted conveniently aiming at different types of natural hydrate geological stratification conditions.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

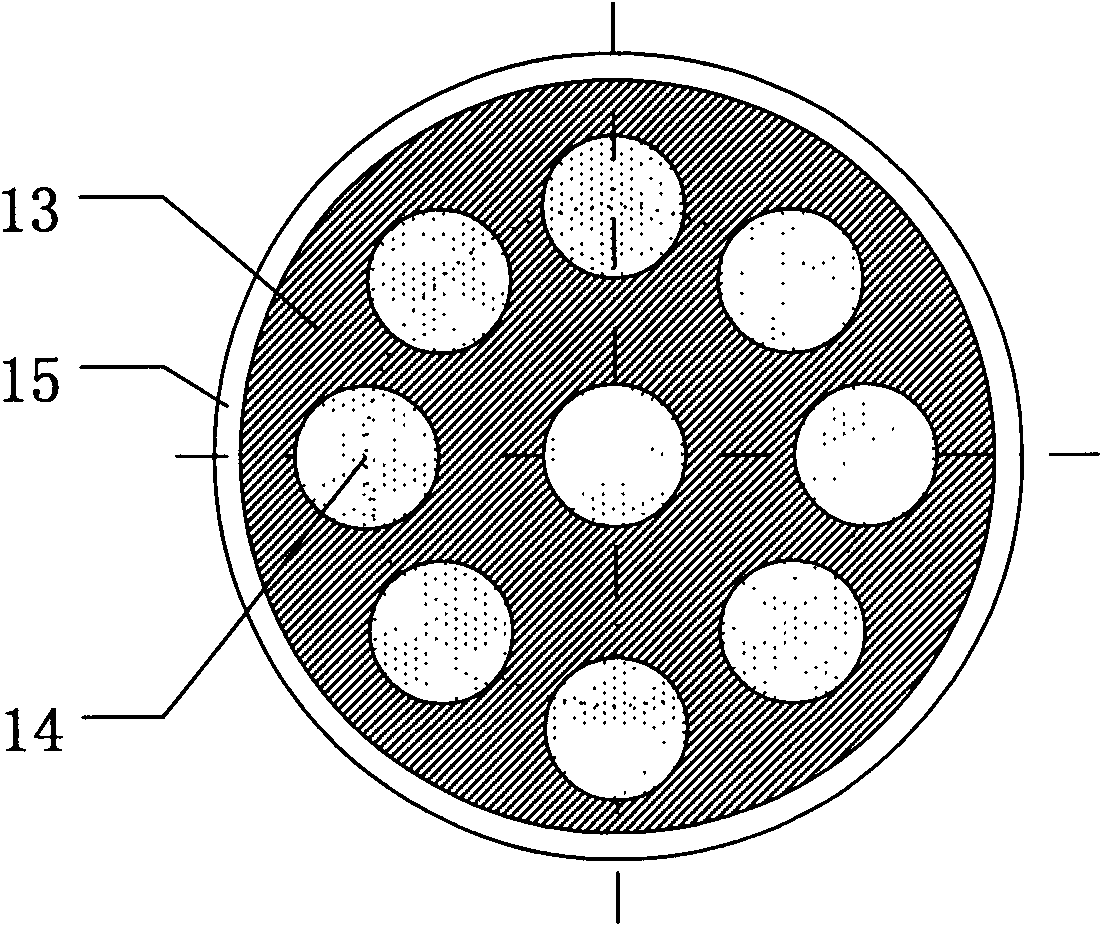

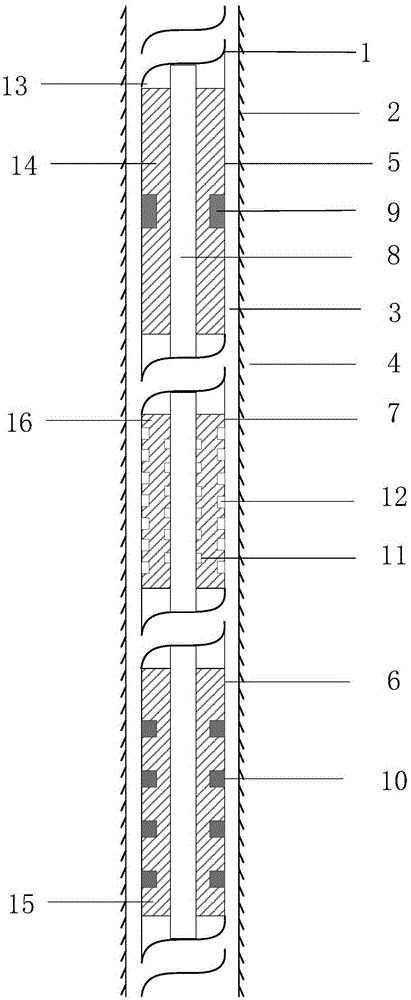

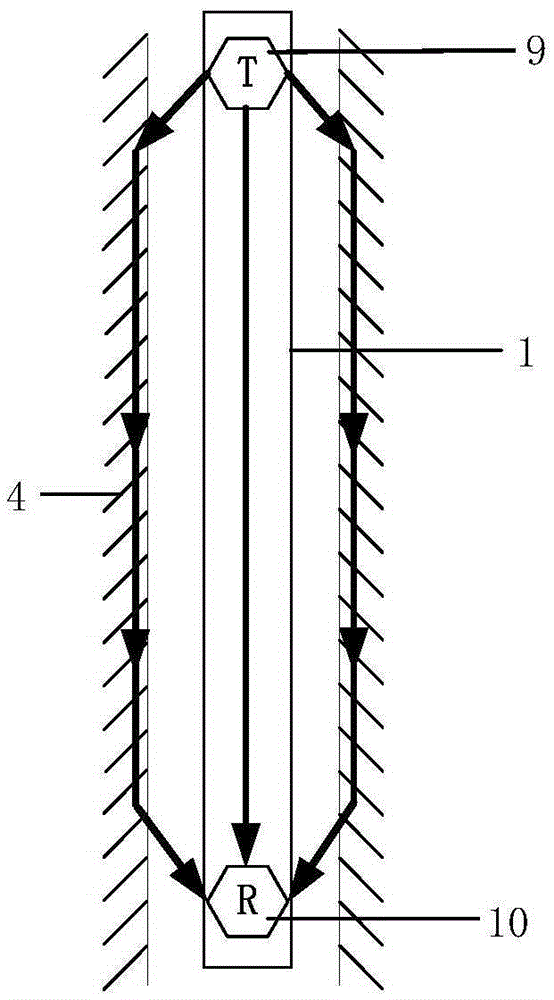

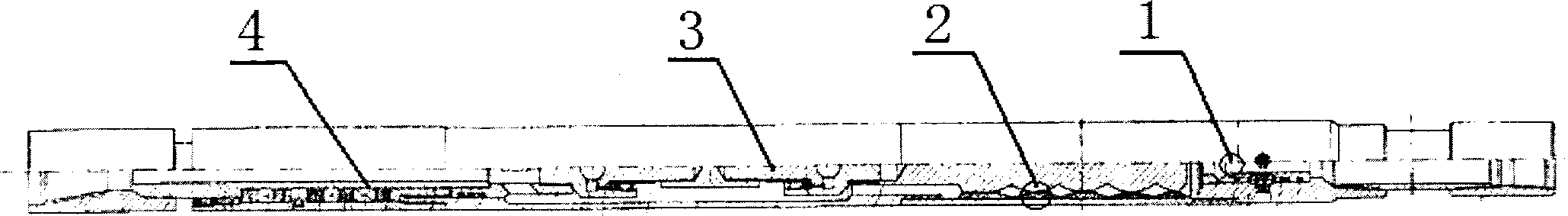

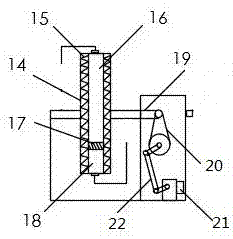

Acoustic logging-while-drilling transmitting unit and device thereof

InactiveCN105257282AWith high temperature resistanceWith high pressureSurveyDrilling rodsTransducerAcoustic wave

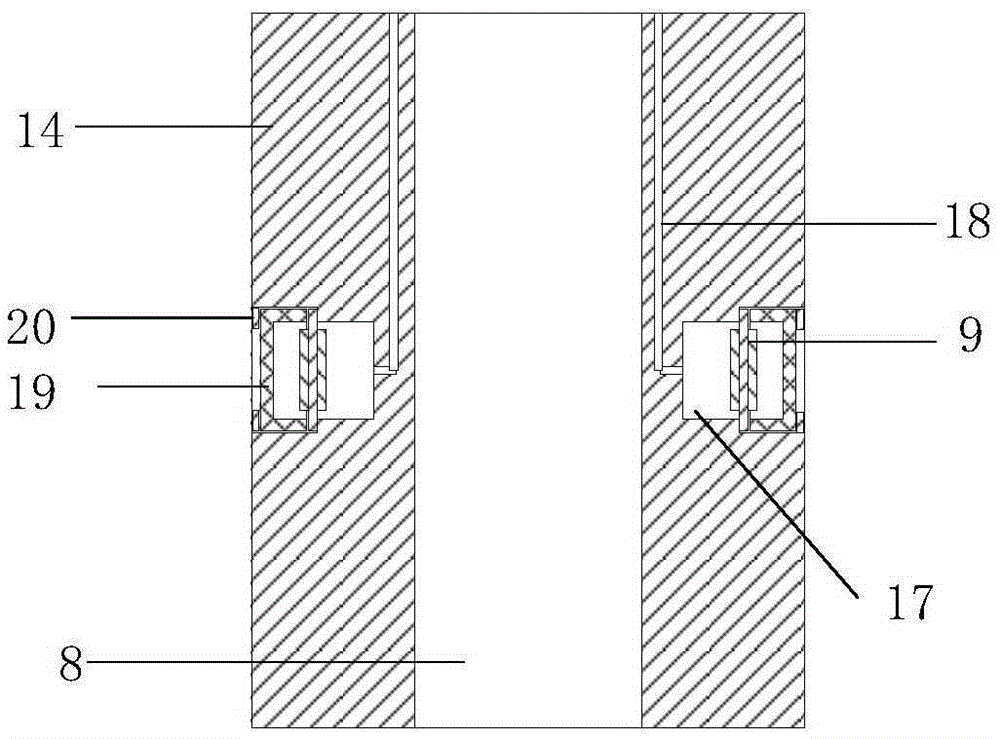

The invention relates to an acoustic logging-while-drilling transmitting unit and a device thereof. The transmitting unit comprises a drill collar chisel groove (17), a transmitting transducer (9) and an acoustic window (19), wherein the drill collar chisel groove (17) is provided with a step; the transmitting transducer (9) is arranged on the step and is used for generating acoustic waves; the acoustic window (19) is arranged on the transmitting transducer (9); the acoustic window (19) and the transmitting transducer (9) form a cavity; oil is injected into the cavity to form a liquid cavity; and the acoustic waves generated by the transmitting transducer (9) are transmitted outwards through the liquid cavity. The multi-pole acoustic logging-while-drilling transmitting device has the advantages of high temperature resistance, high pressure resistance, vibration resistance, small size, easiness in assembly, good insulation and sealing and the like.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

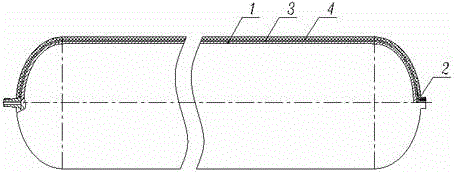

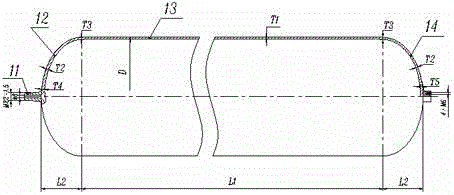

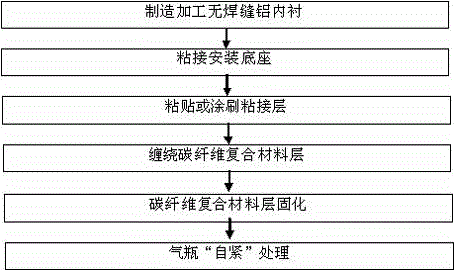

The present invention provides a 100 L carbon fiber wrapped aluminum-lined composite cylinder, including a weldless aluminum liner, a mounting base, an adhesive layer and a carbon fiber composite layer. The mounting base and the weldless aluminum liner form a smooth flattening winding mandrel; the external part of the mandrel is wound by the carbon fiber composite layer; and the adhesive layer is arranged between the mandrel and the carbon fiber composite layer and is used for firmly connecting the weldless aluminum liner and the carbon fiber composite layer. The composite cylinder has the advantages of large volume, high pressure resistance, high efficiency, light weight, high security, low cost and short manufacturing cycle. The present invention also provides a manufacture method of the carbon fiber wrapped aluminum-lined composite cylinder.

Owner:SHANGHAI INST OF SPACE PROPULSION

High temperature deep well screw drilling tool

The invention discloses a tool applicable to petroleum drilling and well repairing operation and mainly relates to a screw drilling tool for a high-temperature deep well. The gimbal part adopts a middle shunting cooling method so as to reduce the temperature of slurry passing through the screw drilling tool; the motor part of the screw drilling tool adopts high-temperature, alkali and acid resistant rubber for vulcanization; the rotor part adopts a tungsten alloy electroplating process; the transmission part of the screw drilling tool adopts 10 sets of serial shafts to lengthen a TC bearing; the transmission shaft part adopts a sealing device, is arranged outside an isolation sleeve or a transmission shaft and inside a transmission shaft shell or a lower nipple and is positioned on the upper end of an upper radial bearing and the lower end of a lower radial bearing respectively; therefore, the screw drilling tool can well bear and buffer vibration transmitted to the screw drilling tool from an underground bit in the operation of the deep well.

Owner:江苏长城石油装备制造有限公司

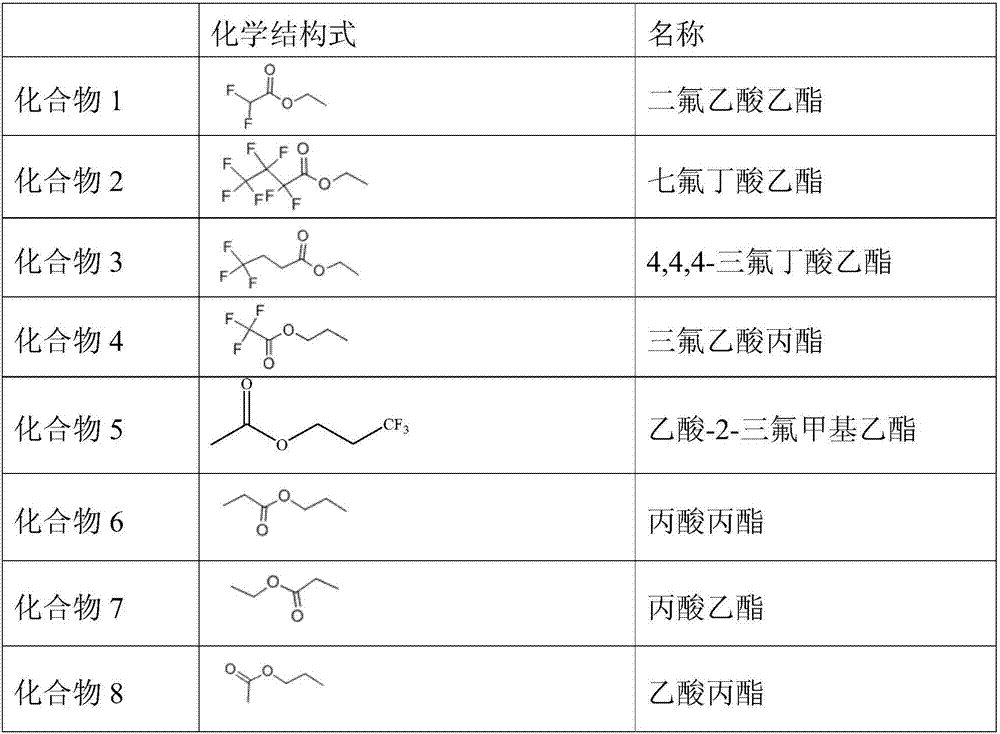

An electrolyte and a lithium ion battery

ActiveCN107359369ALow viscosityImprove ionic conductivitySecondary cellsOrganic solventBoiling point

An electrolyte and a lithium ion battery are provided. The electrolyte includes lithium salts and an organic solvent. The lithium salts include LiPF6 and LiTFSI and / or LiFSI. The organic solvent includes carboxylate and / or fluorinated carboxylate, carbonate and / or fluorinated carbonate, and sulphone. The room-temperature viscosity of the carboxylate is 0.3-0.5 mPa.s. The room-temperature viscosity of the fluorinated carboxylate is less than 0.3 mPa.s. The boiling points under atmospheric pressure of the carboxylate and the fluorinated carboxylate are not lower than 65 DEG C. The weight of the carboxylate and / or the fluorinated carboxylate is 5-30% of the total weight of the organic solvent. The electrolyte has characteristics of low viscosity, good ionic conductivity and resistance to high voltages. The electrolyte can be applied for lithium ion batteries the working voltages of which are 4.5 V or above.

Owner:NINGDE AMPEREX TECH

Sow feeding method of special wild pig

The invention relates to a sow feeding method of a special wild pig. The method comprises the following steps: (1) feeding sows to reach sexual maturity when the sows are 6-7 months old and are 75-80 kg weight and reach body maturity when the sows are 7-8 months old and 80-90 kg weight and mating the sows; feeding and mating 4-6 non-pregnant sows in each pigsty; feeding each sow at the first trimester of pregnancy in a limiting pigsty or in an independent pigsty, 2-4 sows at the mid trimester of pregnancy in each pigsty and 1-2 sows at the later trimester of pregnancy in each pigsty, and feeding the sows on obstetric tables from 7 days before parturition to weaning; (2) reinforcing sow feeding management, meeting nutritional requirements in the non-pregnant to-be-mating period, the first trimester of pregnancy, the mid trimester of pregnancy, the later trimester of pregnancy and the suckling period, preparing daily rations for the different periods, feeding different feeds, and paying attention to rational matching of green and coarse fodders and concentrated feeds. According to the sow feeding method, the feed and the control for feeding are optimized, so that the sows rut quickly, the farrowing rate is high, normally 12-14 piglets are born by each sow, and the survival rate is over 90 percent.

Owner:四川惠远农牧科技有限公司

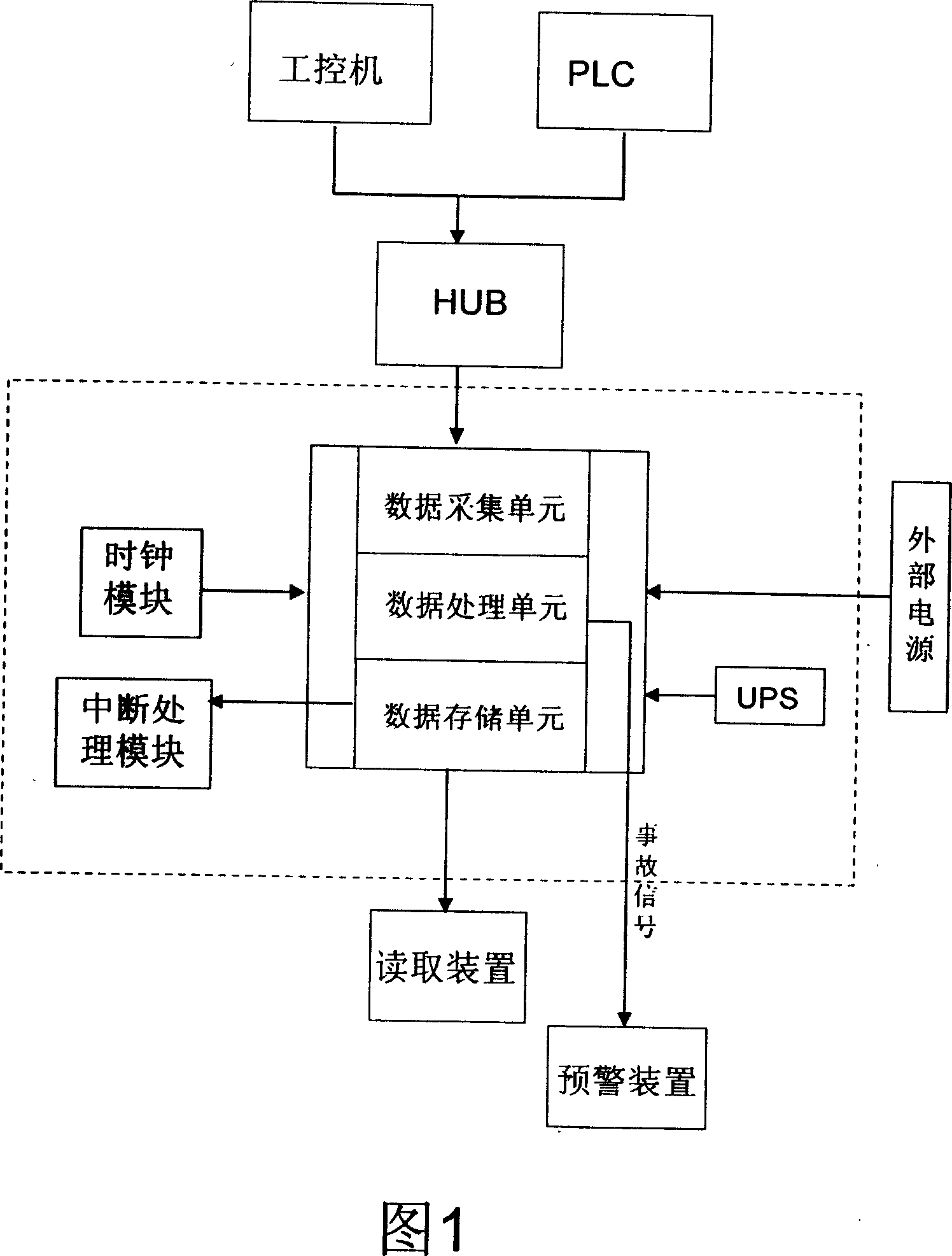

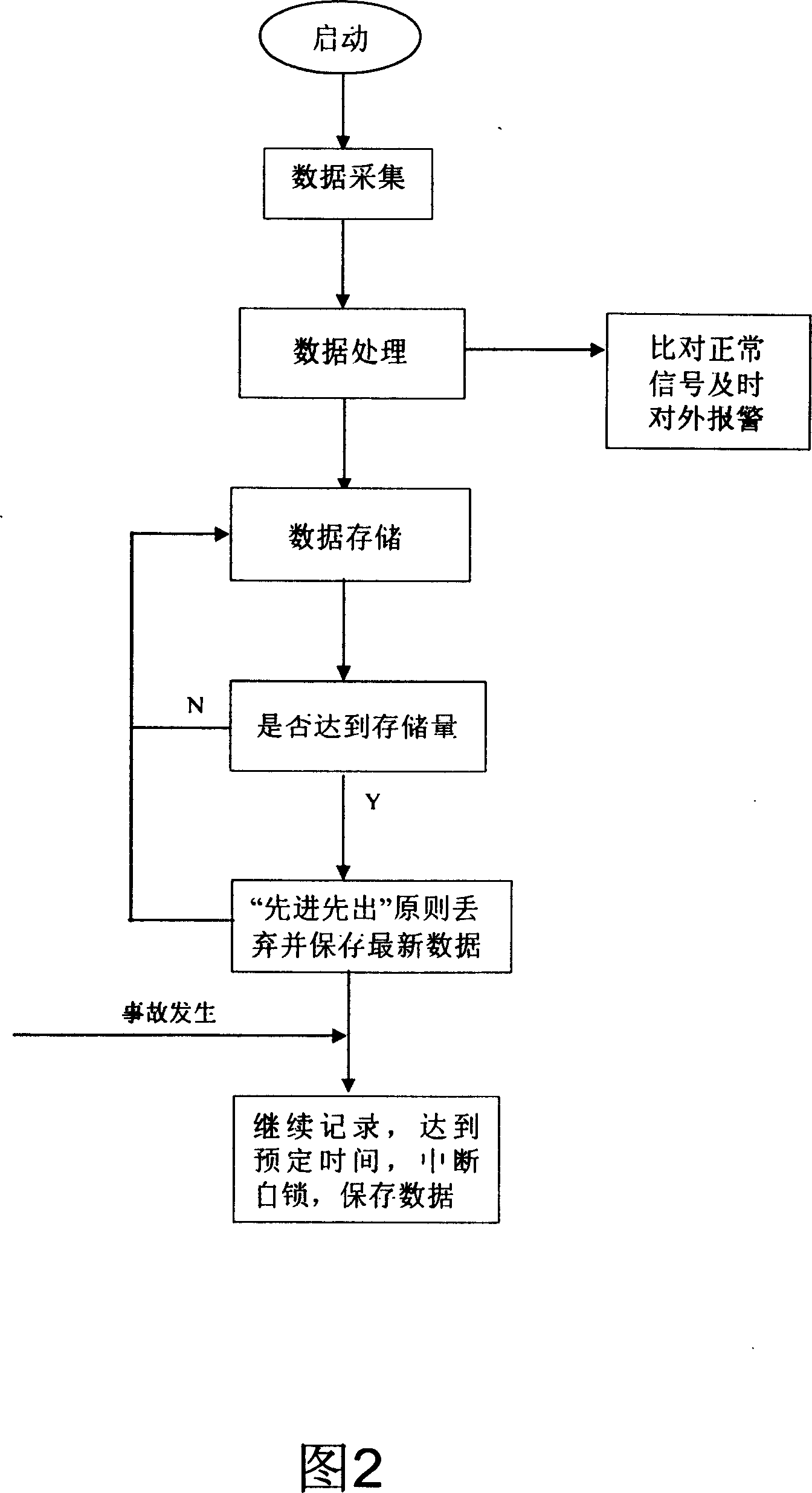

Recording device and method for hoisting machinery operating state

InactiveCN101012044AConvenient summaryHigh temperature resistantLoad-engaging elementsData signalCollections data

The crane mechanic running status recording device and method is set inside the case and connected with the outside power supply, composed of data collection unit, collecting and converting the crane running status signal into data signal, data processing unit analyzing the data signal and coordinating relevant component, completing the data processing, with data storage unit timely storing and updating data. It starts with data processing unit analyzing the data signal and coordinating relevant component, completing the data processing, with data storage unit timely storing and updating data.

Owner:SHANGHAI PORT MACHINERY HEAVY IND

Composite materials with polyvinyl/anhydrite for producing corrugated piping material with double walls

InactiveCN1817958AHigh temperature resistantWith high pressureRigid pipesAgricultural irrigationDouble wall

A polyvinyl chloride / anhydrite composite material for producing double-wall corrugated piping material can be used for drainage, blow-down of agriculture and industry, telecommunication and agricultural irrigation. It uses medical modified anhydrite as filler, has better compatibility for anhydrite and carrier resin and good high-pressure-resistant and anti-impact performances.

Owner:安徽恒泰非金属材料科技有限责任公司

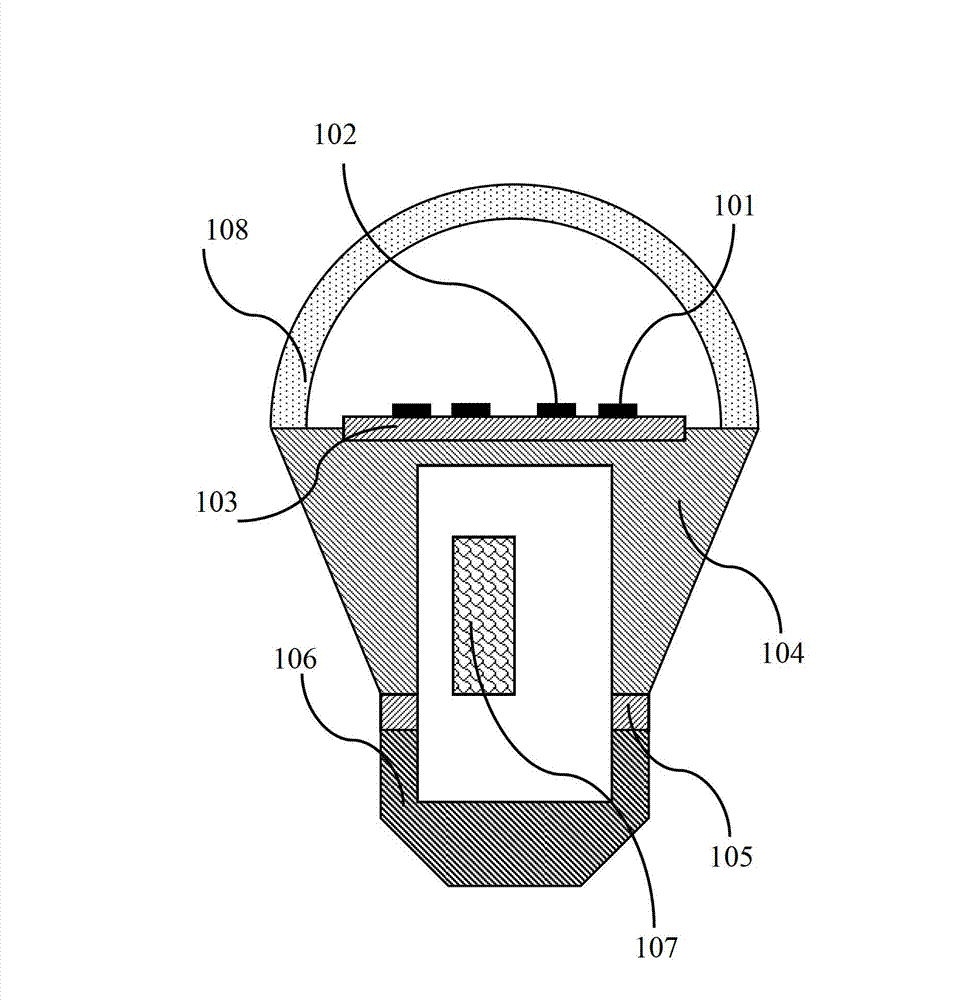

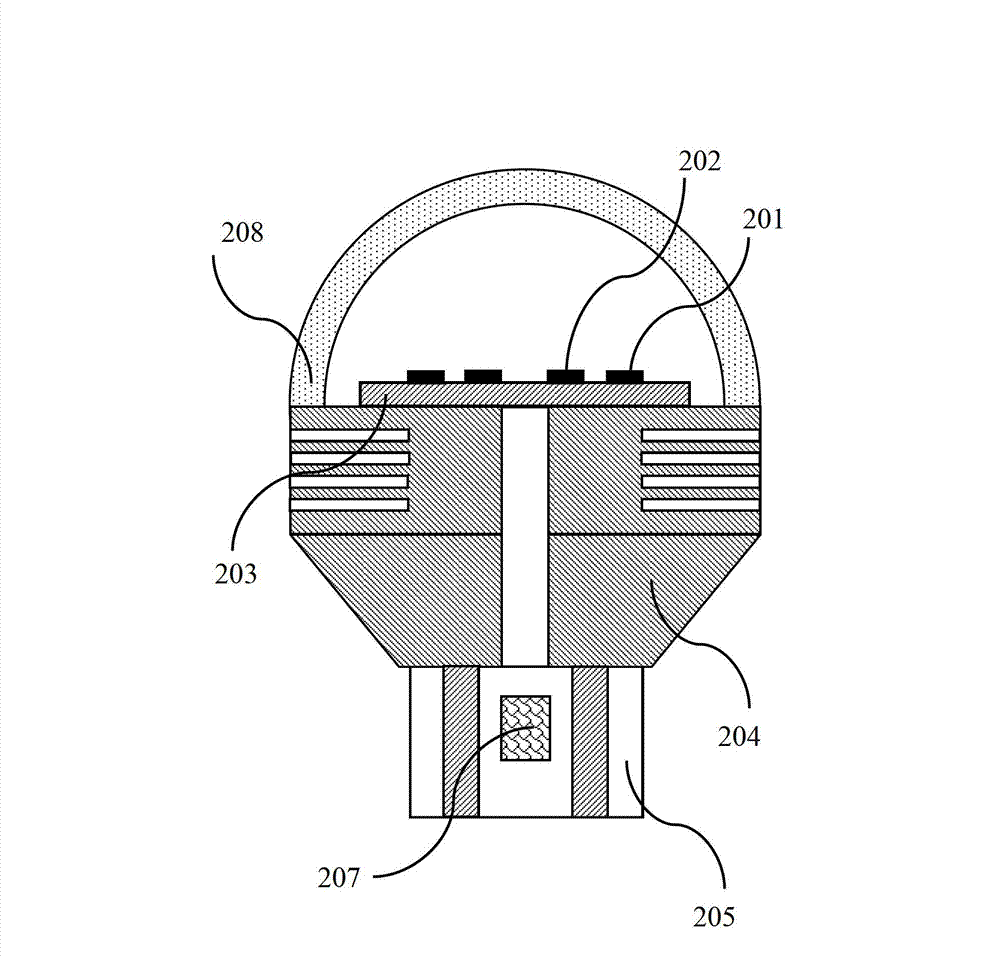

LED (Light Emitting Diode) bulb structure

InactiveCN103032722ASimple structureEasy to manufacturePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention relates to an LED (Light Emitting Diode) bulb structure which is characterized by comprising at least one substrate, at least one heat conductive liner arranged on at least one surface of the substrate, a radiator, at least one LED light source conductively arranged one surface of the heat conductive liner, at least one lamp hood covering the periphery of the LED light source, a heat conductive structure, an installation lamp holder, and a drive power supply which supplies power to the LED light source and / or a control circuit which controls the LED light source. The substrate separates the heat conductive liner from the radiator, and transfers heat of the heat conductive liner to the radiator through the heat conductive structure. The heated, heat conductive and radiating path is formed by the heat conductive liner, the heat conductive structure and the radiator provided by the invention has the advantages of good heated, heat conductive and radiating effects. In addition, the substrate separates the heat conductive liner from the radiator, so that the insulating system formed has the advantages of simple structure, convenience in manufacturing, low cost, and good insulating performance.

Owner:李刚

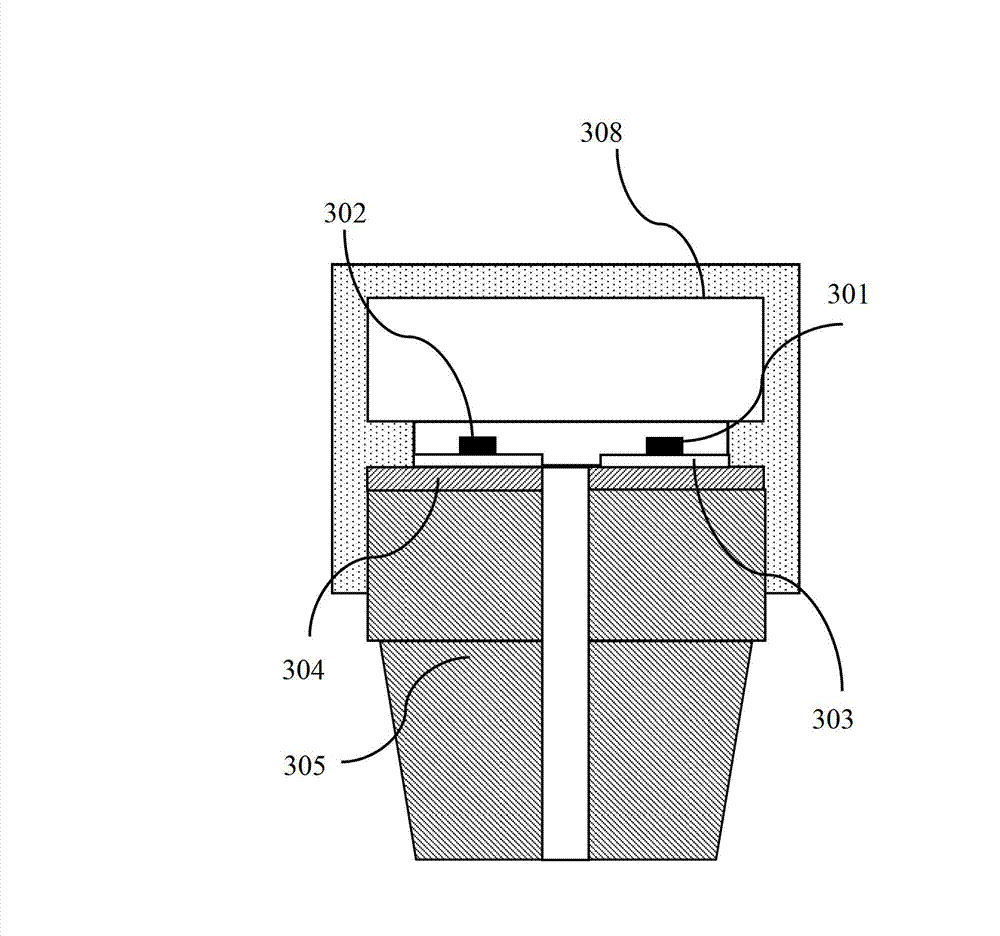

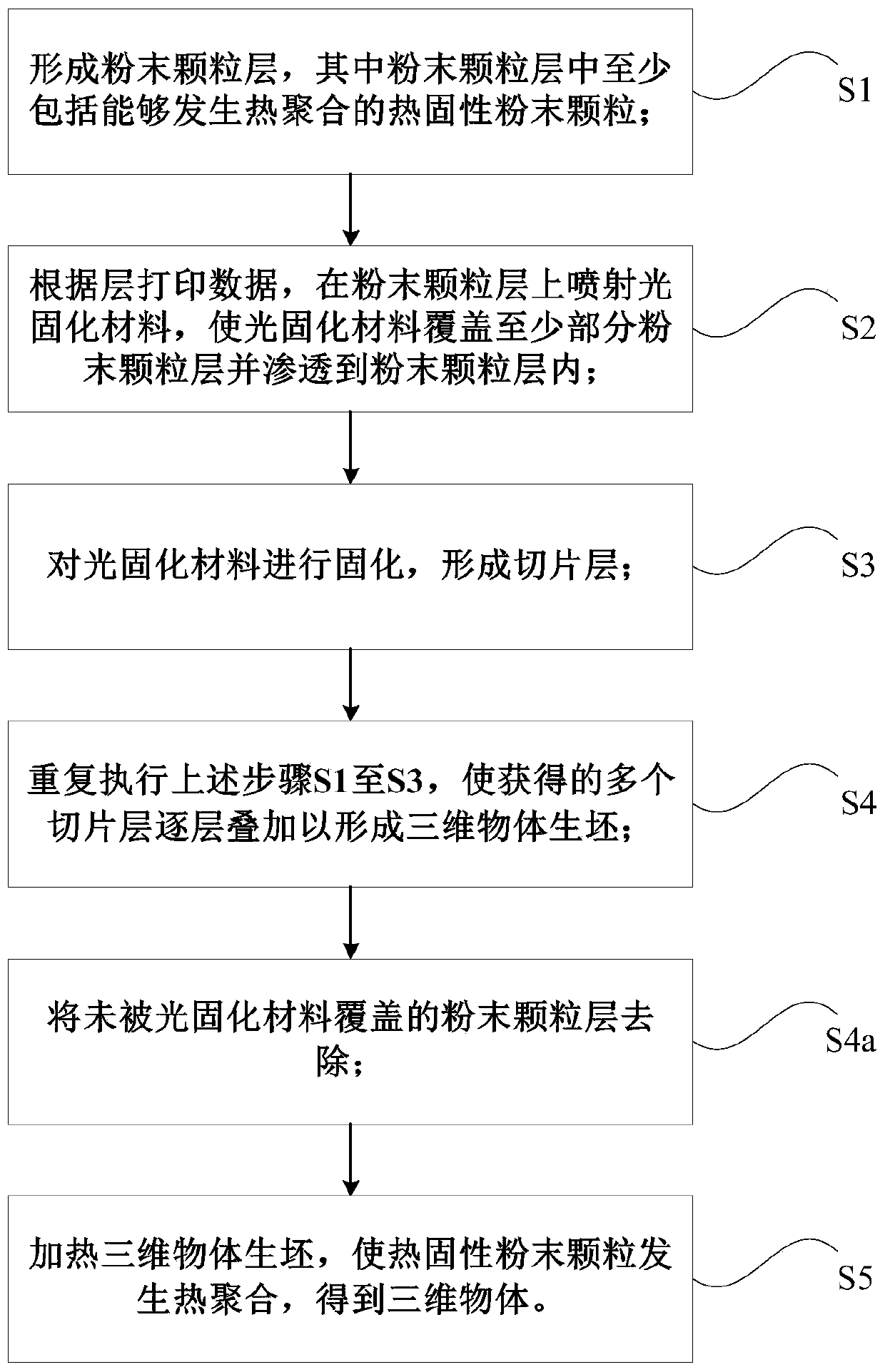

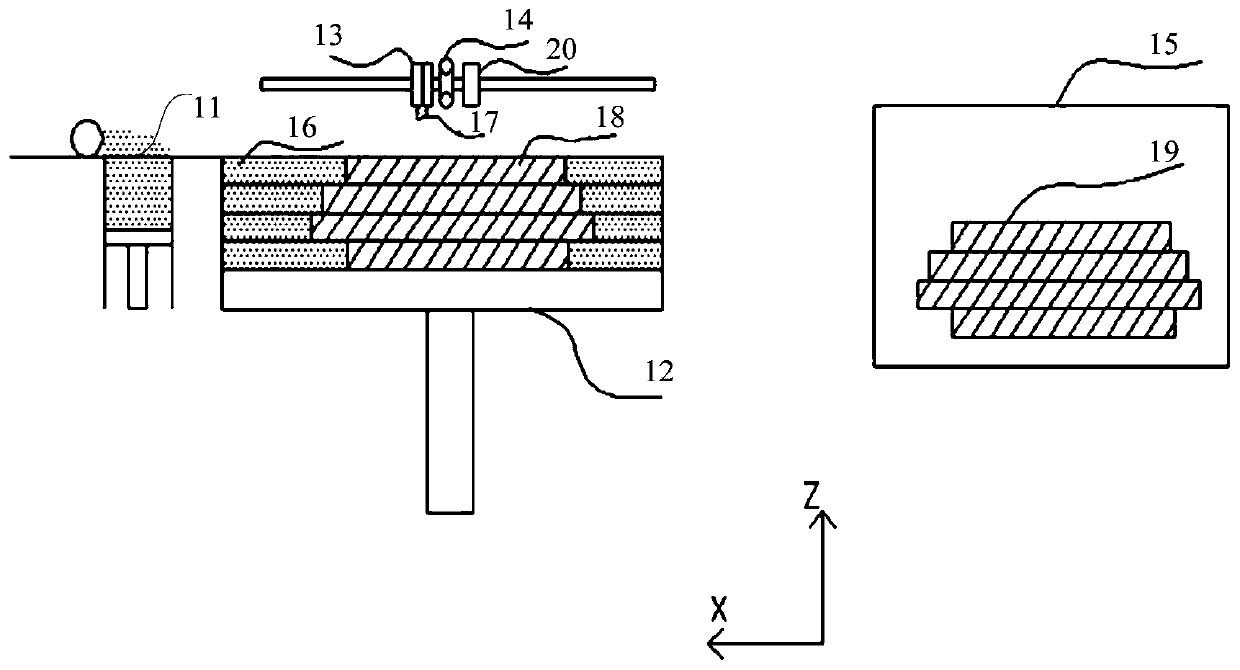

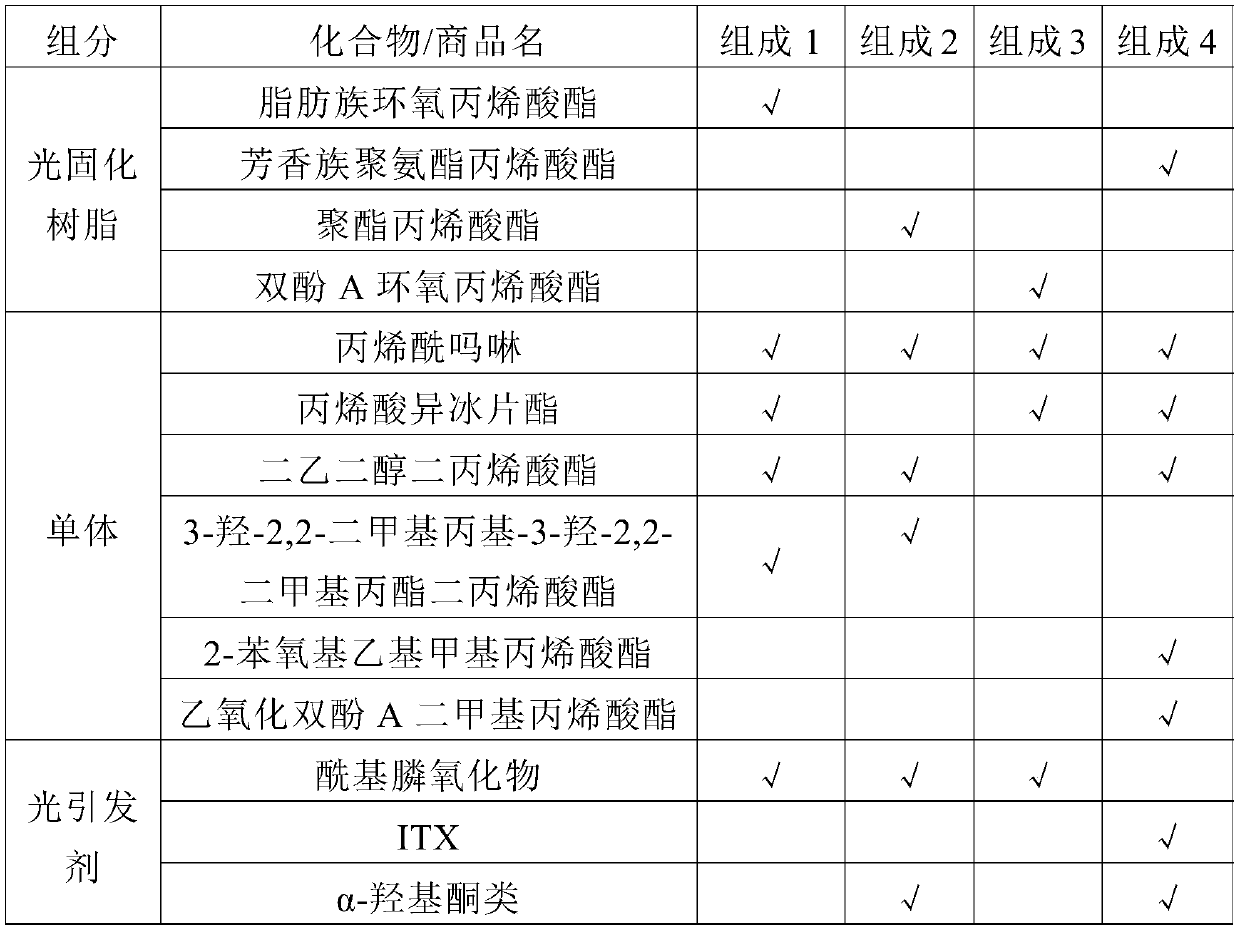

Three-dimensional object forming method and forming device

ActiveCN110065230AHigh temperature resistantWith heat insulationManufacturing platforms/substratesManufacturing heating elementsMechanical propertyMaterials science

The invention provides a three-dimensional object forming method and a forming device. The three-dimensional object forming method comprises the following steps of forming a powder particle layer, wherein the powder particle layer contains at least thermosetting powder particles capable of undergoing thermal polymerization; spraying a photocuring material on the powder particle layer according tolayer printing data, and enabling the photocuring material to cover at least part of the powder particle layer and penetrate into the powder particle layer; curing the photocuring material to form a slicing layer; repeating the steps from the step of forming the powder particle layer to the step of forming the slicing layer, and overlaying the obtained multiple slicing layers layer by layer to form a three-dimensional object green body; and heating the three-dimensional object green body to thermally polymerize the thermosetting powder particles to obtain the three-dimensional object. According to the forming method, the formed three-dimensional object has very good mechanical properties and high forming precision.

Owner:ZHUHAI SAILNER 3D TECH CO LTD

Method for enhancing wear resistant and corrosion resistant performance of over current component of water pump

InactiveCN101418815AImprove surface qualityCorrosion resistancePump componentsPumpsLithium oxideWear resistant

The invention provides an abrasion resistant and corrosion resisting method for water pump over-current components. The method comprises the following steps: (1) blank casting, (2) blank surface treatment, (3) glaze slip preparation, (4) enameling, and (5) firing after drying. In the step (3), the mass ratio of the main components of the frit for preparing the glaze slip is that: 40-60 of monox , 0.1-5 of alumina, 1- 10 of boron oxide, 0.1- 5 of potassium oxide, 6-17 of sodium oxide, 0.5-5 of lithium oxide, 1.5-7 of calcium fluoride, 2-6 of sodium fluosilicate, 1-10 of titanium oxide, and 0-2 of others. Relative to the mass of the frit, 5-6% of clay, 0-5% of quartz powder, 0.5-0.8% of boron sand, 0.2-0.3% of sodium nitrate, 2-5% of melanin, and 50-55% of water are added into the frit, and are put into a ball mill to grind to obtain the glaze slip in colloid state. The thickness of the enamel layer attached on the water pump over-current component after firing is between 300 and 700 mu m. The enamel layer is attached on the surface of the water pump over-current component, and has the characteristics of corrosion resistance, abrasion resistance, high pressure resistance, high temperature resistance, and smooth surface with no adhered materials.

Owner:山东颜山泵业有限公司

Machining process of high-performance stainless steel and seamless steel pipe

The invention process technology comprises the following steps of preparing of the round steel, heating of the round steel, hot-rolling punching, cropping, pickling, coping, lubricating, cold-rolling, defatting, solution heat treating, straightening, pipe-cutting, packing and putting in storage. In the round steel are added copper, Niobium, chlorine, manganese and titanium, wherein the copper 2.5~3.5 percent, Nb 0.2~0.6 percent, Cl 0.05~0.12 percent, Mn less than or equal to 0.5 percent and Ti 0.07~0.13 percent.

Owner:JIANGSU WUJIN STAINLESS STEEL PIPE GRP

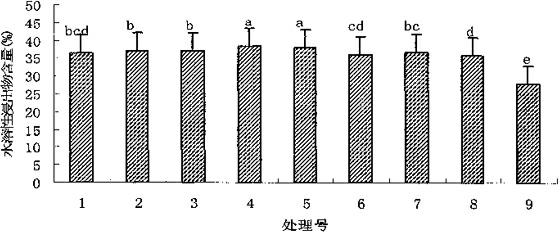

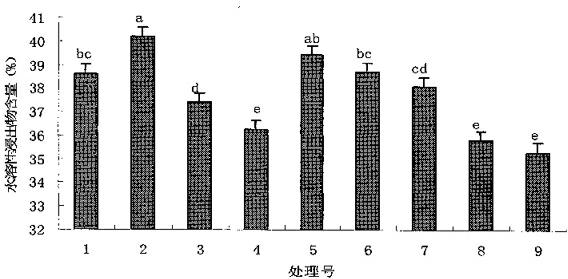

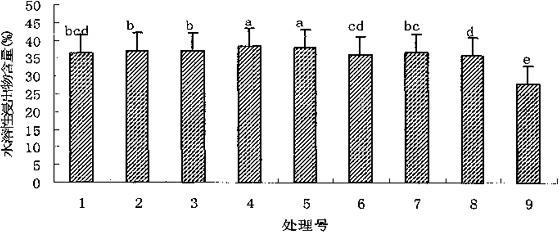

Safflower tea and preparation method thereof

InactiveCN102422955AAnti-inflammatoryAntioxidantTea substituesCodonopsisRadix Astragali seu Hedysari

The invention relates to a safflower tea and a preparation method thereof. The safflower tea is characterized in that: the safflower tea comprises the following active raw materials, by weight, 3-10 parts of safflower tea leaf, 6-12 parts of wolfberry fruit, 9-30 parts of Radix Codonopsis, 9-30 parts of Radix Astragali, and 6-15 parts of jujube. The preparation method of the safflower tea is characterized in that: the preparation method comprises steps of harvesting, choosing, airing, enzyme deactivating, and rolling. The safflower tea has the following advantages: a safflower bud tea has a greenish yellow color, and tea water has a light fragrance, a thin taste and a slightly bitter mouthfeel after the safflower bud tea is processed under optimum conditions; a safflower corolla tea friedwith vinegar has a dark red color and a heavy fragrance, tea water has a light reddish brown color, a thin taste and a slightly bitter mouthfeel, and the extract content reaches 38.2654%; and a safflower corolla tea fried with wine has a dark red color and a light fragrance, tea water has a reddish brown color, a thin taste and a slightly bitter mouthfeel, and the extract content reaches 40.1742%.

Owner:兰州市农业科技研究推广中心

Preventing Bacillus subtilis grown inside diseased plant

This invention relates to Bacillus subtilis and its application. Bacillus subtilis Jaas ed1 is stored in China General Microbiological Culture Collection Center on Dec. 12, 2005 with a number of CGMCC No.1564. Bacillus subtilis Jaas ed1 can enter crops with a low bacteria solution concentration, and colonize in crops. Bacillus subtilis Jaas ed1 has good effect on preventing plant diseases, especially soil-borne diseases. Besides, Bacillus subtilis Jaas ed1 can promote plant growth and produce various antibacterial metabolites, and has such advantages as low cost, easy operation, no pollution and no harm.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Hot-rolled round bar for high-pressure oil pipe and manufacturing method

The present invention discloses a hot-rolled round bar for a high-pressure oil pipe and a manufacturing method of the hot-rolled round bar. The hot-rolled round bar comprises the following chemical components (smelting components) in percentage by mass (wt%): 0.10-0.17% of C, 0.25-0.45% of Si, 1.30-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.20-0.40% of Cr, 0.05-0.10 % of V, 0.025-0.050% of Al, less than or equal to 0.20% of Cu, less than or equal to 0.20% of Ni and the balance of iron and residual trace impurities. By virtue of controlling the appropriate ratio of each element in steel, and adopting heat treatment methods, such as EAF electric furnace smelting, LF refining and VD vacuum degassing, the structure of the hot-rolled round bar,with uniform fine sorbite and bainite metallographic structures, can be obtained and thus the hot-rolled round bar for the high-pressure oil pipe with the advantages of high pressure resistance, corrosion resistance and wear resistance is obtained.

Owner:江苏耀坤液压股份有限公司

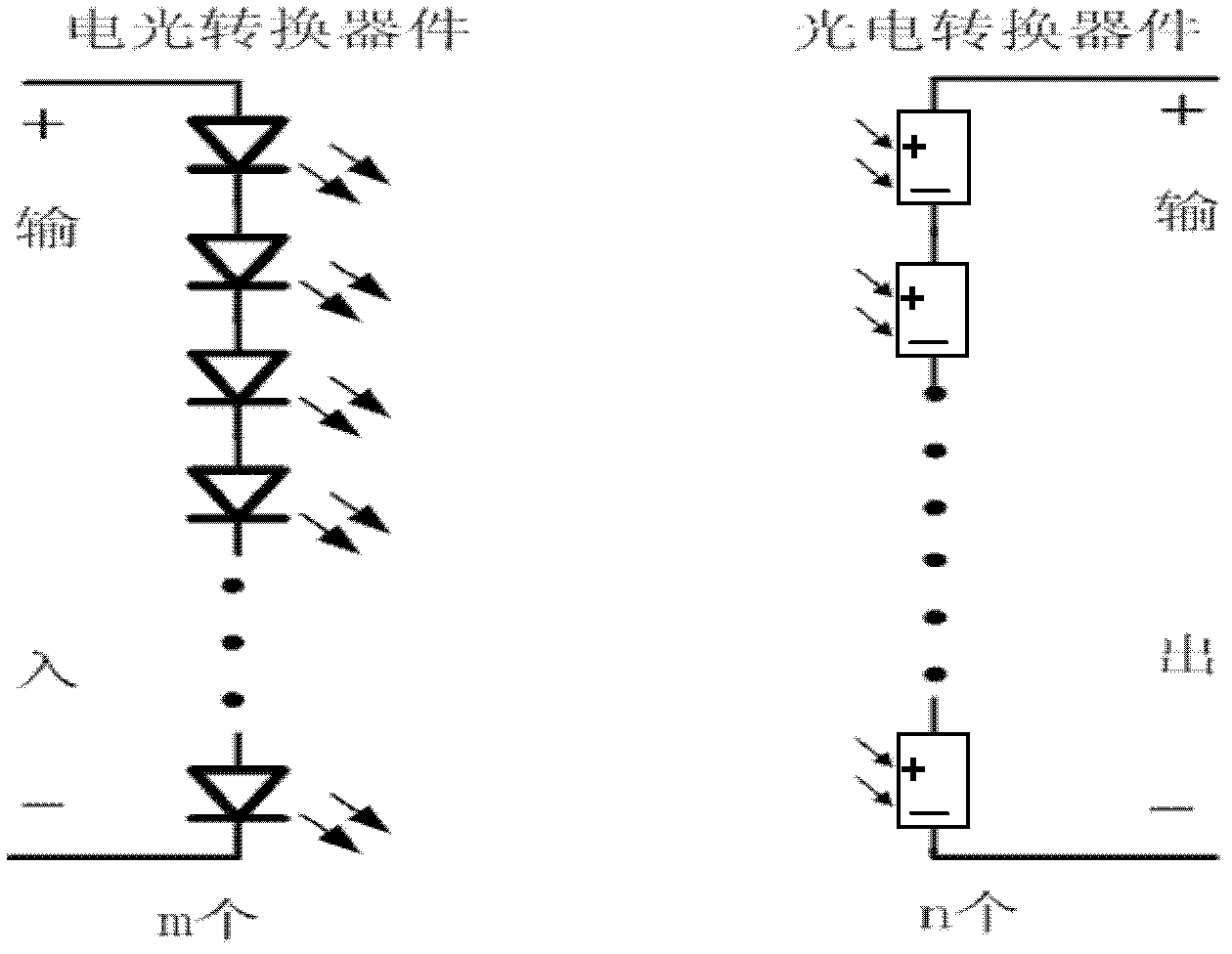

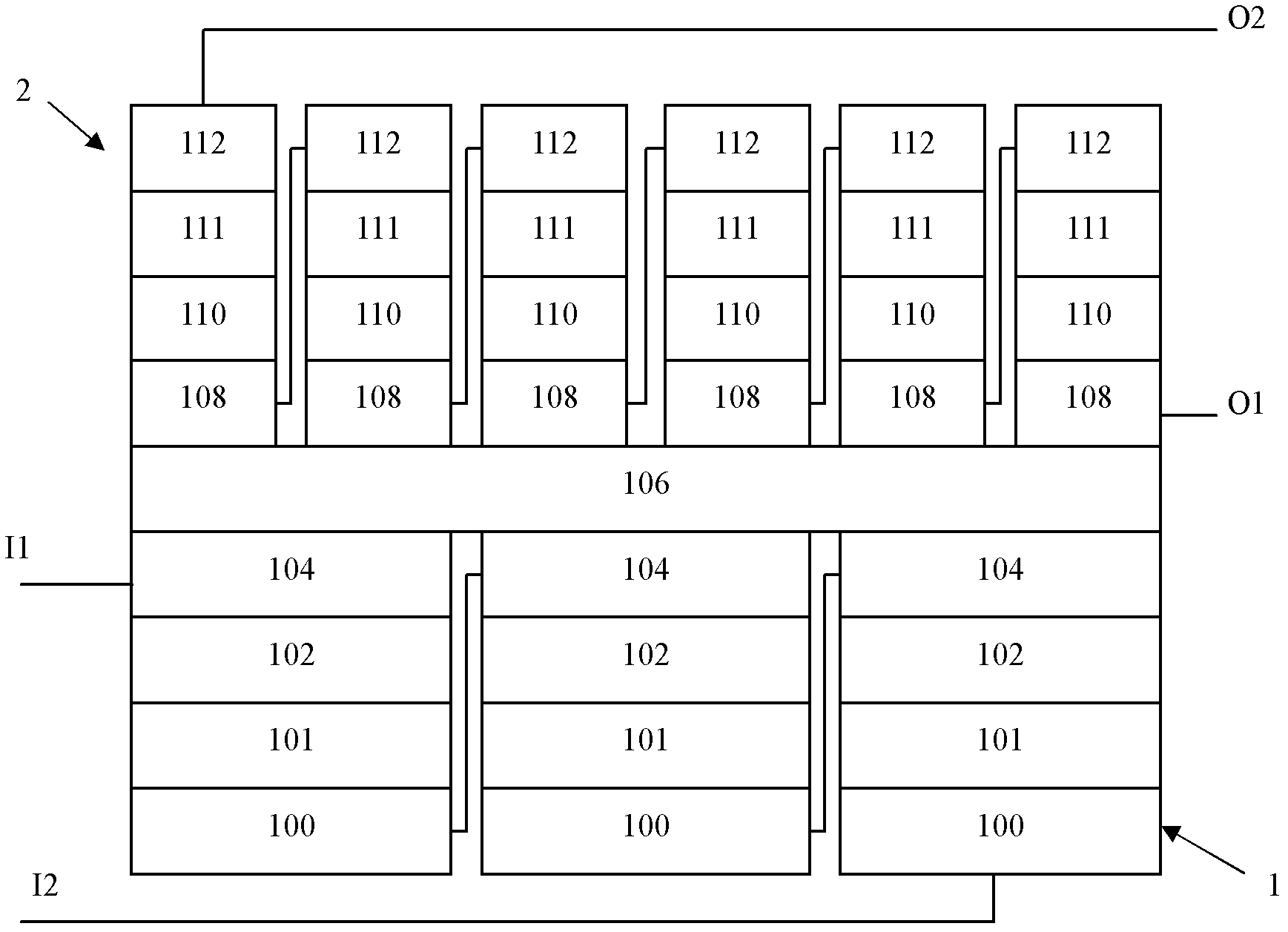

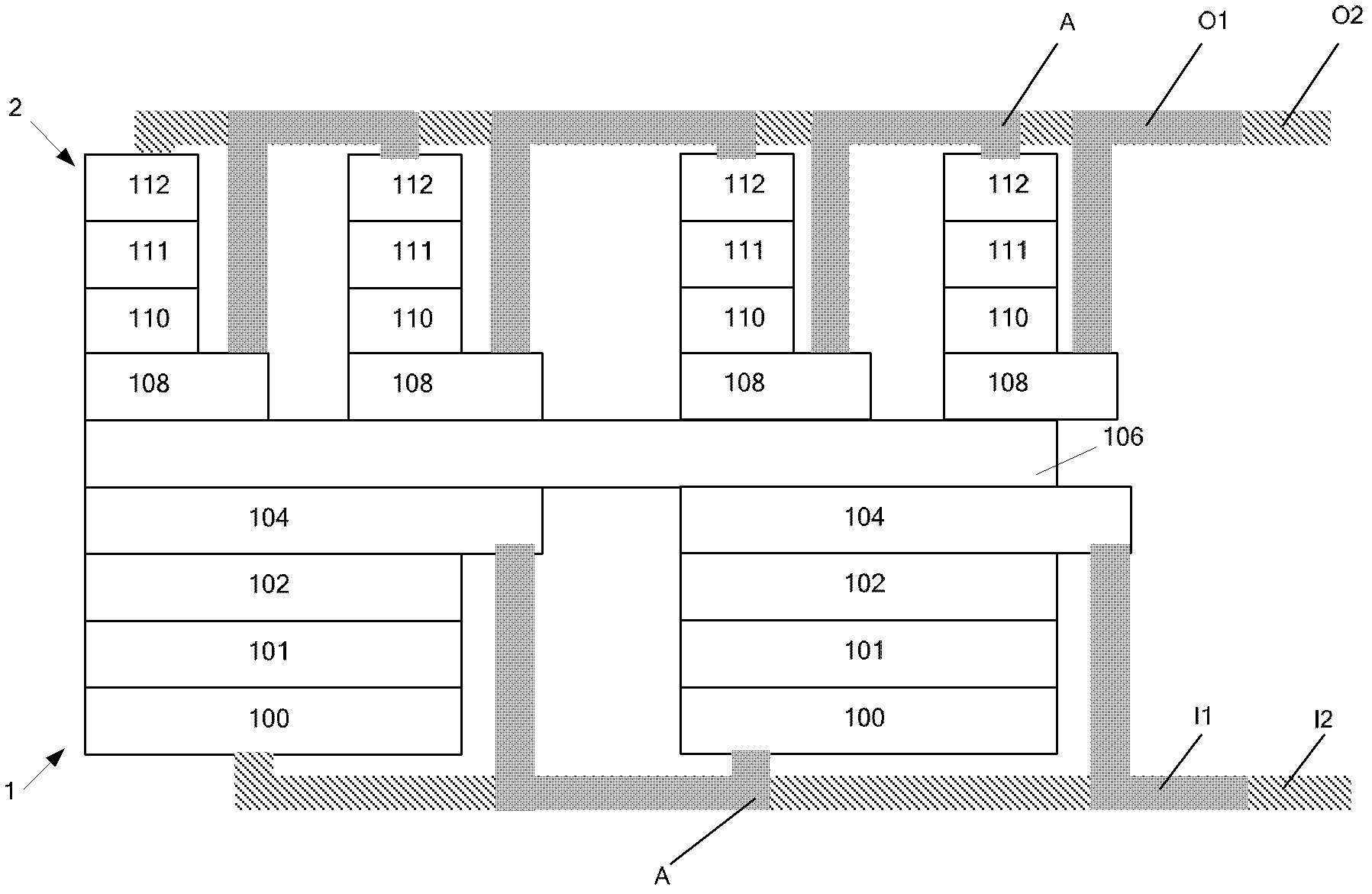

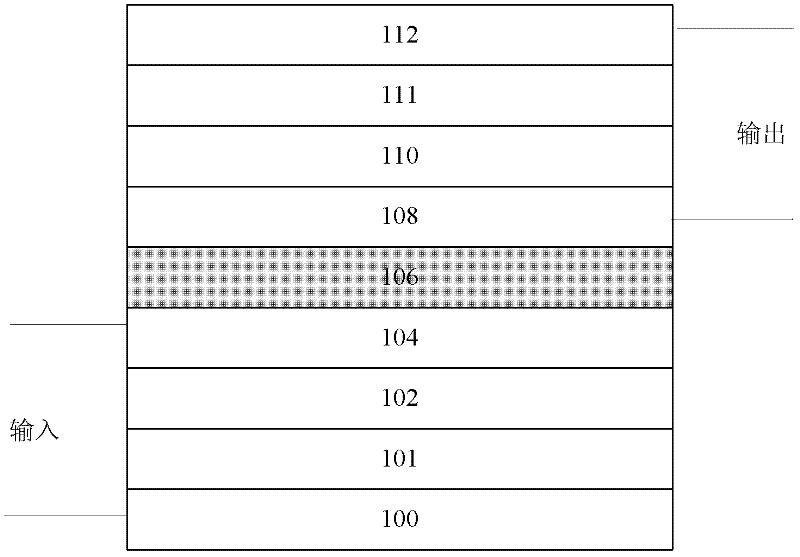

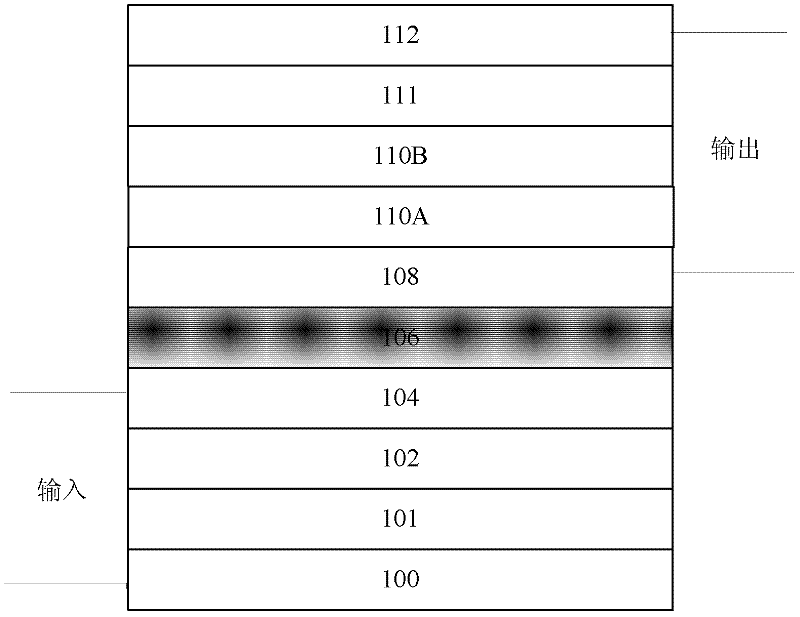

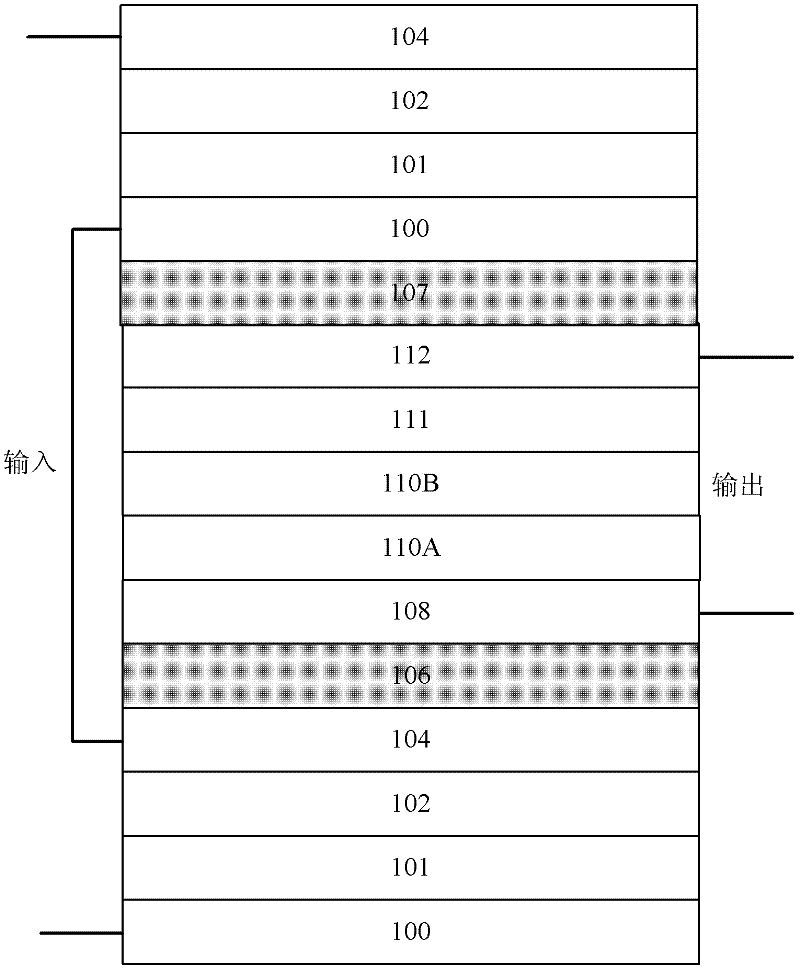

Semiconductor direct current photoelectric transformer

ActiveCN102427094AWorking light transparentGood insulation propertiesSemiconductor devicesTransformerEngineering

The invention provides a semiconductor direct current photoelectric transformer which comprises an isolating layer, a plurality of electrooptical conversion structures and a plurality of photoelectric conversion structures, wherein the electrooptical conversion structures are formed at one side of the isolating layer; the electrooptical conversion structures are mutually connected in series; eachelectrooptical conversion structure comprises a first electrode layer, an electrooptical conversion layer formed on the first electrode layer and a second electrode layer formed on the electroopticalconversion layer; the photoelectric conversion structures are formed at the other side of the isolating layer; the photoelectric conversion structures are mutually connected in series; each photoelectric conversion structure comprises a third electrode layer, a photoelectric conversion layer formed on the third electrode layer and a fourth electrode layer formed on the photoelectric conversion layer; and the isolating layer, the second electrode layer and the third electrode layer are transparent to working light rays emitted by the electrooptical conversion layer. The semiconductor direct current photoelectric transformer of the embodiment of the invention has the advantages of high-voltage resistance, no electromagnetic radiation, no coil structure, no influence by solar radiation, and the like.

Owner:郭磊

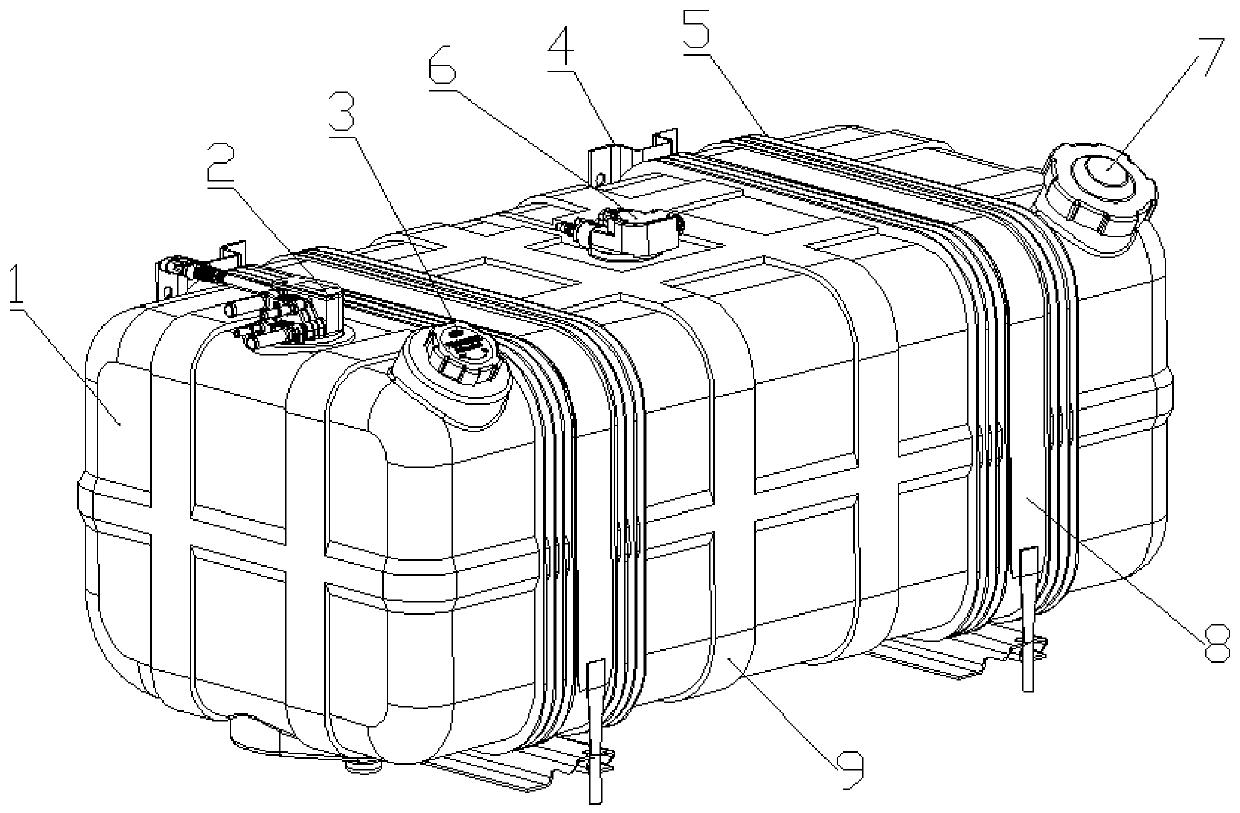

Integrated structure of fuel tank and urea tank, material and process

PendingCN110329060AOptimize layoutReduce volumeExhaust apparatusSilencing apparatusFuel tankEngineering

The invention discloses an integrated structure of a fuel tank and a urea tank, a material and a process, and solves the problem that an existing fuel cavity and a urea cavity are separately arranged,the occupied area in a vehicle is large, the fuel cavity is easy to deform, and the cost of the urea cavity is relatively high. The integrated structure of the fuel tank and the urea tank, the material and the process have the beneficial effects that the fuel cavity and the urea cavity are organically unified, the space is saved, and the quality of the fuel cavity and the urea cavity is reduced.According to the scheme, the integrated structure of the fuel tank and the urea tank comprises a shell, wherein the shell is formed through an injection molding process, and the shell is provided witha length direction and a width direction; a separation plate fixing part and an anti-surge partition plate fixing part are arranged in the shell along the width direction of the shell, the separationplate fixing part and the anti-surge partition plate fixing part are subjected to injection molding together with the shell, and a separation plate is fixedly arranged at the separation plate fixingpart to divide the shell into at least two parts so as to form the urea cavity and the fuel cavity in the shell; an anti-surge partition plate is fixedly arranged at the anti-surge partition plate fixing part, the separation plate and the anti-surge partition plate are both connected with two opposite side walls in the width direction of the shell.

Owner:山东统亚模塑科技实业有限公司

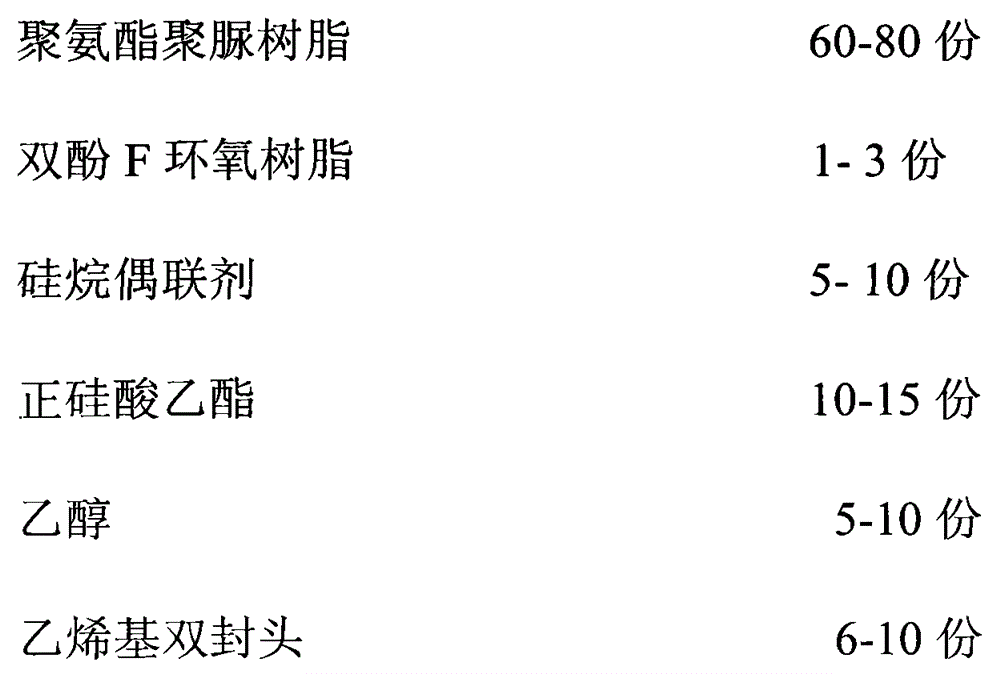

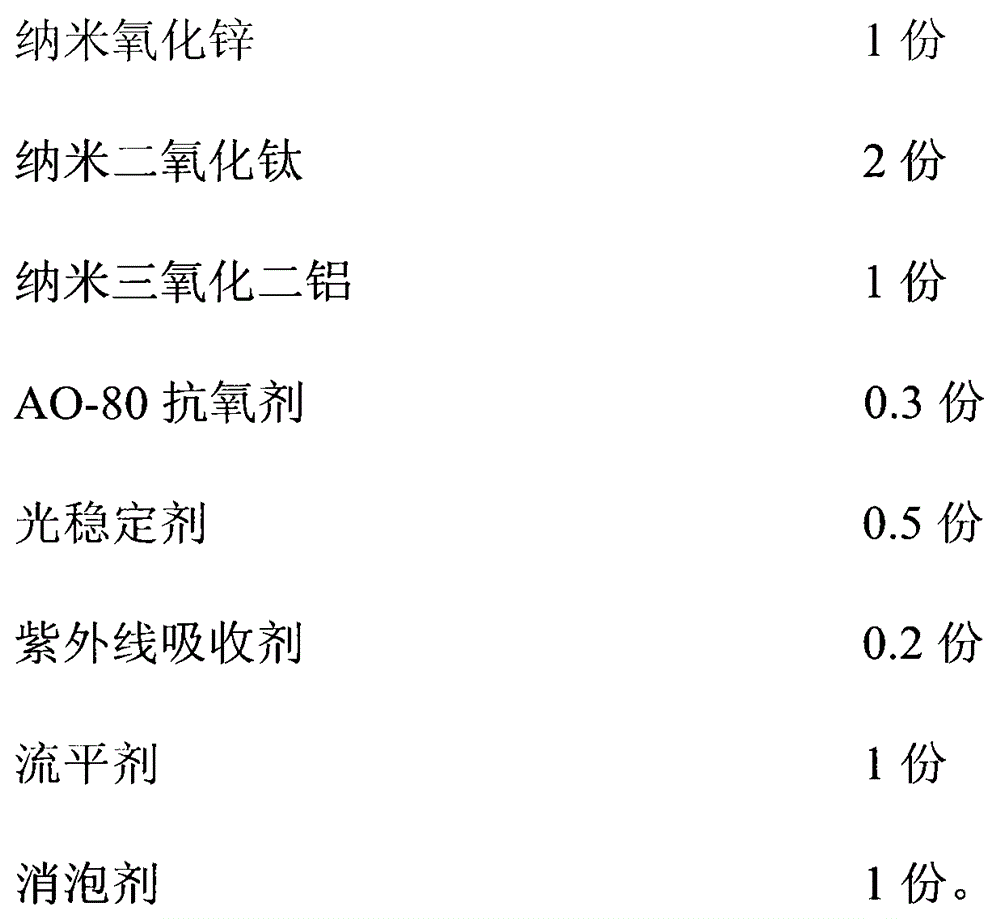

Ultrahigh-solid-content nano-grade high-molecular alloy paint

ActiveCN105001772AHigh temperature resistantWith high pressurePolyurea/polyurethane coatingsAntioxidantAlloy

The invention discloses an ultrahigh-solid-content nano-grade high-molecular alloy paint comprising the following components: polyurethane polyurea resin, bisphenol F epoxy resin, a silane coupling agent, tetraethyl orthosilicate, ethanol, vinyl double cap, nano-grade zinc oxide, nano-grade titanium dioxide, nano-grade aluminum trioxide, an AO-80 antioxidant, a light stabilizer, a UV absorber, a leveling agent, and a defoaming agent. The paint provided by the invention is long-lasting, green and environment-friendly, and has the advantages of ultrahigh hardness, fouling resistance, and easy cleaning.

Owner:张少波

Dispersion material for bottom blowing composite air brick of steel ladle and preparation method of dispersion material

The invention discloses a dispersion material for a bottom blowing composite air brick of a steel ladle and a preparation method of the dispersion material. The dispersion material is mainly prepared from the following raw materials in percentage by weight: 80 to 85 percent of corundum spheres, 5 to 10 percent of alumina micro powder, 1 to 5 percent of chromium oxide green powder, 1 to 5 percent of magnesia-alumina spinel with 200 meshes, and a binding agent accounting for 2.5 to 3.5 percent of total weight of the raw materials. The preparation method comprises the following steps: firstly, adding the weighed raw materials into a forced sand mixer for premixing to obtain a mixed material; secondly, putting the mixed material into an assembled mold and then carrying out compression moulding to obtain a green brick; thirdly, putting the green brick into a dryer for drying, and putting the dried product into a high-temperature kiln for firing; after the firing is ended, carrying out natural cooling to obtain a product, namely the dispersion material. The dispersion material prepared by the technical scheme adopted by the invention has the characteristics endowed by a traditional dispersion breathable material, as well as the characteristics of relatively-high strength, erosion resistance, permeation resistance, high thermal shock property and the like.

Owner:TONGDA REFRACTORY TECH CO LTD +1

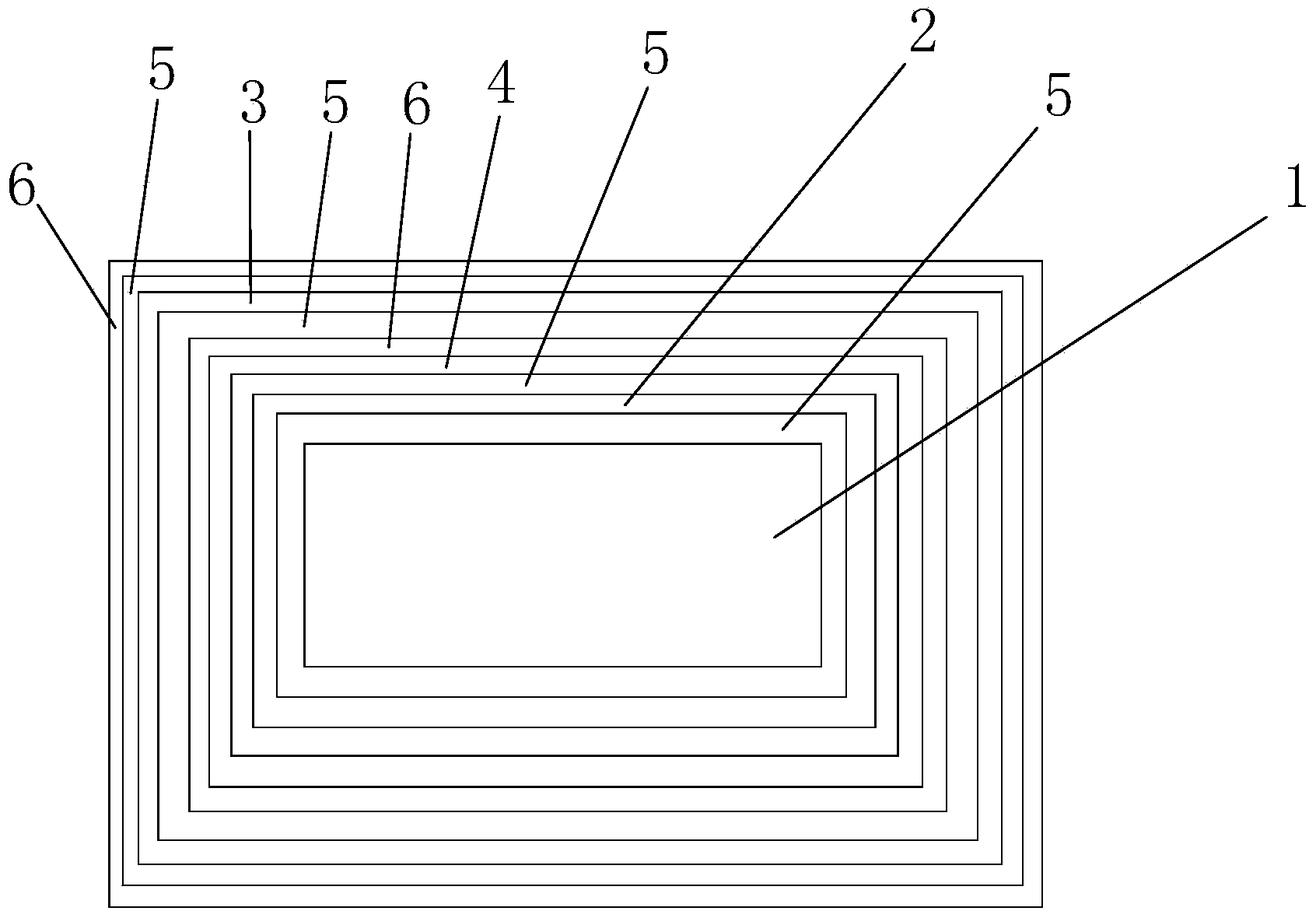

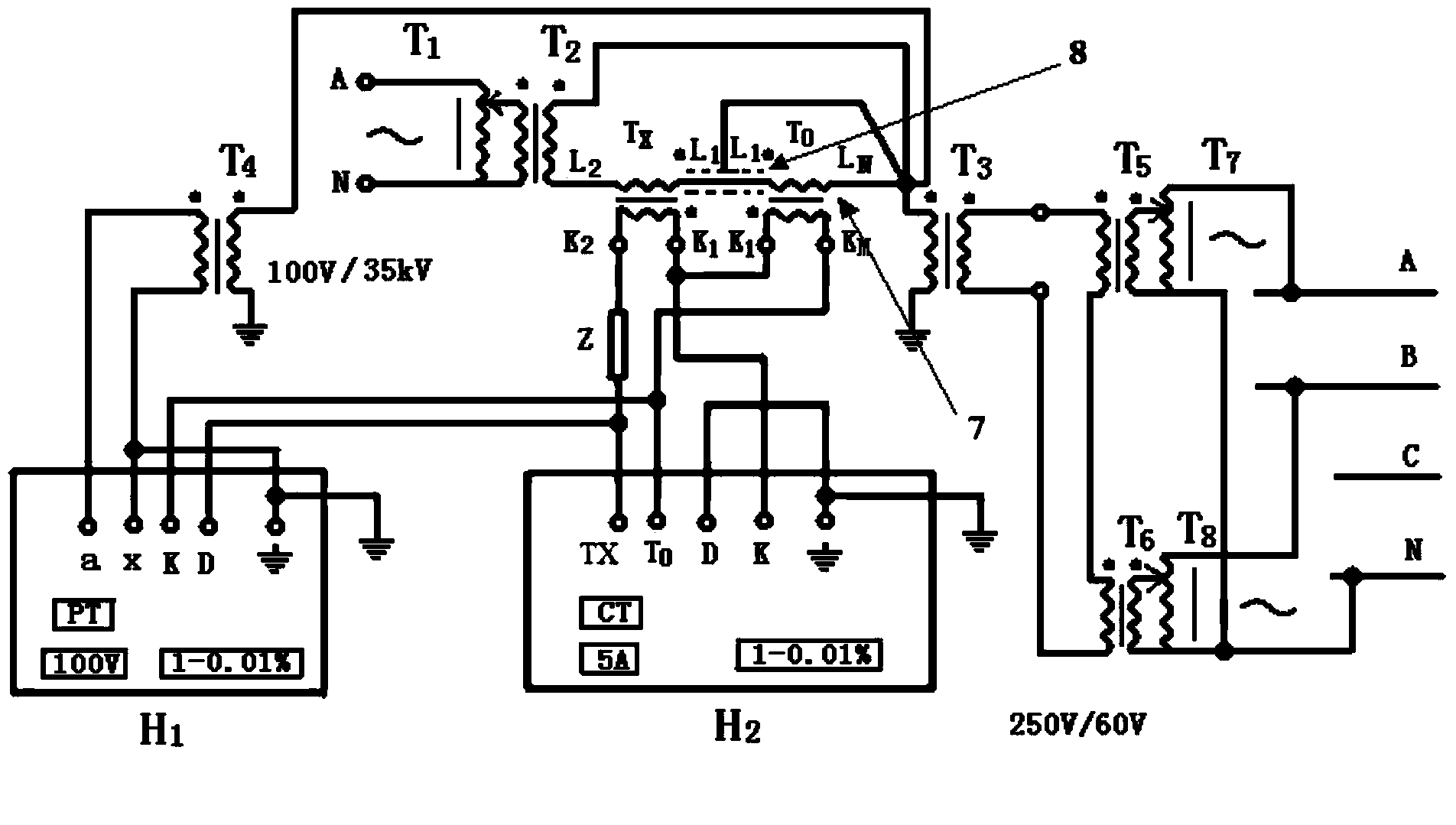

Precise high-voltage current mutual inductor and error testing system and method thereof

ActiveCN104330760AEliminate error variationGuaranteed accuracyVoltage/current isolationInductorEngineering

The invention discloses a precise high-voltage current mutual inductor. A multi-winding multi-tap compensating coil winds an outer layer of an iron core; a first insulating layer is arranged between the multi-winding multi-tap compensating coil and the outer layer of the iron core; a multi-winding multi-tap secondary coil winds the outer layer of the multi-winding multi-tap compensating coil; a second insulating layer is arranged between the multi-winding multi-tap compensating coil and the multi-winding multi-tap secondary coil; a multi-winding multi-tap primary coil winds the exterior of the multi-winding multi-tap secondary coil; a first shielding layer and a third insulating layer are arranged between the multi-winding multi-tap secondary coil and the multi-winding multi-tap primary coil; the second shielding layer winds the exterior of the multi-winding multi-tap primary coil; a fourth insulating layer is arranged between the multi-winding multi-tap primary coil and the second shielding layer; the first shielding layer and the second shielding layer are provided with extension lines. The precise high-voltage current mutual inductor can directly and accurately measure the error of a high-voltage current mutual inductor under actual high-voltage environment.

Owner:STATE GRID CORP OF CHINA +1

Photoconduction type X-ray detector based on high-resistance ZnO monocrystal and manufacturing method thereof

ActiveCN103794674AWith high pressureWith noiseFinal product manufactureSemiconductor devicesHigh resistanceSingle crystal

The invention discloses a photoconduction type X-ray detector based on a high-resistance ZnO monocrystal. The photoconduction type X-ray detector based on the high-resistance ZnO monocrystal comprises a ZnO monocrystal substrate. The upper surface of the ZnO monocrystal substrate is plated with an upper electrode and a protection ring of an annular structure. The upper electrode is located in the middle of the protection ring. Uniform gaps are formed between the protection ring and the upper electrode. The lower surface of the ZnO monocrystal substrate is plated with a lower electrode. The upper electrode and the protection ring respectively comprise a first Al film layer and a first AZO film layer in sequence from top to bottom. The lower electrode comprises a second AZO film layer and a second Al film layer in sequence from top to bottom. The invention further provides a manufacturing method of the photoconduction type X-ray detector based on the high-resistance ZnO monocrystal. The photoconduction type X-ray detector which is based on the high-resistance ZnO monocrystal and manufactured through the manufacturing method has the advantages of being high in high-voltage resistance, low in noise and low in cost.

Owner:XI AN JIAOTONG UNIV

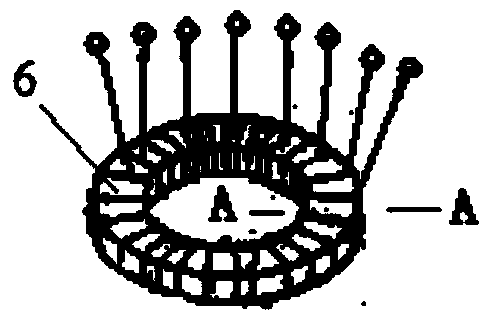

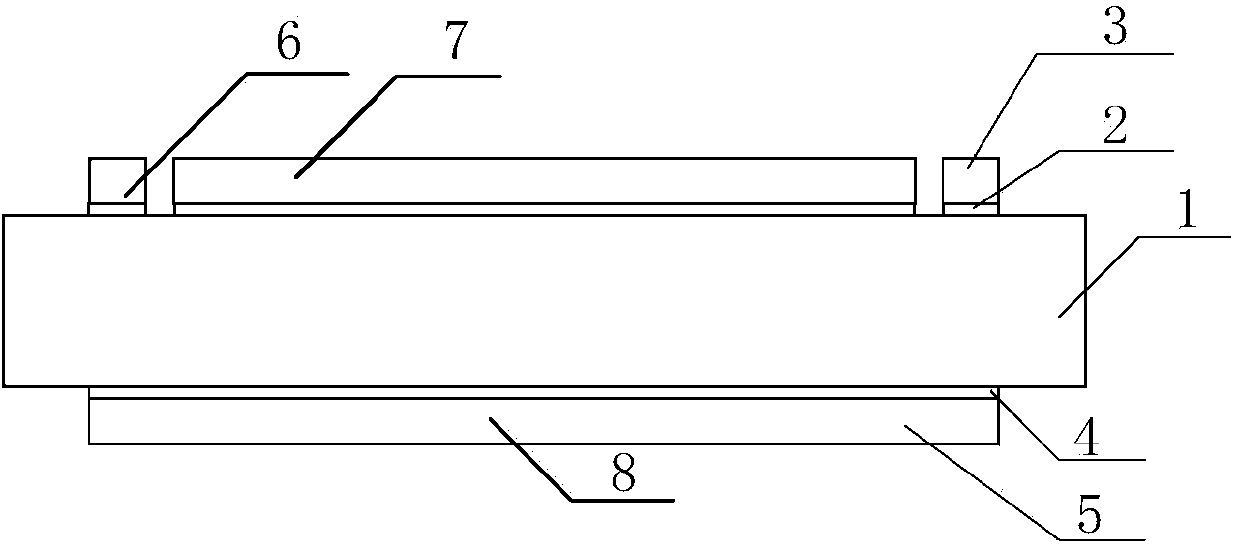

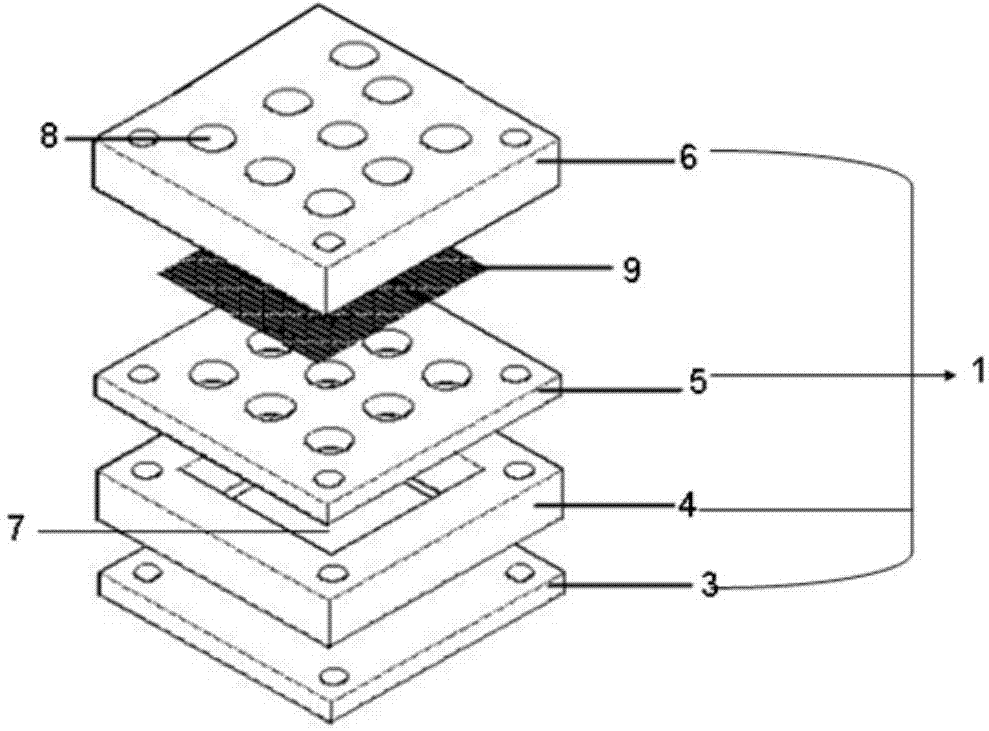

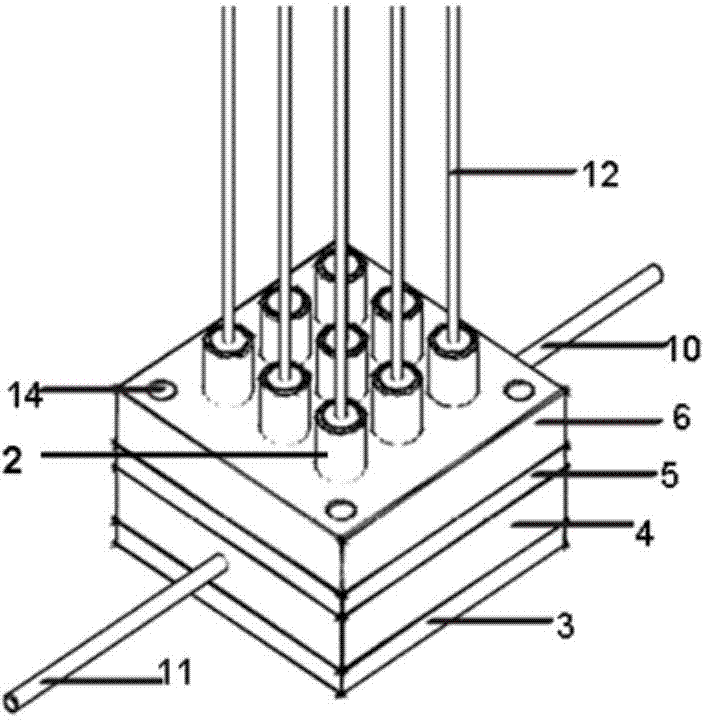

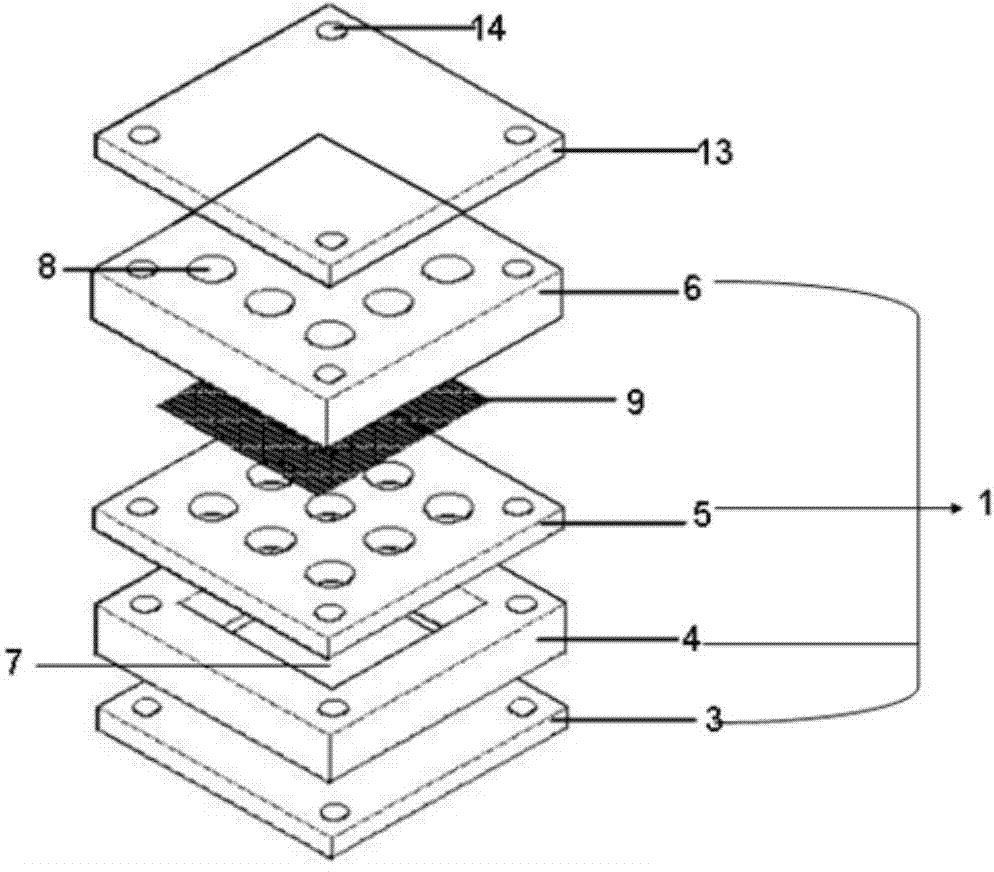

In-situ high flux culture apparatus for sea microbe

InactiveCN104498322AAvoid damageWith high pressureBioreactor/fermenter combinationsBiological substance pretreatmentsHigh fluxCulture environment

The invention discloses an in-situ high flux culture apparatus for sea microbe, which comprises a seawater cabin and an independent culture chamber; the seawater cabin comprises a base plate fixed by bolts, a liquid storage layer, a partition plate and a culture layer from down to up, a reservoir is opened at intermediate part of the liquid storage layer, the circular holes with same size and relative position are opened on the partition plate and the culture layer; a layer of filter membrane is arranged between the partition plate and the culture layer, and the culture chamber is positioned in the circular hole on the culture layer and positioned on the filter membrane. When the apparatus is used for simulating in-situ environment in a laboratory, the apparatus is placed in a constant temperature oscillator, the base plate is a sealing base plate, the culture chamber is sealed by using an independent top cover connected to a conduit; when the apparatus is used for in-situ culture, the base plate is the base plate with sieve apertures, and the top of the culture chamber is sealed with a light transmission top board. The apparatus has the characteristics of integral disinfection, high pressure resistance, temperature difference resistance, and bump resistance. The apparatus can keep stable in-situ culture environment in laboratory and sea environment, and damage on the microbe due to environment change can be reduced.

Owner:OCEAN UNIV OF CHINA

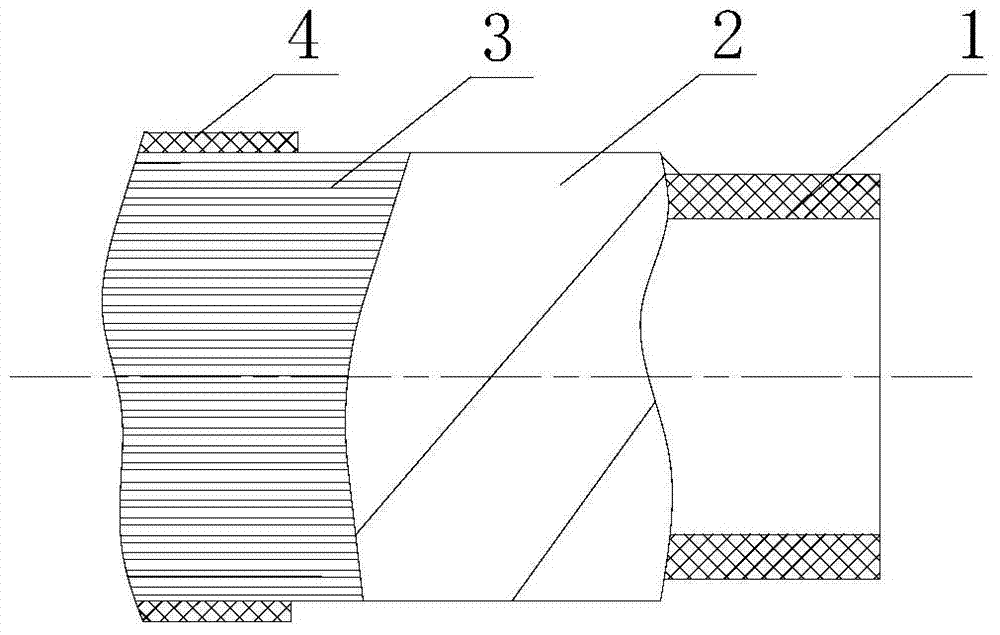

Tensile RTP and manufacturing method thereof

InactiveCN103574183AWith high pressureImprove tensile propertiesCoatingsRigid pipesFiberManufacturing technology

The invention relates to a tensile RTP and a manufacturing method of the tensile RTP. The pipe comprises an inner pipe and a reinforcing layer wound on the inner pipe, the reinforcing layer is wrapped by a protective layer, the reinforcing layer is composed of two winding straps which are wound on the outer wall of the inner pipe in the opposite directions of turning at preset winding angles, a tensile layer is arranged between the reinforcing layer and the protective layer, and the tensile layer is composed of a set of fiber ropes which are evenly distributed in the circumferential direction and are pre-tensioned in the axial direction. Raw materials are placed into an inner pipe extruder to be extruded and cooled for being sized to form the inner pipe, the two high-strength winding straps are wound on the outer wall of the inner pipe in the opposite directions of turning according to the preset winding angles to form the reinforcing layer, the set of fiber ropes are evenly arranged on the outer surface of the reinforcing layer in the direction of the axis of the pipeline after being pre-tensioned to form the tensile layer, raw materials are placed into an outer pipe extruder to be extruded so as to wrap the tensile layer to form the protective layer, and then online continuous production is achieved through coiling. The tensile RTP has the advantages of being high in tensile property and in flexibility, resistant to high temperature and corrosion, safe, reliable and the like, the RTP is formed at one time according to the manufacturing technology, the production period is short, and the production efficiency is high.

Owner:NANJING CHENGUANG COMPOSITE PIPE ENG CO LTD

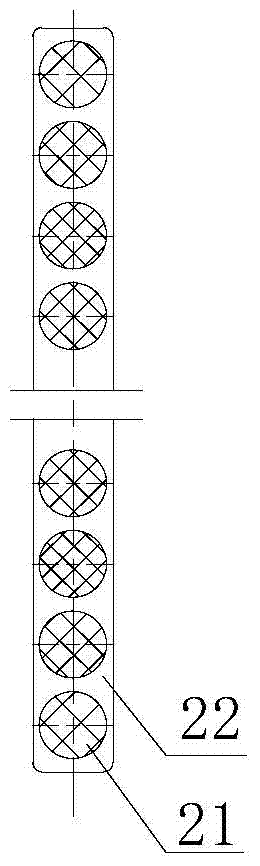

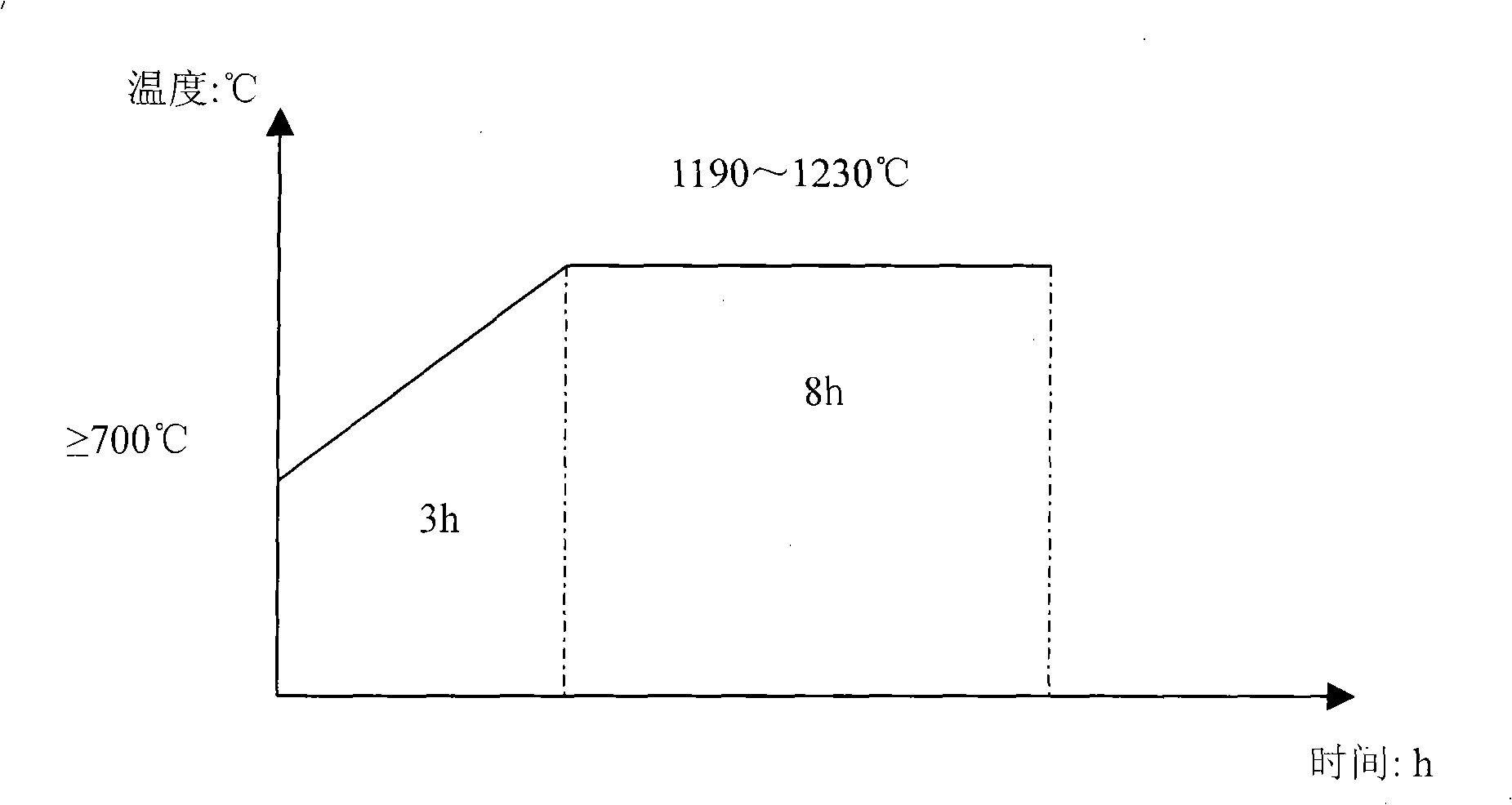

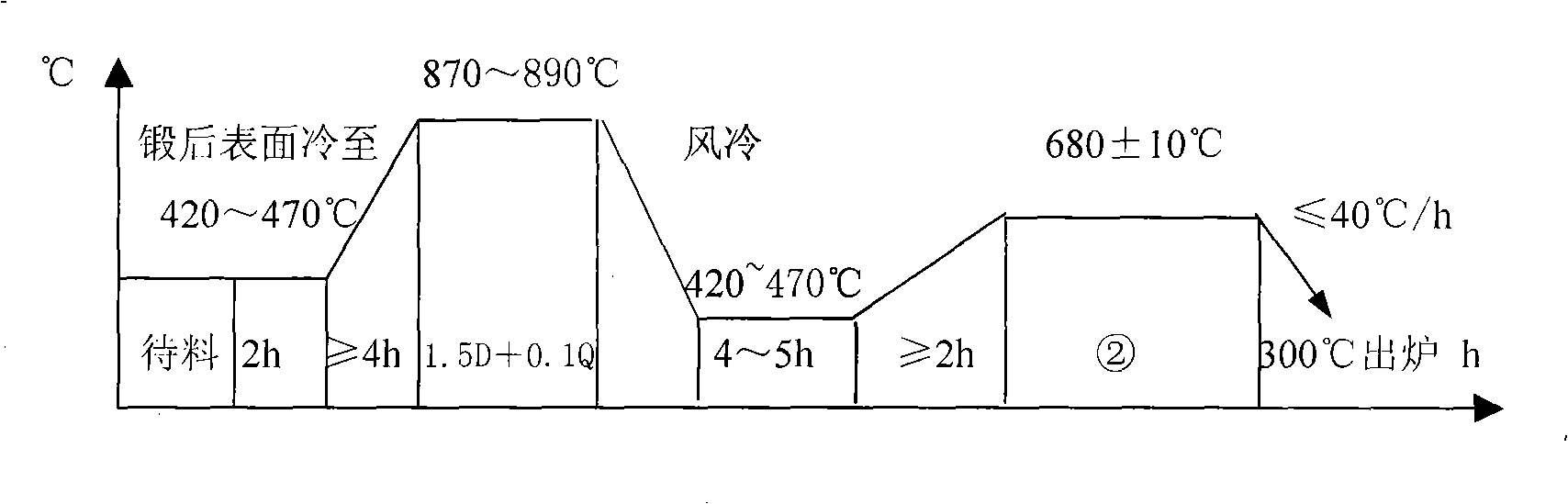

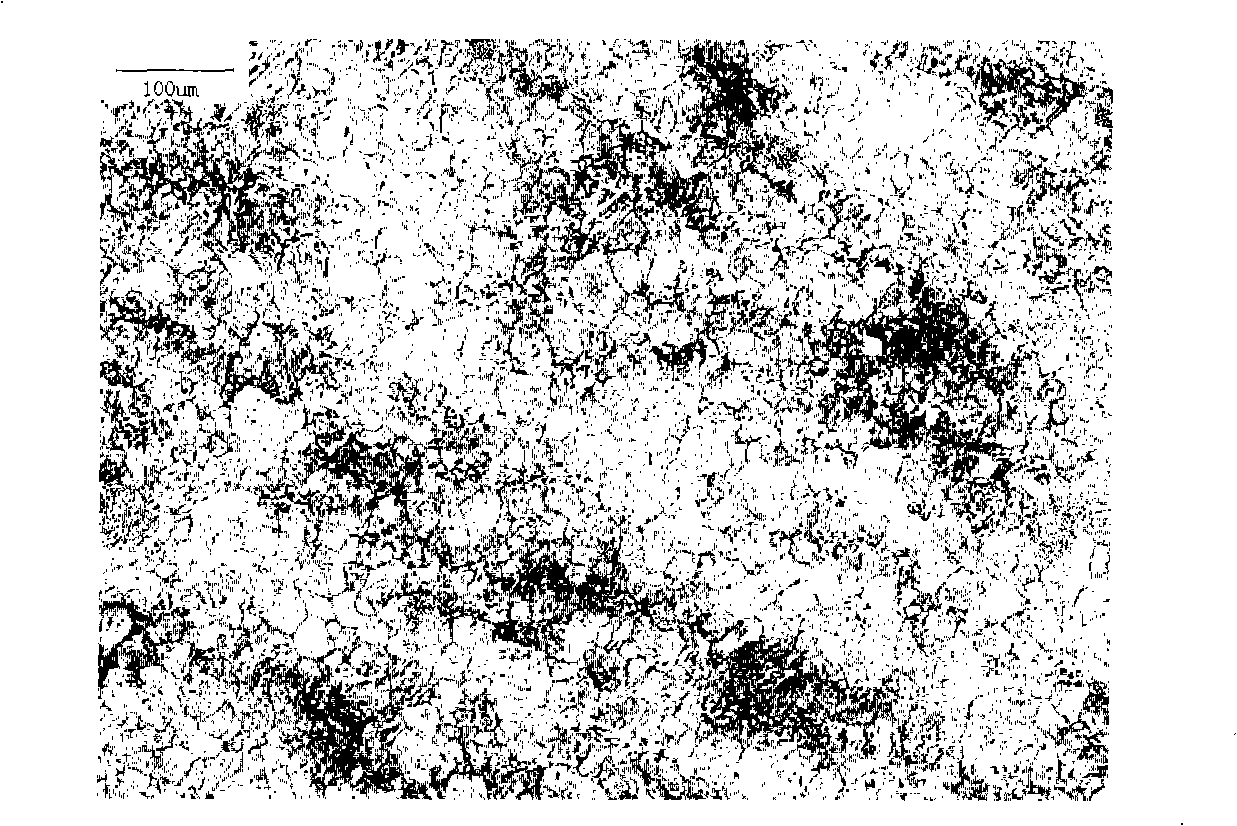

Anti-H2S stress corrosion high pressure resistant forgings and method for manufacturing same

Disclosed is a sulfureted hydrogen-proof stress corrosion high pressure-resistant forge piece, comprising the compositions, in weight percent: C: 0.26 to 0.30, Mn: 0.80 to 1.00, Cr: 0.80 to 1.00, Si: 0.20 to 0.35, Ni: 0.50 to 0.95, Mo: 0.20 to 0.30, P<=0.012, S<=0.010, Cu<=0.20, H<=2ppm, O<=50ppm, N<=85ppm, balance Fe; and a manufacturing method comprises the following steps of: secondary refining and smelting by an electric furnace, and casting for forming ingot; heating and forging, with a heating speed of 100 to 150DEG C / h to rise the temperature to 1190 to 1230DEG C, and then preserving the heat for over 8 hours; forging steel ingot to have the size of a finished product; forging temperature range: 800DEG C to 1130 DEG C; adopting an upsetting drawing process, with a forging ratio >=6; and air cooling to reach a temperature of between 420 and 470DEG C after the forging and preserving the heat for over 2 hours, normalizing, with a temperature of between 870 and 890DEG C, and annealing, with a temperature of between 670 and 690DEG C. The indexes such as yielding, tensile strength, grain size and non-metallic inclusion of the forge piece meet the designed 105MPa pressure demand, and the forge piece is corrosion resistant.

Owner:宝武特种冶金有限公司

Rubber adhesive

InactiveCN102086354AAging resistantWith high pressureNatural rubber adhesivesChitin adhesivesAdhesive cementPolymer science

The invention provides a rubber adhesive, which comprises the following components: natural rubber, styrene butadiene rubber, polyisobutylene rubber, chlorosulfonated polyethylene, lignin, kieselguhr, pineneresin, tert-butyl phenolic resin, promoter M, zinc oxide, stearic acid, anti-aging agent 4010, anti-aging agent DNP, anti-aging agent MB, methylbenzene and chitin, and has the characteristics of aging resistance, high-pressure resistance and high-temperature resistance.

Owner:戚冬梅

Semi-conductor DC photoelectric transformer

InactiveCN102496649AWith high pressureHas electromagnetic radiationEfficient power electronics conversionPhotovoltaic energy generationTransformerEngineering

The invention provides a semi-conductor DC photoelectric transformer which comprises a first electrode layer, an electro-optical conversion layer formed on the first electrode layer, a second electrode layer on the electro-optical conversion layer, a first insulating layer on the second electrode layer, a third electrode layer on the first insulating layer, an electro-optical conversion layer on the third electrode layer, and a fourth electrode layer on the photoelectric conversion layer, wherein, the work rays given by the electro-optical conversion layer can penetrate the first insulating layer, the second electrode layer and the third electrode layer. According to the semi-conductor DC photoelectric transformer provided by the embodiment of the invention, the transformation of a DC voltage can be directly realized, and the advantages of high pressure resistance, electromagnetic radiation prevention, coil structure prevention, sun radiation and sun storm influence prevention, safety and reliability, small size, long service life, light weight, convenience in installation and maintenance, and the like are achieved.

Owner:郭磊

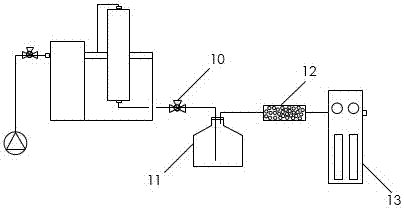

Experimental device and method for measuring solubility of overflowed gas

InactiveCN106950149AGood sealing effectImprove experimental efficiencyMaterial analysisMeasurement deviceEnvironmental geology

The invention relates to an experimental device and an experimental method for measuring solubility of overflowed gas. A measuring device comprises a reaction unit and a measuring unit. Core equipment comprises an intermediate container, a high-temperature high-pressure sample preparer, a separation bottle, a gasometer flask and a constant pressure pump. The method comprises the following steps: filling the high-temperature high-pressure sample preparer with a certain amount of drilling fluid; injecting excessive gas into the high-temperature high-pressure sample preparer through the intermediate container; controlling the temperature and pressure of the high-temperature high-pressure sample preparer by means of a heating element and the constant pressure pump; continuously rotating the high-temperature high-pressure sample preparer, wherein gas and the drilling fluid are in full contact; when dissolving balance is achieved, reversing the high-temperature high-pressure sample preparer; taking out a proper amount of dissolved saturated drilling fluid for gas-liquid separation and separately metering the gas volume and the mass of the drilling fluid; and calculating the solubility at the temperature and pressure condition. The device and method provided by the invention have the beneficial effects that a dissolving reaction of the overflowed gas in the drilling fluid in a wellbore flow condition can be simulated, multiple times of measurement can be realized by sample transferring at a single time, and the testing efficiency is increased.

Owner:SOUTHWEST PETROLEUM UNIV

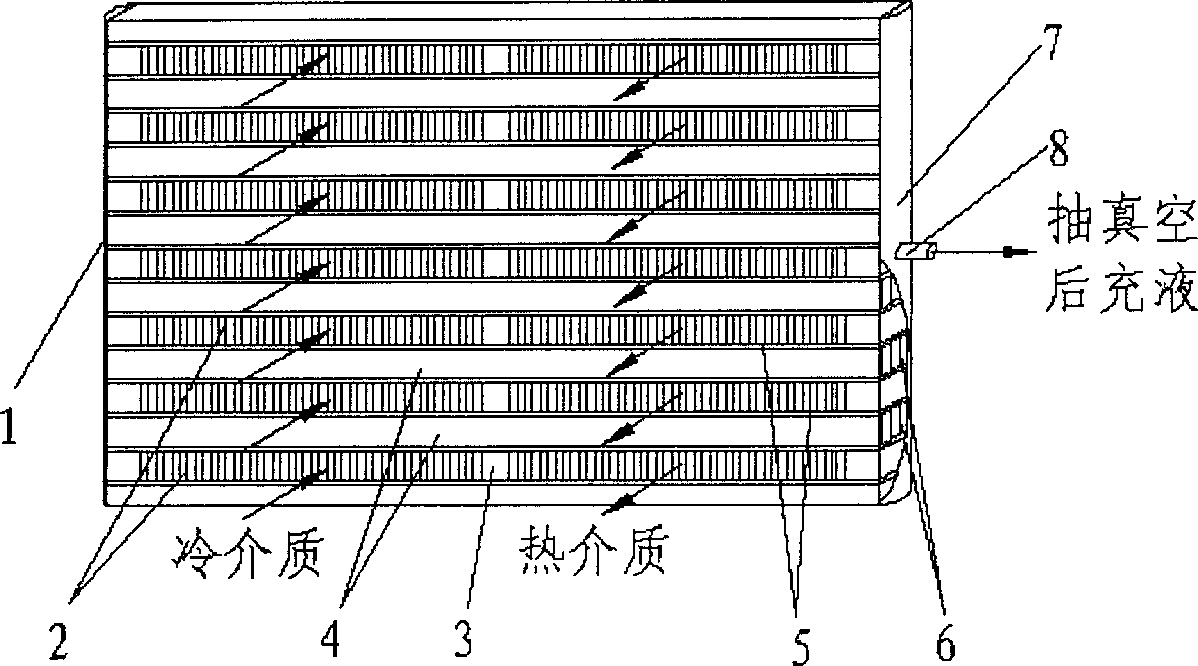

Hot-fin heater exchanger

InactiveCN1374574AHigh temperature resistantWith high pressureDigital data processing detailsSemiconductor/solid-state device detailsEngineeringAir conditioning

The hot finned plate heat exchanger as one new type of heat exchanger is one important mechanism for recovering exhausted wind energy of large air conditioning system, recovering afterheat of high temperature fume and dissipating heat of computer CPU. Its structure includes vacuum liquid-filled end plates and core body, the vacuum liquid-filled end plates are set on two sides of the vacuum liquid-filled passage, and the core body sonsists of the vacuum liquid-filled passage and several finned plate passages. Each of the vacuum liquid-filled passages and the finned plate passages has upper andlower partition boards, side sealing tapes and internal fins. Each of the finned plate passages is separated by one sealing tapes into two parallel hot medium passage and one cold medium passage. After being assembled, the heat exchanger is arranged obliquely or vertically.

Owner:NANJING UNIV OF TECH

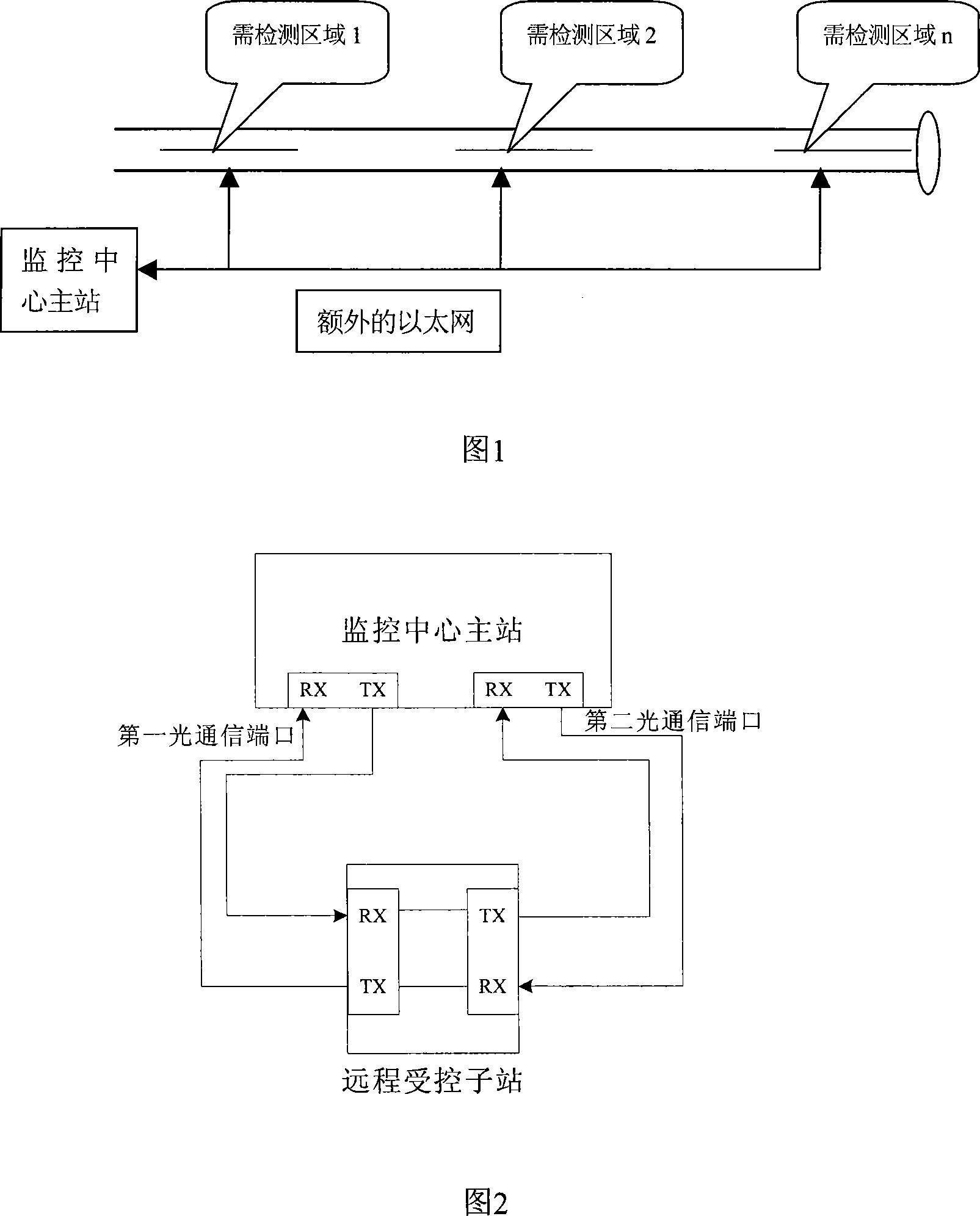

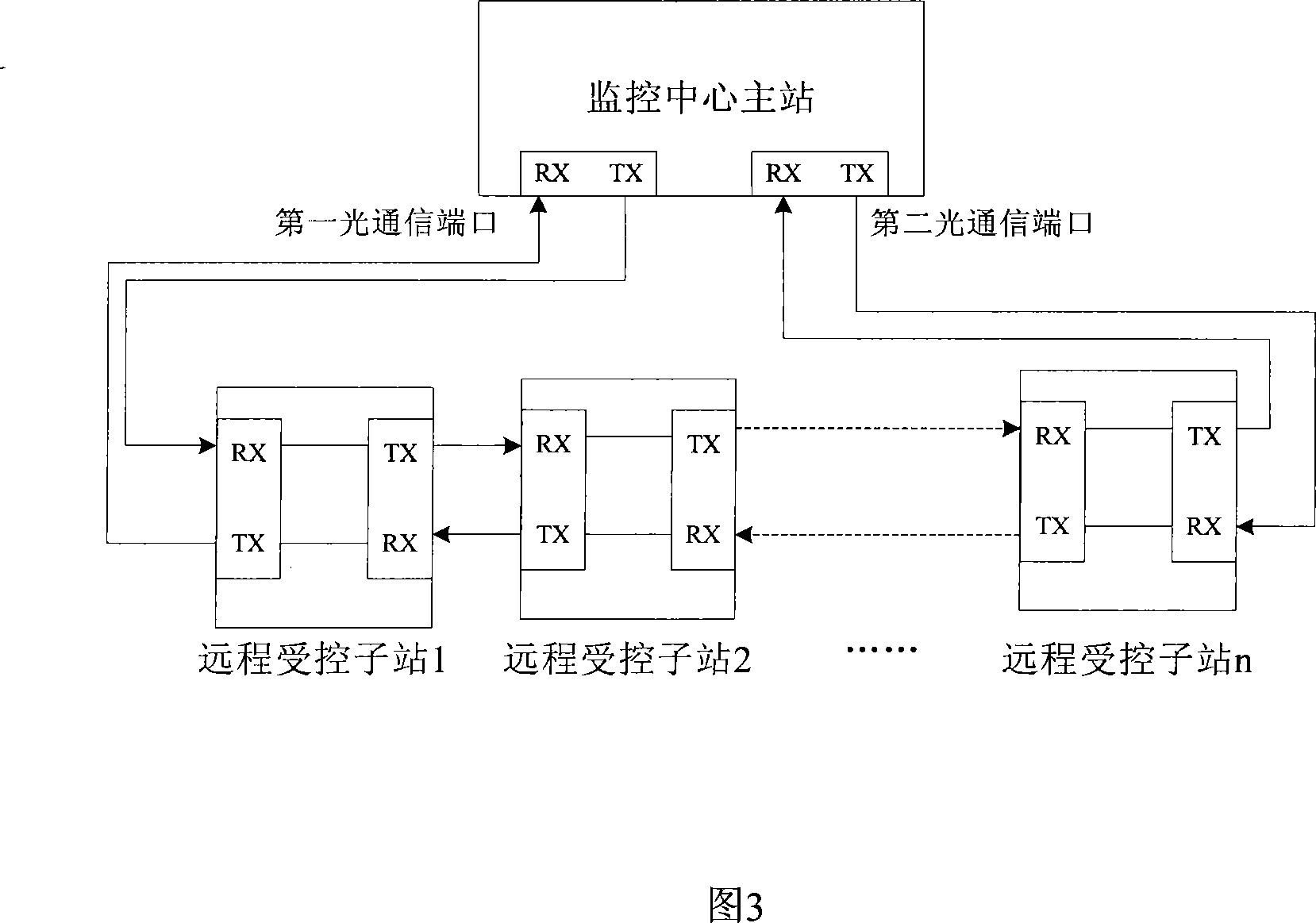

Distributed optical fiber temperature monitoring system

ActiveCN101221693ANo need to increase additional networking costsRF resistantNon-electrical signal transmission systemsTransceiverRemote control

The invention relates to a distribution type optical fiber temperature monitoring system, which comprises a monitoring center master station, and at least one remote controlled substation connected with the monitoring center master station through optical fiber, wherein the remote controlled substation at least comprises a temperature sensor module. The invention is characterized in that: the remote controlled substation at least comprises two optical fiber transceivers; the electric ports of the two optical fiber transceivers are both connected with the temperature sensor module; the optical port of a first optical fiber transceiver of a first remote controlled substation is connected with the first communication port of the monitoring center master station, the optical port of a second optical fiber transceiver of a last remote controlled substation is connected with the second communication port of the monitoring center master station, and each two adjacent remote controlled substations are connected through optical fiber. The invention does not need extra networking cost; signal transmission is sent to the monitoring center master station through a two-way loop, and when the optical fiber at one side of one remote controlled substation encounters abnormality, the signal is transmitted to the monitoring center master station through the optical fiber at the other side.

Owner:浙江振东光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com