High temperature deep well screw drilling tool

A technology for screw drilling tools and deep wells, which is applied in the direction of drilling driving devices, drilling equipment, earthwork drilling and production in boreholes, etc. It can solve the problem that the overall structure application does not have much change, and the high temperature resistance performance of the screw drill cannot be fully exerted. Damage and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

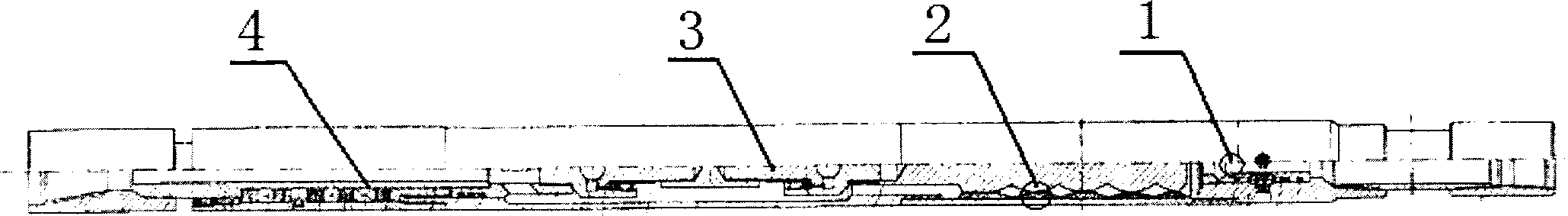

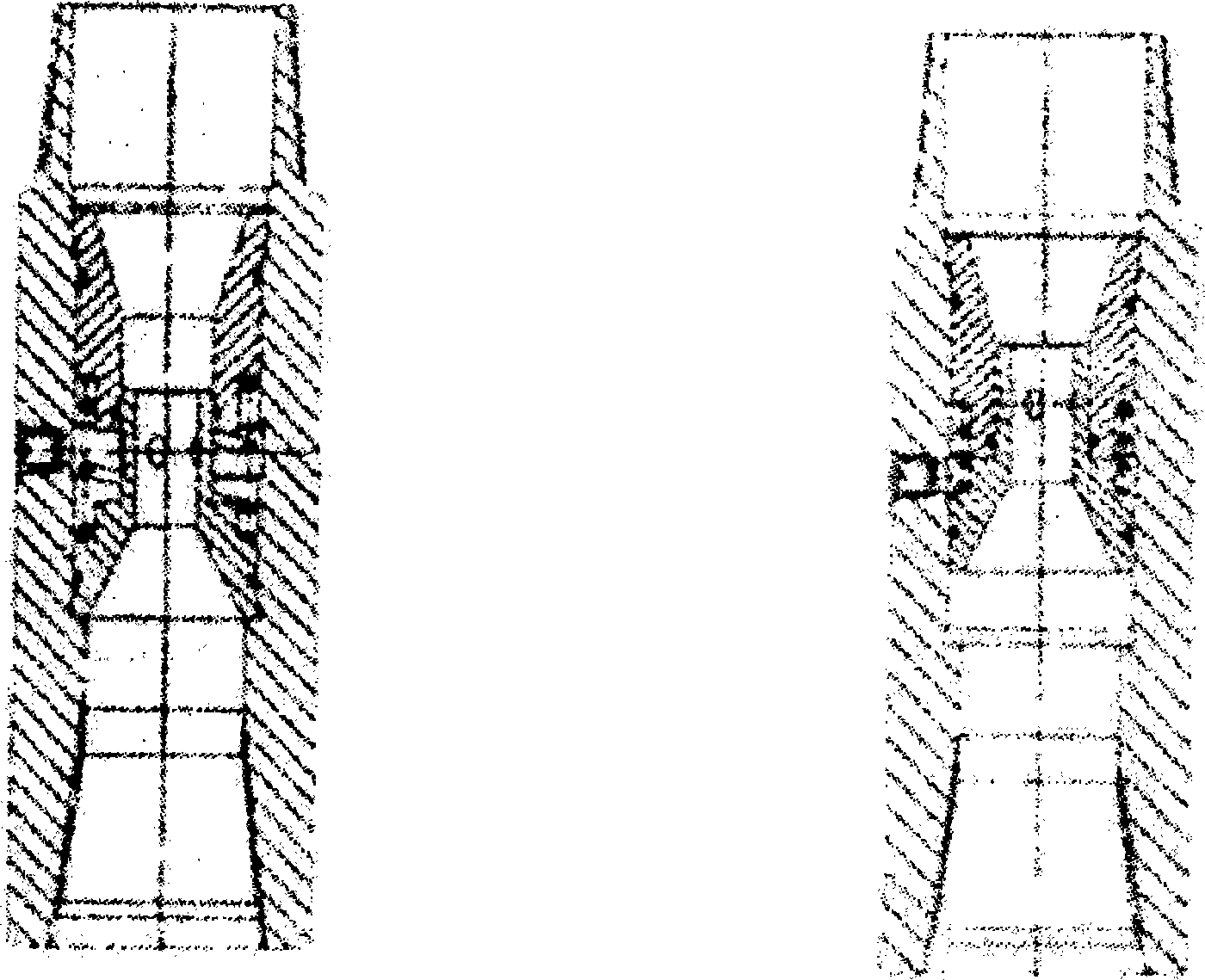

[0029] The utility model relates to a tool used in oil drilling and workover operations, and mainly relates to a high-temperature deep well screw drilling tool. The universal joint part adopts the intermediate shunt cooling method to reduce the temperature of the mud passing through the screw drilling tool. In the motor part of the screw drilling tool, the stator part is vulcanized with high temperature resistant, alkali and acid resistant rubber, and the rotor part is made of tungsten alloy electroplating process, which has excellent Deep plating ability and Jun plating ability. In the transmission part of the screw drilling tool, 10 sets of string bearings are used, and the TC bearing is lengthened by 50mm. The upper end of the radial bearing and the lower end of the lower radial bearing, so that the screw drilling tool can better withstand the vibration transmitted from the downhole drill bit to the screw drilling tool in deep well work. The screw drilling tool bypass valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com