Precise high-voltage current mutual inductor and error testing system and method thereof

A high-voltage current and transformer technology, applied in voltage/current isolation, instruments, measuring devices, etc., can solve the problem of inability to directly measure the error of high-voltage current transformers, and achieve the effect of eliminating error changes and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

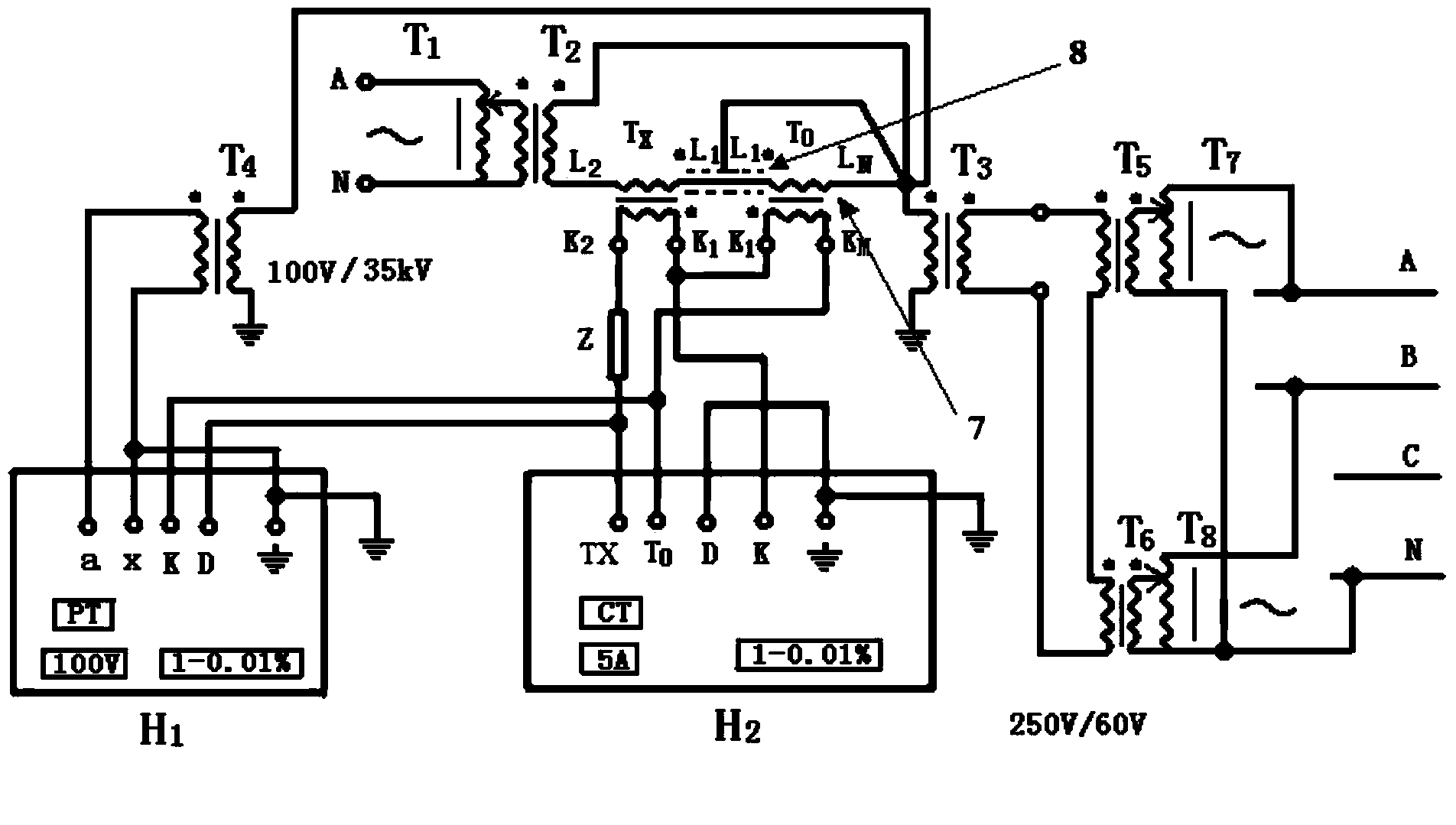

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

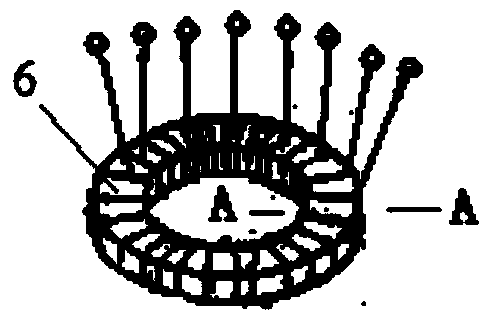

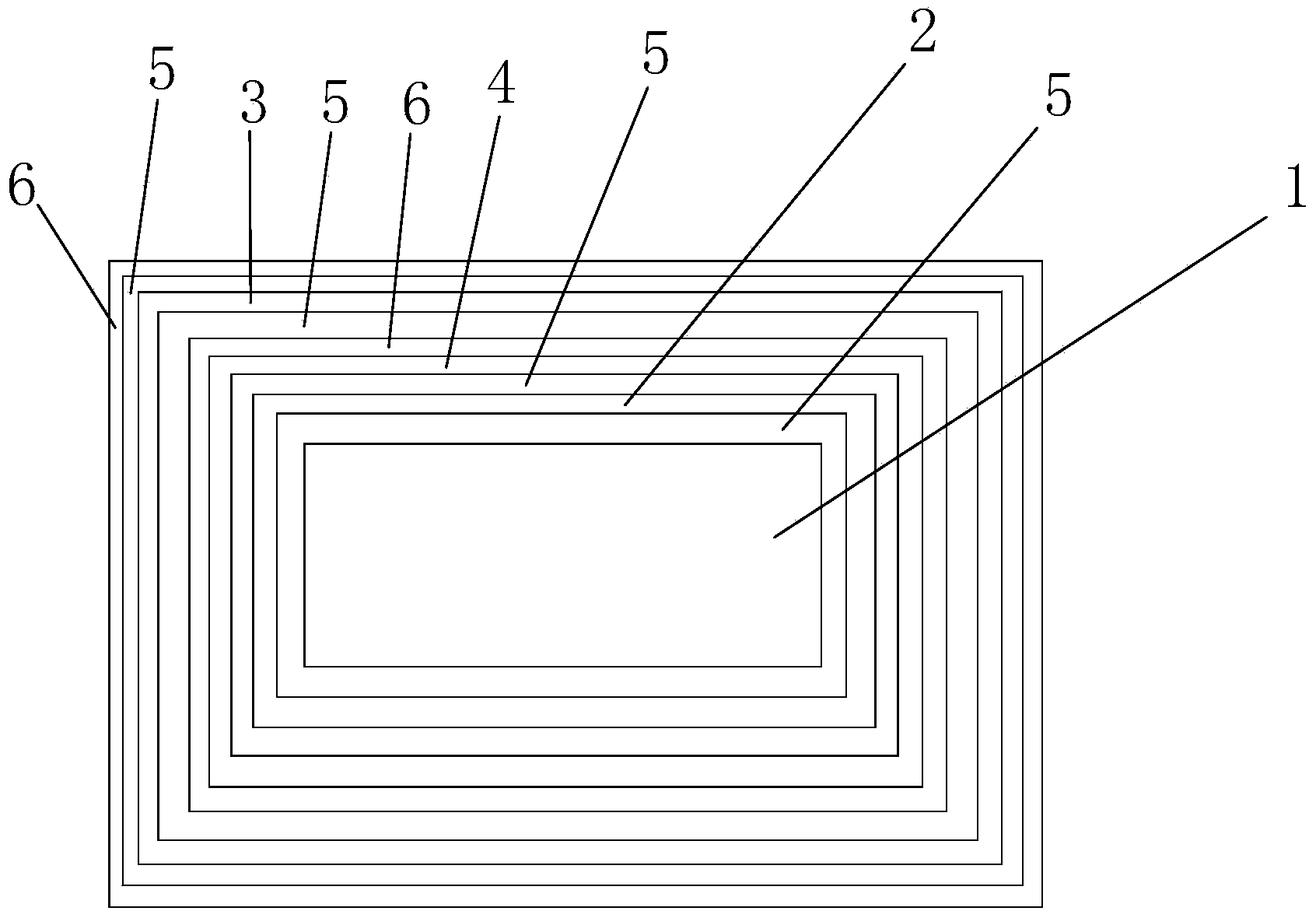

[0030] Such as Figure 1~3 The precision high-voltage current transformer shown includes an iron core 1, a compensation coil 2 with multiple windings and multiple taps, a primary coil 3 with multiple windings and multiple taps, a secondary coil 4 with multiple windings and multiple taps, an insulating layer 5 and a shielding layer 6, Wherein, the outer layer of the iron core 1 is wound with a multi-winding and multi-tap compensation coil 2, and a first insulating layer 5 is arranged between the multi-winding and multi-tap compensation coil 2 and the outer layer of the iron core 1;

[0031] The outer layer of the multi-winding and multi-tap compensation coil 2 is wound with a multi-winding and multi-tap secondary coil 4, and a second insulating layer 5 is arranged between the multi-winding and multi-tap compensation coil 2 and the multi-winding a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com