Integrated structure of fuel tank and urea tank, material and process

A urea tank, an integrated technology, applied in the field of auto parts, can solve the problems of not easy to control the wall thickness of the tank, high cost of the urea tank, limited rotational molding raw materials, etc., to reduce the invalid liquid level area and high product economy , to reduce the effect of the sum of the mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

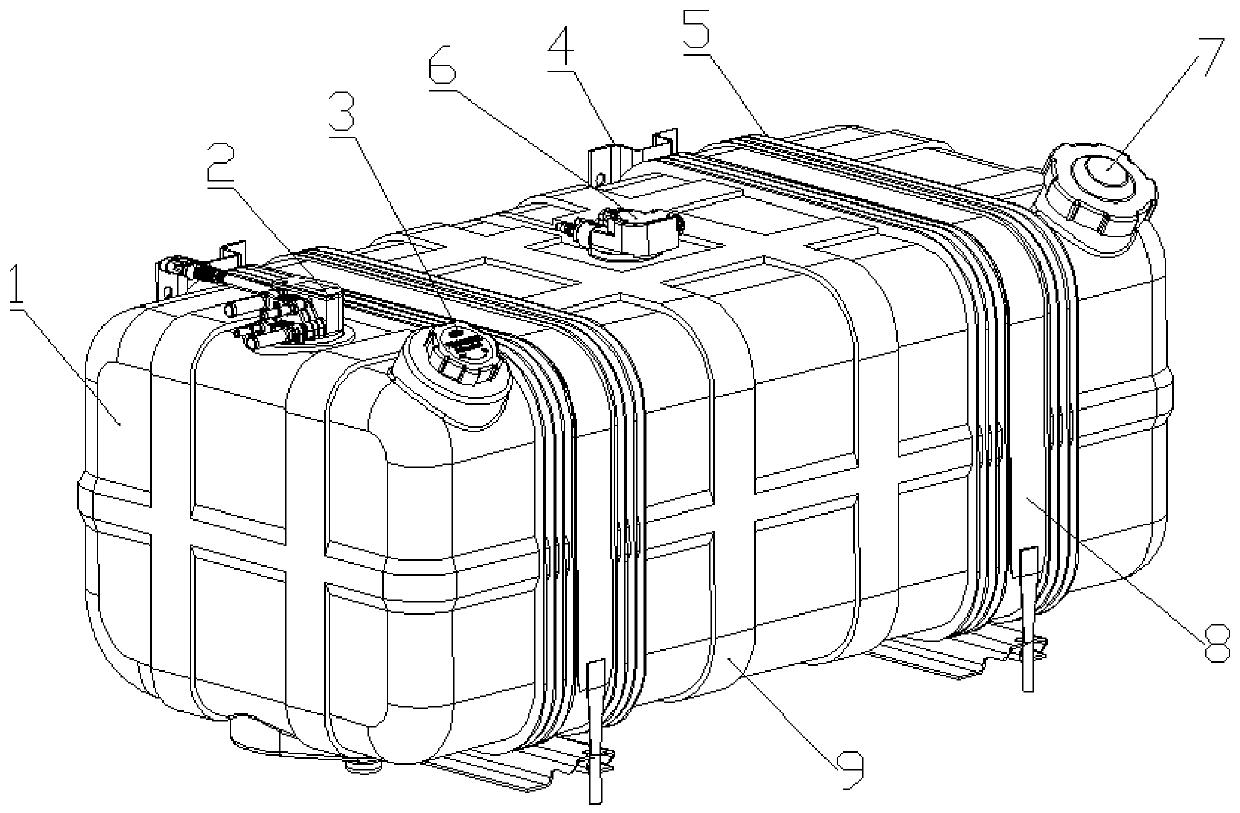

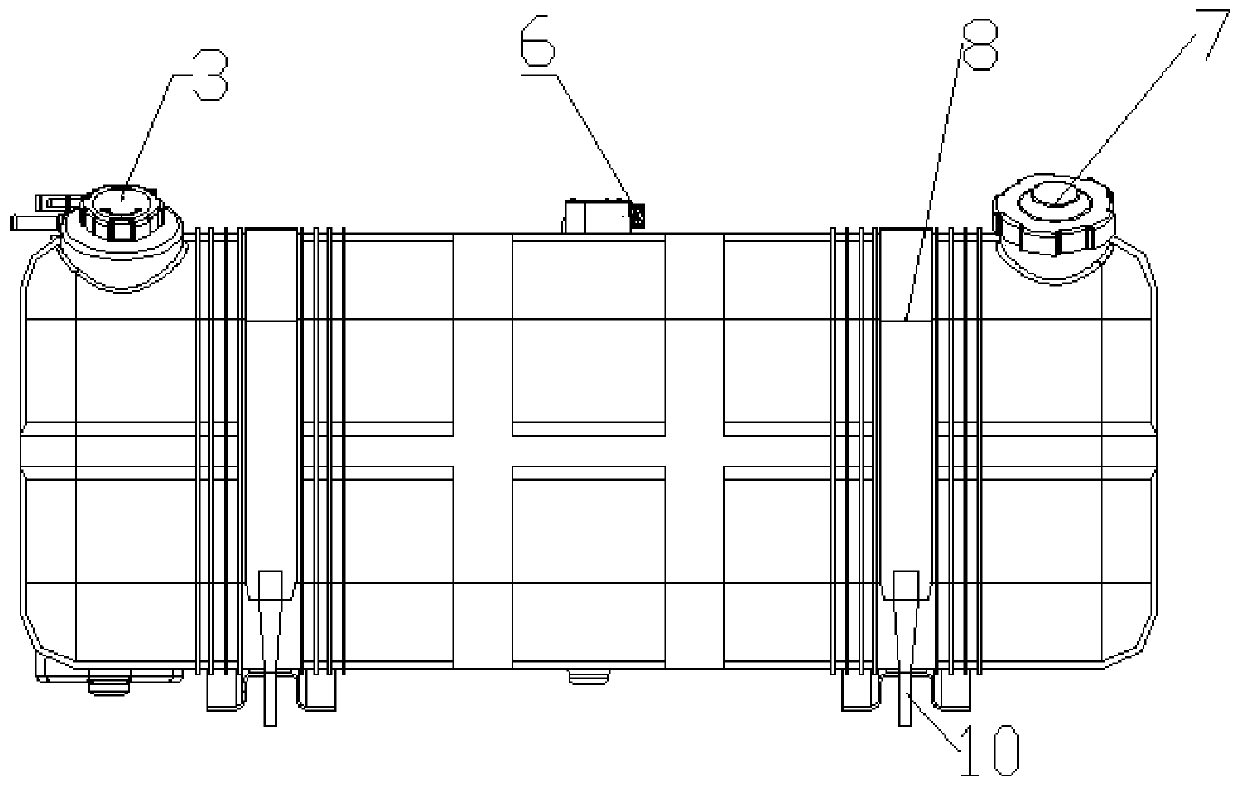

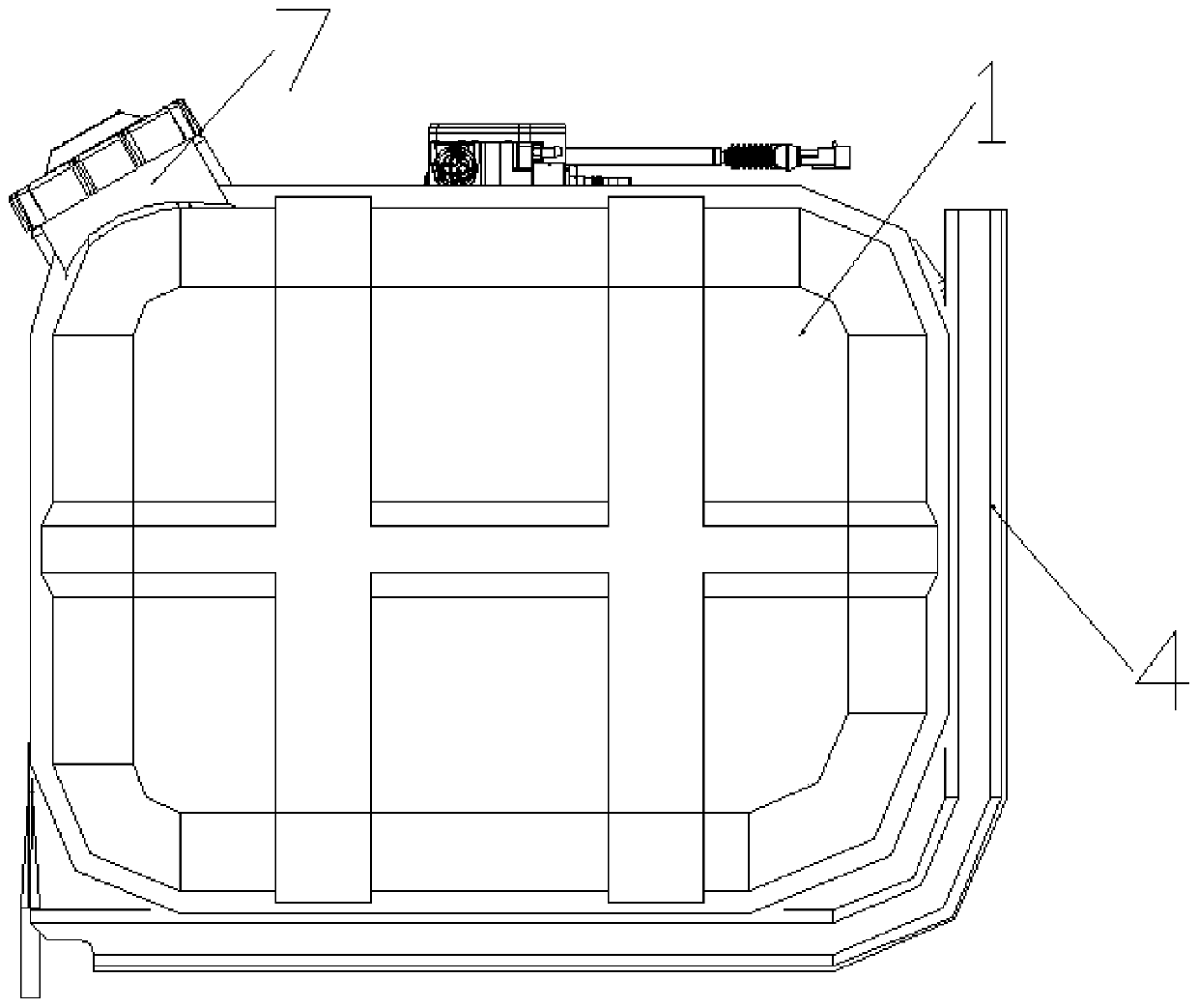

[0050] In a typical embodiment of the present invention, such as figure 1 with figure 2 As shown, an integrated structure of a fuel tank and a urea tank includes a housing 1, and a partition plate 17 is arranged inside the housing 1 to form a fuel chamber on one side of the partition board 17 and a urea chamber on the other side. At least one anti-surge partition 18 is provided in the fuel chamber of the casing 1, and the partition 17 and the anti-surge partition 18 are arranged along the width direction of the casing 1, and the partition 17 must ensure that the cavities on both sides Specifically, the partition plate 17 is injection molded together with the casing 1, and the anti-surge partition 18 is provided with a through hole or there is a set space between the anti-surge partition 18 and the inner wall of the casing 1, so that the entire fuel oil The fuel oil in the cavity is connected, and through the setting of the anti-surge partition 18, it is used to form multiple...

Embodiment 2

[0065] An integrated structure of fuel tank and urea tank, using anti-permeation polyamide material, the specific materials used in the composition of the anti-permeation polyamide material include ethylene-octene copolymer, anti-UV additives, flame retardant and nylon 6 , and the proportions of the components are: 5-7 parts, 0.15-0.2 parts, 0.1-2 parts and 91-95 parts. When making the shell, the above four components are fused with each other to form an impermeable polyamide material.

[0066] The main chain of ethylene-octene copolymer (POE) is ethylene, the side chain is octene, and the molar content of octene is 20%-25%. POE will also have excellent properties such as aging resistance, ozone resistance, and chemical medium resistance. By cross-linking POE, the heat-resistant temperature of the material is increased by 30%, and the mechanical properties such as impact resistance and toughness are improved by more than 10 times.

[0067] Anti-UV additives, the main component...

Embodiment 3

[0071] A manufacturing process of an integrated structure of a fuel tank and a urea tank, comprising the following contents:

[0072] Using the anti-permeation polyamide materials disclosed in Example 2, the upper casing 14 and the lower casing 13 of an integral structure are manufactured by injection molding, and the partition plate fixing part for fixing the partition plate has been formed during the manufacturing process. And the card groove and locking groove used to fix the anti-surge partition. The injection molding adopts a high-precision servo injection molding machine. By controlling the mold temperature and injection pressure, the injection pressure is ≤50Mpa, the molding temperature is 265±5°C, and the injection pressure is 90- 100bar; injection is carried out three times, and the speed of each section is reduced in turn; injection time is 15±2S; cooling time is 40±5S, so as to reduce the warping deformation of the product as much as possible, meet the welding proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com