Patents

Literature

62results about How to "Improve anti-scour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hollow fiber type composite nano-filtration membrane and preparation method thereof

ActiveCN103223300AHigh strengthImprove anti-scourSemi-permeable membranesHollow fibreFiltration membrane

The invention relates to a hollow fiber type composite nano-filtration membrane and a preparation method thereof. The hollow fiber type composite nano-filtration membrane comprises a hollow fiber microporous base membrane adopted as a supporting layer, a polysulfone transition layer, and a polyamide composite layer, wherein the polysulfone transition layer is positioned inside membrane holes of the hollow fiber microporous base membrane, and the polyamide composite layer is positioned inside membrane holes of the polysulfone transition layer. The preparation method comprises: adopting a thermally induced phase separation method to obtain an asymmetric microporous base membrane, adopting an impregnation phase transformation method to obtain the polysulfone transition layer in the micro holes, and adopting pressure control and an interface condensation polymerization reaction to obtain the polyamide composite layer. The hollow fiber type composite nano-filtration membrane provides a sodium chloride salt solution entrapment rate of more than 90%, a divalent salt ion entrapment rate of more than 95%, and a pollutant entrapment rate of more than 99% under 0.2-0.8 MPa, such that the hollow fiber type composite nano-filtration membrane has characteristics of high strength, washing resistance, large flux and the like, wherein the pollutants have a molecular weight of 300-200,000 Daltons.

Owner:TSINGHUA UNIV

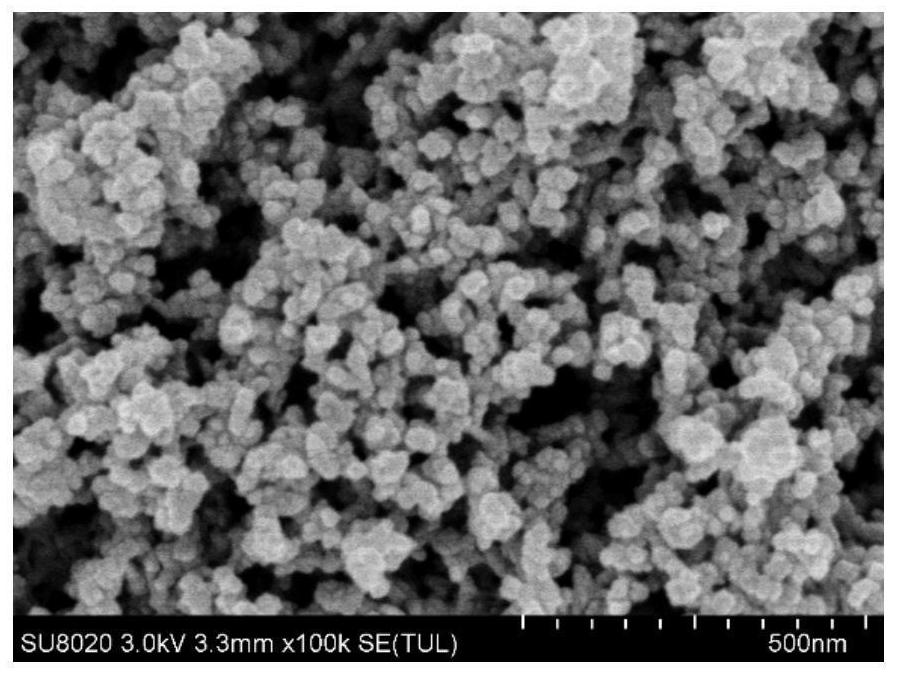

Preparation method of high-strength and antioxidant rare-earth-based smoke denitration catalyst

ActiveCN104209117AReduce escape rateReduce productionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumGlass factory

The invention discloses a preparation method of a high-strength and antioxidant rare-earth-based smoke denitration catalyst. The preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst comprises the following steps: by taking titanium dioxide and montmorillonite as carriers and ammonium metatungstate, cerous nitrate and lanthanum nitrate as active components, mixing, ageing, kneading, forming, drying and roasting with the accompanying of auxiliary materials. The auxiliary materials comprise ammonia water, lactic acid, citric acid, stearic acid, glass fiber, wood pulp, hydroxypropyl methyl cellulose, polyoxyethylene, monoethanolamine and water. The product prepared by the method is separated under a high SO2 smoke condition, nitric oxide in the smoke can be decomposed; meanwhile, the purpose of removing mercury and dioxin can be achieved. According to the preparation method of the high-strength and antioxidant rare-earth-based smoke denitration catalyst, the rare earth elements, namely cerium and lanthanum are used as the active components, so that the addition amount of vanadium is reduced, the toxicity of the product is reduced or the product is non-toxic product, the pressure of the post treatment of the product is reduced; the environmental protection pressure is reduced; the product is environmentally friendly; the product can be widely used in the field of thermal power plants, glass factories and chemical plants.

Owner:山东信义汽车配件制造有限公司

Environment-friendly stemming for blast furnace and preparation method thereof

The invention provides environment-friendly stemming for a blast furnace. The stemming is prepared from aggregate, silicon carbide, titanium dioxide, white mud, coke dust, micropowder and a binding agent. The method for preparing the stemming comprises the following steps: proportioning aggregate, silicon carbide, titanium dioxide, white mud, coke dust and micropowder according to the mass percentage; performing dry mixing and grinding, adding the binding agent, and performing wet mixing and grinding to obtain the environment-friendly stemming for a blast furnace. The stemming has the advantages of small shrinkage rate, excellent thermal shock resistance, excellent washing resistance and excellent erosion resistance, and once tapping time reaches 100-180 minutes; in-situ generated TiC has an effect of protecting the furnace, and the service life of the furnace can be prolonged; T60 carbon-containing resin and phenolic resin are used as the binding agent to reduce generation of cancerogenic smoke and improve the operation environment.

Owner:BEIJING JINGYEYUAN NEW MATERIALS

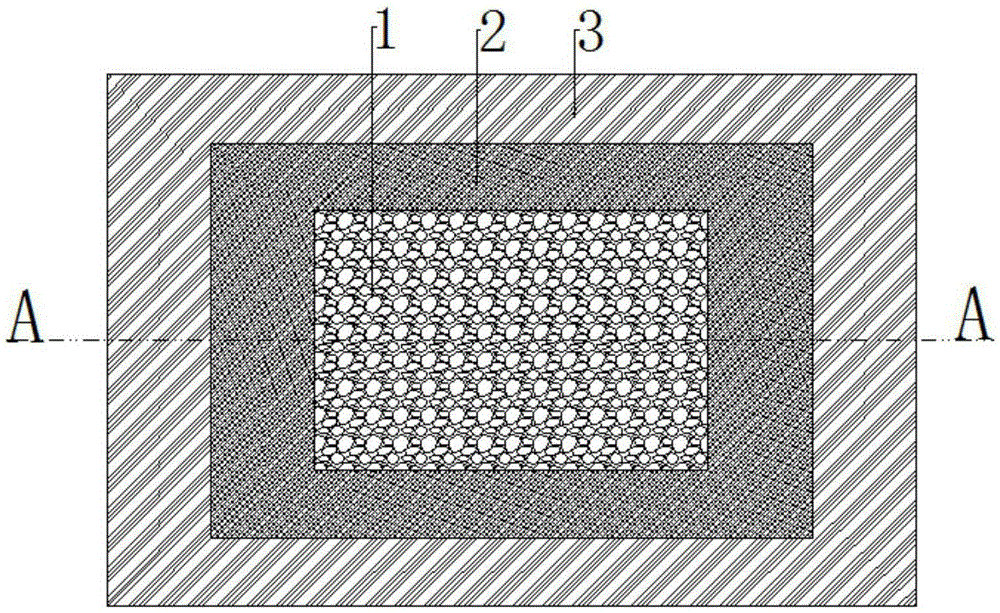

Temperature gradient controlled mass concrete for bridges

ActiveCN105418006AImprove densification performanceLimit crackingBridge engineeringMaterials science

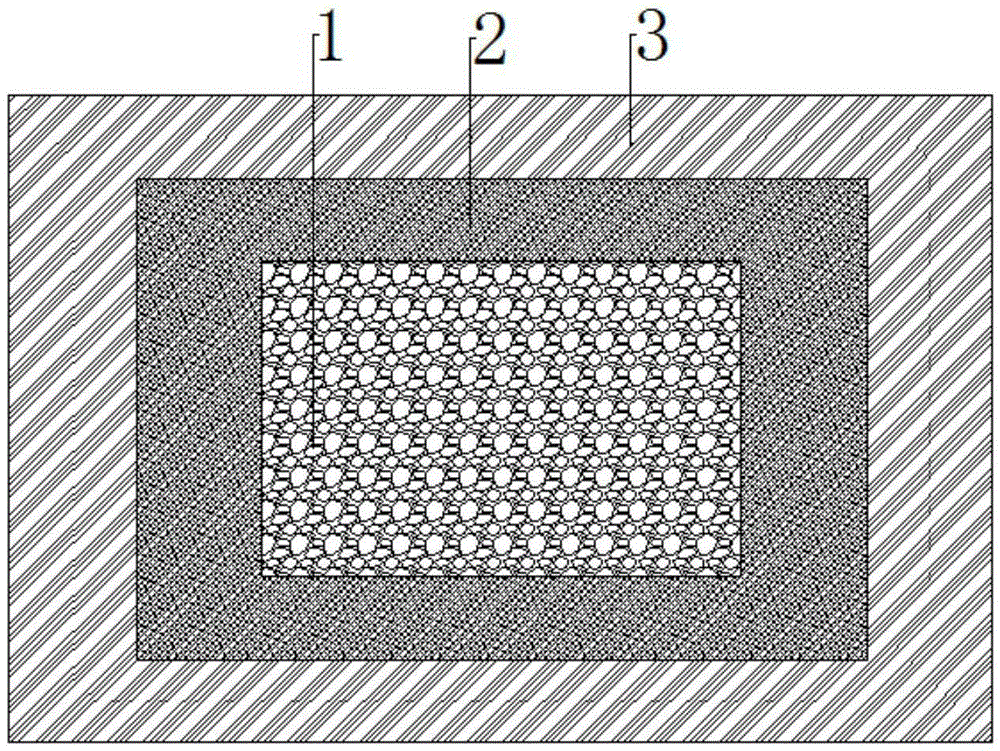

The invention discloses a temperature gradient controlled mass concrete for bridges. The mass concrete comprises an inner layer of low-temperature rise anti-crack concrete I, a middle layer of low-temperature rise anti-crack concrete II and an outer layer of high-tenacity high-crack resistance concrete from the inside to the outside. According to the mass concrete disclosed by the invention, under combination of the low-temperature rise anti-crack concrete (the inner layer of low-temperature rise anti-crack concrete I and the middle layer of low-temperature rise anti-crack concrete II) and the high-tenacity high-crack resistance concrete structure, hydration heat of cementing materials on various layers is respectively absorbed through the characteristics of a high phase-transition temperature of a composite temperature control material in the inner layer of low-temperature rise anti-crack concrete and a low phase-transition temperature of a composite temperature control material in the middle layer of low-temperature rise anti-crack concrete; the inside and the middle temperatures of the concrete are lowered; meanwhile, different thicknesses and layout forms of two concrete materials are optimized and designed; reduction of the temperature difference between the layers is achieved; the overall temperature stress level is reduced; the technical problem of crack of the mass concrete widely existing in bridge engineering can be effectively solved; and the temperature gradient controlled mass concrete for the bridges is applicable to popularization and application.

Owner:HUBEI UNIV +1

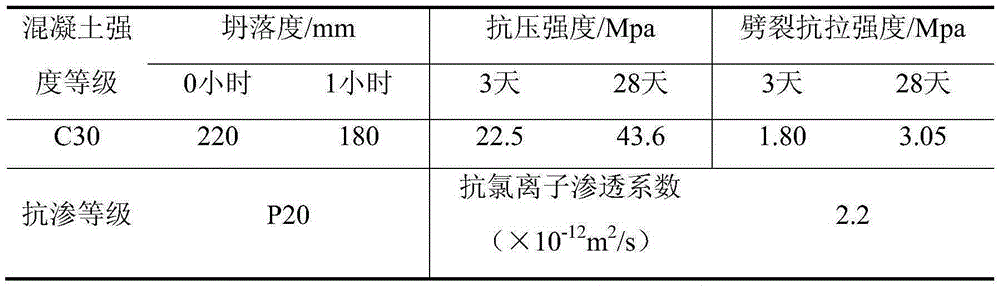

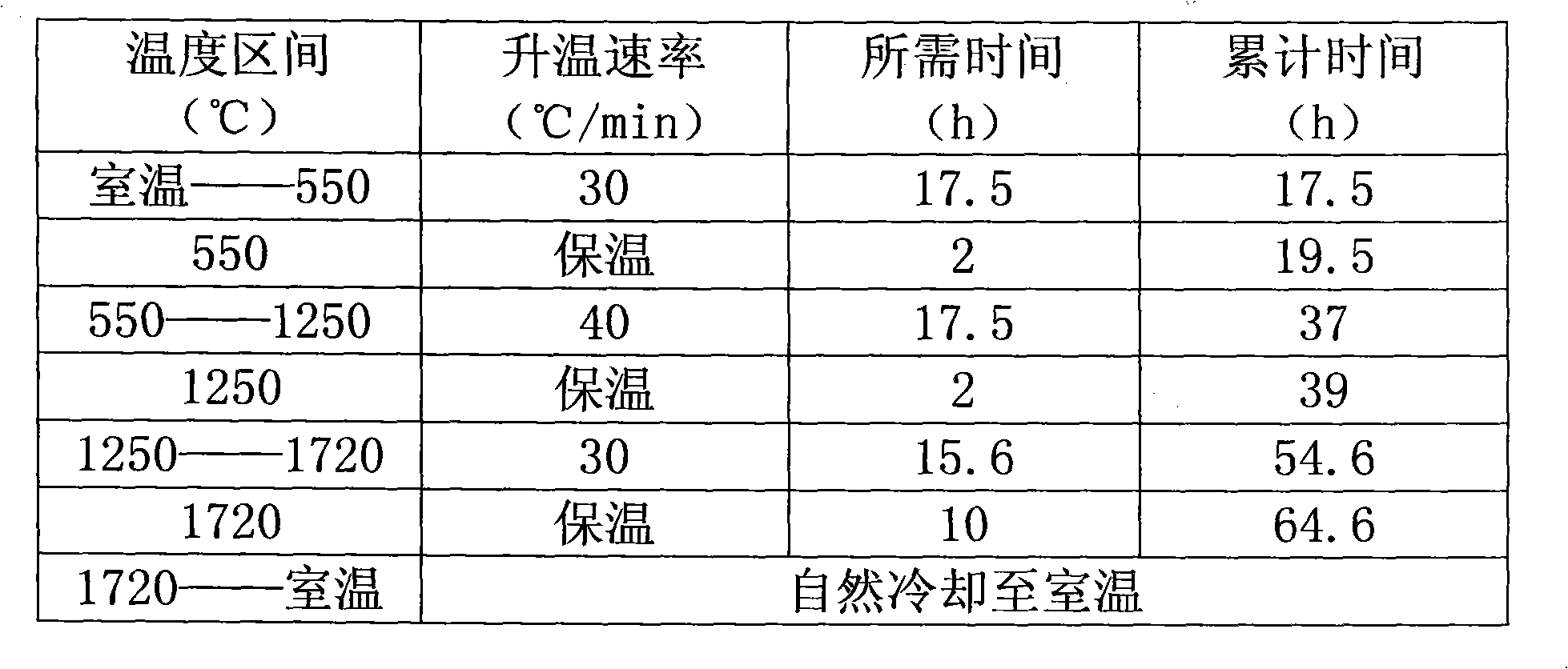

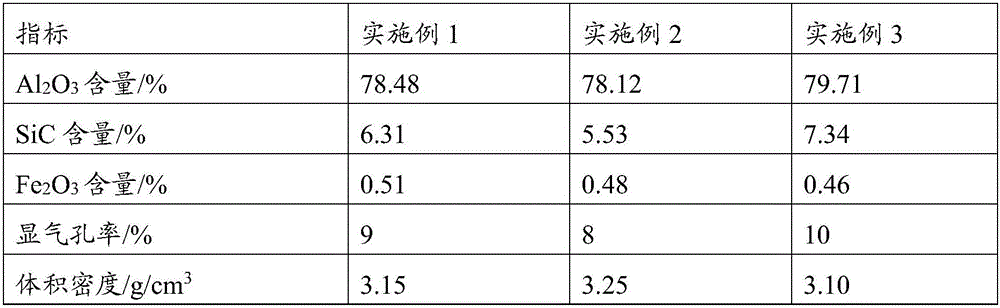

95 chromium-aluminum-zirconium brick for coal water slurry pressurized gasifier and preparation method thereof

The invention belongs to the technical field of refractory materials, and discloses a 95 chromium-aluminum-zirconium brick for a coal water slurry pressurized gasifier and a preparation method thereof. The 95 chromium-aluminum-zirconium brick comprises electrically fused chromium oxide, chromium oxide green, fine zirconium oxide powder, fine alpha-Al2O3 powder and an adhesive serving as raw materials in percentage by weight; the preparation method comprises the following steps of: (1) weighing the raw materials in percentage by weight; (2) mixing and rolling the raw materials in a wet mill toform slurry; (3) pressing the slurry in a friction press to prepare a half-finished product; (4) drying the half-finished product in a drying kiln; (5) firing the dried half-finished product in an automatic shuttle kiln; and (6) taking the finished product out of the kiln, and checking the appearance and the physicochemical property of the product. Compared with the conventional 90 chromium-aluminum-zirconium brick, the 95 chromium-aluminum-zirconium brick has the advantages that the scour resistance, corrosion resistance, volume density, and ambient compressive strength are improved and the service life of the 95 chromium-aluminum-zirconium brick is improved by 20 to 50 percent.

Owner:李正平

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

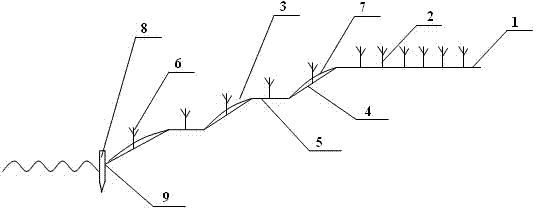

Soil, plant and biological stabilizing method of agricultural watershed riparian zone side slope

ActiveCN104762923ANatural performance disturbance is smallReduce sputteringCoastlines protectionSustainable biological treatmentAmorpha fruticosaEngineering

The invention relates to stabilizing methods of the ecological agriculture, particularly to a soil, plant and biological stabilizing method of an agricultural watershed riparian zone side slope. The soil, plant and biological stabilizing method comprises starting from a position close to a river way to plant three rows of annual Salix integra and planting three rows of annual Amorpha fruticosa along the direction parallel to a river bank after artificial leveling and performing cross planting on the Salix integra and the Amorpha fruticosa according to the order in turn; performing artificial trimming on a side slope protection zone and setting the integral side slope protection section into a step-shaped structure in which three small side slopes are connected with two small platforms; protecting the small side slopes of the side slope protection section through polypropylene non-woven fabrics, laying the non-woven fabrics on the small side slopes, fixing the top end and the bottom of every small side slope through rivets respectively and performing vegetation cutting in the middle of every small side slope; performing Salix integra cutting on every small side slope of the side slope protection section and performing cutting in the middle of each small platform of the side slope protection section through a row of Amorpha fruticosa. According to the soil, plant and biological stabilizing method of the agricultural watershed riparian zone side slope, the artificial disturbance is less, the cost is low, the recovery is rapid, the effect is good, the soil, the close-to-natural-landscape effect is achieved, and the artificial maintenance is not required by the later period of ecological slope protection and pollution control.

Owner:CHENGBANG ECO ENVIRONMENT CO LTD

Dispersion material for bottom blowing composite air brick of steel ladle and preparation method of dispersion material

The invention discloses a dispersion material for a bottom blowing composite air brick of a steel ladle and a preparation method of the dispersion material. The dispersion material is mainly prepared from the following raw materials in percentage by weight: 80 to 85 percent of corundum spheres, 5 to 10 percent of alumina micro powder, 1 to 5 percent of chromium oxide green powder, 1 to 5 percent of magnesia-alumina spinel with 200 meshes, and a binding agent accounting for 2.5 to 3.5 percent of total weight of the raw materials. The preparation method comprises the following steps: firstly, adding the weighed raw materials into a forced sand mixer for premixing to obtain a mixed material; secondly, putting the mixed material into an assembled mold and then carrying out compression moulding to obtain a green brick; thirdly, putting the green brick into a dryer for drying, and putting the dried product into a high-temperature kiln for firing; after the firing is ended, carrying out natural cooling to obtain a product, namely the dispersion material. The dispersion material prepared by the technical scheme adopted by the invention has the characteristics endowed by a traditional dispersion breathable material, as well as the characteristics of relatively-high strength, erosion resistance, permeation resistance, high thermal shock property and the like.

Owner:TONGDA REFRACTORY TECH CO LTD +1

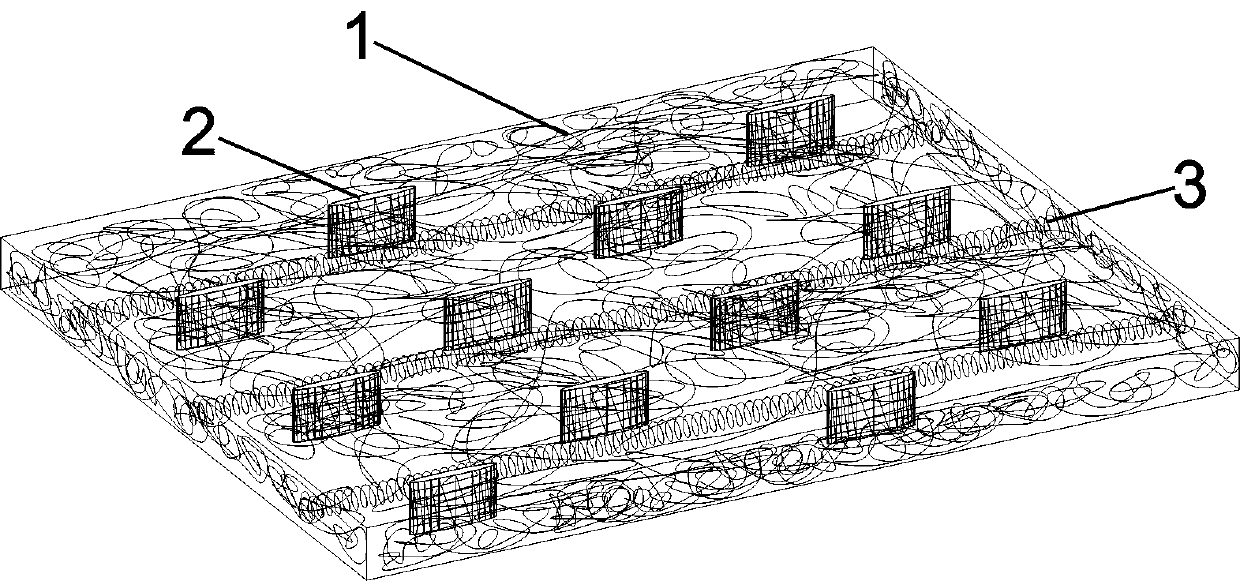

Plastic geocell

The invention discloses a plastic geocell, which comprises bar plastic cell sheets and connecting clamps, wherein the cell sheets are arranged side by side; the connecting clamps are clamped on connecting parts of the cell sheets and are fixed with rivets; the cell sheets connected together form a grid-shaped three-dimensional cell; each cell unit of the grid-shaped three-dimensional cell is internally provided with a connecting rope; both ends of the connecting rope are connected with the connecting clamps respectively; and the bar cell sheets are provided with drain holes. The plastic geocell has the advantages of simple structure, easy manufacturing and low cost. The plastic geocell can be convenient for water to flow and drain the water in time, can also prevent soil and sand filled in the geocell from shifting, can improve the scouring resistance and the erosion resistance, can improve the stability, prolongs the service life, reduces maintenances and is convenient to popularize and use.

Owner:宜兴市明辉塑料制品有限公司

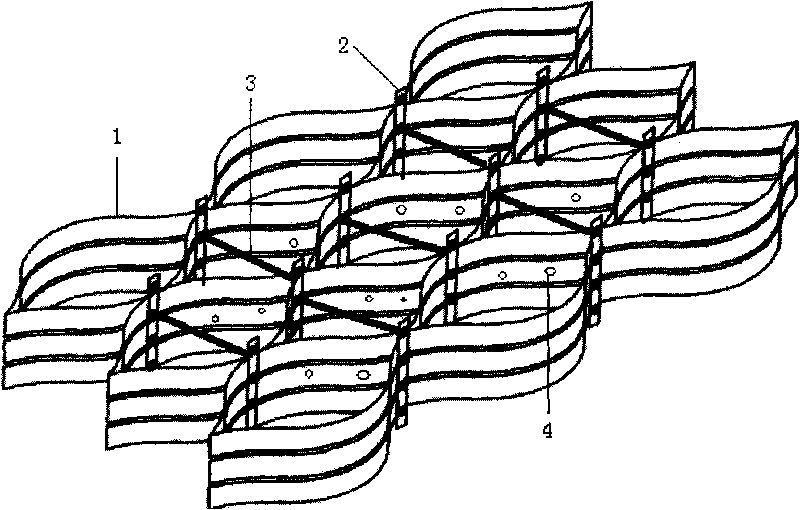

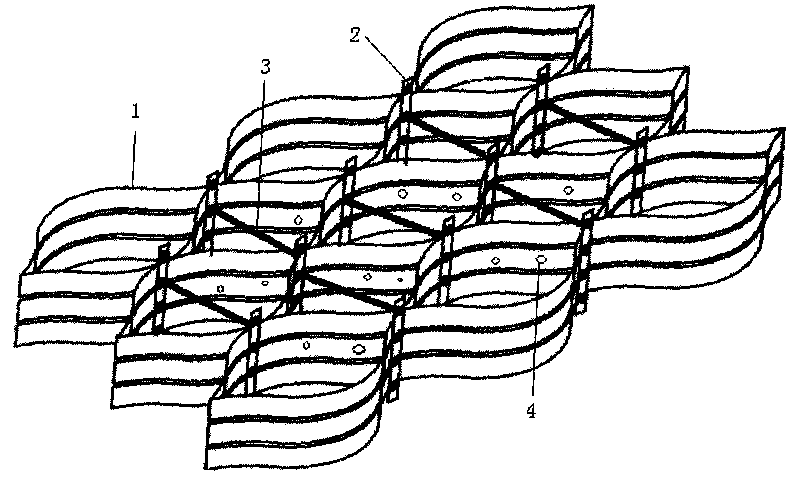

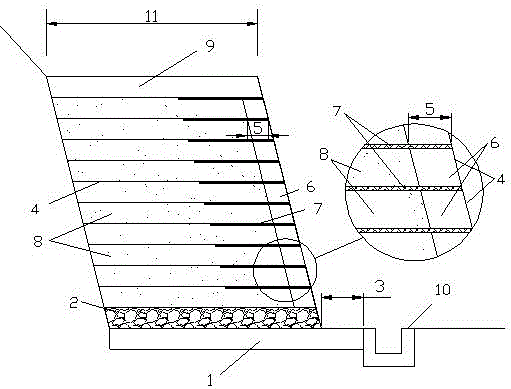

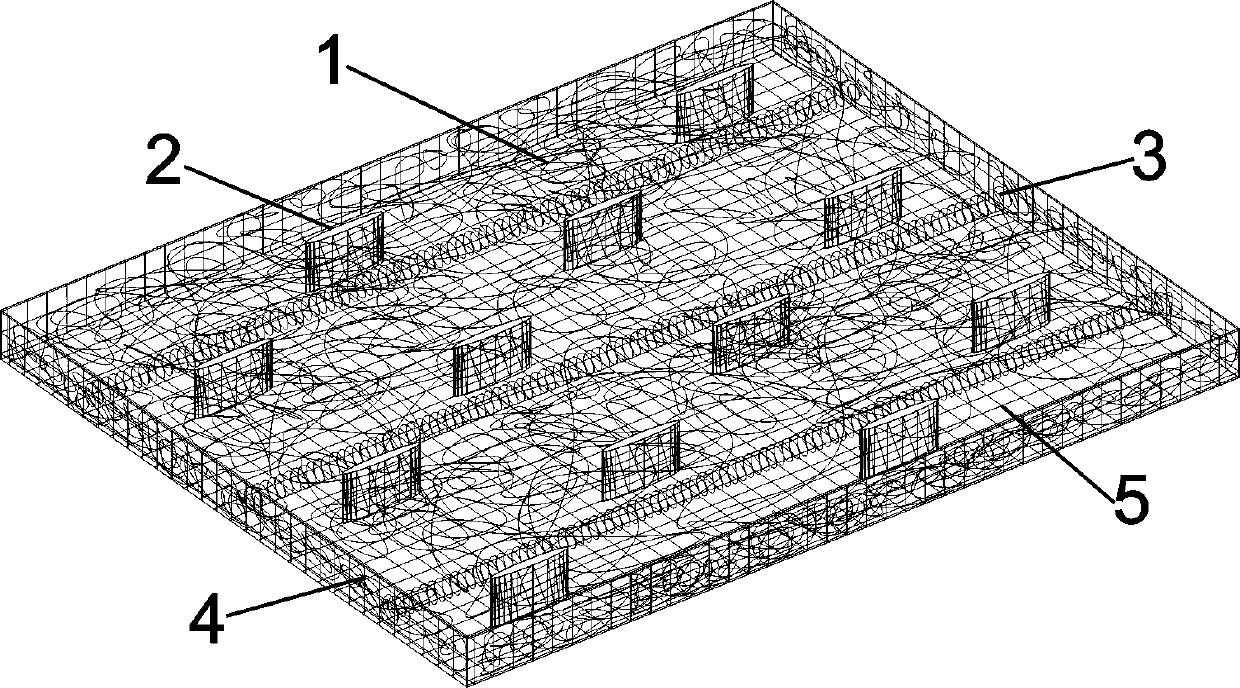

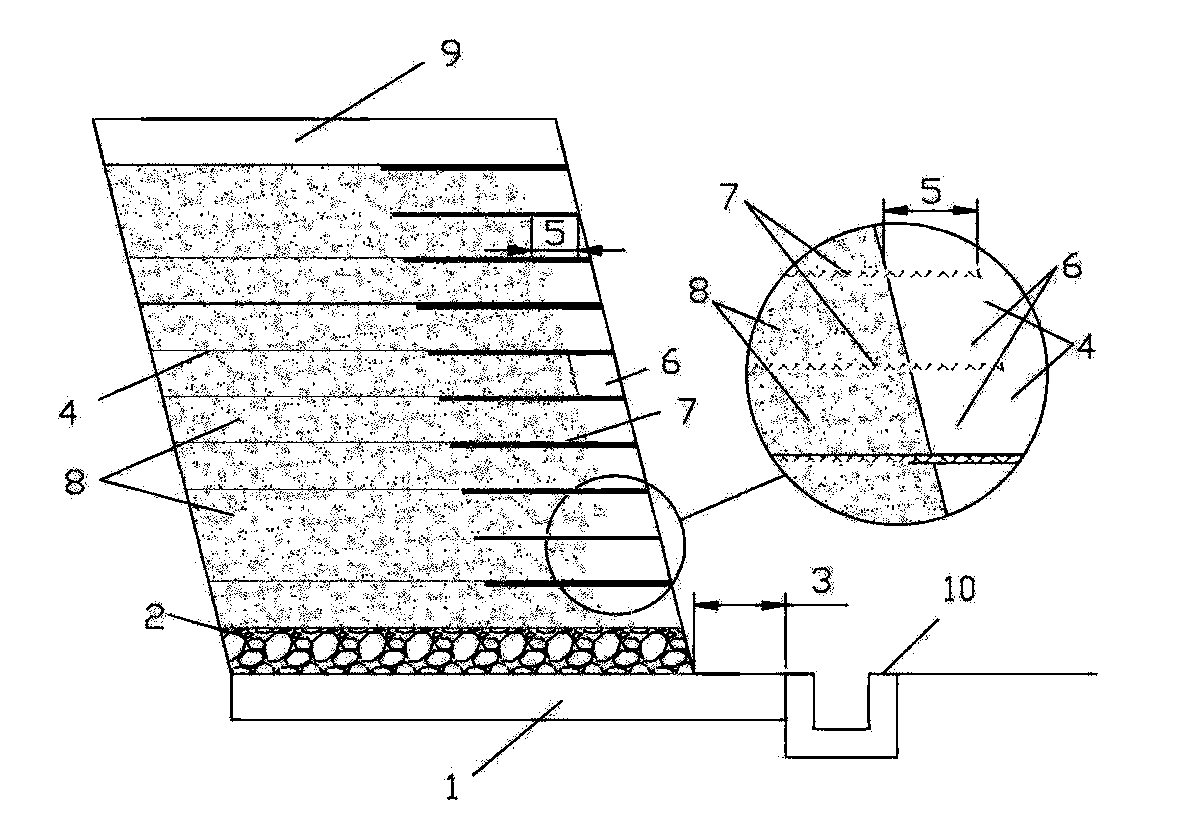

Cement modified soil strengthened geogrid reinforced soil structure and construction method thereof

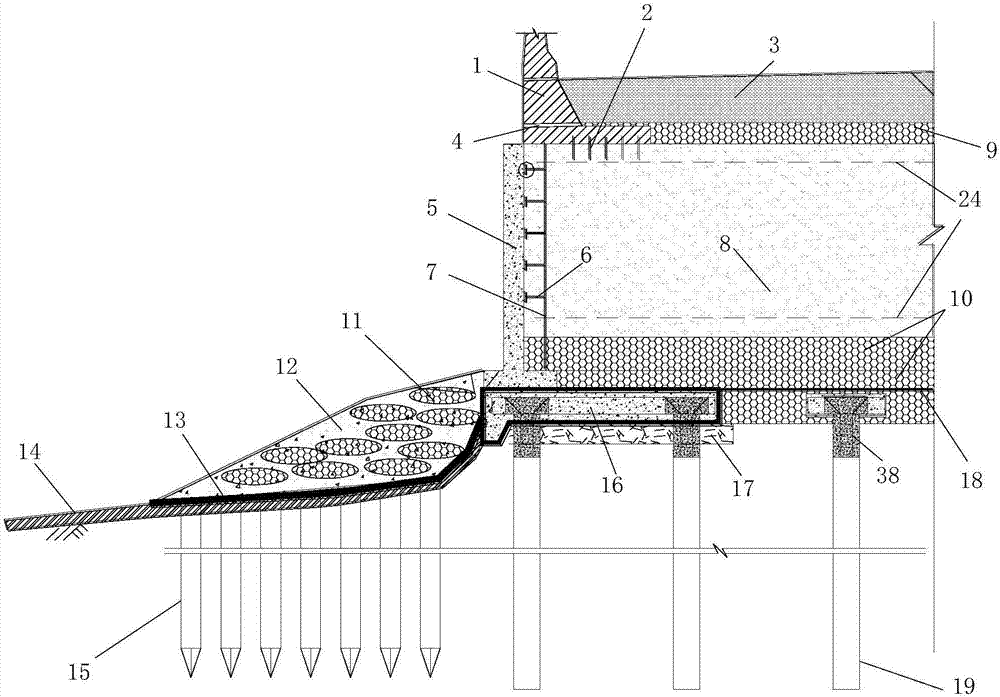

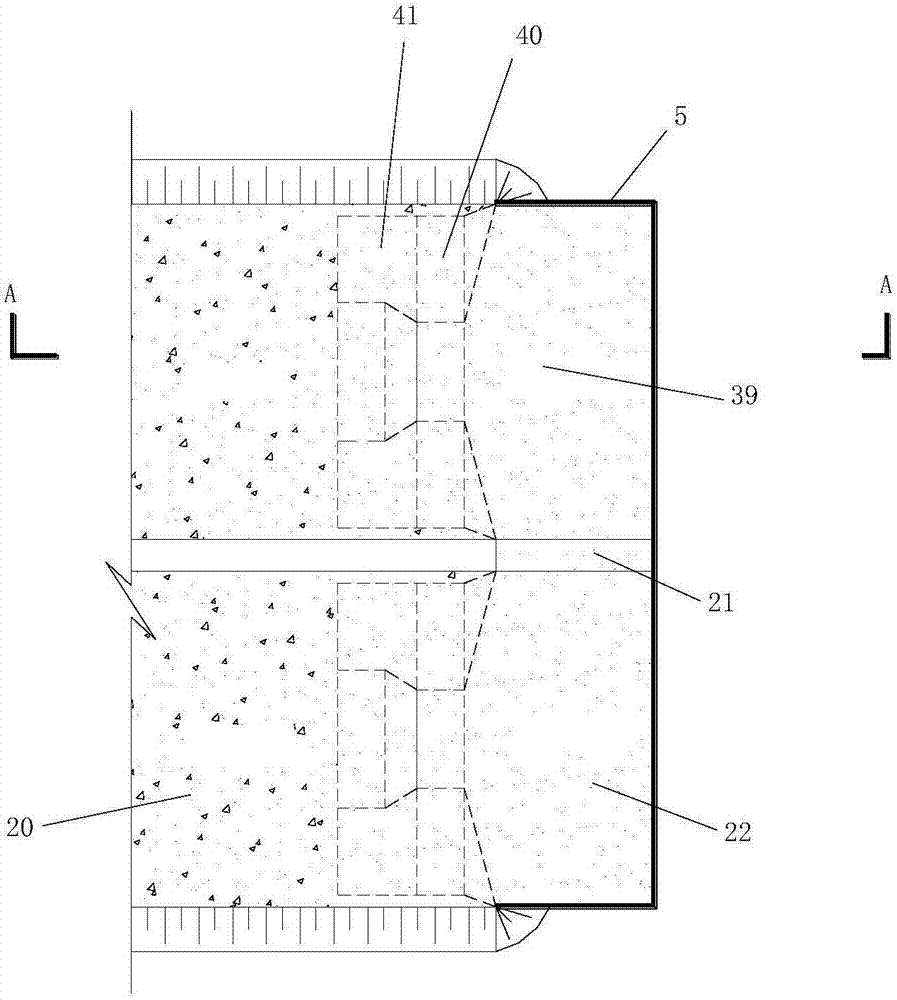

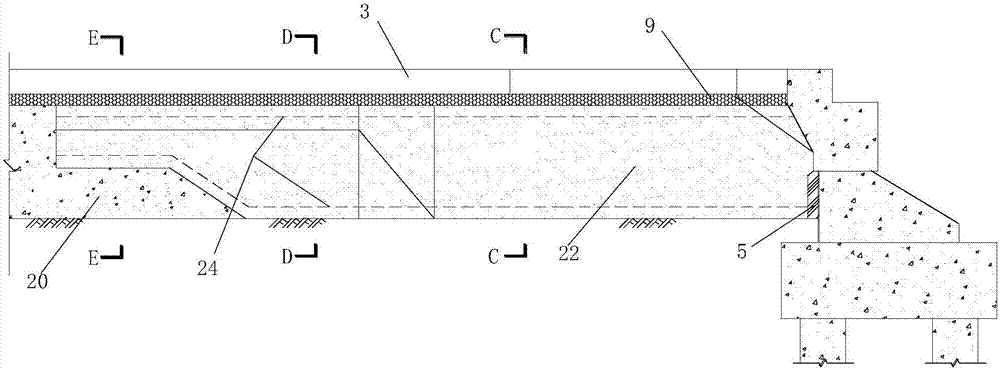

The invention discloses a cement modified soil strengthened geogrid reinforced soil structure and a construction method thereof. The cement modified soil strengthened geogrid reinforced soil structure (shown in a figure 1) is composed of four parts including a base layer (1) and a cover layer (9) composed of cement modified soil, a water drainage layer (2) and a cement modified soil strengthened geogrid reinforced soil layer thereof, and is a novel geogrid reinforced soil structure which is formed by improving similar structures through utilizing good properties including solidification, high wetting resistance, high anti-scouring and flood damage resisting properties, high shearing strength and the like of cement modified soil. Compared with an existing similar structure, the novel geogrid reinforced soil structure and the construction method thereof, provided by the invention, can realize panel-free construction of an abrupt-slope reinforced soil structure, and can also remarkably improve the wetting resistance, anti-scouring property and whole shearing strength of the geogrid reinforced soil structure; the cement modified soil strengthened geogrid reinforced soil structure is especially suitable for protecting and reinforcing edge slopes, which are easy to scour and damage by flood, of abrupt-slope sections.

Owner:湖南高速华达工程有限公司

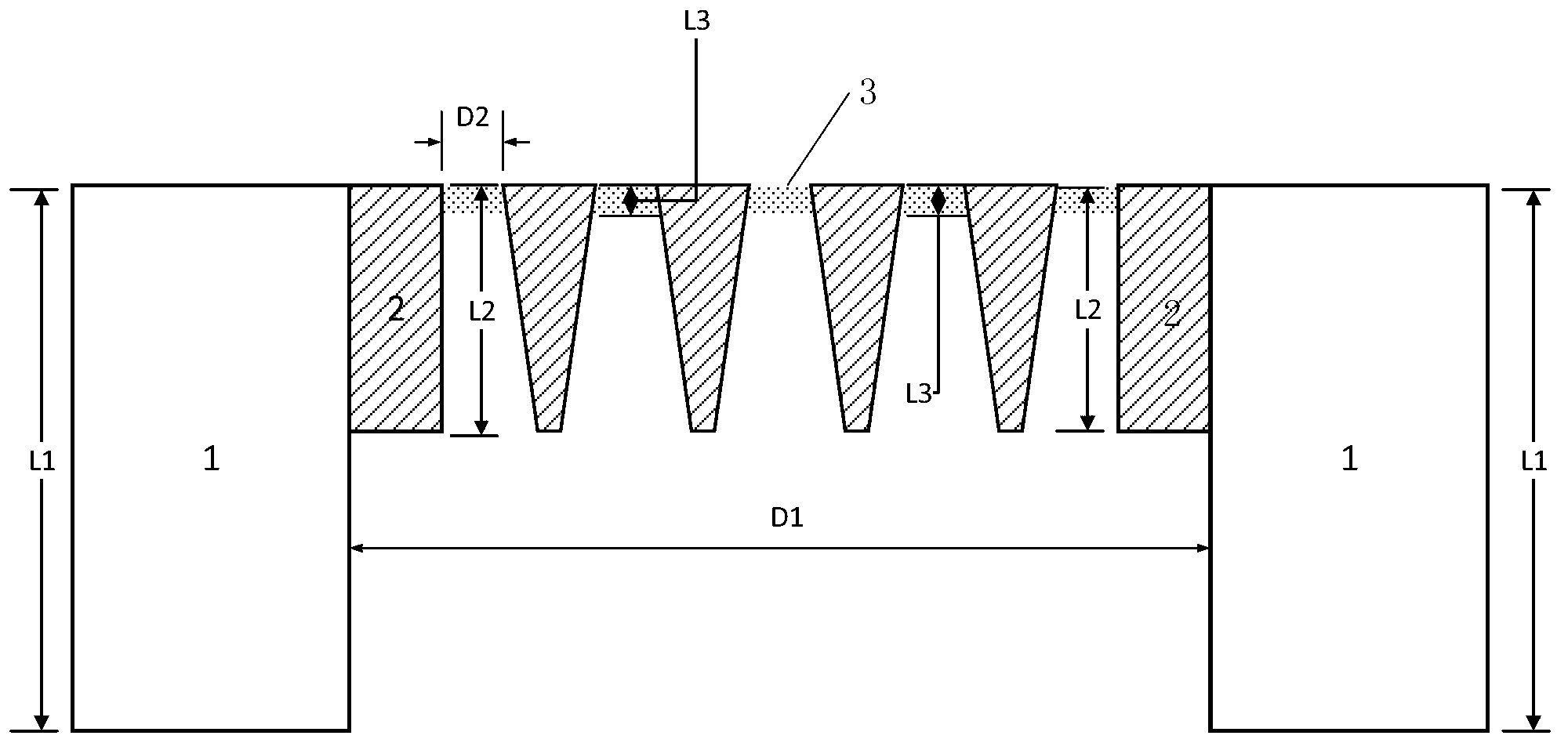

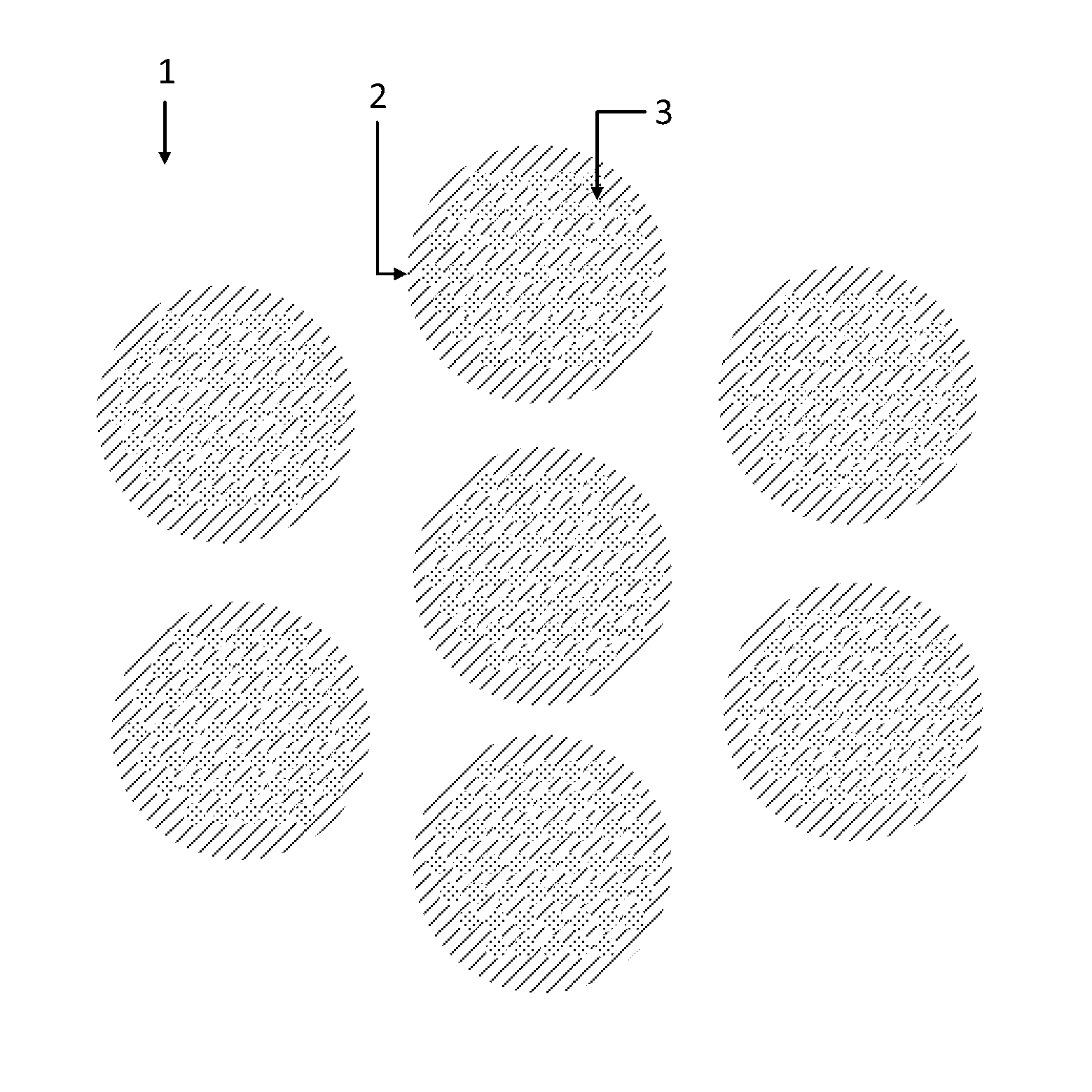

River erosion segment pile-supported-type foam concrete lightweight embankment structure, and construction method thereof

ActiveCN107190602APrevent jumpingImprove construction progressRoadwaysCoastlines protectionFoam concreteReinforced concrete

The invention relates to a river erosion segment pile-supported-type foam concrete lightweight embankment structure. According to the river erosion segment pile-supported-type foam concrete lightweight embankment structure, plain concrete piles are arranged on soft roadbed, the upper parts of plain concrete piles are provided with pile caps; the pile caps are connected with a bearing platform; a reinforced concrete protection panel is anchored in the bearing platform; a reinforced concrete protection panel vertical-type roadbed is adopted; the reinforced concrete protection panel is connected with a support pillar; the bottom of a fence pedestal is provided with anti-slip steel; a foam concrete stair groove is connected with a foam concrete roadbed successively; the lower part of the foam concrete roadbed is provided with a high stone content slag padding layer; the foam concrete stair groove is divided into a processing segment foam concrete groove, a transition segment foam concrete groove, and a connection segment foam concrete groove. The beneficial effects are that: problems such as bump at bridge-head can be solved because of the self-supporting performance, low elastic shock absorption performance, adjustable strength, and durability of foam concrete after curing, excellent technical economic benefit is achieved; integral lifting type sliding steel moulding plate construction is adopted in construction of the reinforced concrete protection panel, so that construction speed is accelerated.

Owner:ZHEJIANG UNIV CITY COLLEGE +1

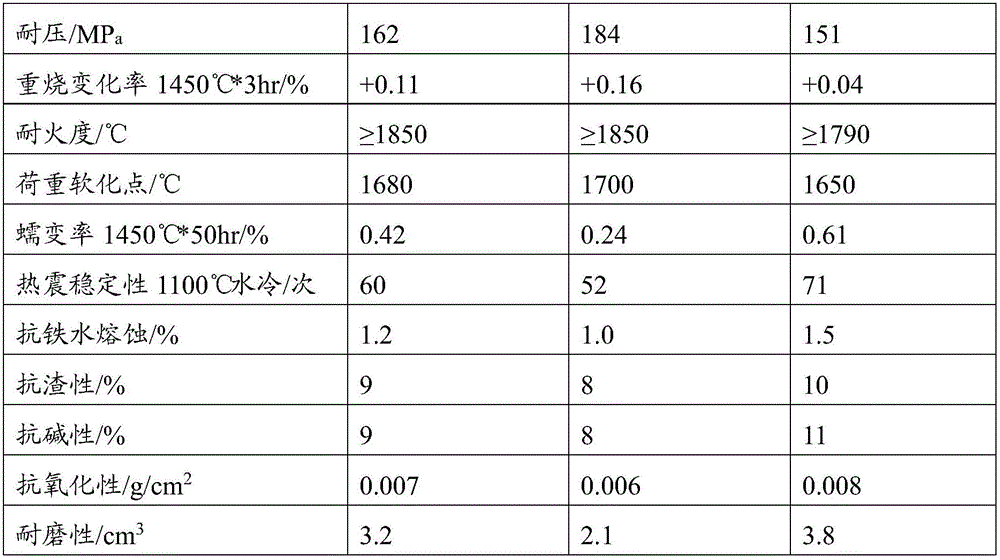

Refractory material and tuyere composite brick

The invention provides a refractory material and a tuyere composite brick. The refractory material is prepared from the following raw materials in parts by weight: 66 to 76 parts of a particle material with a particle size of 0.088 to 8 mm, and 24 to 34 parts of fine powder with a particle size larger than 0 and less than 0.088 mm, wherein the particle material comprises brown fused alumina, andalusite, sillimanite and quartz sand with a mass ratio of (50-70): (3-7): (2-6): (1-3); and the fine powder comprises corundum powder, silicon carbide powder, calcined alpha alumina micropowder, silicon dioxide micropowder and mullite raw meal with a mass ratio of (7-11): (5-9): (3-7): (2-6): (2-6). The refractory material uses corundum and silicon carbide as main raw materials, and adopts the andalusite, the sillimanite, the quartz sand, the calcined alpha alumina micropowder, the silicon dioxide micropowder and the mullite raw meal to improve the crystal phase structure of the refractory material, so the apparent porosity of the refractory material is reduced; and scour resistance, slag resistance, alkali resistance, oxidation resistance, wear resistance and thermal shock resistance of the refractory material are improved.

Owner:HUNAN XIANGGANG RUITAI TECH

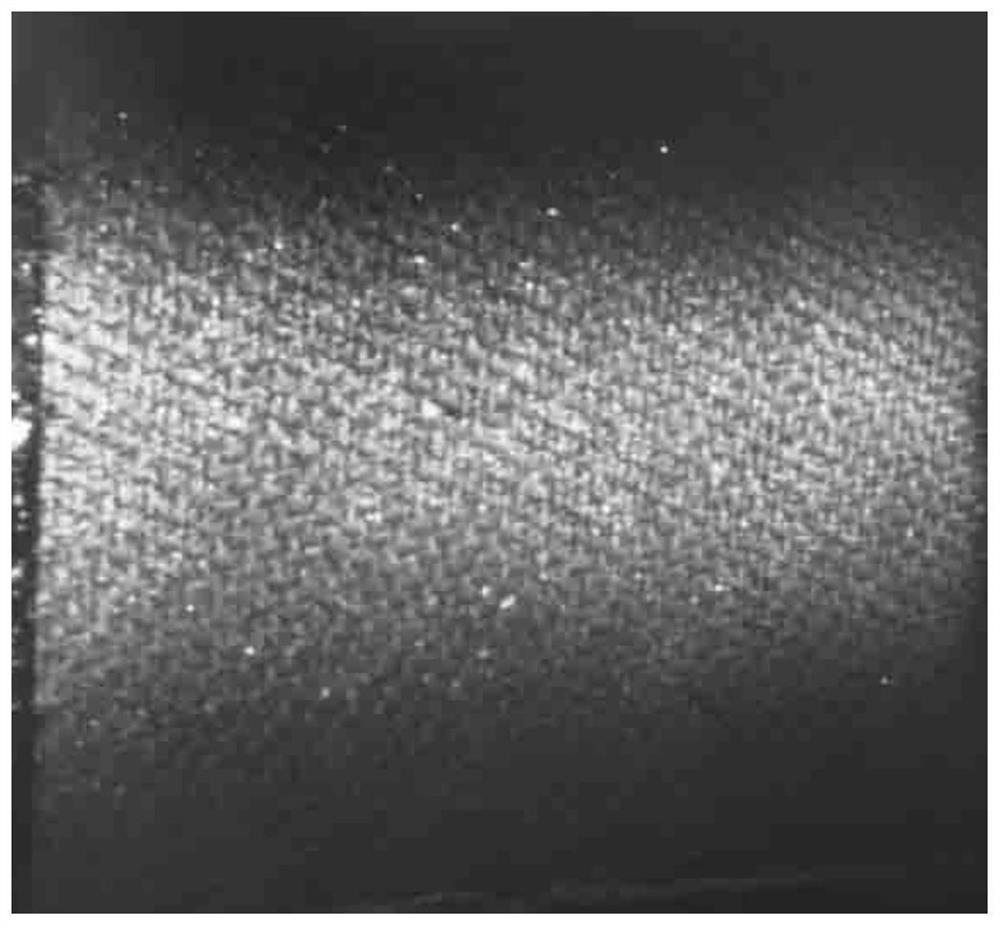

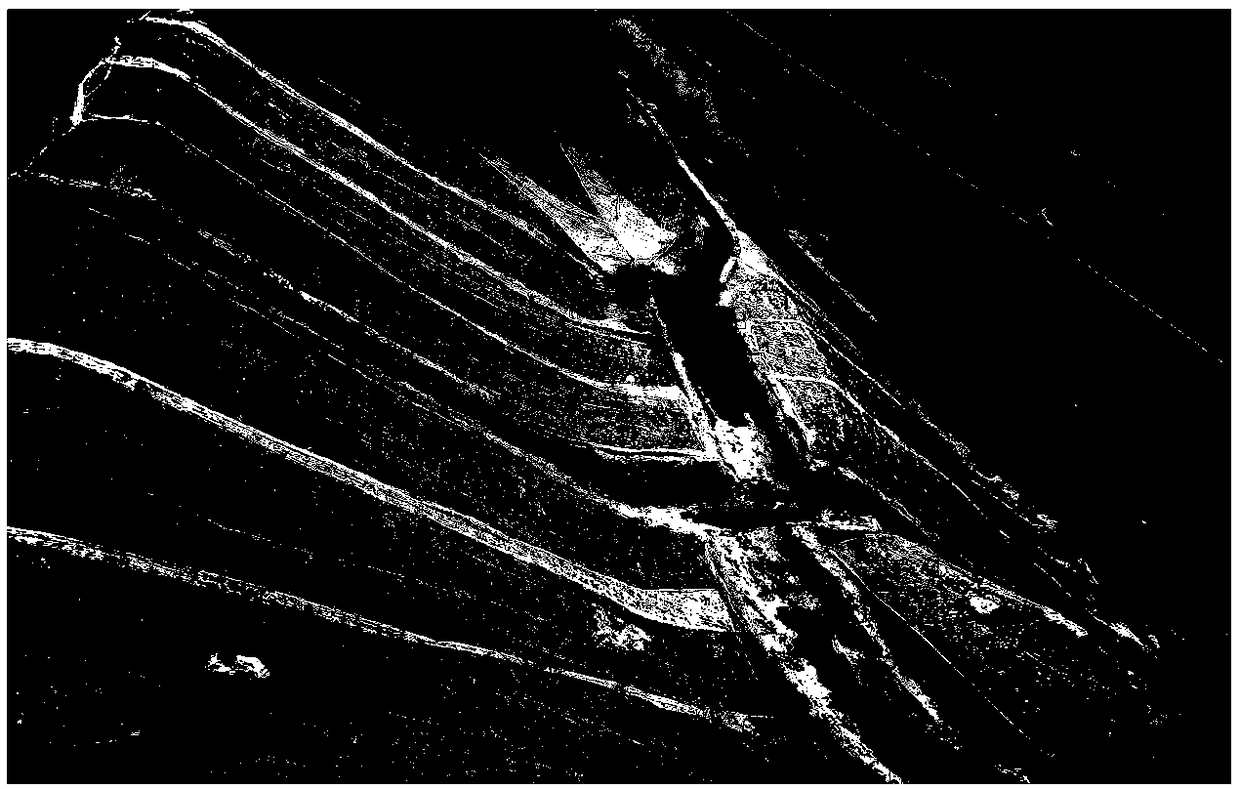

Coating layer-free light ablation-resistant thermal insulation composite material and preparation method thereof

ActiveCN112321894AHigh specific heat capacityImprove temperature resistanceWeight reductionGlass fiberThermal insulation

The invention relates to a coating layer-free light ablation-resistant thermal insulation composite material and a preparation method thereof. The method comprises the steps: preparing an organic-inorganic hybrid precursor glue solution by taking phenolic resin and tetraethoxysilane as main raw materials, and compounding the organic-inorganic hybrid precursor glue solution with a multi-density prefabricated body consisting of surface glass fiber / quartz fiber mixed woven cloth and a lower quartz mesh felt in a high-pressure-resistant forming mold, and through sol-gel reaction and drying at normal temperature and normal pressure, the coating layer-free light ablation-resistant thermal insulation composite material is obtained. The prepared light ablation-resistant thermal insulation composite material does not need additional coating layer protection, and has excellent ablation resistance and heat-insulating property through good temperature resistance of the organic-inorganic hybrid aerogel and a glass-phase compact protective film formed by the multi-density prefabricated body at a specific application temperature; and the composite material has huge potential in application in a thermal protection structure of a hypersonic aircraft running at a high speed for a long time in the atmosphere.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

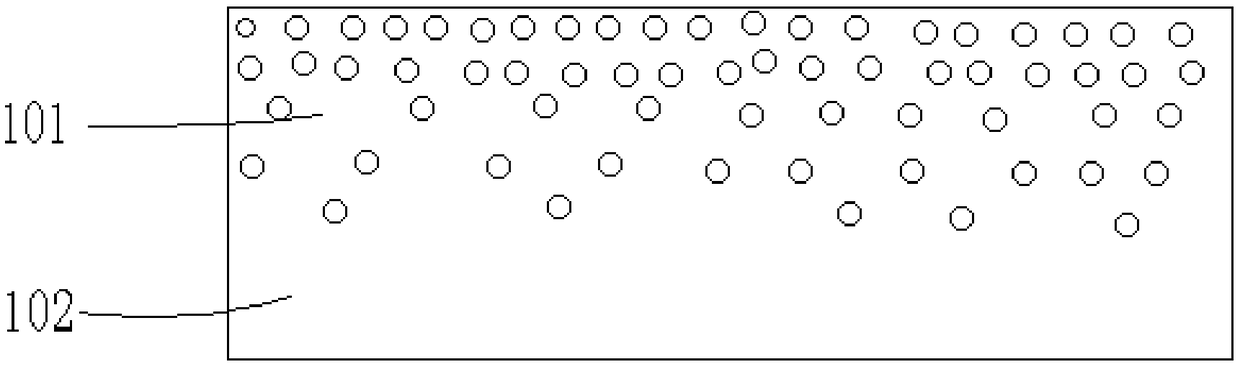

Economical and environment-friendly vine felt for cultivation of eel grass as submerged plants

InactiveCN109511422AImprove colonization rateImprove survival ratePlanting bedsPlant cultivationApparent densityWater cluster

The invention provides an economical and environment-friendly vine felt for cultivation of eel grass. Environmentally friendly plastic in a viscous flow state is processed into three-dimensional circular filament vine felt with the customizable thickness, wherein multiple irregular filaments are staggered disorderly and bound together at the contact points. The vine felt is an elastic planting bedwith very low apparent density and can overcome the limitation of climate and hydrological conditions in the existing cultivation technology of eel grass, and eel grass plants can planted into the cultivation holes indoors. Under the condition of high transparency water in deep winter or early spring, large-scale, large-area, economical and fast throwing and planting of eel grass is carried out without draining water. The method has great practical values in water and soil conservation, aquatic ecological restoration and construction, ecological aquaculture, ornamental waterscape pools and water cluster boxes in China.

Owner:程旭东

Oil field tubular product and electroplating method and material of oil field tubular product

The invention discloses an oil field tubular product and an electroplating method and material of the oil field tubular product. The electroplating material comprises bottom layer electroplating liquid, middle layer electroplating liquid and surface layer electroplating liquid; the bottom layer electroplating liquid contains an additive which is amines containing hydroxyl and / or amino; and the middle layer electroplating liquid contains a first preparing agent, a filling and leveling agent and a brightener, wherein the first preparing agent is polydisulfamate sodium sulfonate and / or phenyl polydisulfamide sodium sulfonate, the filling and leveling agent is N-diethylenediamine acid ethyl ester-omega-sulfato de sodio and / or morpholinyl aminodithioformic acid ethyl ester-omega-sulfato de sodio, and the brightener is thiazoline dithiopropane sulfonate sodium and / or 2-sulfydryl benzimidazole. The bottom layer electroplating liquid, the middle layer electroplating liquid and the surface layer electroplating liquid of the electroplating material adopt unique recipe, stress generated by nickel on the bottom layer and nickel on the surface layer can be reduced, the bonding performance of the middling layer, the bottom layer and the surface layer can be strengthened, phenomena of peeling, falling and the like are prevented, and leakage points are completely eliminated.

Owner:SHENGLI OILFIELD SHENGXIN ANTISEPSIS

Double-gradient heat-insulation anti-ablative coating and preparation method thereof

InactiveCN109338270AImprove thermal shock resistanceTaking into account the bonding strengthMolten spray coatingPorosityTotal thickness

The invention provides a double-gradient heat-insulation anti-ablative coating and a preparation method thereof, and relates to the technical field of high-temperature environment protection coatings.According to the double-gradient heat-insulation anti-ablative coating provided by the invention, the total thickness of the double-gradient heat-insulation anti-ablative coating is 200mum to 500mum;the double-gradient heat-insulation anti-ablative coating comprises multiple sublayers; the sublayers are provided with porosity structures and material compositions with gradient changes; the porosity of the first sublayer is less than or equal to 1 percent, and the coating material composition of the first sublayer is 100 percent of MCrAlYX; the porosity of the last sublayer is less than or equal to 30 percent, and the coating material composition of the last sublayer is 100 percent of M-ZrO2; the porosity and the coating material of the middle sublayer are in layer-by-layer transition; andthe coating material composition of the middle sublayer is a mixed layer of the MCrAlYX and the M-ZrO2. The invention relates to a coating preparation method. The coating is prepared by adopting a double-powder-feeding atmospheric plasma spraying technology, so that the resistance to heat shock, the oxidation resistance and the heat-insulating property of the heat-insulation anti-ablative coatingon the surface of a metal matrix are improved.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

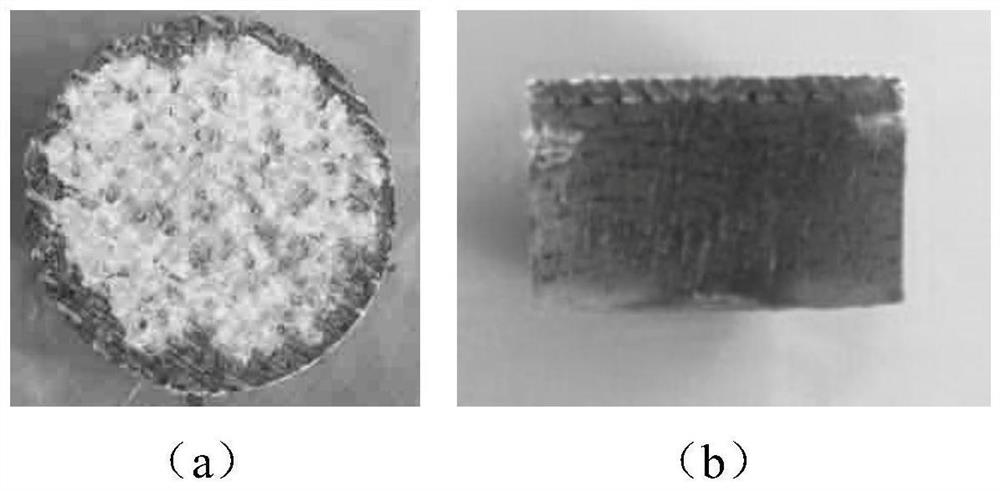

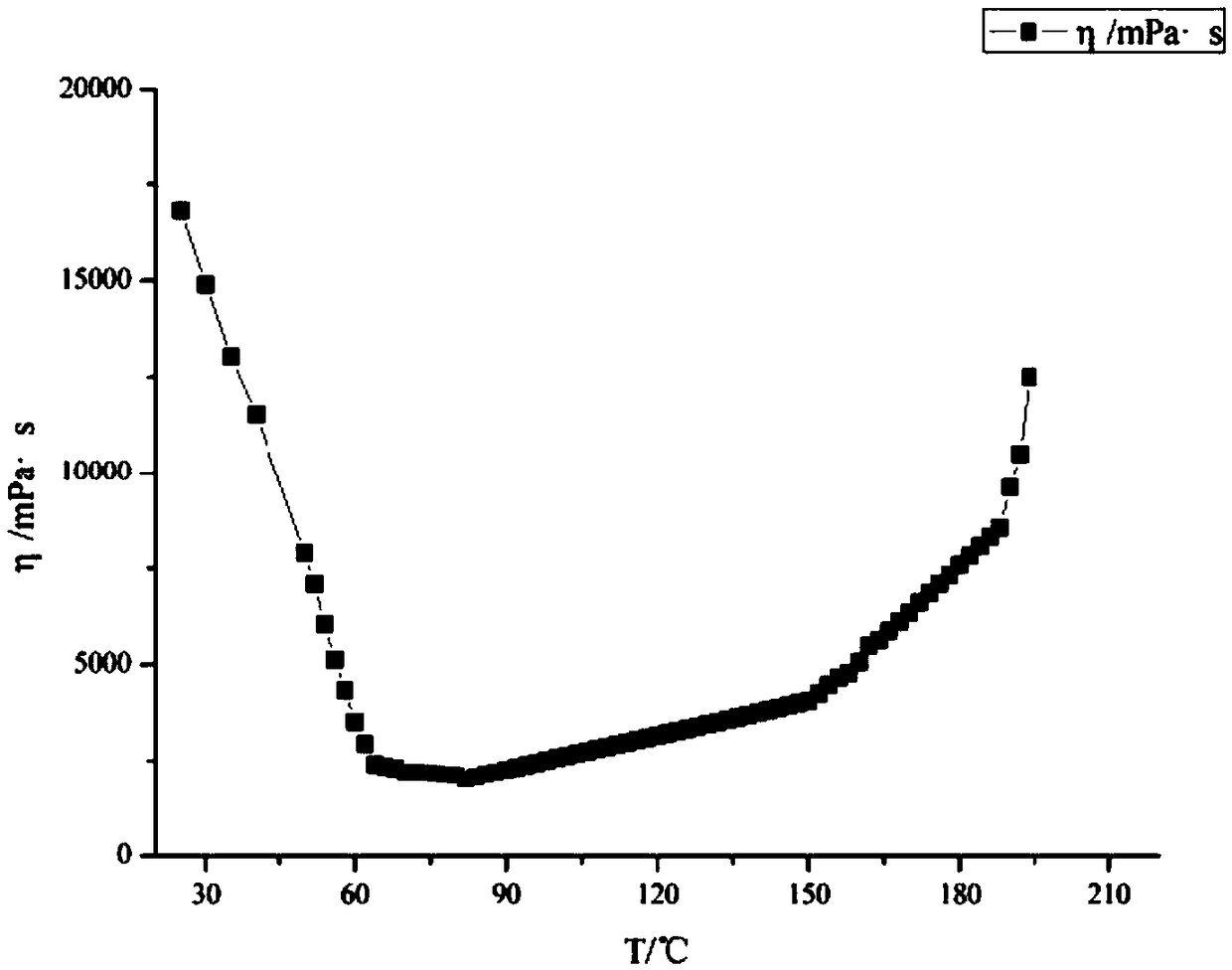

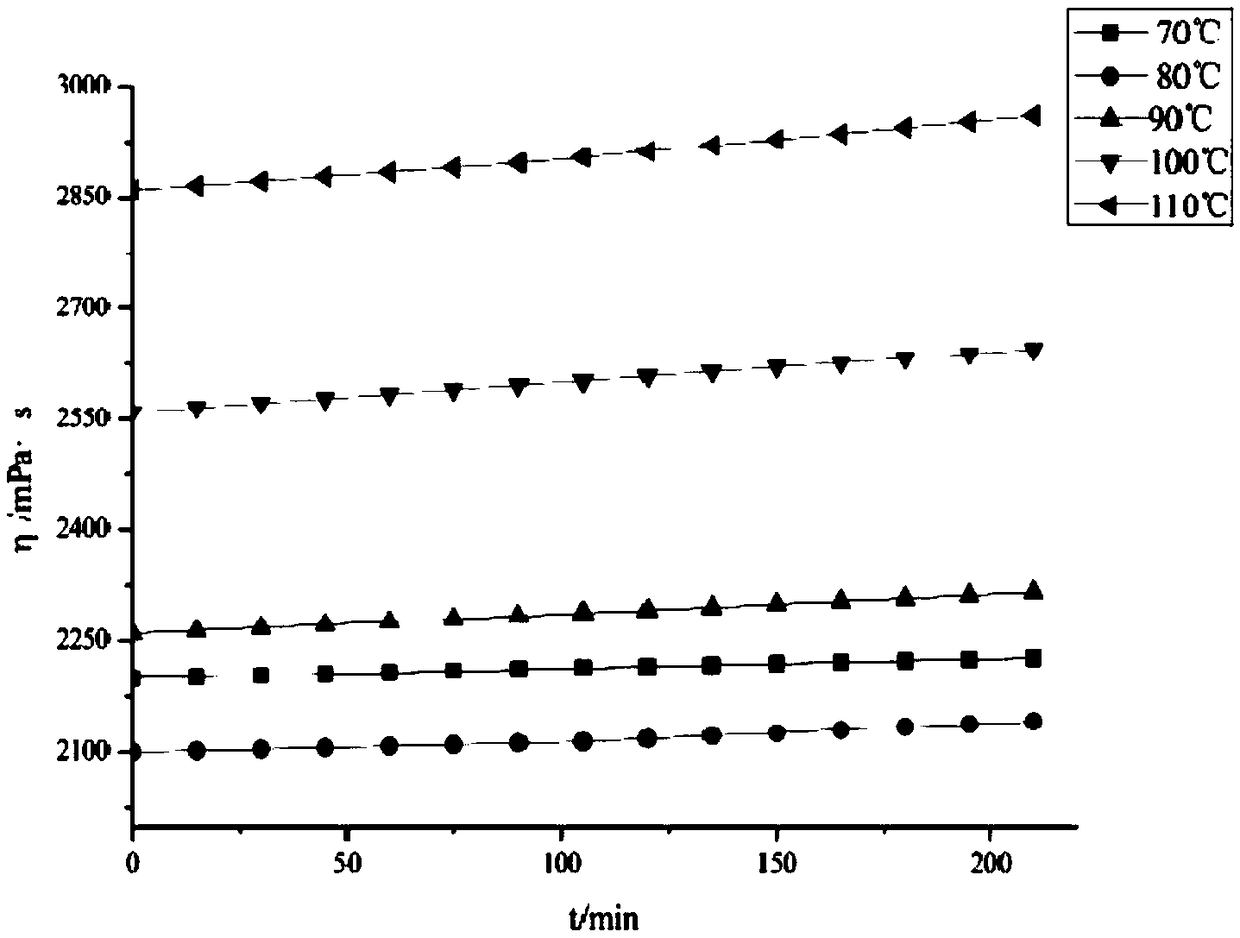

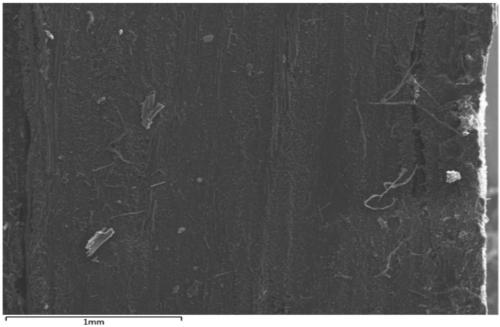

High-compactness high-temperature porcelain phenolic resin permeable membrane suitable for RFI (Radio Frequency Interference) molding process and preparation method thereof

The invention discloses a high-compactness high-temperature porcelain phenolic resin permeable membrane suitable for an RFI (Radio Frequency interference) molding process and a preparation method thereof. The preparation method comprises the following steps: heating 100 parts of RTM (resin transfer molding) phenolic resin system, 150-200 parts of magnesia-alumina spinel particles, 120-150 parts offorsterite particles, 80-100 parts of silicon carbide whiskers, mixing, stirring, and then calendering to form a membrane; and taking out, and cooling to a room temperature to prepare the membrane of0.6 to 0.8 mm. When the membrane prepared by the method is at the temperature of 70 DEG C-80 DEG C, the viscosity of the membrane obviously declines, the membrane has a good melt infiltration property, and a fiber braided fabric can be infiltrated through an RFI process to prepare a composite material; when the membrane is at the temperature of 150 DEG C to 180 DEG C, the membrane is molded due to thermocuring; when the membrane is at the temperature of above 1000 DEG C, a phenolic matrix in the porcelain phenolic resin membrane is thermally cracked, and meanwhile is converted into a highly compact anti-scouring ceramic layer together with the silicon carbide whiskers and high-temperature phase-changing inorganic particles. The high-compactness high-temperature porcelain phenolic resin permeable membrane is applied to advanced spacecraft components to resist thermal environments of high heat flow and high scour.

Owner:WUHAN UNIV OF TECH

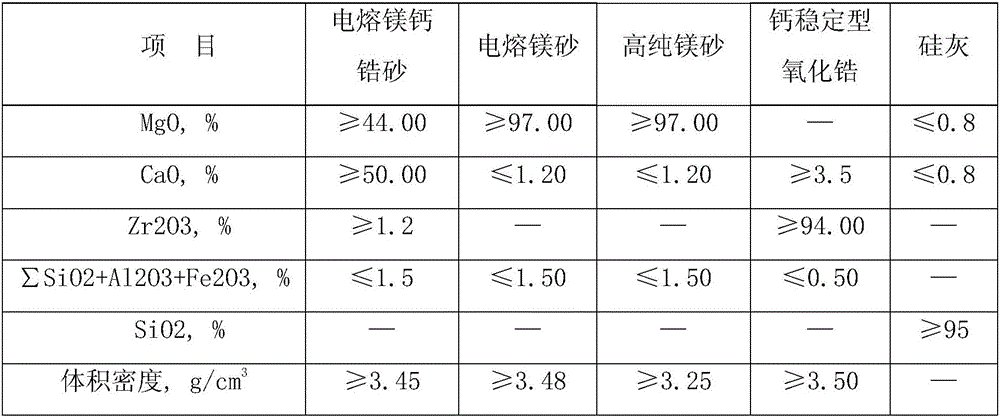

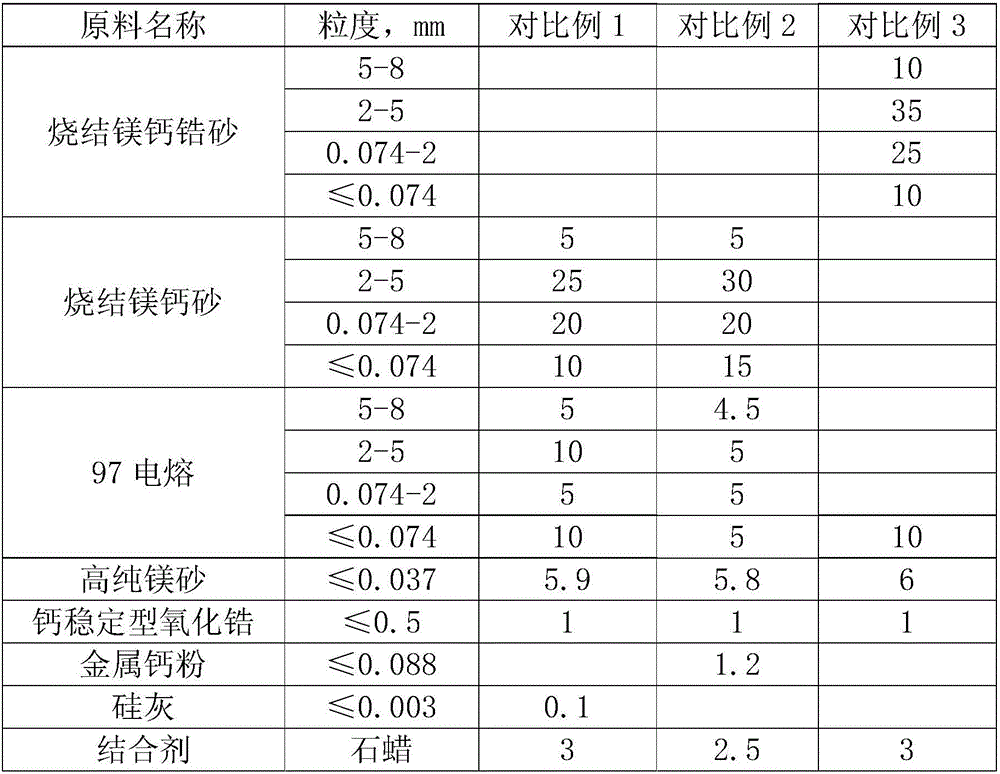

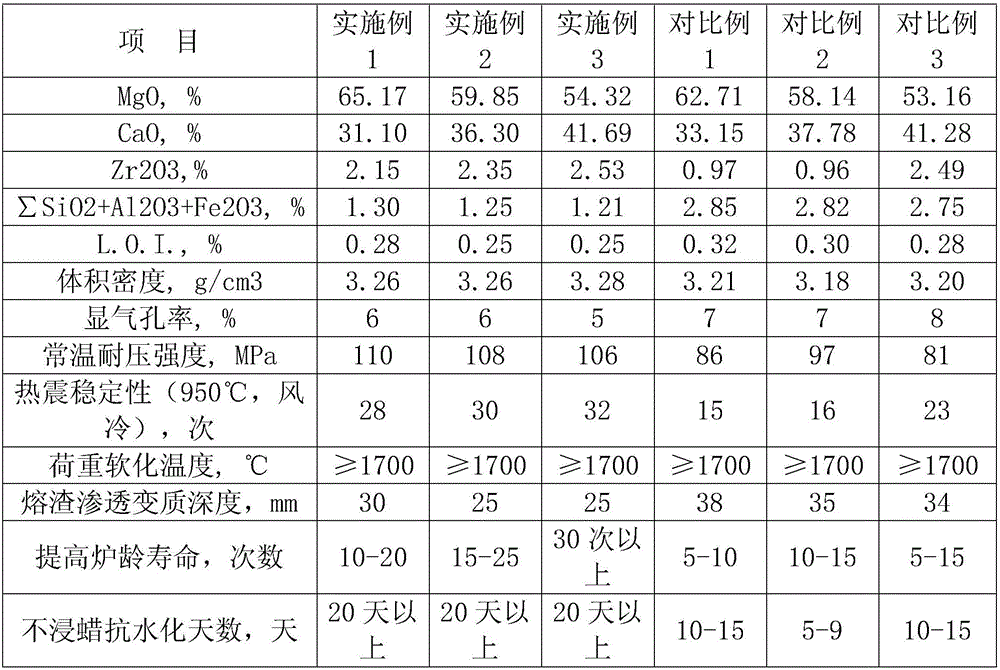

Zirconium composite high-performance electrofused magnesium-calcium zirconium brick and manufacturing method thereof

The invention belongs to the technical field of refractories for steel smelting furnaces, and in particular relates to a zirconium composite high-performance electrofused magnesium-calcium zirconium brick and a manufacturing method thereof; the zirconium composite high-performance electrofused magnesium-calcium zirconium brick comprises 5-10% of electrofused magnesium-calcium zirconium sand with a partical size of 5-8mm, 20-35% of electrofused magnesium-calcium zirconium sand with a partical size of 2-5mm, 20-30% of electrofused magnesium-calcium zirconium sand with a partical size of 2-0.074mm, 10-15% of electrofused magnesium-calcium zirconium sand fine powder with a partical size of 0.074mm or less, 1-5% of electrofused magnesium sand with a partical size of 5-8mm, 1-10% of electrofused magnesium sand with a partical size of 2-5mm, 1-5% of electrofused magnesium sand with a partical size of 2-0.074mm, 5-10% of electrofused magnesium sand fine powder with a partical size of 0.074mm or less, 5-10% of electrofused magnesium sand super-fine powder with a partical size of 0.037mm or less, 0.5-1.2% of calcium stabilized zirconia with a partical size of 0.5mm or less, 0.5-2% of metal calcium powder with a partical size of 0.088mm or less, 0.1-0.5% of silica fume with a partical size of 0.003mm or less and 2-5% of a binder. The method can obviously improve the physical and chemical performance indexes of the magnesium-calcium zirconium brick, anti-penetration, anti-erosion, anti-erosion and anti-spalling and other use performances of the magnesium-calcium zirconium brick can be improved, and most importantly, the magnesium-calcium zirconium brick can meet the requirements of current smelting conditions.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Anti-crack concrete

The invention discloses anti-crack concrete, prepared from the following components by a weight ratio: 2.5-30 parts of aggregate, 20-90 parts of cement, 1-5 parts of steel fiber or carbon fiber, 1-10 parts of an additive, 10-15 parts of polypropylene glycol fiber and 1-3 parts of phosphorus slag powder, wherein the lengths of the steel fiber and the carbon fiber are 1-20mm. The anti-crack concrete is high in crack resistance, and a prepared concrete product has long service life.

Owner:JIANGSU BAIRUIJI NEW MATERIAL

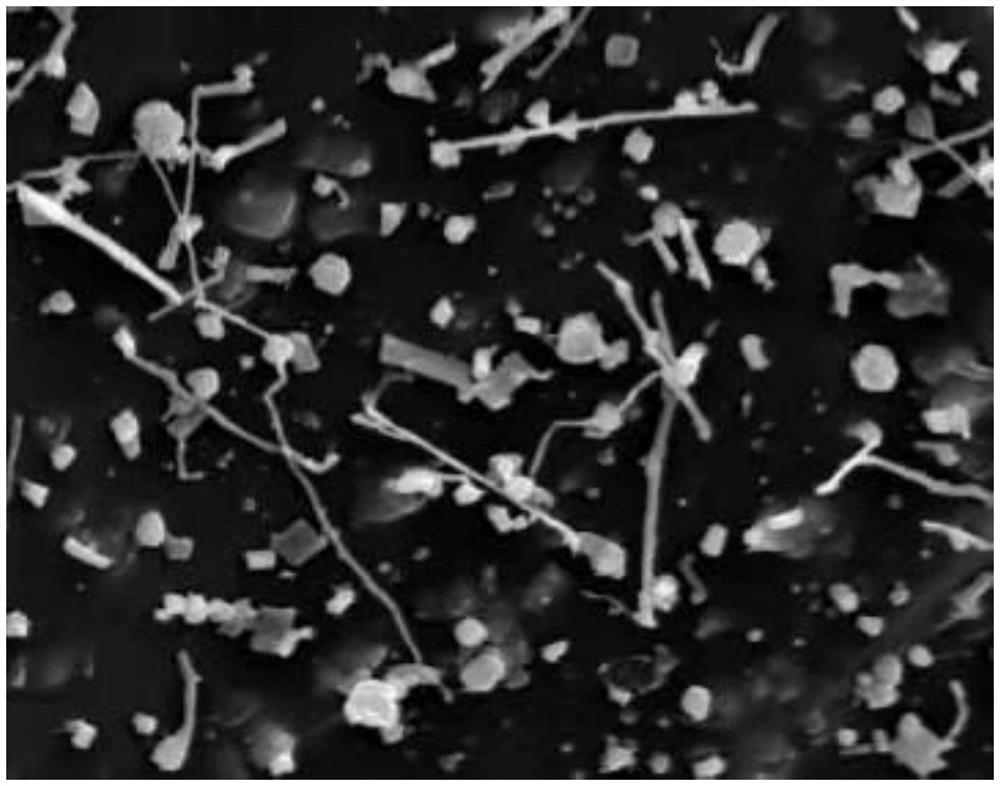

Aluminum-zirconium-carbon sliding plate brick prepared by combining nickel-aluminum alloy-containing organic silicon resin with high-temperature firing and production method of aluminum-zirconium-carbon sliding plate brick

The invention provides an a luminum-zirconium-carbon sliding plate brick prepared by combining nickel-aluminum alloy-containing organic silicon resin with high-temperature firing. The aluminum-zirconium-carbon sliding plate brick is prepared from the following raw materials in percentage by weight: 50 to 65 percent of corundum, 15 to 30 percent of fused zirconia corundum, 6 to 12 percent of activated aluminum oxide micropowder, 1 to 3 percent of monoclinic zirconium oxide, 1 to 2 percent of metal silicon micropowder, 1 to 3 percent of carbon black, 1 to 2 percent of carbon-containing resin powder and 0.5 to 1 percent of boron carbide. The aluminum-zirconium-carbon sliding plate brick further comprises organic silicon resin accounting for 3-4% of the total amount of the above raw materials and nickel-aluminum alloy powder accounting for 0.2-1% of the total amount of the above raw materials. According to the invention, a nickel-aluminum alloy raw material is introduced, in-situ fibrous nanocarbon is generated between aggregate and a matrix in a high-temperature firing process under the catalytic action of nickel, the bonding strength and toughness between the aggregate and the matrix are improved, and then the thermal shock resistance and other performance of the material are improved; and the prepared aluminum-zirconium-carbon sliding plate brick has the advantages of long service life, stable performance and the like.

Owner:HENAN RONGJIN HIGH TEMPERATRUE MATERIALS CO LTD

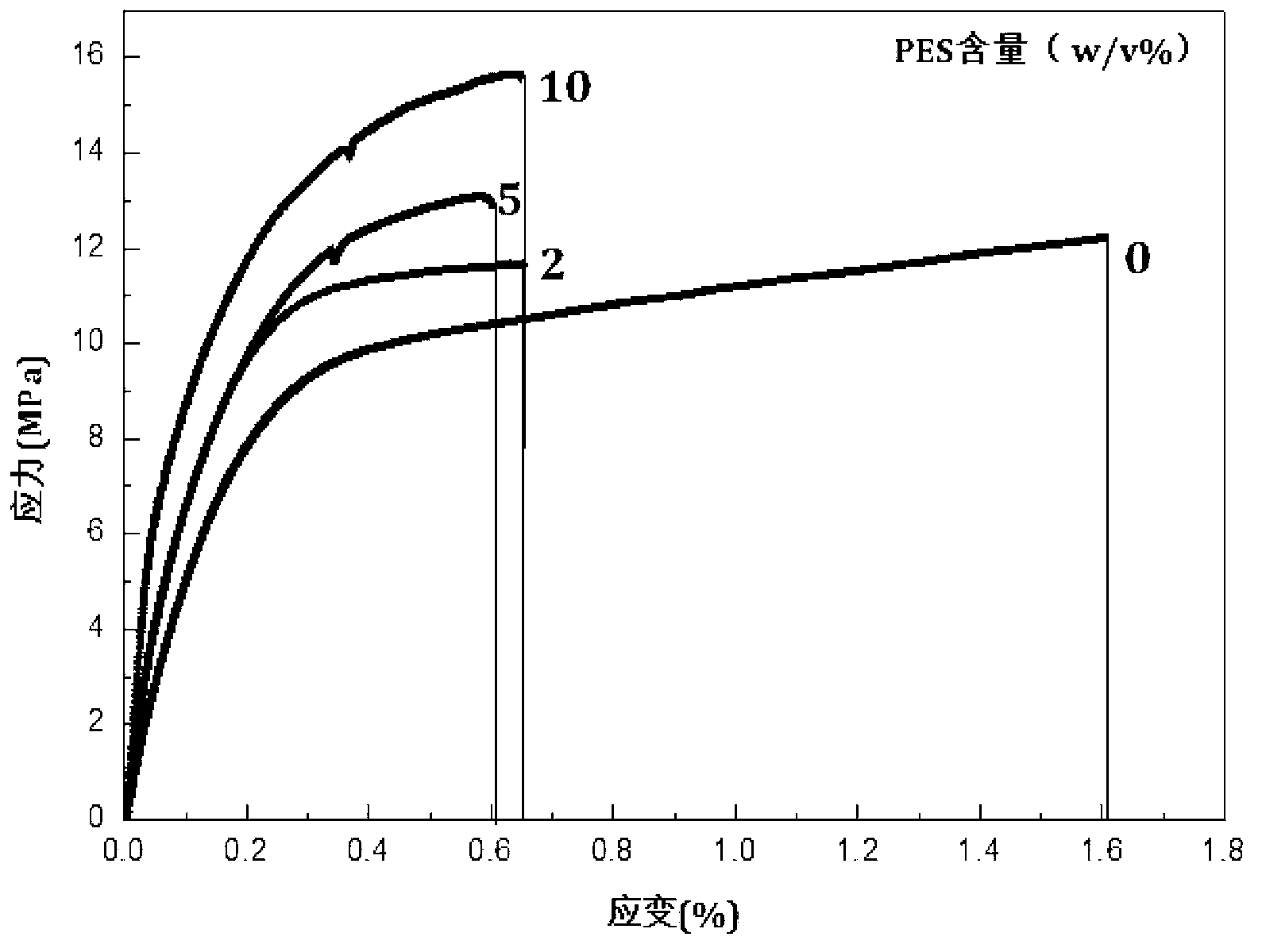

Perlite porous sound absorption material for rail traffic and preparation method thereof

Aiming at the problems of current sound absorption materials in aspects of sound absorption performance, mechanical properties, weatherability, practicality, cost and the like, the invention provides a perlite porous sound absorption material for rail traffic and a preparation process method thereof. The material comprises the following raw materials by weight 10-20 parts of perlite, 60-80 parts of portland cement, 3-5 parts of rapid-hardening cement, 1-4 parts of polymer emulsion, 1-1.5 parts of balling agents, 1-2.5 parts of plasticizers, and 25-35 parts of water. The preparation method comprises the following steps: preparing materials; dissolving the balling agent, the polymer emulsion and the plasticizer in water to prepare a solution in reserve; adding the perlite and the solution into a stirrer for stirring; adding the portland cement and the rapid-hardening cement into the stirrer for stirring so as to allow the materials to become an original slurry material with a lot of particles; pouring the original slurry material into a mold, pressing by a pressing plate for molding; performing conserving after molding to obtain a finished product. The sound absorption material of the invention has both strength and sound absorption performance, and has multifrequency sound absorption capability.

Owner:SICHUAN SOUTHWEST JIAOTONG UNIV RAILWAY DEV

Coastal soft foundation soil solidifying and reinforcing material and application thereof

InactiveCN104891893AImprove corrosion resistanceImprove anti-scourSolid waste managementVoid ratioSlag

The present invention provides a coastal soft foundation soil solidifying and reinforcing material, comprising the following components by weight: 5-10 parts of cement, 2-6 parts of a powder, 0.5-1 part of a water reducer, 0.5-1 part of a permeability-reducing agent, and 1-2 parts of an enhancer. The invention also provides application of the above solidifying and reinforcing material to the preparation of cement stirring piles. Aiming at the special environmental conditions of high water content, large void ratio and strong corrosion of the coastal soft foundation, some materials are added on the basis of existing material for cement stirring pile, so as to improve the corrosion resistance, erosion resistance, water seepage resistance, strength and bearing capacity of cement stirring pile. Furthermore, the invention uses non-toxic and green materials; the fly ash, slag powder, cinder and steel slag powder are recycled wastes. The coastal soft foundation soil solidifying and reinforcing material is in favor of haze control and has good economic and social values.

Owner:HOHAI UNIV

Novel automobile body structural member die-casting die steel and preparation process thereof

InactiveCN110241358AImprove hardenabilityImprove red hardnessProcess efficiency improvementThermal fatigueDie casting

The invention provides novel automobile body structural member die-casting die steel and a preparation process thereof. The die steel comprises the following components of, by mass, 0.25%-0.35% of C, 0.20%-0.40% of Si, 0.20%-0.60% of Mn, less than or equal to 0.002% of P, less than or equal to 0.001% of S, 7%-9% of Cr, 2.5%-3.5% of Mo, 0.30%-0.50% of V, 0.40%-0.60% of W, 0.10%-0.30% of Nb, 0.005%-0.10% of N, 0.05%-0.20% of Ti and the balance Fe and inevitable impurities. Therefore, the novel automobile body structural member die-casting die steel has good hardenability, wear resistance and thermal fatigue resistance.

Owner:NINGBO HELI TECH CO LTD

Ramming material based on alumina-chrome slag for ferrous metallurgy intermediate frequency furnaces and preparation method thereof

The invention relates to a ramming material based on alumina-chrome slag for ferrous metallurgy intermediate frequency furnaces and a preparation method thereof. According to the technical scheme, thepreparation method includes: mixing, by weight, 55-60% of alumina-chrome slag particles, 10-15% of tabular corundum particles, 15-20% of alumina-chrome slag fine powder, 2-5% of silica micropowder, and 5-8% of magnesia fine powder, adding 5-8% by weight of phosphoric acid solution, stirring well, and packaging to obtain the ramming material based on alumina-chrome slag for ferrous metallurgy intermediate frequency furnaces. The ramming material based on alumina-chrome slag for ferrous metallurgy intermediate frequency furnaces and the preparation method thereof have the advantages that the preparation method is simple, resources are comprehensively utilized, energy is saved, environment is protected, and the prepared ramming material has good resistance to molten iron and resistance to slag scouring, as well as good resistance to molten iron erosion and slag erosion.

Owner:WUHAN UNIV OF SCI & TECH

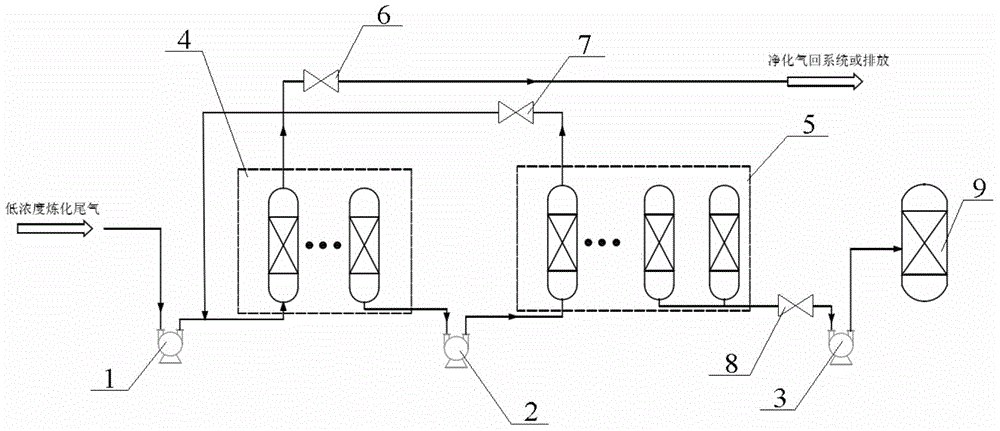

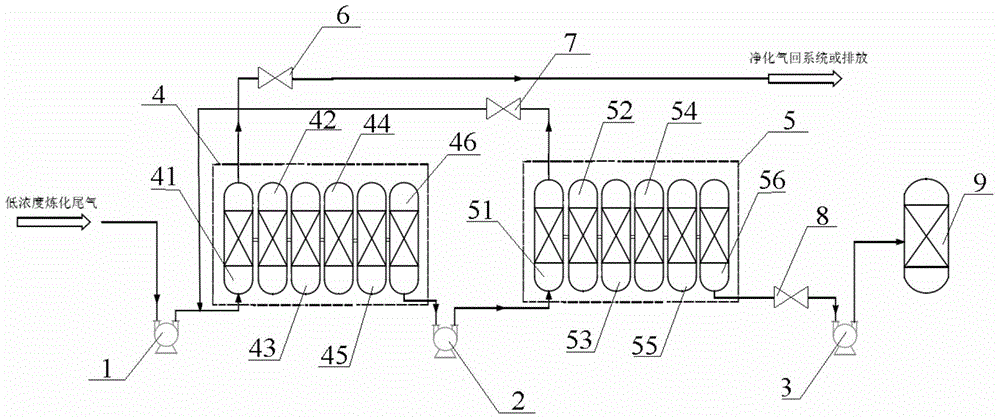

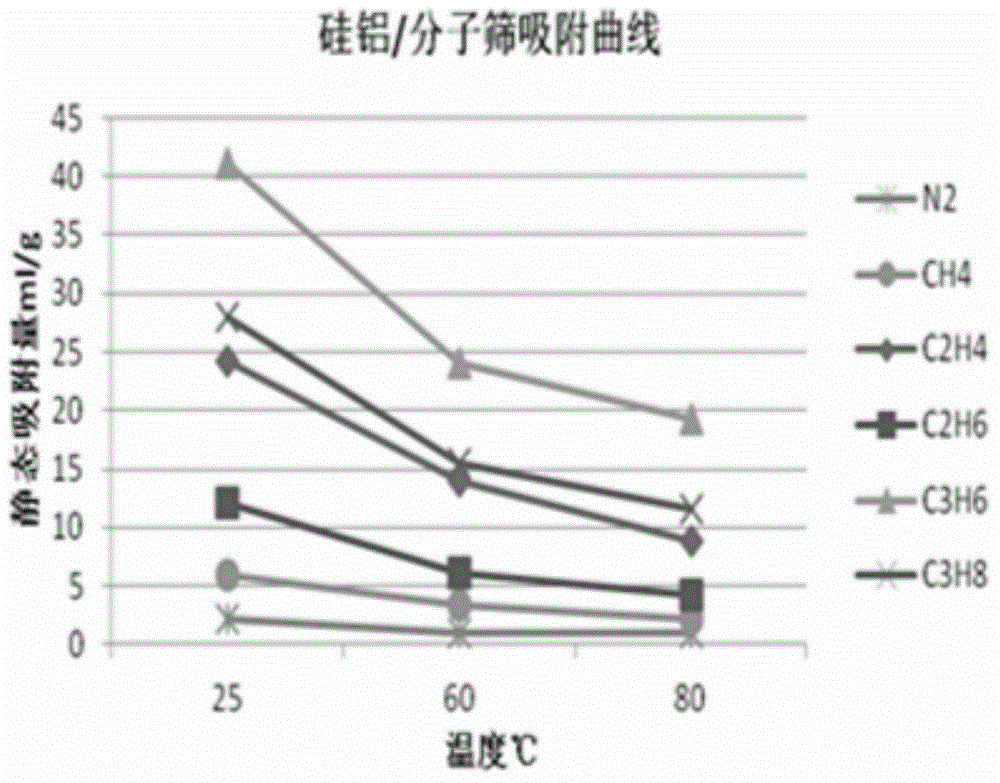

Device and method for recycling low-concentration multicomponent low-pressure refined tail gas

ActiveCN105056697AReduce energy costsLow running costMethane captureDispersed particle separationProcess engineeringEnvironmental engineering

The invention discloses a device for recycling low-concentration multicomponent low-pressure refined tail gas. The device comprises a fan, a first vacuum pump, a second vacuum pump and an adsorption device, wherein the adsorption device comprises a first-stage adsorption device and a second-stage adsorption device, the fan is connected with the first-stage adsorption device, a first program-controlled valve is also arranged at the outlet end of the first-stage adsorption device, and the first-stage adsorption device is connected with the second-stage adsorption device; the outlet end of the second-stage adsorption device is connected with the inlet end of the first-stage adsorption device, a second program-controlled valve is arranged between the outlet end of the second-stage adsorption device and the inlet end of the first-stage adsorption device, the second-stage adsorption device is connected to a main body device, and a third program-controlled valve is arranged between the second-stage adsorption device and the second vacuum pump. The invention further discloses a method for recycling the low-concentration multicomponent low-pressure refined tail gas. The device is simple in structure, treated purified gas can return a system or reach a discharging standard, and recovered hydrocarbon components can be reused as chemical raw materials, so that pollution on atmosphere is reduced, the cost is reduced, and resources are saved.

Owner:JIANGSU WISDOM ENG TECH

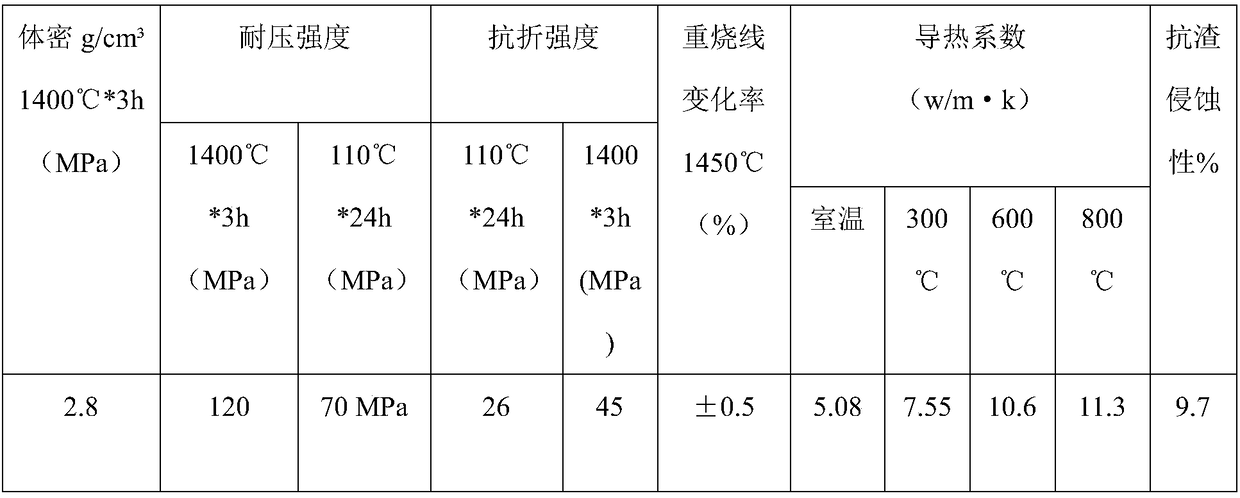

High strength composite material for blast furnace cooling walls, preparation method of high strength composite material, and application of high strength composite material in protection of cooling walls

The invention discloses a high strength composite material for blast furnace cooling walls, a preparation method of the high strength composite material, and application of the high strength compositematerial in protection of the cooling wall. The high strength composite material for the blast furnace cooling walls is prepared from a composite fiber material, aluminum nitride micro-powder, high-purity silicon carbide, mullite, alumina powder, silica powder, montmorillonite, sericite, a binding agent and a water reducing agent composite material. Practice proves that the composite material hasgood thermal conductivity, and can transfer heat to the cooling wall in time, so that the hot surface temperature is significantly reduced, and a stable slag crust is formed and does not easily falloff, that is, the slag crust can be well formed on the hot surface of the cooling wall; the high strength composite material can prevent the slag crust from falling off, so that the permanent and stable slag crust is realized, and the service life of the cooling wall is greatly prolonged. The high strength composite material is good in construction workability, is molded by pumping and self-flow forming and is free from vibration, so that a dense high-strength whole can be formed in an embedding groove of the cooling wall. The high strength composite material has a good application prospect inthe protection of the blast furnace cooling walls.

Owner:HENAN HUAXI FURNACE REFRACTORY

Method for compositing and producing tundish impact plate through combination of stopper turning material and waste sliding plate

ActiveCN109369147AImprove anti-scourImprove erosion abilityCeramic materials productionClaywaresSocial benefitsBrick

The invention discloses a method for compositing and producing a tundish impact plate through combination of a stopper turning material and a waste sliding plate. According to the method, a waste sliding plate brick and the stopper turning material are introduced into the impact plate, sliding plate granules and stopper granules are obtained through secondary processing, tabular corundum in the recycled sliding plate is taken as an aggregate and is combined with a certain amount of aluminum-rich spinel of the stopper turning material, the high-temperature flushing resistance of corundum particles and the slag corrosion resistance of the aluminum-rich spinel are adequately utilized and effectively combined, and the novel tundish impact plate is produced by virtue of thermoplastic phenolic resin, so that the flushing resistance and corrosion resistance of the impact plate in the high-temperature use process are improved, the safety of the impact plate is substantially improved, and the service life of the impact plate is substantially prolonged; the flushing resistance, corrosion resistance and thermal shock resistance of the produced tundish impact plate are superior to existing products in the use process, the circular and efficient utilization of waste refractory materials is realized, the regeneration of resources is realized, the energy is saved, the environment is protected, and the social benefit is obvious.

Owner:甘肃酒钢集团科力耐火材料股份有限公司

Sludge improved base material for slope greening and preparation method thereof

The invention discloses a sludge improved base material for slope greening and a preparation method thereof. The base material comprises the following components: sludge, peat soil, loess, rice husk fibers, cement, mycorrhiza, a water-retaining agent, an adhesive, a compound fertilizer and a microbial starter. Due to the fact that the sludge is improved into the available slope greening base material, the environment is improved, and waste is turned into wealth. Most of the base materials used in the method come from sludge, local mountainous area loess and common peat soil, and compared withspecial planting soil, the manufacturing cost is greatly reduced. The cement is added to enhance the scouring resistance and shear strength of the base material. The rice husk fibers are added, so that soil can be loosened, a large number of trace elements are contained, growth of plants can be better facilitated through fermentation, and a good growth environment is provided for the plants. The microbial leavening agent is added, a large number of beneficial substances easy to absorb by plants can be generated, and healthy growth of the plants is achieved.

Owner:DALIAN JIAOTONG UNIVERSITY

A cement-modified soil-reinforced geogrid-reinforced soil structure and its construction method

The invention discloses a cement modified soil strengthened geogrid reinforced soil structure and a construction method thereof. The cement modified soil strengthened geogrid reinforced soil structure (shown in a figure 1) is composed of four parts including a base layer (1) and a cover layer (9) composed of cement modified soil, a water drainage layer (2) and a cement modified soil strengthened geogrid reinforced soil layer thereof, and is a novel geogrid reinforced soil structure which is formed by improving similar structures through utilizing good properties including solidification, high wetting resistance, high anti-scouring and flood damage resisting properties, high shearing strength and the like of cement modified soil. Compared with an existing similar structure, the novel geogrid reinforced soil structure and the construction method thereof, provided by the invention, can realize panel-free construction of an abrupt-slope reinforced soil structure, and can also remarkably improve the wetting resistance, anti-scouring property and whole shearing strength of the geogrid reinforced soil structure; the cement modified soil strengthened geogrid reinforced soil structure is especially suitable for protecting and reinforcing edge slopes, which are easy to scour and damage by flood, of abrupt-slope sections.

Owner:湖南高速华达工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com