Device and method for recycling low-concentration multicomponent low-pressure refined tail gas

A multi-component, low-concentration technology, applied in low-concentration recovery, tail gas recovery equipment, low-pressure refinery tail gas equipment, and multi-component fields, can solve the problem of non-methane total hydrocarbons that are difficult to meet environmental protection standards, compression systems and low-temperature condensation Problems such as high system investment and affecting the safety and stability of the compressor system can achieve the effect of improving product purity and system stability, easy desorption and regeneration, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

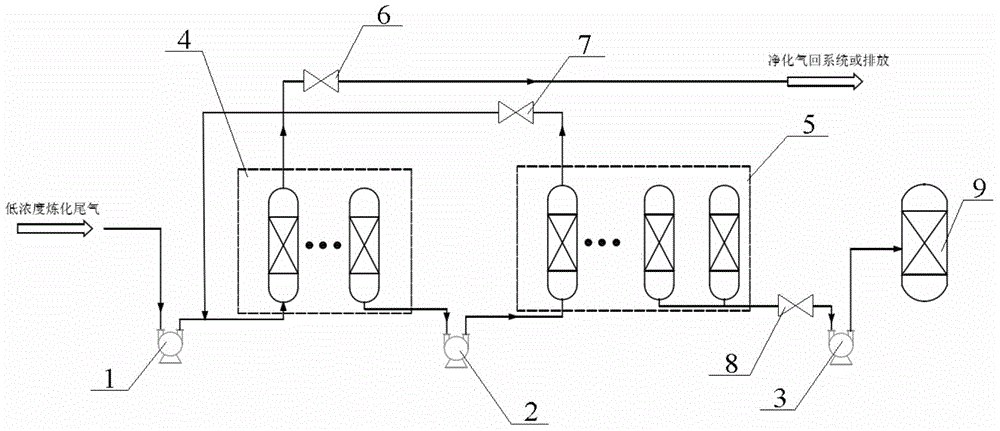

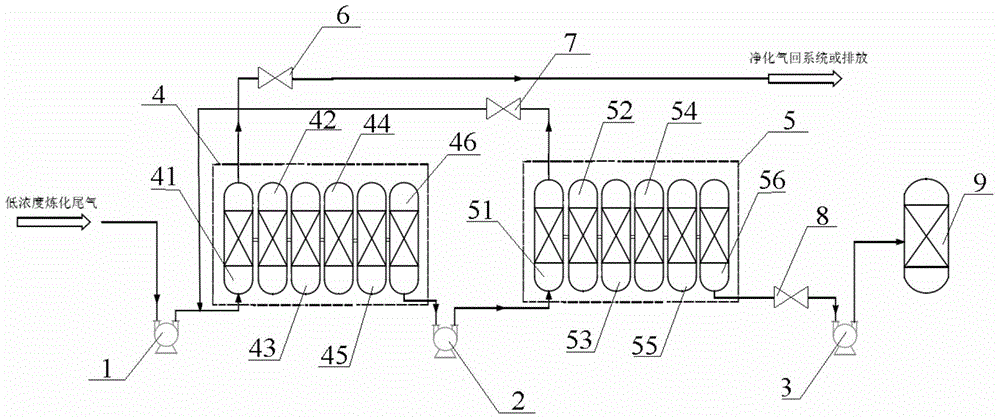

[0033] structured as figure 1As shown, a device for recovering low-concentration, multi-component, and low-pressure refinery tail gas provided in this embodiment includes a fan 1, a first vacuum pump 2, a second vacuum pump 3 and an adsorption device, and the fan 1 is arranged at the inlet of the adsorption device At the end, recovery of low-concentration, multi-component, low-pressure refinery tail gas enters the adsorption device through fan 1, and then the second vacuum pump 3 sends the tail gas through the adsorption device to the main device, wherein:

[0034] The adsorption device includes a first-stage adsorption device 4 and a second-stage adsorption device 5 arranged side by side, and there are six towers or more in each of the first-stage adsorption device 4 and the second-stage adsorption device 5, and each of them is in different working steps to alternately switch operation, and there is always one tower for adsorption , the two towers equalize the pressure and in...

Embodiment 2

[0039] This embodiment provides a method for recovering low-concentration, multi-component, and low-pressure refinery tail gas, which includes the following steps:

[0040] (1) The first program-controlled valve 6, the second program-controlled valve 7 and the third program-controlled valve 8 are all closed before the gas volume concentration of hydrocarbon components is not lower than 13%. At the same time, the stop valves in the first-stage adsorption device 4 and the second-stage adsorption device 5 are also in the closed state, and the low-concentration, multi-component, low-pressure refining tail gas enters the bottom of the first-stage adsorption tower 41 through the fan 1, and is connected with the first-stage adsorption tower 41. The adsorbent in the adsorption tower 41 is contacted for purification, and when the volume concentration of non-methane total hydrocarbons in the purified gas is less than 1%, the first pass control valve 6 discharges the purified gas up to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com