Patents

Literature

209results about How to "Reduce sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

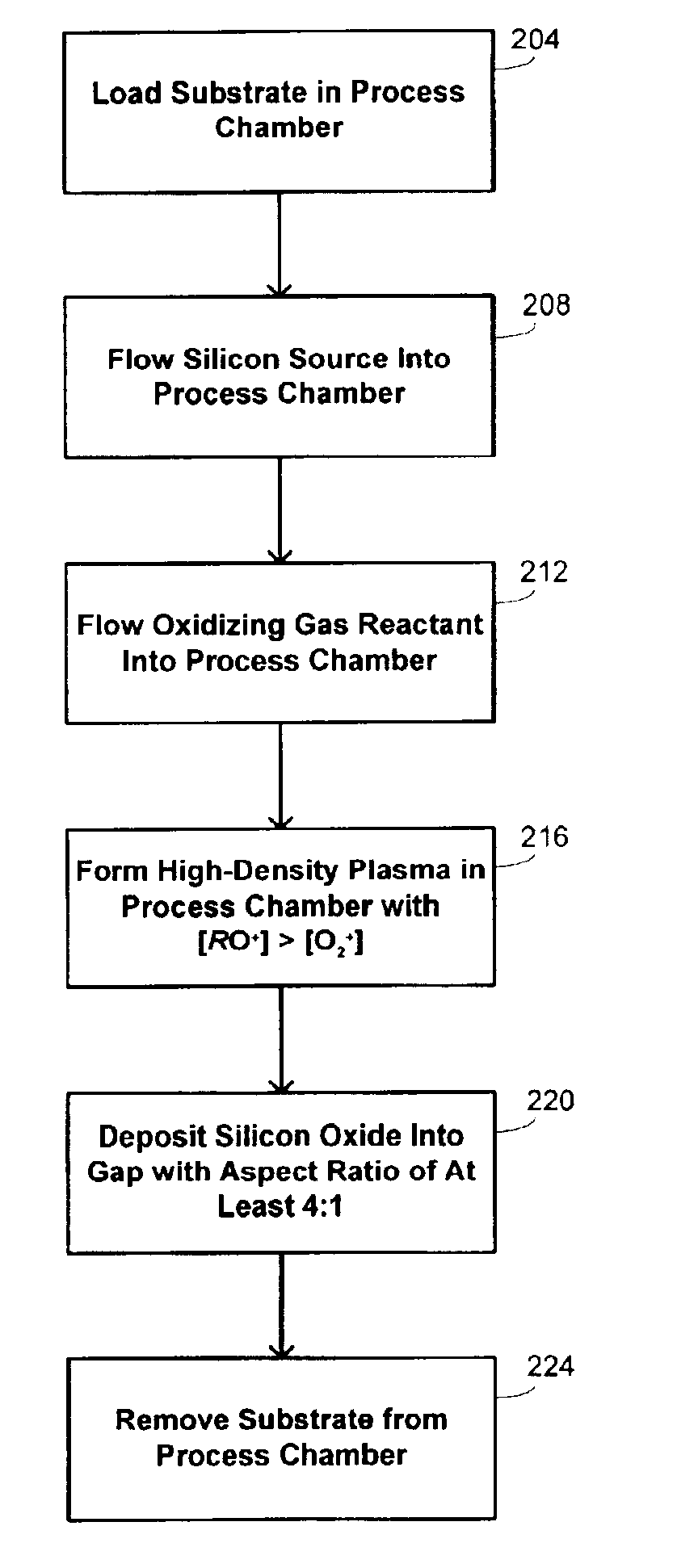

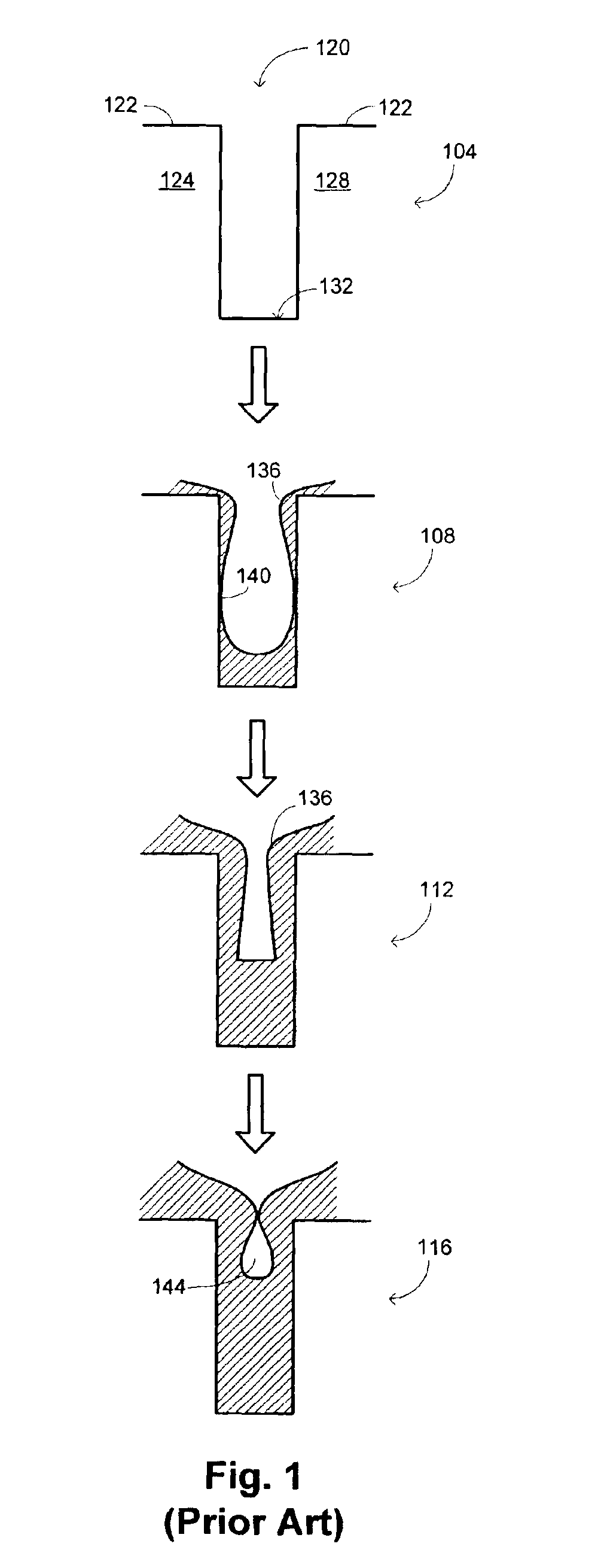

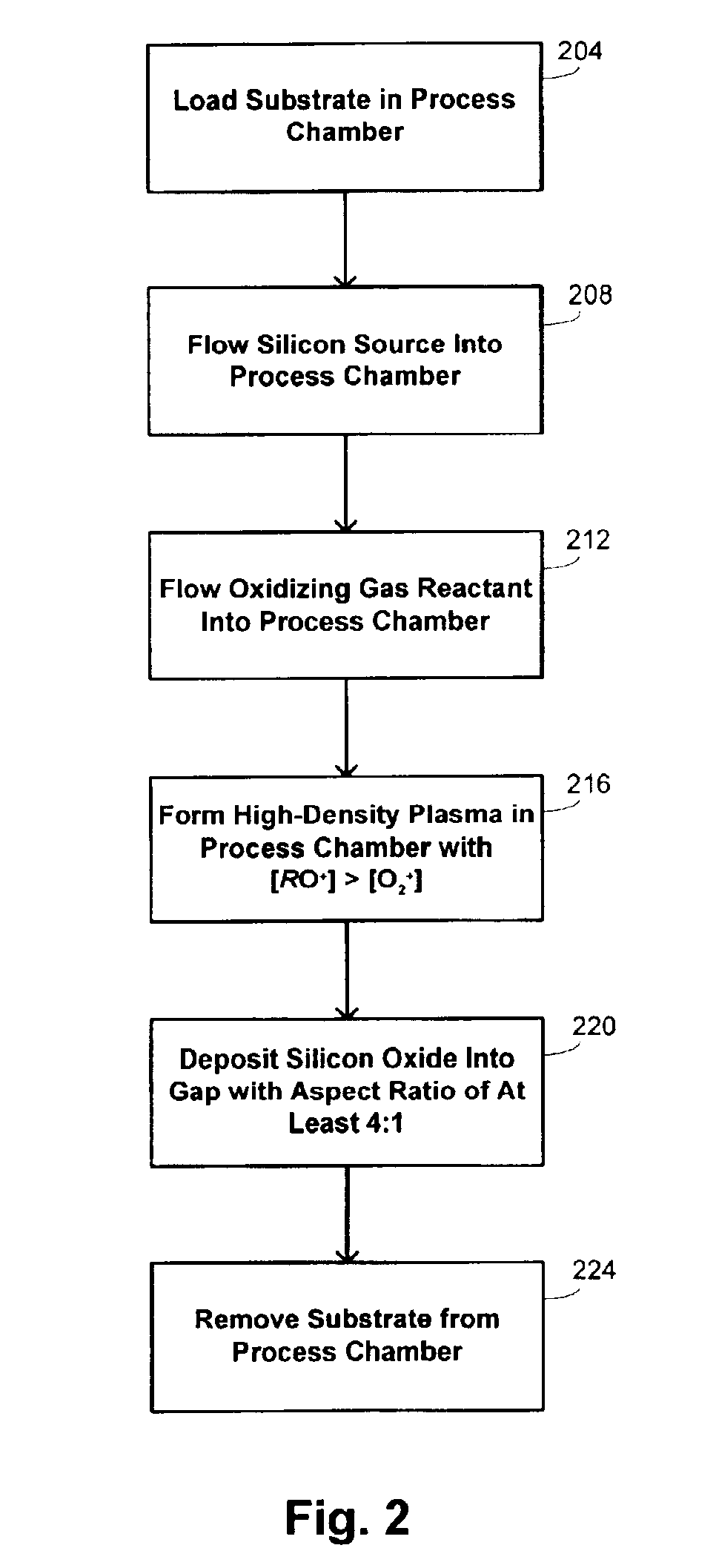

Methods and systems for high-aspect-ratio gapfill using atomic-oxygen generation

InactiveUS6958112B2Improved redeposition characteristicReduce the impactVacuum evaporation coatingSemiconductor/solid-state device manufacturingIon densitySilicon oxide

Methods and systems are provided for depositing silicon oxide in a gap on a substrate. The silicon oxide is formed by flowing a process gas into a process chamber and forming a plasma having an overall ion density of at least 1011 ions / cm3. The process gas includes H2, a silicon source, and an oxidizing gas reactant, and deposition into the gap is achieved using a process that has simultaneous deposition and sputtering components. The probability of forming a void is reduced by ensuring that the plasma has a greater density of ions having a single oxygen atom than a density of ions having more than one oxygen atom.

Owner:APPLIED MATERIALS INC

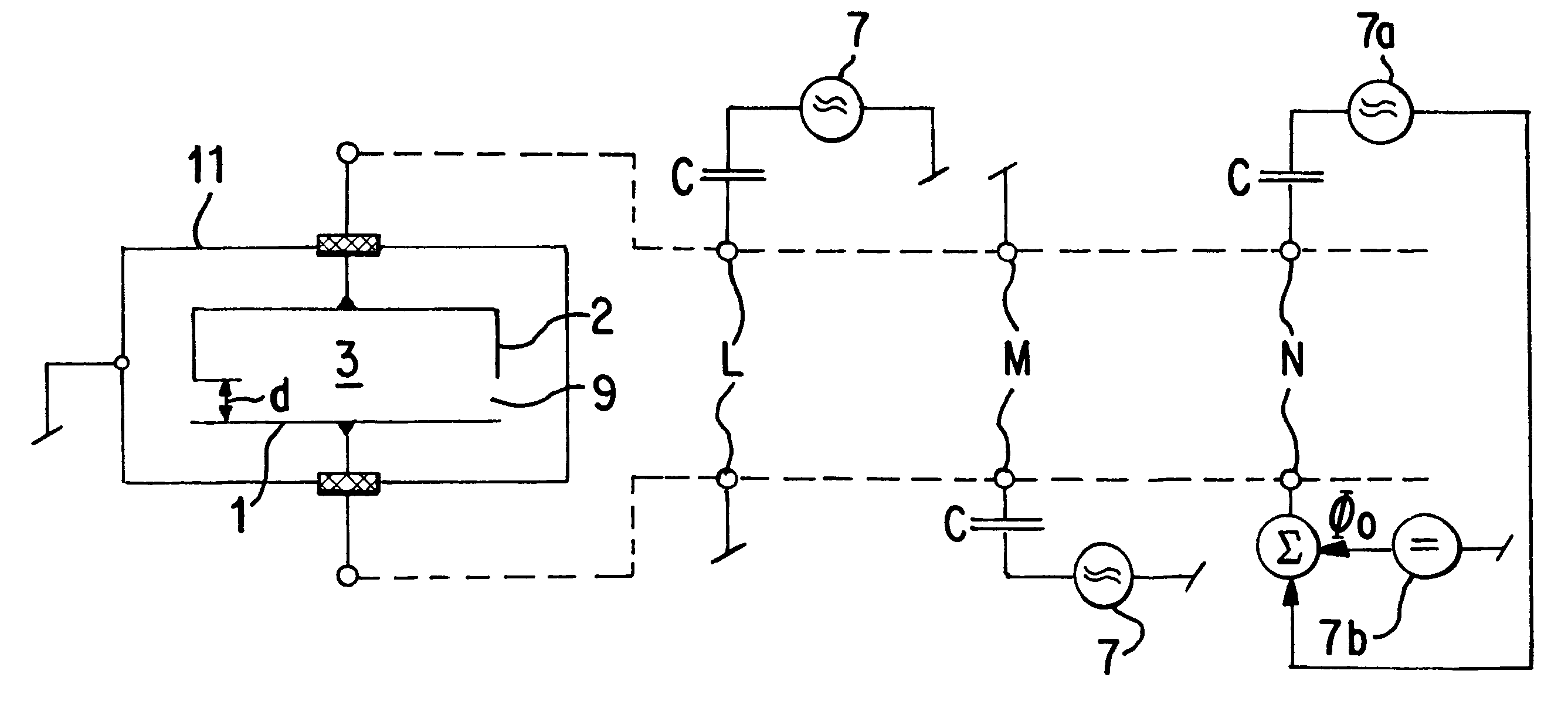

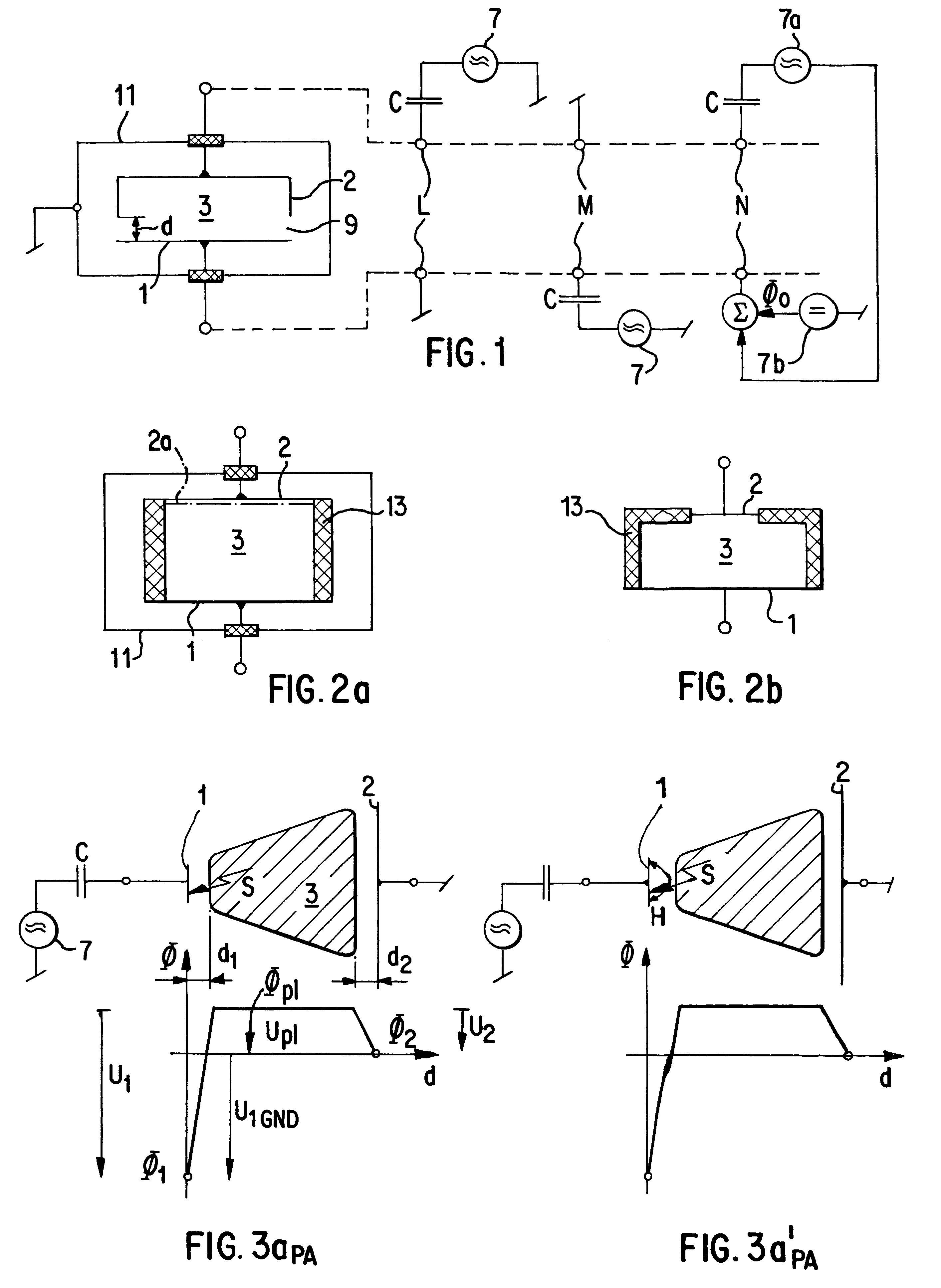

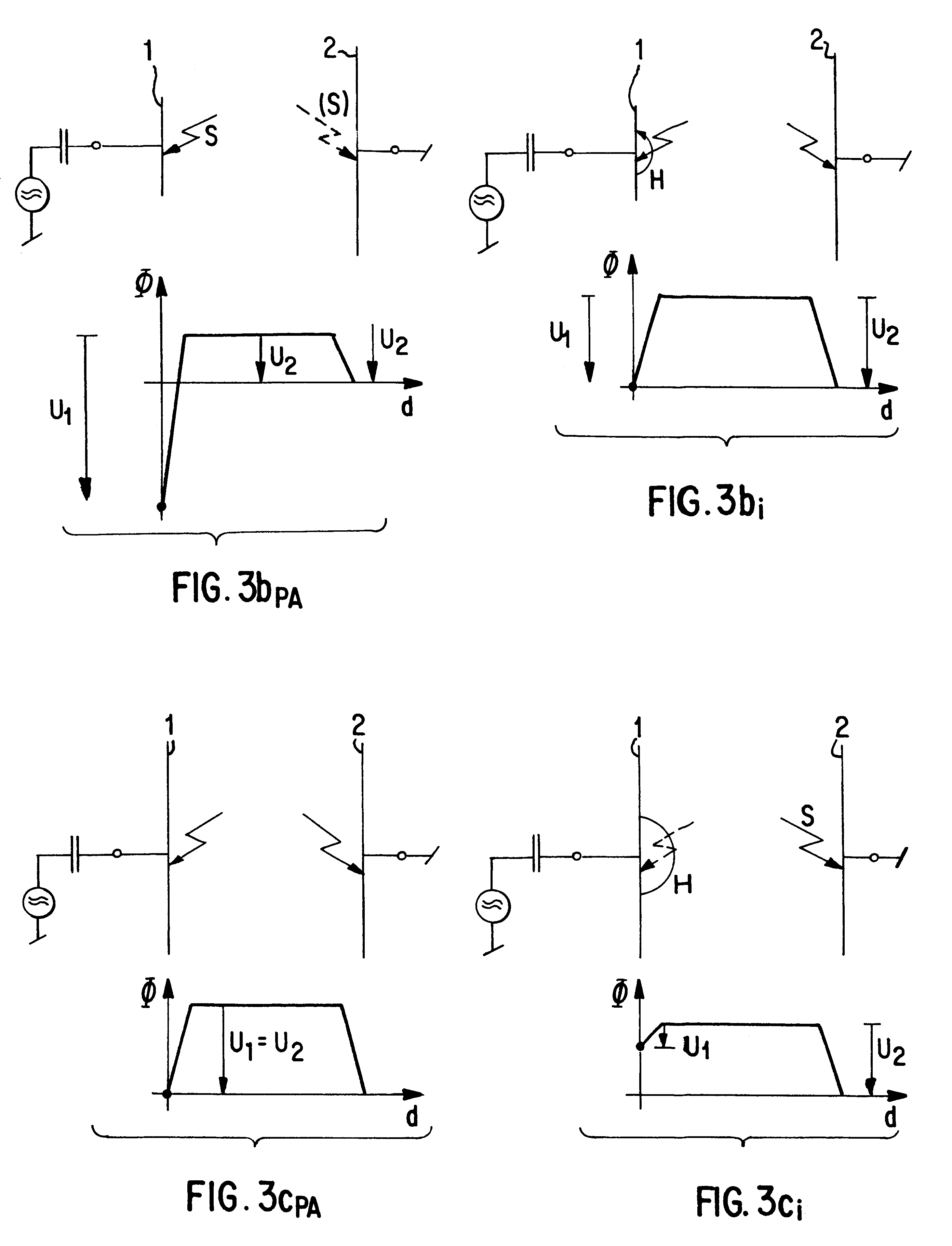

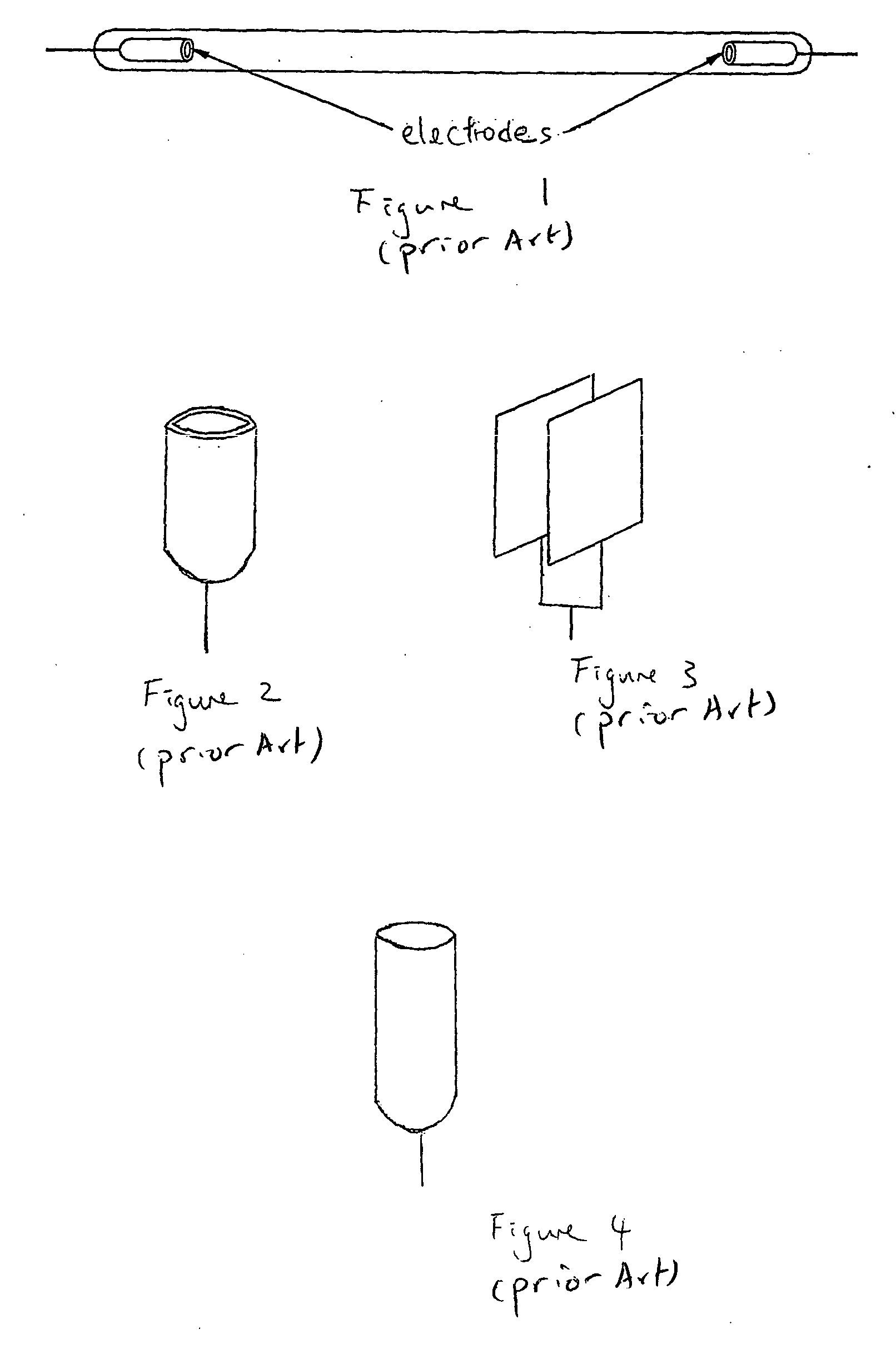

Process and apparatus for sputter etching or sputter coating

InactiveUS6248219B1Increased sputteringReduce sputteringCellsElectric discharge tubesLine of forceEtching

A problem which occurs in the sputtering of a substance by means of a high-frequency discharge between two electrodes, is that both electrode surfaces are sputtered away when the electrode surface that is actually not to be sputtered is not at least ten times as large as the surface of the electrode carrying the substance. To prevent an undesirable cosputtering, in on embodiment, a vacuum recipient at a selected gas pressure has first and a second electrodes which are selected so that their surface areas form a ratio RA 12 such that 0.3<=RA12<=3. A discharge space in the vacuum recipient is confined to the electrode surfaces. An RF plasma discharge is generated in the discharge space by applying an electric RF field between the electrode surface, so that a first dark space region with a first drop of time-averaged electric potential and a second dark space region with a second drop of time-averaged electric potential, are respectively provided adjacent each electrode. The surface of an object to be coated is disposed in the second dark space region adjacent said larger electrode surface so that the surface of the object is at a floating electric potential to perform diode sputtering. A magnetic field is generated within the discharge space, a large part of its lines of force being tunnel-like shaped on the first electrode surface and extending across aid first dark space region to enhance sputtering of the surface of the object.

Owner:OERLIKON ADVANCED TECH

Package to dispense a foaming composition

ActiveUS20170174413A1Prevents packageReduce sputterCosmetic preparationsHair cosmeticsVapor pressureEngineering

Disclosed is a package to dispense a composition, wherein the package comprises: a flexible inner container made of gas-impermeable material and holding the composition wherein the composition comprises a blooming agent in an emulsified liquid form; a sealed rigid outer container which encloses the flexible inner container and which is filled with a driving gas compressing the inner container; anda dispenser attached to the inner container and in a fluid connection with the composition by which the composition is allowed to be dispensed by the pressure of the driving gas; wherein the pressure of the driving gas is higher than the vapor pressure of the emulsified liquid blooming agent in the inner container, throughout the usage of the package until the exhaustion of the composition in the inner container.

Owner:THE PROCTER & GAMBNE CO

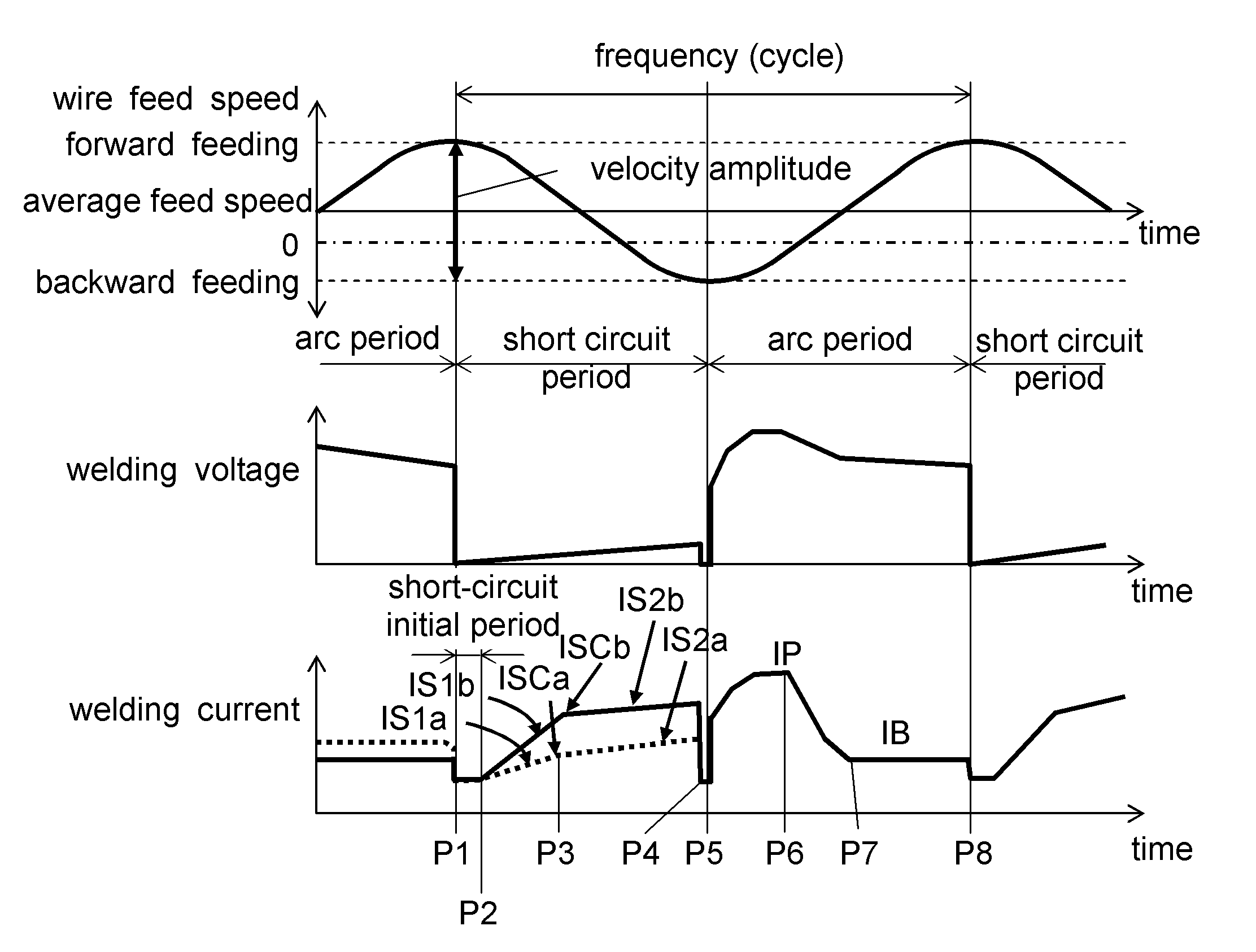

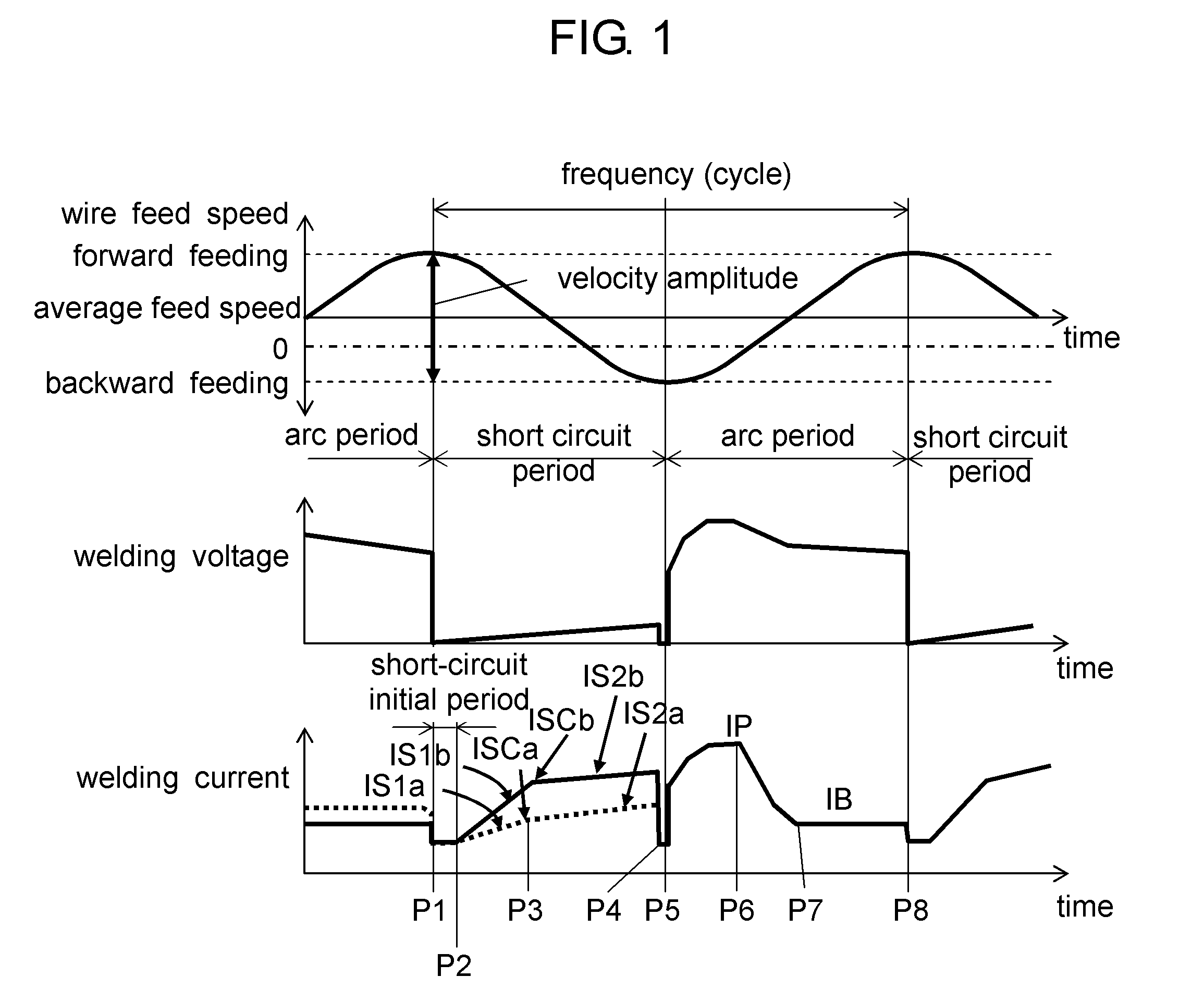

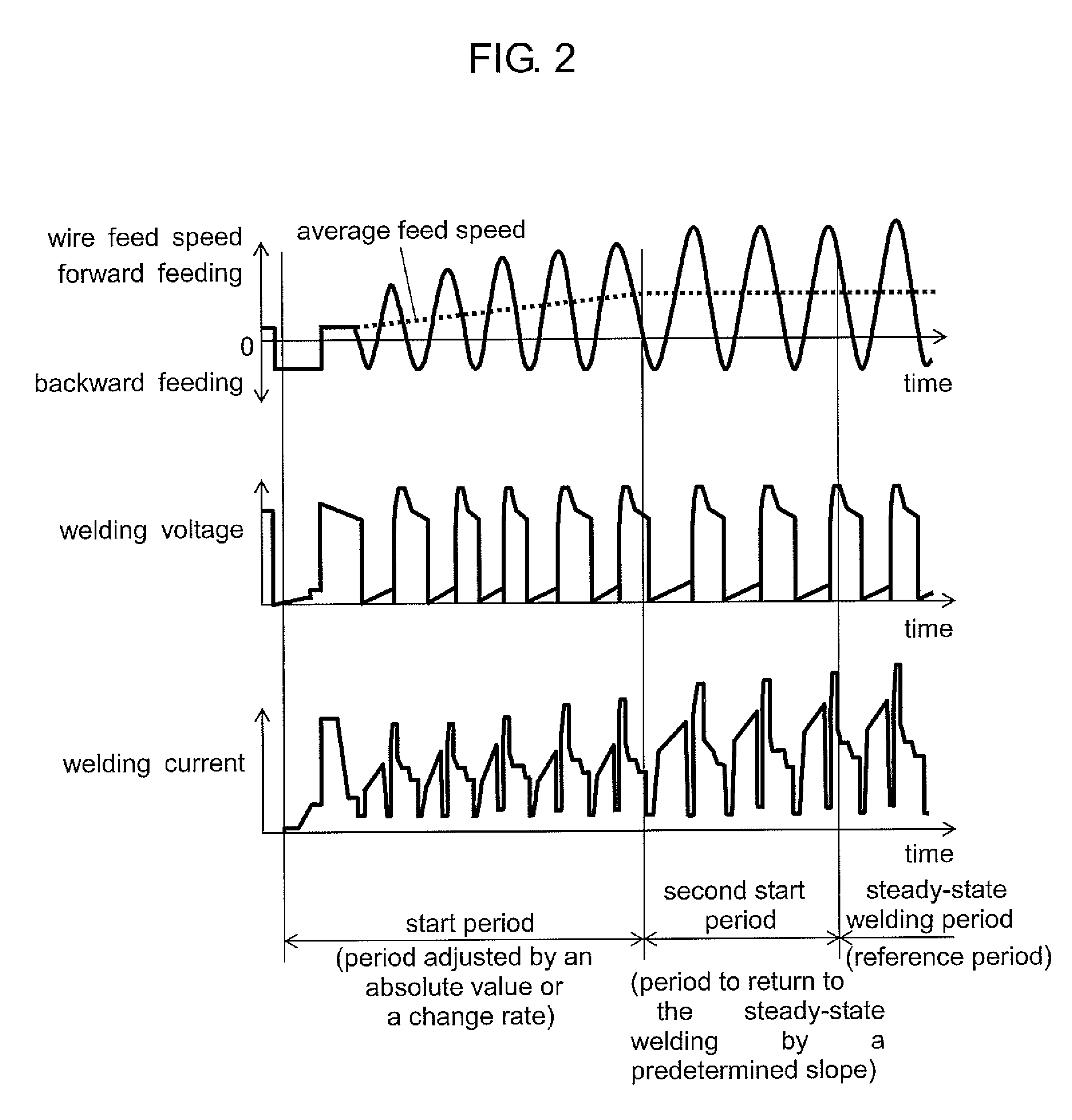

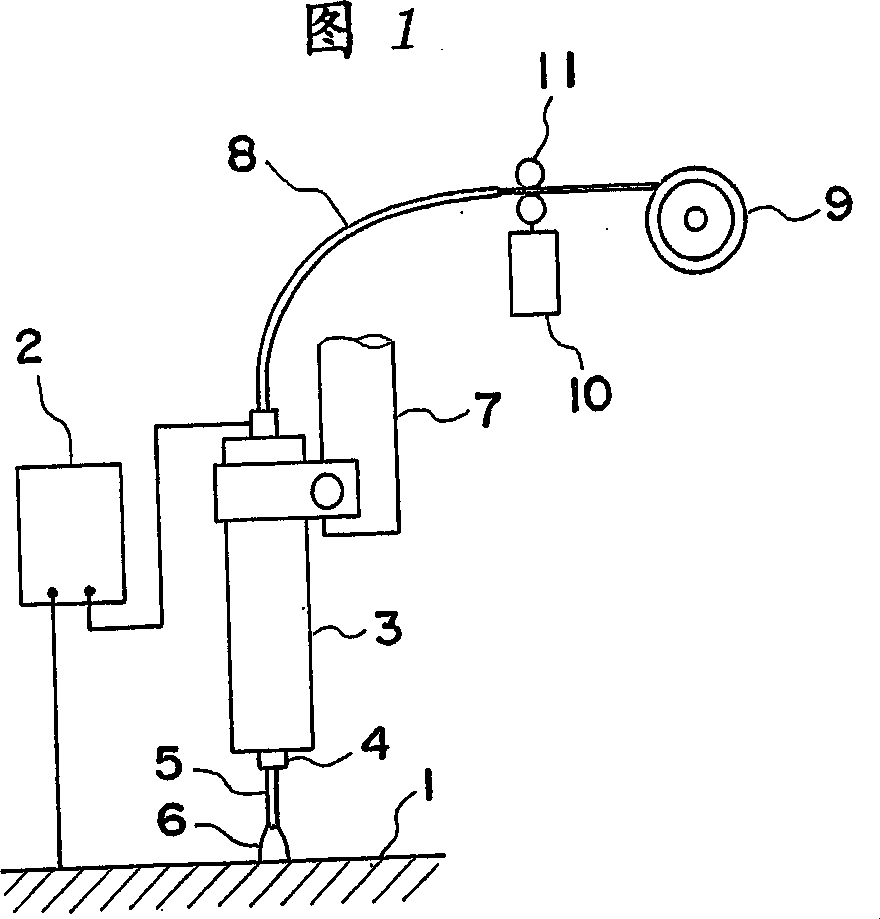

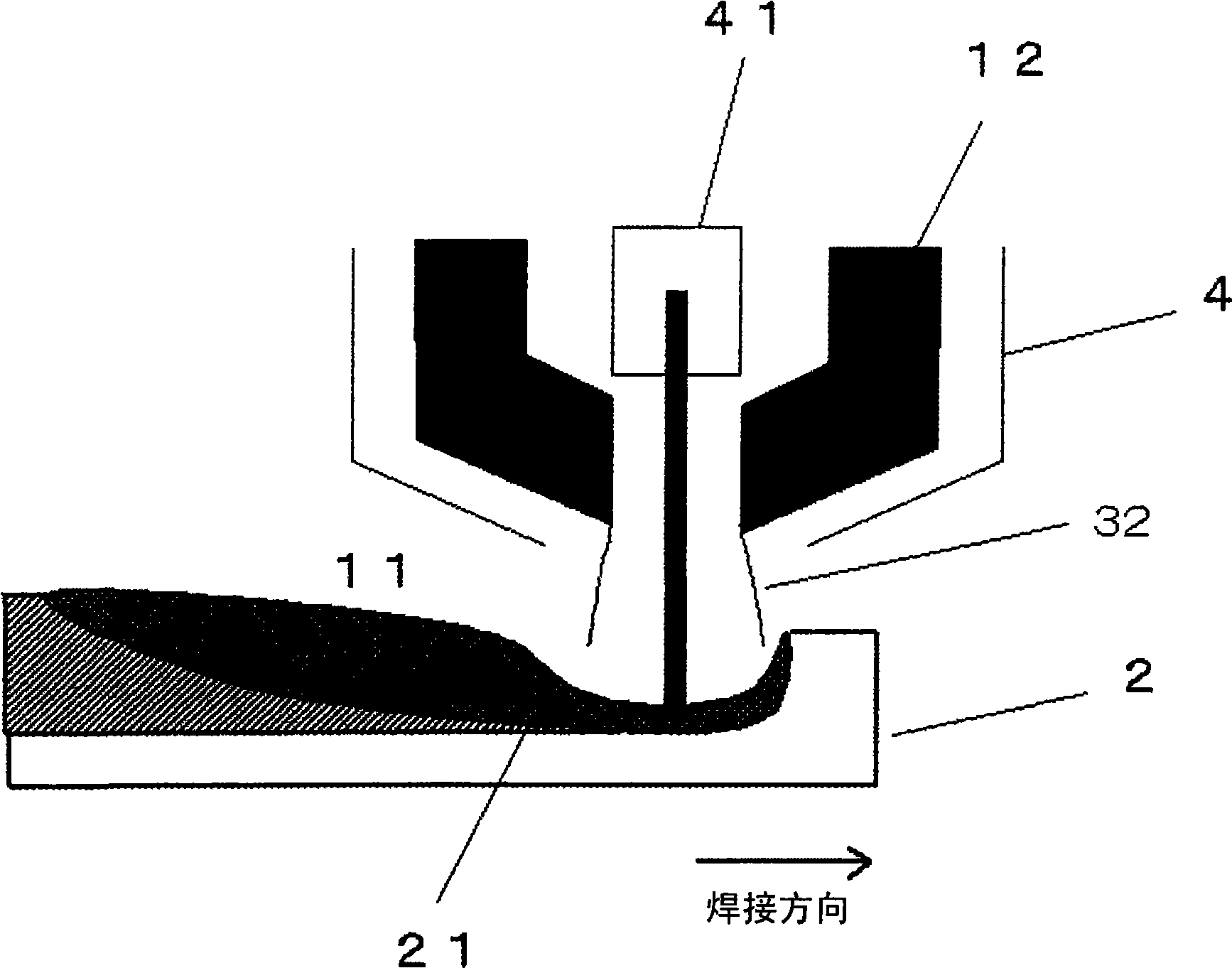

Arc welding method and arc welding device

ActiveUS20120255940A1Decrease increaseReduce sputteringArc welding apparatusWelding/cutting media/materialsElectric arcEngineering

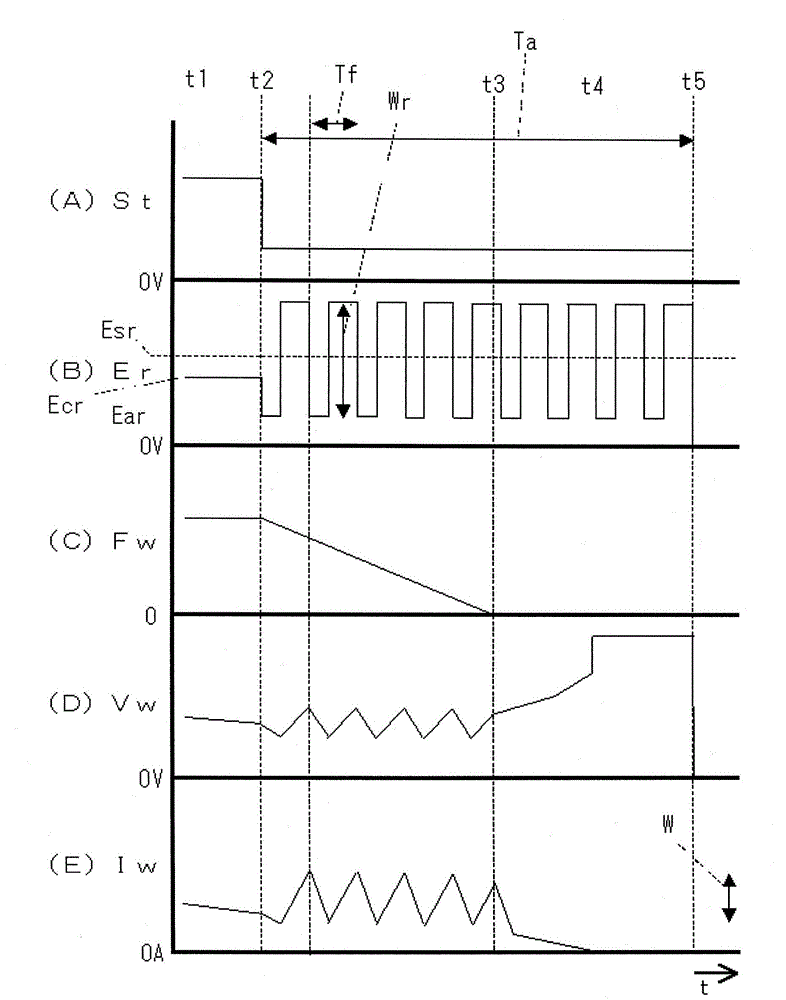

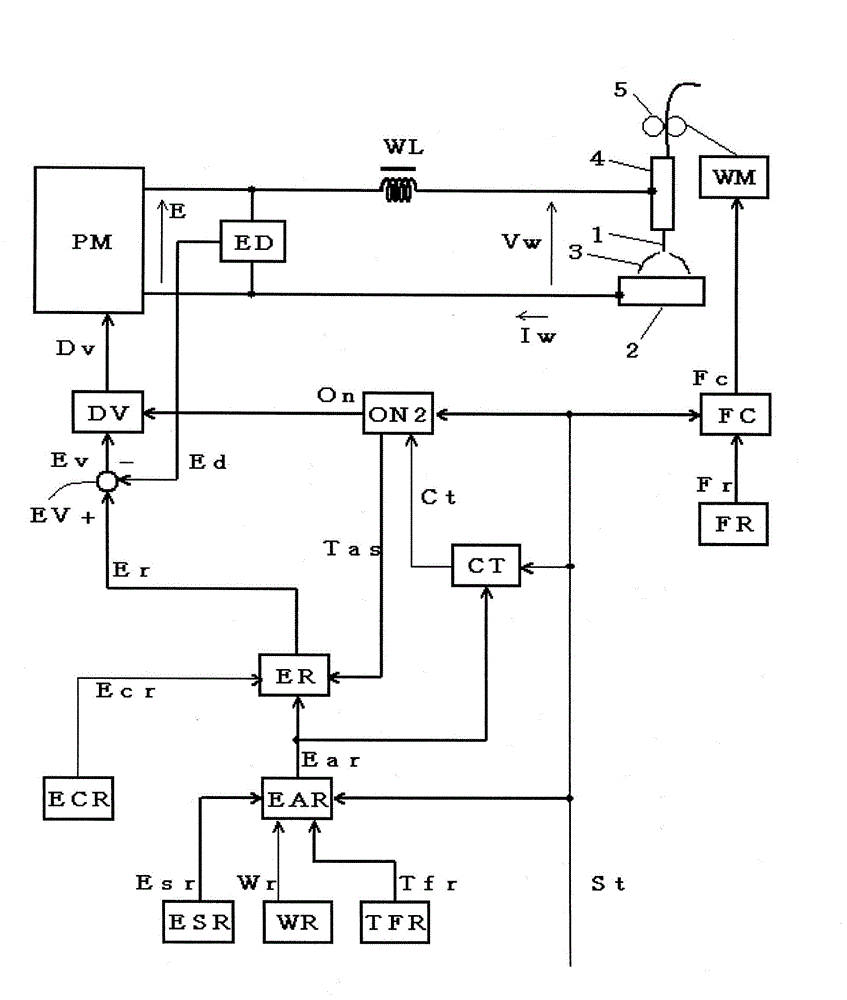

A method for arc welding can control the increase slopes of the short-circuit current and the inflection point of the increase slopes in the welding start period to be smaller than in the steady-state welding period. Thus, the increase slopes of the short-circuit current and the inflection point are made different between the welding start period and the steady-state welding period, thereby reducing sputtering in the welding start period.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

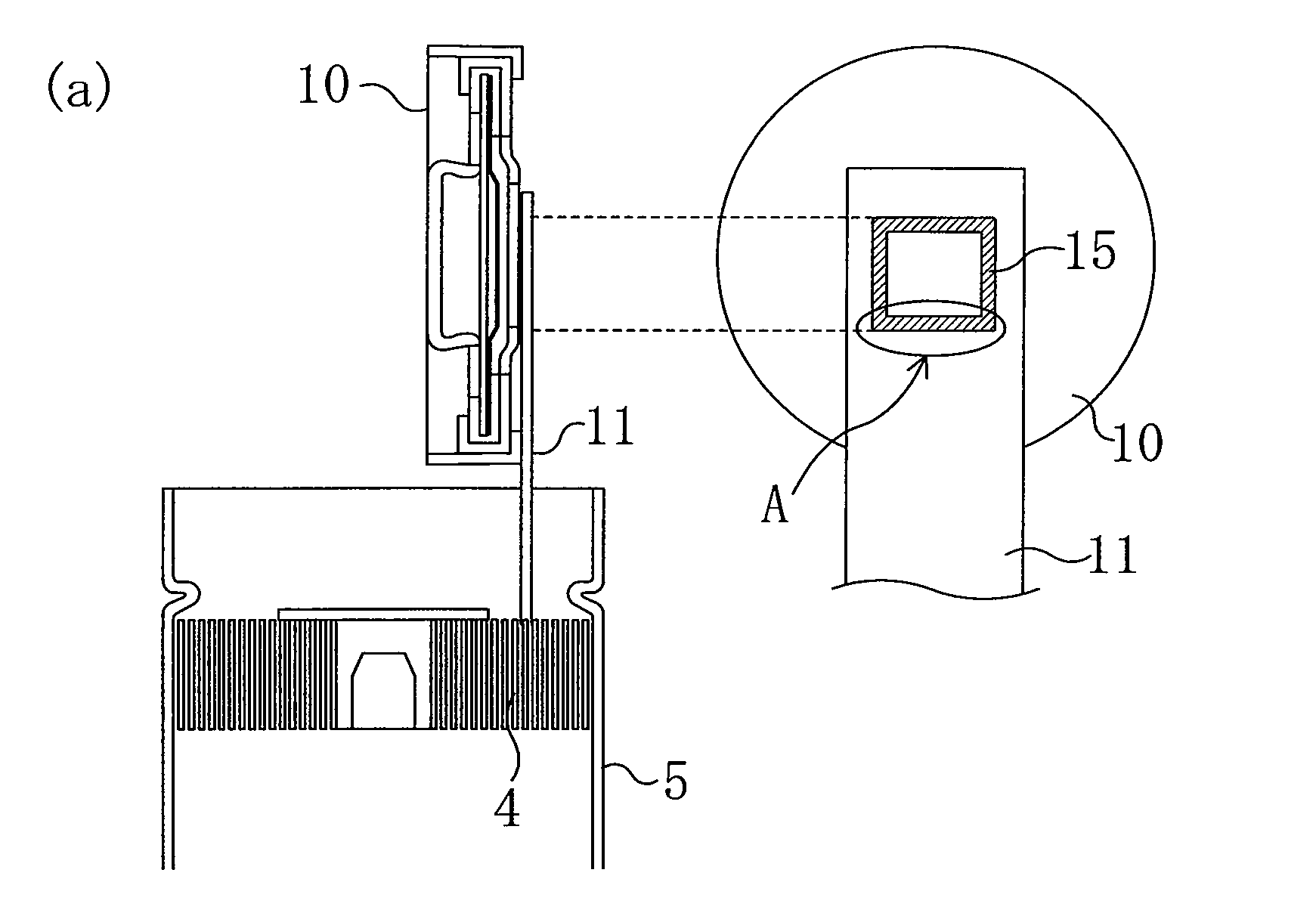

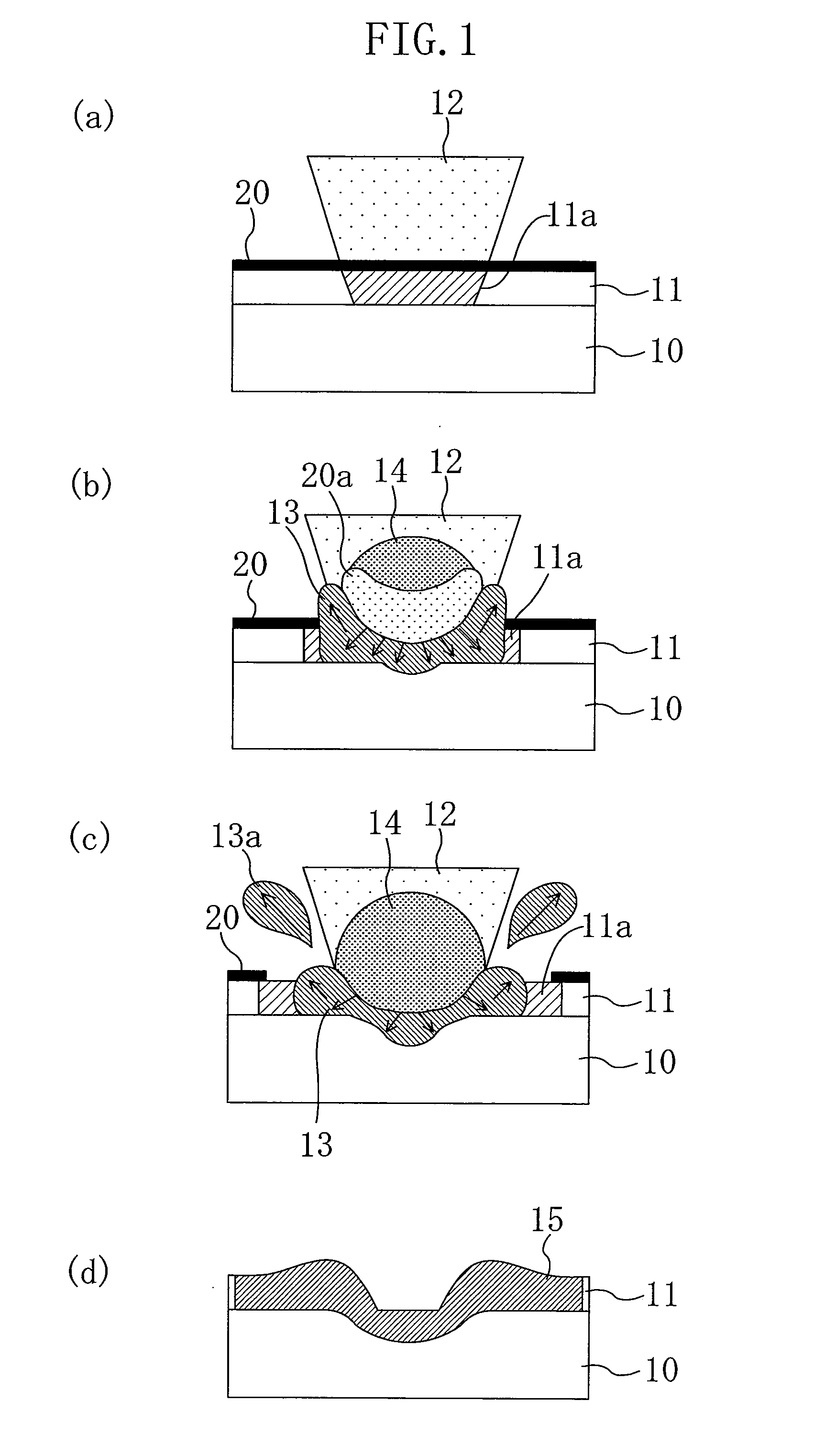

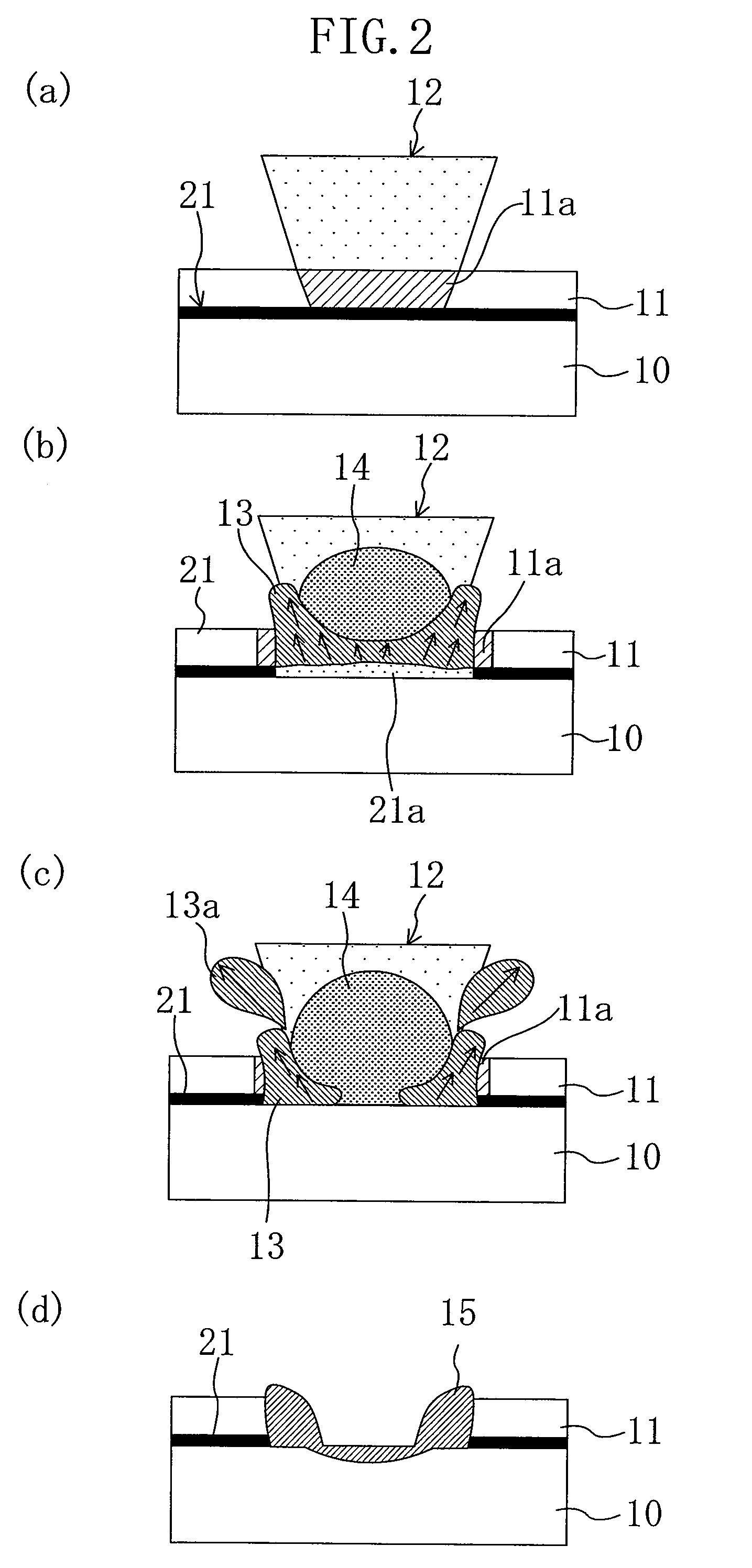

Sealed secondary battery, and method for manufacturing the battery

ActiveUS20100247992A1Stable and reliableReduce sputteringSmall-sized cells cases/jacketsElectrode carriers/collectorsEngineeringElectrical and Electronics engineering

An electrode group 4 formed by stacking or winding a positive electrode plate 1 and a negative electrode plate 2 with a separator 3 interposed therebetween, is housed in a battery case 5. An opening of the battery case 5 is sealed with a sealing plate 10. A lead 11 extending from one of the positive and negative electrode plates in the electrode group 4 is laser-welded to the sealing plate 10 by application of a laser beam 12 having a spot diameter smaller than a thickness of the lead 11.

Owner:PANASONIC CORP

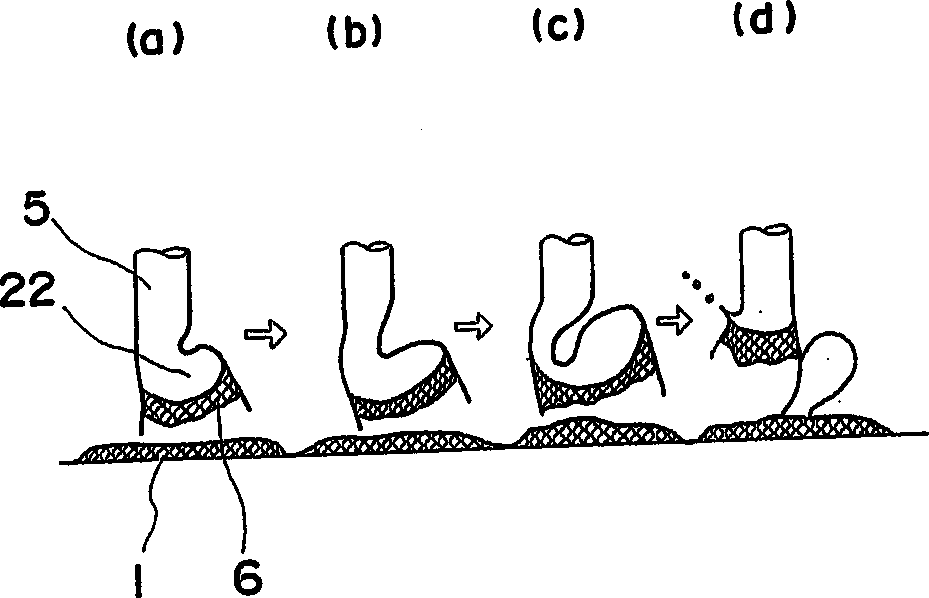

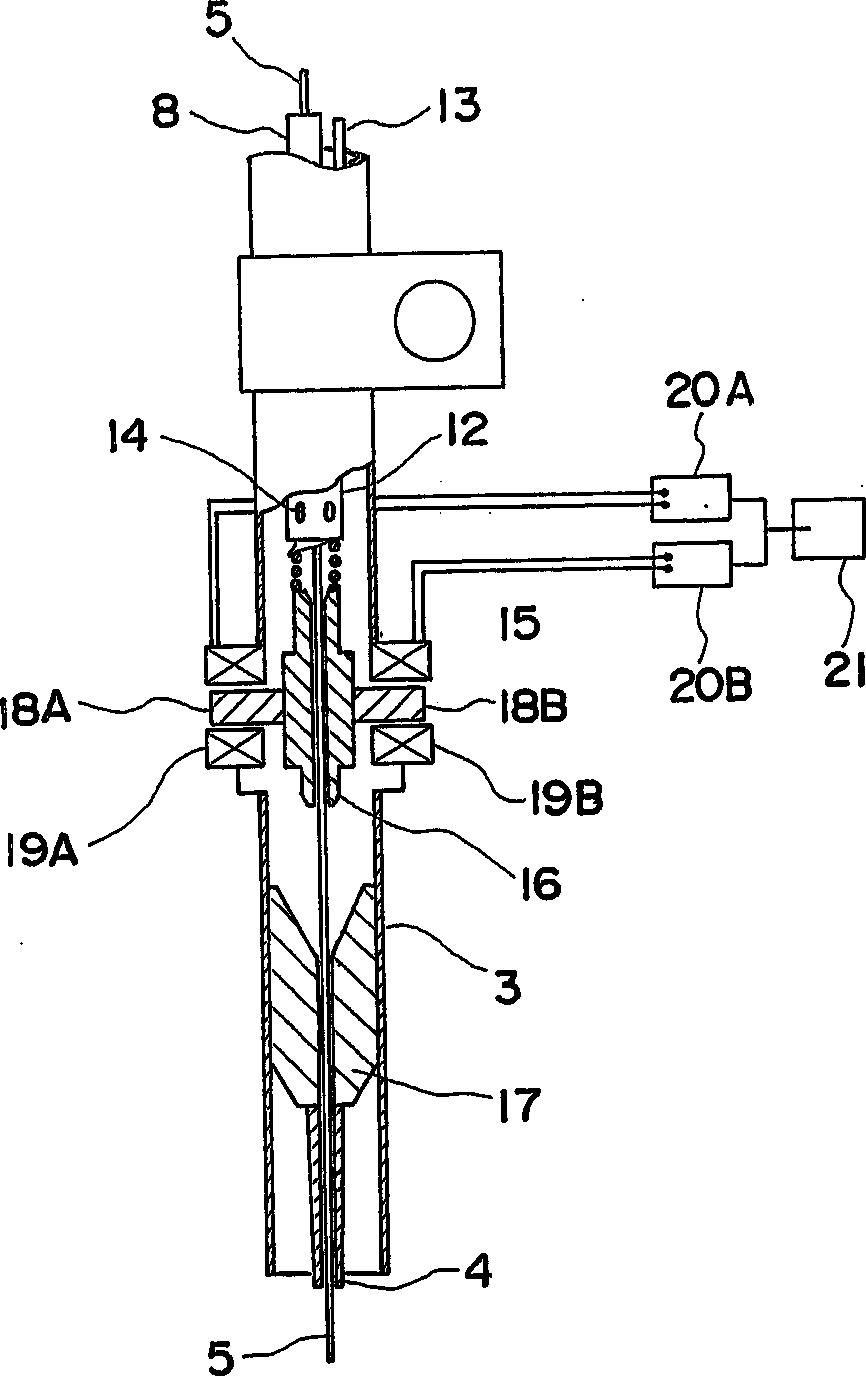

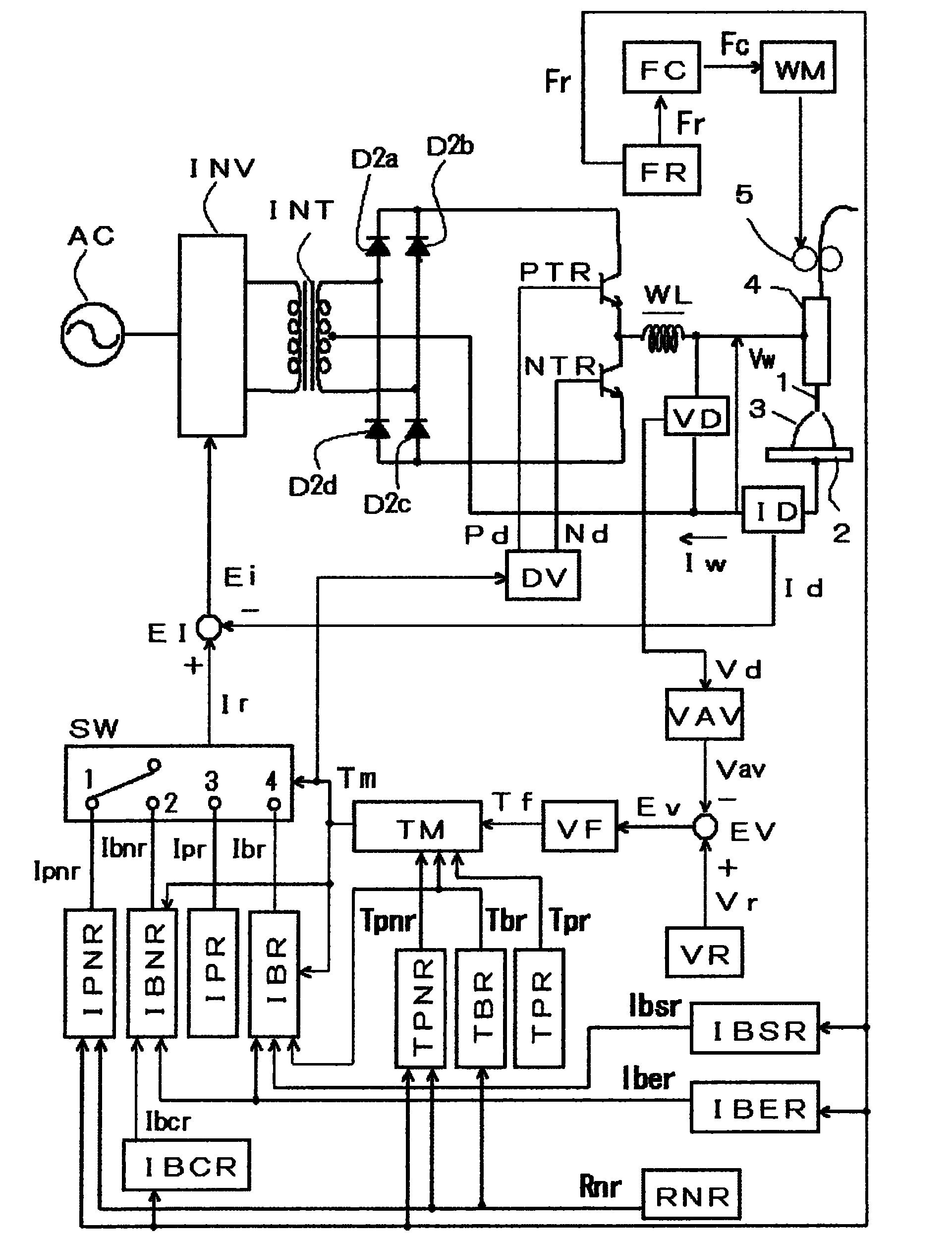

Consumable electrode type arc welding method and device therefor

The present invention provides simple and inexpensive welding method and apparatus adapted to extremely reduce spatters occurring and scattering during a welding operation, even in a welding operation carried out at not lower than substantially 2 m / min. The consumable electrode type arc welding apparatus according to the present invention is provided with a welding power source 23 for controlling a welding current and a welding voltage, a unit 25 for feeding a welding wire to a base metal, a unit 26 for giving the welding wire feeding unit an instruction to feed the welding wire, on the basis of a signal from a short-circuiting / short-circuiting cancellation detector 29, a welding condition setter 24 for setting the welding condition, a welding speed setter 27, a unit 28 for moving a welding torch in accordance with the welding speed, and the short-circuiting / short-circuiting cancellation detector 29 for detecting short-circuiting or short-circuiting cancellation.

Owner:YASKAWA DENKI KK

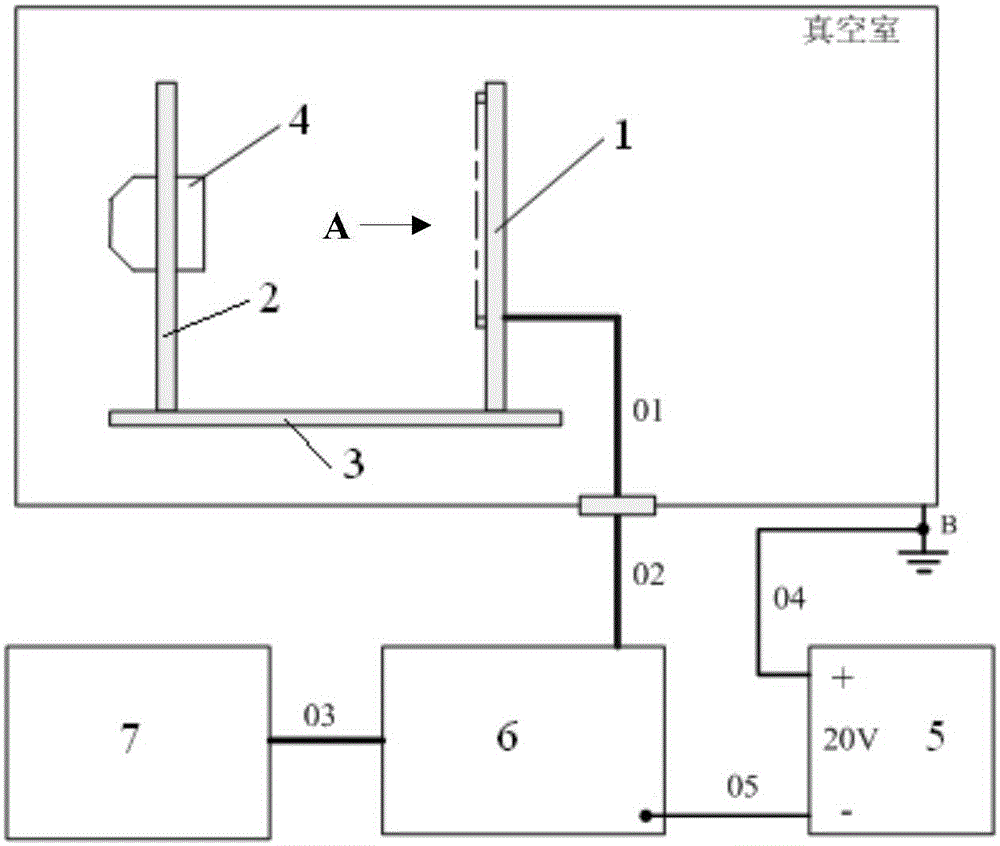

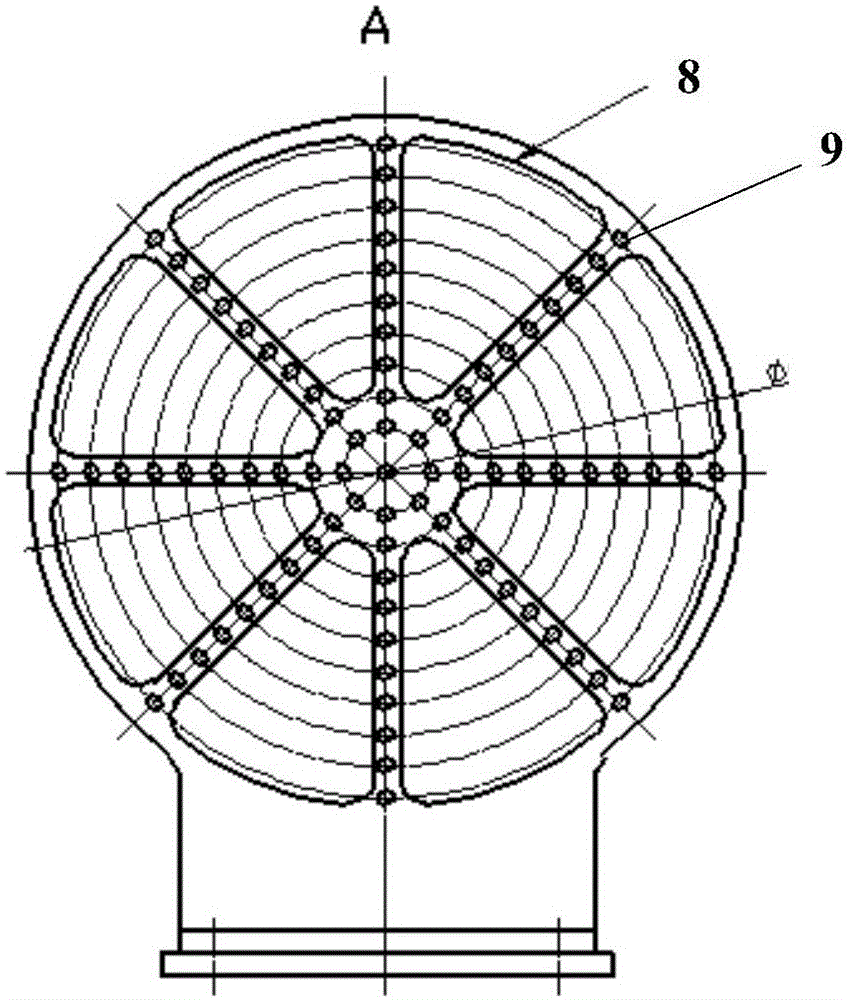

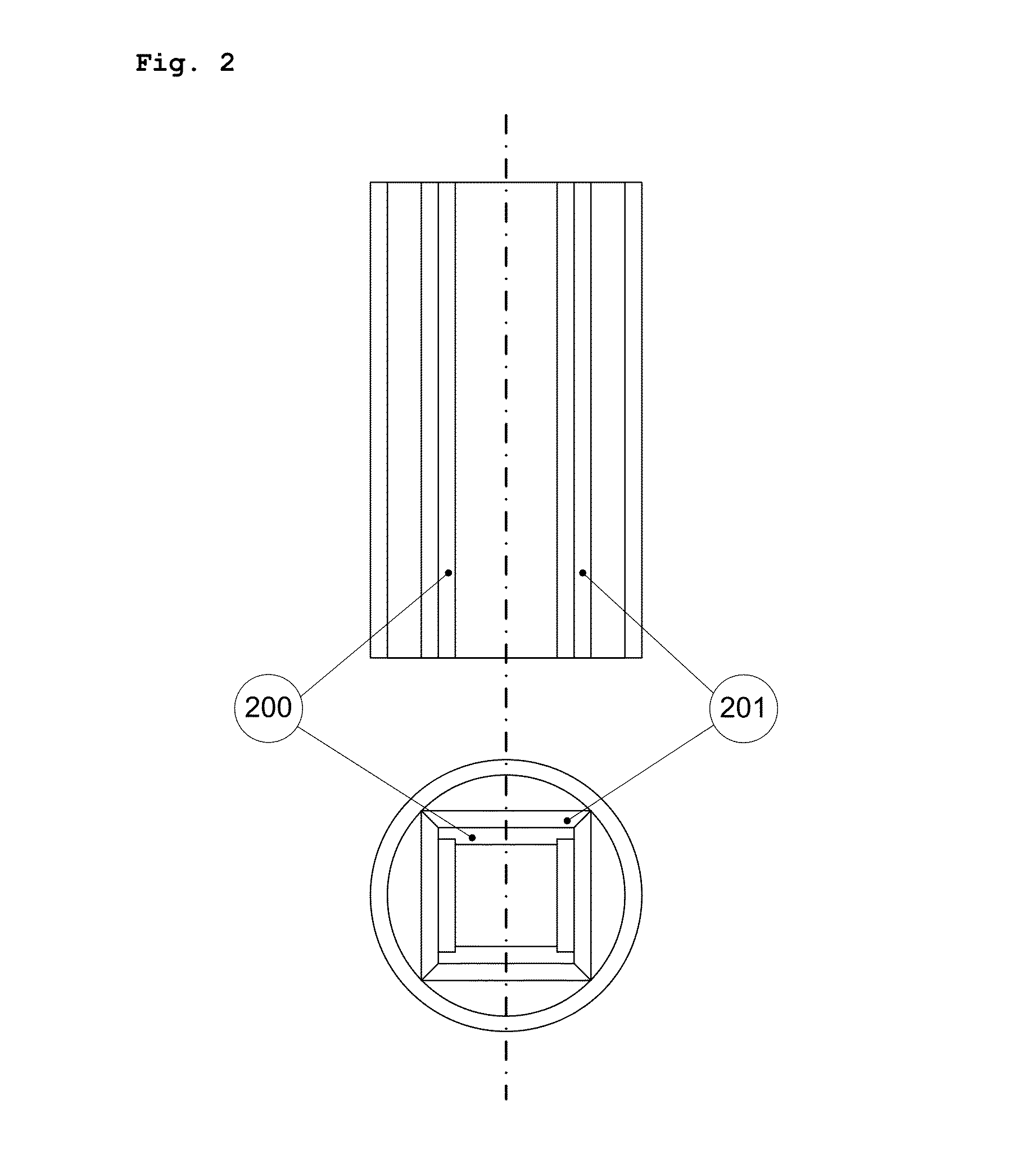

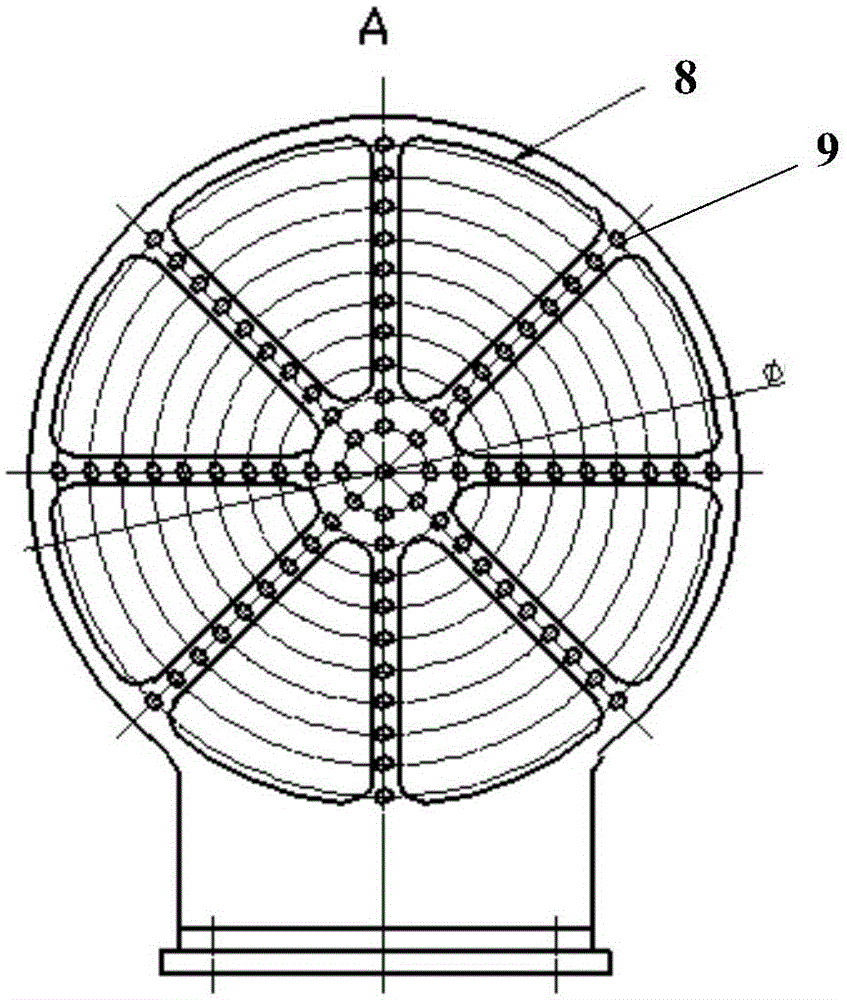

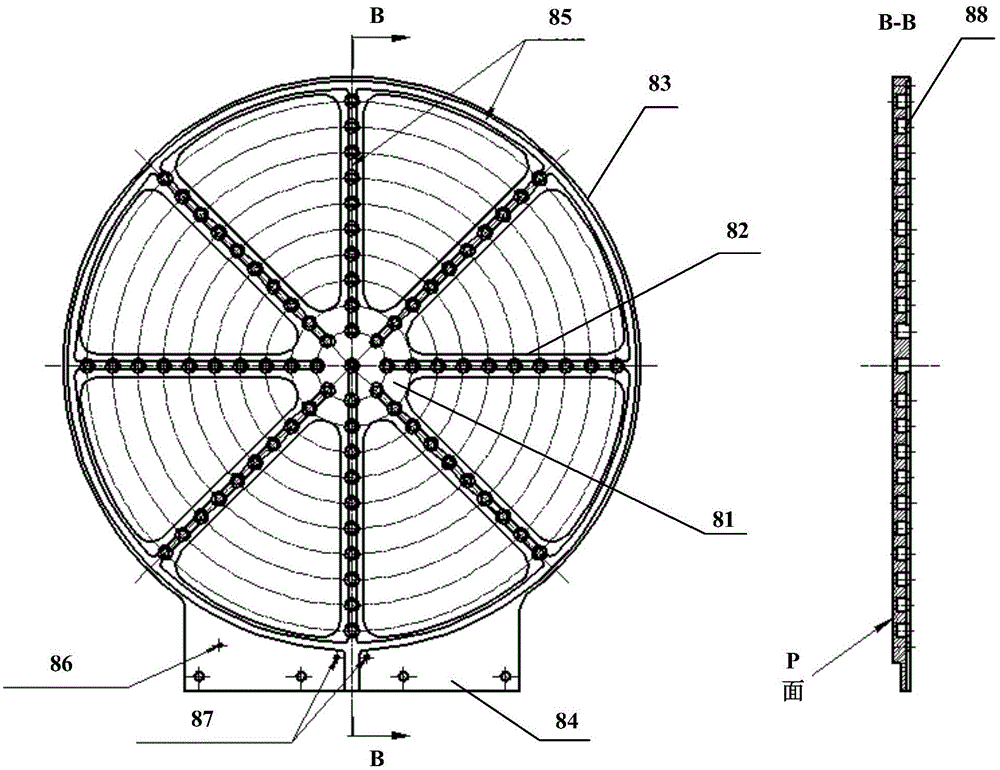

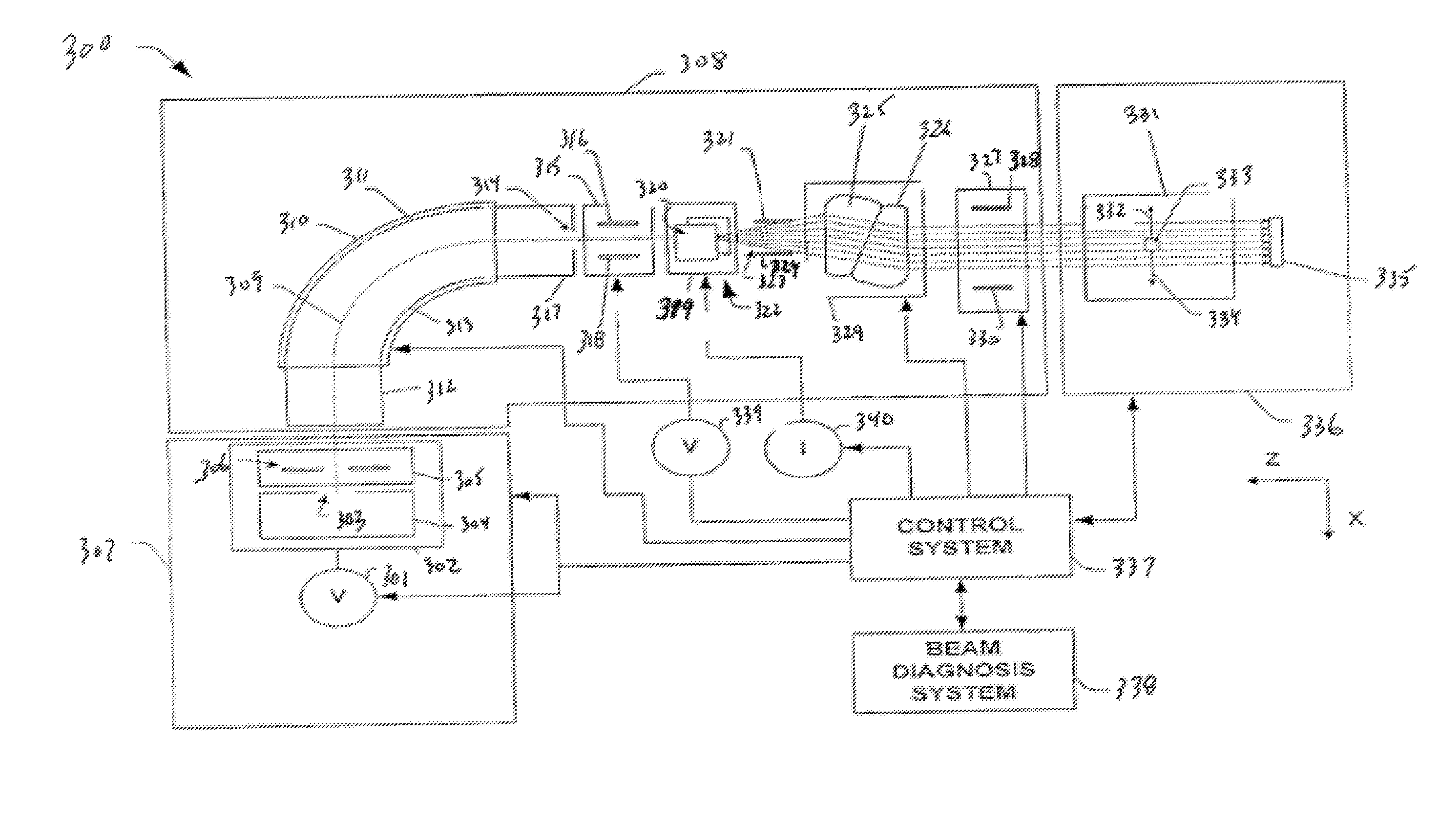

Ion thruster beam test method based on Faraday probe array

ActiveCN105116435ALarge amount of data informationReduce in quantityX/gamma/cosmic radiation measurmentPhysicsType metal

The present invention discloses an ion thruster beam test method based on a Faraday probe array which can test the ion thruster beam distribution, a beam divergence angle and a thrust vector deflection angle simultaneously. All probe test signals are acquired synchronously, the data information amount is large, and the whole test and the data processing can be finished usually in only several minutes. A shielding outer sleeve is arranged at the outer side of an ion current catch tray of each Faraday probe and is directly and electrically connected with a disc-type metal support by metal contact, so that a bias voltage can be supplied to the disc-type metal support by just one conducting wire, and the number of the probe leads is reduced substantially. When the beam divergence angle is calculated, the ion beam current density flow value of which a test current value is less than 5% of an average value is set as zero, thereby reducing a measurement error. A test point is located in the center of a small test area, the beam density measured by the test point is defined as a beam average value of the small area, thereby simplifying the calculation.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

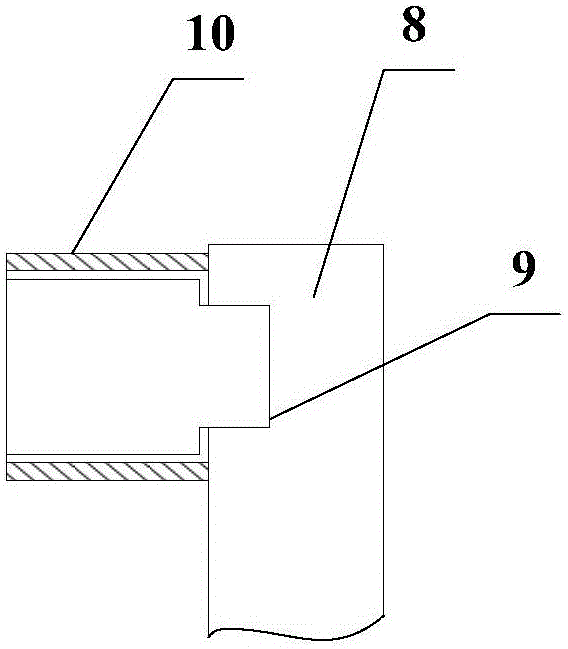

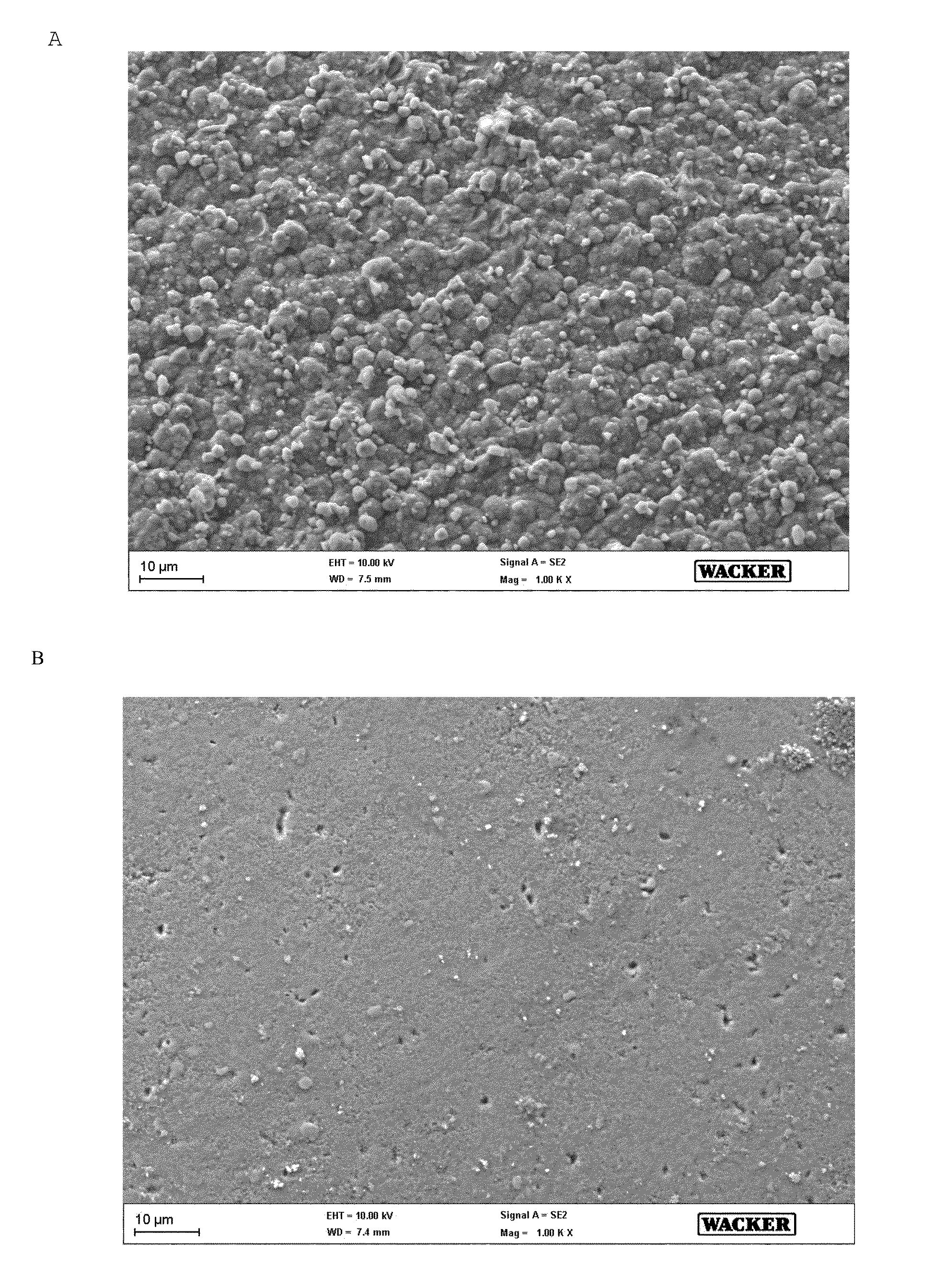

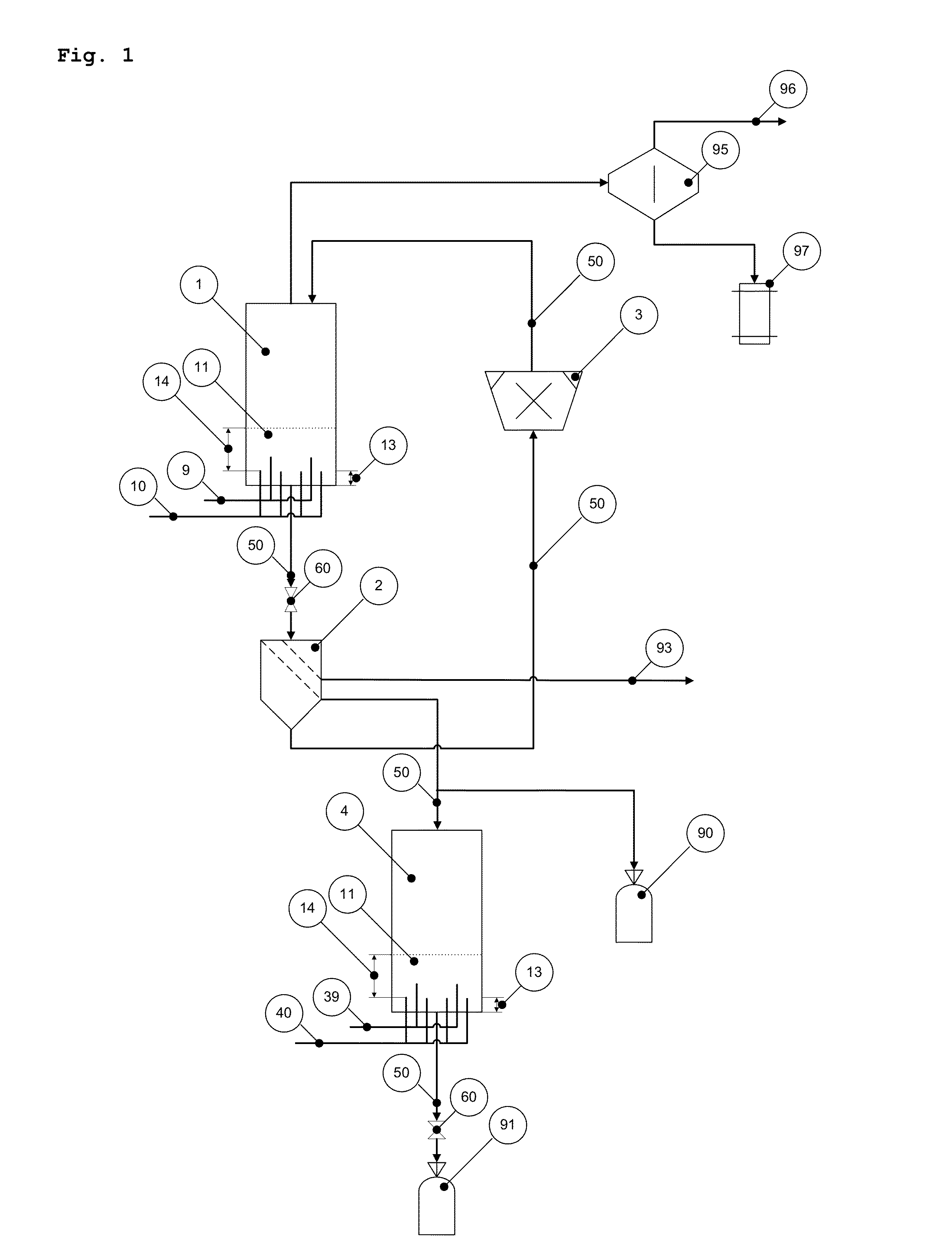

Granular polycrystalline silicon and production thereof

ActiveUS20130295385A1Reduce contentReduce sputteringLiquid surface applicatorsSiliconFluidized bedPhysical chemistry

Granular polycrystalline silicon includes a compact matrix including radiating acicular crystal aggregates of crystal size from 0.001-200 μm. A process for producing granular polycrystalline silicon includes producing granular silicon in a fluidized bed reactor from a gas mixture containing TCS (20-29 mol %) and hydrogen at a fluidized bed temperature of 900-970° C., dividing the granular silicon in a screen system having at least one screen deck into at least two screen fractions, the smallest screen fraction being ground in a grinding system to give seed particles having a size of 100-1500 μm and a mass-based median value from 400 to 900 μm, and these seed particles being supplied to fluidized bed reactor, and a further screen fraction being supplied to a fluidized bed reactor, and being surface-treated with a gas mixture containing TCS (5.1-10 mol %) and hydrogen at a fluidized bed temperature of 870-990° C.

Owner:WACKER CHEM GMBH

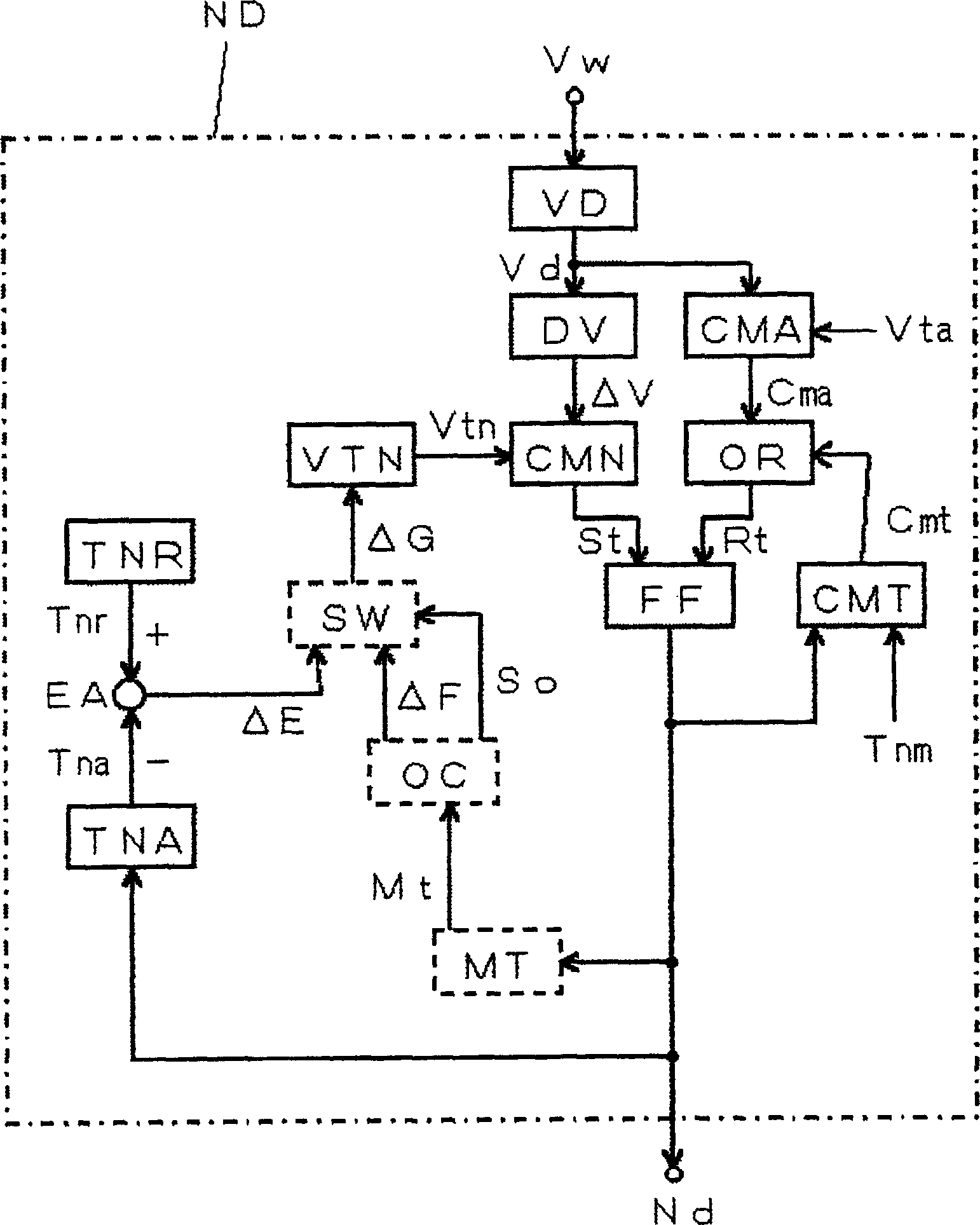

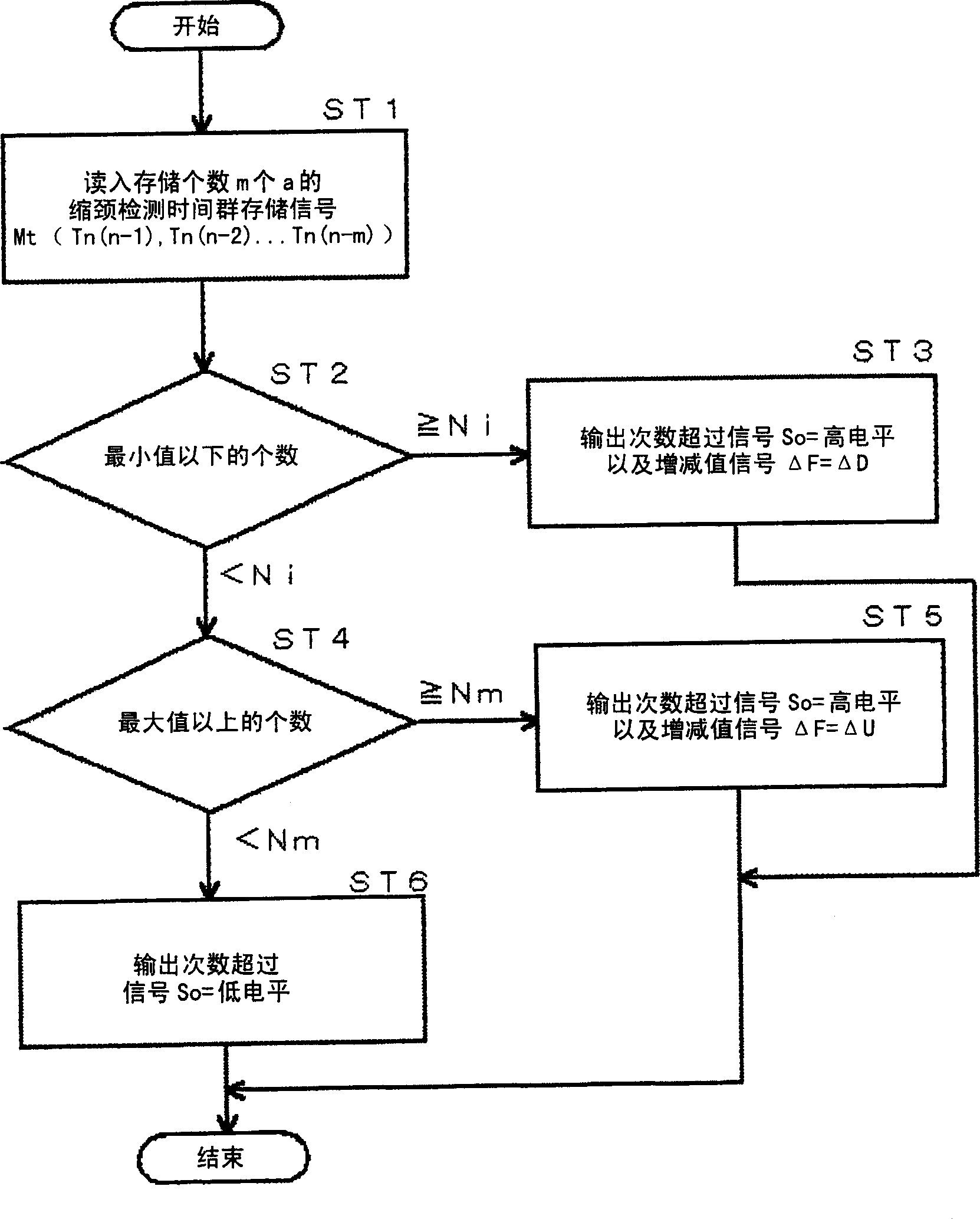

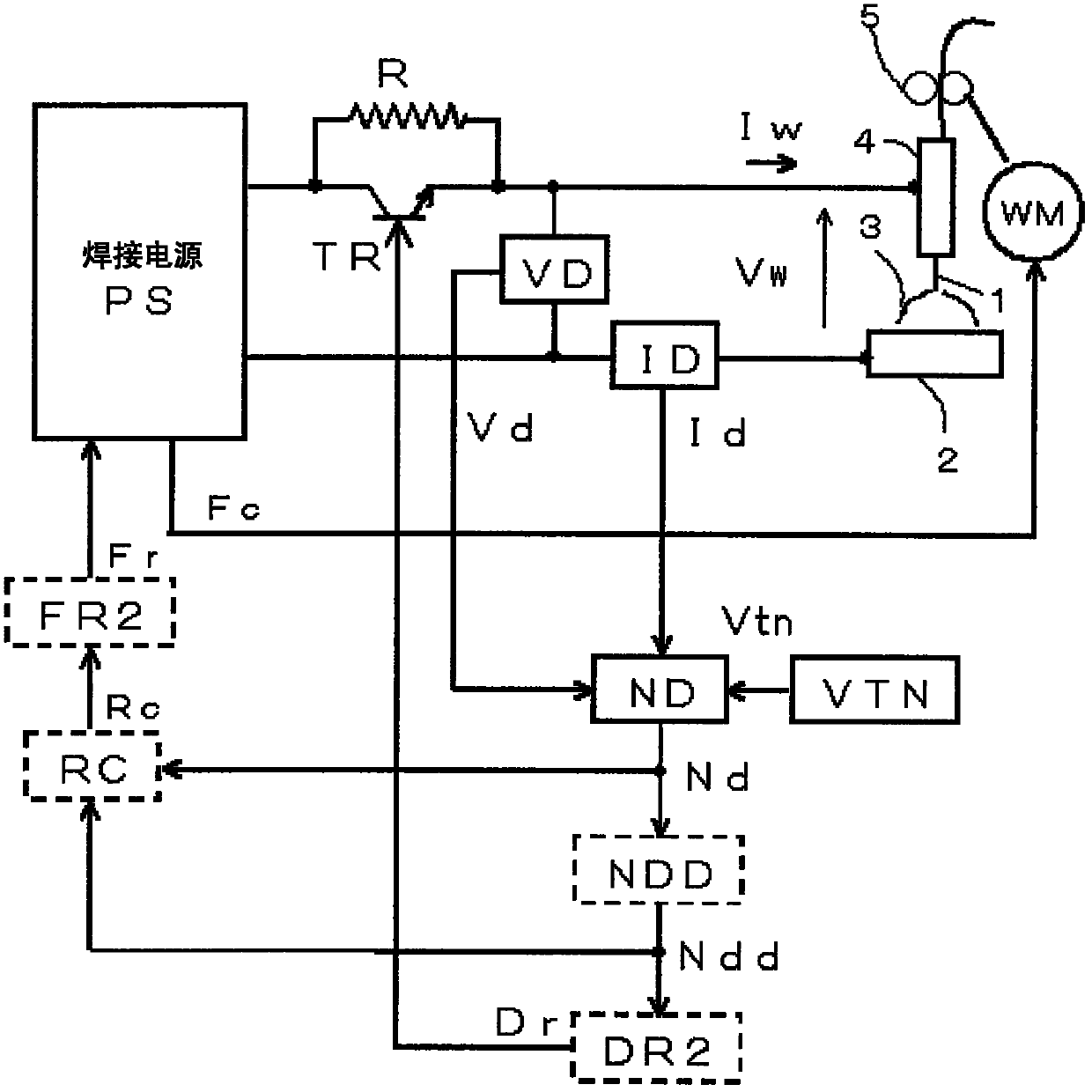

Necking checking and control method for melted electrode arc welding

ActiveCN1840277ACorrection will not be excessiveThe control system is stableArc welding apparatusElectrical resistance and conductancePower flow

The present invention purposes to improve accuracy of detecting constriction in a method for detecting / controlling constriction in consumable electrode arc welding attended with a short circuit. In this method for detecting / controlling constriction in consumable electrode arc welding, the constrictive phenomenon of a droplet as a sign phenomenon of regeneration of arc from a short-circuit state is detected by that a change in a voltage or resistance value between a consumable electrode and a base metal reaches a reference value Vtn for detecting the constriction, thereby a welding current is rapidly reduced. The constriction detecting time is detected for each short-circuit, storing the detecting time from the current point of time retroactively to the prescribed number of time in the past (MT). When the number of each stored constriction detecting time (Mt) below the minimum value inclusive is not less than the minimum number, the reference value Vtn for detecting the constriction is decreased by the variation [Delta]F. When the number of each stored constriction detecting time (Mt) above the maximum value inclusive is not less than the maximum number, the reference value Vtn for detecting the constriction is increased by the variation [Delta]F. Thus, the reference value Vtn for detecting the constriction is optimized.

Owner:DAIHEN CORP

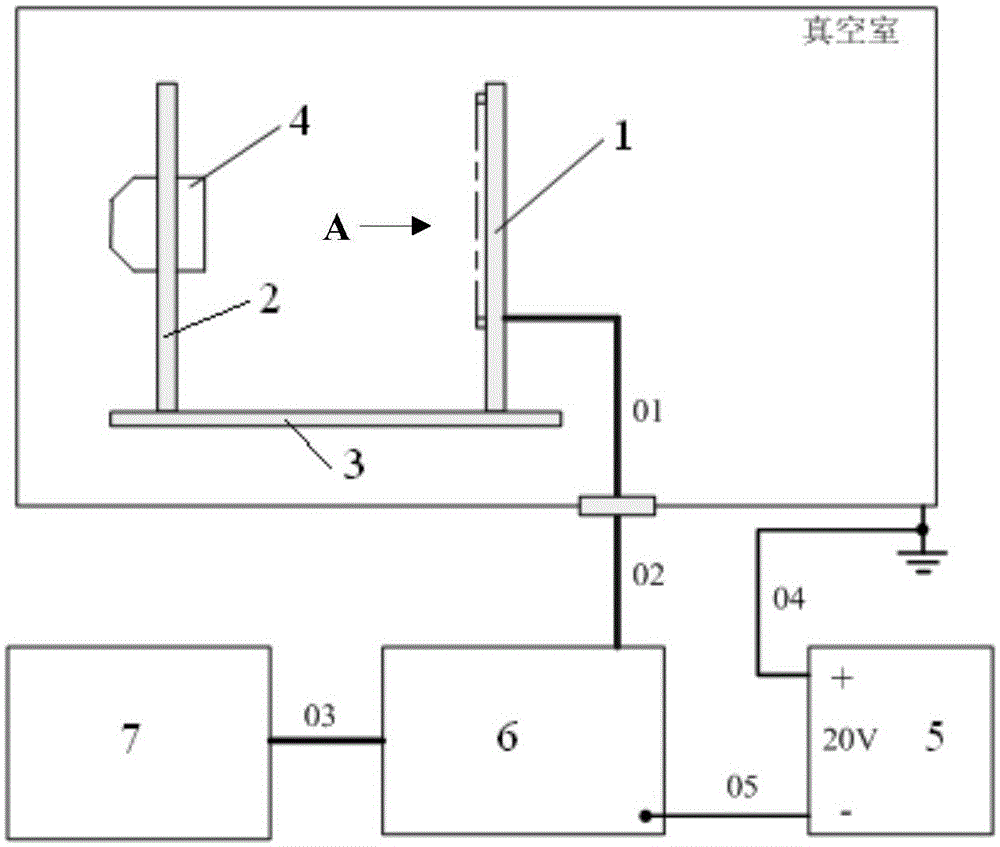

Ion thruster beam test system based on Faraday probe array

ActiveCN105116436ALarge amount of data informationRealize positioning installationX/gamma/cosmic radiation measurmentElectricityIon current

The present invention discloses an ion thruster beam test system based on a Faraday probe array. According to the present invention, the Faraday probes are arranged in a surface array manner, all probe test signals are acquired synchronously, the data information amount is large, and the whole test and the data processing can be finished usually in only several minutes. A shielding outer sleeve is arranged at the outer side of an ion current catch tray of each Faraday probe and is used to shield the stray ions flying to the side surface of the ion current catch tray, thereby guaranteeing that the ions are only collected on the right side of the ion current catch tray. The shielding outer sleeve is directly and electrically connected with a disc-type metal support by the metal contact, so that a bias voltage can be supplied to the disc-type metal support by just one conducting wire, and the biggest advantages of the mode are that: the number of the probe leads is reduced substantially, the structure is simplified, and the reliability is improved.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

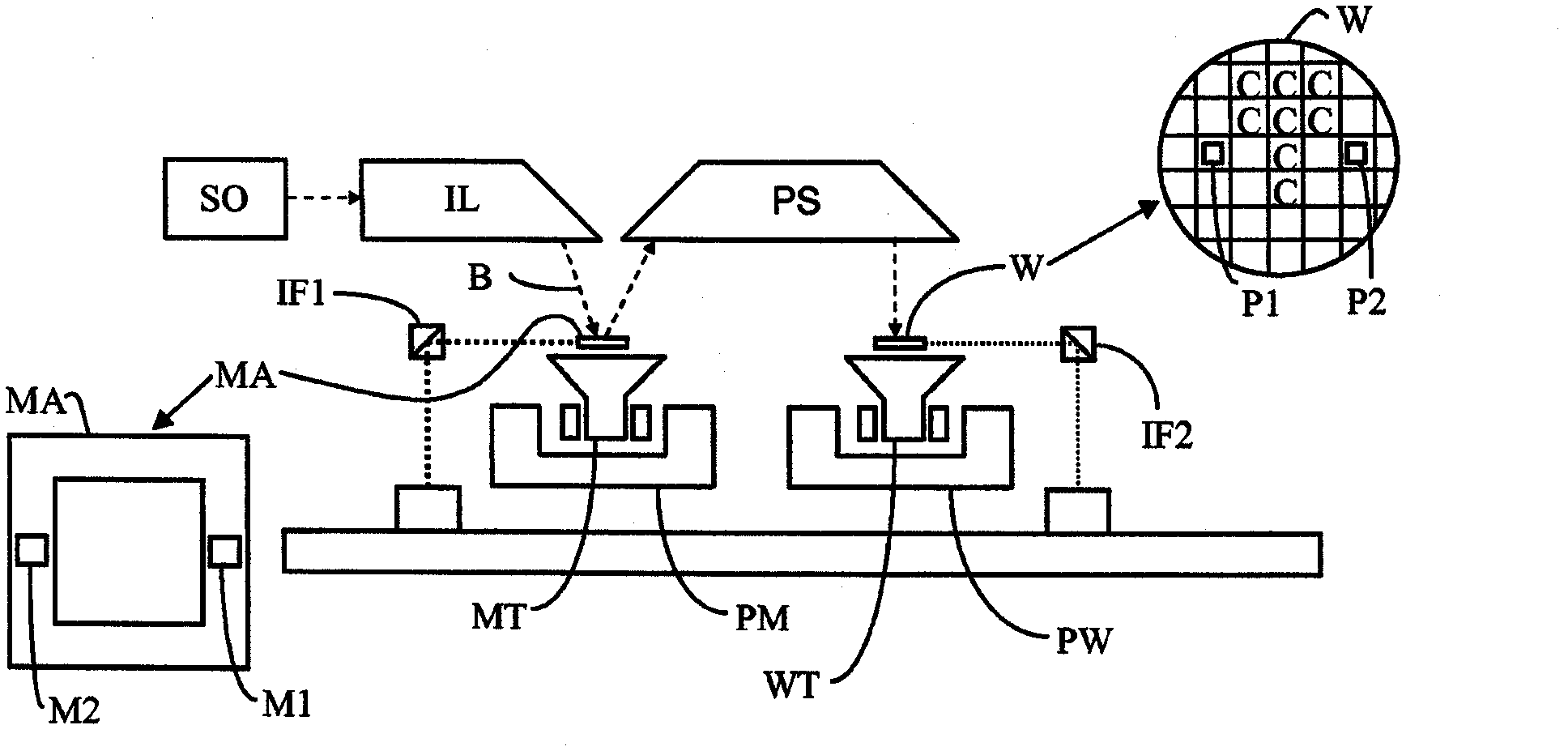

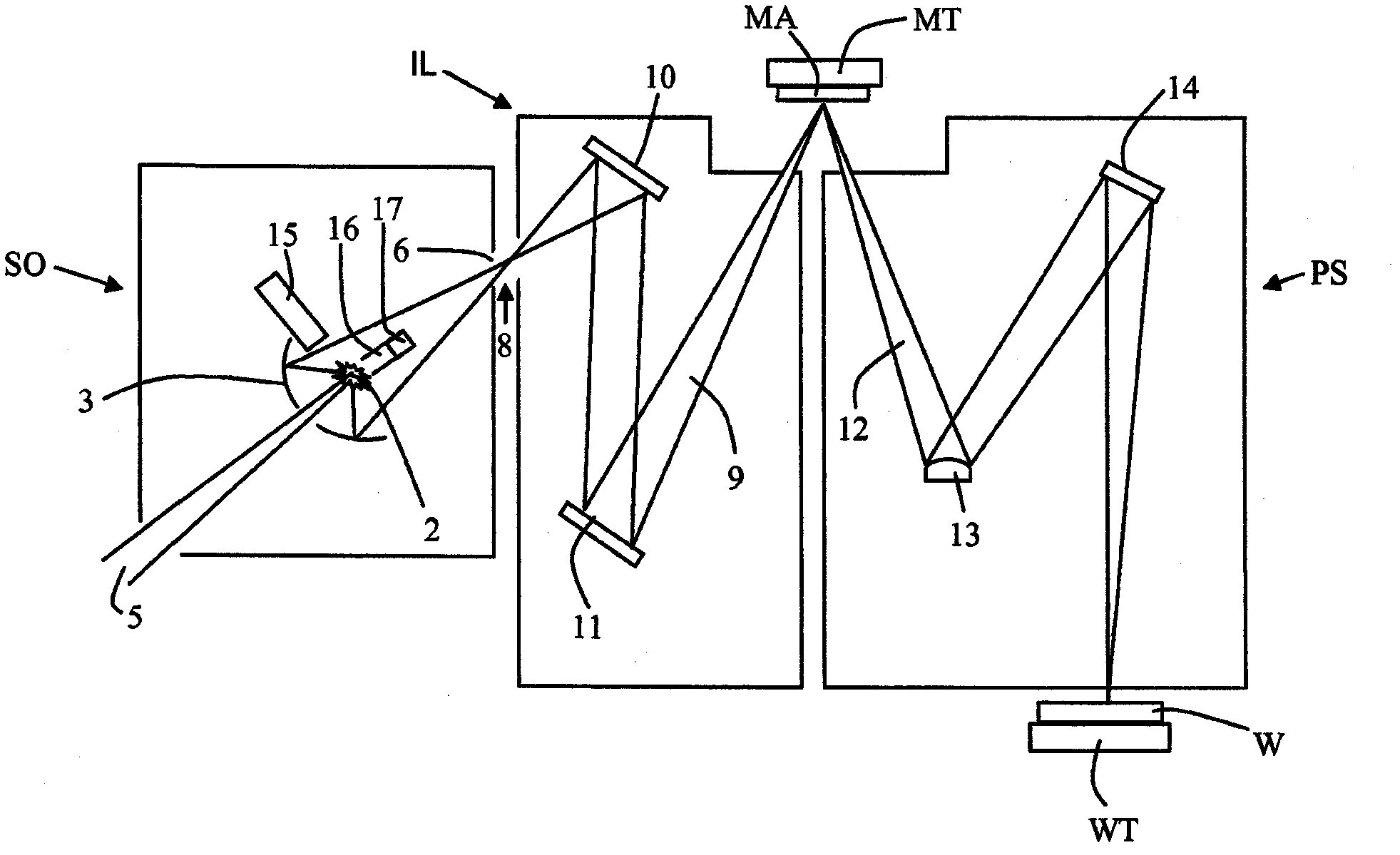

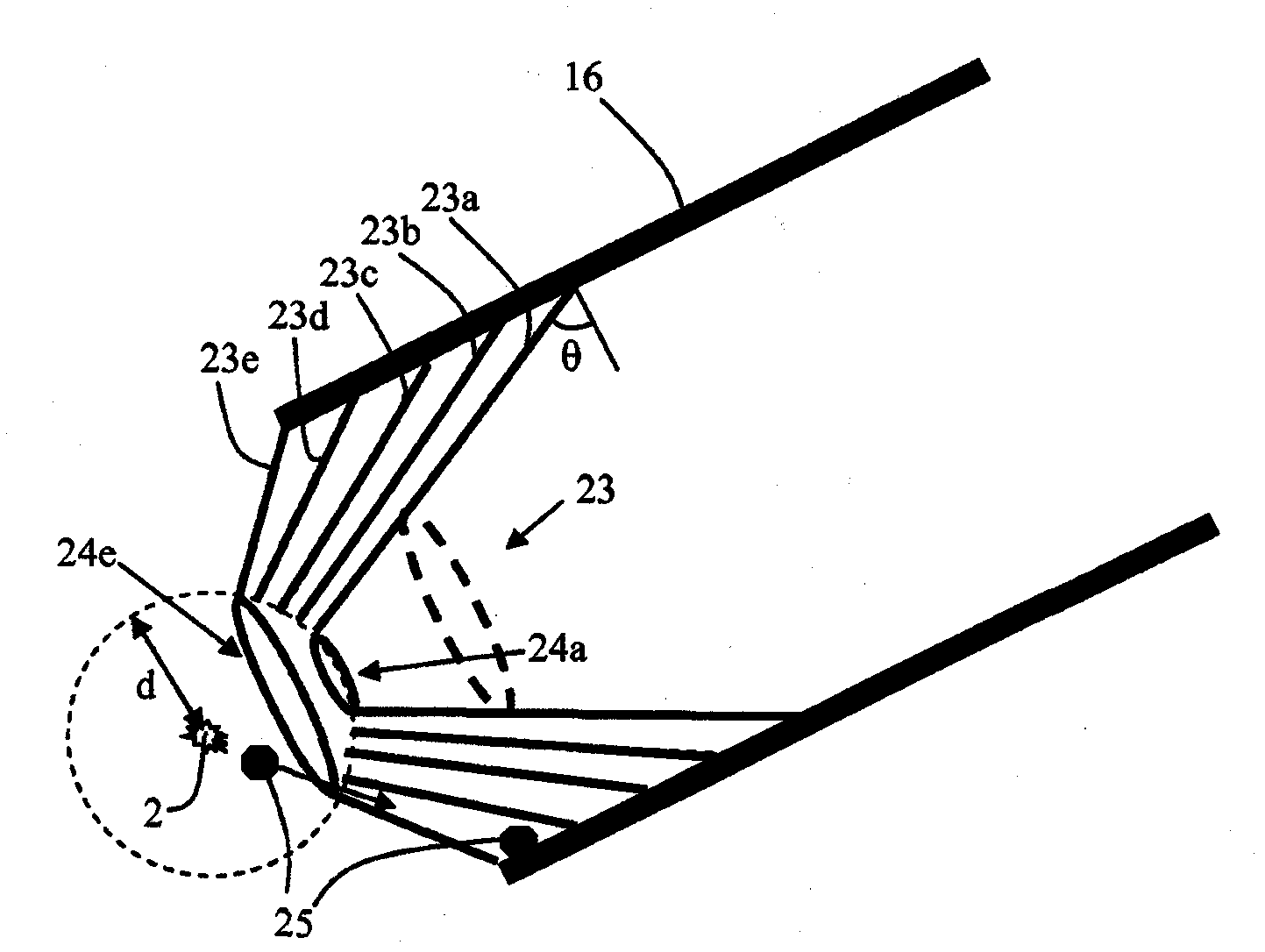

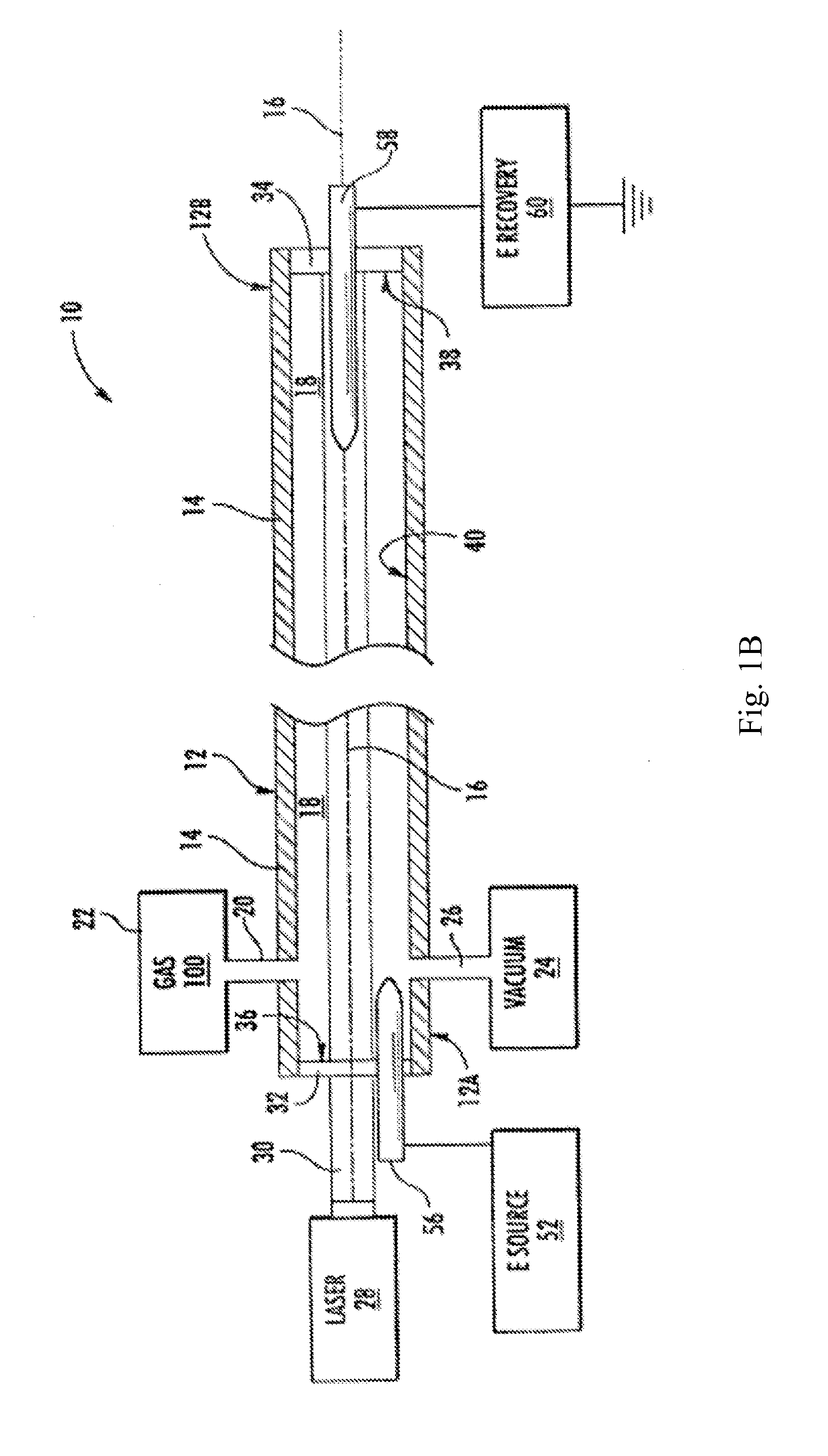

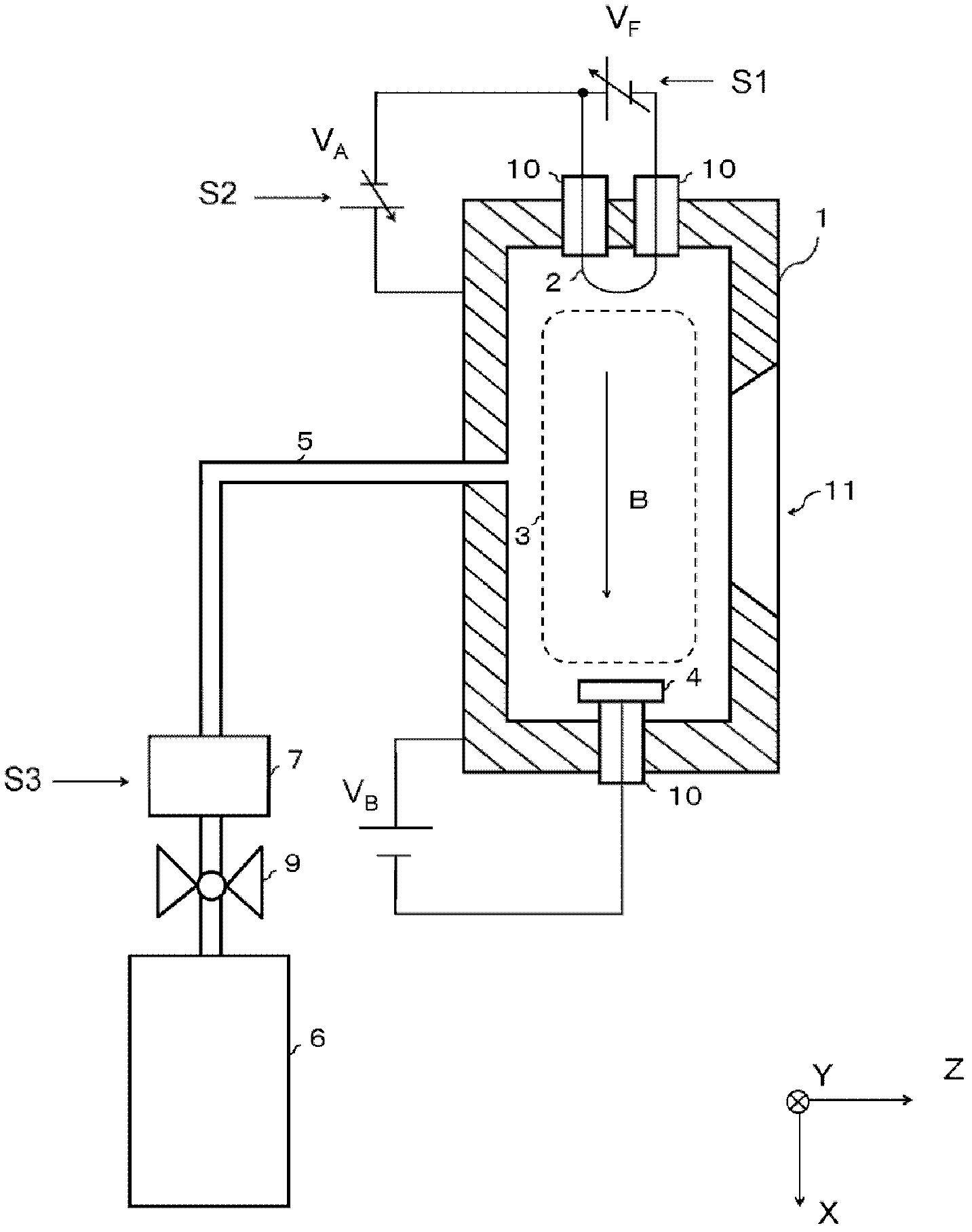

Radiation source and lithographic apparatus

ActiveCN102144191AReduce scatterReduce sputteringSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusUltraviolet radiationExtreme ultraviolet

A radiation source (SO) is configured to generate extreme ultraviolet radiation. The radiation source (SO) includes a plasma formation site (2) located at a position in which a fuel will be contacted by a beam of radiation (5) to form a plasma, an outlet (16) configured to allow gas to exit the radiation source (SO), and a contamination trap (23) at least partially- located inside the outlet (16). The contamination trap is configured to trap (23) debris particles that are generated with the formation of the plasma.

Owner:ASML NETHERLANDS BV

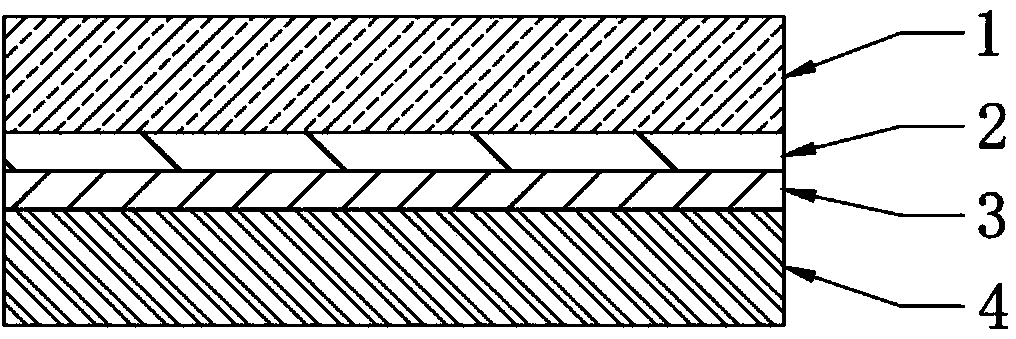

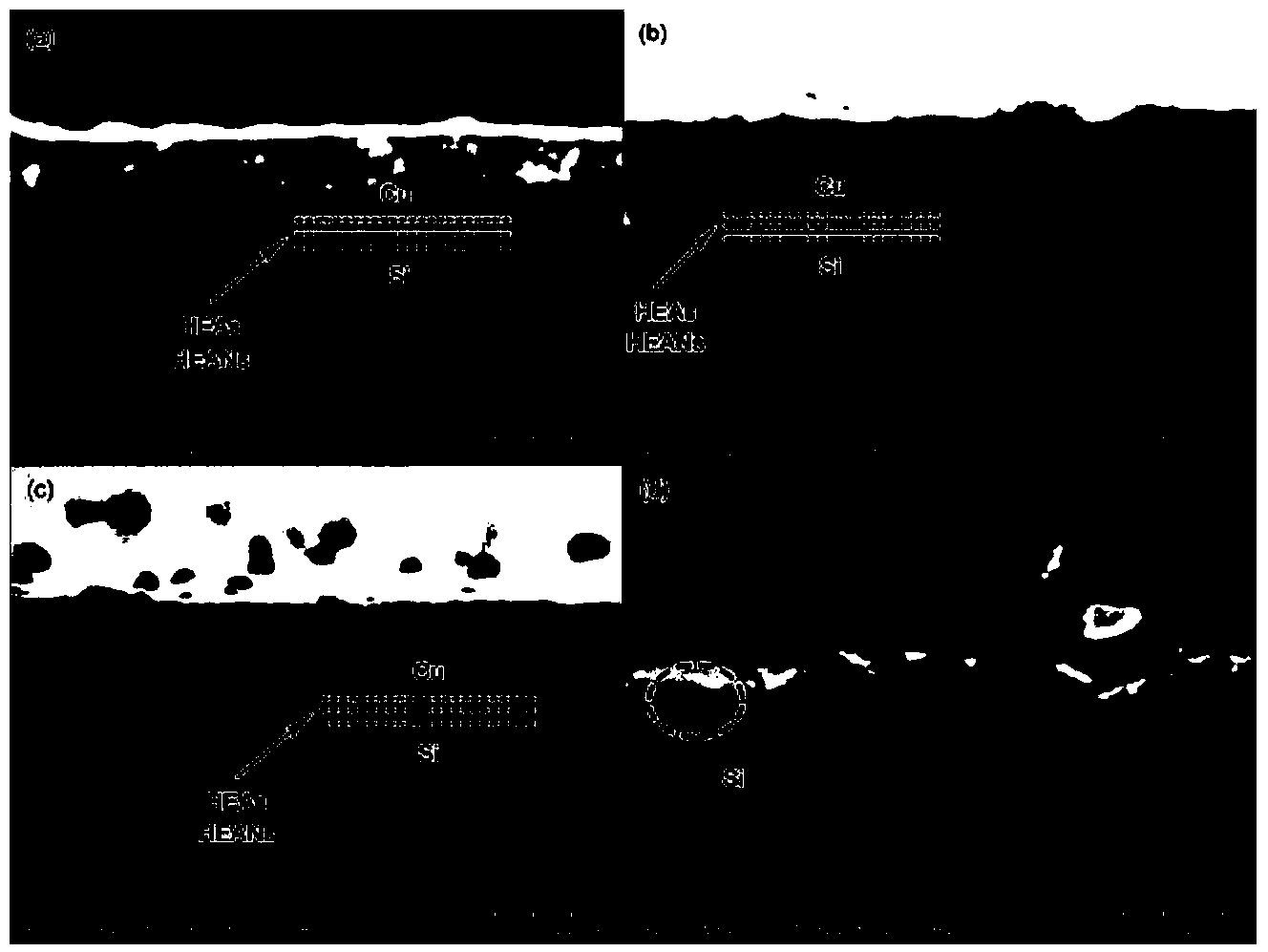

Preparing method for double-layer high-entropy alloy diffusion barrier layer

InactiveCN103966566AImprove thermal stabilityHigh bonding strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysMegasonic cleaning

The invention discloses a preparing method for a double-layer high-entropy alloy diffusion barrier layer. The method comprises the following steps: cleaning a single crystal Si base in an ultrasonic way; removing impurities in the single crystal Si base in an anti-sputtering cleaning way, and removing impurities in target materials and target sheets in a pre-sputtering cleaning way; depositing an HEANs thin film on the single crystal Si base in a sputtering way under the condition that the flow ratio of Ar to N is 1:(0.65-0.9); depositing an HEAs thin film on the ANs thin film in a sputtering way by using the Ar as the working gas when the thickness of the HEANs thin film reaches the designed thickness; adjusting the vacuum degree in a furnace to the degree not lower than 10-3 Pa when the thickness of the HEAs thin film reaches the designed thickness, and naturally cooling and releasing from the furnace to obtain the double-layer high-entropy alloy diffusion barrier layer. For the double-layer high-entropy alloy diffusion barrier layer obtained by the method, the method has the advantages that the bonding strength among the base, the Cu and the barrier layer is improved, and the whole heat stability of the diffusion barrier layer is improved. The method also has the characteristics of skillful technique for the preparing technology, low cost, low pollution and the like.

Owner:SICHUAN UNIV

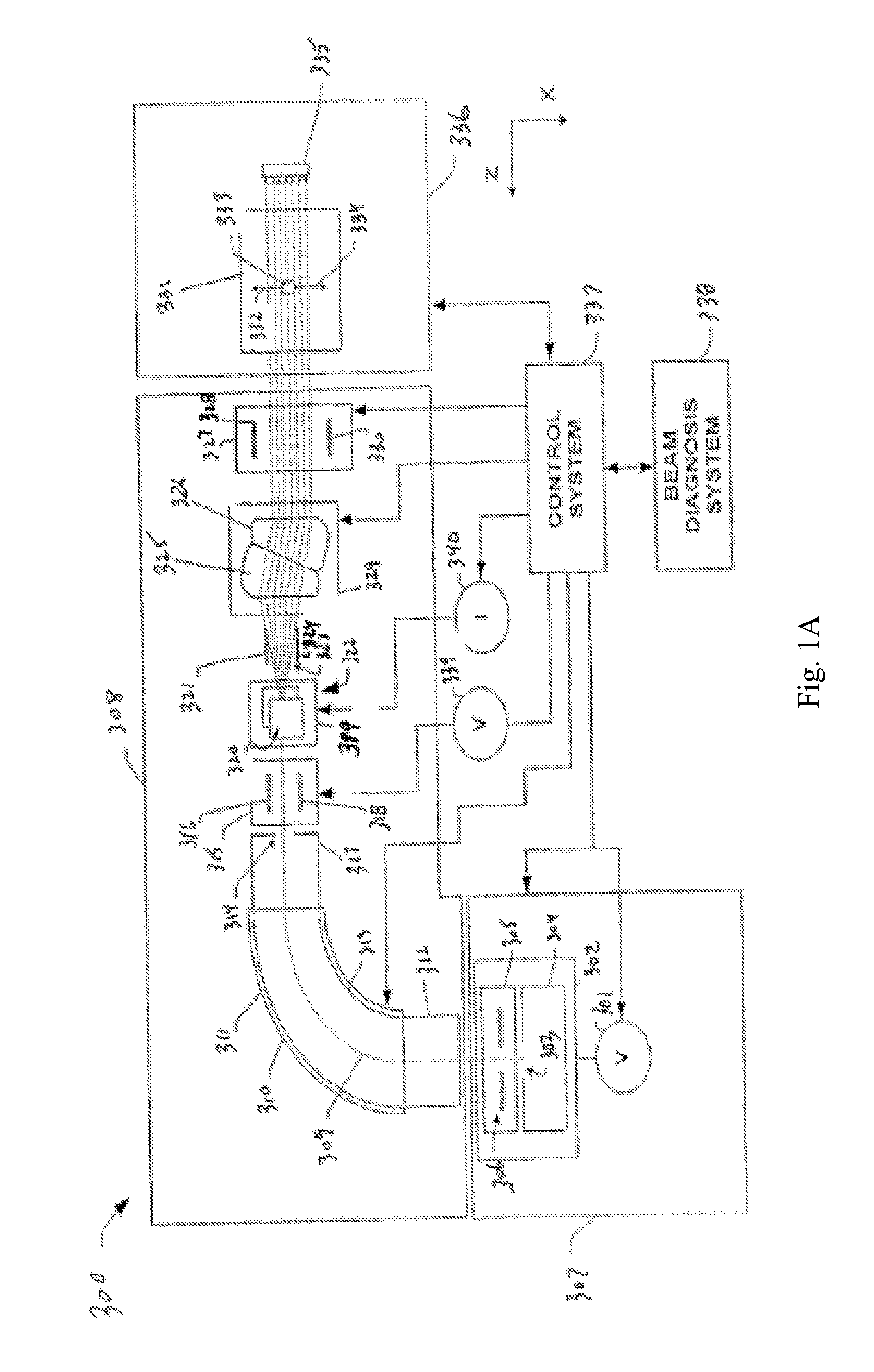

Adjustable mass resolving aperture

ActiveUS20140261173A1Improve uniformityIncrease productivityLiquid surface applicatorsVacuum evaporation coatingElectrical conductorMass ratio

Embodiments of the invention relate to a mass resolving aperture that may be used in an ion implantation system that selectively exclude ions species based on charge to mass ratio (and / or mass to charge ratio) that are not desired for implantation, in an ion beam assembly. Embodiments of the invention relate to a mass resolving aperture that is segmented, adjustable, and / or presents a curved surface to the oncoming ion species that will strike the aperture. Embodiments of the invention also relate to the filtering of a flow of charged particles through a closed plasma channel (“CPC”) superconductor, or boson energy transmission system.

Owner:GLENN LANE FAMILY LIMITED LIABILITY

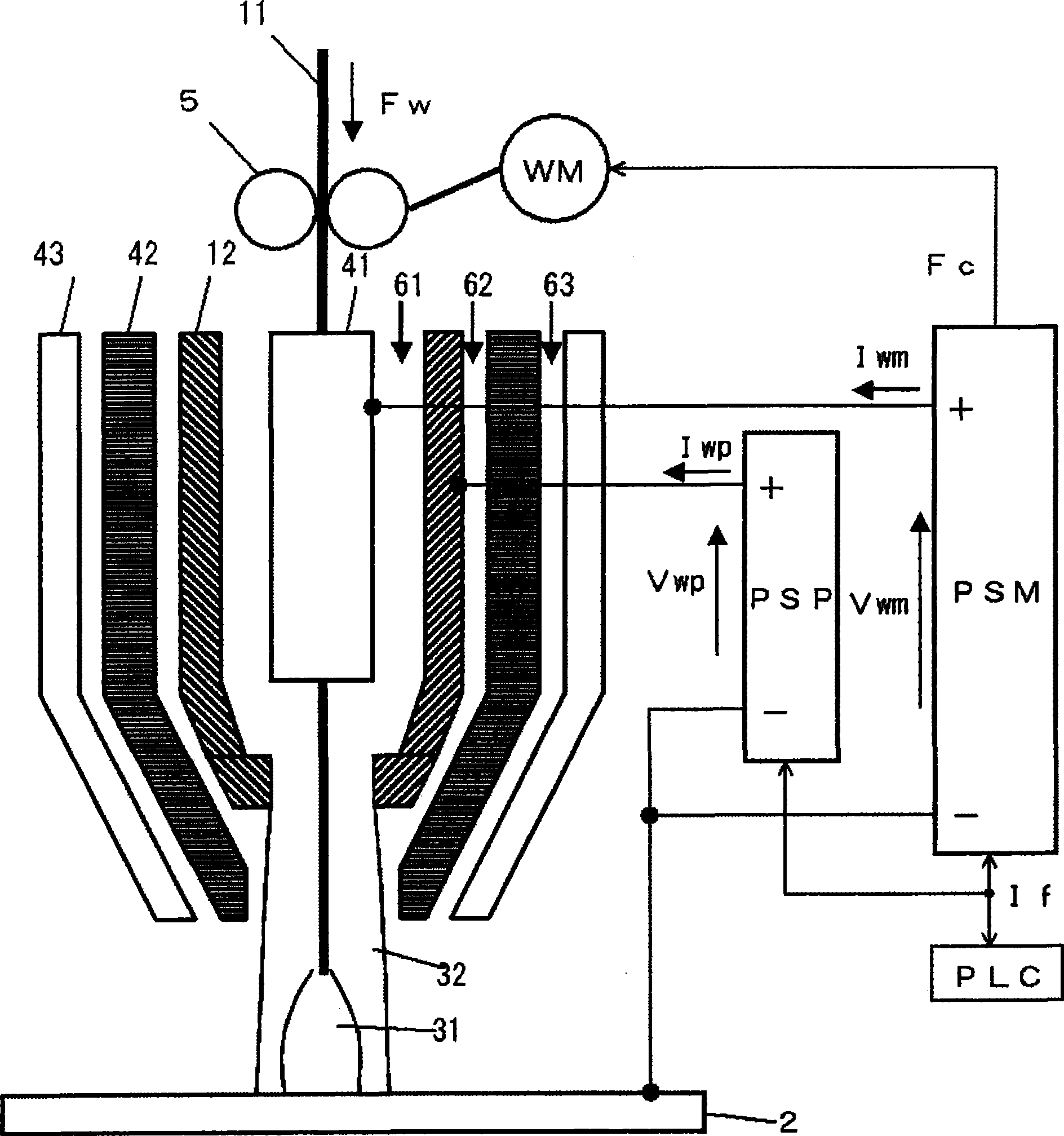

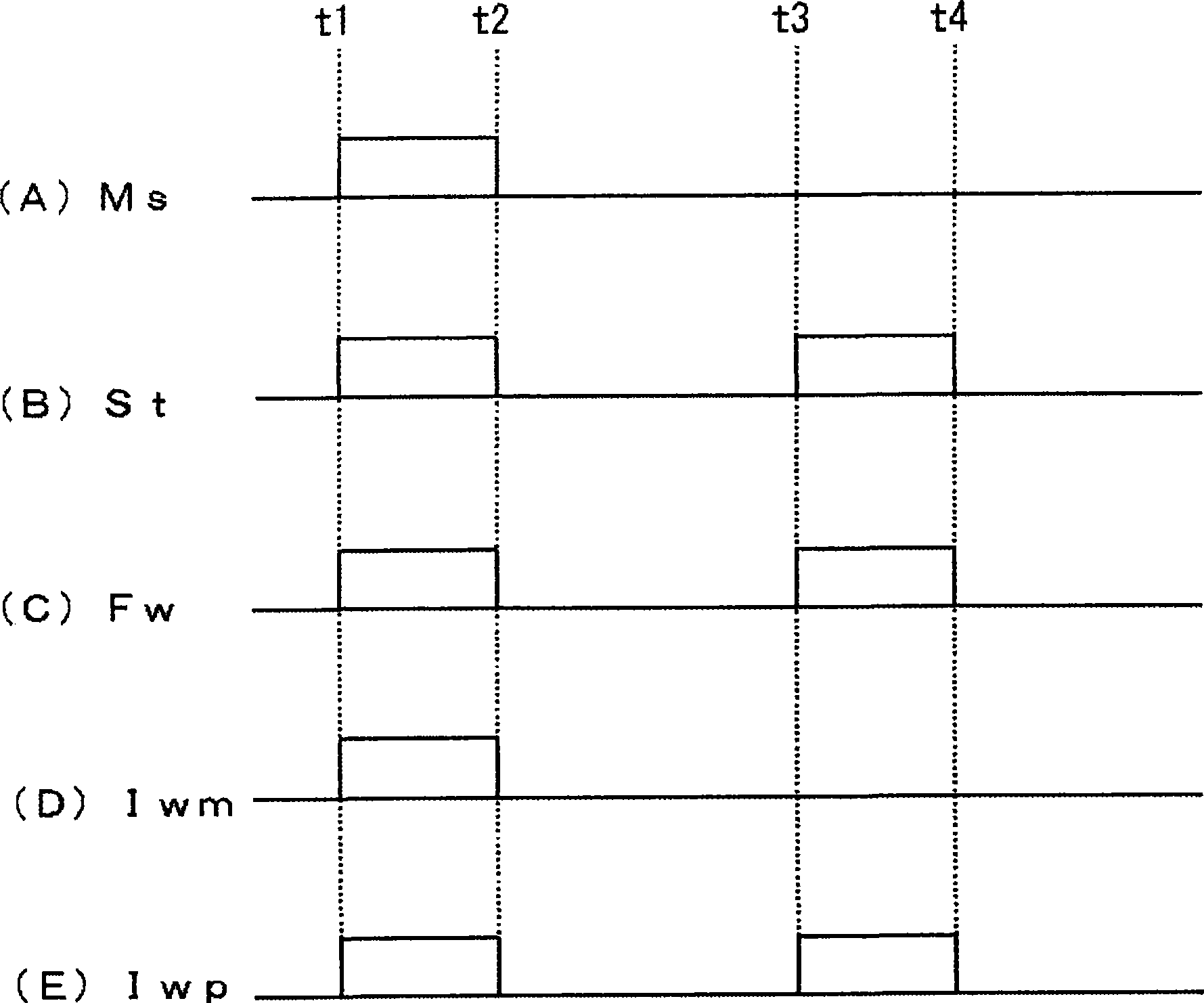

Welding method of plasma pole noble gas protection

The present invention provides a welding method of plasma pole noble gas protection, in the plasma metal pole noble gas protection welding method, a welding wire (11) inside a gas protection injecting nozzle (43) and welding blow lamp of a plasma electrode (12) make metal pole noble gas electric arc (31) caused by the welding wire (11) and plasma electric arc (32) caused by the plasma electrode (12) generated and welded at the same time; a welding mode selective signal, and when the welding mode selective signal is in plasma metal pole noble gas welding mode, the plasma electric arc (32) and the metal pole noble gas electric arc (31) are generated at the same time; when the welding mode selective signal is in plasma welding mode, the plasma electric arc (32) is generated and the metal pole noble gas electric arc (31) is not generated, which only feeds to the welding wire (11), and melts the welding wire (11) while welding through the plasma electric arc (32). Hence, the plasma pole noble gas protection welding is suitable for easy burnt electric arc or weld bead appearance work piece in high quality without added sputter.

Owner:DAIHEN CORP

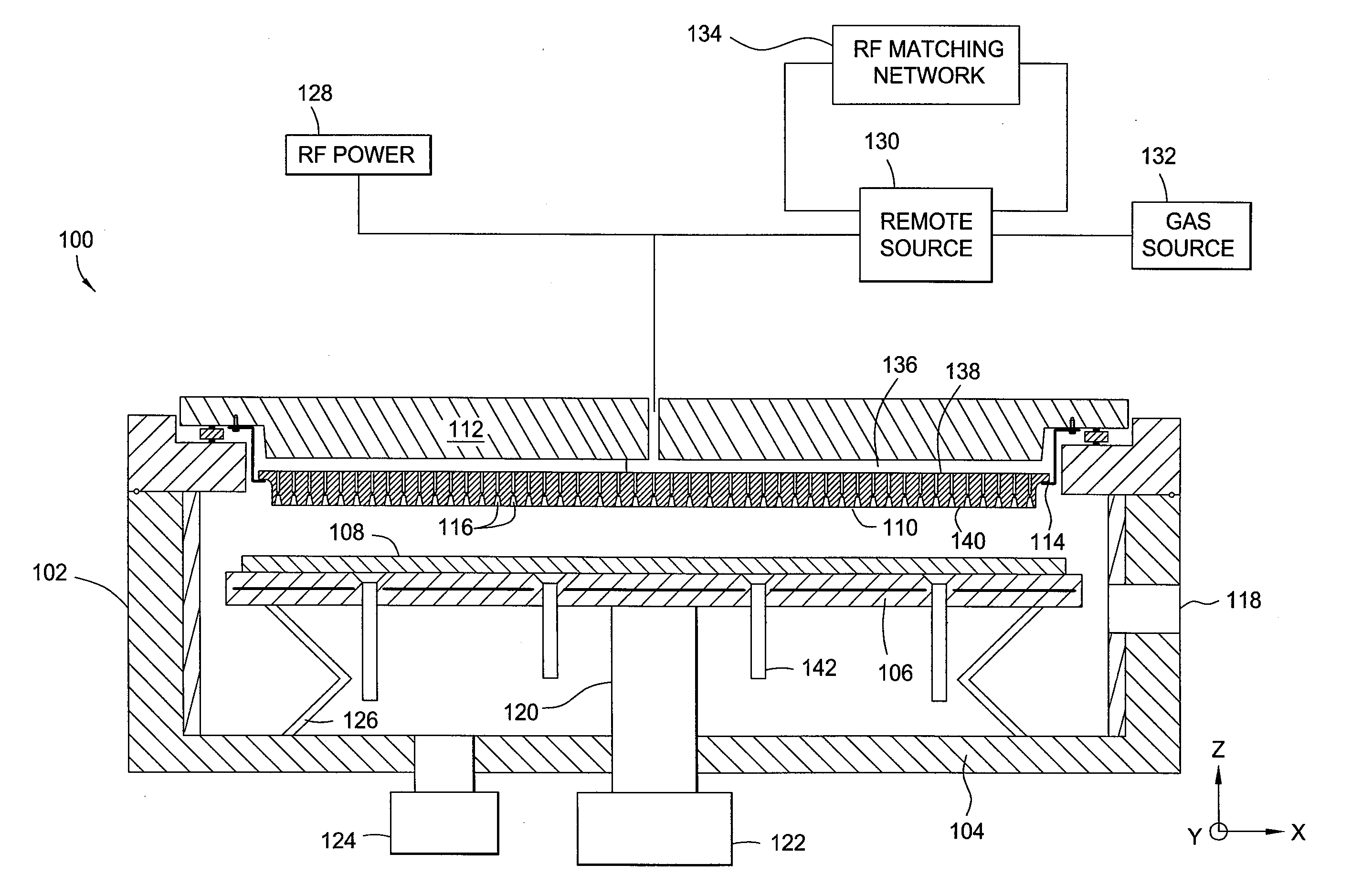

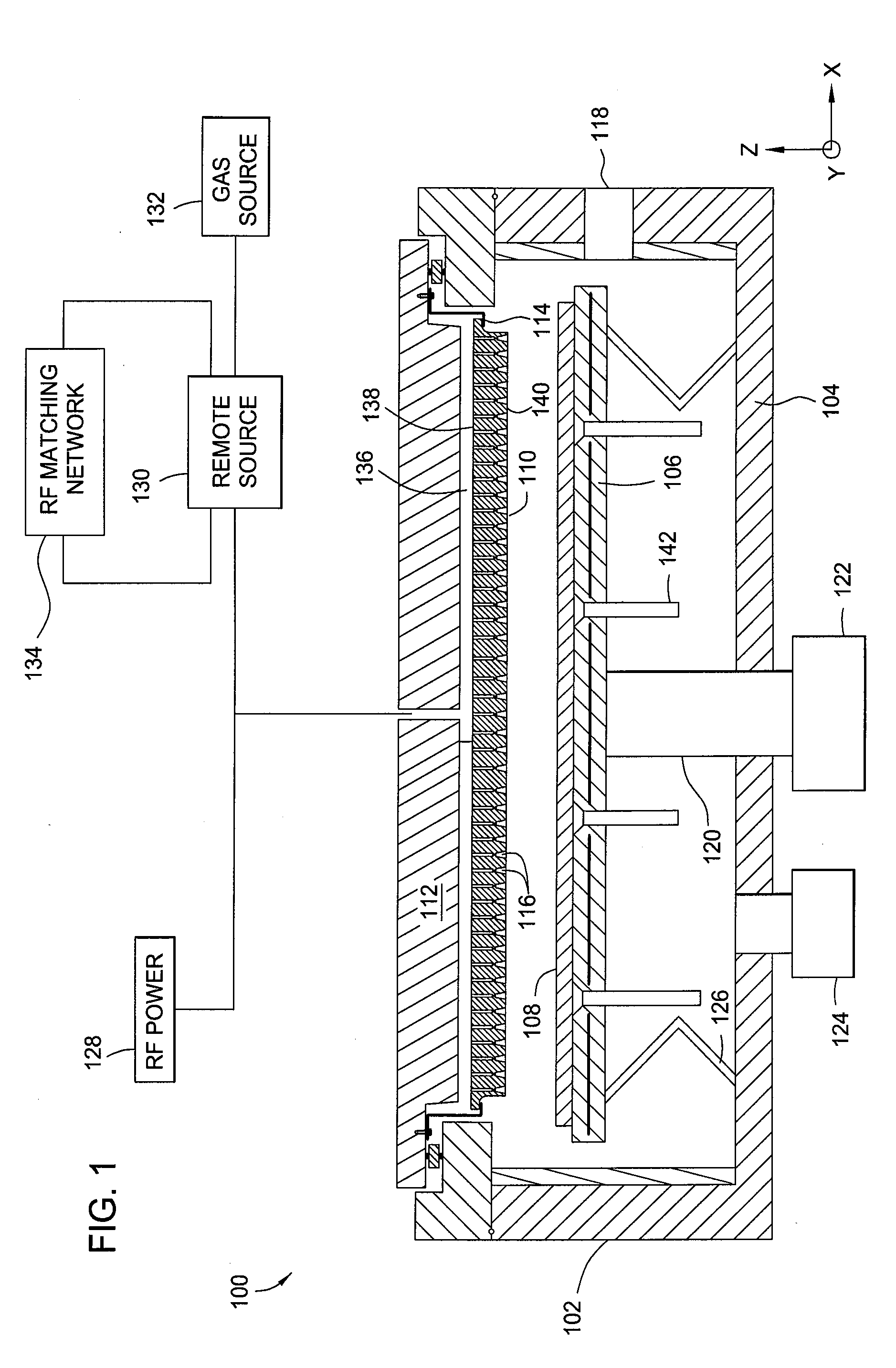

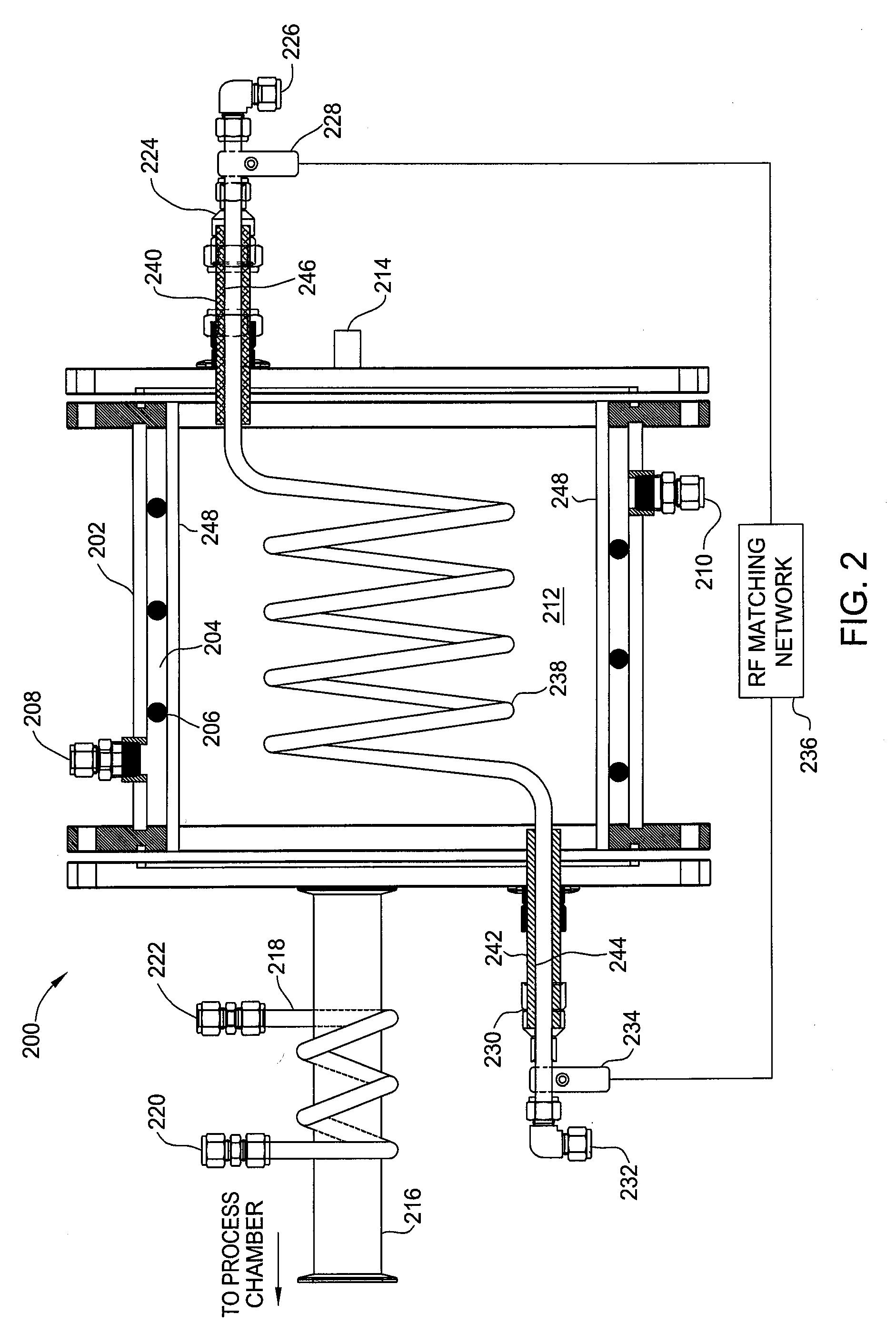

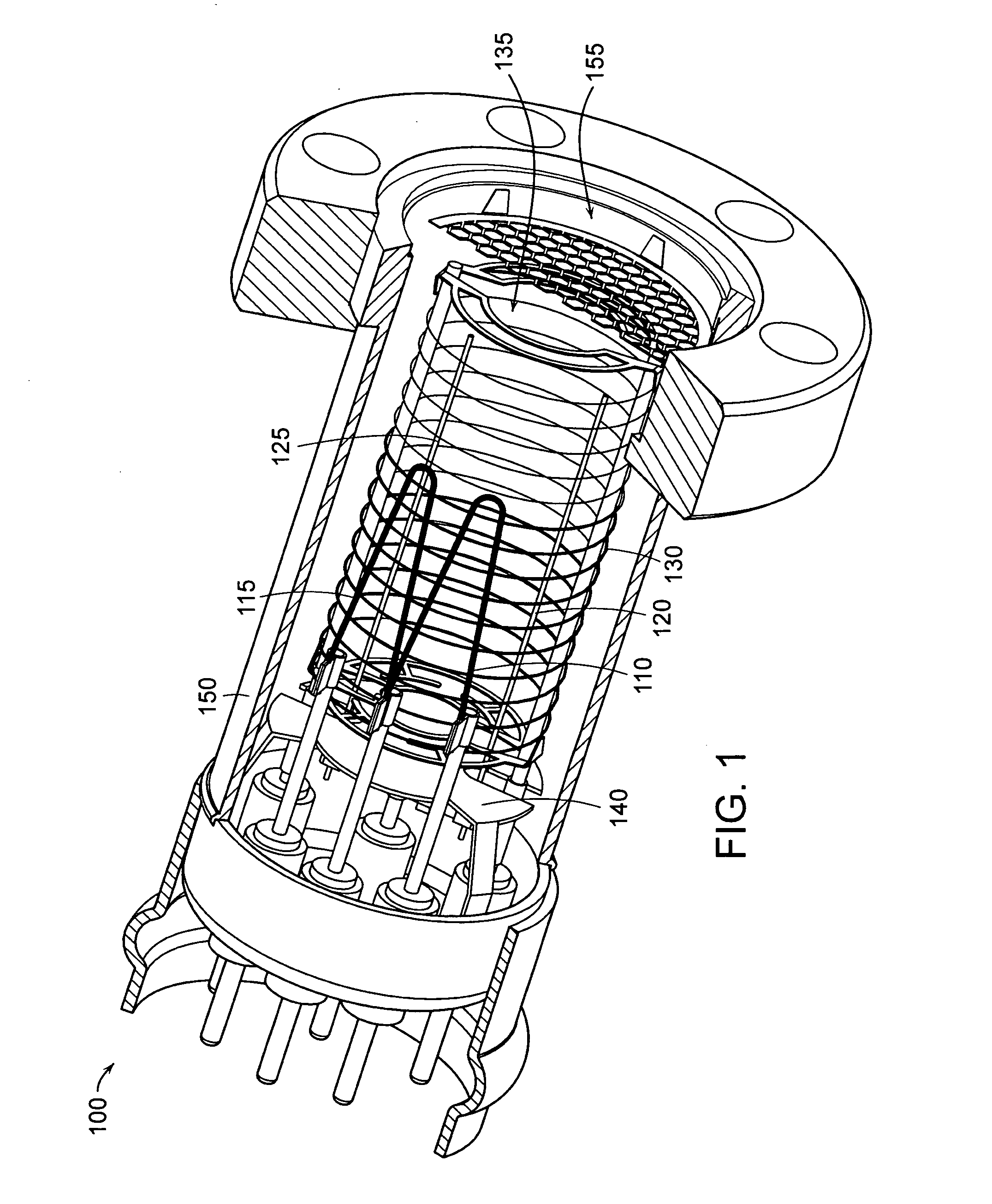

Remote inductively coupled plasma source for CVD chamber cleaning

InactiveUS20090008239A1Extended service lifeReduce sputtering of the coilElectric discharge tubesChemical vapor deposition coatingSputteringRemote plasma

The present invention generally includes a remote plasma source and a method of generating a plasma in a remote plasma source. Cleaning gas may be ignited into a plasma in a remote location and then provided to the processing chamber. By flowing the cleaning gas outside of a cooled RF coil, a plasma may be ignited at either high or low pressure while providing a high RF bias to the coil. Cooling the RF coil may reduce sputtering of the coil and thus reduce undesirable contaminants from being fed to the processing chamber with the cleaning gas plasma. Reduced sputtering from the coil may extend the useful life of the remote plasma source.

Owner:APPLIED MATERIALS INC

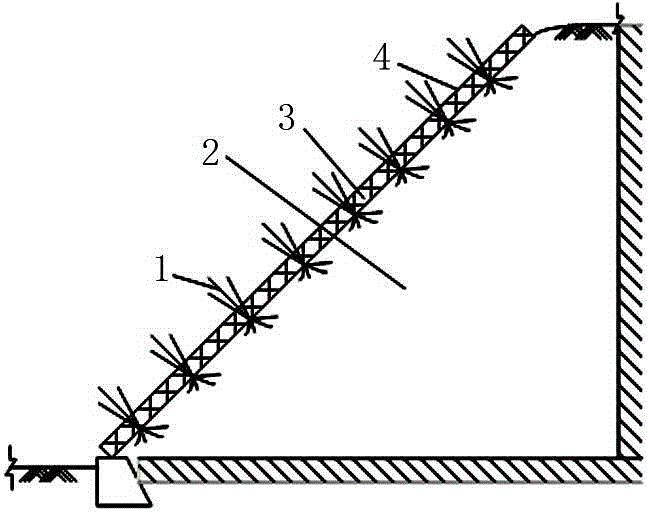

Ecological protecting method for low liquid limit powdery clay side slope

InactiveCN105165325ASimple construction processEasy to operateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersFiberSuper absorbent

The invention discloses an ecological protecting method for a low liquid limit powdery clay side slope and relates to the technical field of protection of the low liquid limit powdery clay side slope. The method comprises: trimming a side slope; covering the side slope with a base material layer; sowing a seed layer; covering the seed layer with a non-woven fabric; carrying out maintenance; removing the non-woven fabric and the like. The base material layer contains low liquid limit powdery clay digging soil generated by building a road, straw fiber which is subjected to compost treatment in advance, indigenous plant seeds, farm manure, a composite fertilizer, super-absorbent resin and polyacrylamide; the seed layer comprises indigenous plant seeds; the raw materials are wide in source and low in cost, the method is simple in construction process, good in side slope protecting effect and suitable for being applied to ecological protection of the low liquid limit powdery clay side slope formed by projects such as traffic, construction, municipal administration, water conservancy and the like in a large area.

Owner:NORTH CHINA INST OF AEROSPACE ENG

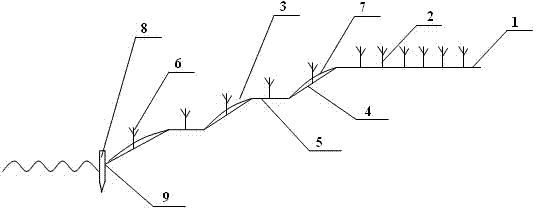

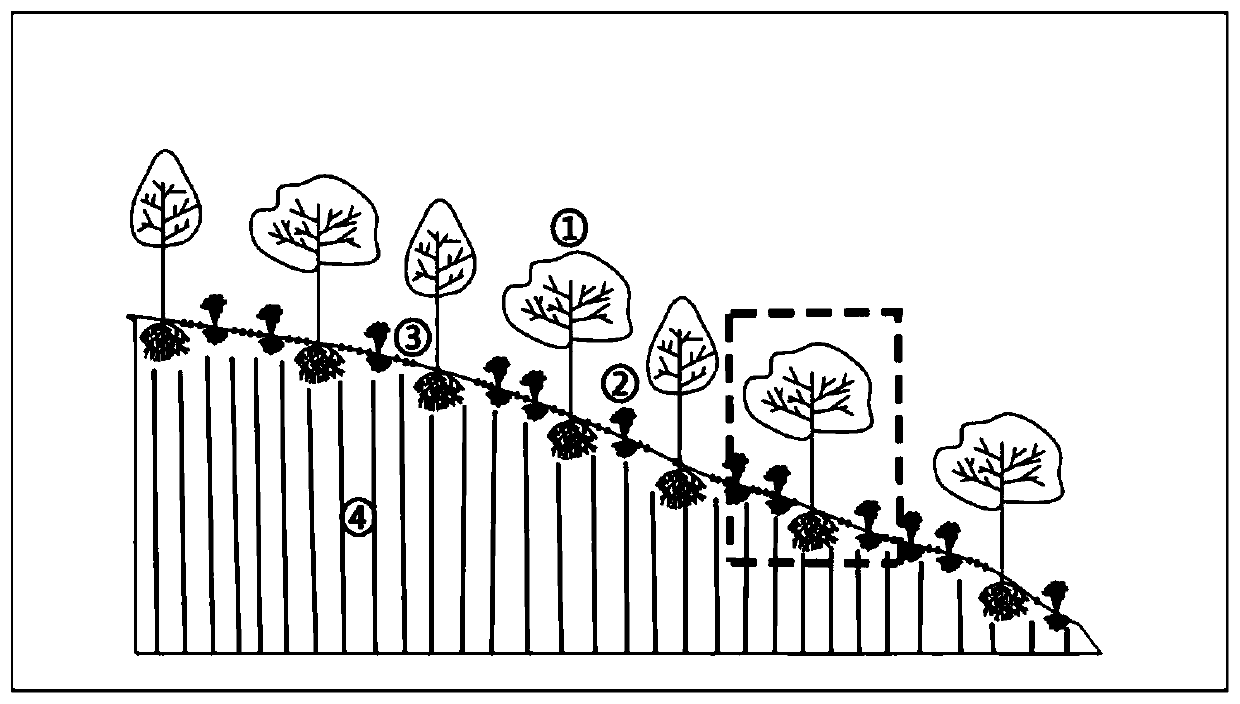

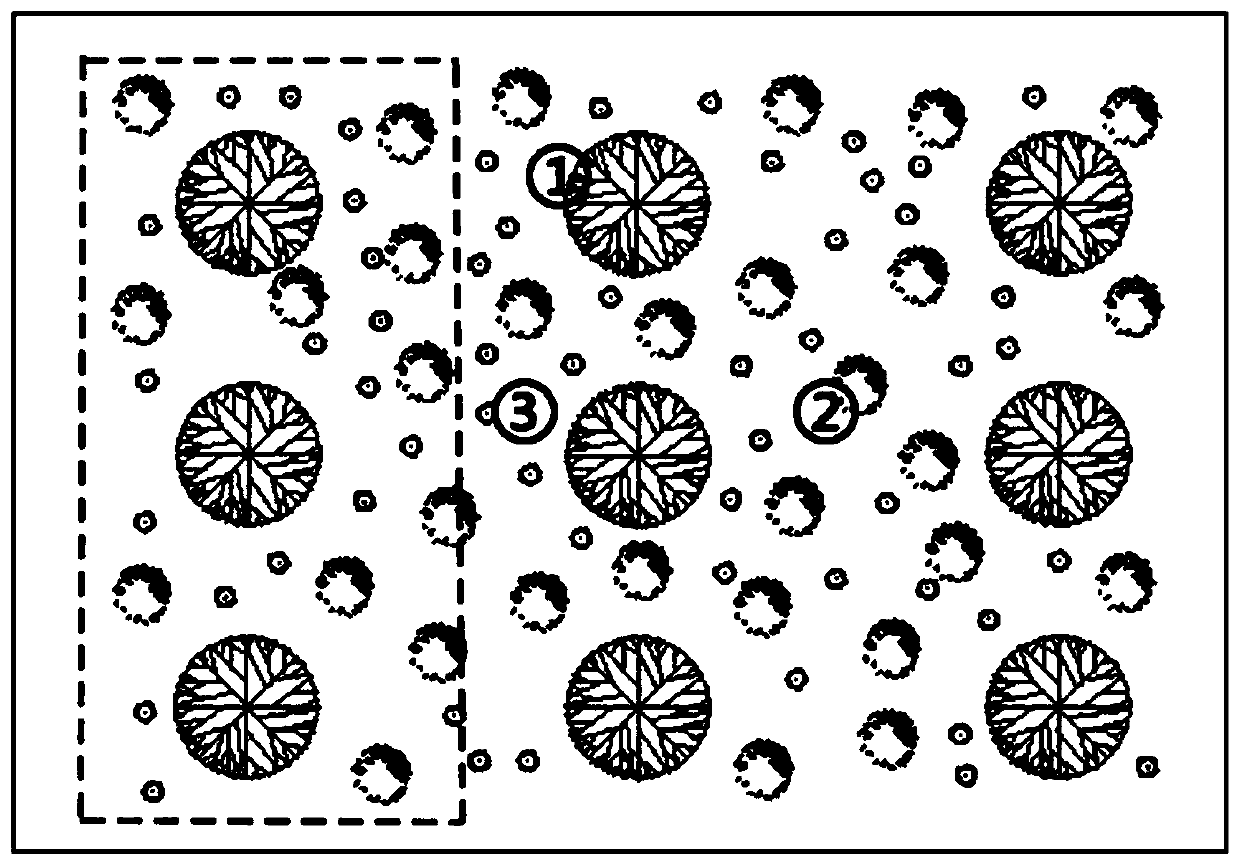

Soil, plant and biological stabilizing method of agricultural watershed riparian zone side slope

ActiveCN104762923ANatural performance disturbance is smallReduce sputteringCoastlines protectionSustainable biological treatmentAmorpha fruticosaEngineering

The invention relates to stabilizing methods of the ecological agriculture, particularly to a soil, plant and biological stabilizing method of an agricultural watershed riparian zone side slope. The soil, plant and biological stabilizing method comprises starting from a position close to a river way to plant three rows of annual Salix integra and planting three rows of annual Amorpha fruticosa along the direction parallel to a river bank after artificial leveling and performing cross planting on the Salix integra and the Amorpha fruticosa according to the order in turn; performing artificial trimming on a side slope protection zone and setting the integral side slope protection section into a step-shaped structure in which three small side slopes are connected with two small platforms; protecting the small side slopes of the side slope protection section through polypropylene non-woven fabrics, laying the non-woven fabrics on the small side slopes, fixing the top end and the bottom of every small side slope through rivets respectively and performing vegetation cutting in the middle of every small side slope; performing Salix integra cutting on every small side slope of the side slope protection section and performing cutting in the middle of each small platform of the side slope protection section through a row of Amorpha fruticosa. According to the soil, plant and biological stabilizing method of the agricultural watershed riparian zone side slope, the artificial disturbance is less, the cost is low, the recovery is rapid, the effect is good, the soil, the close-to-natural-landscape effect is achieved, and the artificial maintenance is not required by the later period of ecological slope protection and pollution control.

Owner:CHENGBANG ECO ENVIRONMENT CO LTD

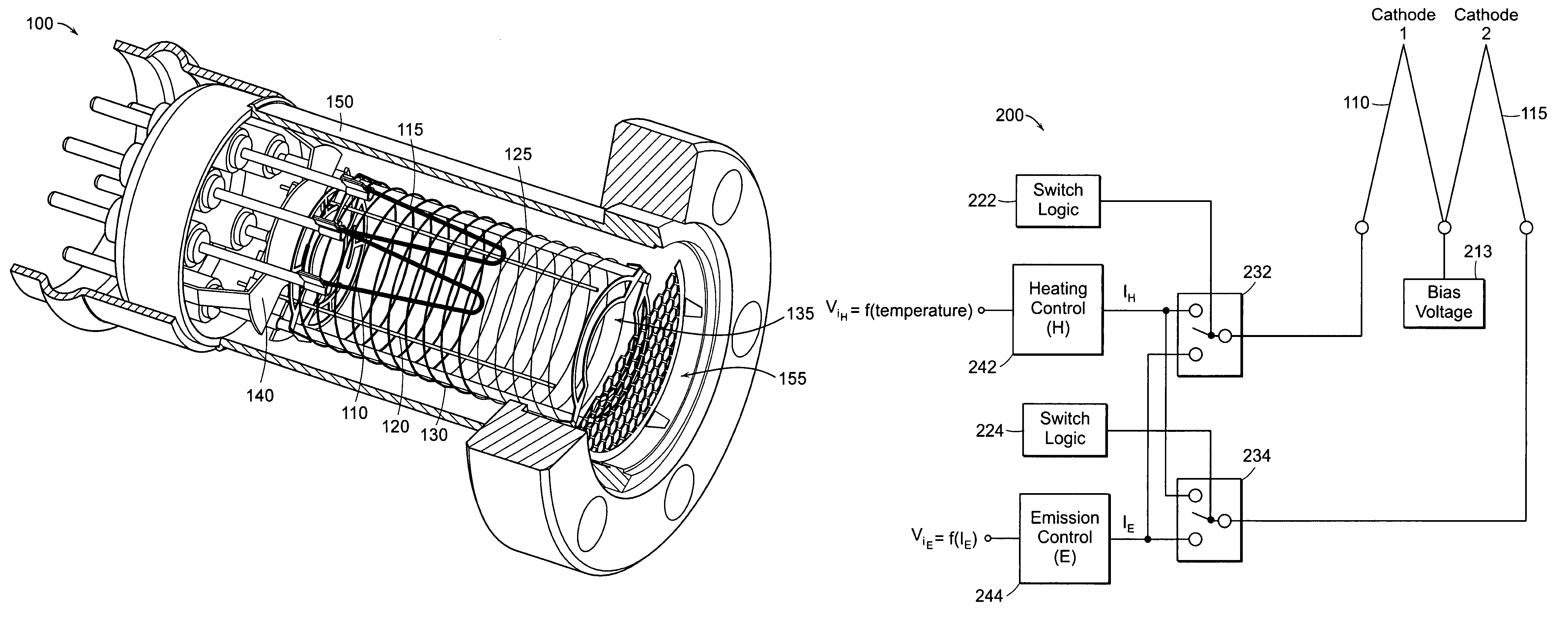

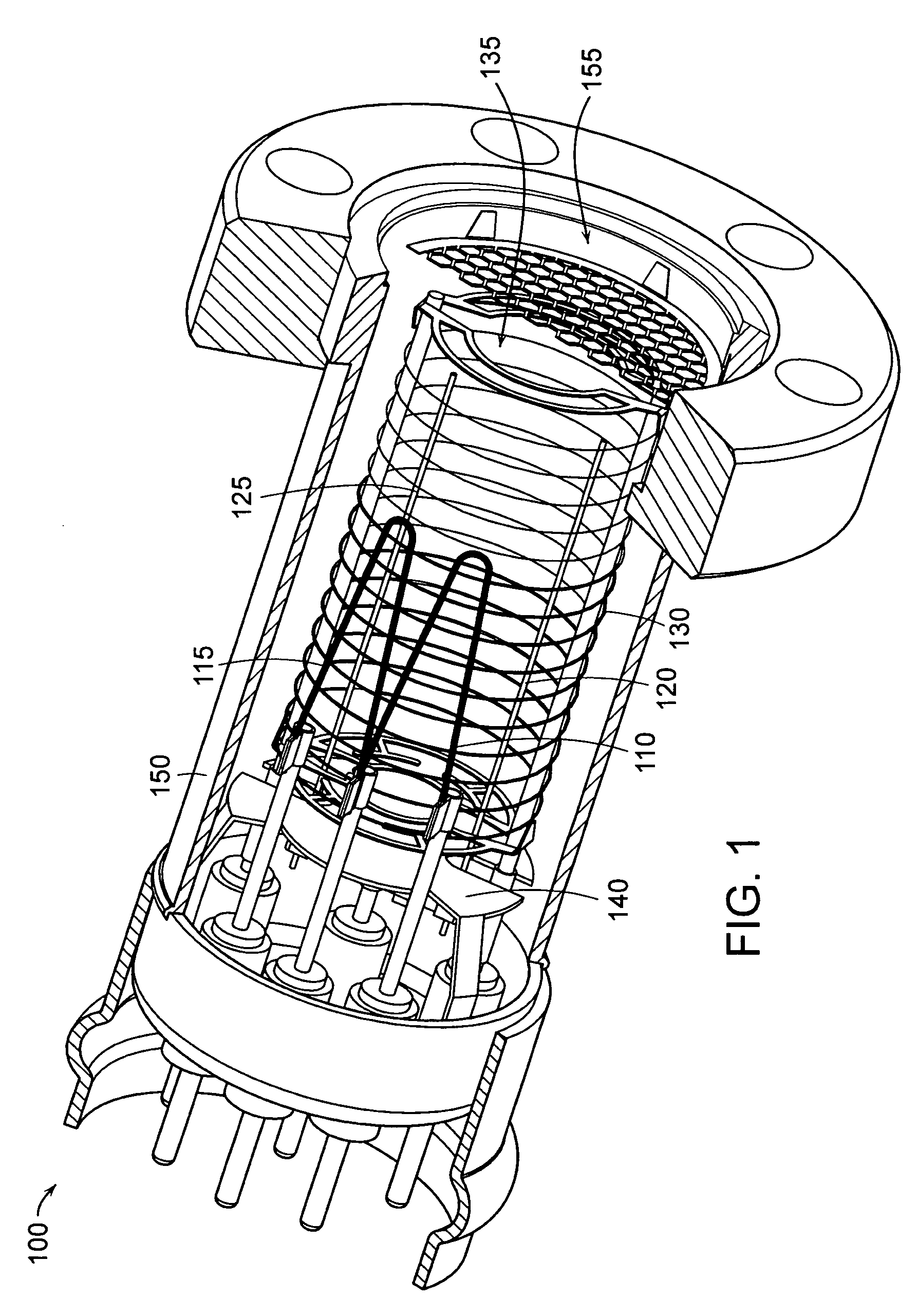

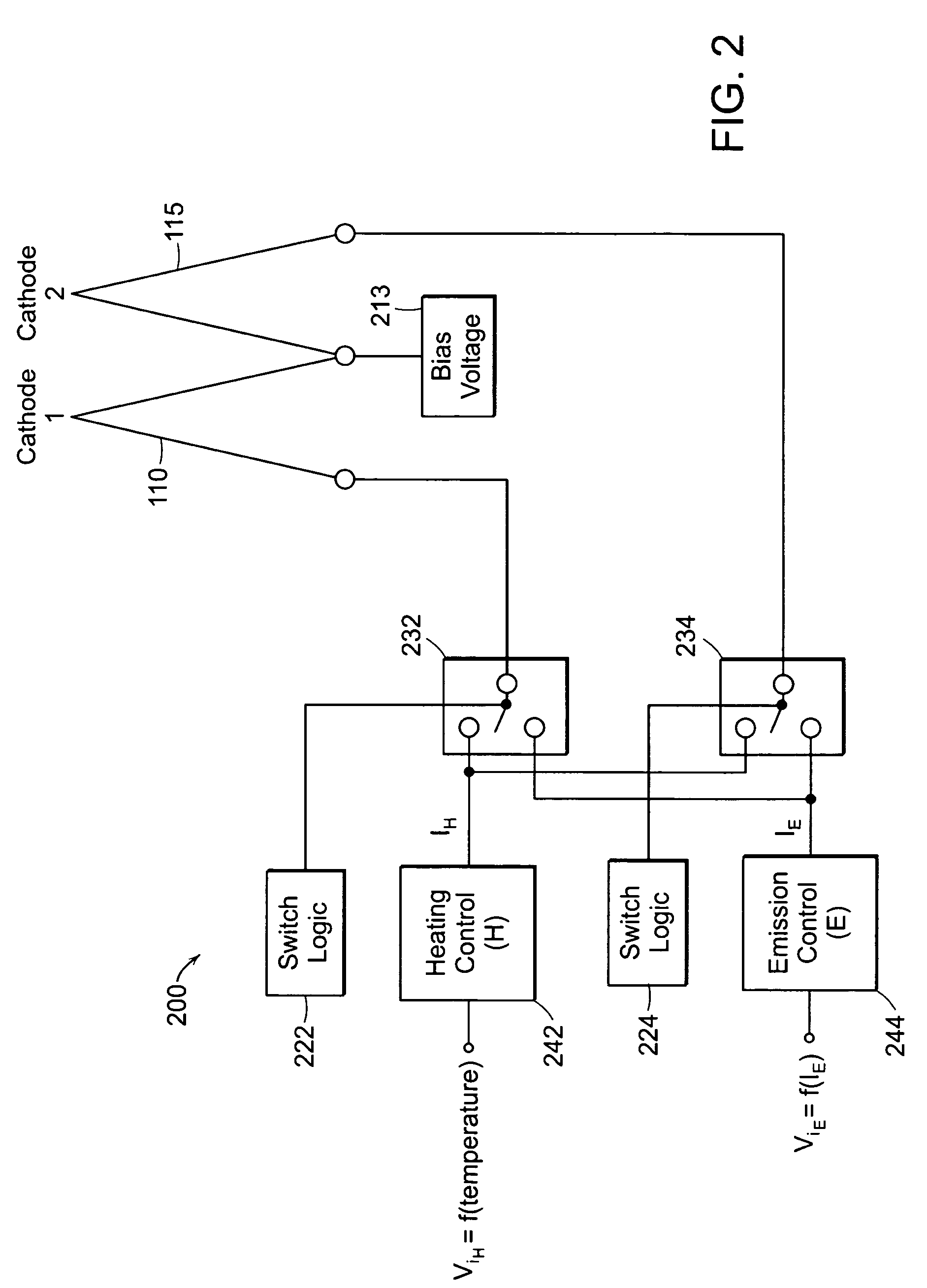

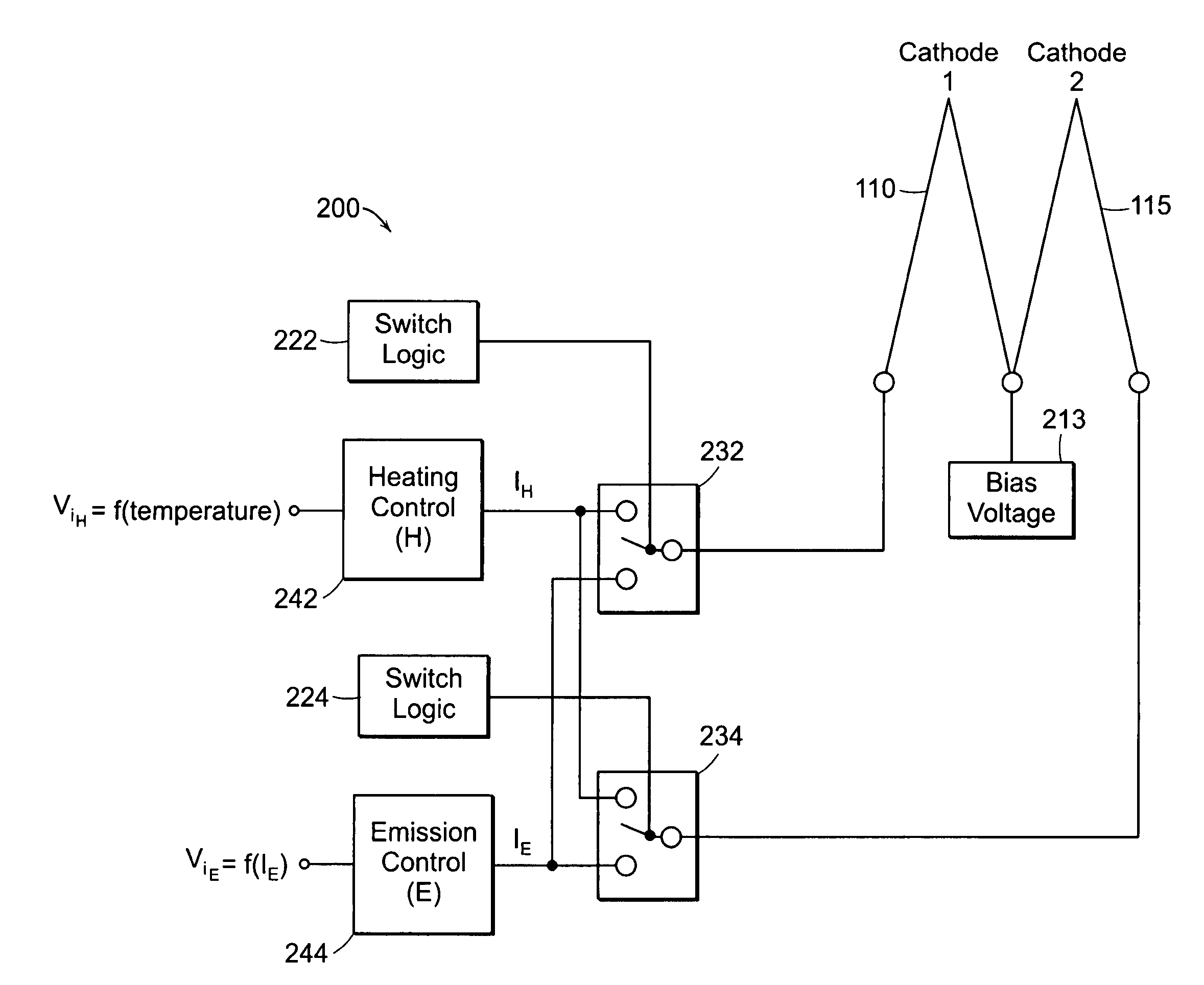

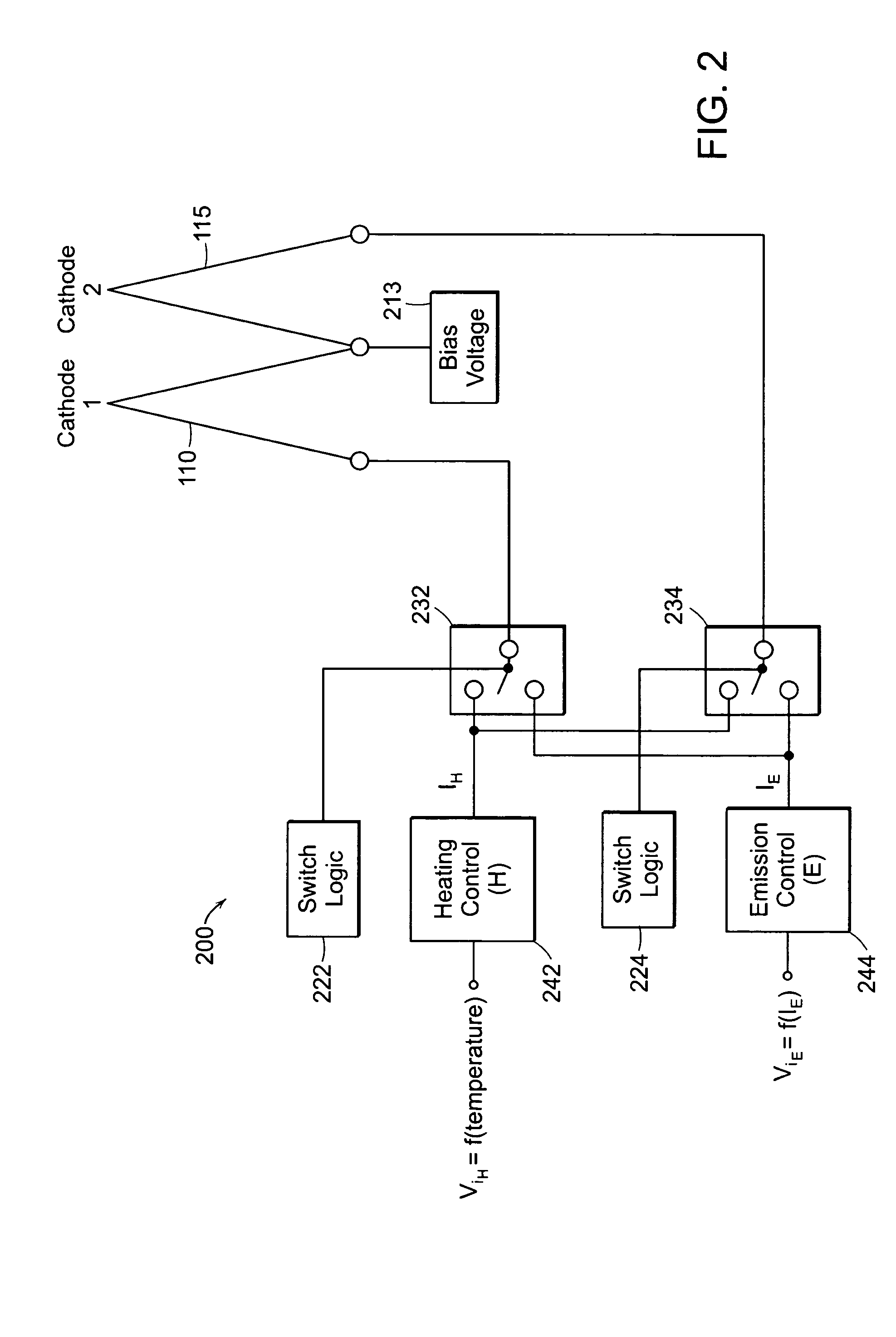

Method and apparatus for maintaining emission capabilities of hot cathodes in harsh environments

ActiveUS7429863B2Easy to operateReduce material usageVacuum gauge using ionisation effectsElectric lighting sourcesEngineeringIonization

A method and apparatus for operating a multi-hot-cathode ionization gauge is provided to increase the operational lifetime of the ionization gauge in gaseous process environments. In example embodiments, the life of a spare cathode is extended by heating the spare cathode to a temperature that is insufficient to emit electrons but that is sufficient to decrease the amount of material that deposits on its surface or is optimized to decrease the chemical interaction between a process gas and a material of the at least one spare cathode. The spare cathode may be constantly or periodically heated. In other embodiments, after a process pressure passes a given pressure threshold, plural cathodes may be heated to a non-emitting temperature, plural cathodes may be heated to a lower emitting temperature, or an emitting cathode may be heated to a temperature that decreases the electron emission current.

Owner:MKS INSTR INC

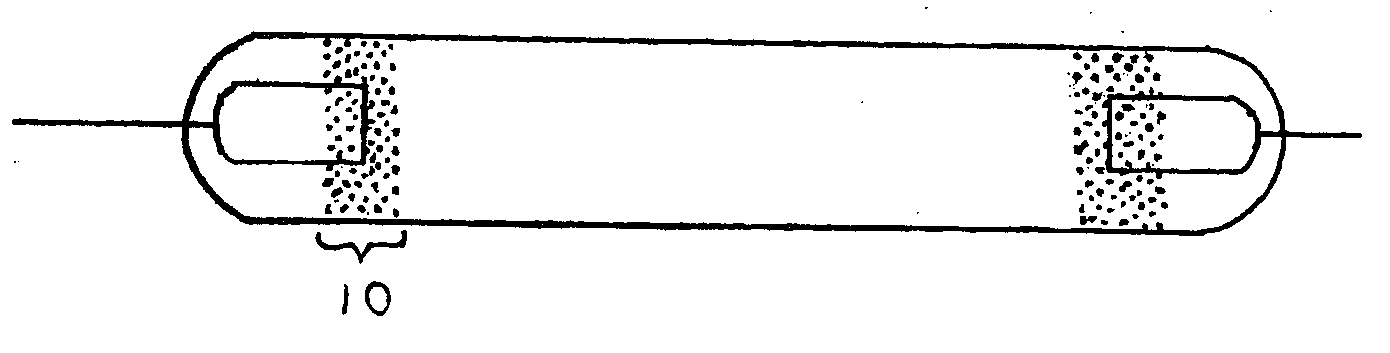

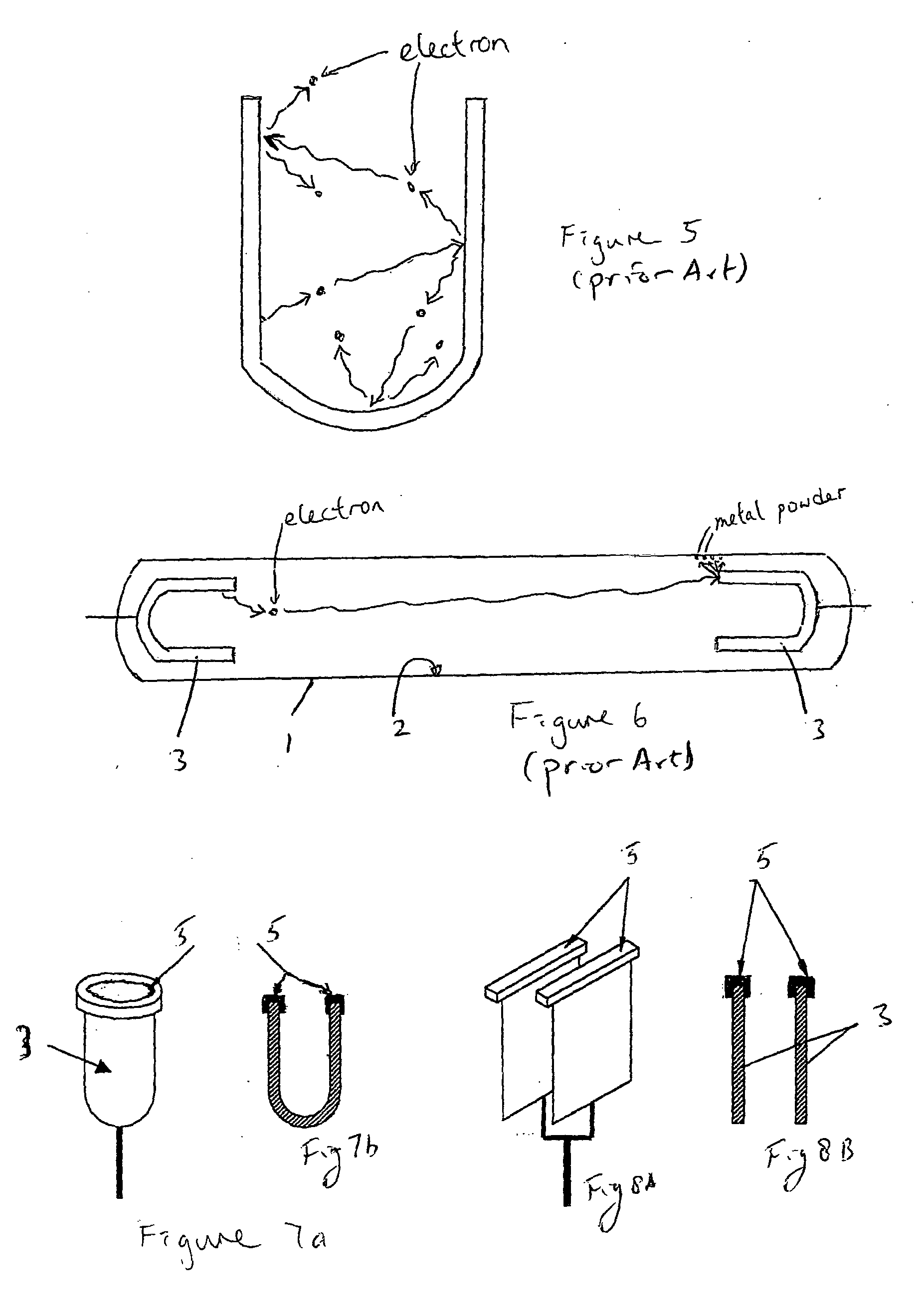

Cold cathode fluorescent lamps

InactiveUS20050057143A1Extended service lifeReducing and eliminating sputteringDischarge tube luminescnet screensElectrode and associated part arrangementsElectric dischargePhosphor

A cold-cathode fluorescent lamp, comprising a sealed lighting enclosure provided with a phosphor coating on at least part of an inner surface thereof the lighting enclosure. An electrode is provided juxtaposed a region of the inner surface of the lighting tube, the electrode energisable from an external source of energy via an electric lead supporting the electrode, and positioned adjacent the main ionisation region within the lighting enclosure. The phosphor is to be excited by radiation to be generated inside the lighting tube by electric discharge from the electrode to provide visible radiation. At least part of the surface(s) of that portion of the electrode proximal most to the ionisation region are overlaid by a cap made from a high heat resistive and non conductive material.

Owner:COLOR STARS

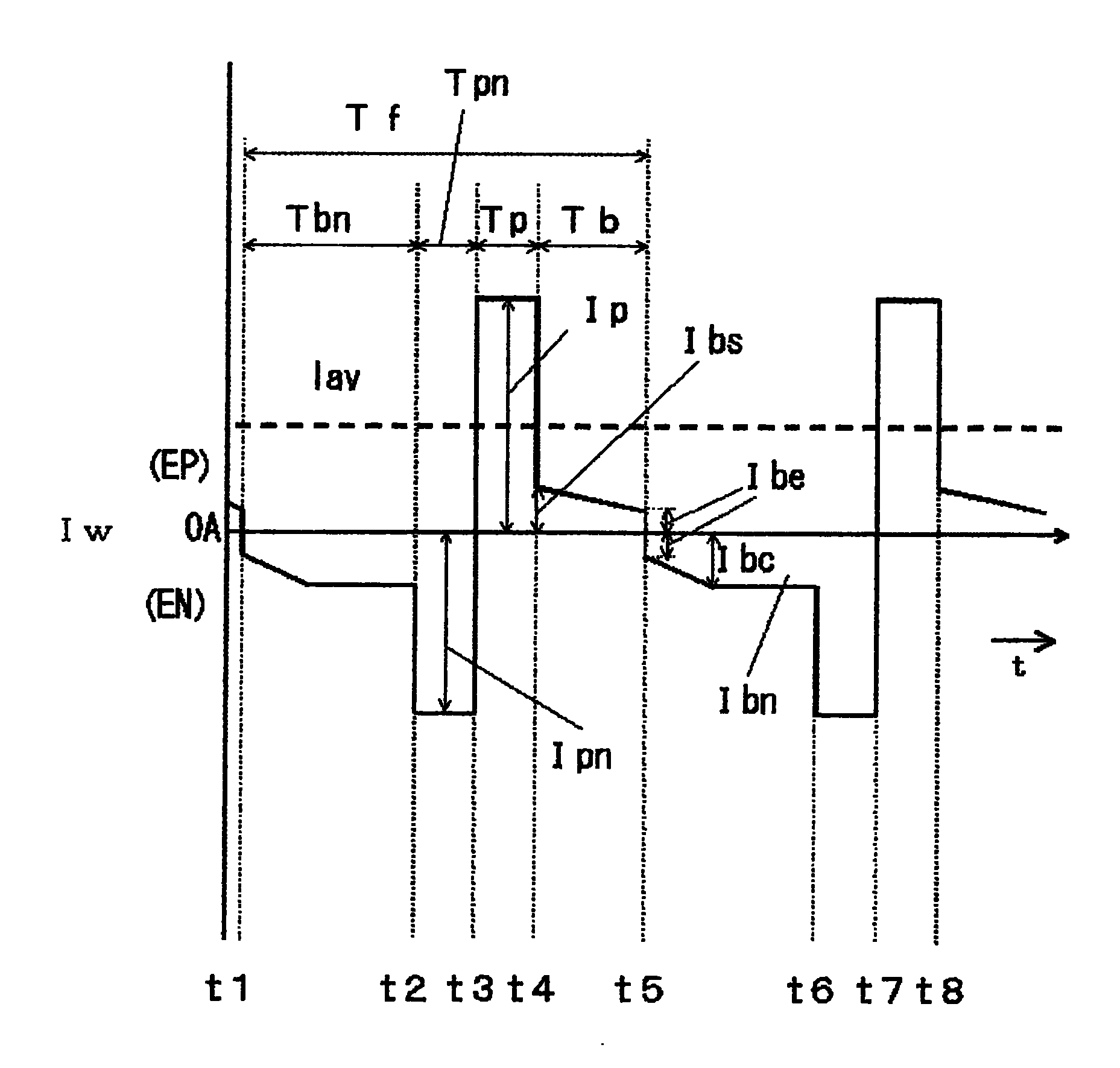

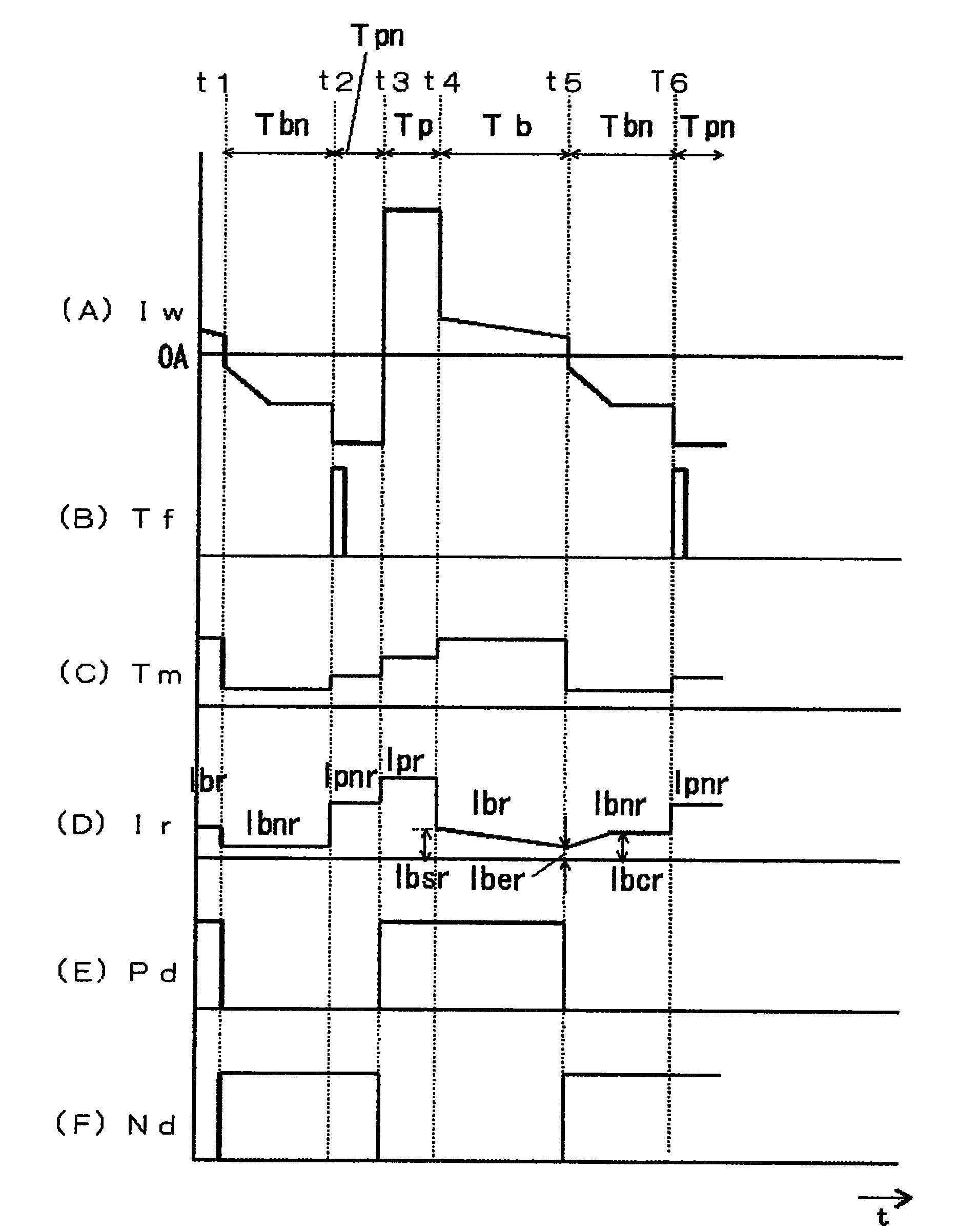

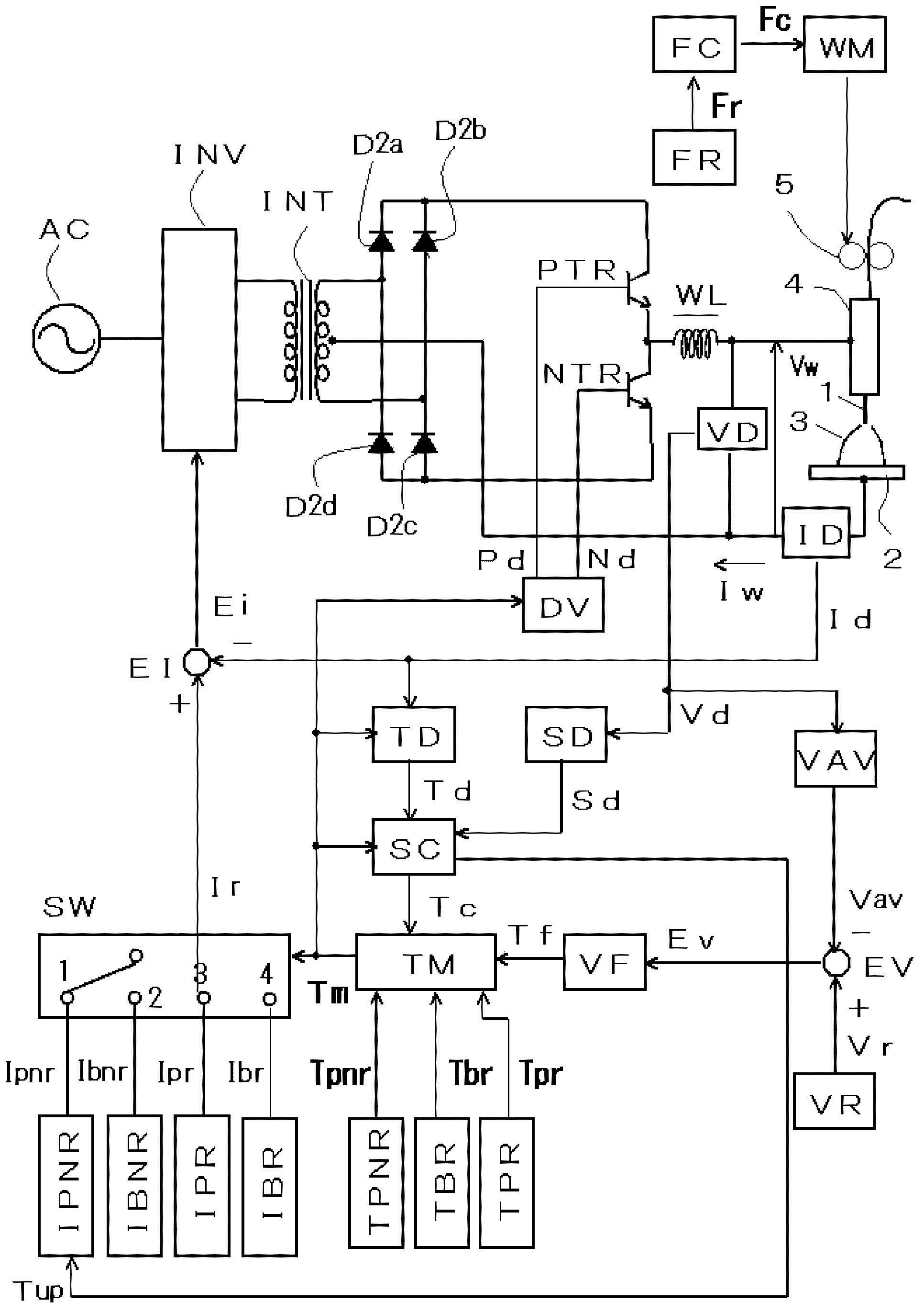

AC pulse arc welding control method

ActiveCN102430840AInhibition lossReduce the current valueArc welding apparatusSputteringElectrode polarity

The invention provides an AC pulse arc welding control method, wherein during the negative electrode polarity-based period (Tbn), the negative electrode polarity-based current (Ibn) smaller than the critical value is electrified. During the negative electrode peak-based period (Tpn), the negative electrode peak-based current (Ipn) greater than the negative electrode polarity-based current is electrified. During the positive electrode peak-based period (Tp), the positive electrode peak-based current (Ip) greater than the critical value is electrified. During the positive electrode polarity-based period (Tb), the positive electrode polarity-based current (Ib) smaller than the critical value is electrified. Therefore, the welding can be performed. The positive electrode polarity-based current (Ib) is inclined to be smaller along the passing of time. The front half part of the positive electrode polarity-based current (Ib) is capable of increasing so as to inhibit the disappearing of electric arc. The rear half part of the positive electrode polarity-based current (Ib) is capable of decreasing so as to reduce the sputtering of electric arc.

Owner:DAIHEN CORP

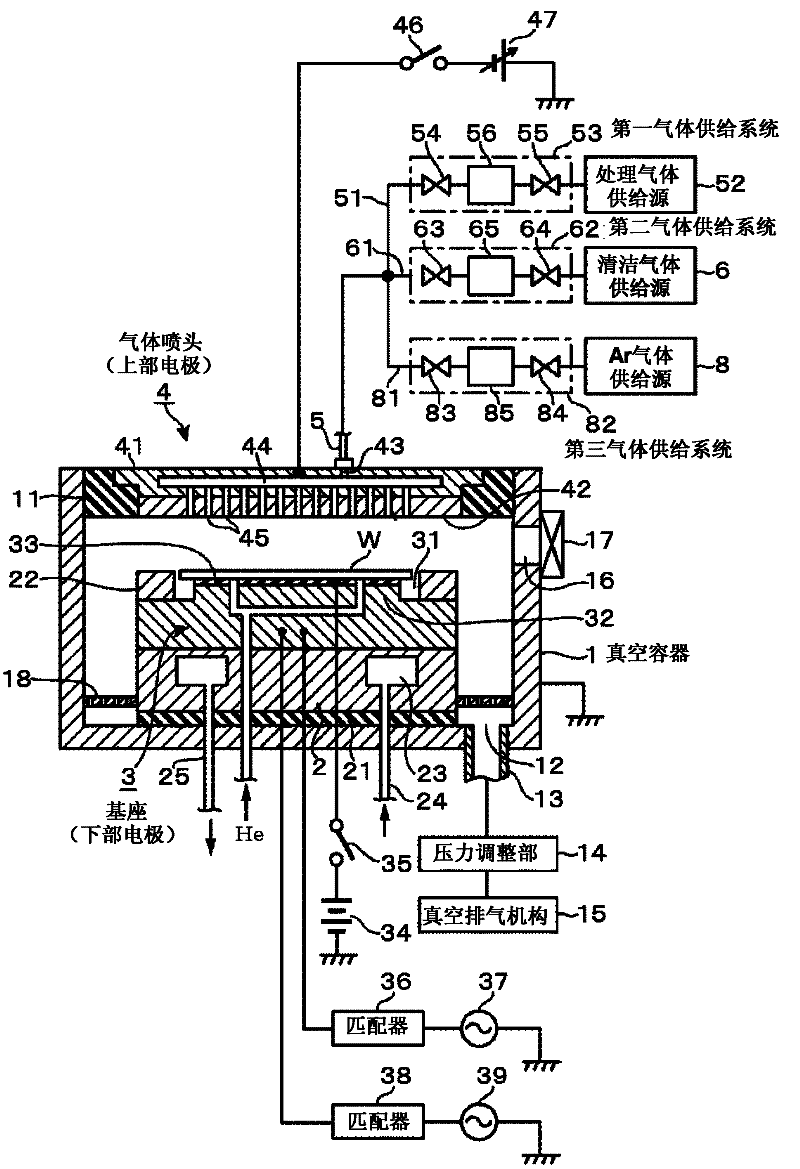

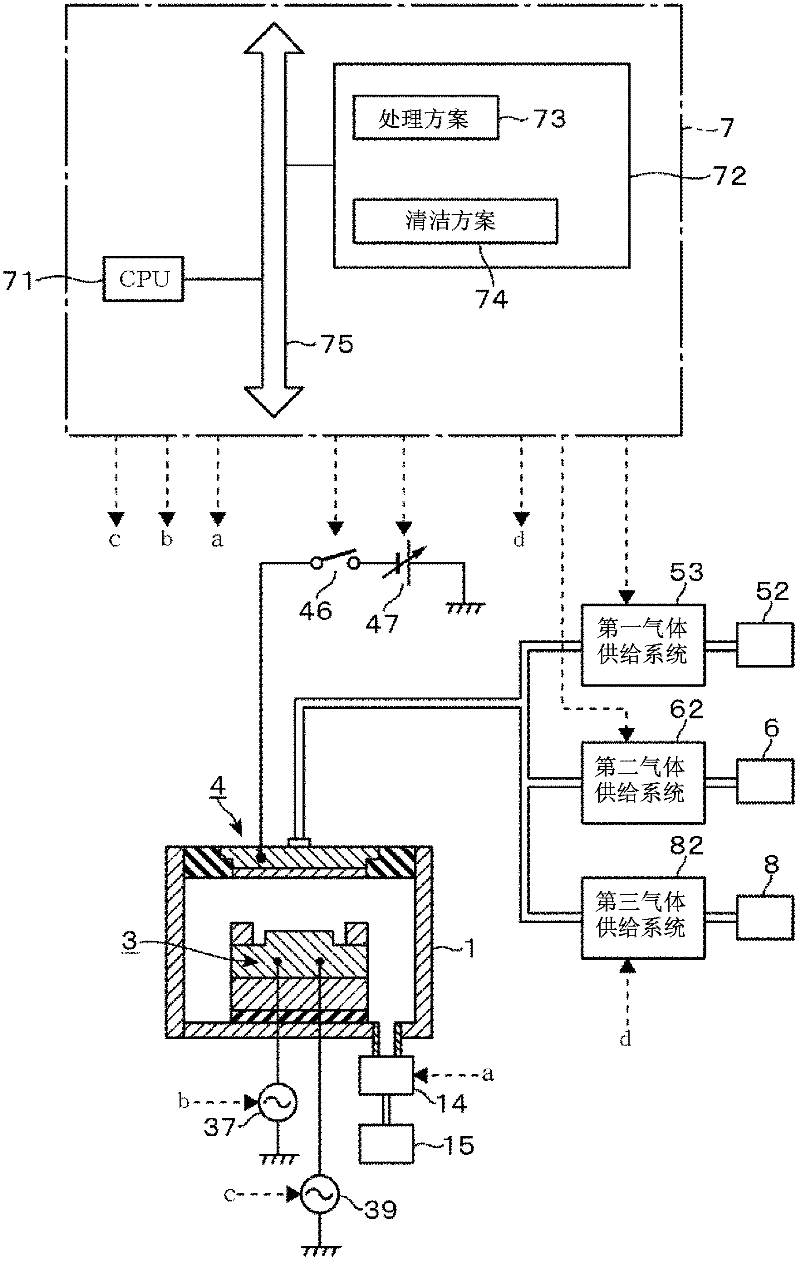

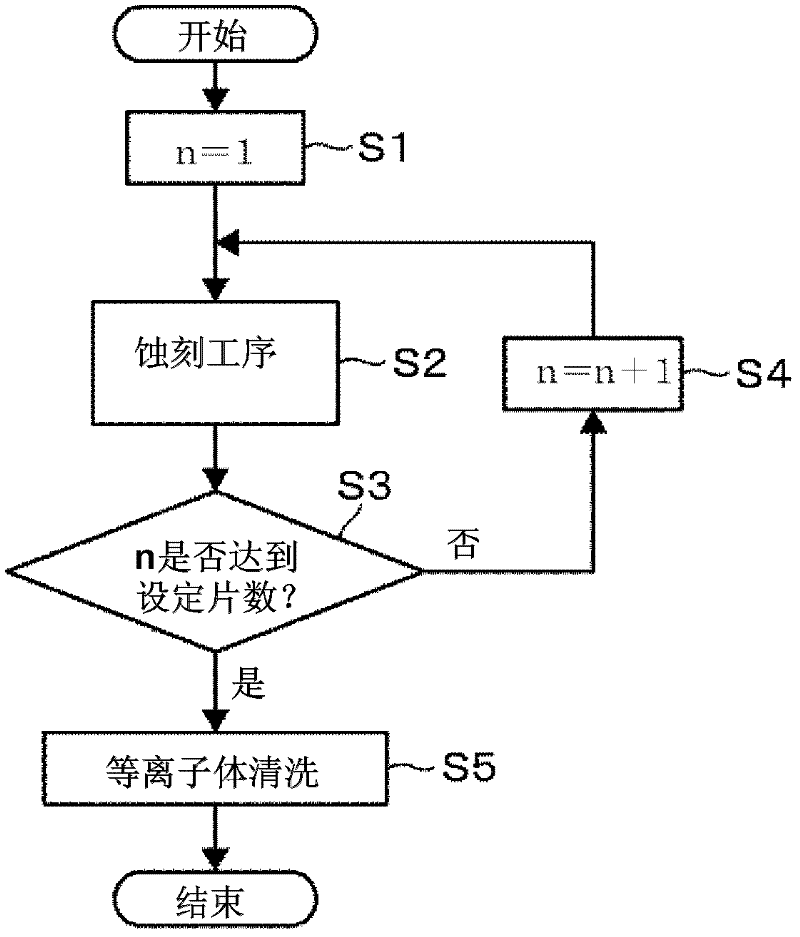

Plasma processing apparatus and plasma processing method

InactiveCN102693892ALower ion energyAvoid damageElectric discharge tubesSemiconductor/solid-state device manufacturingSusceptorHigh density

Owner:TOKYO ELECTRON LTD

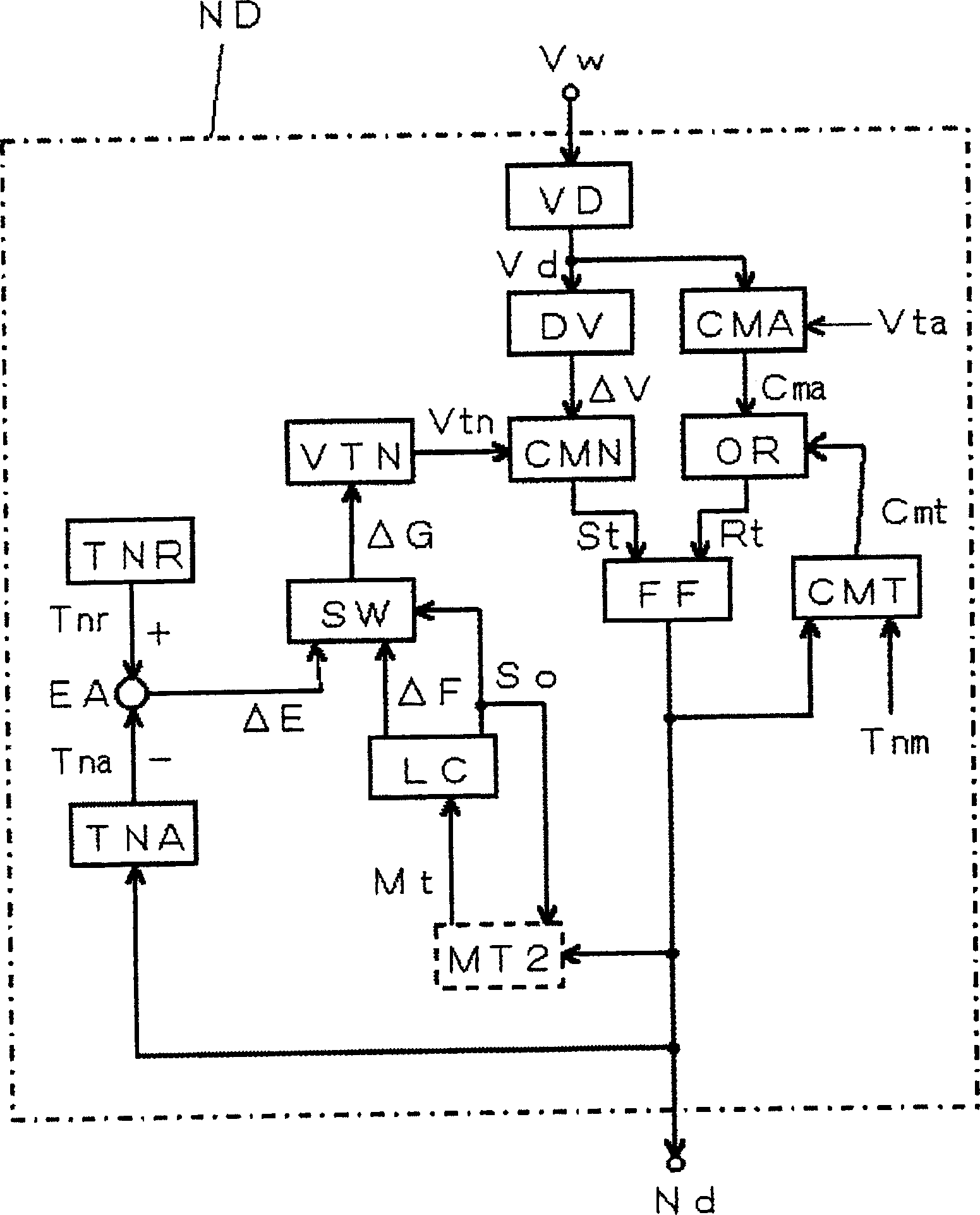

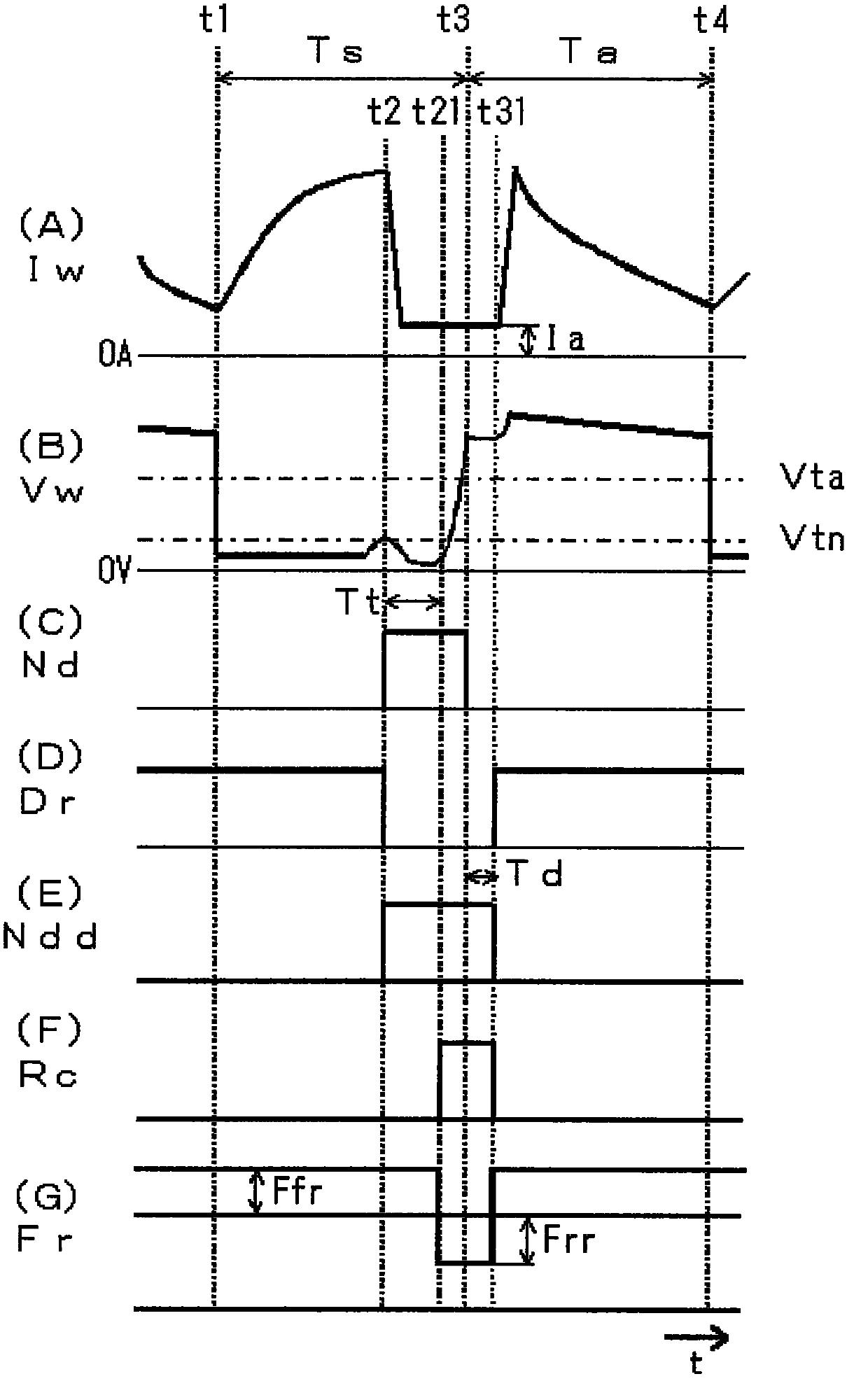

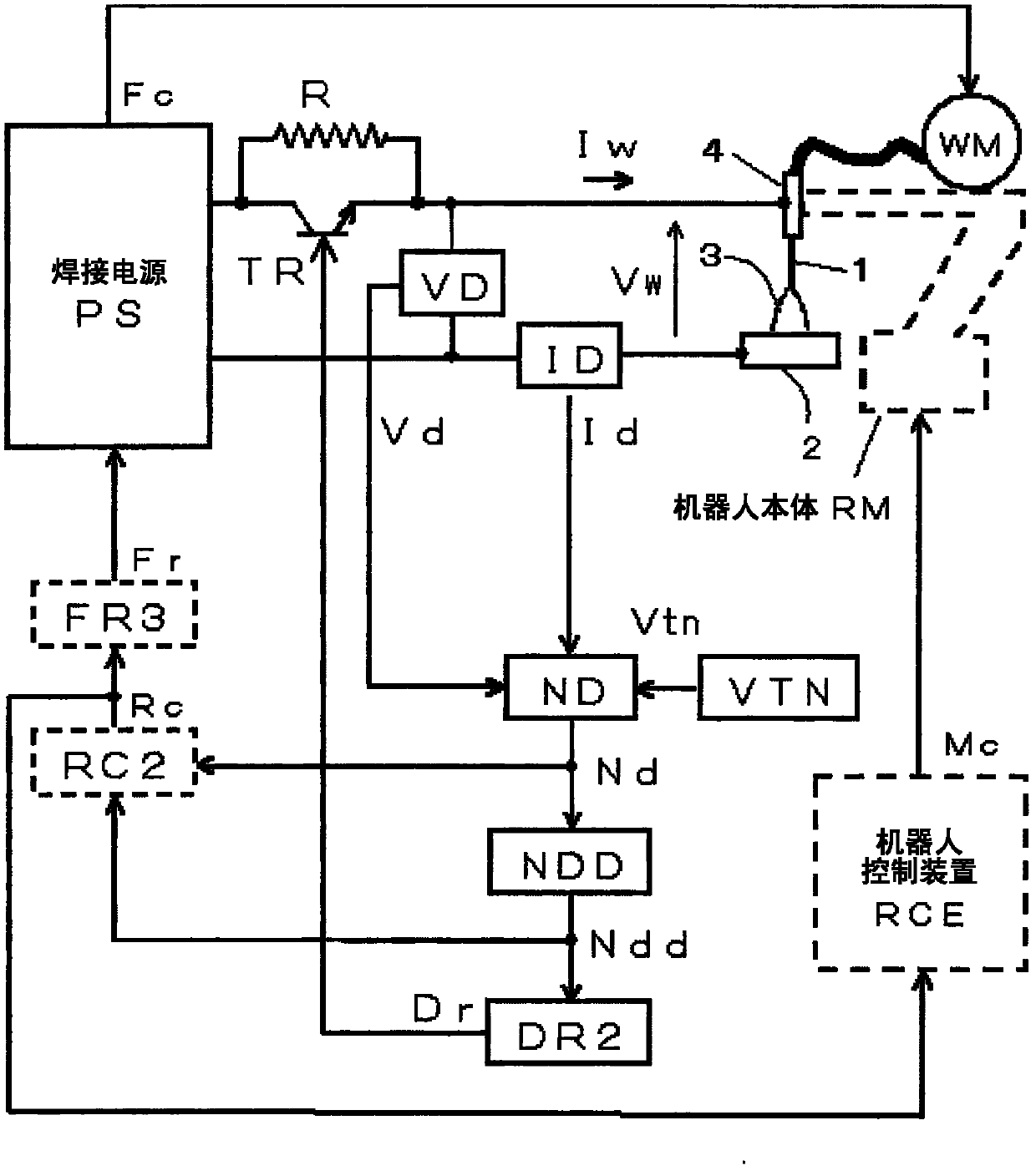

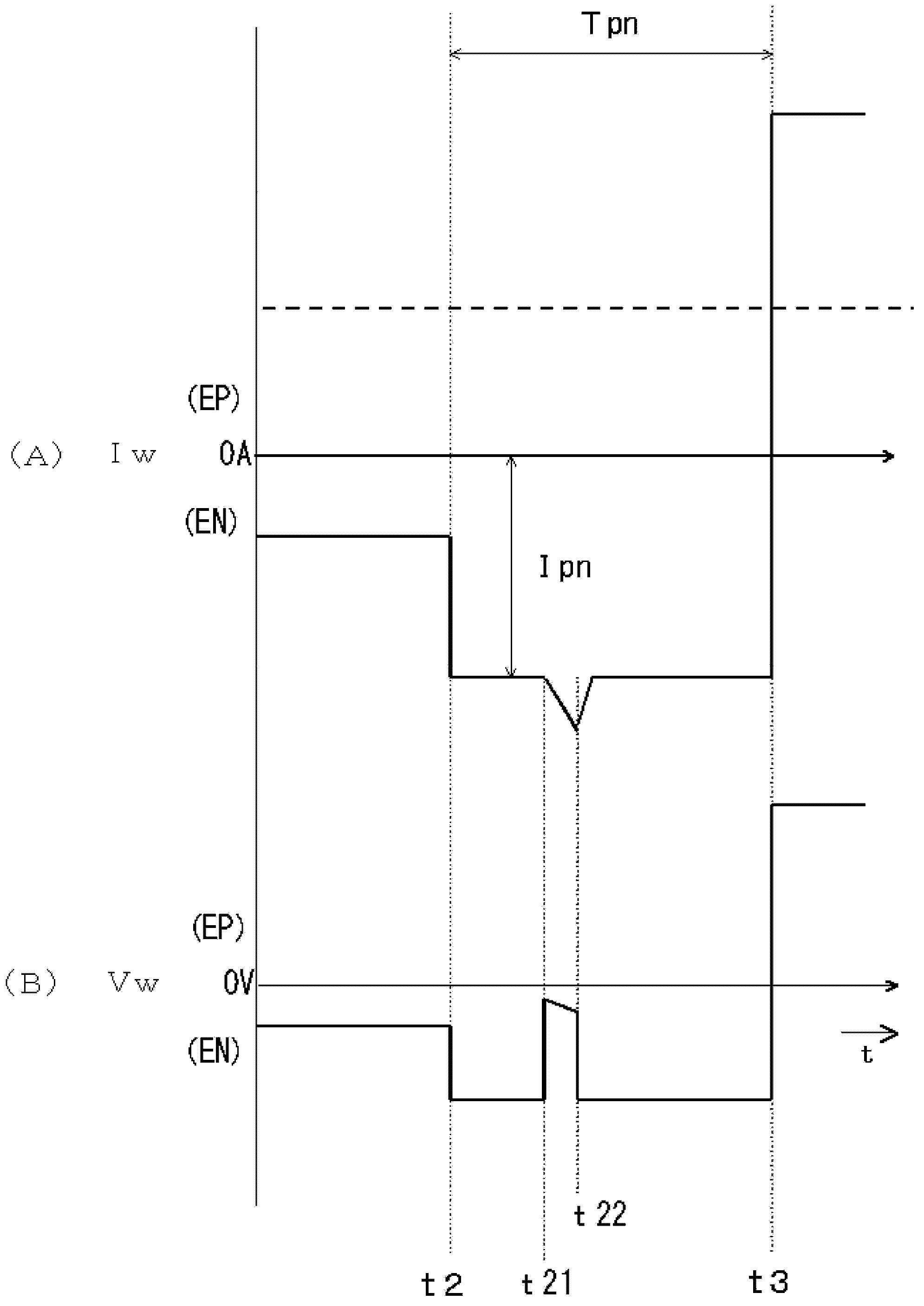

Necking detecting and controlling method for melted-electrode arc welding

ActiveCN102380691AReliable reproductionRegenerate patencyArc welding apparatusElectrical resistance and conductanceEngineering

The invention provides a necking detecting and controlling method for melted-electrode arc welding. During the melted-electrode arc welding, an electric arc can be smoothly regenerated even if molten drop necking is wrongly detected. Through the change in a voltage value (Vw) or a resistance value (Vw / Iw) of a welding wire and a base material, the premonitory phenomena of electric arc regeneration under the short-circuit state, i.e., molten drop necking, is detected according to a necking detection reference value. The welding current (Iw) which powers on a short-circuit load is reduced from the necking detection time (t2), so as to enable the regeneration (t3) of the electric arc. If the electric arc is regenerated, then the welding current is increased. When the self-necking detection period of time reaches the reference time (Tt) before the regeneration of the electric arc (t21), the necking detection is judged to be wrong. The welding wire is reversely moved at a set reverse feeding speed (Frr) so as to be far away from the base material, so that the electric arc is smoothly regenerated. If the electric art is regenerated, then the welding wire is moved at a set forward feeding speed (Ffr).

Owner:DAIHEN CORP

Method and apparatus for maintaining emission capabilities of hot cathodes in harsh environments

ActiveUS20080018337A1Easy to operateReduce material usageVacuum gauge using ionisation effectsElectric lighting sourcesEngineeringIonization

A method and apparatus for operating a multi-hot-cathode ionization gauge is provided to increase the operational lifetime of the ionization gauge in gaseous process environments. In example embodiments, the life of a spare cathode is extended by heating the spare cathode to a temperature that is insufficient to emit electrons but that is sufficient to decrease the amount of material that deposits on its surface or is optimized to decrease the chemical interaction between a process gas and a material of the at least one spare cathode. The spare cathode may be constantly or periodically heated. In other embodiments, after a process pressure passes a given pressure threshold, plural cathodes may be heated to a non-emitting temperature, plural cathodes may be heated to a lower emitting temperature, or an emitting cathode may be heated to a temperature that decreases the electron emission current.

Owner:MKS INSTR INC

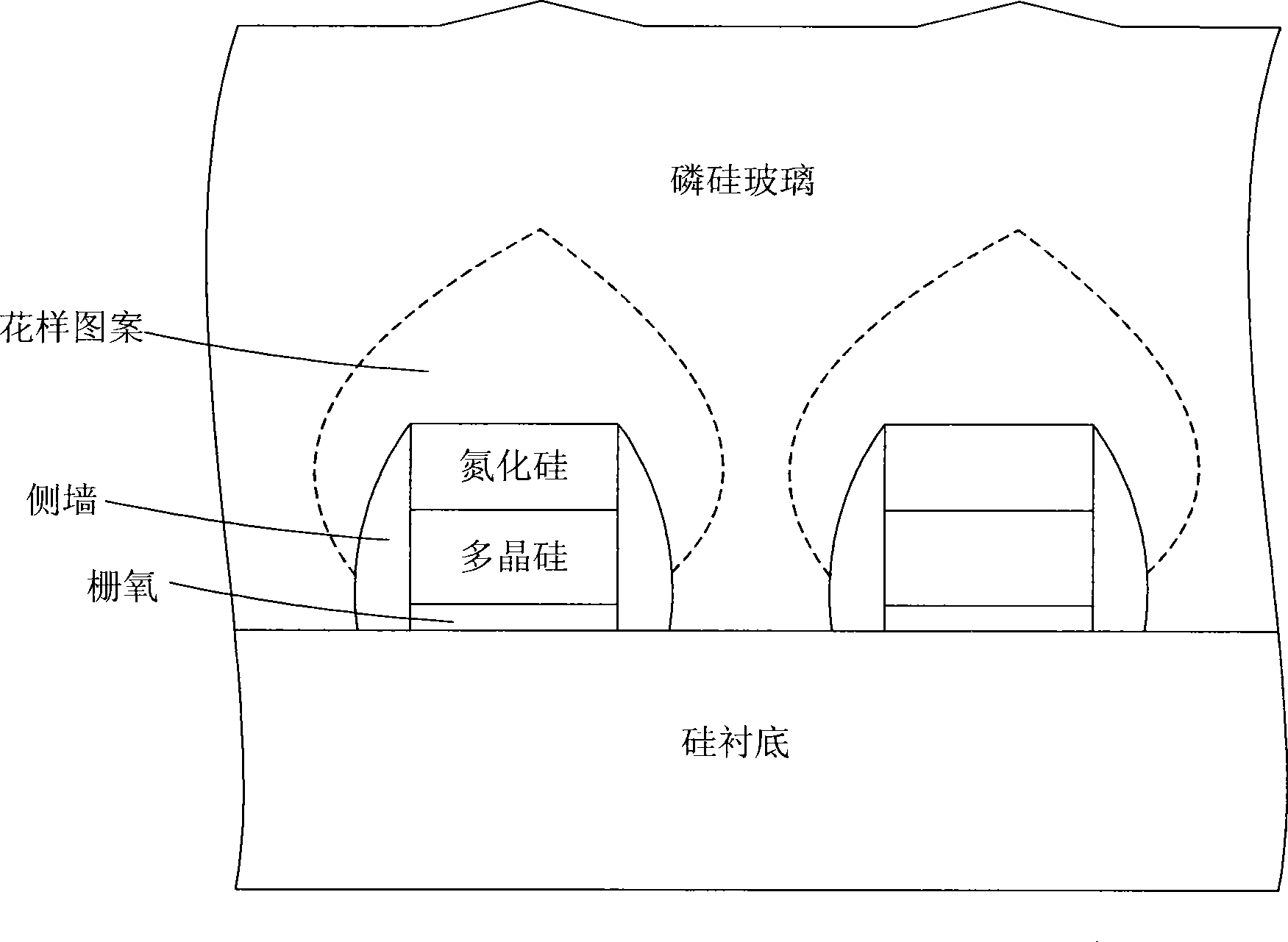

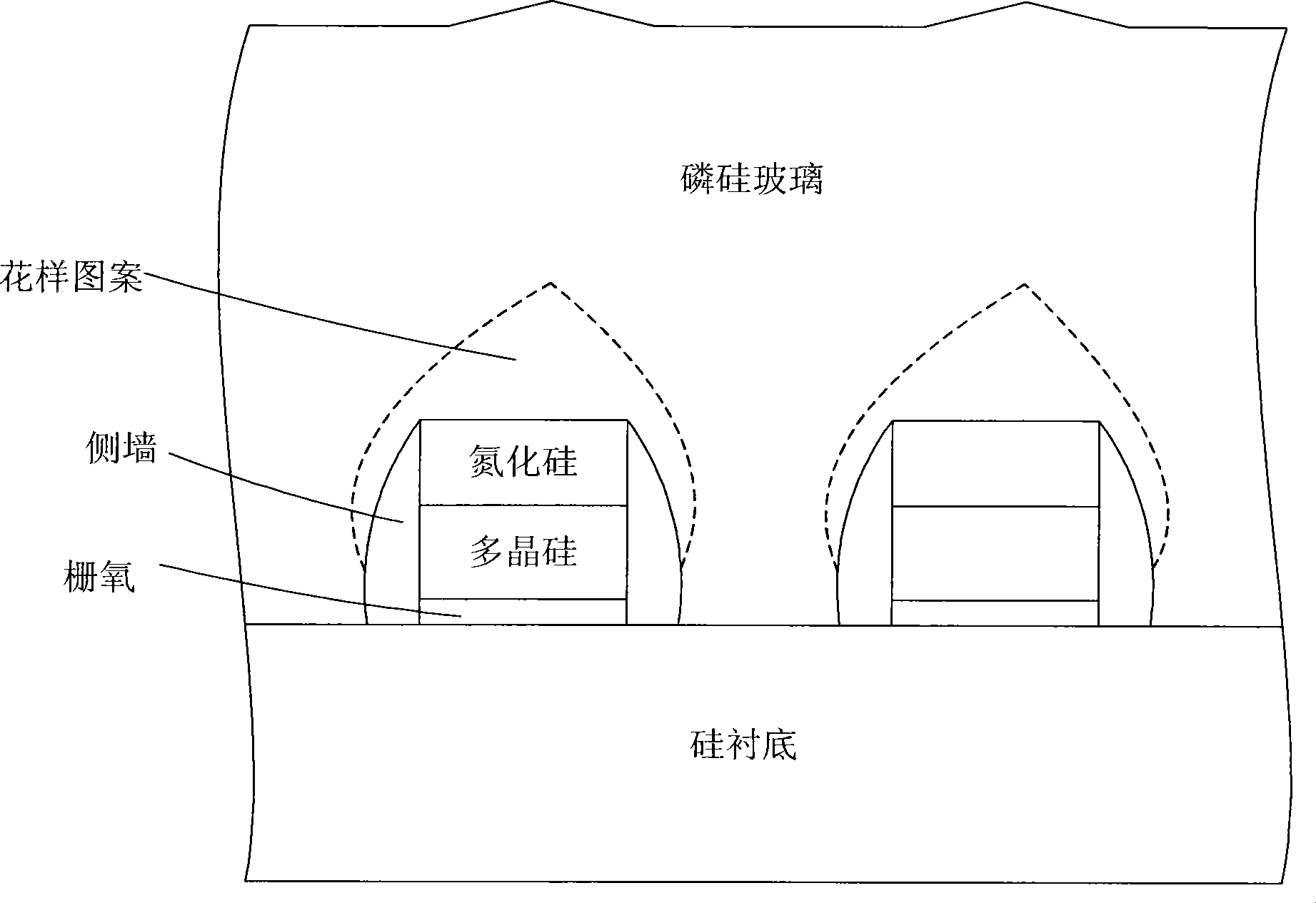

Method for preparing phosphorosilicate glass

The invention discloses a preparation method of phoshosilicate glass, which is characterized in that silane is used as reaction gas, high-density plasma deposition technology is utilized for preparation, and continuous deposition is carried out by using technological conditions of various multi-step deposition sputtering ratios in the process of deposition. During the first-step deposition, the deposition is carried out by using the technological condition of deposition sputtering ratio between 5.7 and 6.7; and then deposition is carried out by using the technological condition of deposition sputtering ratio less than 5.5 in the deposition steps. The preparation method can obviously reduce the horizontal width and vertical height of patterns in phoshosilicate glass layers and is suitable for semiconductor device manufacture.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

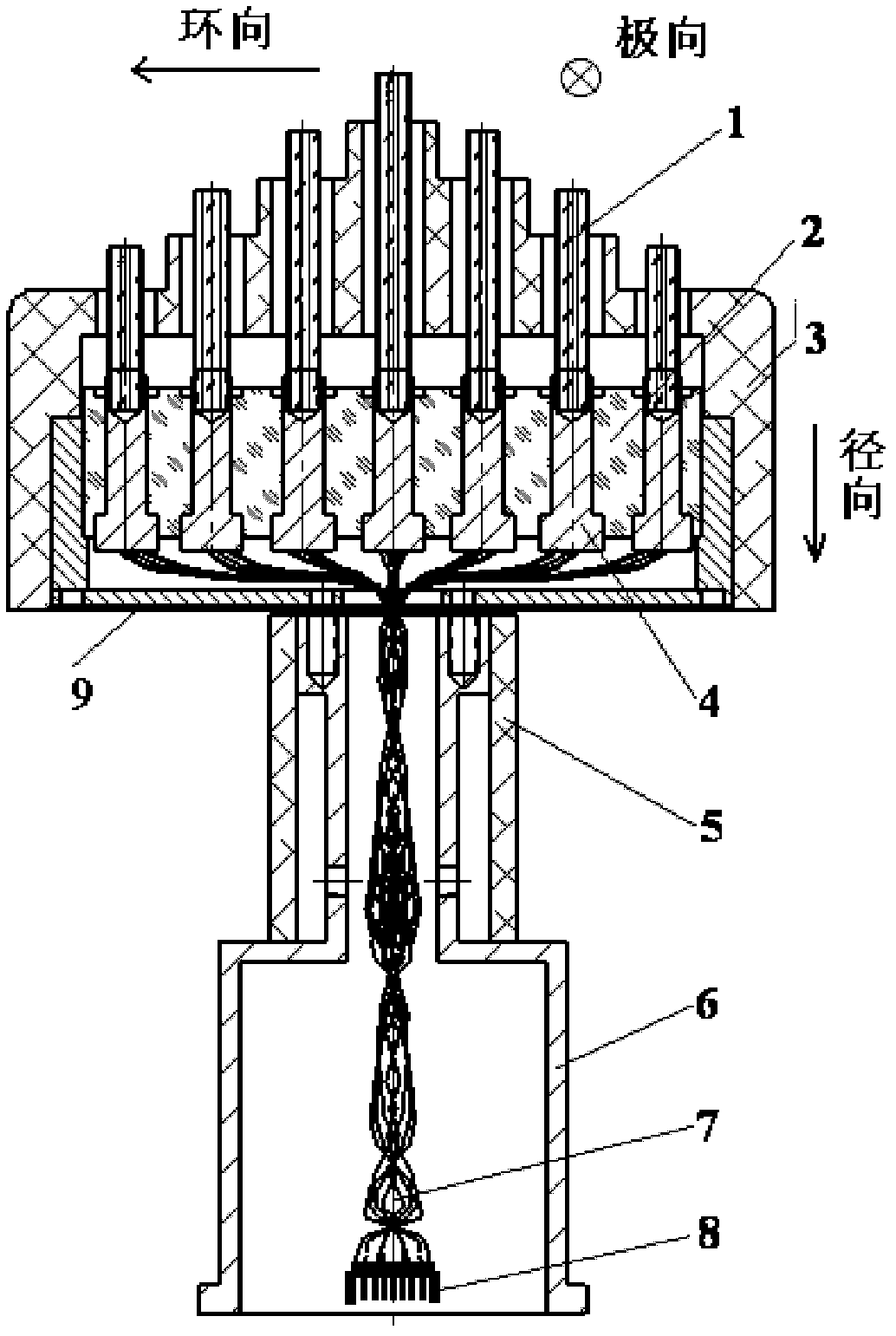

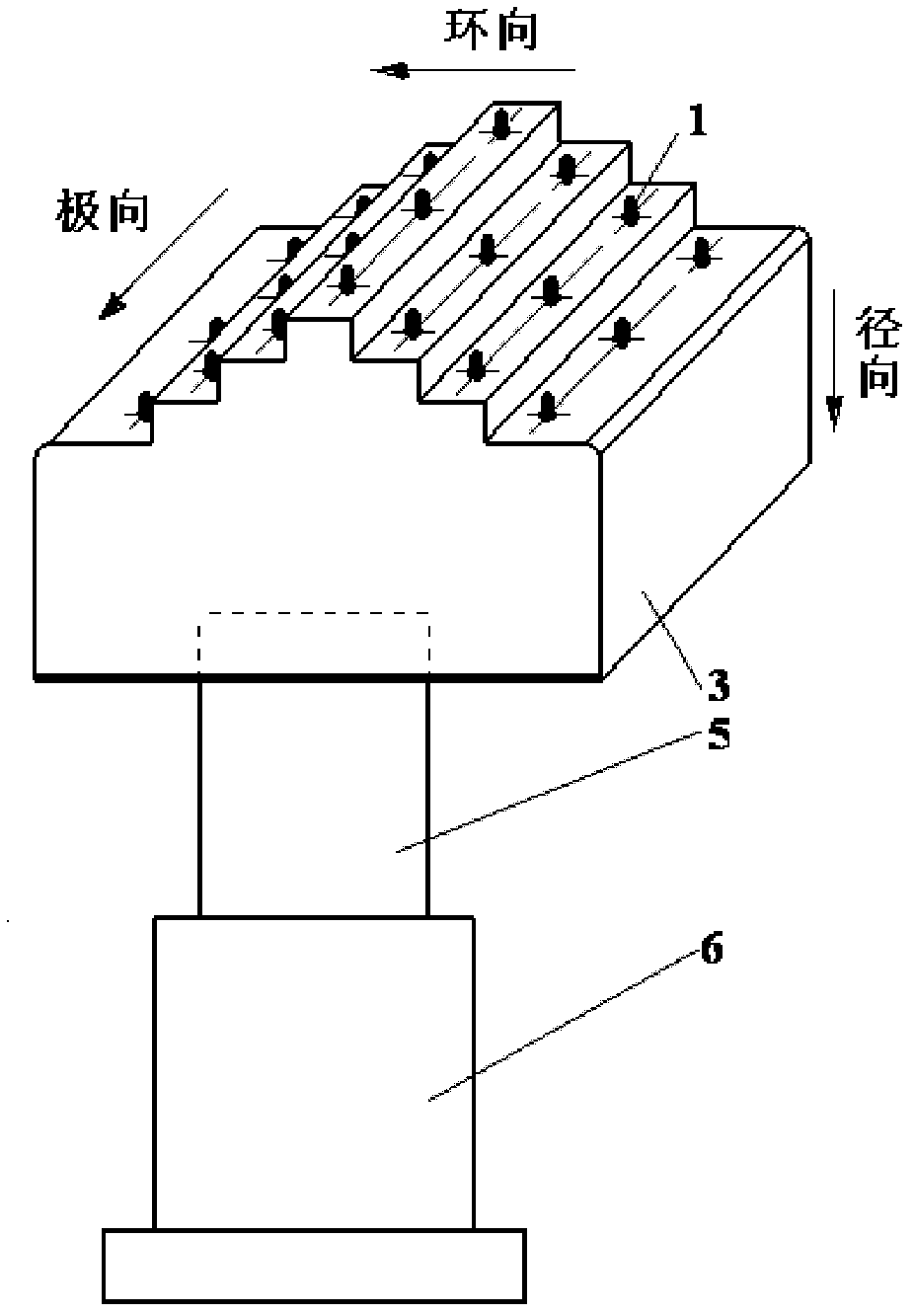

Turbulent momentum transport probe array

ActiveCN103187105AReduce pollutionDistribution data is accurate and reliableNuclear energy generationThermonuclear fusion reactorMomentumNuclear fusion

The invention belongs to the technical field of nuclear fusion, and particularly relates to a turbulent momentum transport probe array. A rectangular groove at the lower part of a pyrolytic graphite protecting sleeve A is connected with a connecting plate to form a rectangular cavity; a step-shaped cavity fixed connecting piece is arranged at the center of the lower side of the connecting plate; a two-way four-step symmetrical structure is arranged at the upper part of the pyrolytic graphite protecting sleeve A; the middle of the symmetrical structure is high and the two sides of the symmetrical structure are reduced gradually; twenty-one pyrolytic graphite probes are divided into seven rows equally and distributed on steps in parallel; the lower end of each pyrolytic graphite probe is connected with a lead copper tube; the lower ends of the lead copper tubes are collected together by cable leads; the collected cable leads penetrate through a center hole of the connecting plate, and enter the interior of the fixed connecting piece; the lower ends of the cable leads are connected with movable plugs; and insulation sleeves are arranged in the rectangular cavity formed by the pyrolytic graphite protecting sleeve A and the connecting plate, and arranged among the lead copper tubes. With the adoption of the probe array, a macroparameter of plasma of an HL-2A tokamak device can be measured in a discharging process.

Owner:SOUTHWESTERN INST OF PHYSICS

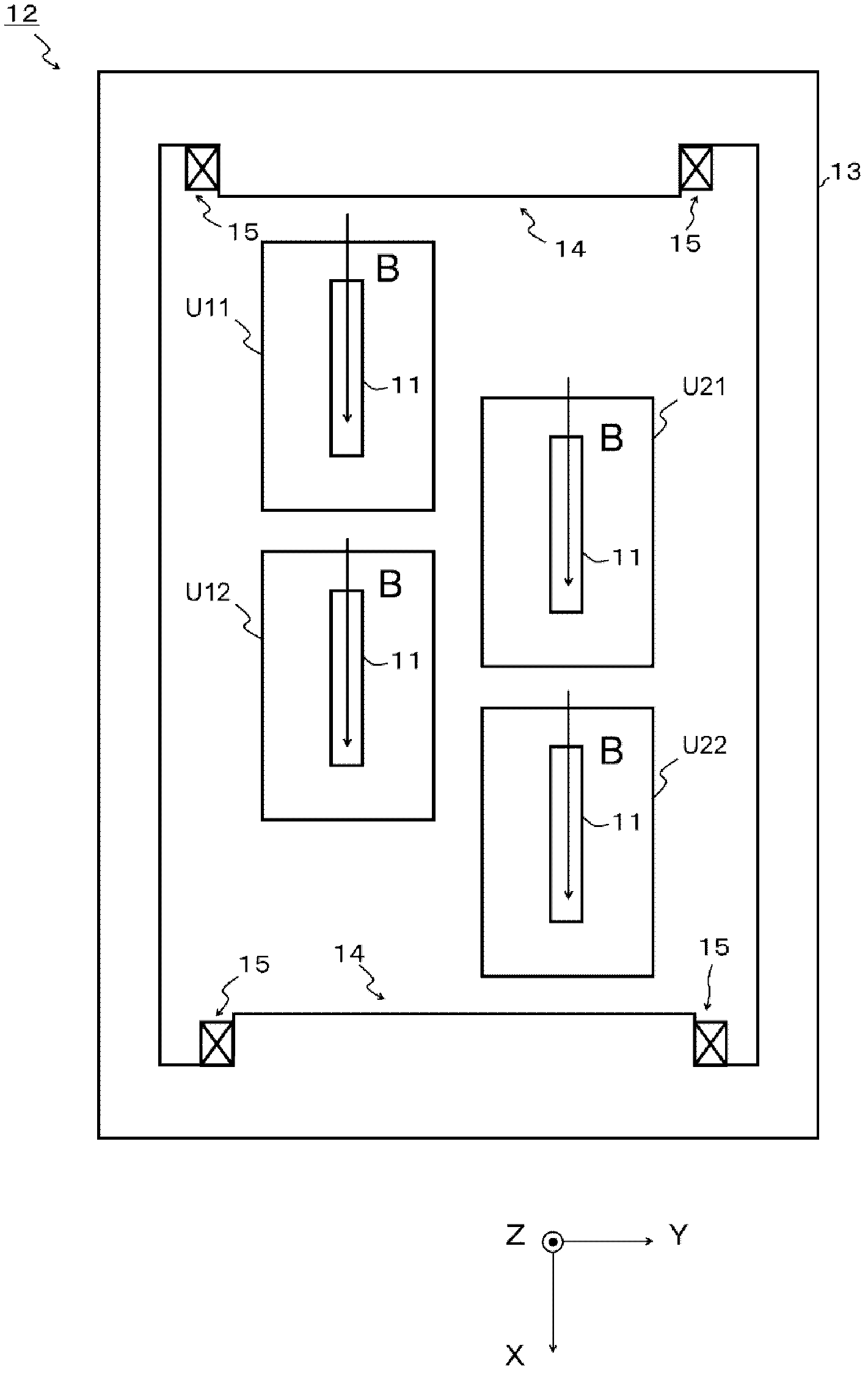

Ion source and ion implantation apparatus

The invention provides an ion source and an ion implantation apparatus. Compared with conventional ion sources, the ion source provided by the invention has relatively few disconnected filaments (cathode) and can stably generate large-scale and high-current ion beams. The ion source (8) comprises a plurality of plasma generating containers (U11 to U42) each containing a slit-shaped opening part (11) and at least one cathode which is arranged at the front end part projecting to the inside and does not contact with plasma (3); a magnetic field generating mechanism (12) for generating the magnetic fields in the plasma generating containers (U11 to U42) along a longitudinal direction of the slit-shaped opening part (11); and a leading-out electrode (6) for leading out banding-shaped ion beams (19) with substantially-rectangular cross-section shape from the slit-shaped opening part (11). Viewed from a short-side direction of the substantially-rectangular cross-section, the banding-shaped ion beams (19) led-out from the plasma generating containers (U11 to U42) overlap with each other at one end thereof in the longitudinal direction of the substantially-rectangular cross-section.

Owner:NISSIN ION EQUIP CO LTD

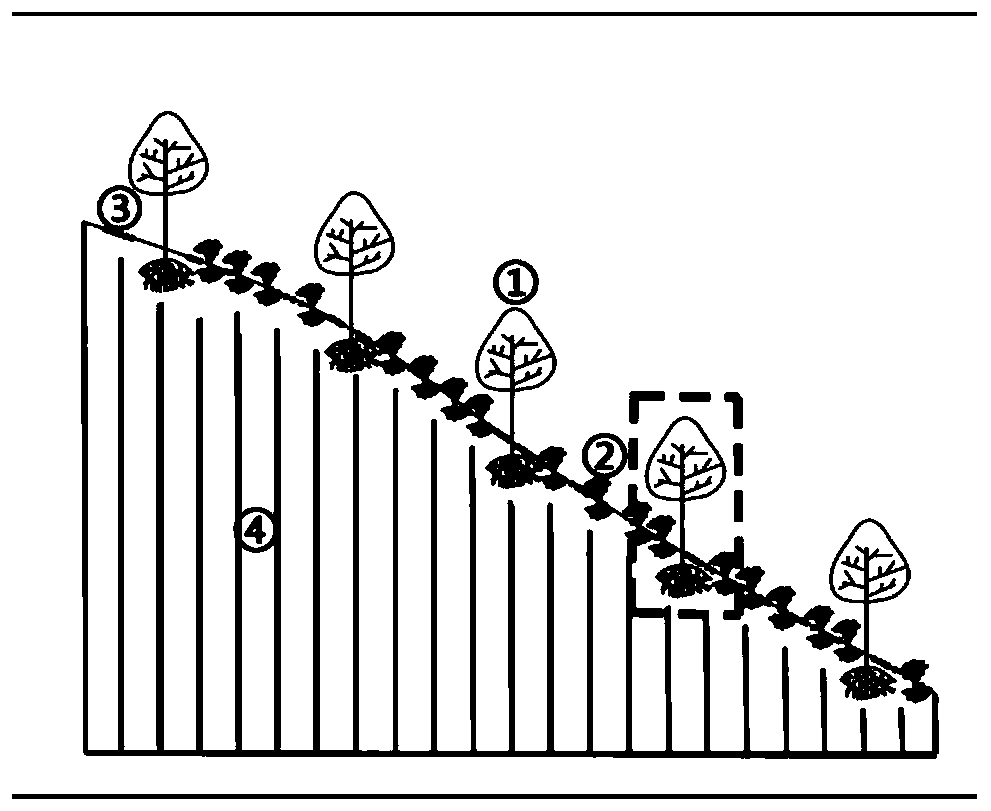

Plant root group dam ecological engineering construction method for prevention and control of mud flow in loess plateau

InactiveCN110063182AReduce erosionImprove cohesionHops/wine cultivationTurf growingPlant rootsEcological environment

The invention provides a plant root group dam ecological engineering construction method for prevention and control of mud flow in the loess plateau, and belongs to the field of ecological environmentimprovement. The method comprises the following steps: S1, dividing the slope gradient of the loess plateau; S2, rationally arranging arbor species, shrub species and herbaceous plants of different types and different root group depths under different slope gradients; S3, tending, managing and protecting grow plants in plated lands in the later stage to ensure that the plants can grow healthily.The plant root group dam ecological engineering construction method provided by the invention fully utilizes the root layer of three layers of trees, shrubs and herbaceous plants to realize the reinforcement of the shallow soil of the loess plateau, thereby reducing soil erosion as well as water and soil loss.

Owner:甘肃有色工程勘察设计研究有限公司

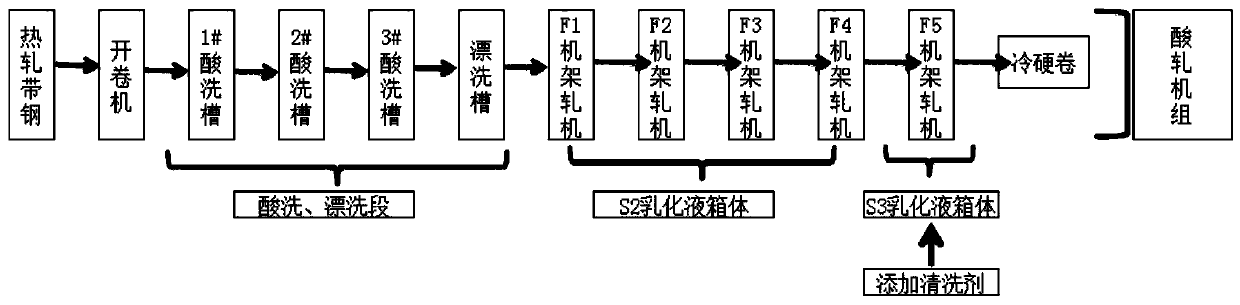

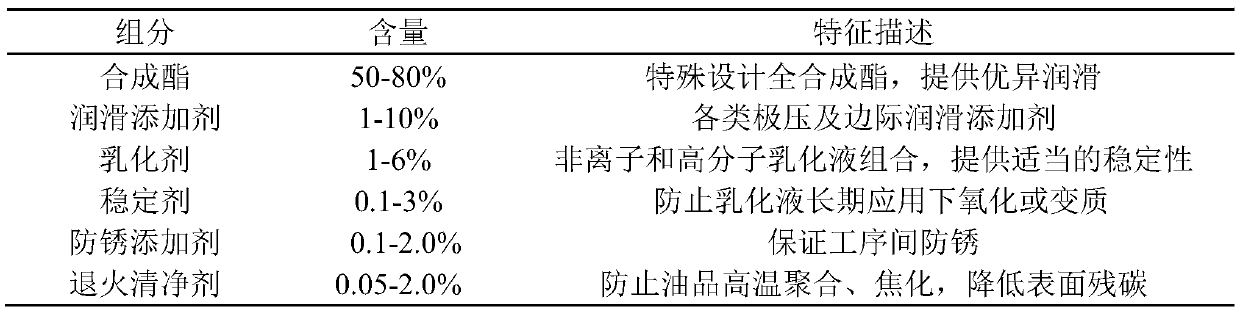

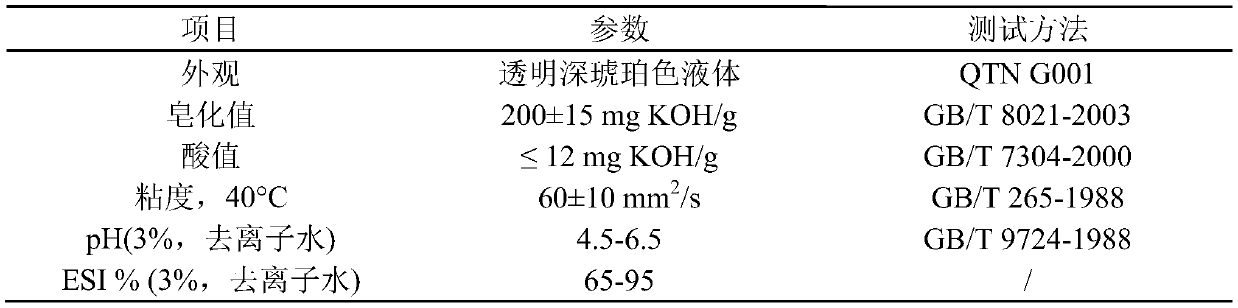

Method for improving rolled hard coiled strip steel surface reflectivity

ActiveCN111014315AImprove reflectivityClean thoroughlyWork cleaning devicesMetal rolling arrangementsStrip steelCleansing Agents

The invention belongs to the technical field of cold rolling acid pickling rolling, and relates to a method for rolled hard coiled strip steel cold rolling acid pickling rolling. The method comprisesthe following steps that acid pickling is carried out, specifically strip steel is placed into an acid pickling tank for acid pickling; rinsing is carried out, specifically the strip steel is placed in a rinsing tank for rinsing; emulsification cleaning is carried out, specifically the strip steel is placed on a frame rolling machine for emulsifying and cleaning the strip steel to obtain cold hardcoiled strip steel, and degreasing cleaning is carried out, specifically a cleaning agent is added, and emulsion and the cleaning agent are pre-mixed to be used for strip steel cleaning, wherein thefinal volume concentration of the cleaning agent added in an emulsion tank S3 is 0.2%, and a partition plate is arranged between frame rolling machines. The surface reflectivity of the rolled hard coiled strip steel produced through the method can be stably controlled to be about 75%, and higher-quality raw materials are provided for production of subsequent galvanized steel materials and the like.

Owner:马钢(合肥)钢铁有限责任公司

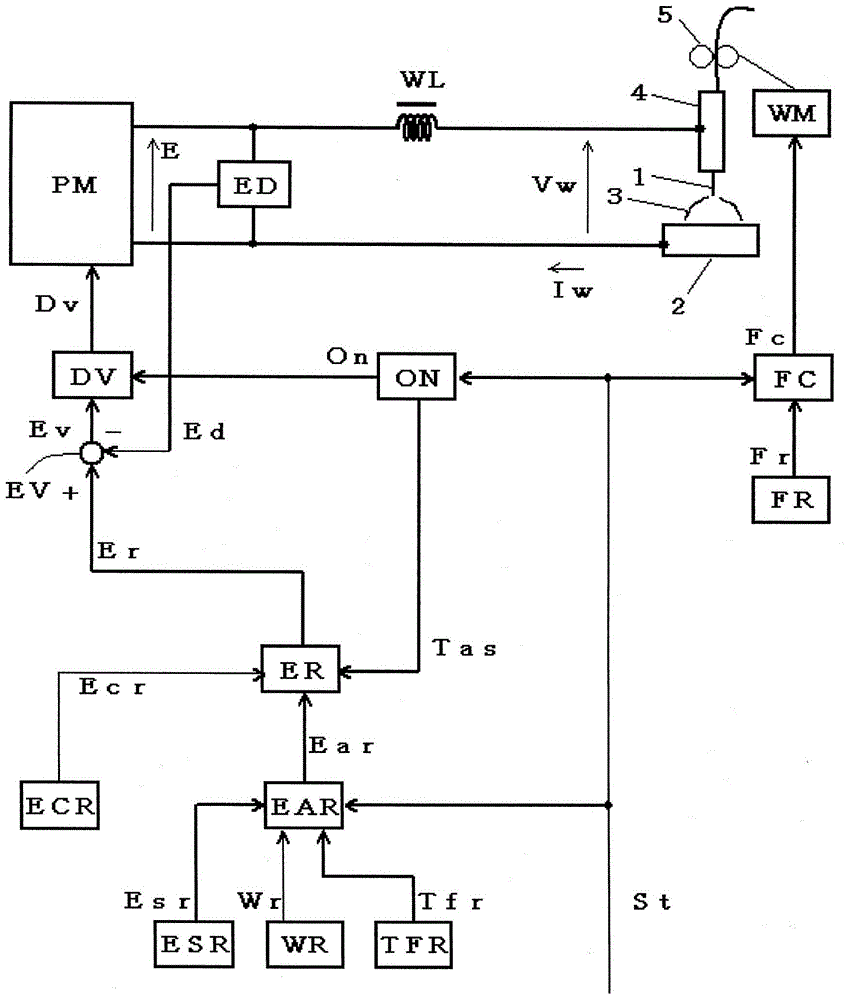

Anti-viscin thread control method

The invention provides an anti-viscin thread control method comprising the following the steps: feeding a solder wire doped with solder agent; carrying out constant voltage control according to a voltage setting signal (Er), thus outputting a welding voltage (Vw) and a welding current (Iw), and carrying out welding; if a welding start signal (St) is changed into a stop instruction, than the voltage setting signal (Er) is switched into an anti-viscin thread voltage setting value (Ear), thus stop welding. The anti-viscin thread voltage setting value (Ear) is set in vibration waveform, so the welding current (Iw) is set to vibration waveforms of triangle shape or sine wave shape, and the anti-viscin thread voltage setting value (Ear) is set to prevent short circuit in an anti-viscin thread control period (Ta); welding agent in the solder wire can be gasified so as to prevent slags from attaching to the front end of the solder wire. The solder wire with solder agent is used for arc welding so as to prevent slags from attaching to the front end of the solder wire, thus providing better arcing property.

Owner:DAIHEN CORP

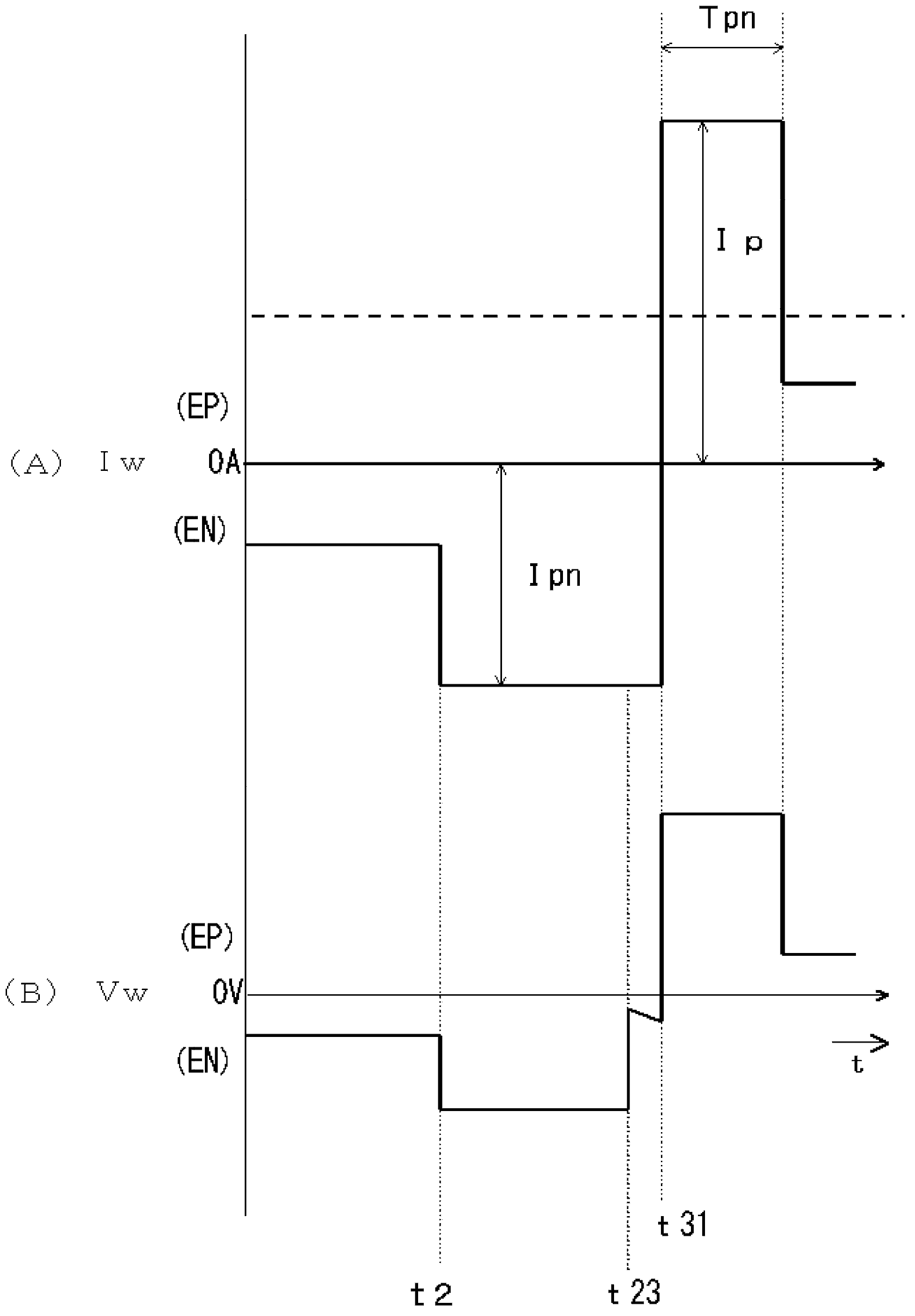

Method for controlling ac pulse electric arc welding

ActiveCN103418888AFacilitate droplet transferReduce sputteringArc welding apparatusPower flowElectrical polarity

The invention provides a method for controlling AC pulse electric arc welding, which is intended to maintain a stable welding state even an electrode negative polarity current ratio is set to be a large value in sacrificial electrode AC pulse electric arc welding. Therefore, a background current is powered during the electrode negative polarity base value, an electrode negative polarity peak current (Ipn) is powered during the electrode negative polarity peak value (Tpn), a peak current is powered during the electrode positive polarity peak value, a background current is powered during the electrode positive polarity base value. A short circuit occurs during the electrode positive polarity peak value. When a value of a short circuit generating time point relative to a molten drop dimension is lower than a reference value , the current during the short circuit is added, and when the value relative to the molten drop dimension is larger than the reference value, the value is converted in the electrode positive polarity peak value period at the short circuit generating time point. Therefore, molten drop transition is smoothly performed irrespectively with the molten drop dimension, thereby maintaining the stable welding state.

Owner:DAIHEN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com