Method for controlling ac pulse electric arc welding

A technology of arc welding and control method, which is applied in the direction of arc welding equipment, welding equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

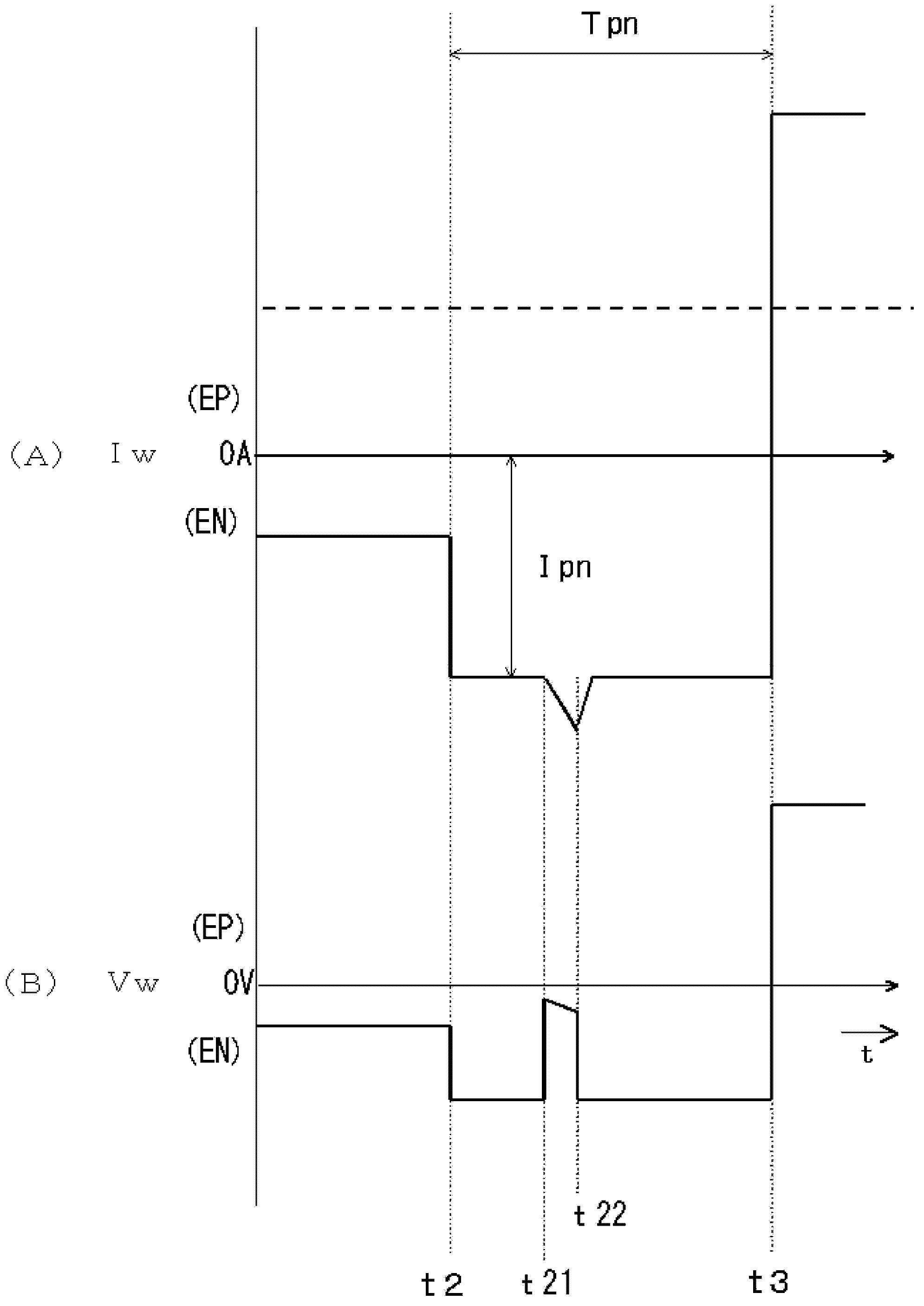

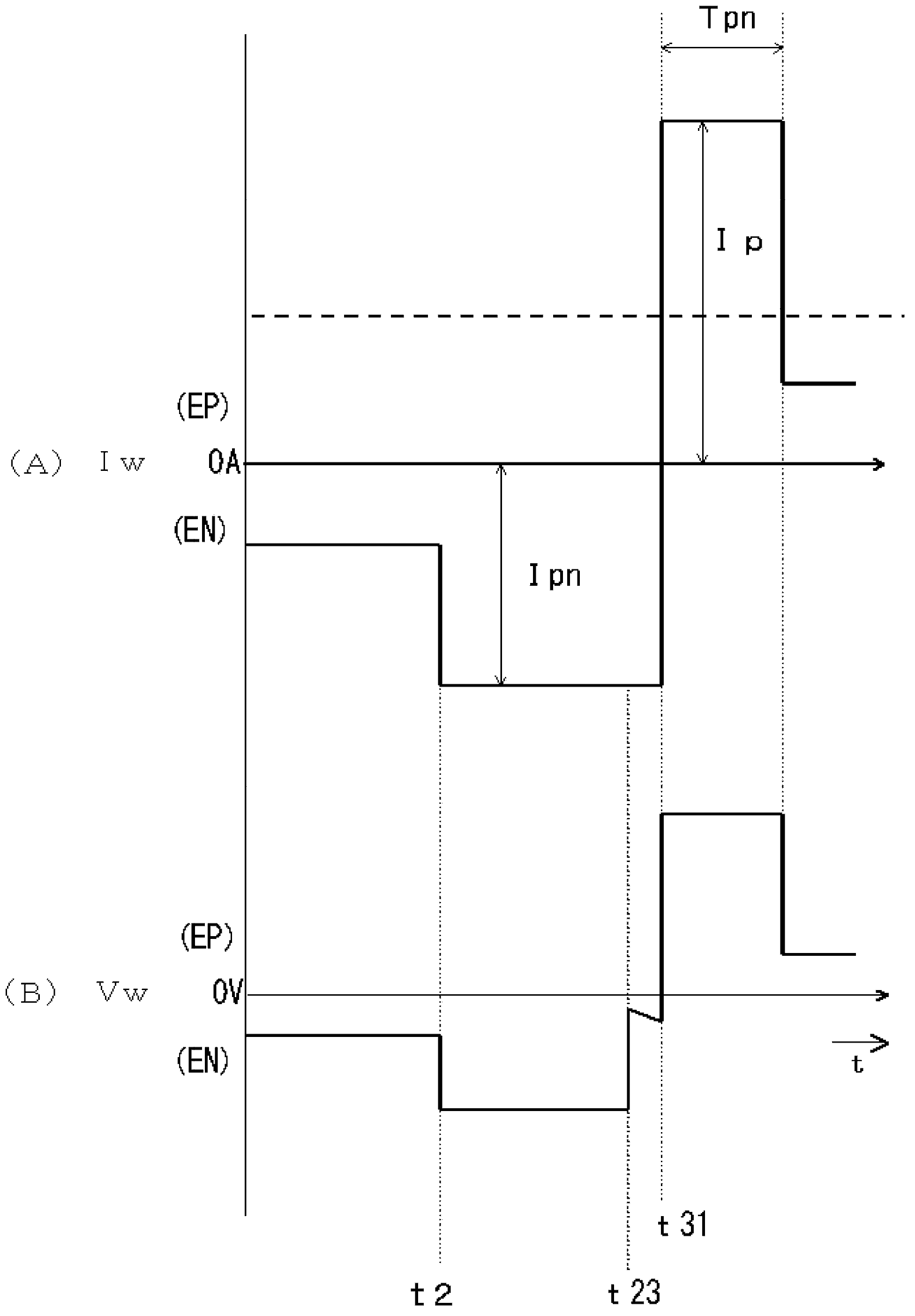

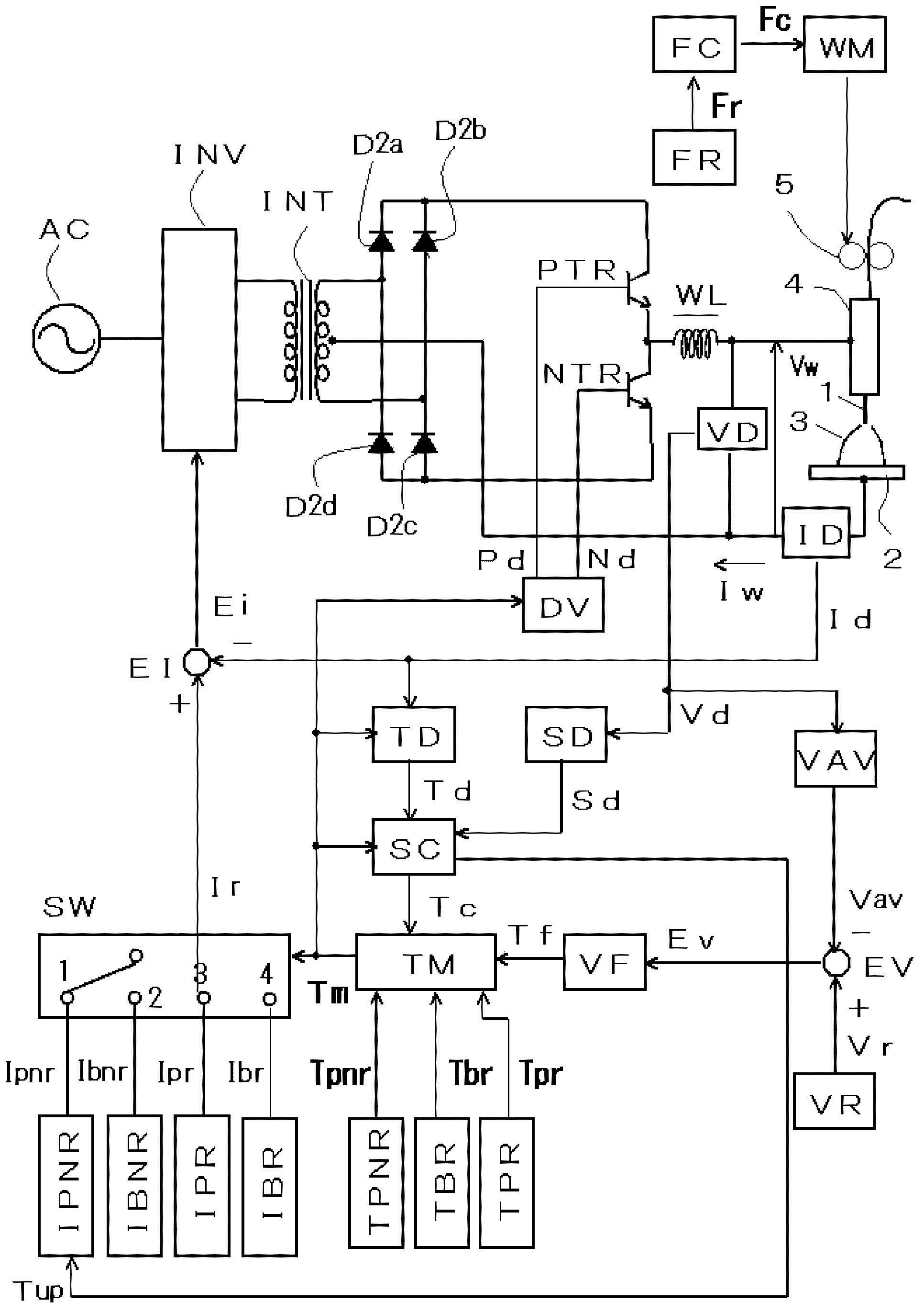

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0029] The welding current waveform of the AC pulse arc welding control method according to the embodiment of the present invention is different from the above-mentioned Figure 4 same. That is, there are cases where the electrode negative polarity base period Tbn → the electrode negative polarity peak period Tpn → the electrode positive polarity peak period Tp → the electrode positive polarity base period Tb is one pulse period Tf, and the electrode negative polarity base period The case where Tbn→electrode negative polarity peak period Tpn→electrode positive polarity peak period Tp is taken as one pulse period Tf. However, in the present embodiment, the welding current waveform when a short circuit occurs during the electrode negative polarity peak period Tpn is different from the conventional art, and will be described below.

[0030] figure 1 is in the above Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com