Patents

Literature

36results about How to "Welding state is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Squeezing detection control method for consumable electrode arc welding

ActiveUS20070221642A1Solve problemsIncrease currentArc welding apparatusElectrical resistance and conductanceEngineering

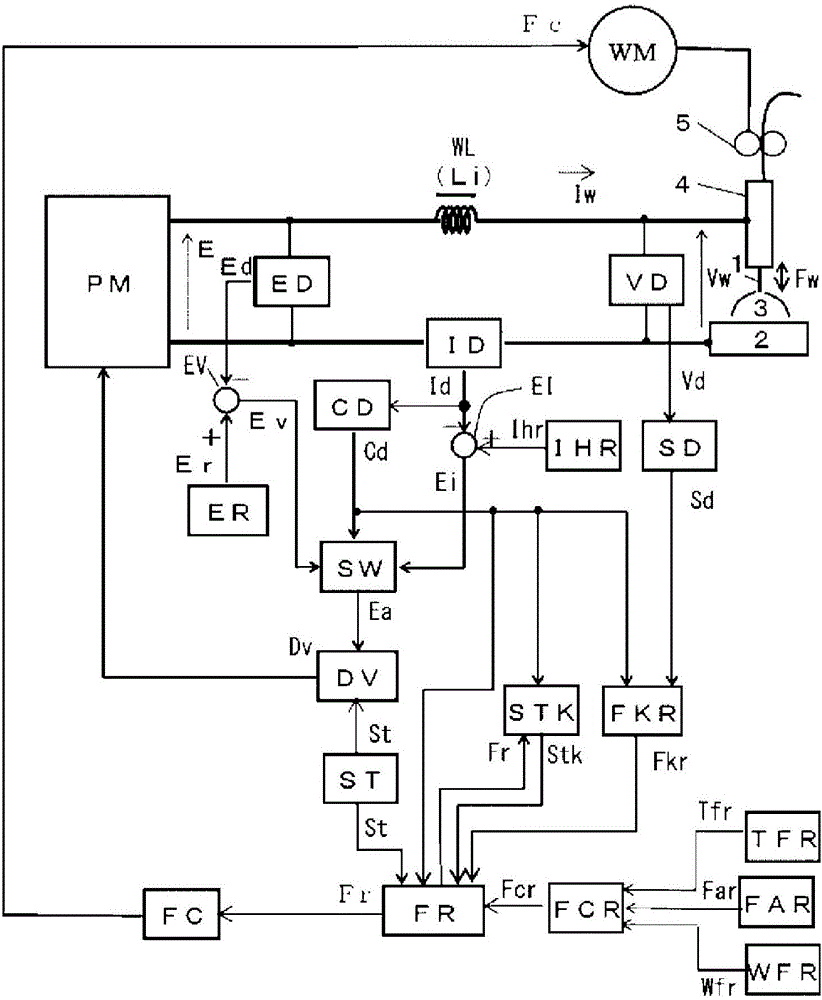

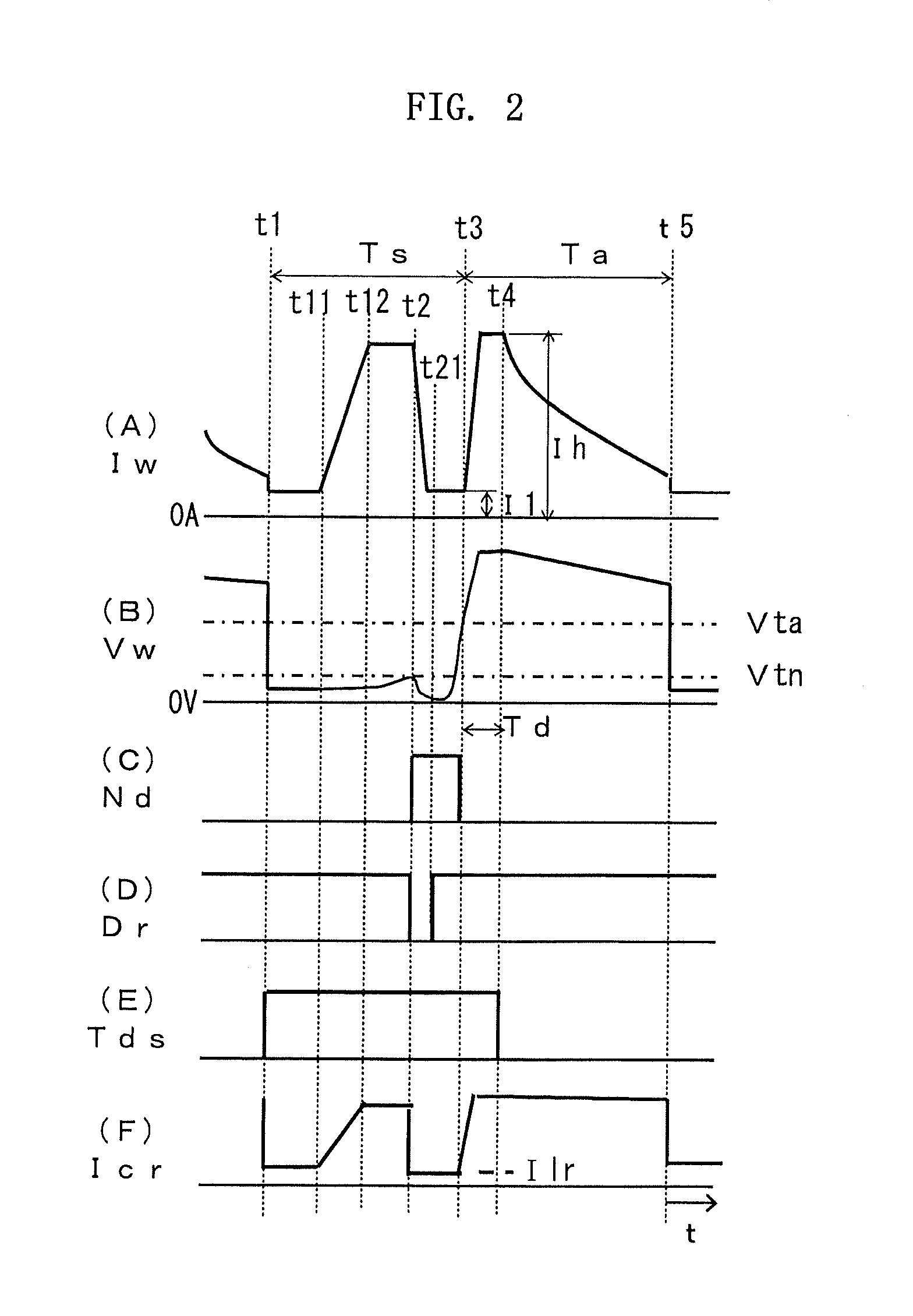

A squeezing detection control method is provided for consumable electrode arc welding in which a cycle of arc generation and short-circuiting is repeated between a consumable electrode and a base metal. First, squeezed droplet is detected as a premonitory sign of arc recurrence at the end of the short-circuiting. This detection is based on a fact that a squeeze detection reference value is attained by a differential value of the voltage or resistance between the consumable electrode and the base metal. Then, a welding current supplied to a short-circuit load is rapidly decreased upon detection of the squeezed droplet. Upon recurrence of the arc, the welding current is increased. This arc recurrence is detected by a fact that the differential value attains an arc recurrence reference value which is greater than the squeeze detection reference value.

Owner:DAIHEN CORP

Ac pulse arc welding control method

A control method for AC pulse arc welding performed upon application of cyclic AC welding current is provided. The welding current has a cycle including an electrode negative polarity period and an electrode positive polarity period subsequent to the electrode negative polarity period. In the control method, an electrode negative polarity base current and a subsequent electrode negative polarity peak current are applied during the electrode negative polarity period. The electrode negative polarity base current has an absolute value smaller than a first critical value, and the electrode negative polarity peak current has an absolute value greater than the first critical value. Then, an electrode positive polarity peak current is applied during the electrode positive polarity period. The electrode positive polarity peak current has a value greater than a second critical value.

Owner:DAIHEN CORP

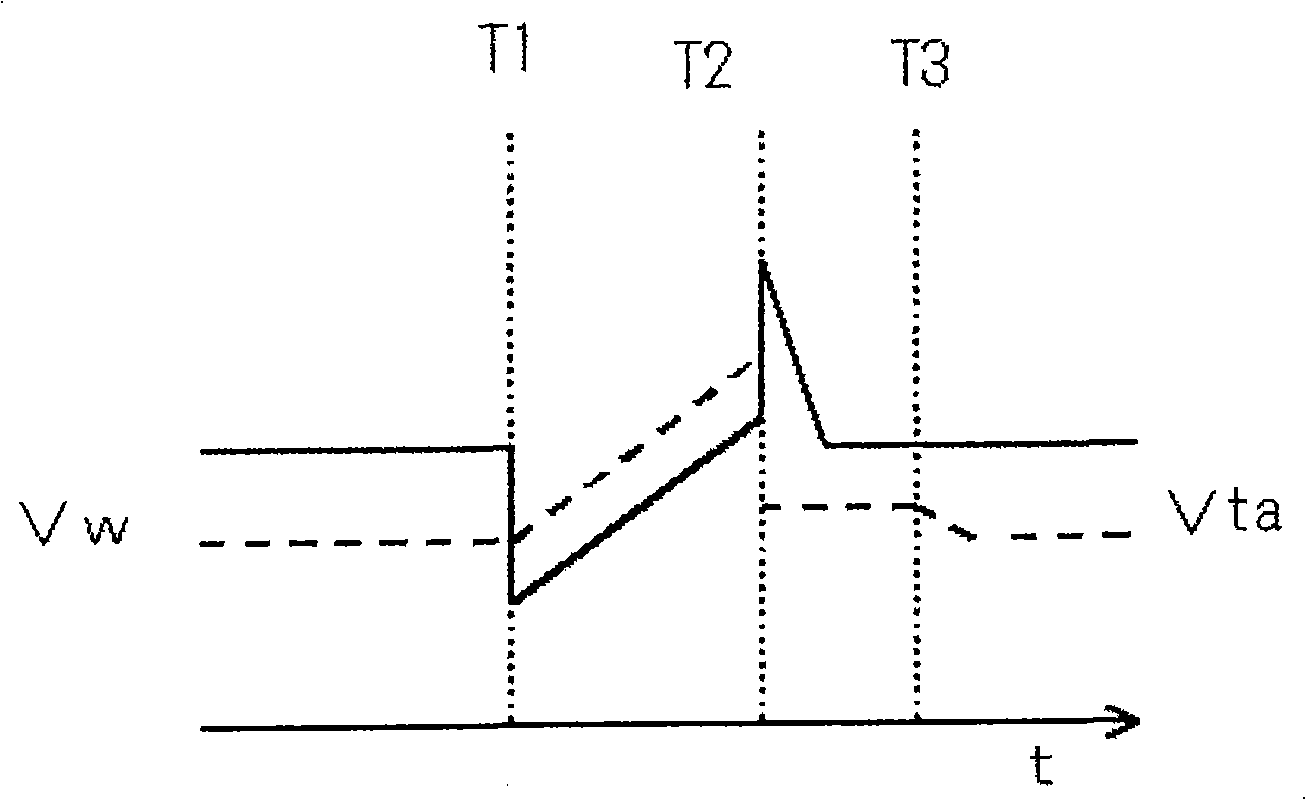

Short circuit determination method for electrode fused arc welding

ActiveCN101513689AAvoid misjudgmentWelding state is stableArc welding apparatusElectric arcEngineering

The invention provides a short circuit judgment method for electrode fused arc welding, by which even the electric cable for welding is long in the electrode fused arc welding, whether the welding filament and the base metal in short circuit status or arc generation status can be accurately determined, and welding of high quality can be executed. A welding voltage (Vw) is compared with a short circuit standard value (Vt), a short circuit status is judged when the welding voltage (Vw) is lower than the short circuit standard value (Vt), while an arc generation status is judged when the welding voltage (Vw) is higher than the short circuit standard value (Vt). The short circuit standard value (Vt) varies according to the welding current value, and an upper limit is set in the arc generation status, which is a function of the welding current. Therefore, error judgment of short circuit status caused by welding voltage sudden decrease after arc generation can be prevented.

Owner:DAIHEN CORP

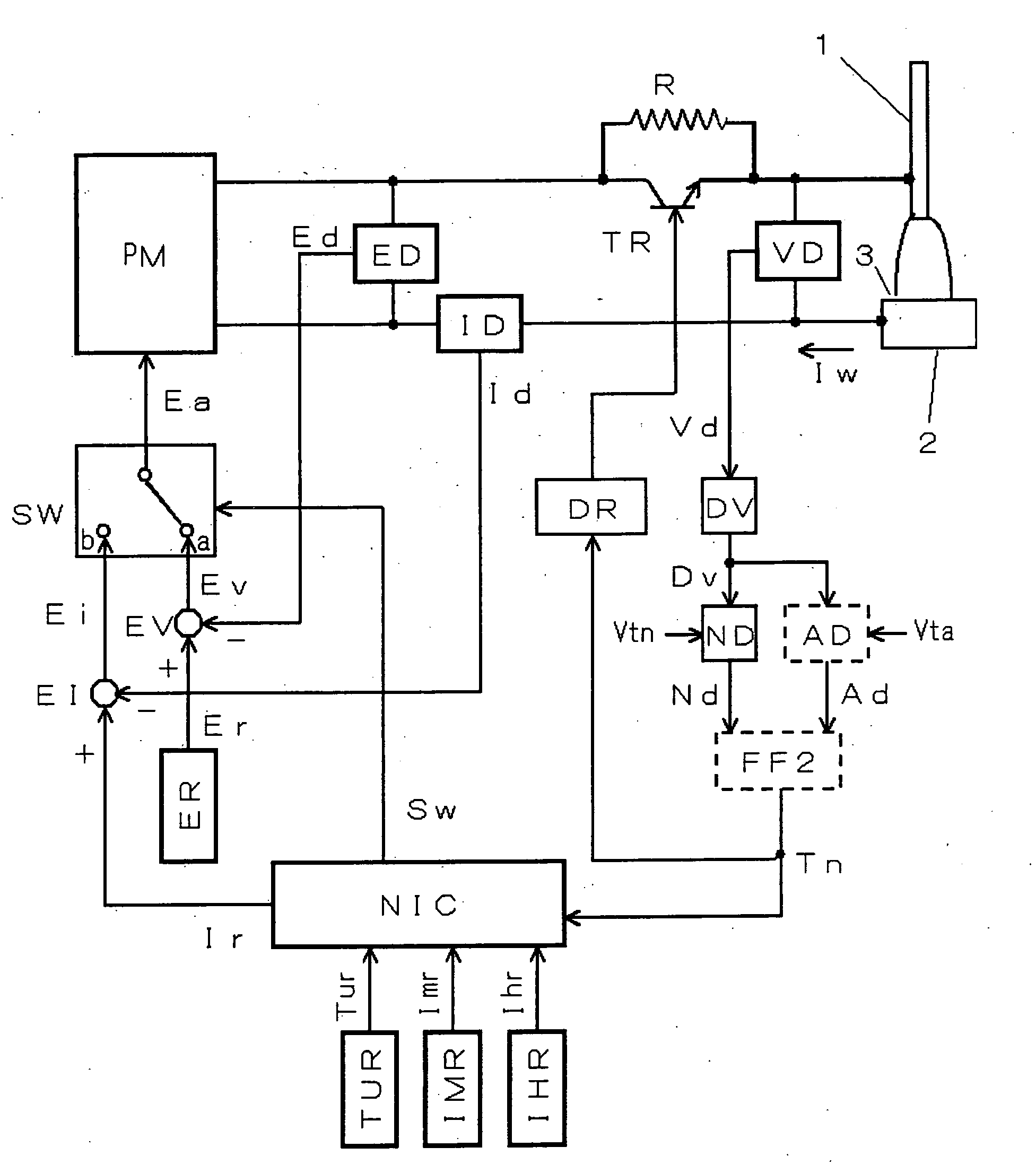

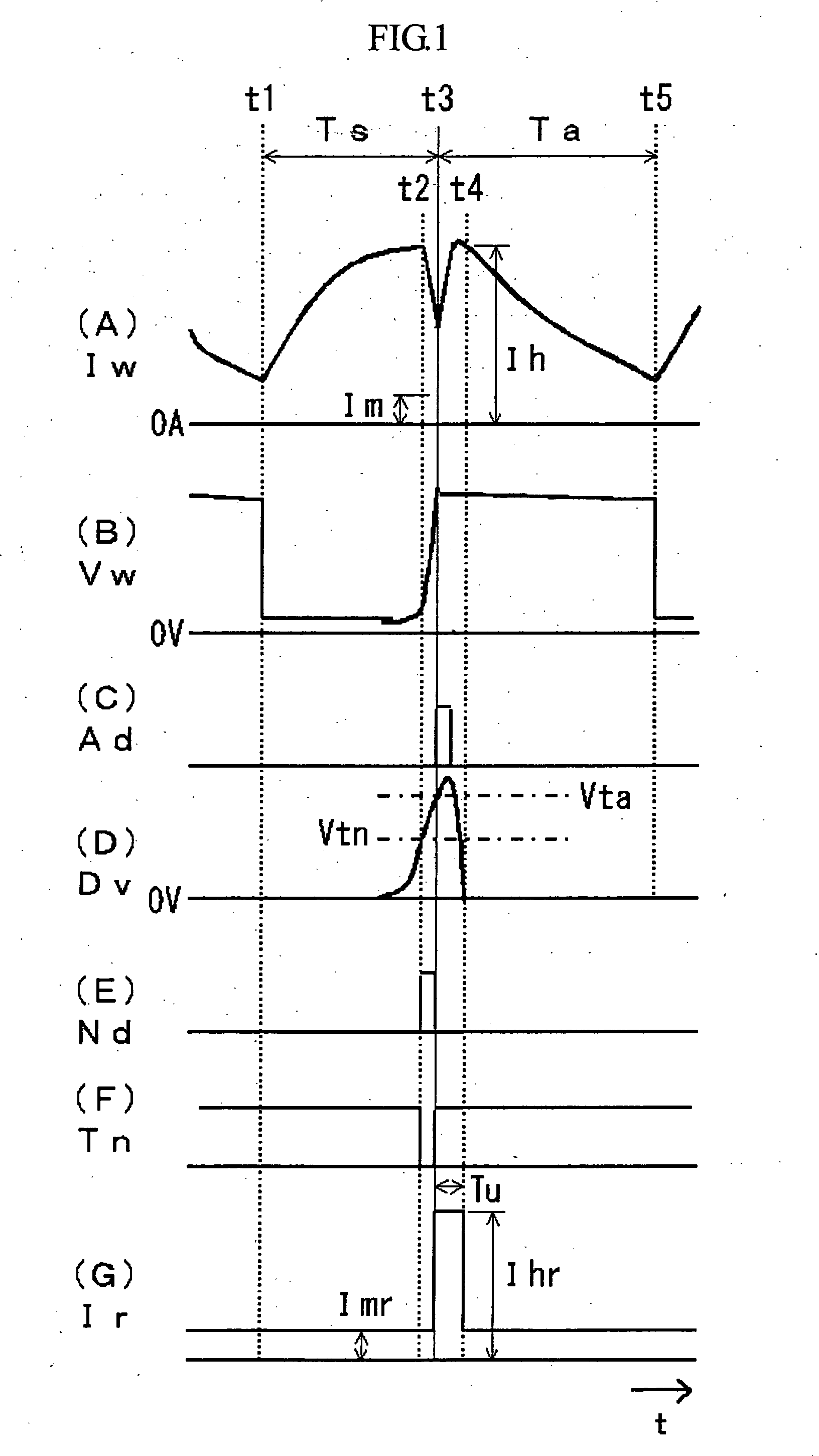

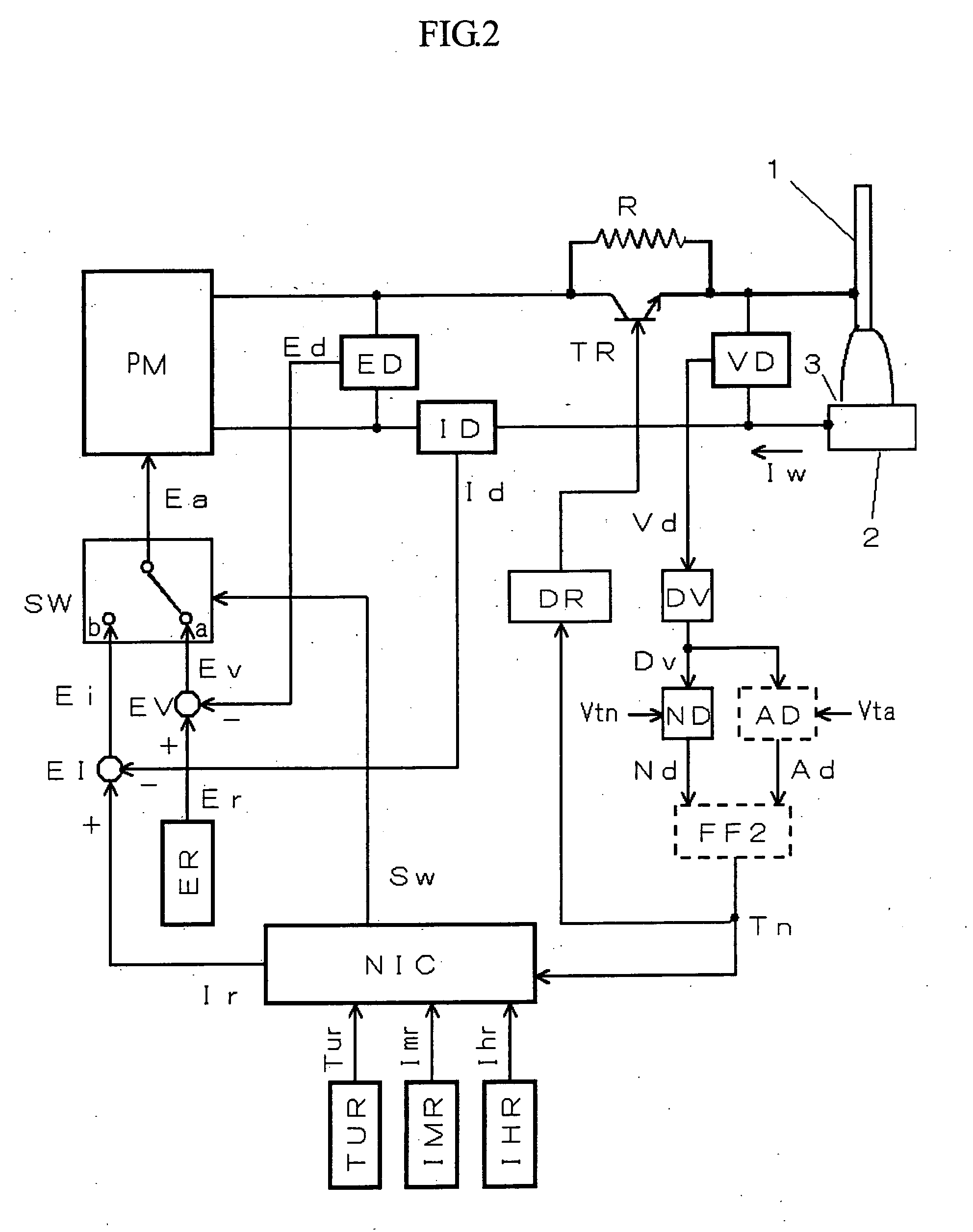

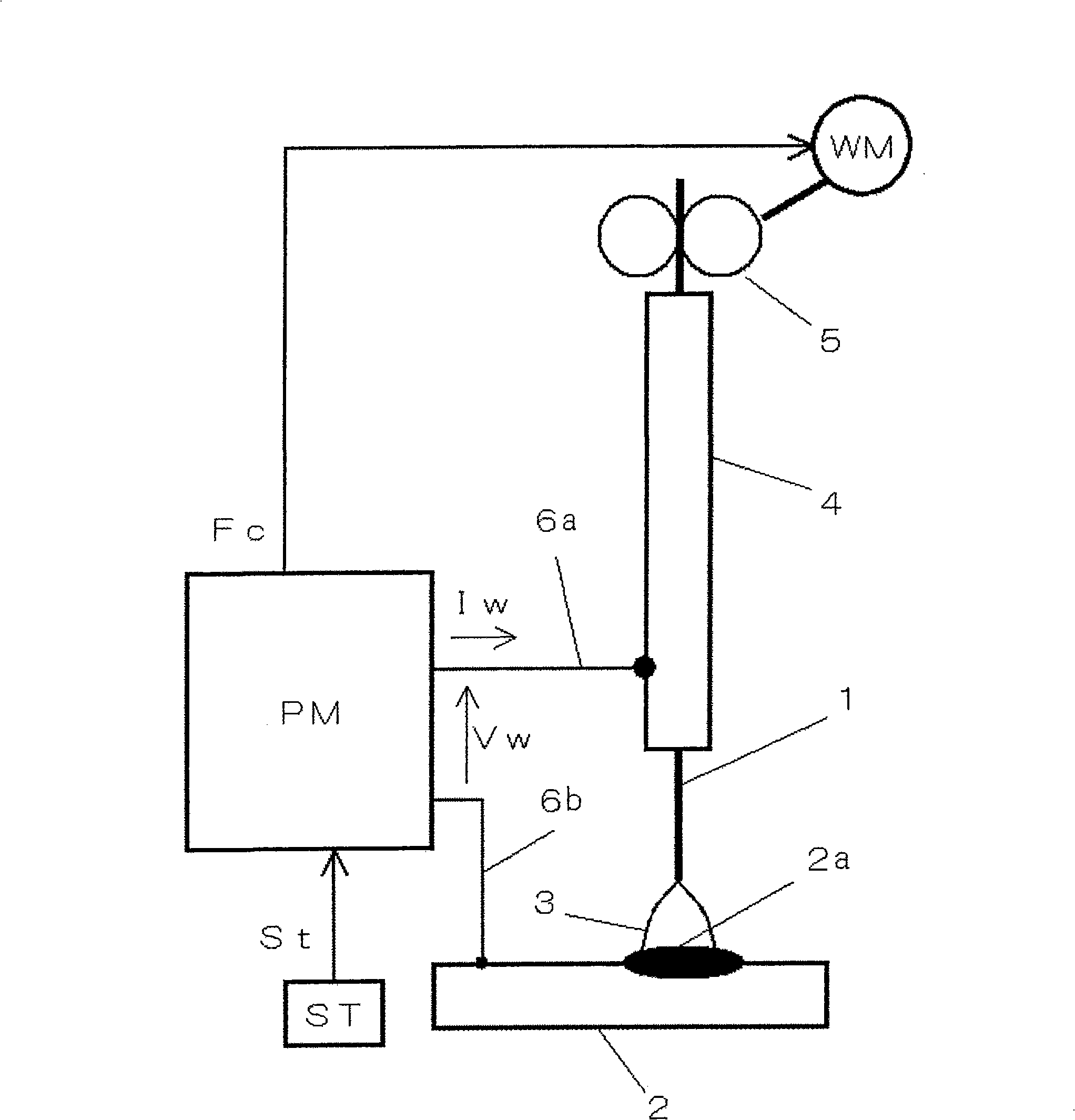

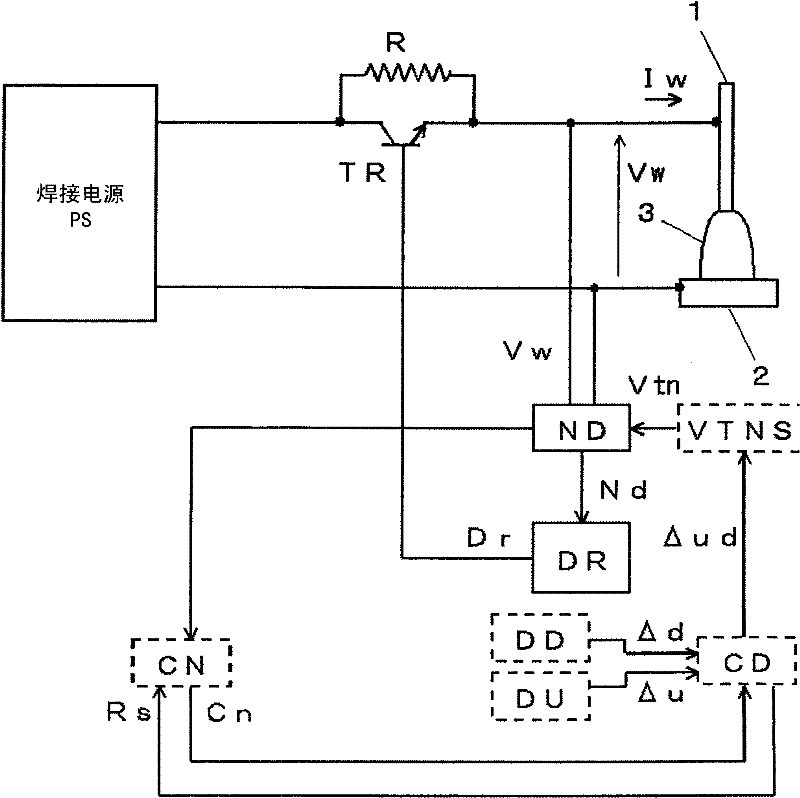

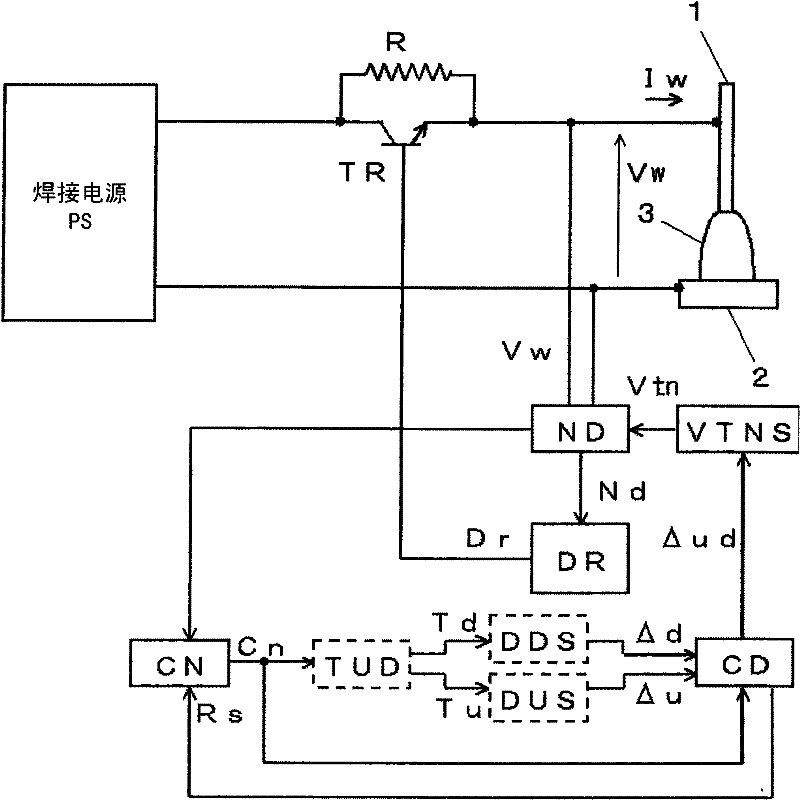

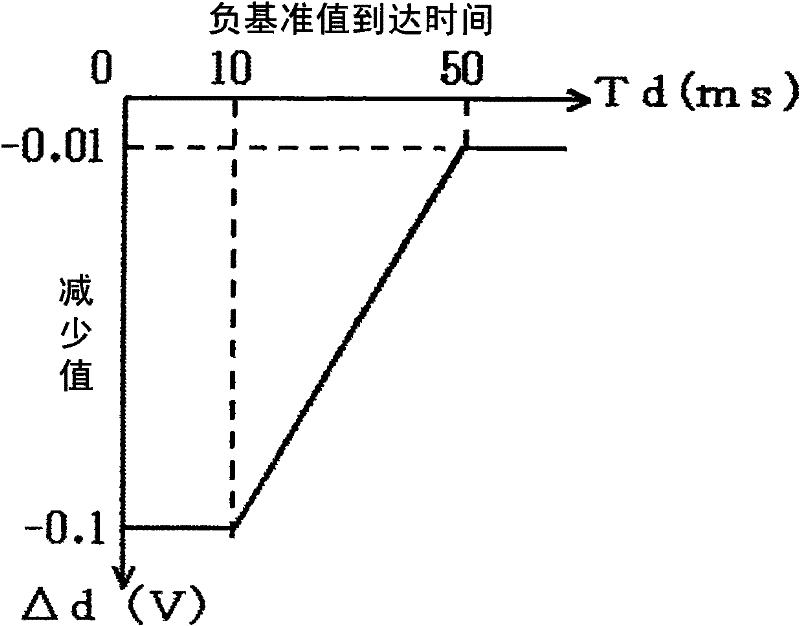

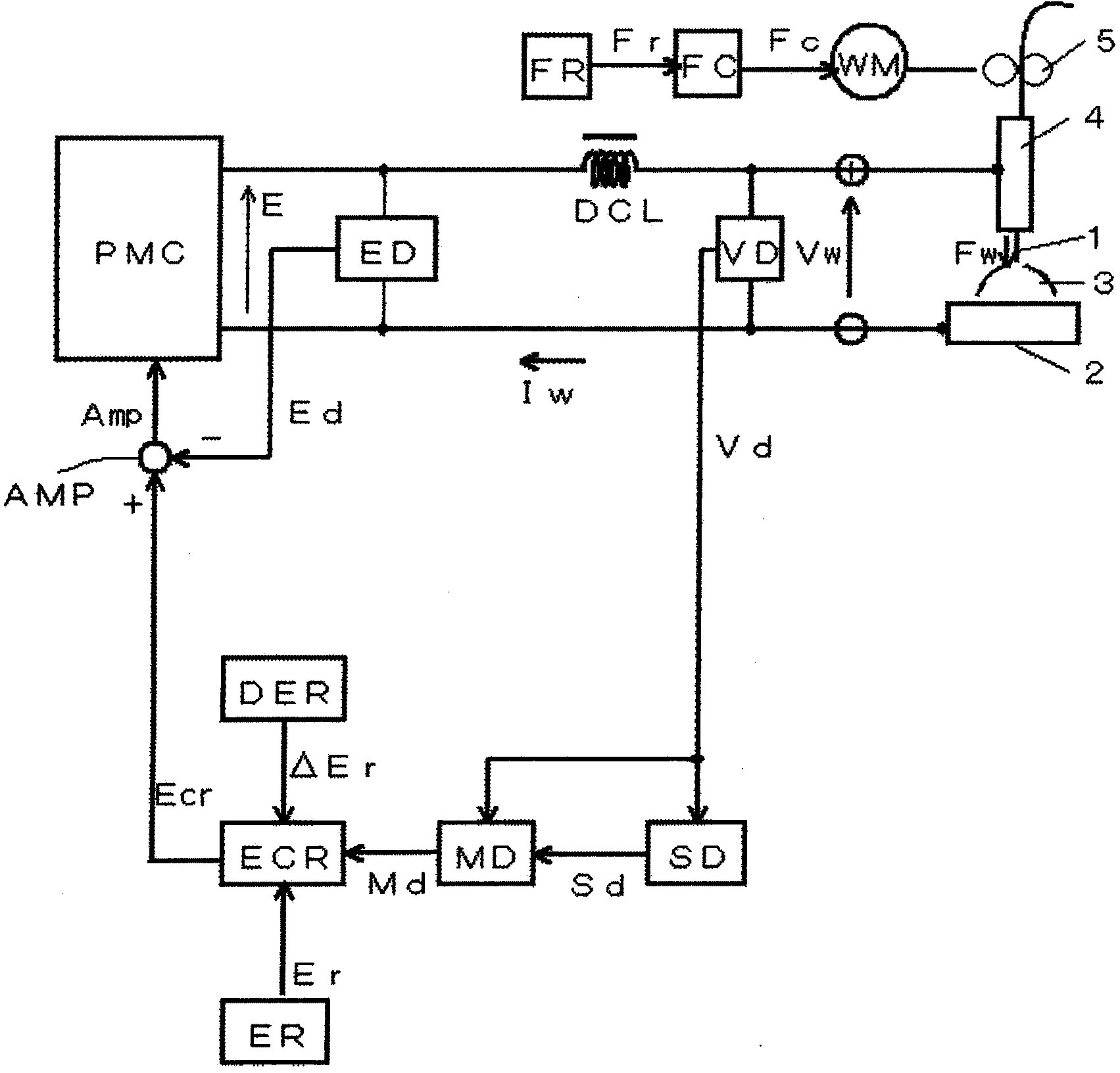

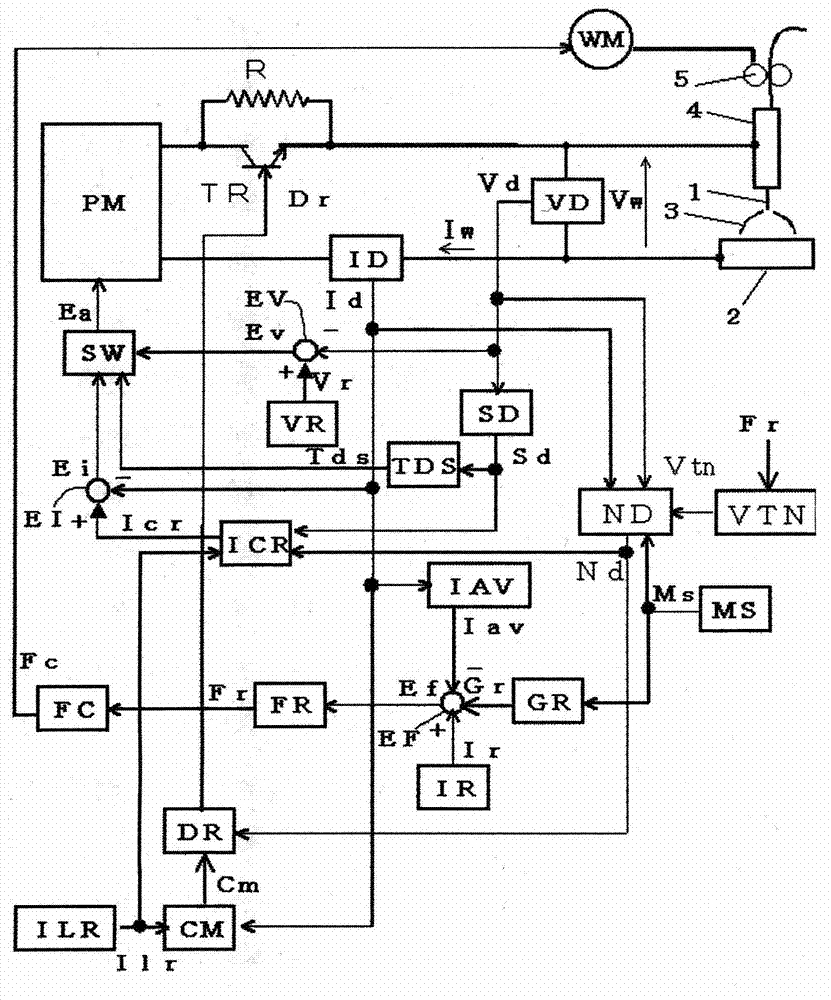

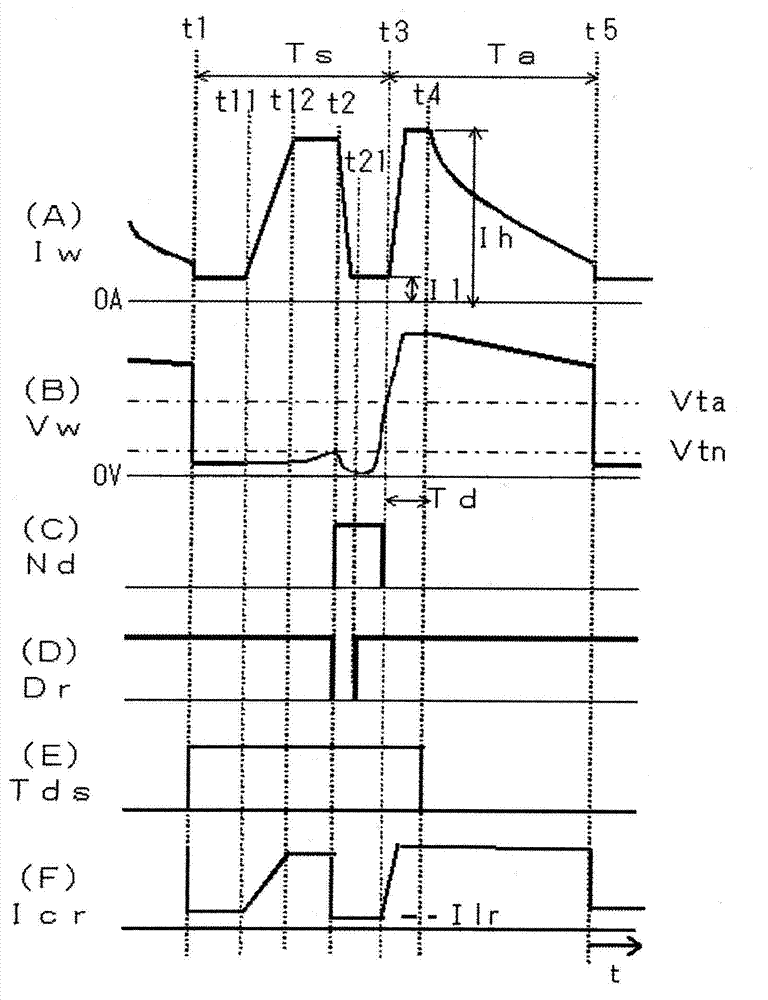

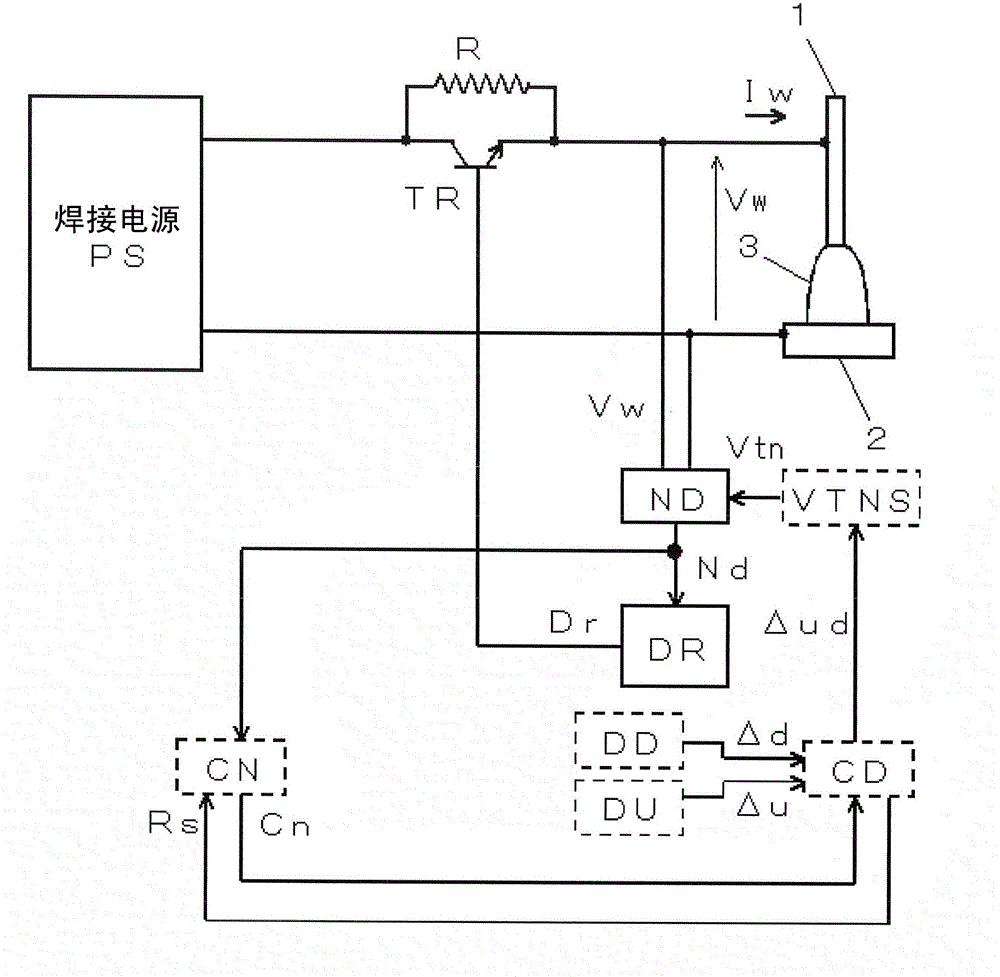

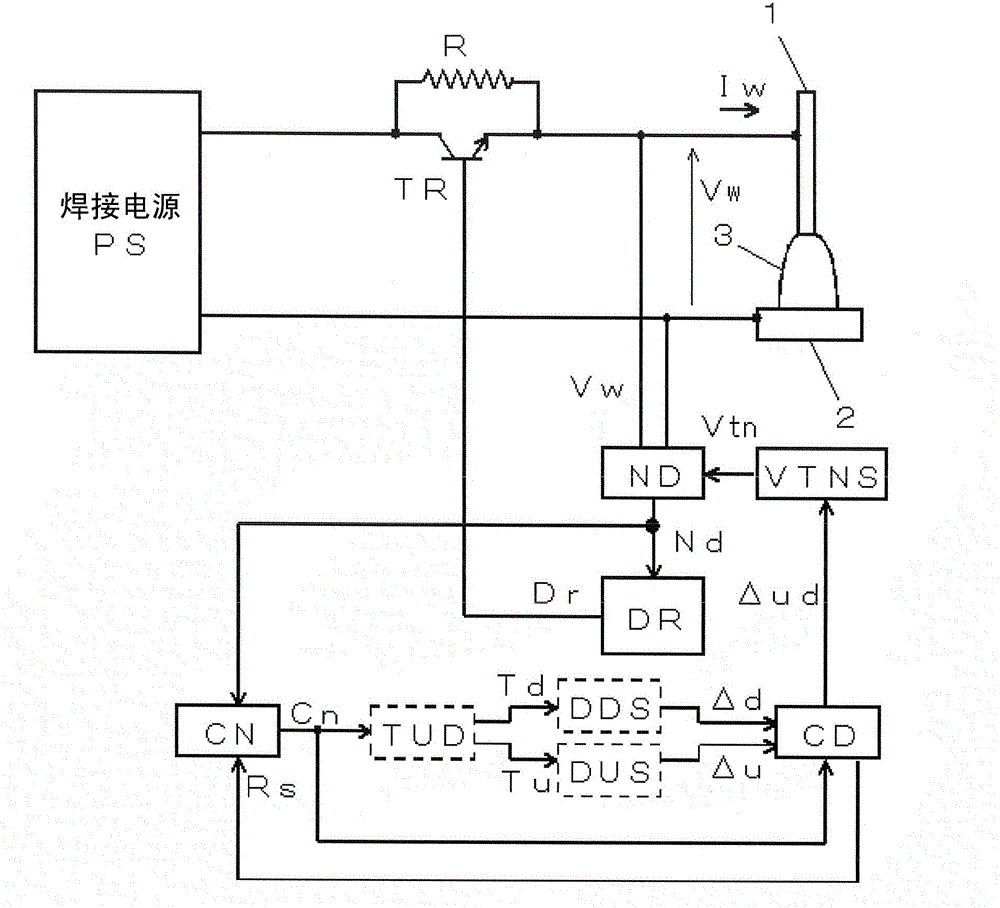

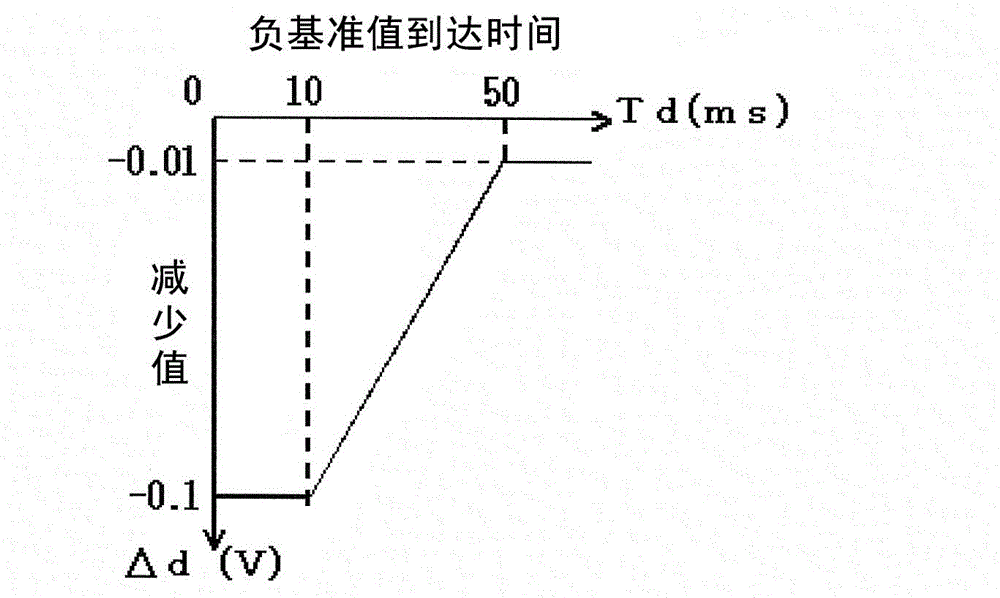

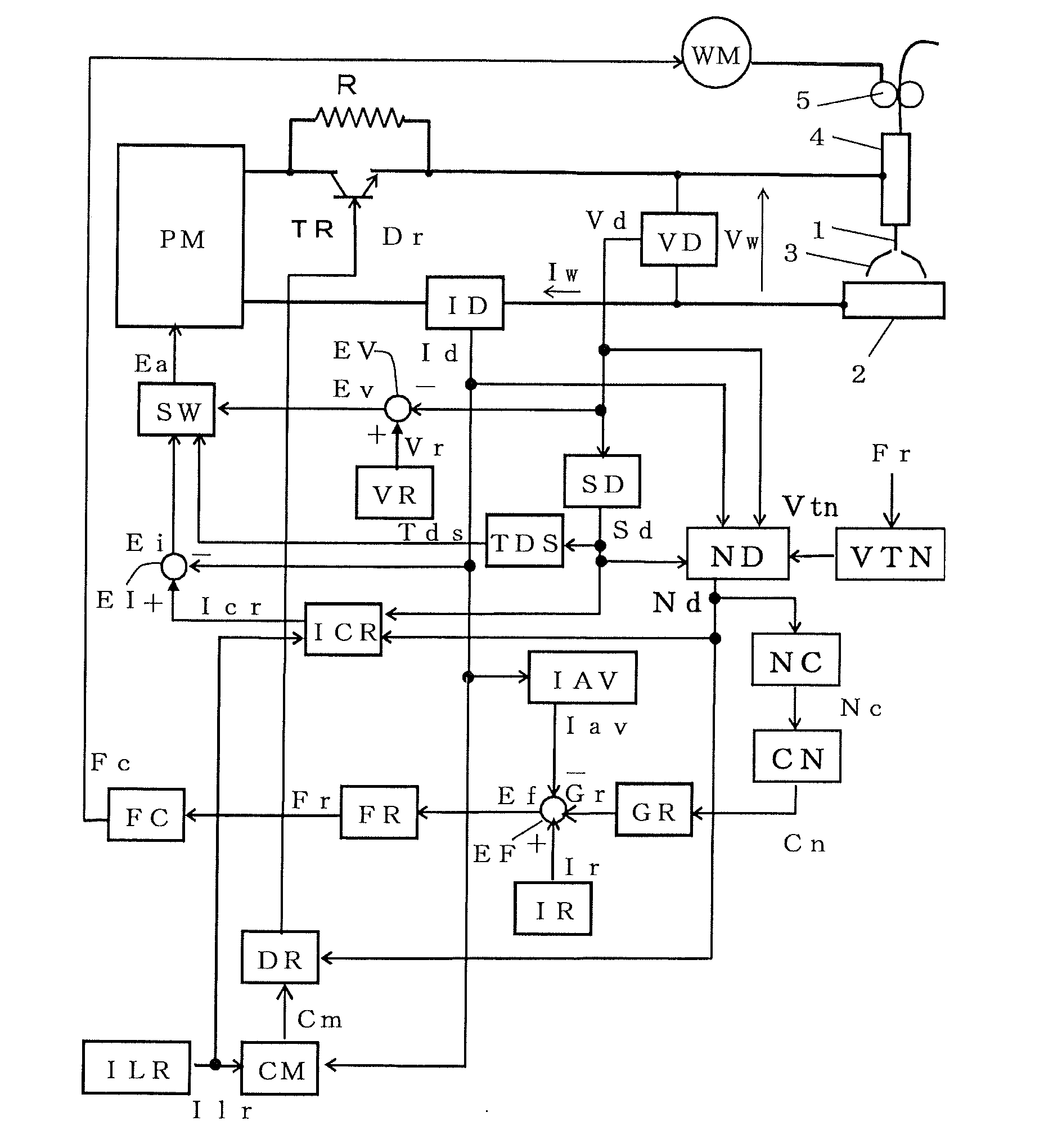

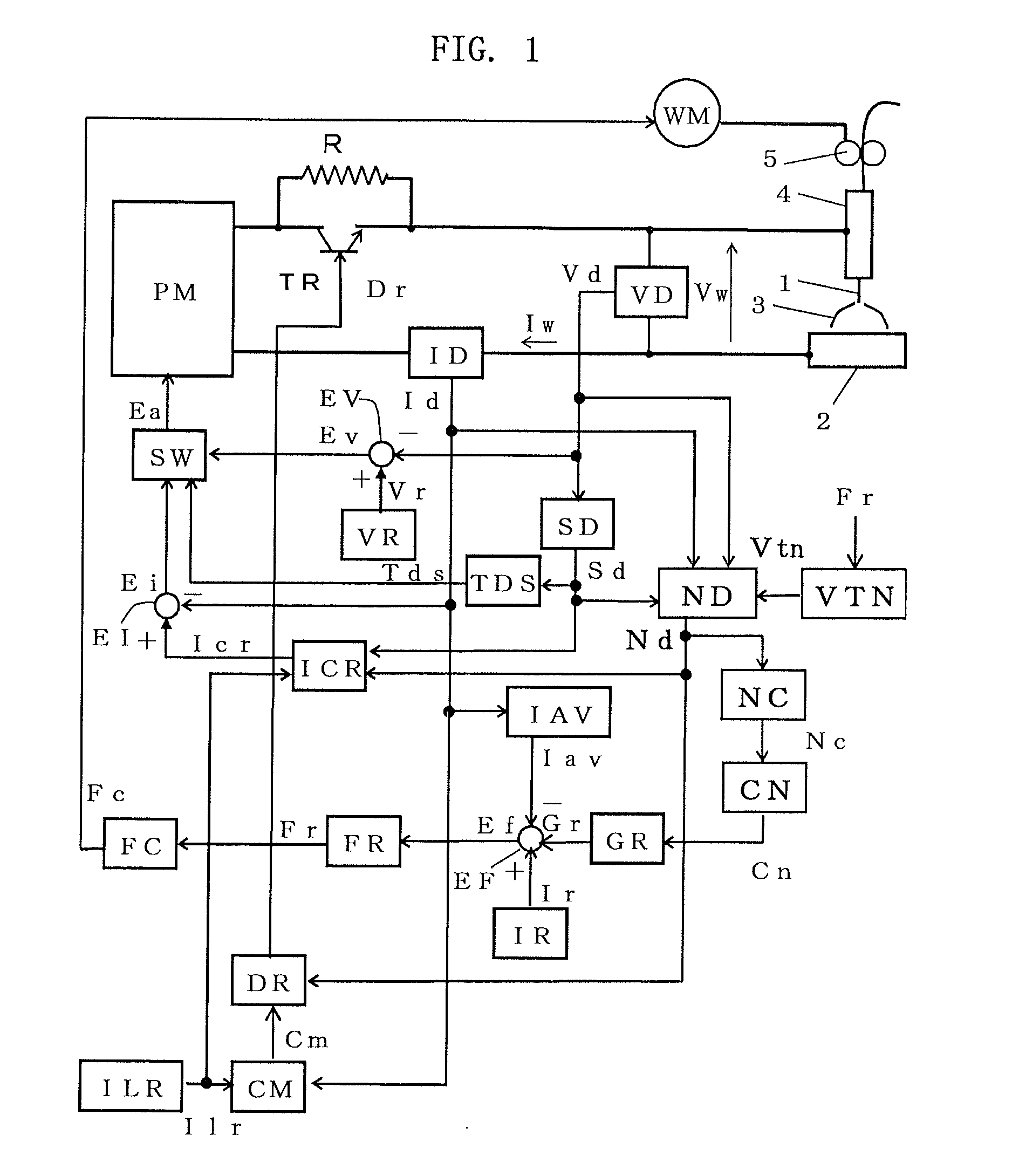

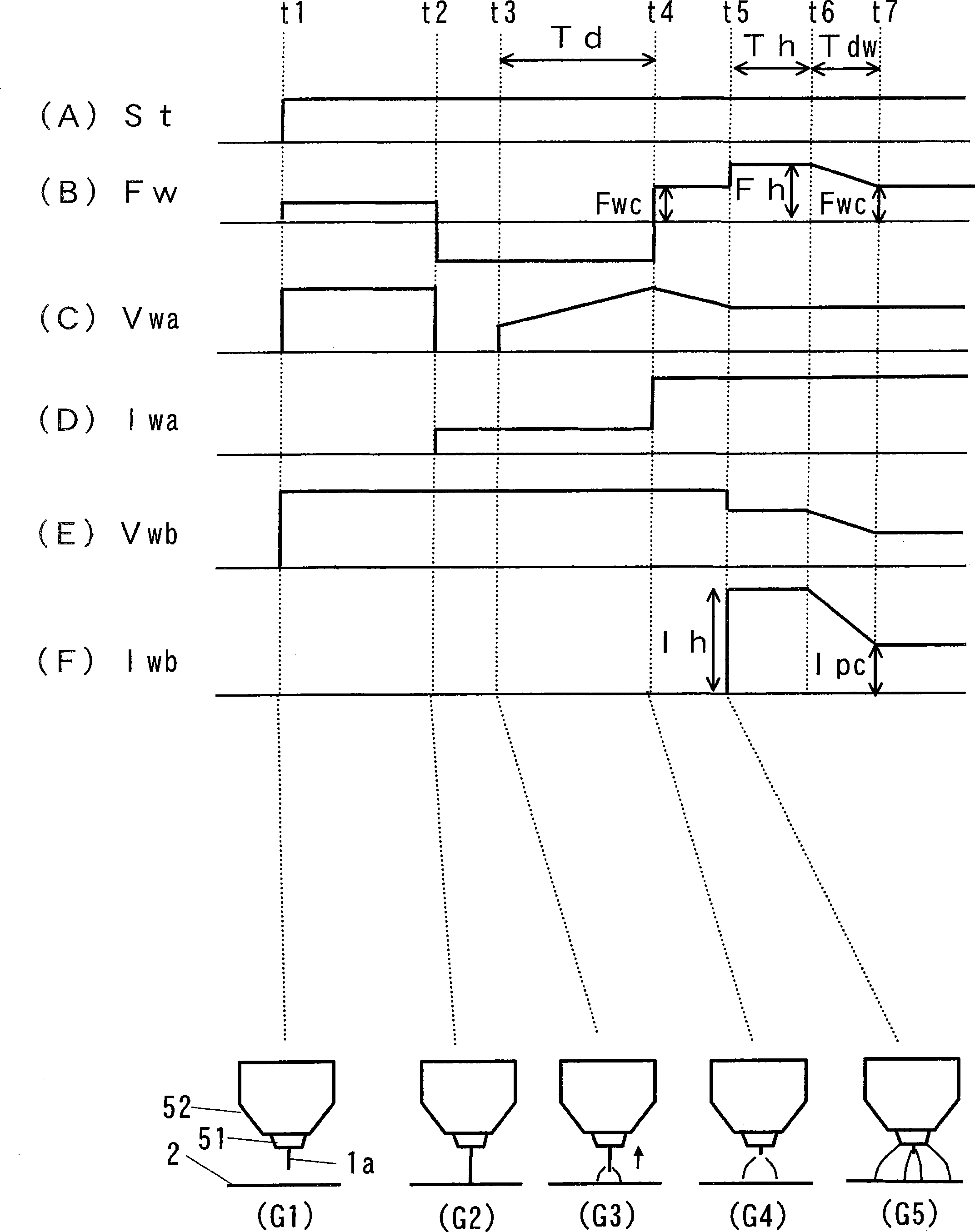

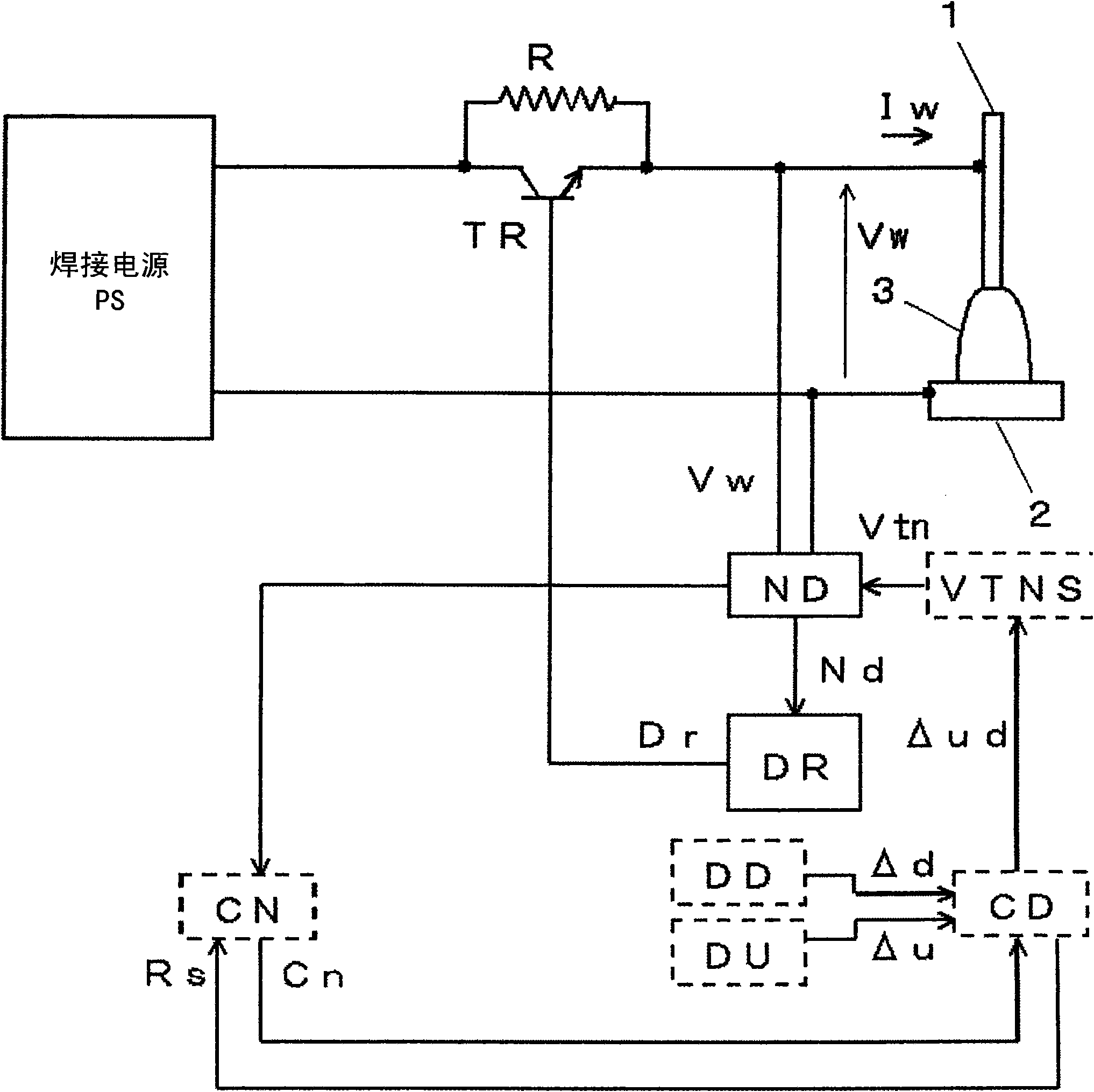

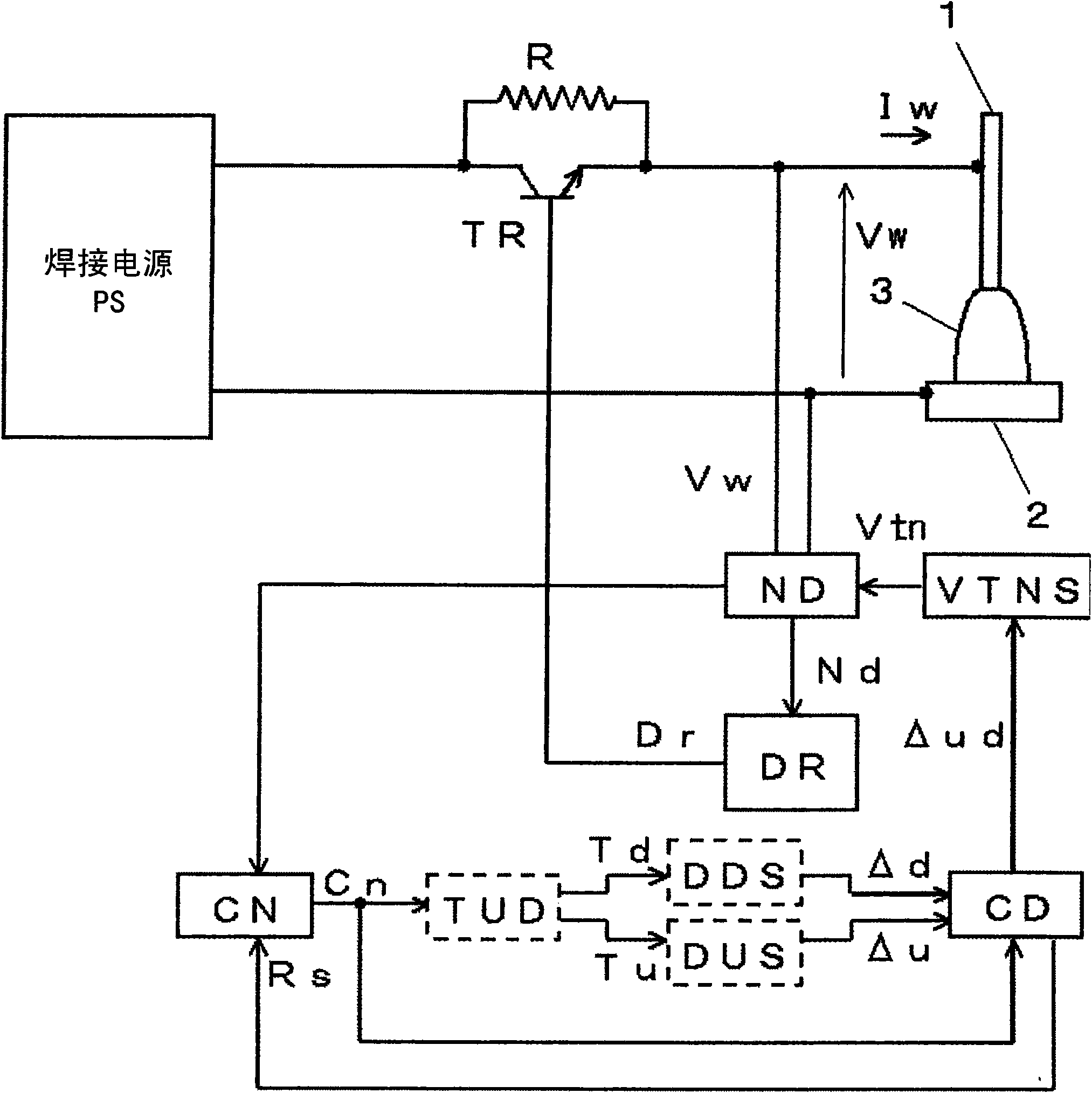

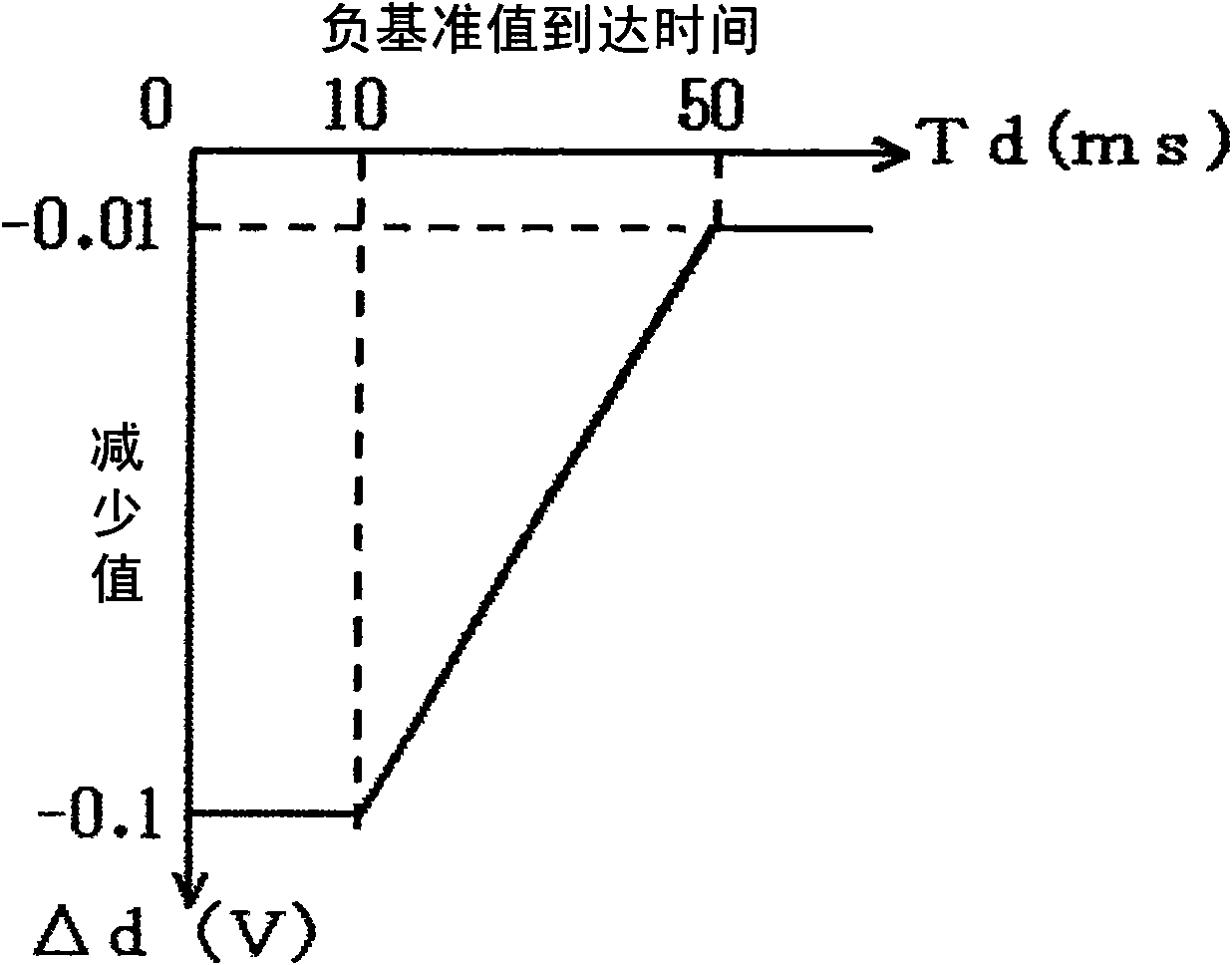

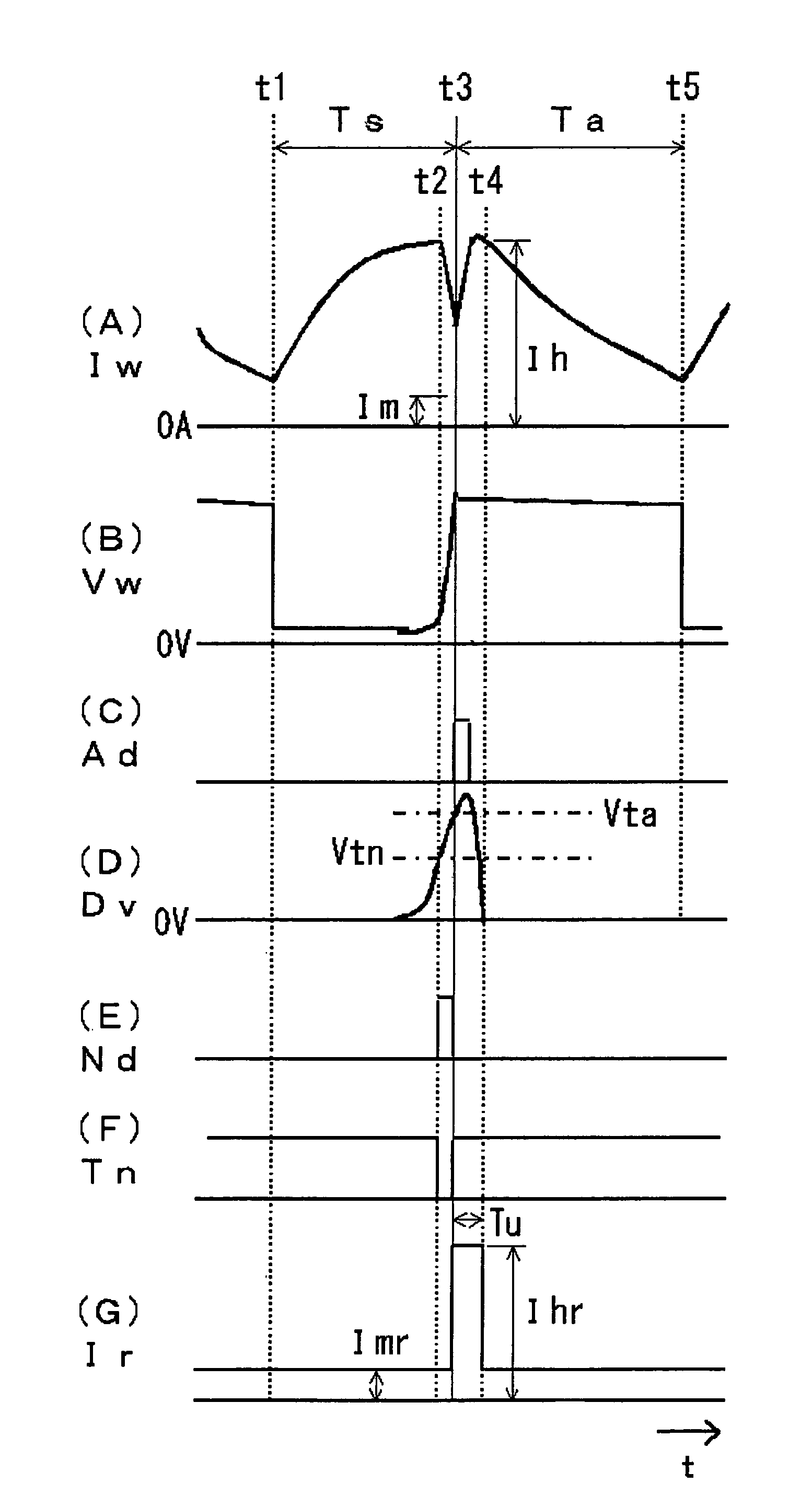

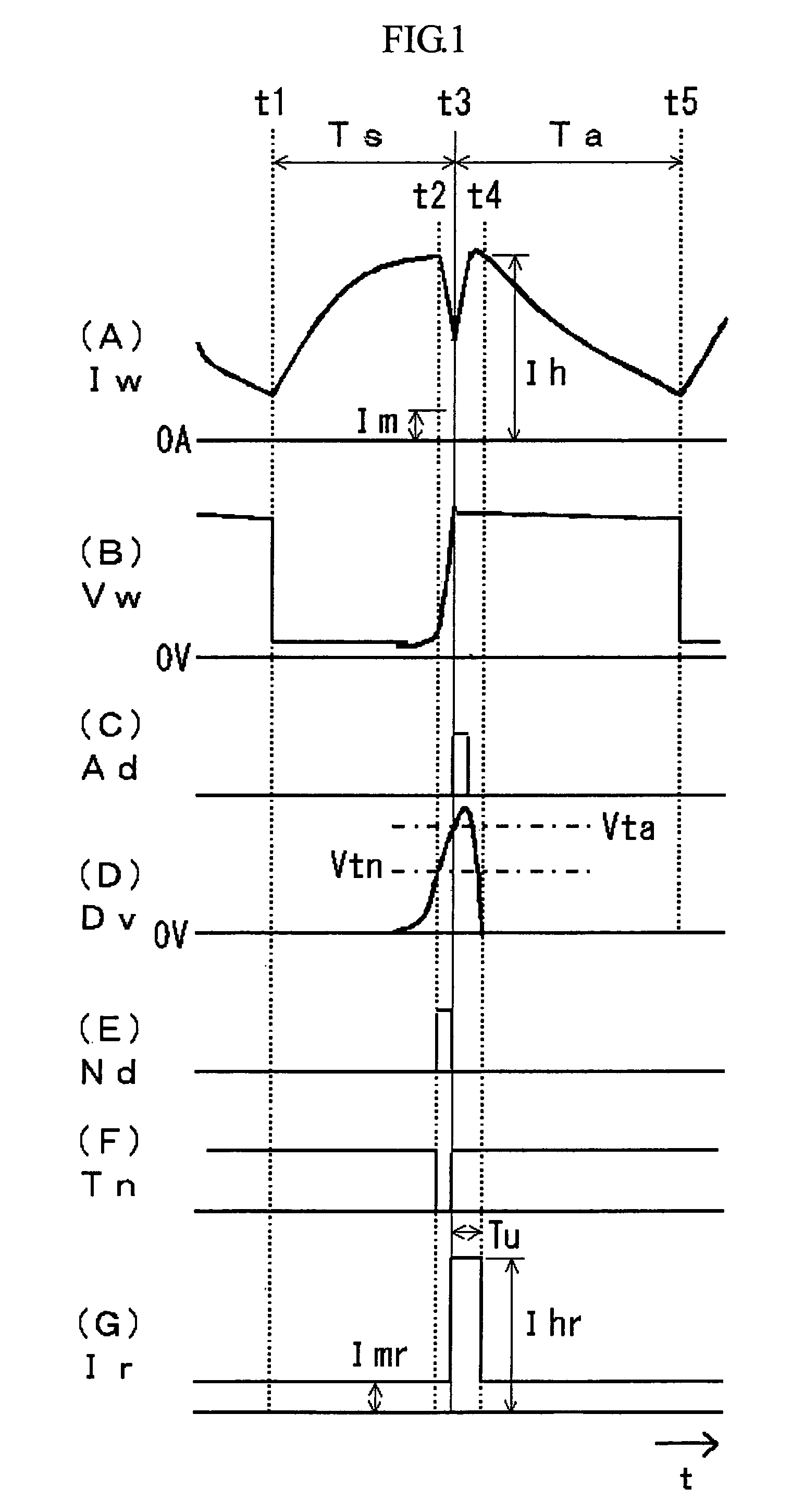

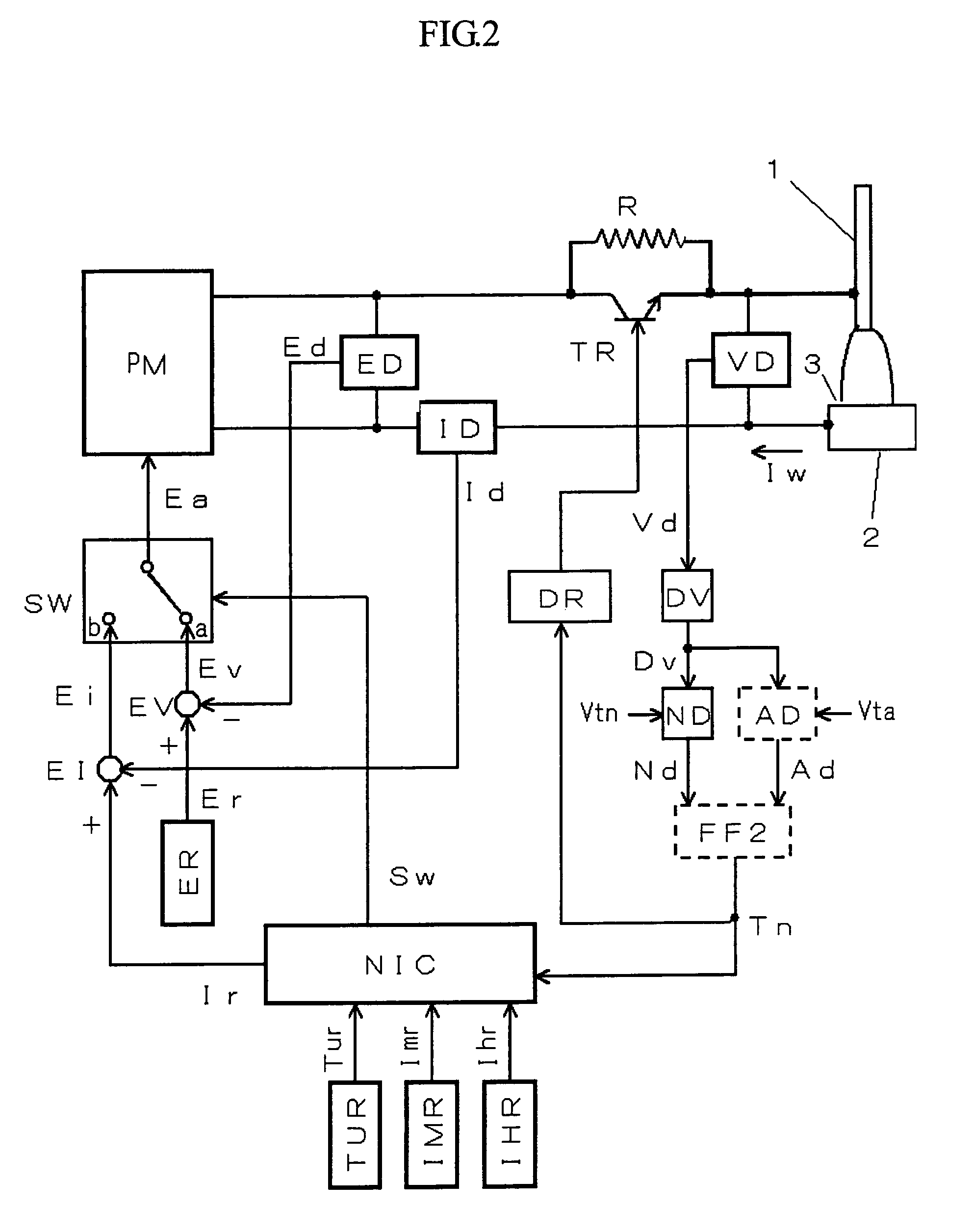

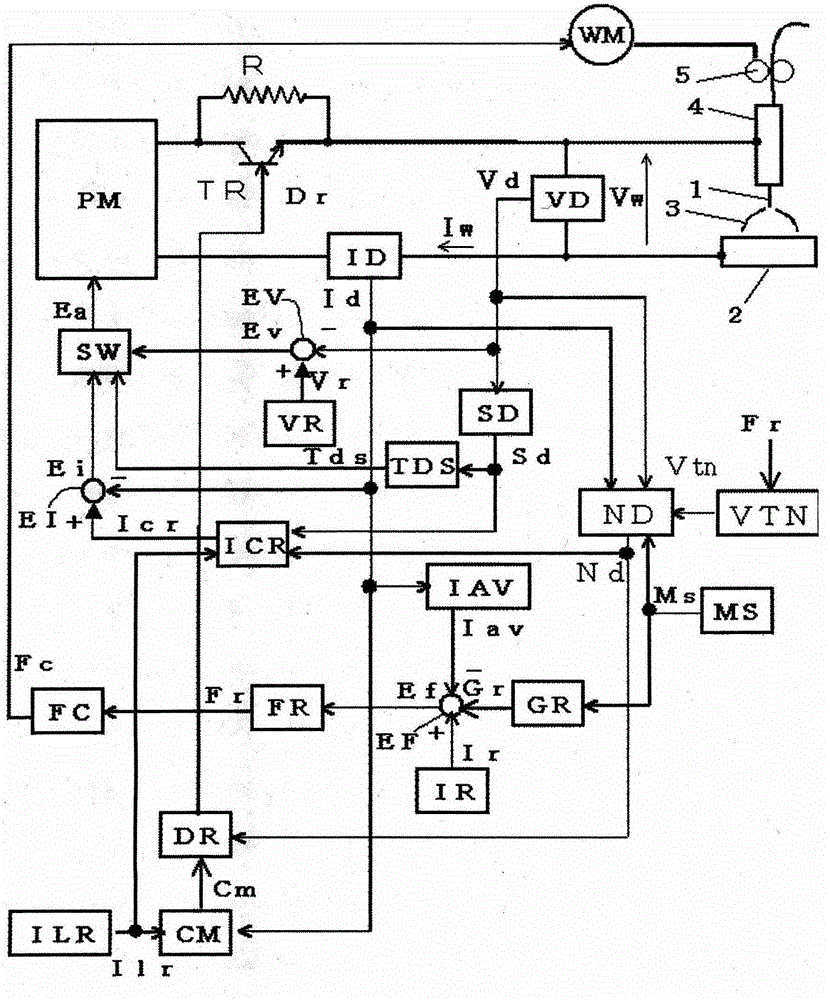

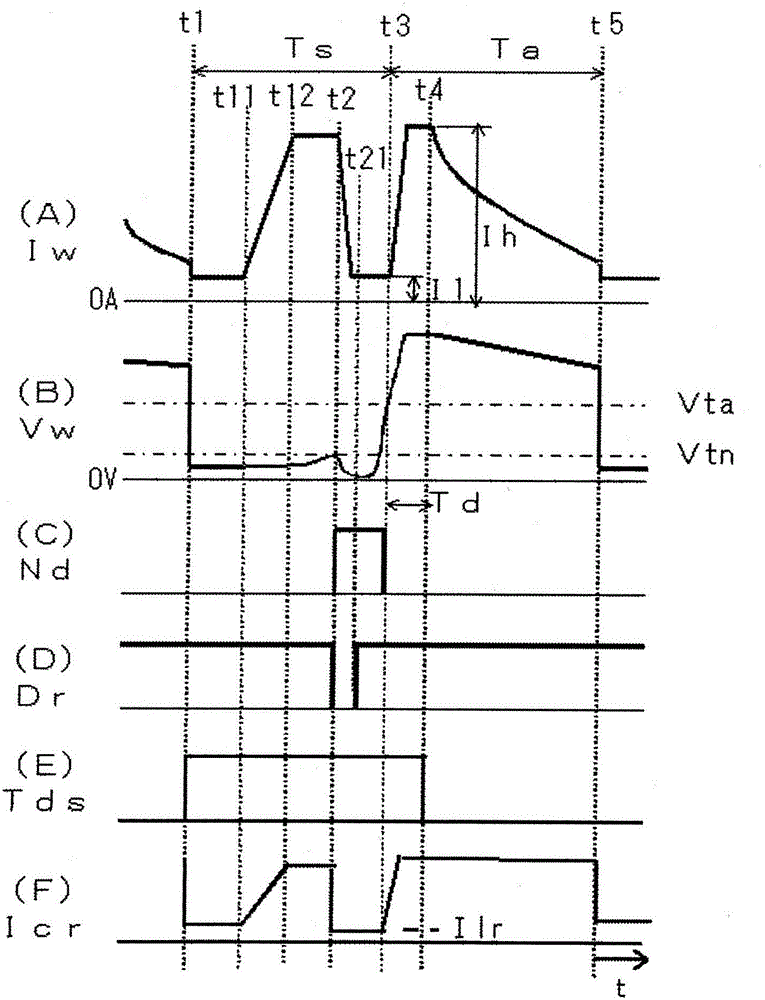

Necking detection and control method of melting electrode and electric arc welding

ActiveCN102233470AHigh sensitivityEnhanced inhibitory effectArc welding apparatusLower limitEngineering

The invention provides a necking detection and control method of melting electrode and electric arc welding in order to improve the detection precision of the necking during the melting of electrode and electric arc. The necking of droplets can be detected in a manner that the change of a resistance value between a melting electrode (1) and a base material (2) reaches to a necking detection reference value (Vtn). If necking is detected, the welding current is reduced, and output control can be conducted under the state of low current value, regenerating electric arc. The necking detection time is calculated from the detection time of the necking phenomenon to the regeneration of electric arc based on each short circuit. When the necking detection time is below a lower limit time, one is subtracted from a count value. When the necking detection time is above an upper limit time, one is added to the count value. When the count value reaches to a negative reference value, the necking detection reference value (Vtn) is reduced. When the count value reaches to a positive reference value, the necking detection reference value (Vtn) is increased. Accordingly, as the necking detection reference value (Vtn) can be appropriate, the detection precision of the necking can be improved.

Owner:DAIHEN CORP

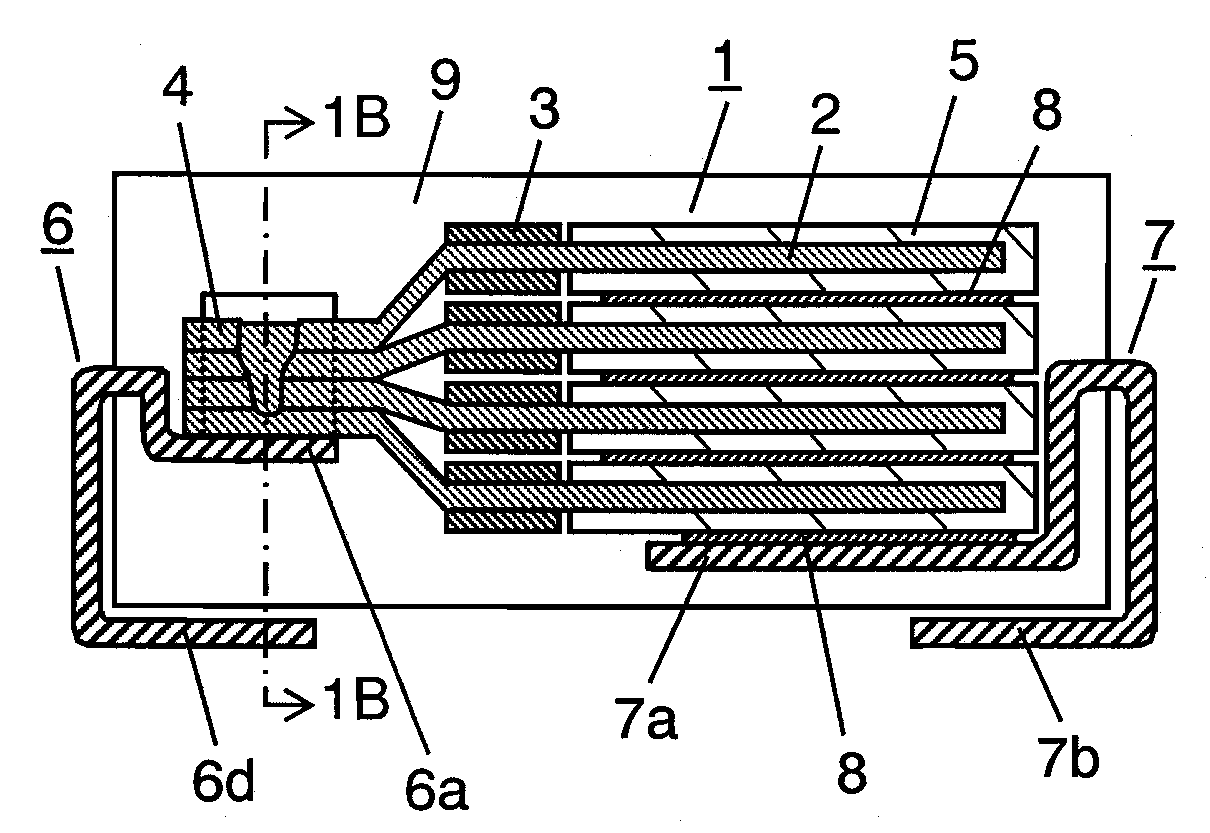

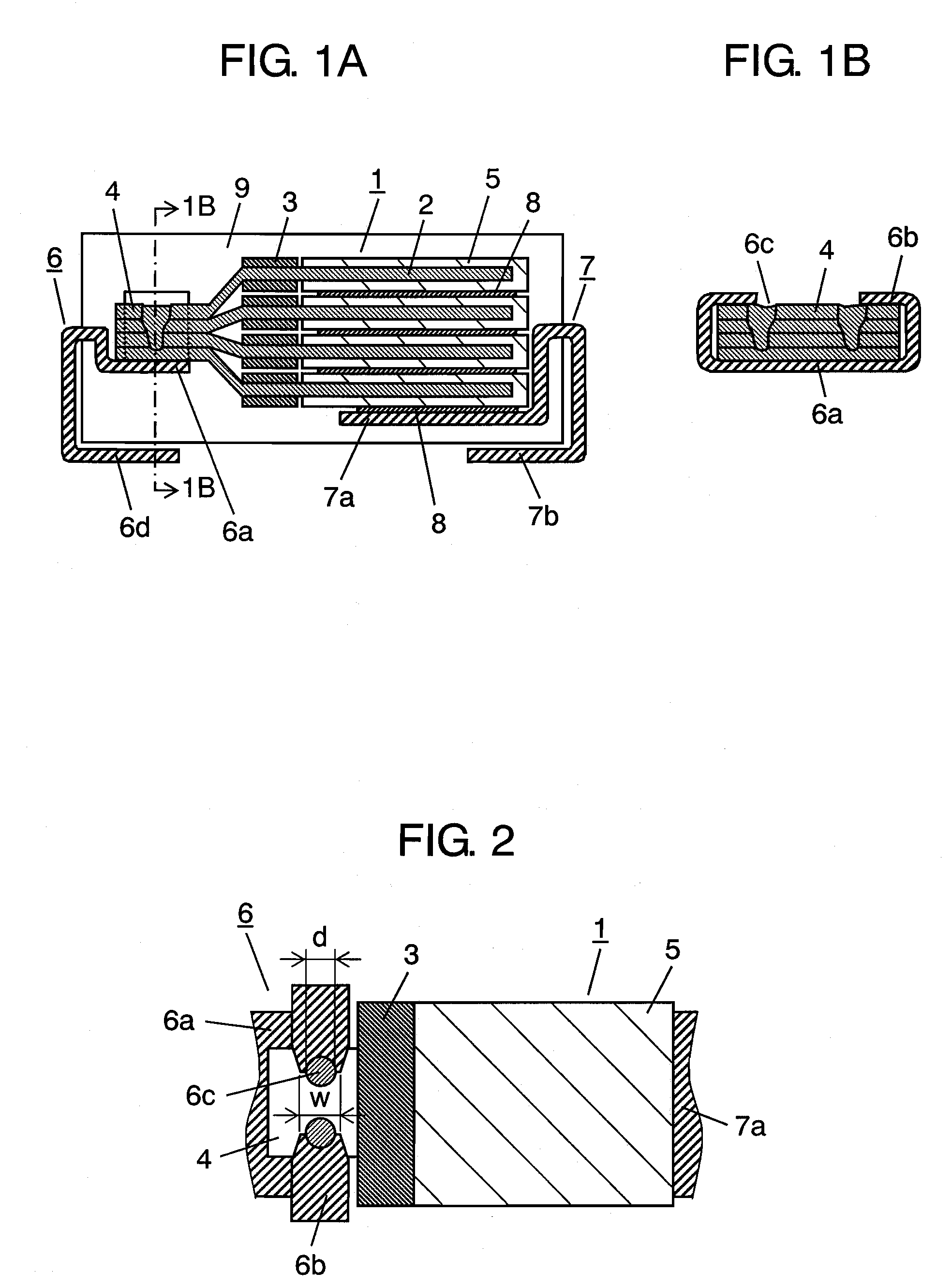

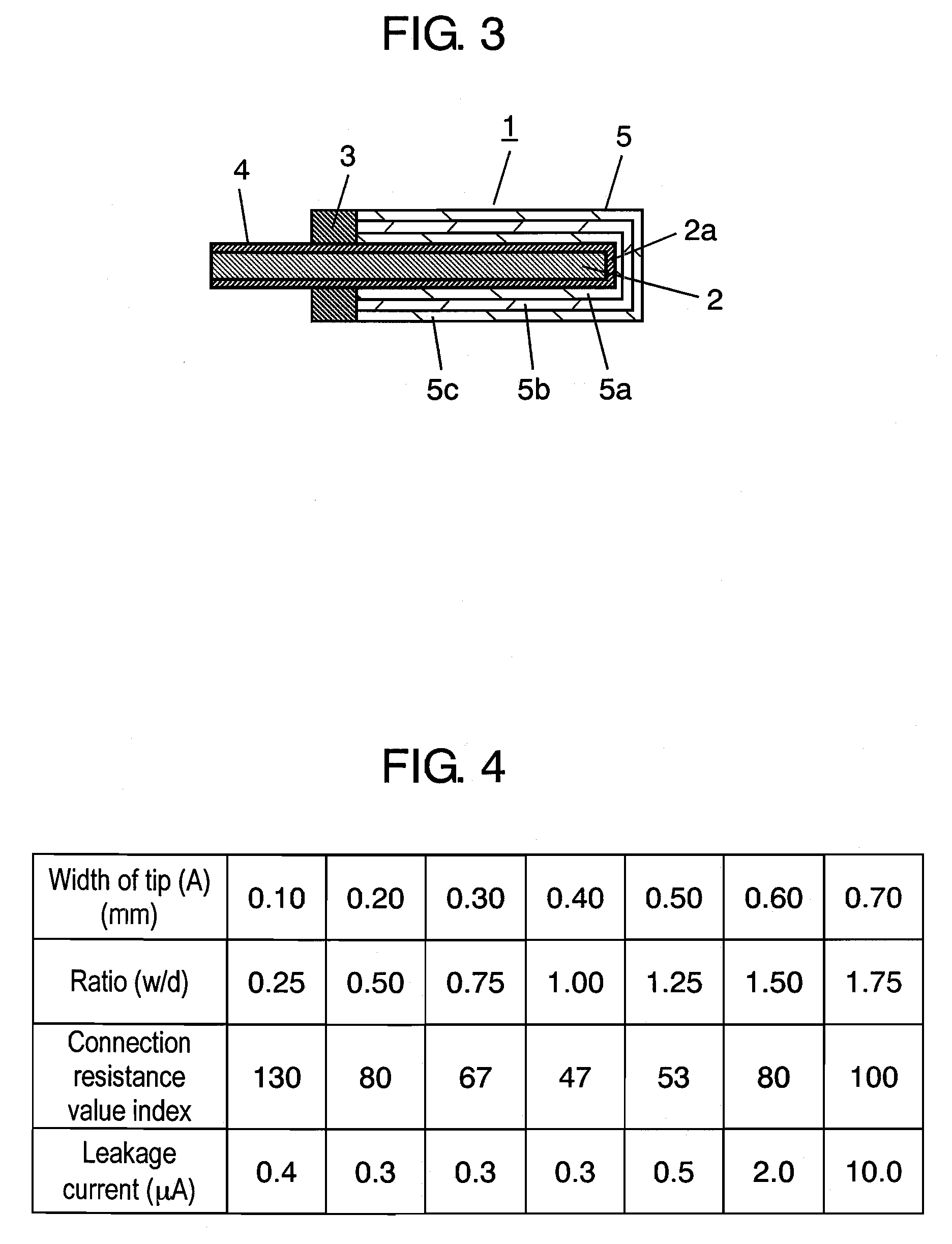

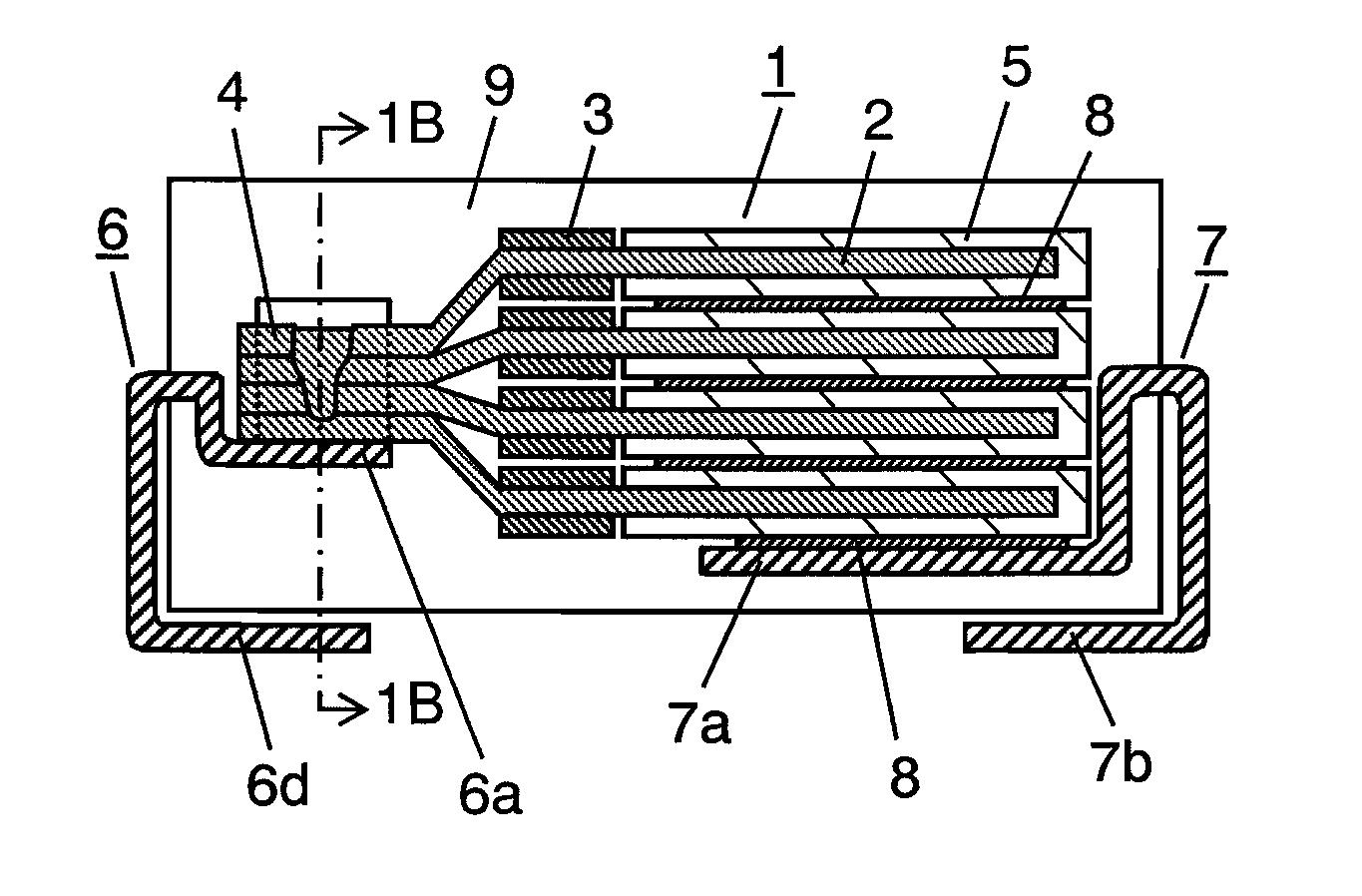

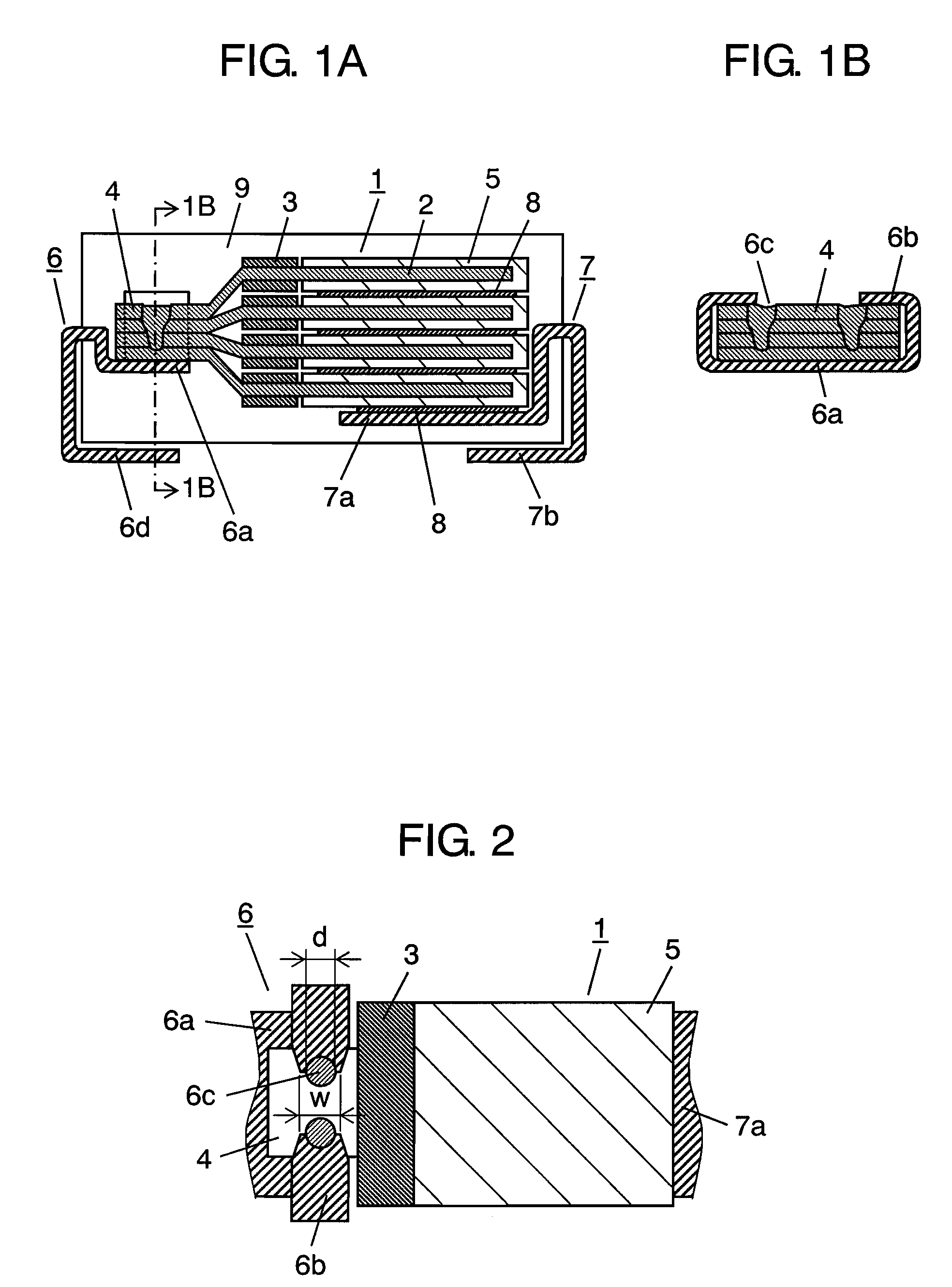

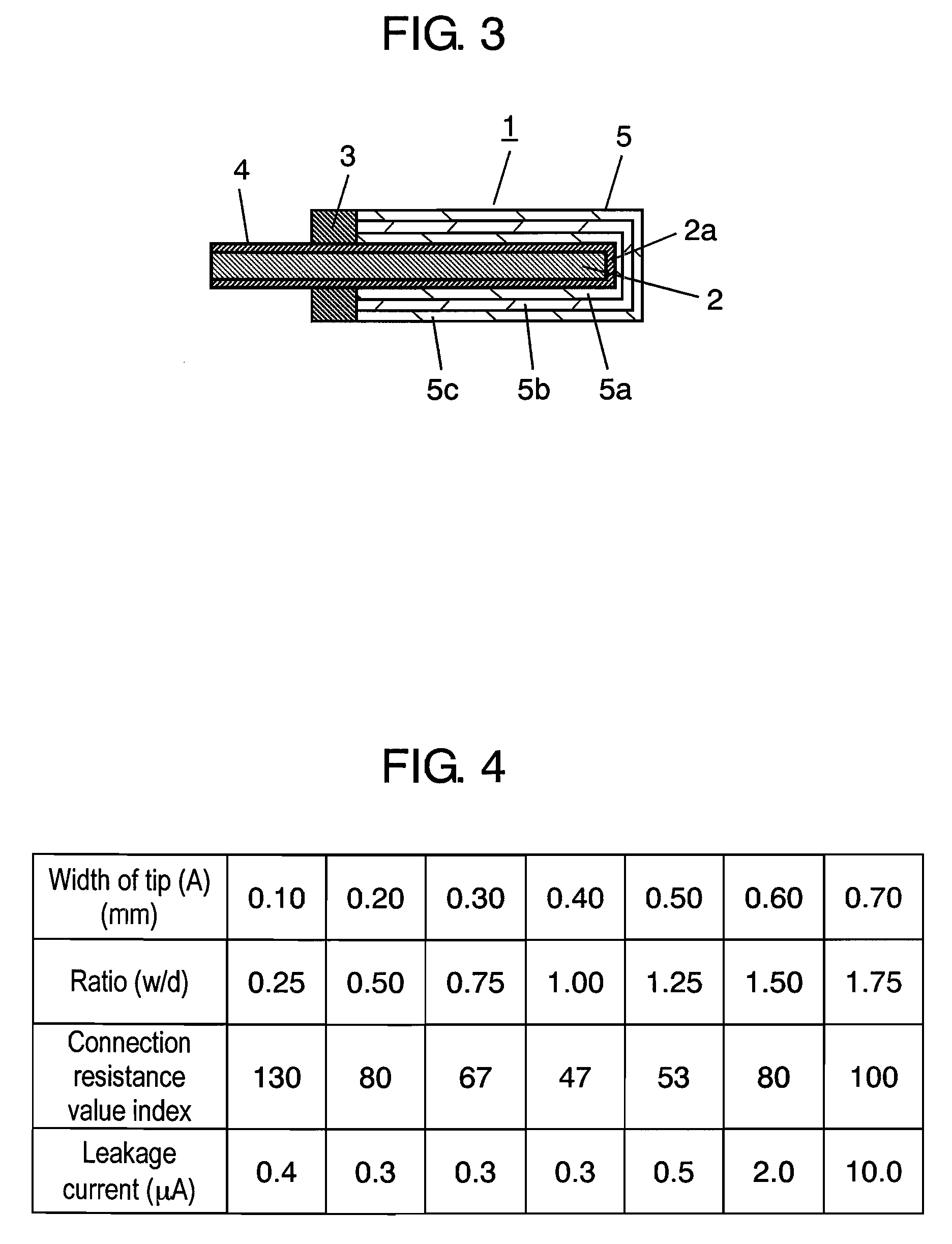

Solid electrolytic capacitor

ActiveUS20080232027A1Welding state is stableLow ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsAdhesiveEngineering

Cathode electrode part 5 of flat plate-like element 1 is joined with cathode com terminal 7 with a conductive adhesive or the like. Element mounting part 6a of anode terminal 6 is provided with a pair of joint parts 6b for wrapping anode electrode part 4 from both sides. The tips of joint parts 6b and anode electrode part 4 are joined by laser welding such that the ratio (w / d) of the width (w) of each tip of joint parts 6b and the diameter (d) of the welding trace to be welded is 0.5 to 1.5, and more preferably, 0.5 to 1.25 for providing low ESR means for concentrating the quantity of heat at the time of welding on welding parts 6c without escape. Therefore, a stable welded state is obtained, so that the ESR is improved for achieving low ESR of the solid capacitor.

Owner:PANASONIC CORP

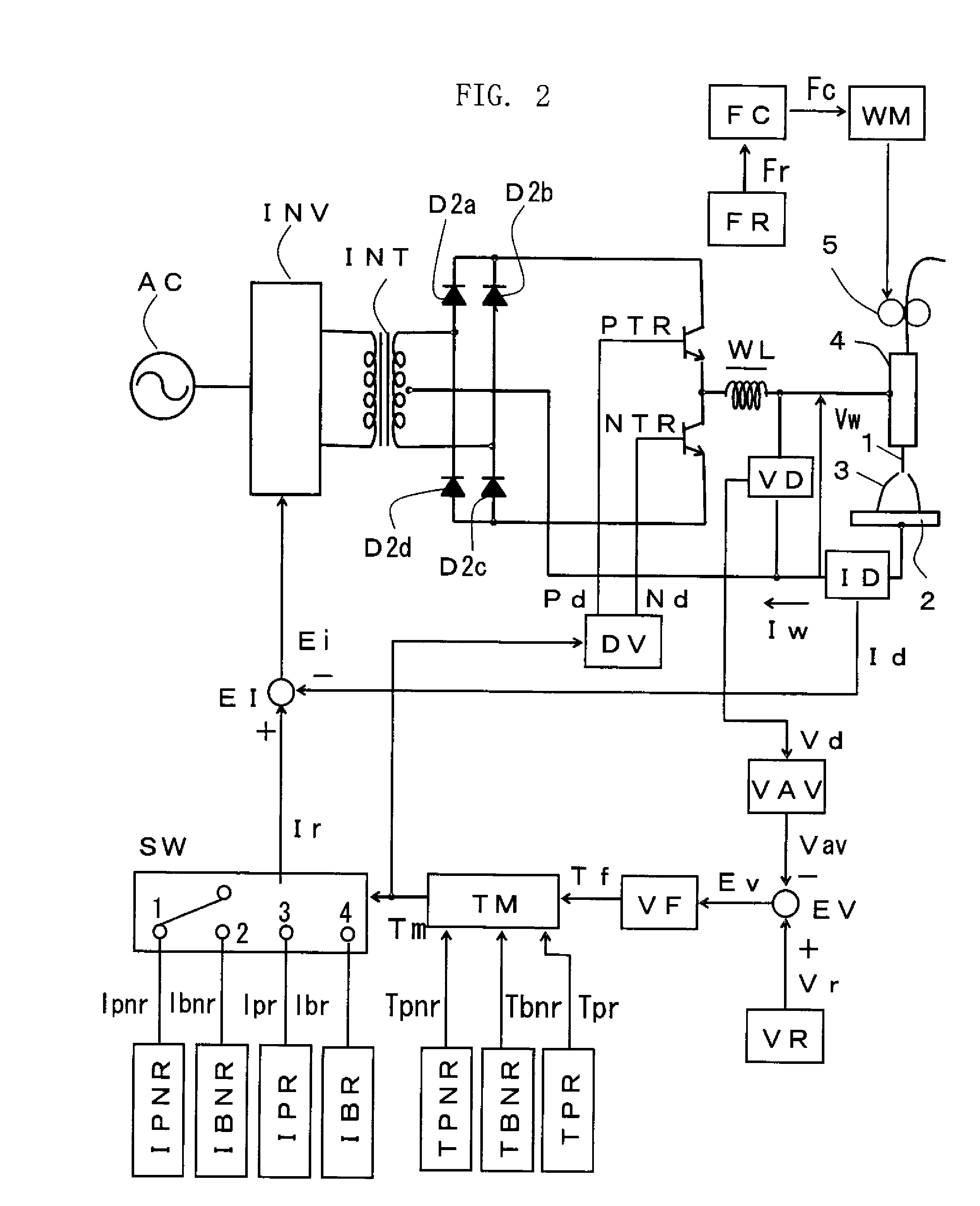

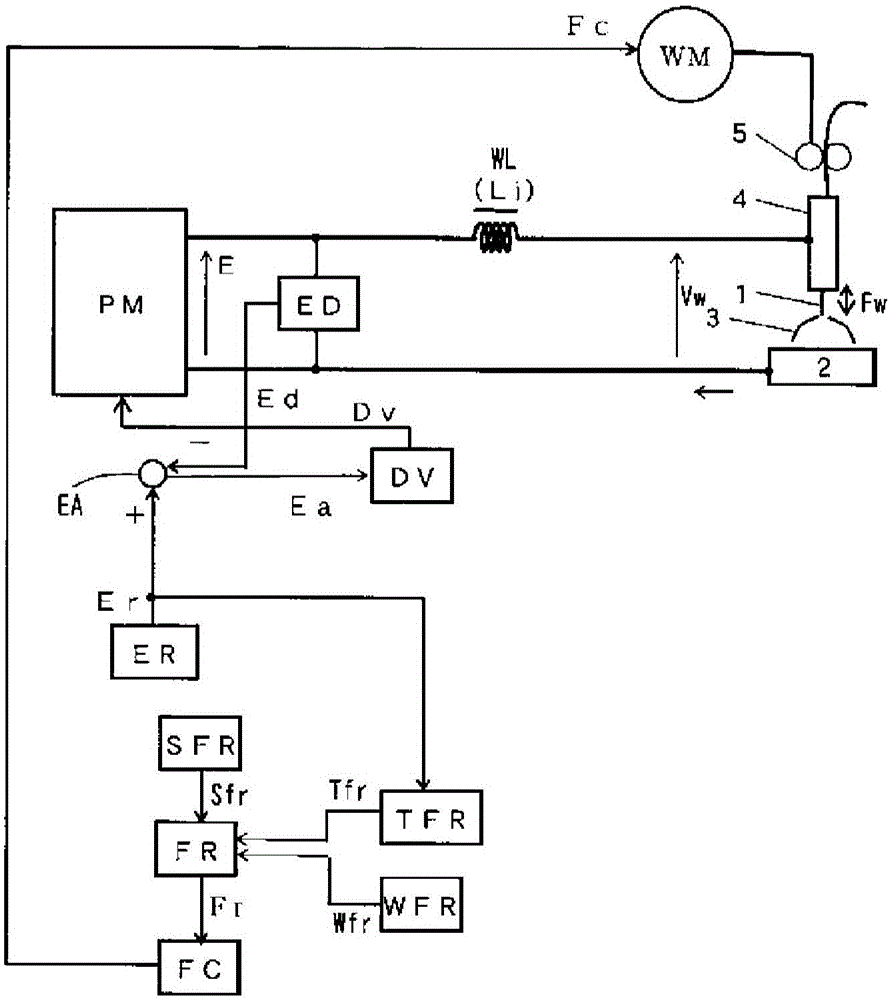

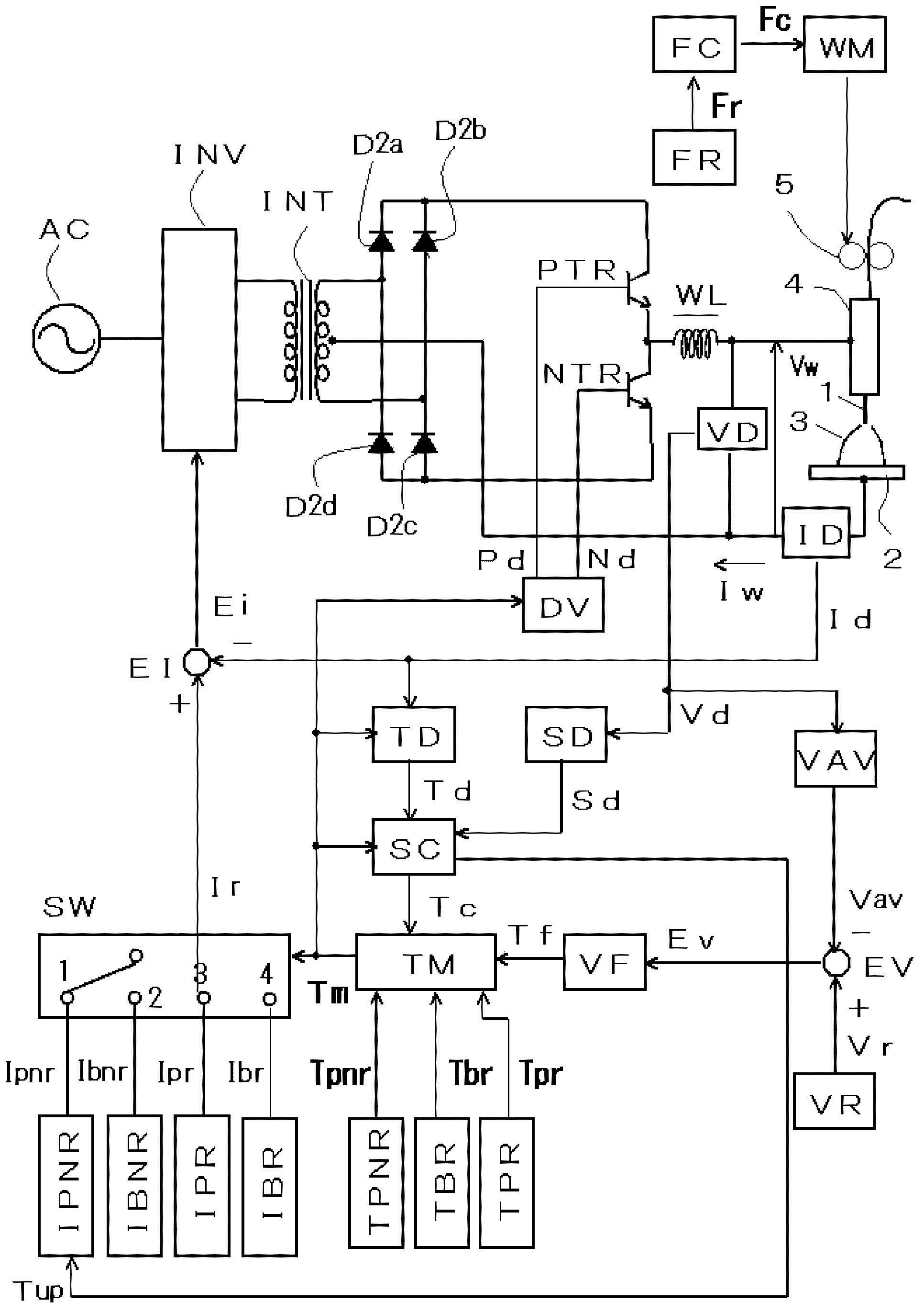

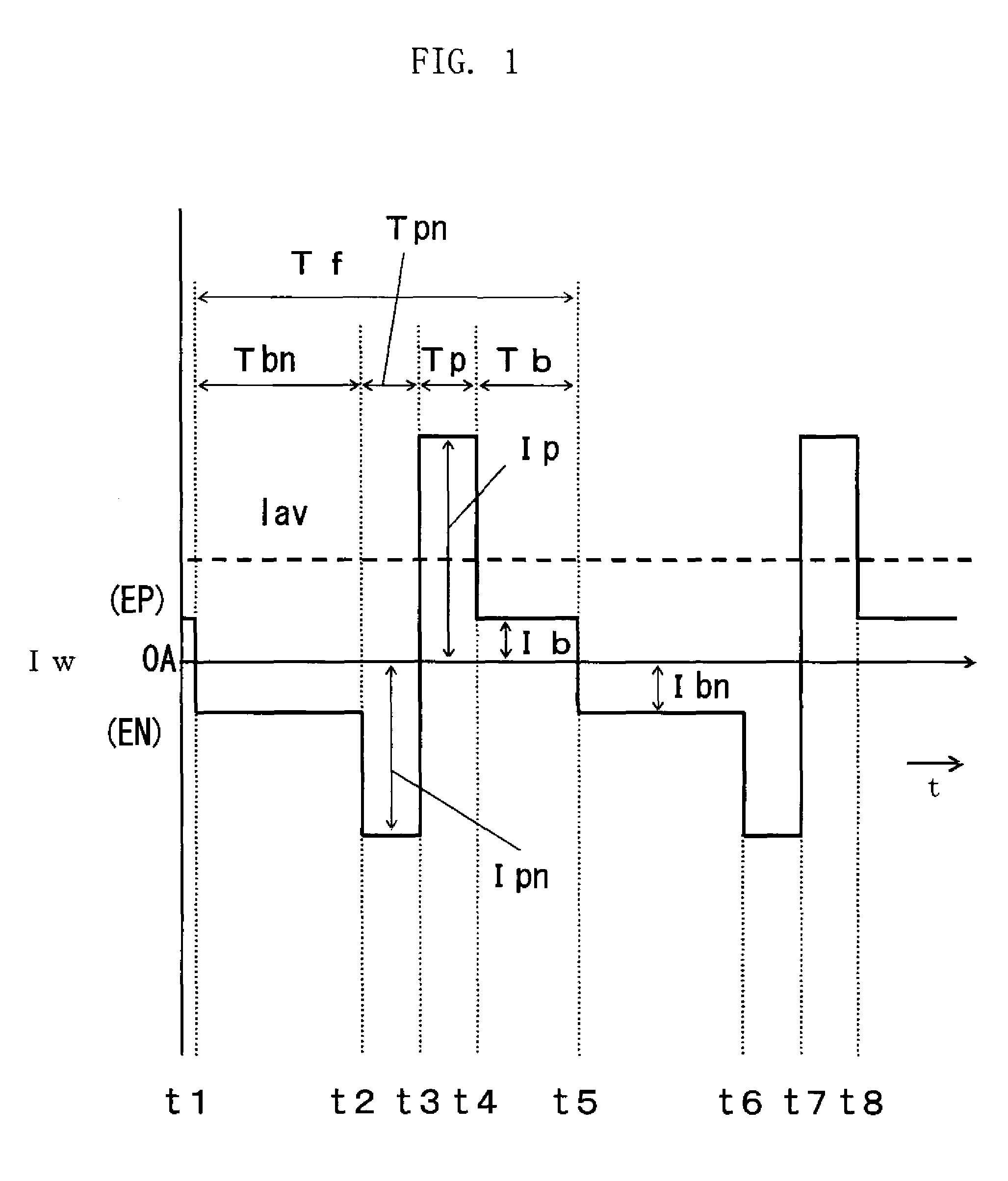

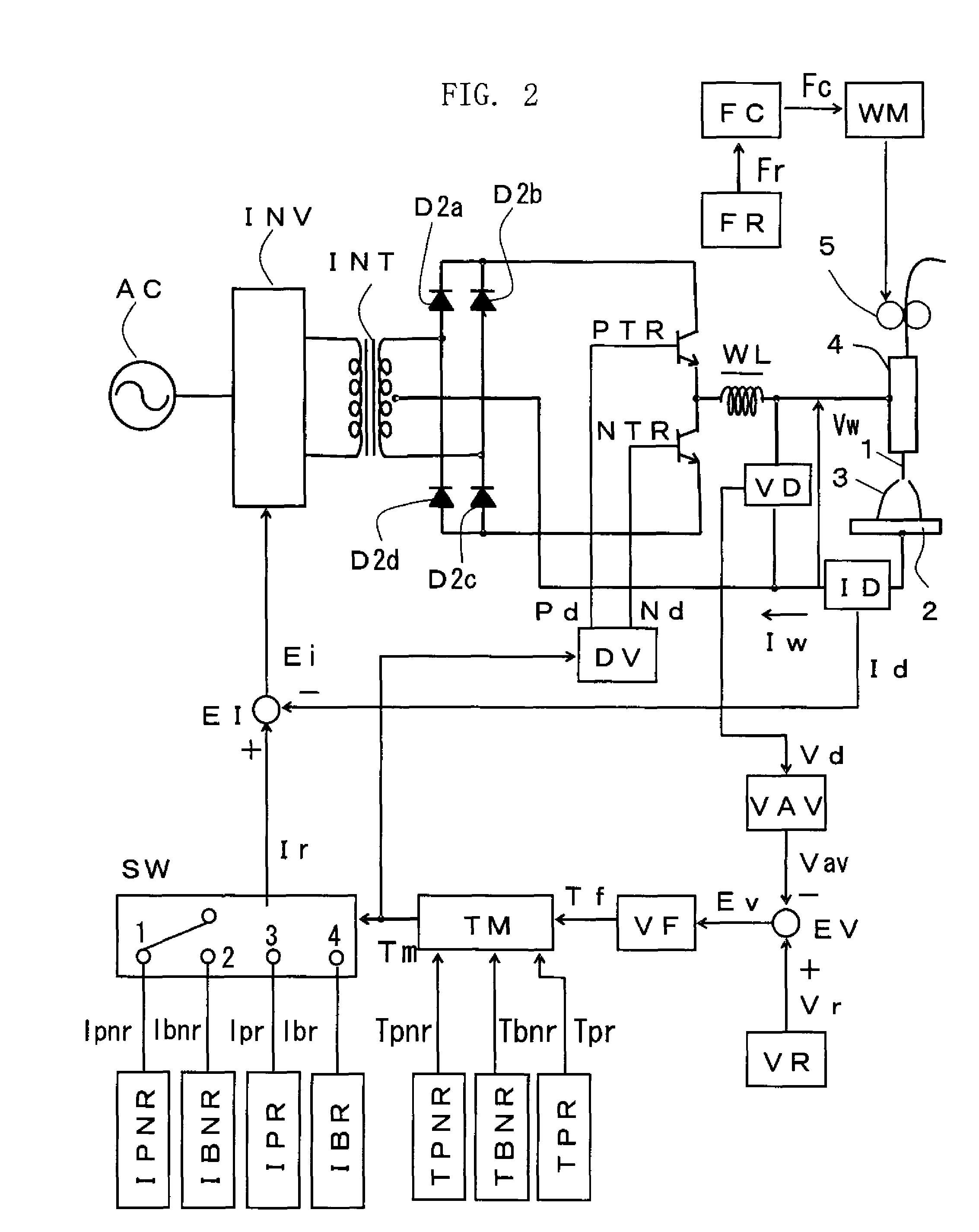

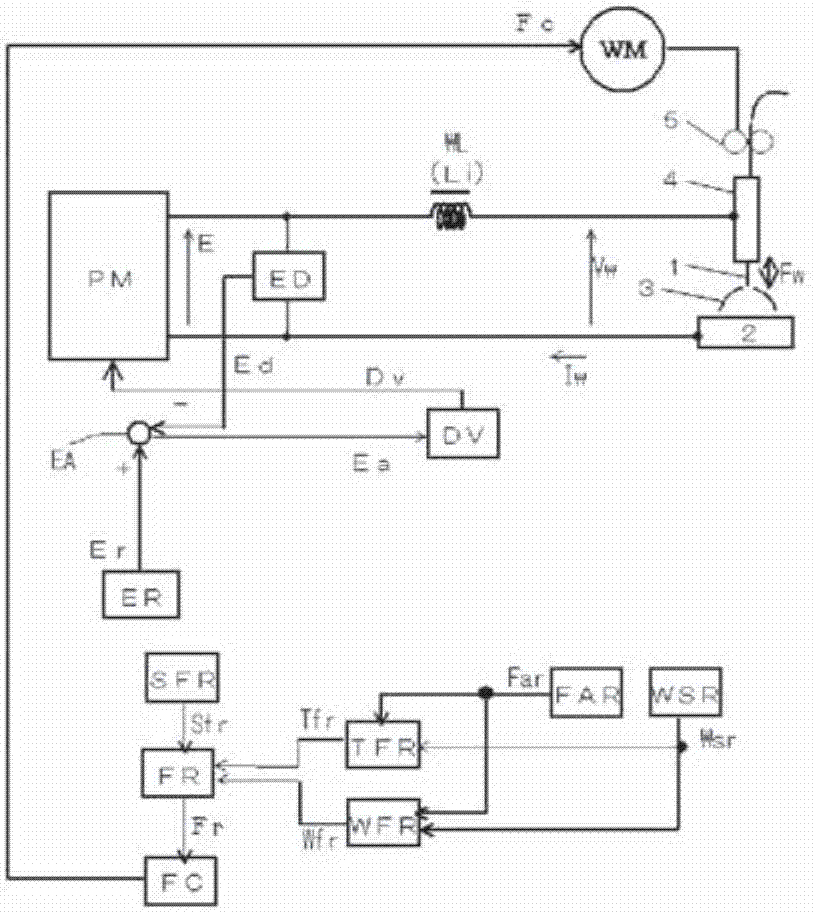

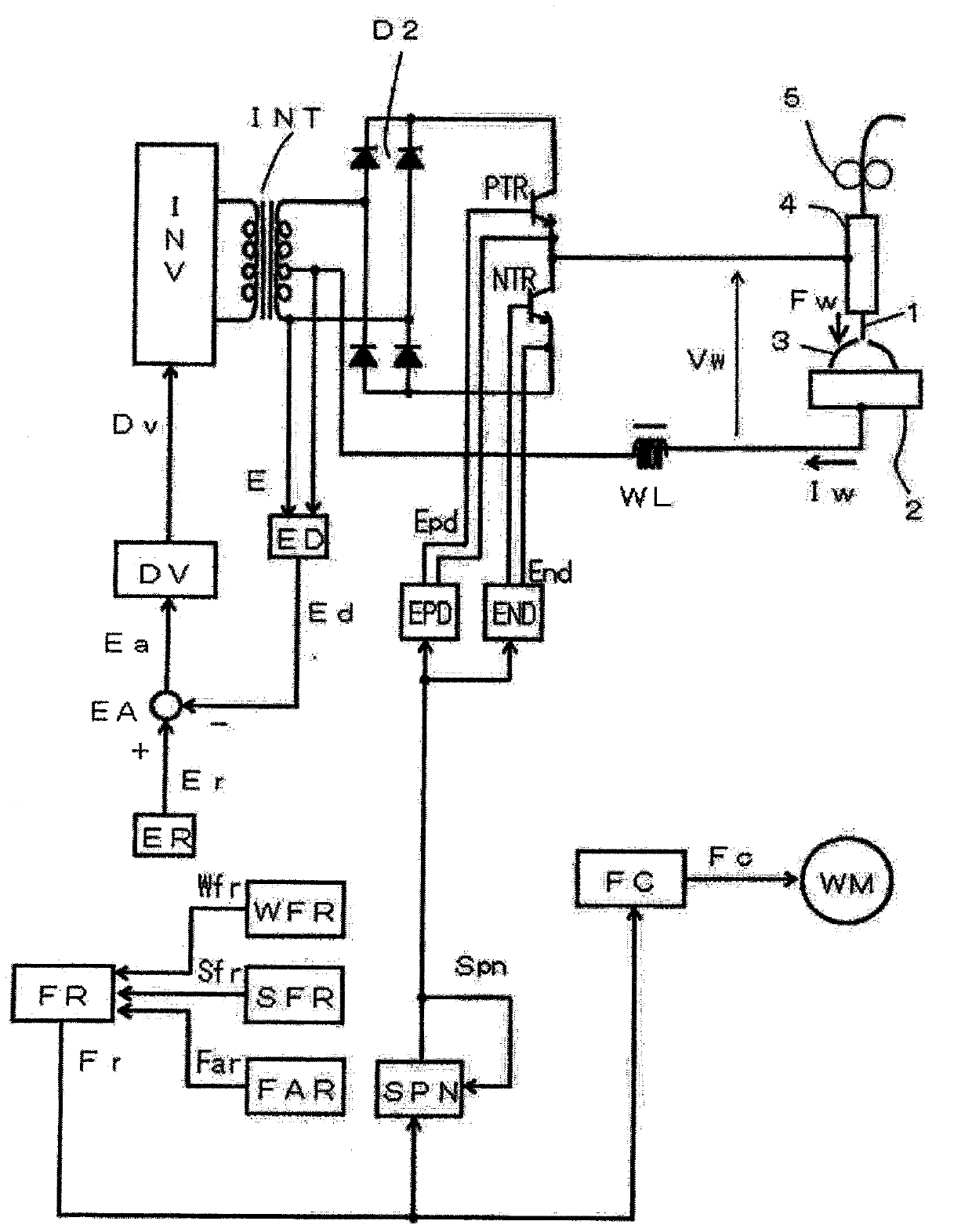

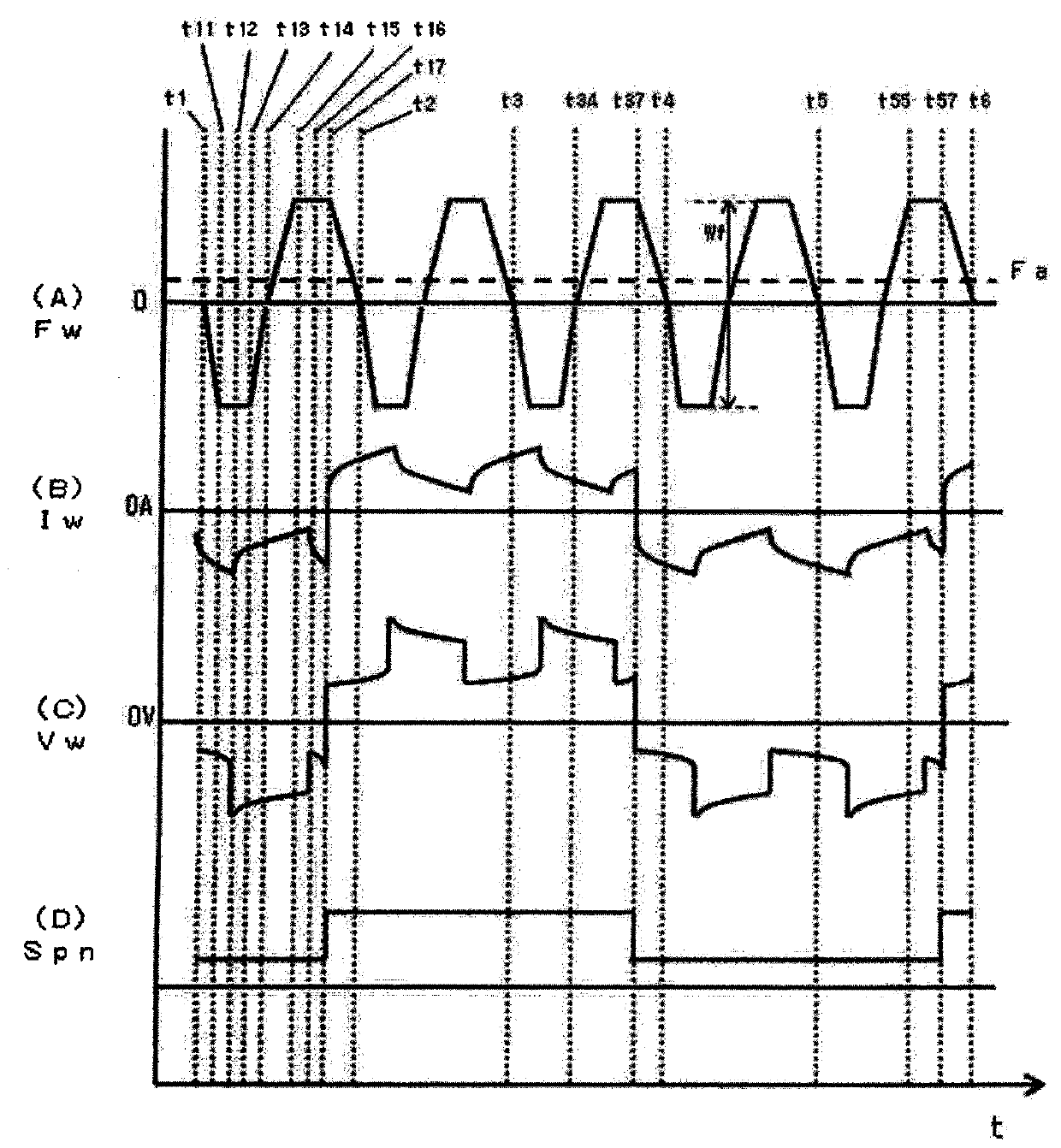

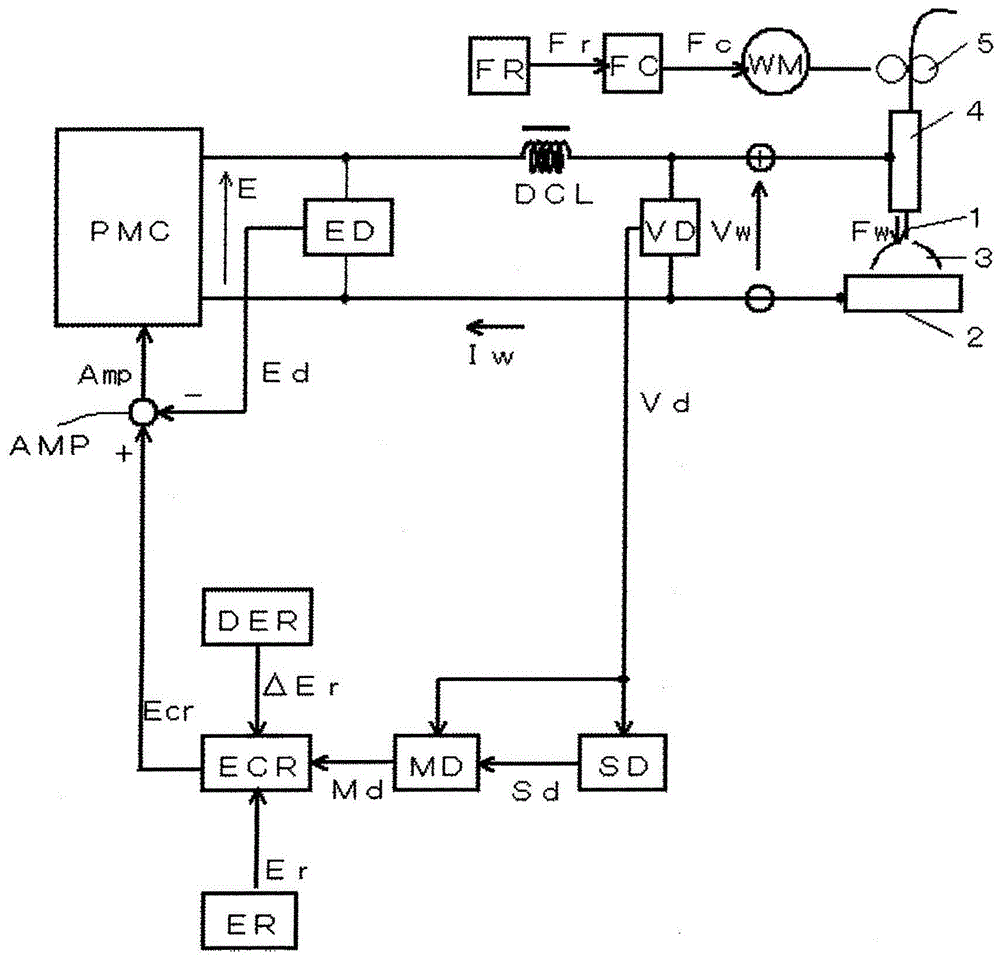

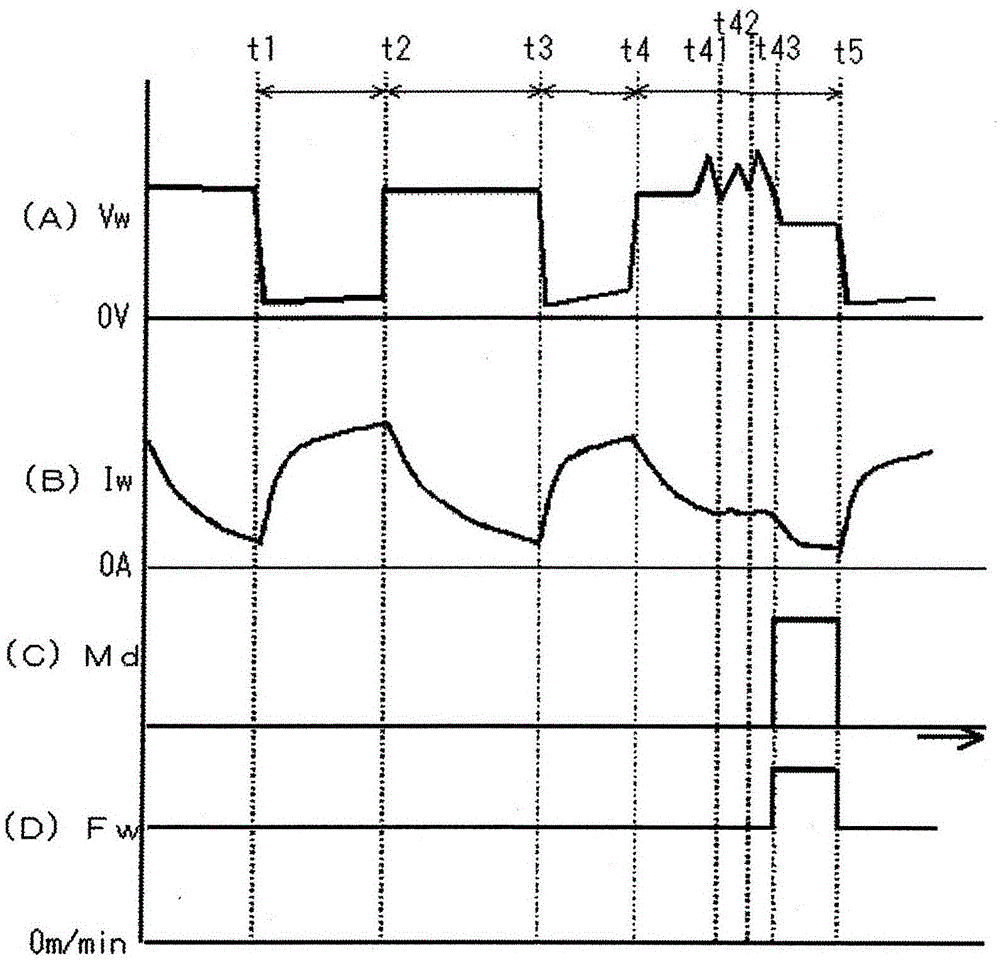

Arc welding control method

ActiveCN106457445AWelding state is stableStable to maintain welded stateArc welding apparatusFeedback controlVoltage

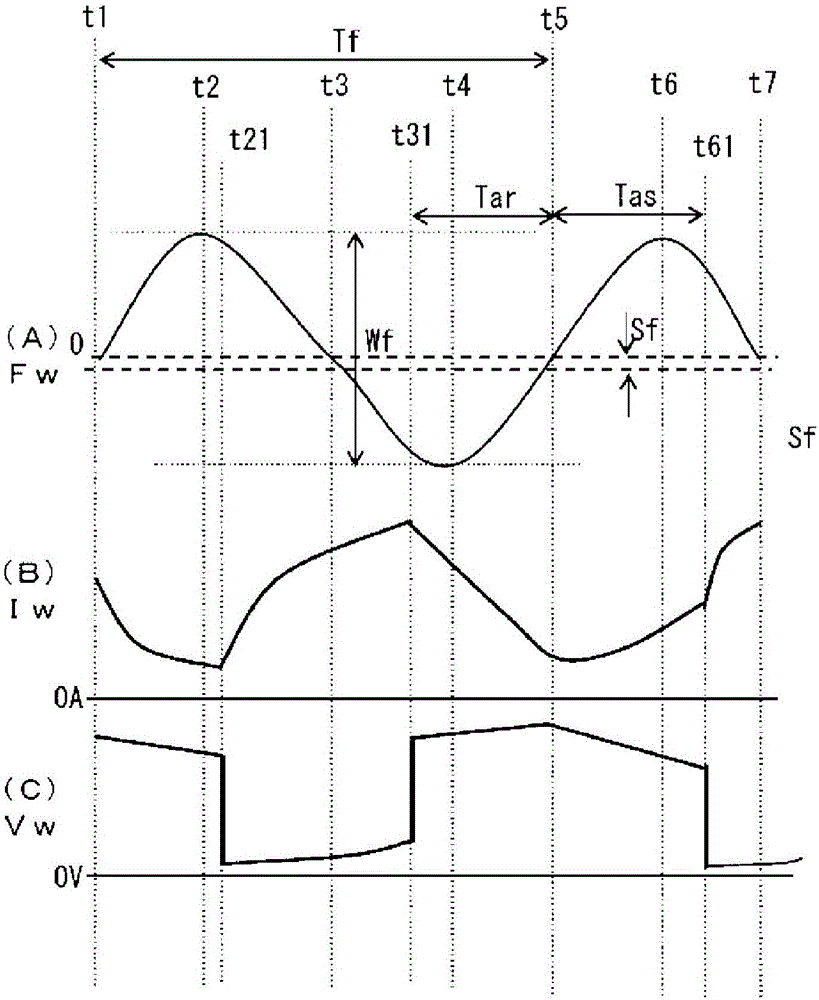

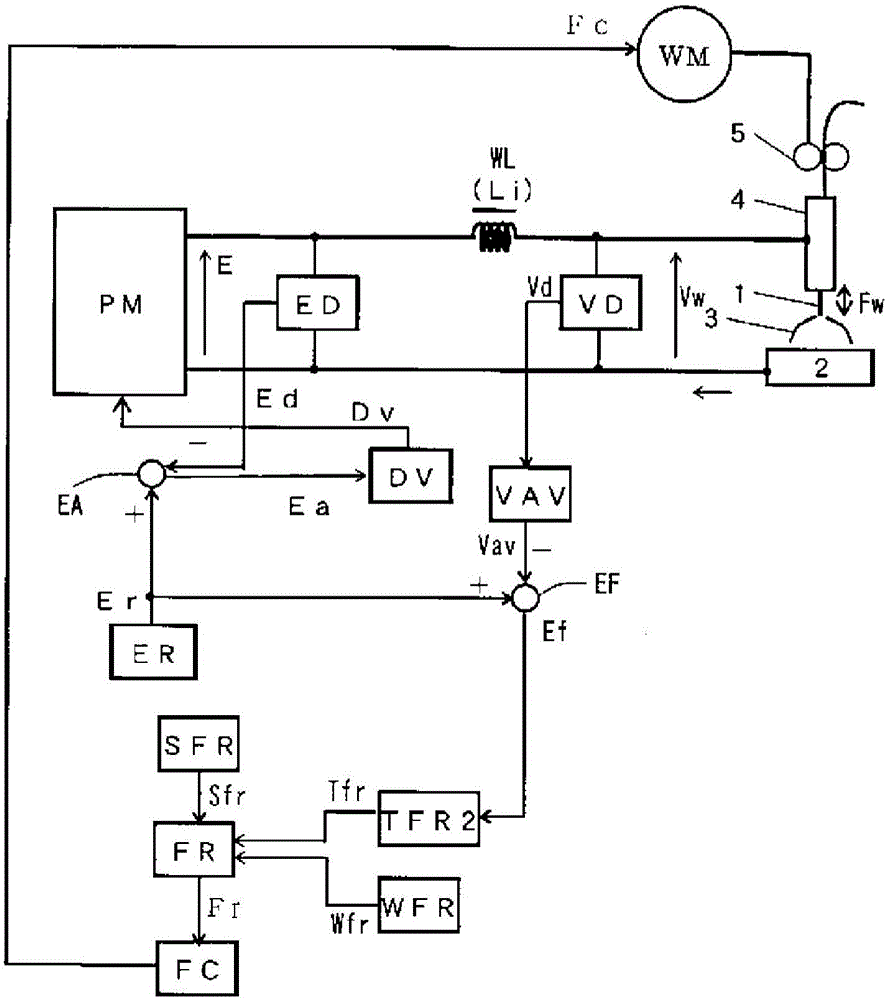

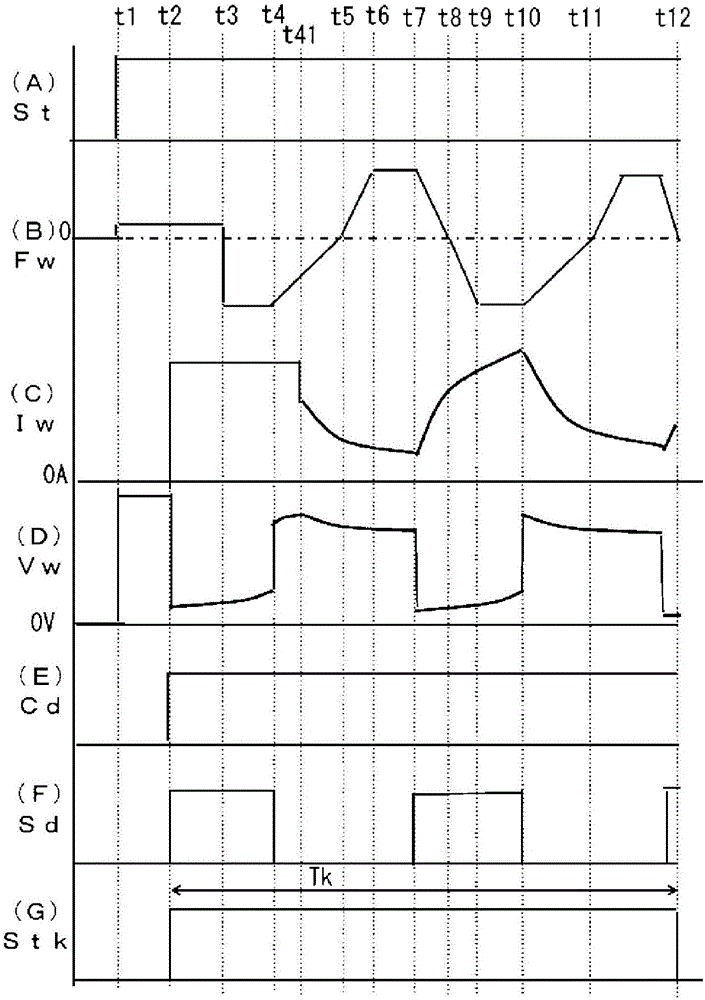

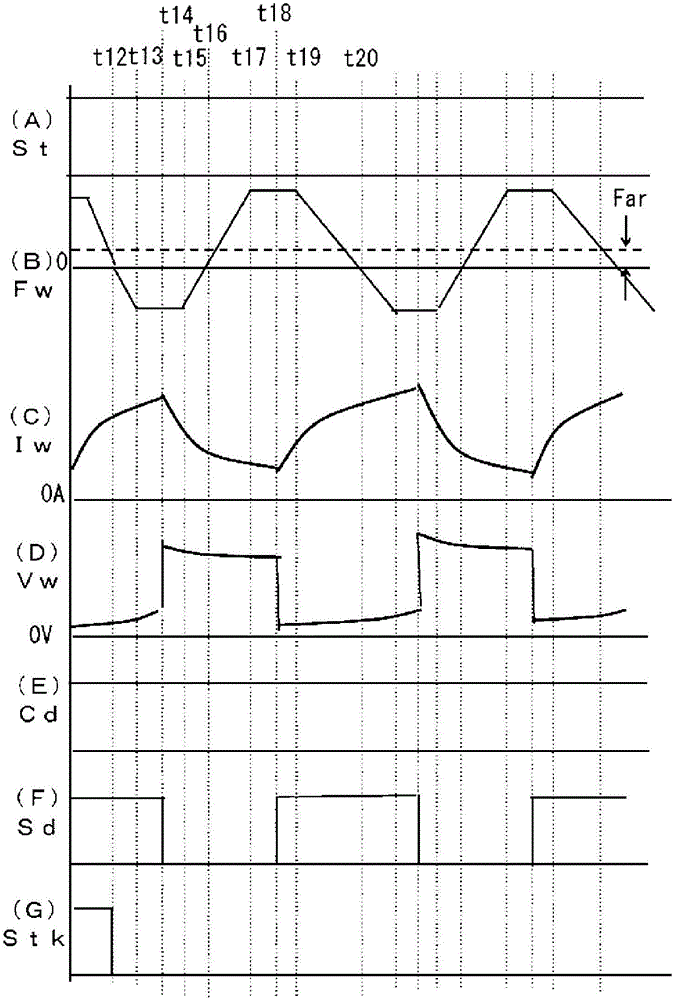

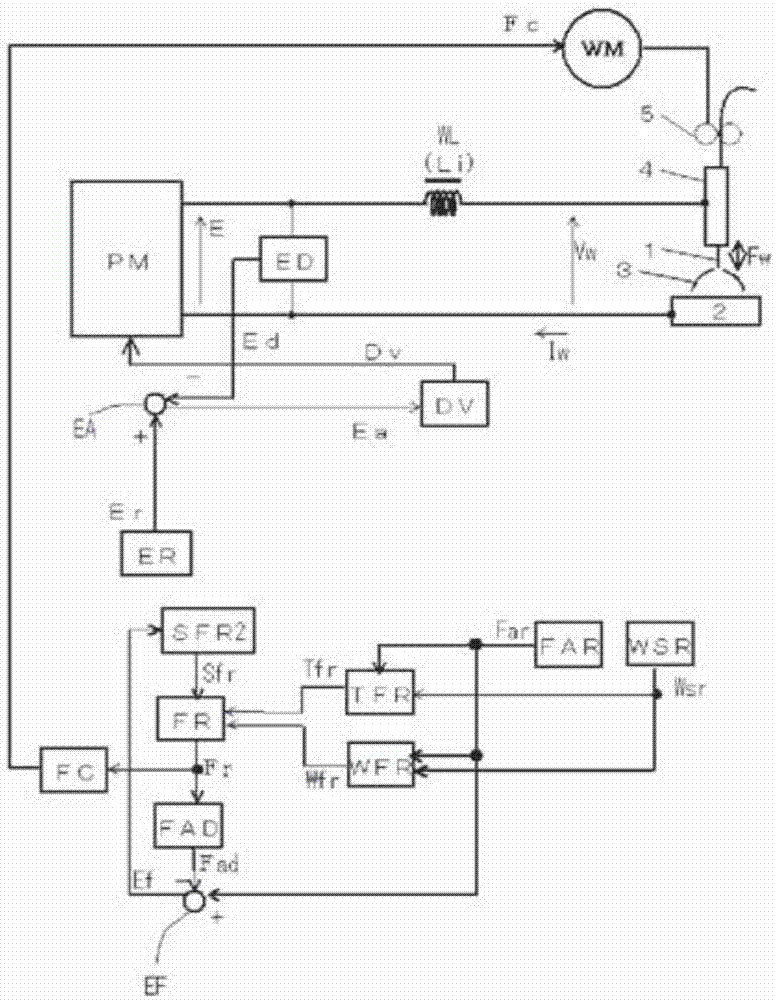

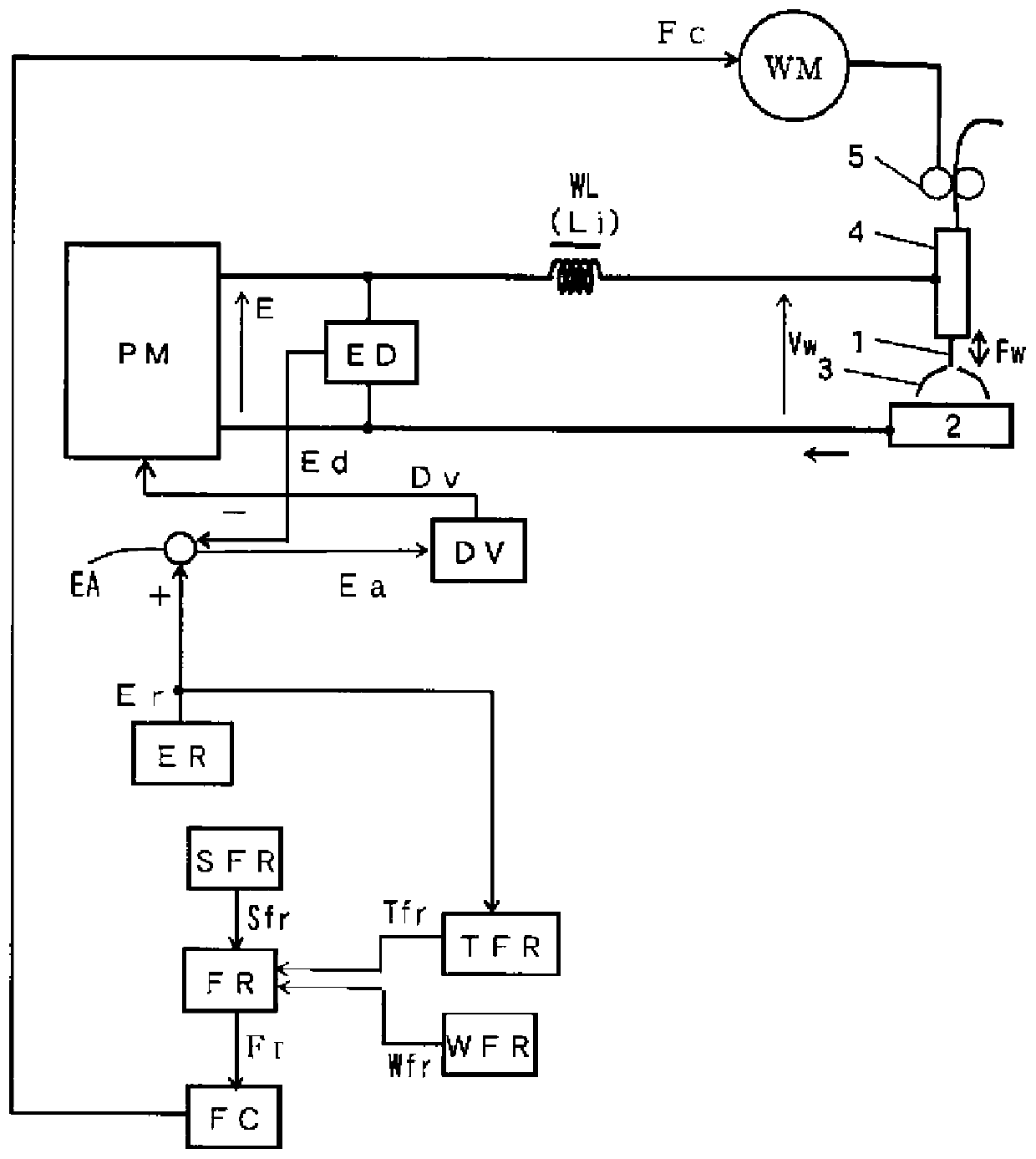

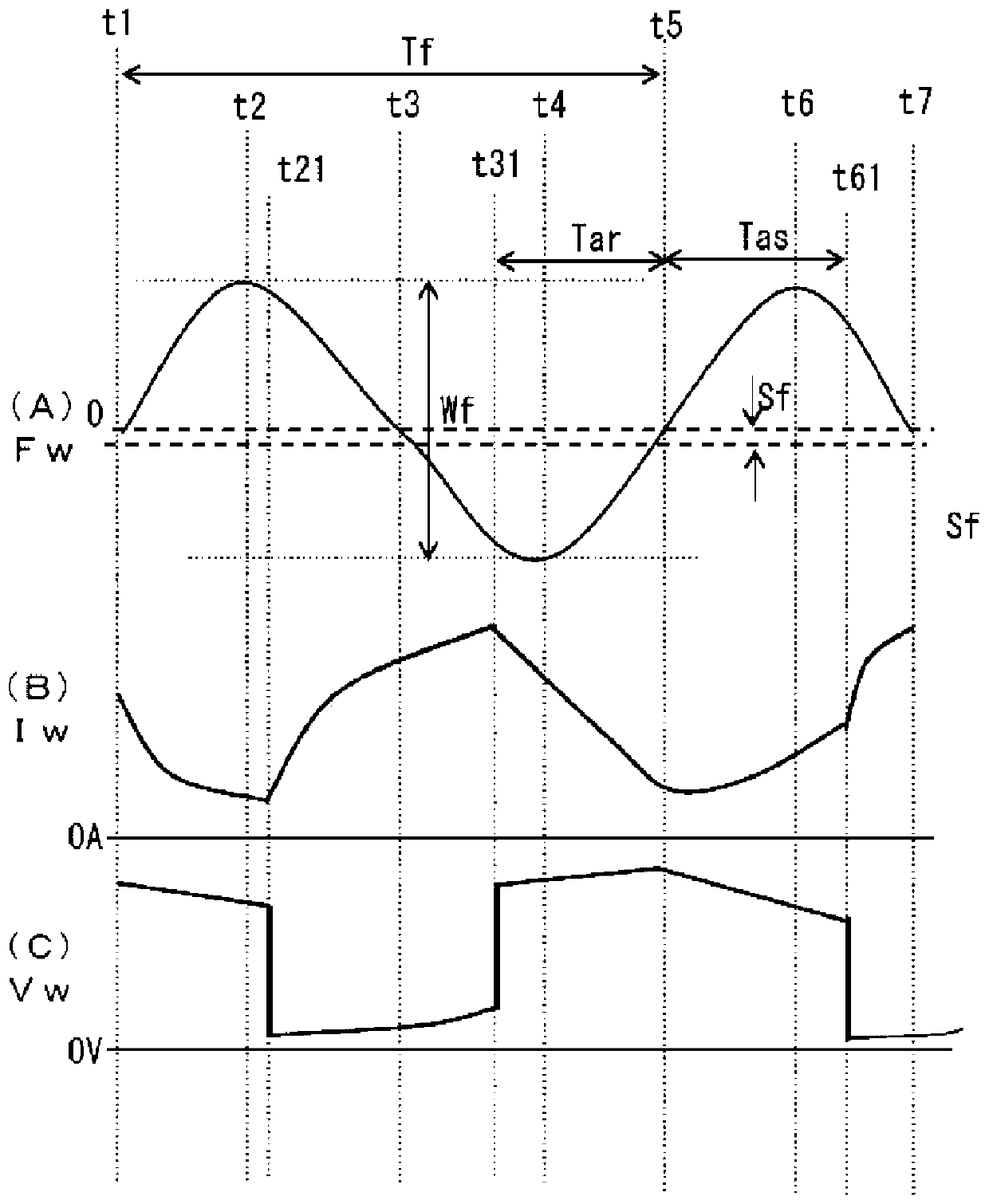

Provided is an arc welding control method that performs welding by alternately switching feed rate (Fw) for welding wire (1) between a forward feed period and a reverse feed period, controlling welding voltage (Vw) on the basis of a voltage setting value, and repeating a short period and an arc period, wherein a smoothed value for welding voltage (Vw) is detected and a cycle (Tf) of the feed rate (Fw) is feedback controlled such that this smoothed value for welding voltage and the voltage setting value are the same. Thereby, the cycle (Tf) of the feed rate (Fw) is made appropriate in correspondence with changes in the metal transfer mode accompanying changes in voltage setting value; therefore, it is possible to control occurrences of synchronization offsets in the cycle of forward feed and reverse feed for the feed rate (Fw) and the cycle of the short period and the arc period, and maintain stable welding conditions.

Owner:DAIHEN CORP

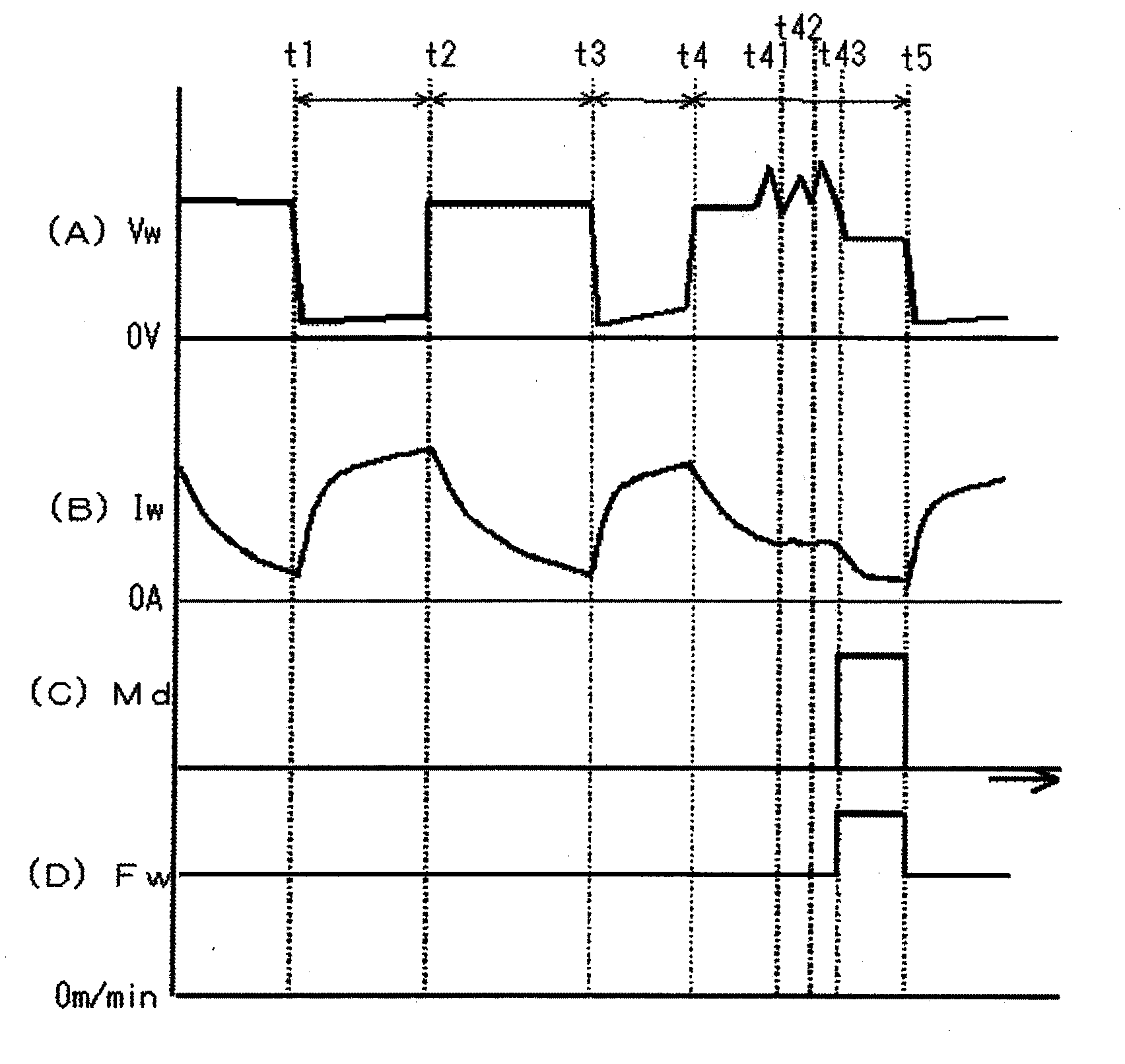

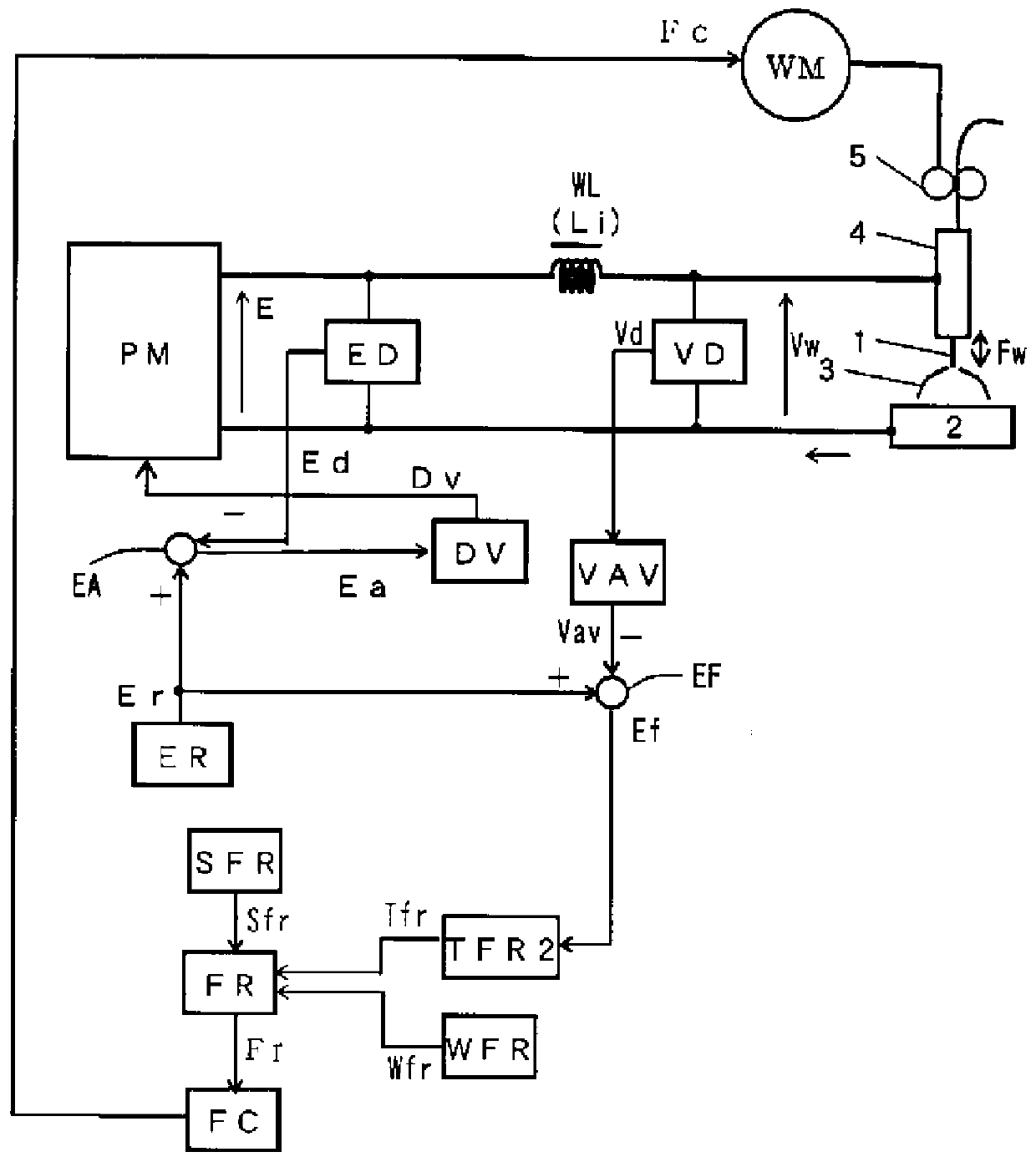

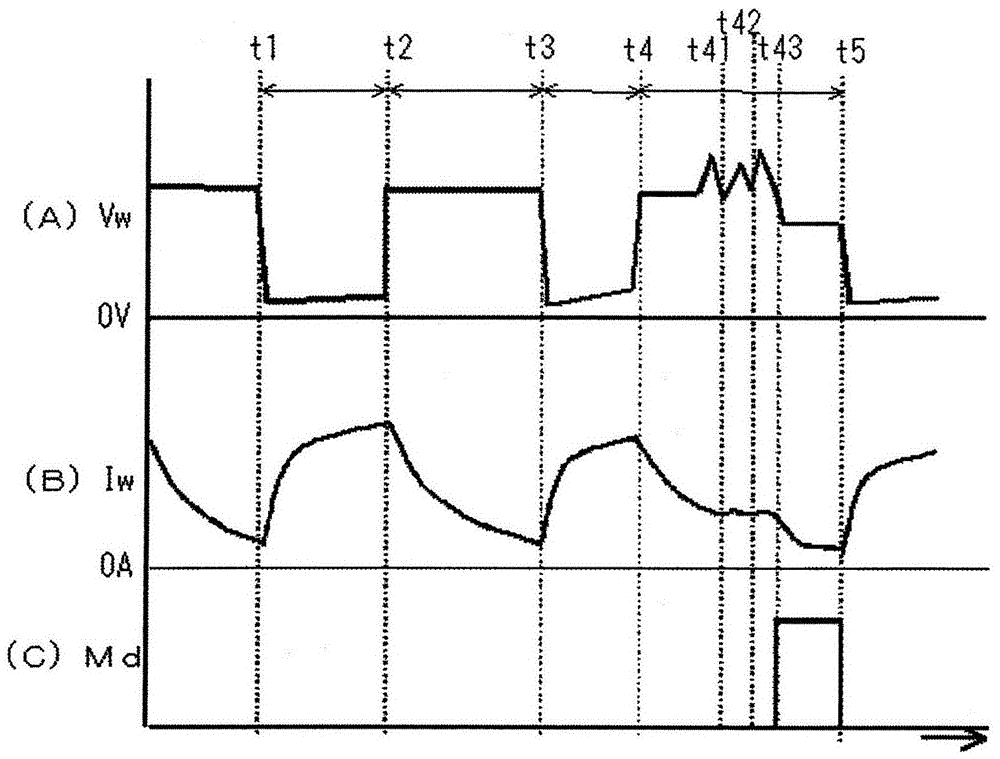

Welding source output control method

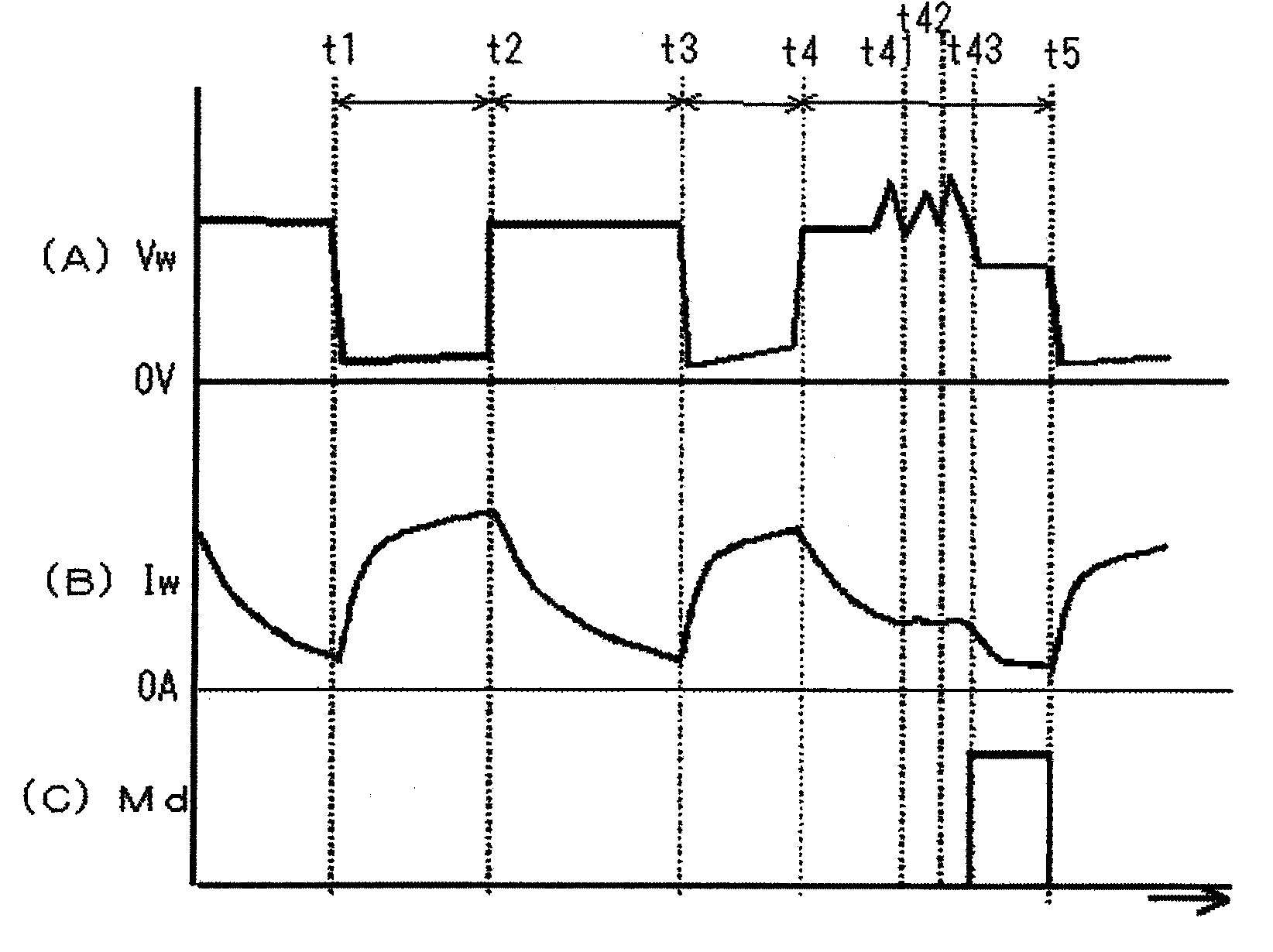

The invention provides a welding source output control method which suppresses the prolonging of electric arc period caused by the spray out of gases from a weld pool during the carbon dioxide electric arc welding. The welding source output control method controls the output of the welding source, which is used for the electric arc welding during the repeated short circuit period and the electric arc period between a welding wire and a base metal, through the feedback control of the welding voltage. During the electric arc period of t3-t5, the variation of the welding voltage (Vw) repeatedly exceeds the preset reference valve more than twice (t41, t42, and t43), the welding current (Iw) is reduced to the starting time (t5) of a next short circuit period. Therefore, the welding current (Iw) is immediately reduced when the spray out of gases is determined, so that the prolonging the electric arc period can be suppressed and the increasing of sputtering generation can be prevented.

Owner:DAIHEN CORP

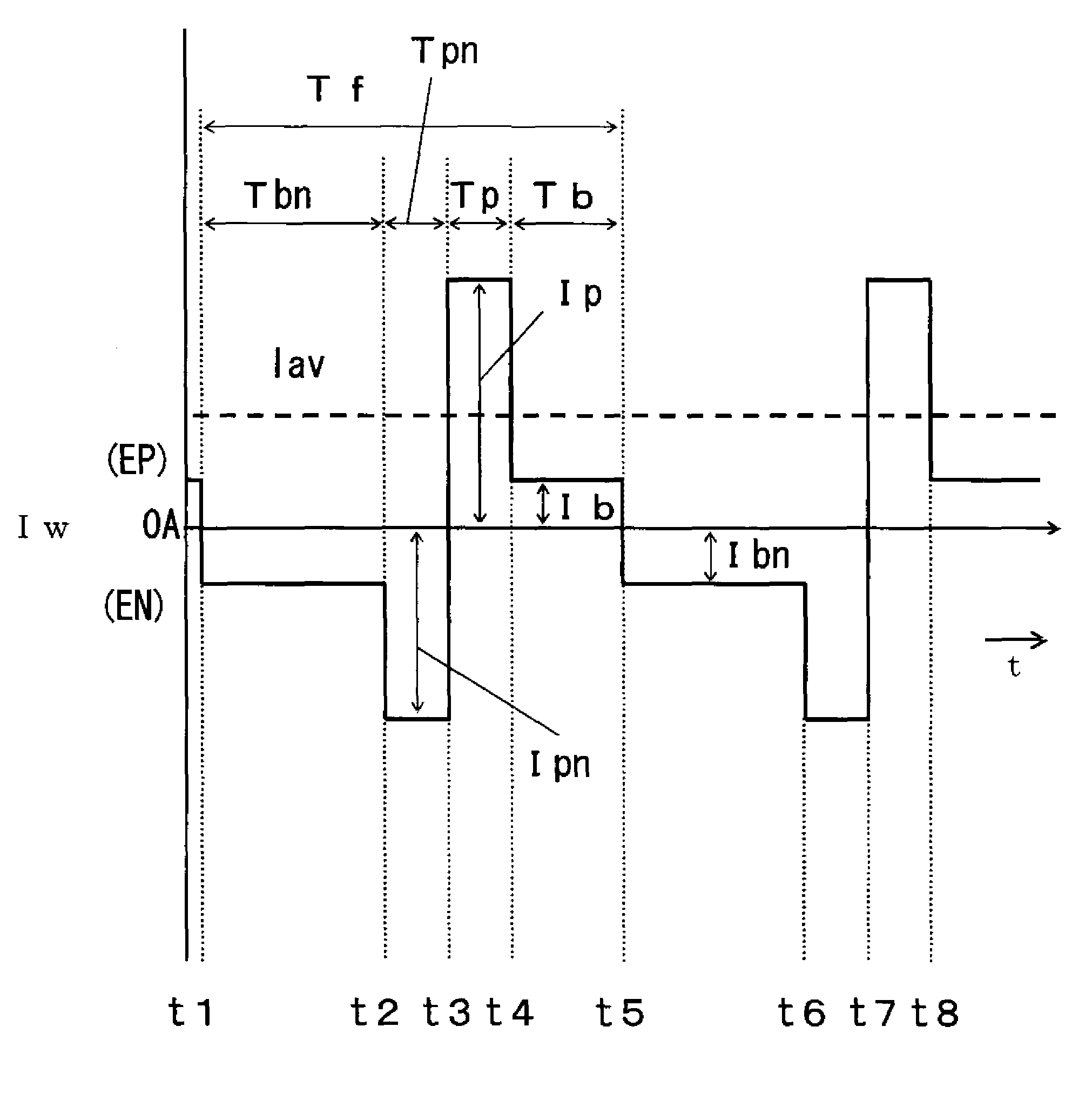

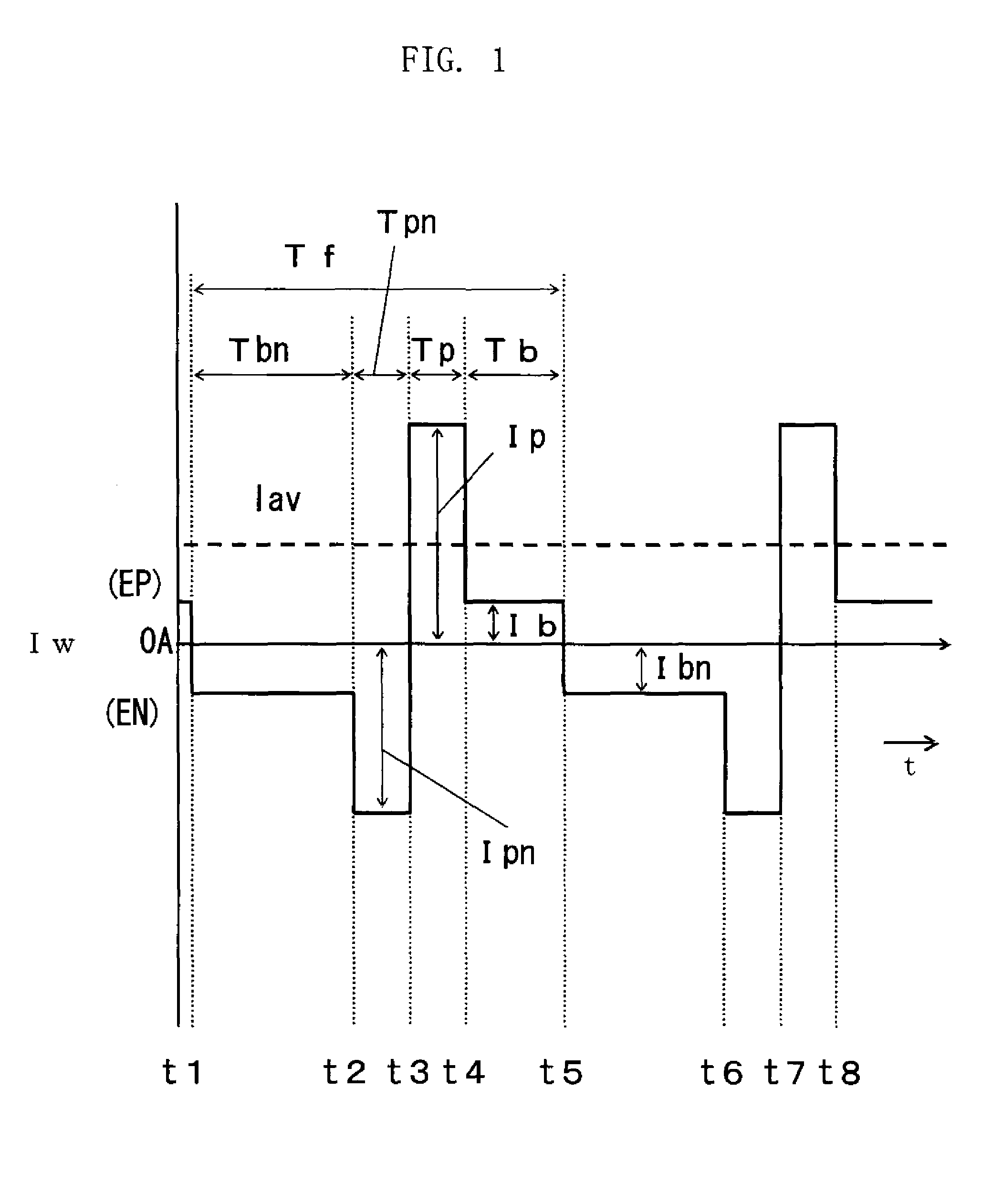

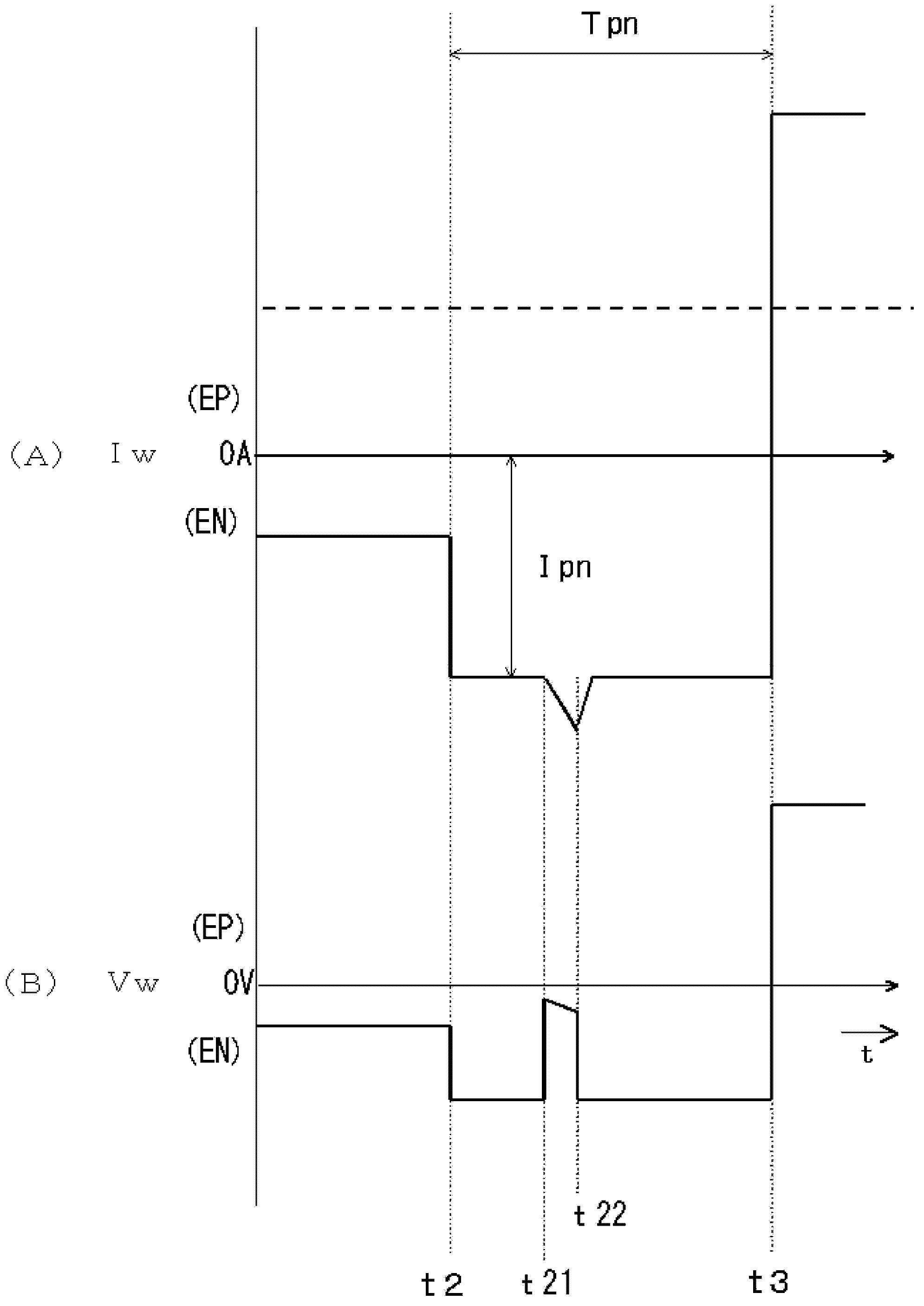

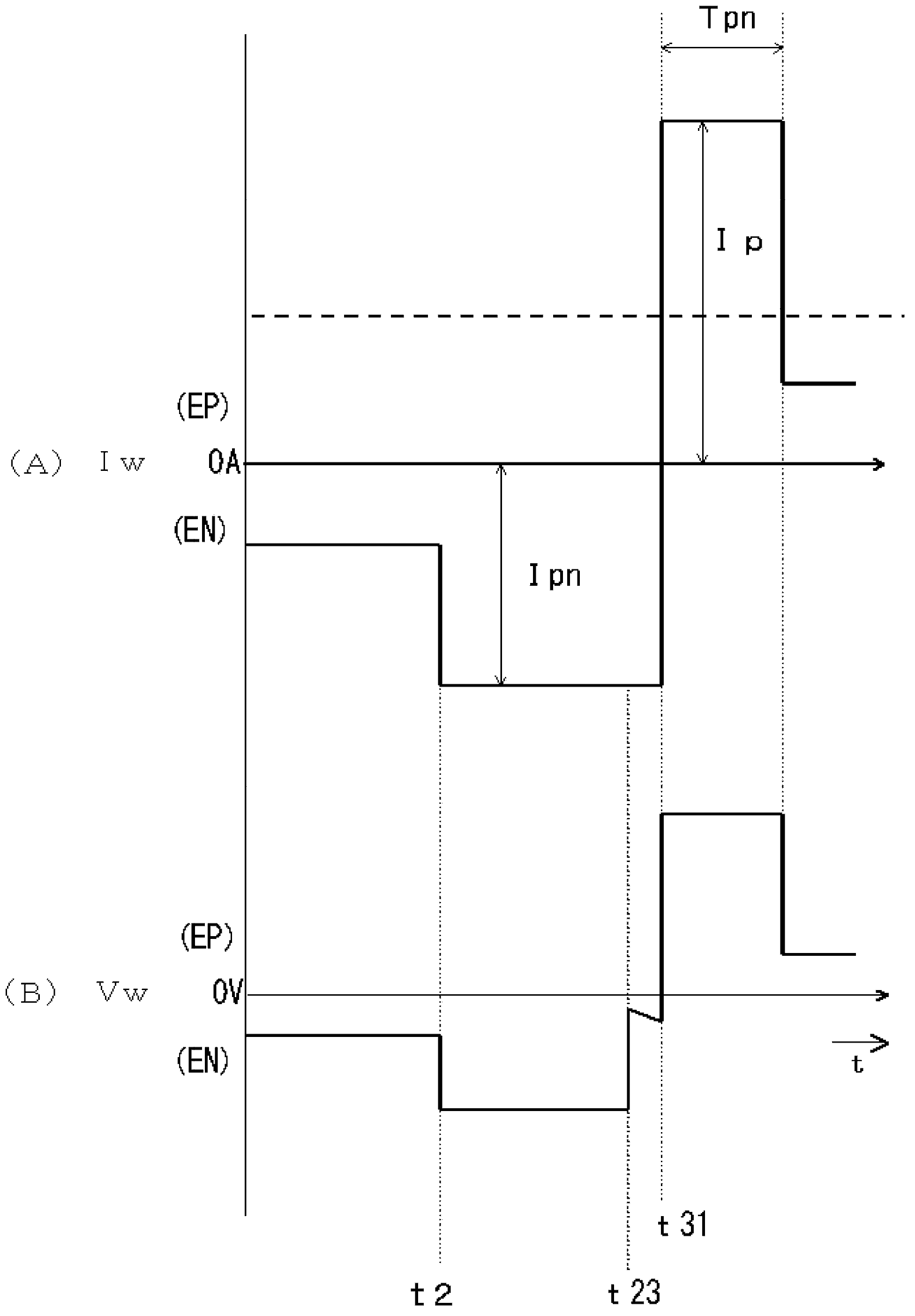

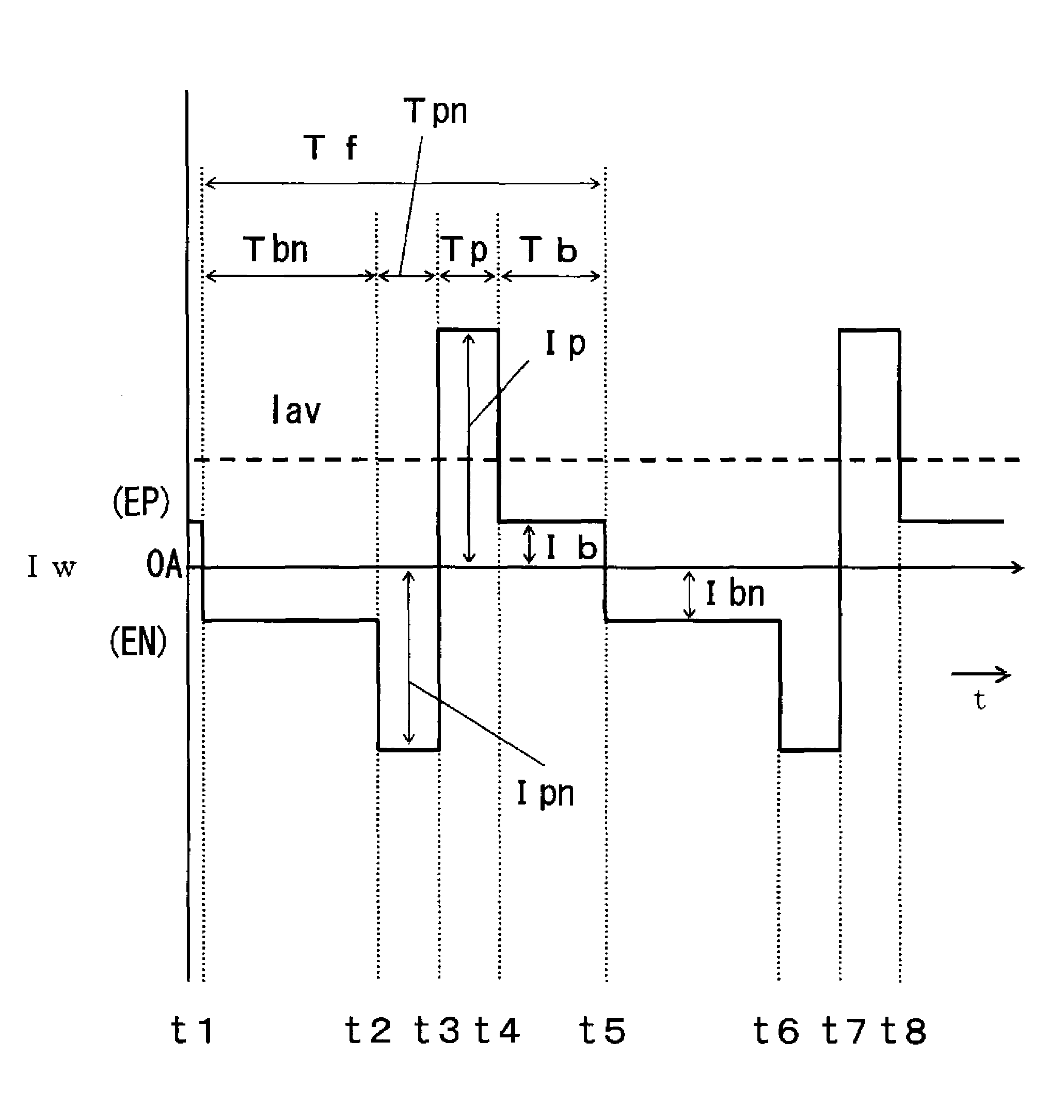

Method for controlling ac pulse electric arc welding

ActiveCN103418888AFacilitate droplet transferReduce sputteringArc welding apparatusPower flowElectrical polarity

The invention provides a method for controlling AC pulse electric arc welding, which is intended to maintain a stable welding state even an electrode negative polarity current ratio is set to be a large value in sacrificial electrode AC pulse electric arc welding. Therefore, a background current is powered during the electrode negative polarity base value, an electrode negative polarity peak current (Ipn) is powered during the electrode negative polarity peak value (Tpn), a peak current is powered during the electrode positive polarity peak value, a background current is powered during the electrode positive polarity base value. A short circuit occurs during the electrode positive polarity peak value. When a value of a short circuit generating time point relative to a molten drop dimension is lower than a reference value , the current during the short circuit is added, and when the value relative to the molten drop dimension is larger than the reference value, the value is converted in the electrode positive polarity peak value period at the short circuit generating time point. Therefore, molten drop transition is smoothly performed irrespectively with the molten drop dimension, thereby maintaining the stable welding state.

Owner:DAIHEN CORP

AC pulse arc welding control method

A control method for AC pulse arc welding performed upon application of cyclic AC welding current is provided. The welding current has a cycle including an electrode negative polarity period and an electrode positive polarity period subsequent to the electrode negative polarity period. In the control method, an electrode negative polarity base current and a subsequent electrode negative polarity peak current are applied during the electrode negative polarity period. The electrode negative polarity base current has an absolute value smaller than a first critical value, and the electrode negative polarity peak current has an absolute value greater than the first critical value. Then, an electrode positive polarity peak current is applied during the electrode positive polarity period. The electrode positive polarity peak current has a value greater than a second critical value.

Owner:DAIHEN CORP

Solid electrolytic capacitor

ActiveUS7835139B2Welding state is stableLow ESRSolid electrolytic capacitorsLiquid electrolytic capacitorsAdhesiveEngineering

Cathode electrode part 5 of flat plate-like element 1 is joined with cathode com terminal 7 with a conductive adhesive or the like. Element mounting part 6a of anode terminal 6 is provided with a pair of joint parts 6b for wrapping anode electrode part 4 from both sides. The tips of joint parts 6b and anode electrode part 4 are joined by laser welding such that the ratio (w / d) of the width (w) of each tip of joint parts 6b and the diameter (d) of the welding trace to be welded is 0.5 to 1.5, and more preferably, 0.5 to 1.25 for providing low ESR means for concentrating the quantity of heat at the time of welding on welding parts 6c without escape. Therefore, a stable welded state is obtained, so that the ESR is improved for achieving low ESR of the solid capacitor.

Owner:PANASONIC CORP

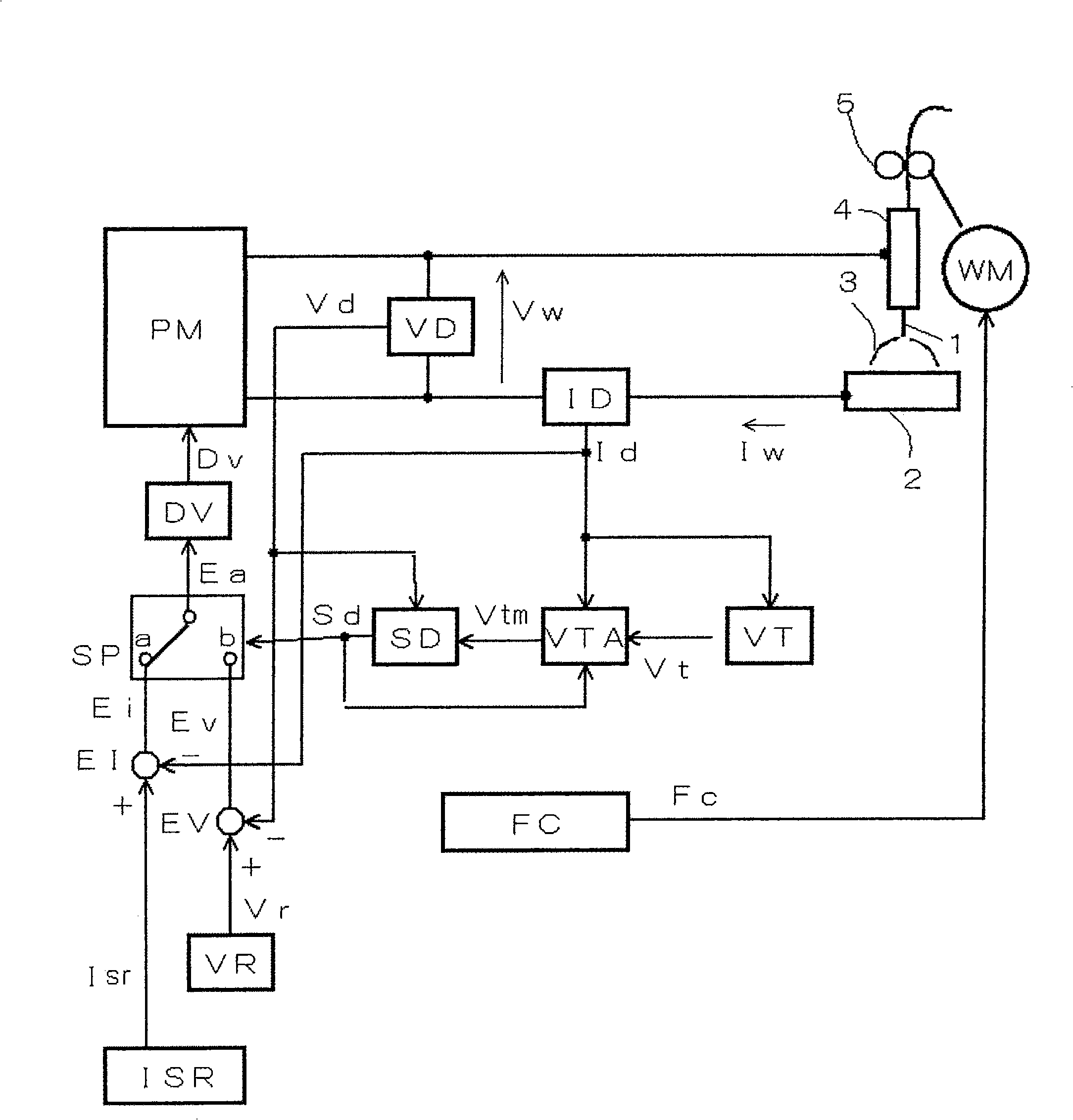

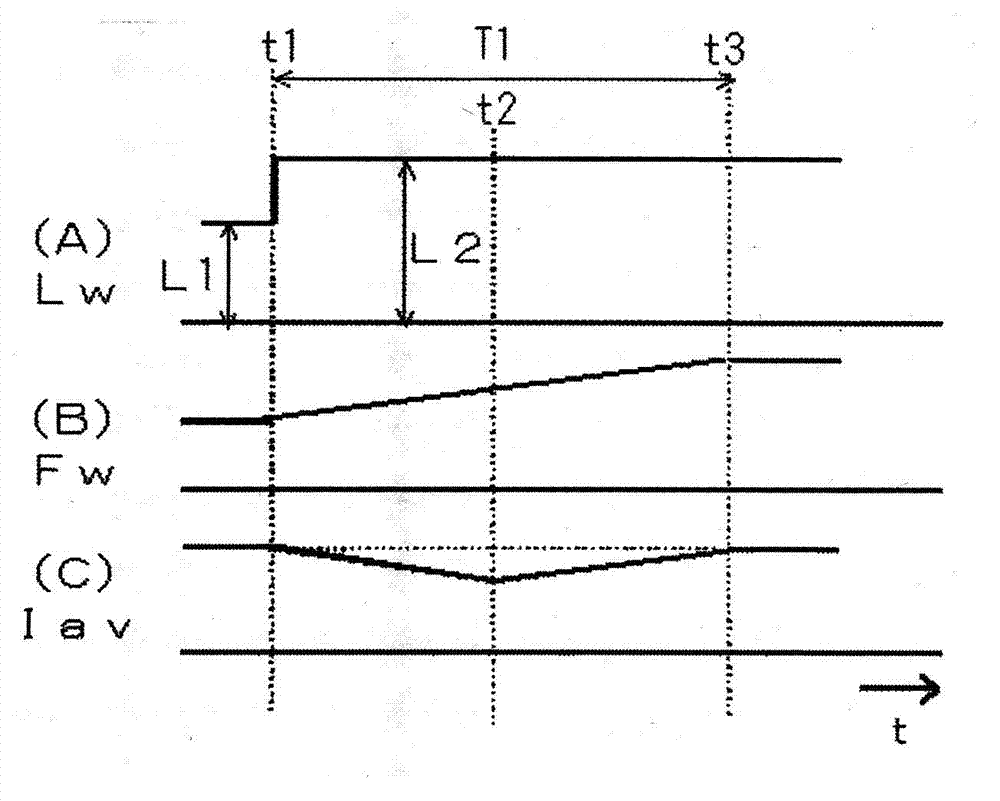

Control method for consumable electrode arc welding

The invention provides a control method for consumable electrode arc welding. If constriction of molten droplet is detected, a welding current powered to a short circuit load is reduced so as to generate a constriction detection and control of the arc again. A feedback control (feed speed variable control) for the feed speed (Fw) is carried out according to a manner of a welding current smoothed value (Iav) equal to a predetermined current set value, so as to weld. The control method comprises an action mode for acting the constriction detection control and a forbidden mode for forbidding the constriction detection control. A transition response time (T1) of the feedback control in the action mode is longer than that in the forbidden mode. Therefore, the feed speed (Fw) changes slowly in relative to the change of a distance between a power chip and a base material, thereby keeping the welding state stably. The method can inhibit that the welding state becomes unstable when the constriction detection control acts together with the feed speed variable control at a constant welding current.

Owner:DAIHEN CORP

Necking detection control method in consumable electrode electric arc welding

The invention provides a necking detection control method in the consumable electrode electric arc welding. In the consumable electrode electric arc welding, the molten drop necking detection precision can be improved. The necking of the molten drop is carried out through making the change of the resistance between a consumable electrode (1) and a base metal (2) reach to a necking detection reference value, and if the necking phenomenon is detected, the output control is carried out through reducing the welding current Iw and generating the arc in a low current state. In each short circuit, the necking detection time from the necking phenomenon detection time to the arc regeneration time is detected. When the necking detection time is below a lower limit time, 1 is subtracted from a counter, and when the necking detection time is above an upper limit time, 1 is added into a counter. When the value of the counter reaches to a negative reference value, the necking detection reference value Vtn is reduced, and when the value of the counter reaches to a positive reference value, the necking detection reference value Vtn is added. In such a manner, the necking detection reference value Vtn becomes proper, and the necking detection precision is improved.

Owner:DAIHEN CORP

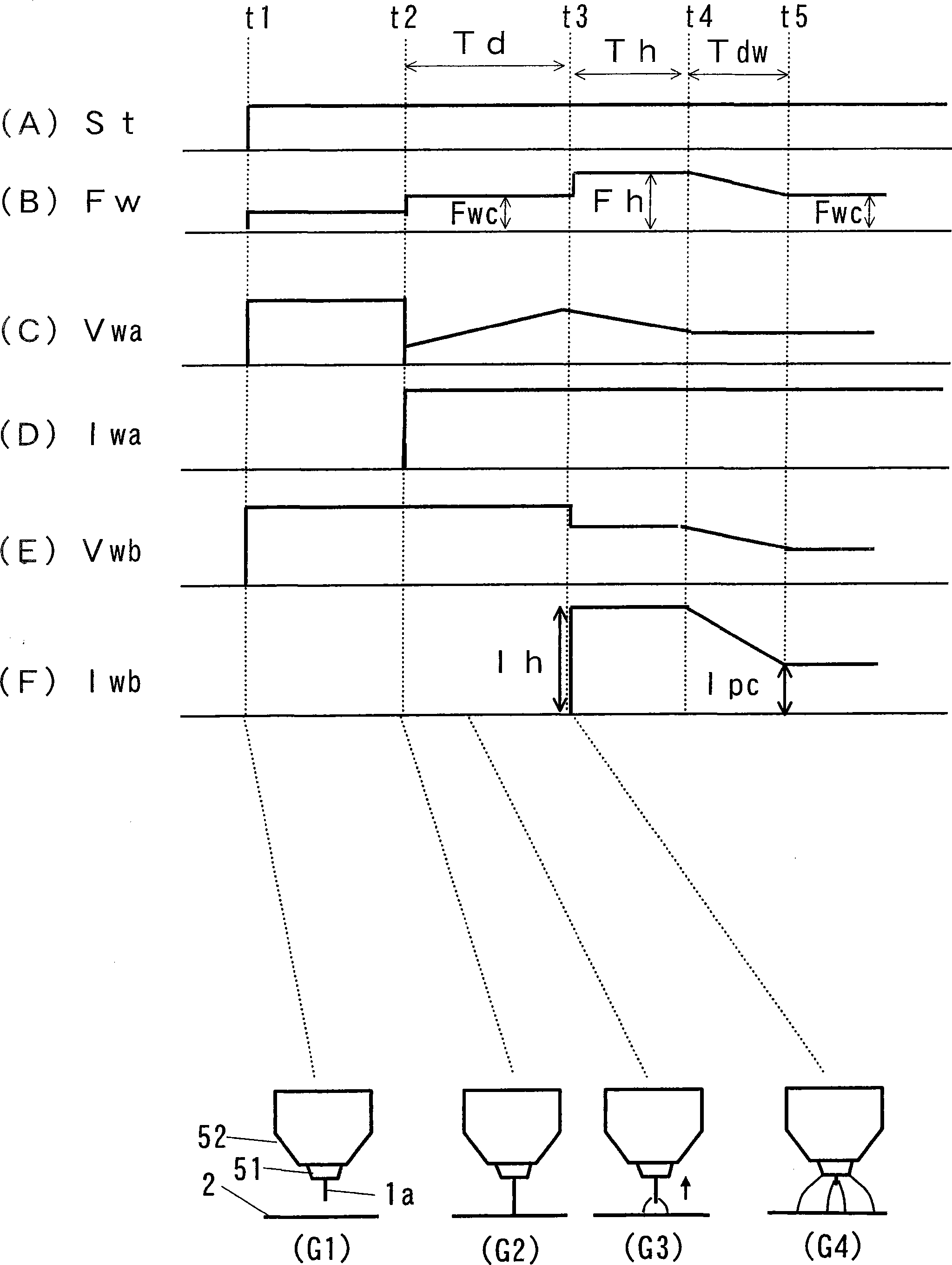

Arc welding control method

Provided is an arc welding control method that carries out forward-reverse feed control alternately switching a welding wire feed rate (Fw) between a forward feed period and a reverse feed period and performs welding by generating a short period and an arc period, wherein during a transient welding period (Tk), a transition to the forward feed period occurs when the arc period comes during the reverse feed period and a transition to the reverse feed period occurs when the short period comes during the forward feed period, and during a steady welding period, switching is carried out alternately between a prescribed forward feed period and a prescribed reverse feed period. Thus, because forward-reverse feed control that differs from that during the steady welding period is carried out during the transient welding period (Tk), the welding state during the transient welding period (Tk) can be stabilized.

Owner:DAIHEN CORP

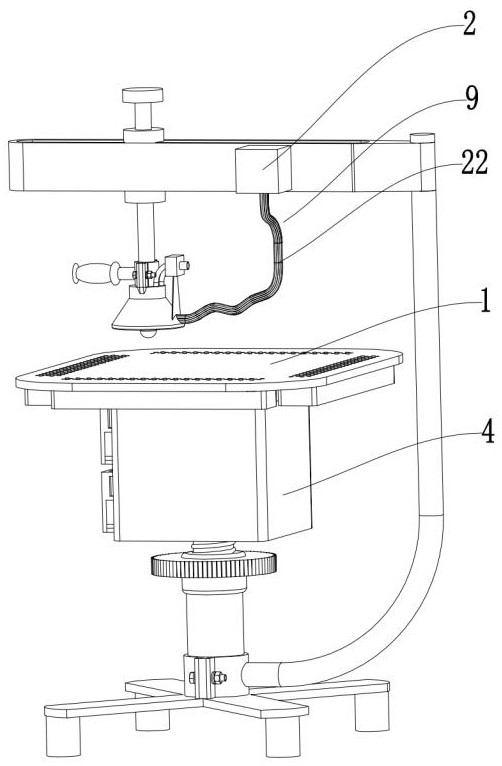

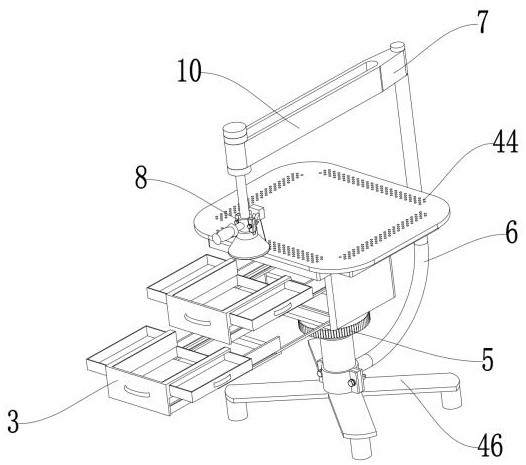

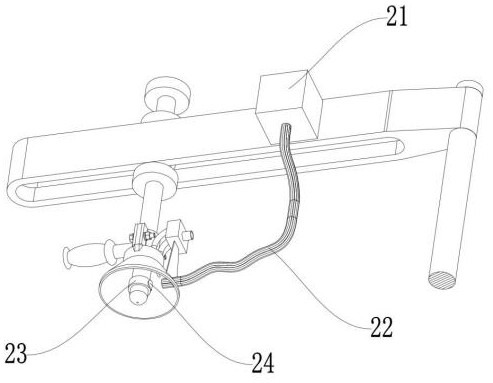

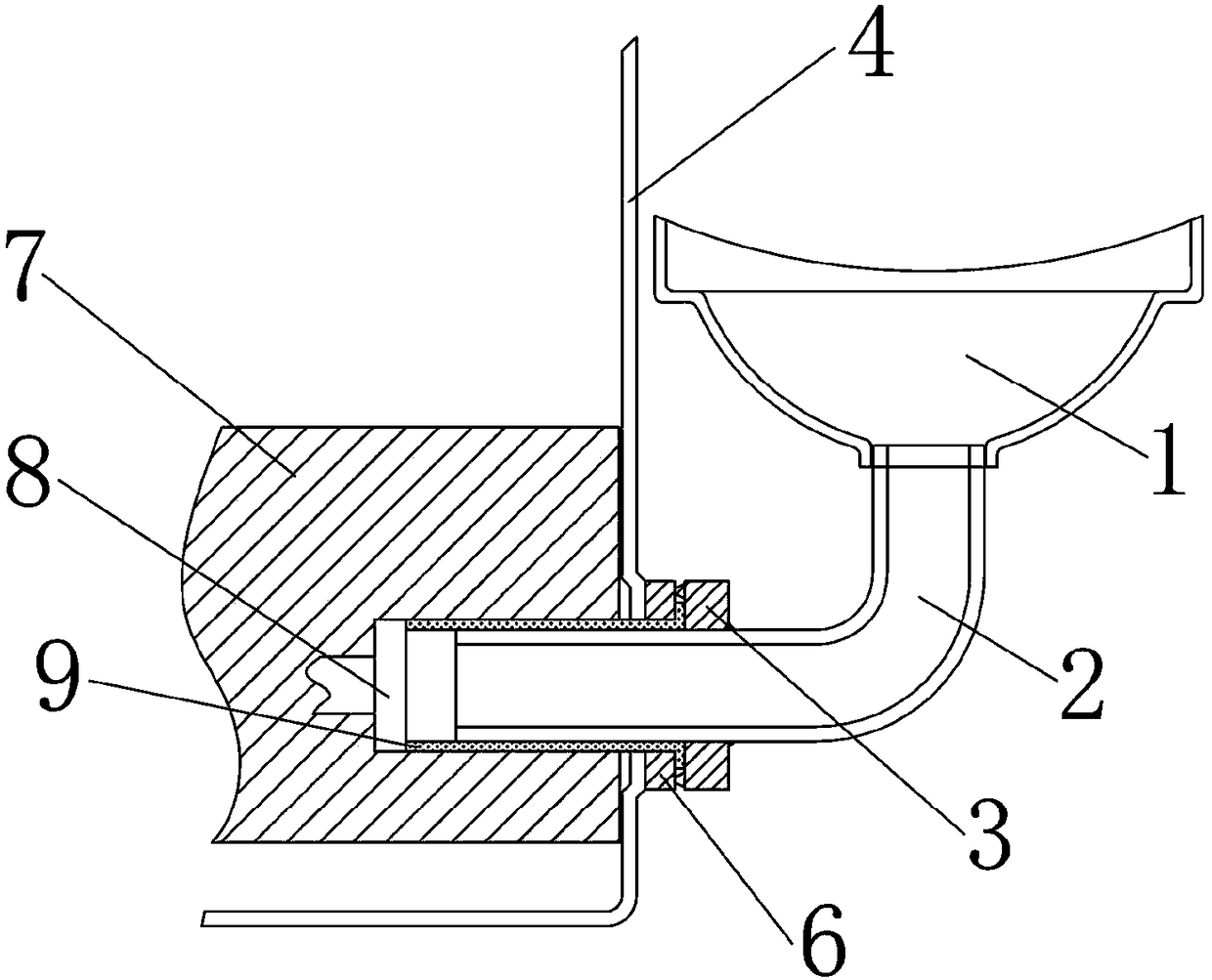

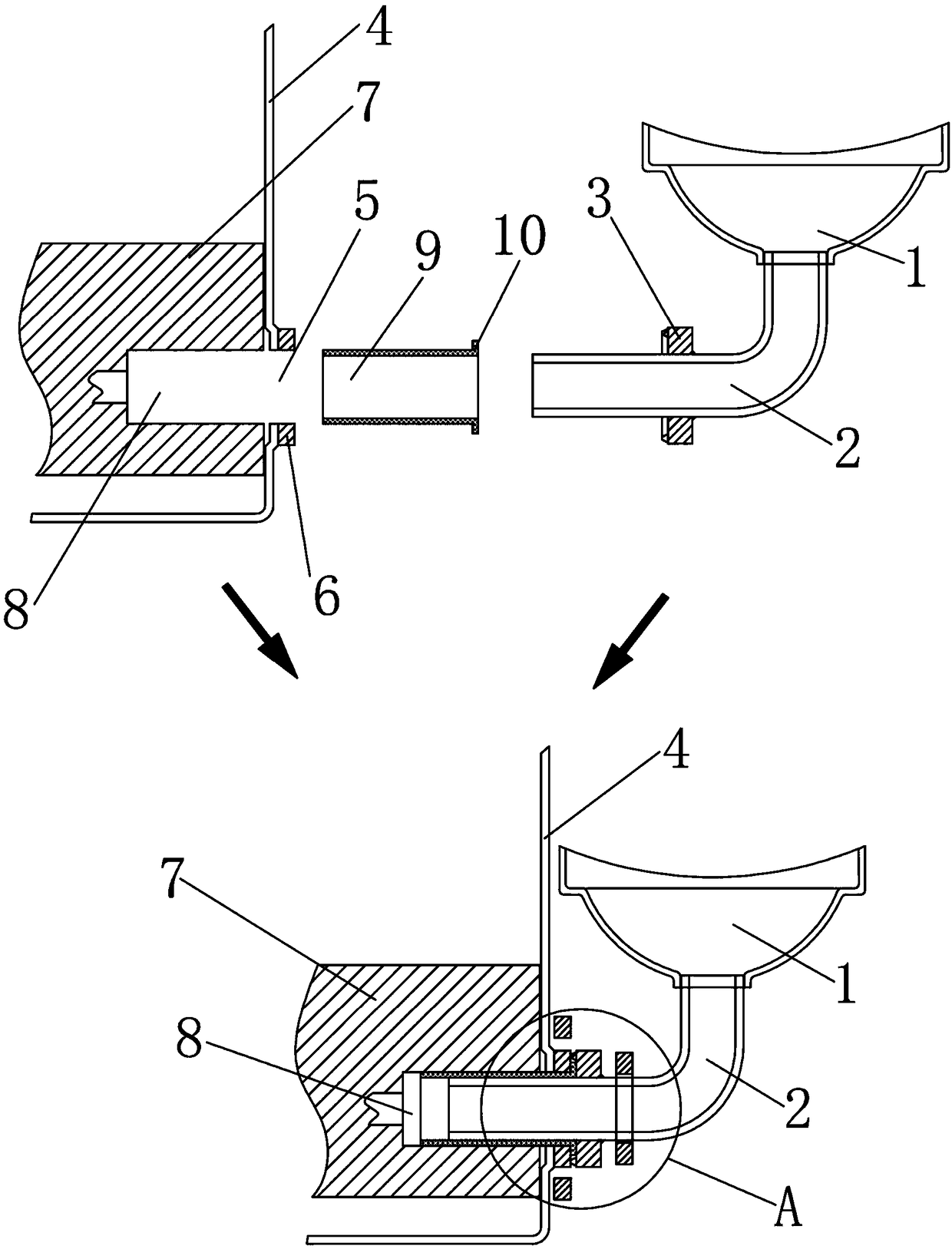

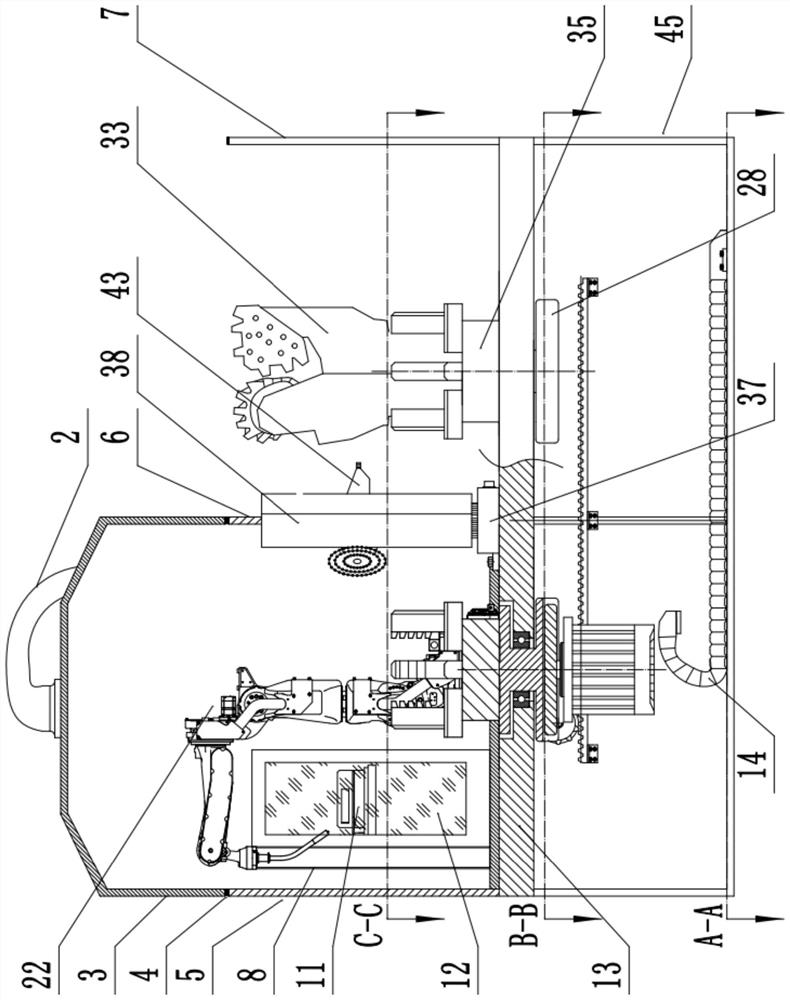

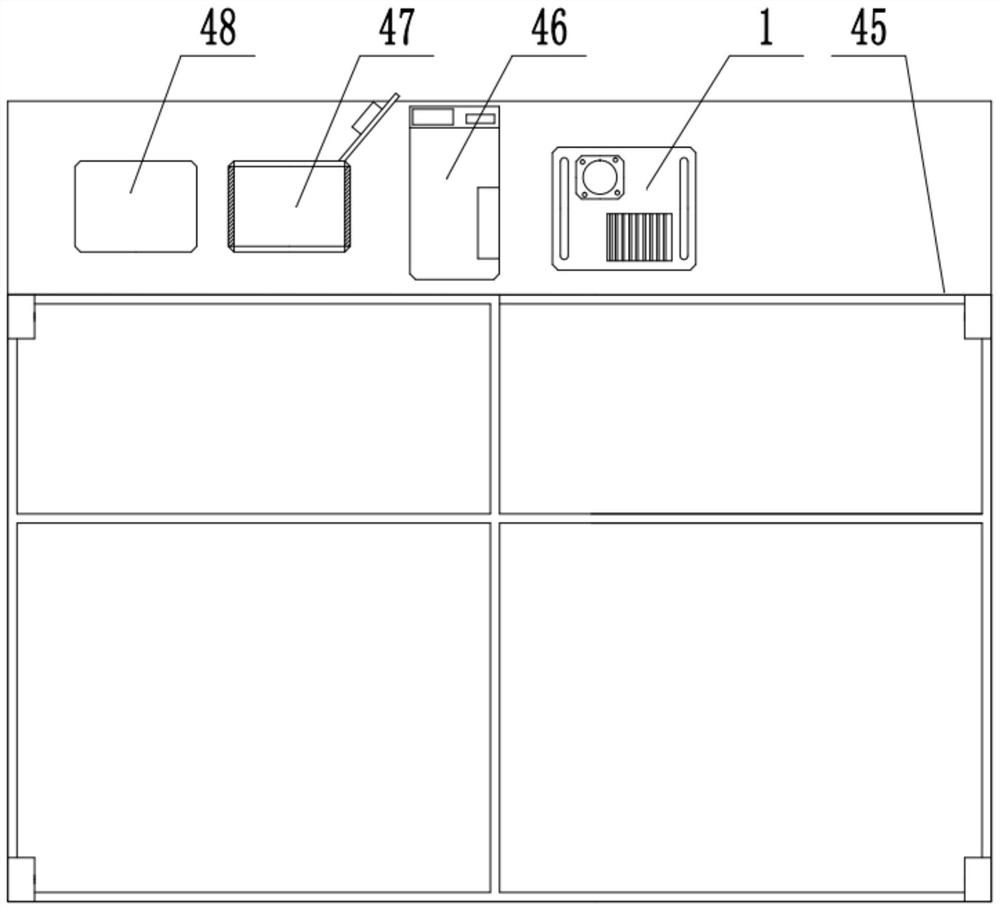

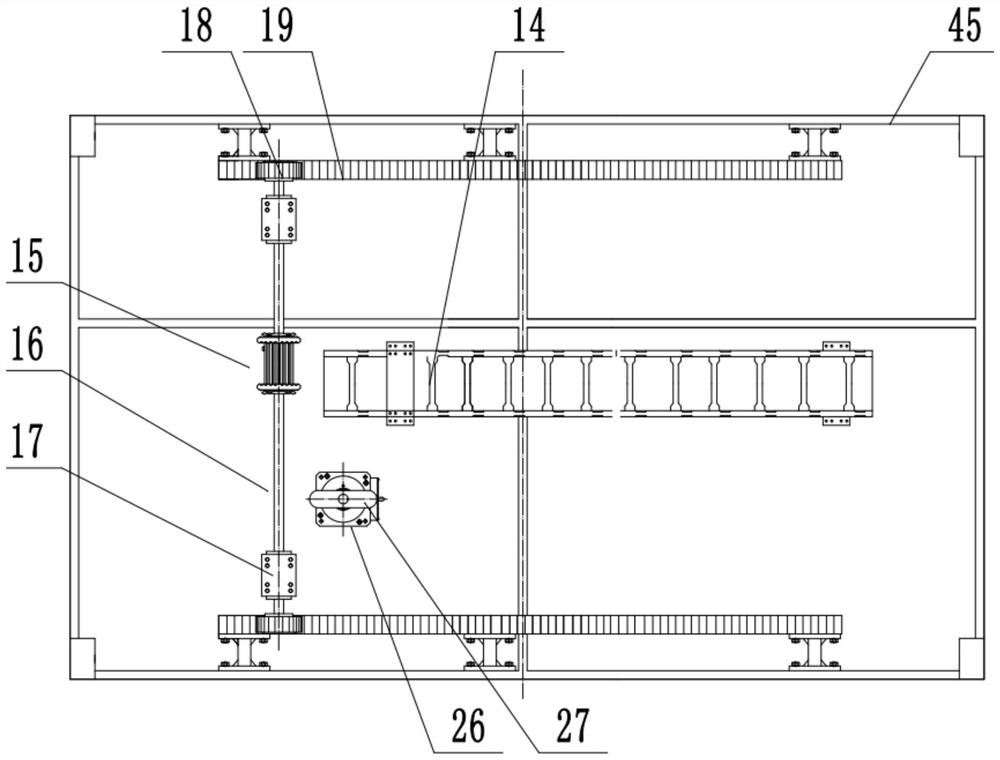

Krah tube electric hot melting connecting device and method

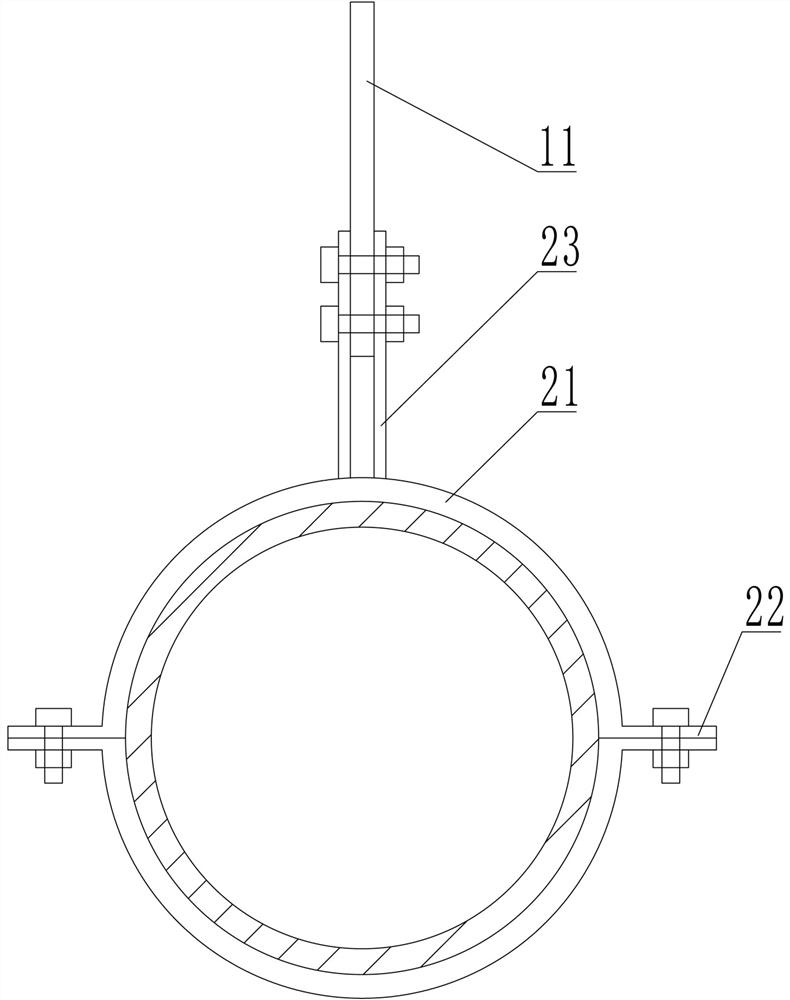

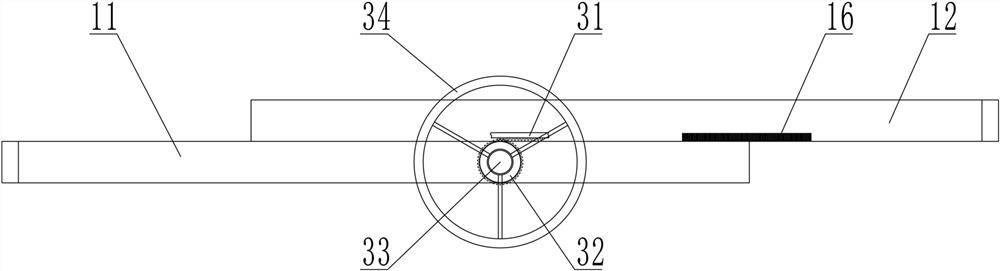

ActiveCN113733587AThe distance is easy to adjustWelding state is stableTubular articlesGear wheelEngineering

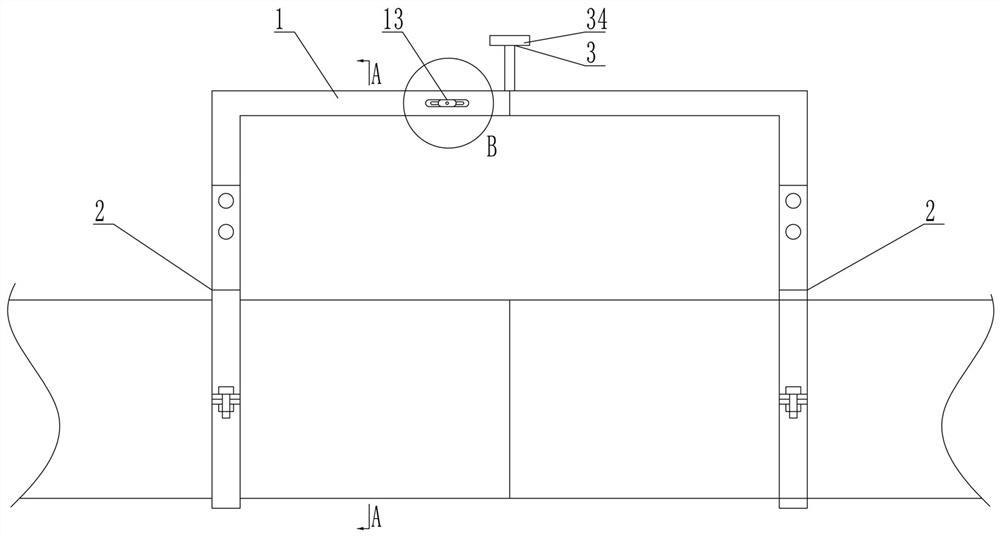

The invention provides a Krah tube electric hot melting connecting device and method. The Krah tube electric hot melting connecting device comprises an adjusting arm, clamping pieces and a driving mechanism, wherein the two ends of the clamping pieces are respectively provided with two clamping pieces, connecting plates of the clamping pieces are connected with a left arm and a right arm of the adjusting arm respectively, a rack and a gear of the driving mechanism are connected with the left arm and the right arm of the adjusting arm respectively, the two ends, close to each other, of two Krah tubes are clamped through circular clamping rings formed by two semicircular arc plates of the clamping pieces, the driving mechanism drives the left arm and the right arm to drive the two clamping pieces to be close to or away from each other, in the welding process, Krah tube end materials can be fully fused, the welding quality is improved, later repair welding caused by leakage points is avoided, the construction efficiency is improved, and operations are simple and convenient.

Owner:长江生态环保集团有限公司

Consumable electrode arc welding method

ActiveUS20140027423A1Achieve effectAvoid welding qualityElectric heatingArc welding apparatusEngineeringFeedback control

A consumable electrode arc welding method includes the detecting of a constriction formed in a molten droplet of the welding wire so as to reduce the welding current, the detecting of a smoothed value of the welding current, and the feedback controlling of the feed rate of the welding wire so as to make the smoothed value of the welding current correspond to a predetermined current setting value. The constriction detection is performed repetitively in a predetermined cycle.In each time of the repetition, the length of a constriction time, from the constriction detection till the arc generation, is measured. The number of constriction time lengths falling outside a predetermined range is counted. When the counted number is not less than a reference number, the transient response time of the feedback control is made longer.

Owner:DAIHEN CORP

Welding device with telescopic structure for agricultural machinery

ActiveCN114131257BImprove cooling effectEasy to adjust the positionWelding/cutting auxillary devicesAuxillary welding devicesFluorescenceHigh energy

Owner:徐州博尔越智能制造有限公司

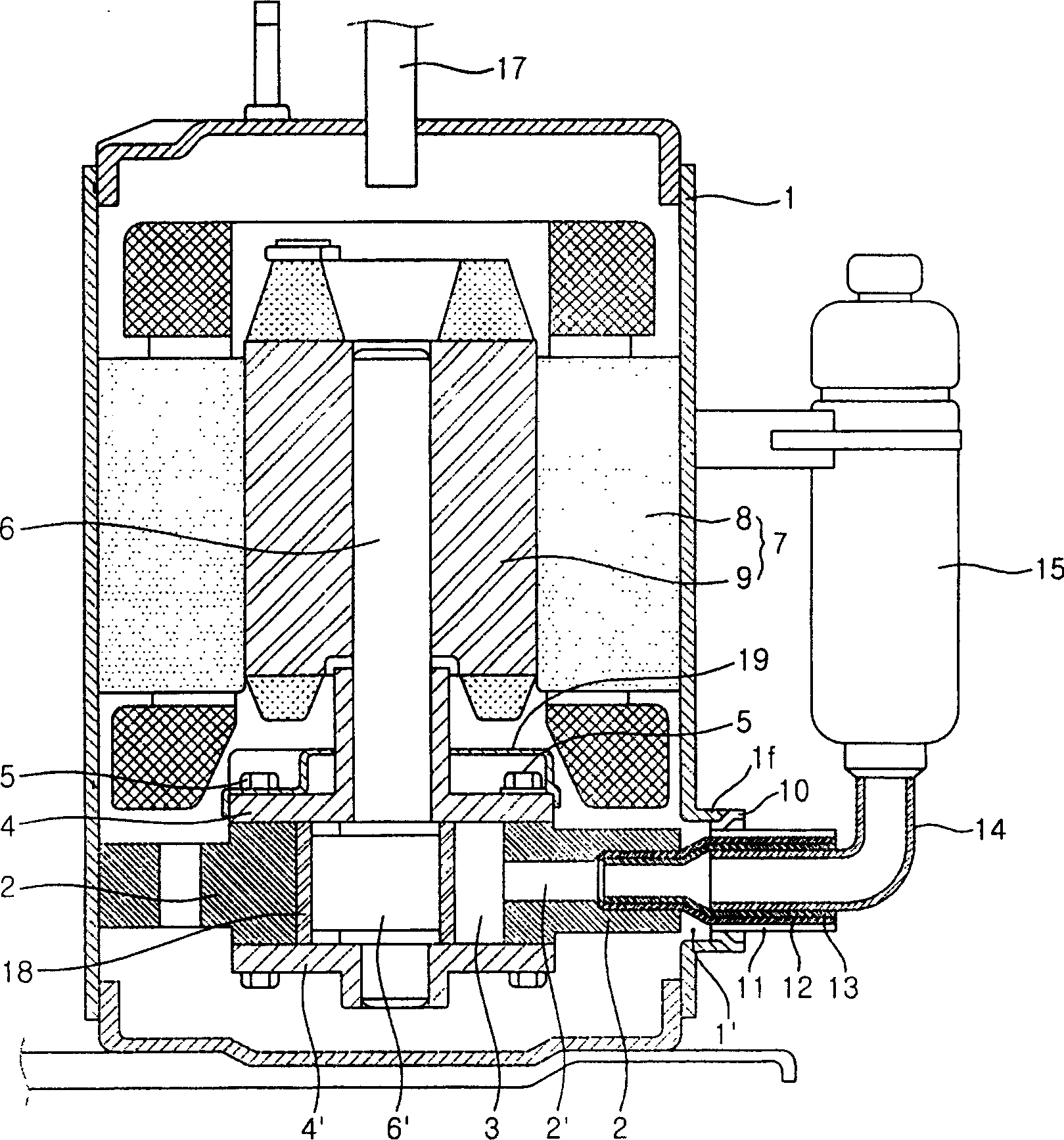

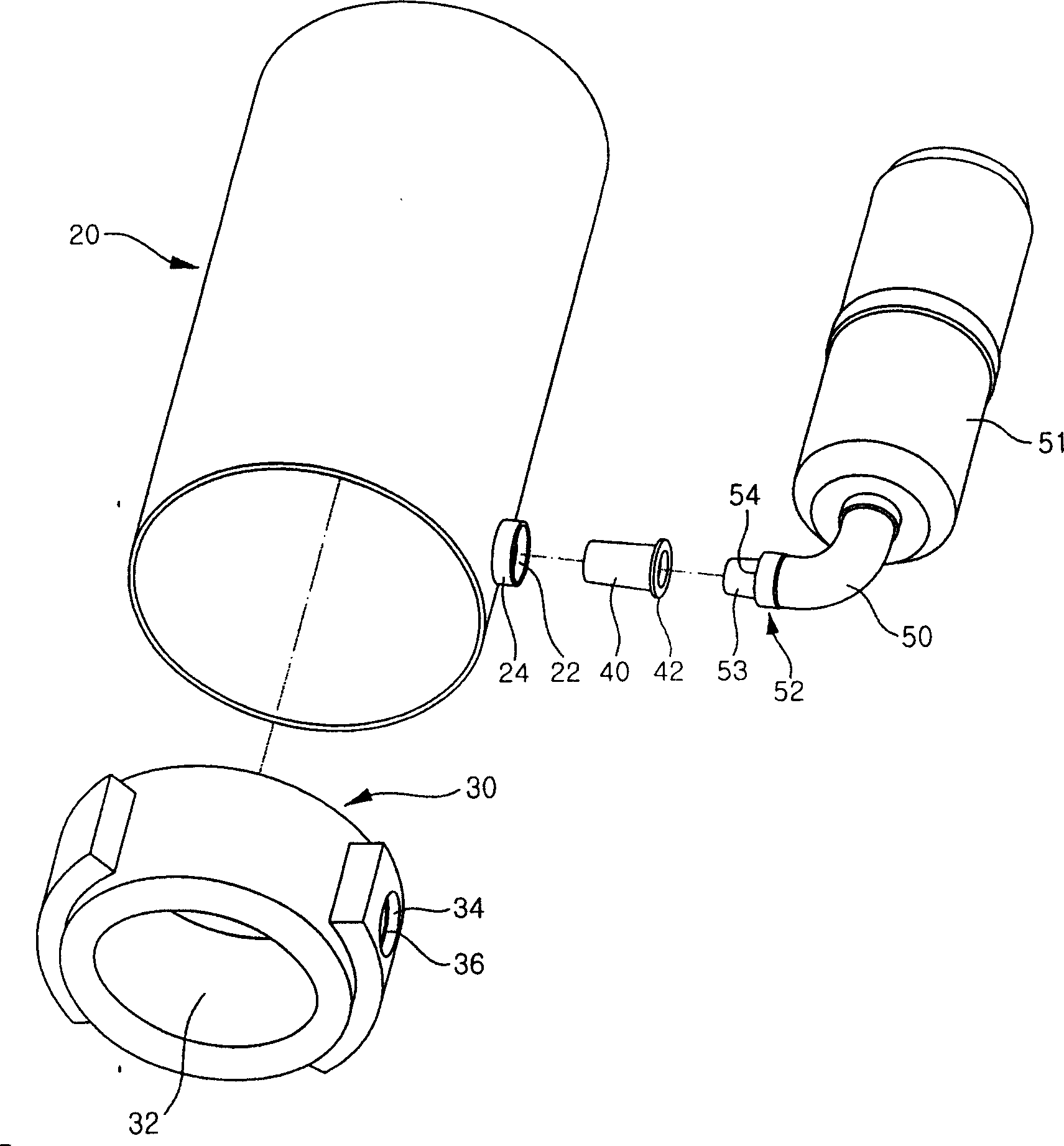

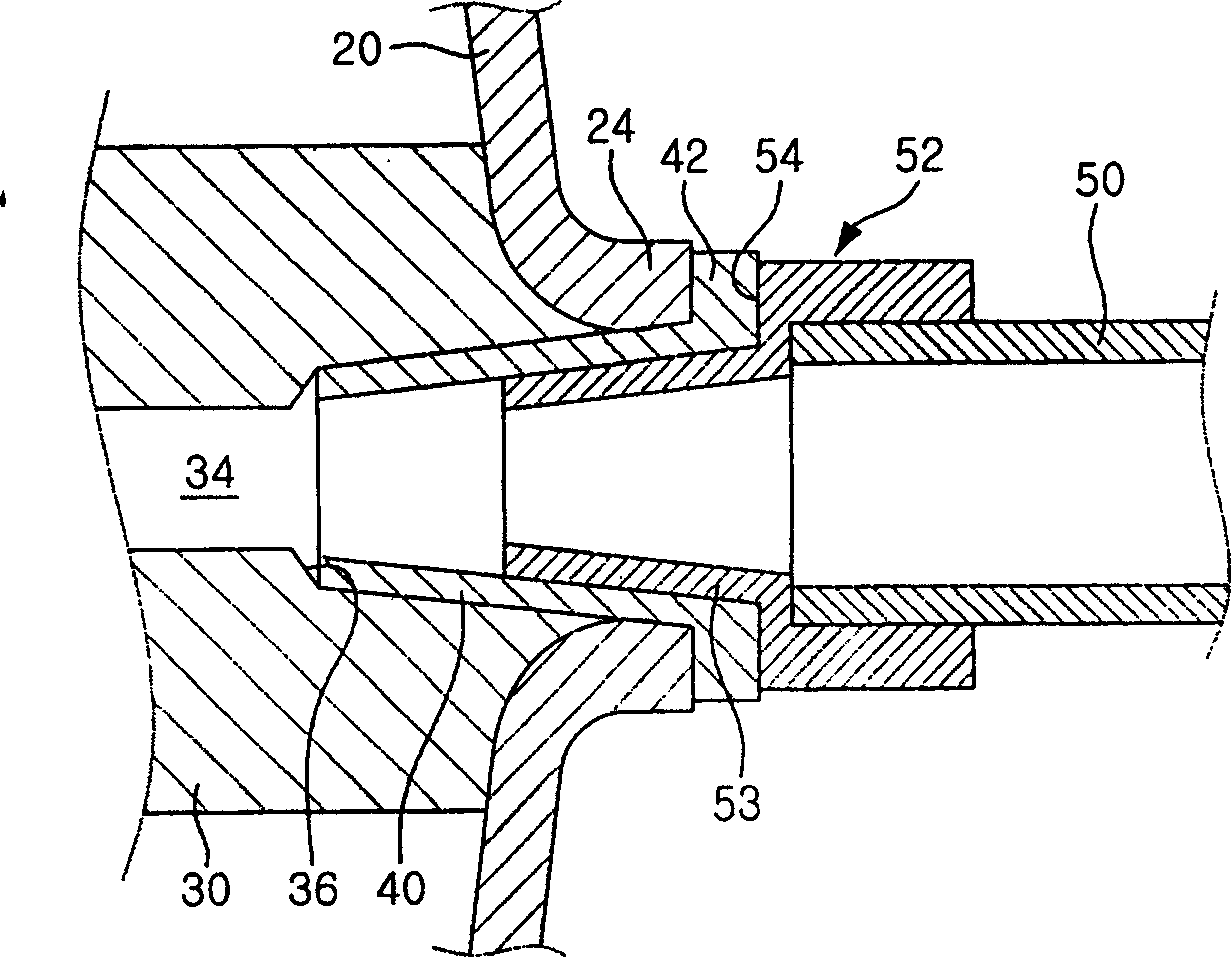

Connecting method for connecting structure of reservoir and air conditioner compressor

InactiveCN108637442AImprove sealingGuaranteed tightnessResistance welding apparatusInterference fitPower flow

The invention discloses a connecting method for a connecting structure of a reservoir and an air conditioner compressor and belongs to the technical field of refrigeration parts. The connecting structure comprises a reservoir body and a compressor shell. The reservoir body is provided with a reservoir air outlet iron pipe. A second flange is welded to the reservoir air outlet iron pipe and is provided with a convex ring. A compressor cylinder is arranged in the compressor shell and is provided with an air inlet. A pump air suction pipe is arranged in the air inlet. The end of the pump air suction pipe is pressed into the air inlet of the compressor cylinder in an interference fit mode. The turned edge of the pump air suction pipe abuts against a first flange and the second flange. The first flange, the turned edge of the pump air suction pipe and the second flange can be combined through one time of welding. Meanwhile, the second flange is arranged as a welding clamping point, thus welding of the first flange and the second flange is convenient, the second flange is provided with the convex ring, electric currents can be focused conveniently during electric resistance welding, andwelding quality is improved.

Owner:SHENGZHOU XINGAOLUN REFRIGERATION EQUIP

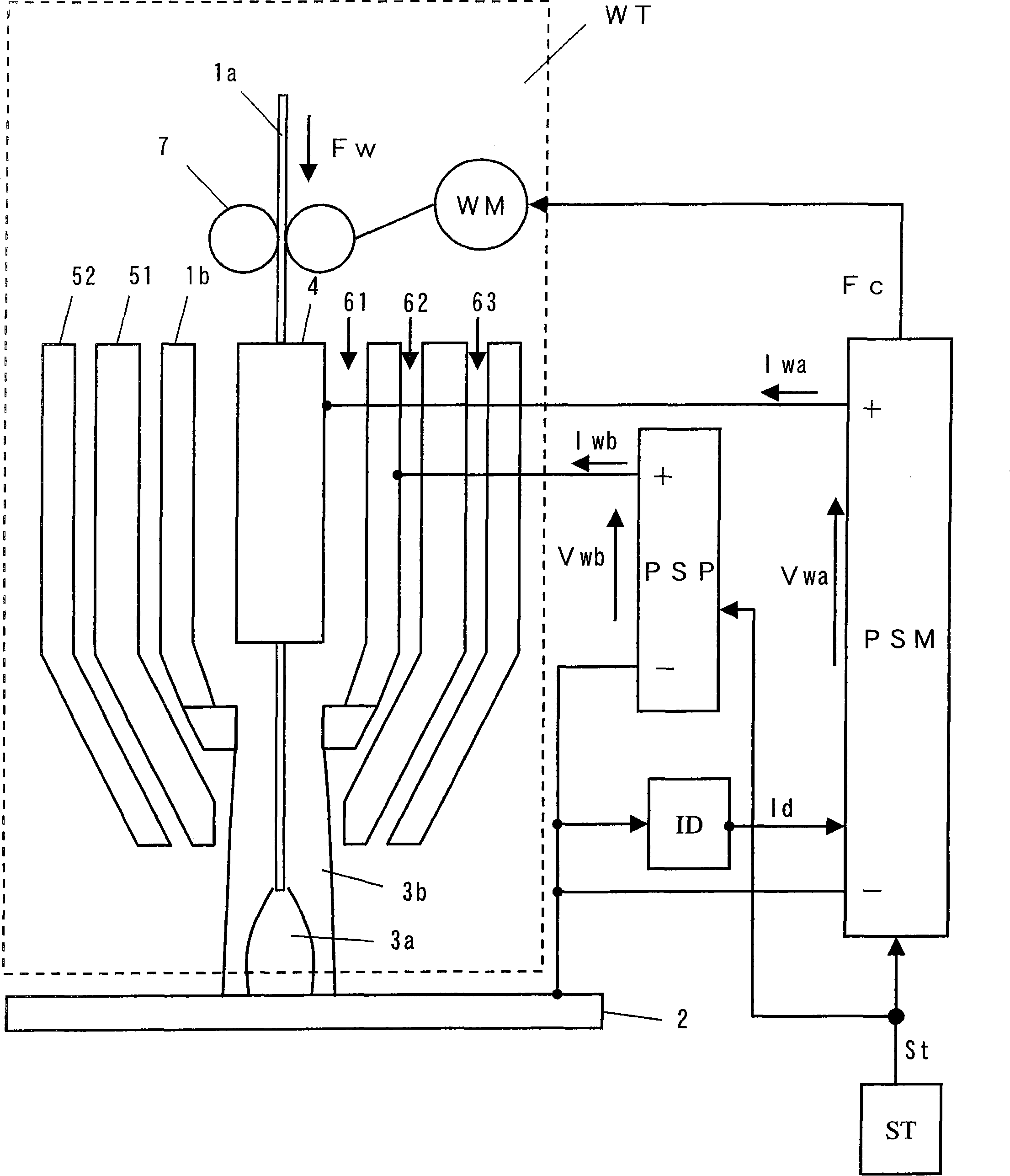

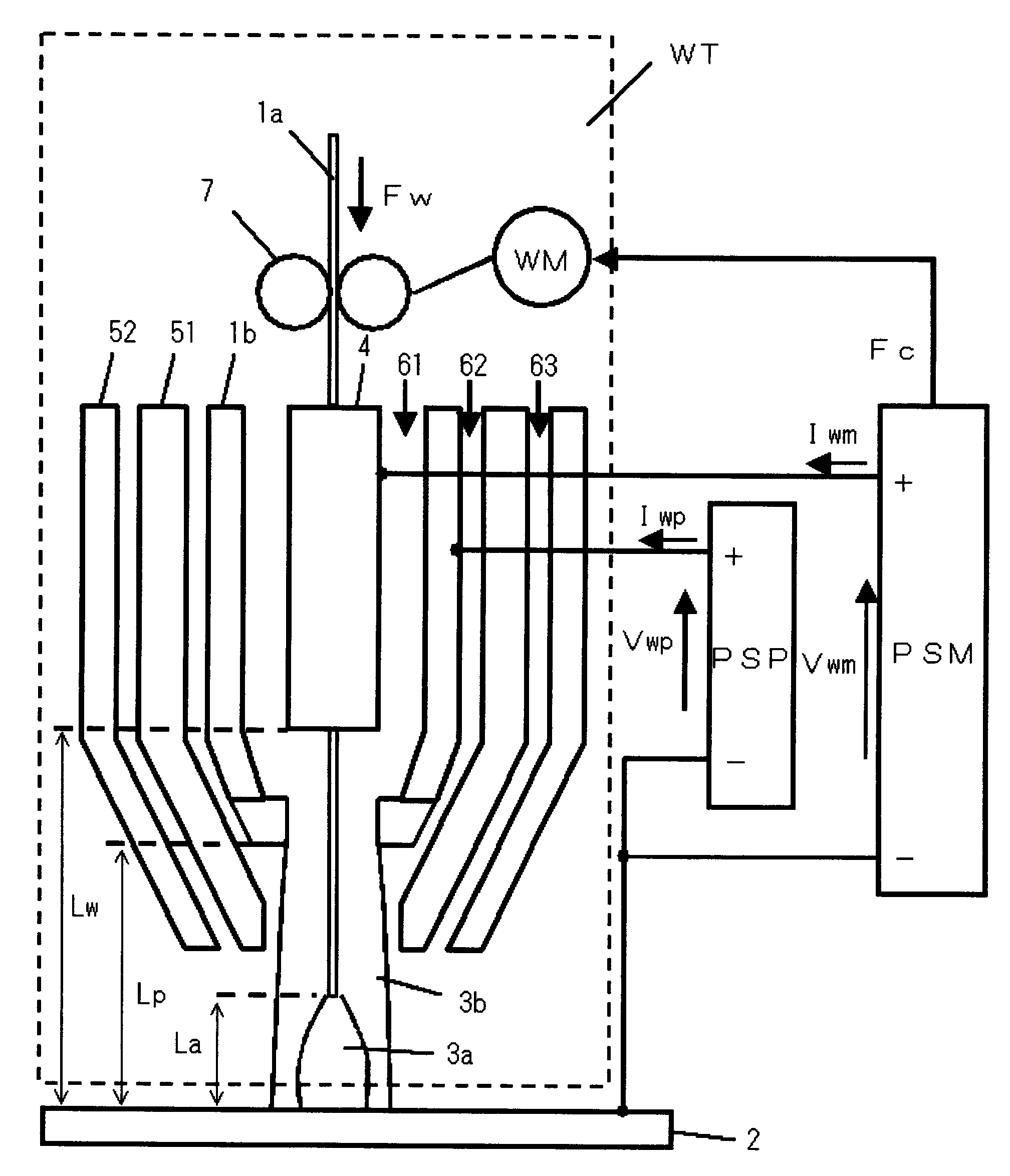

Arc striking control method for double-electrode electric arc welding

PROBLEM TO BE SOLVED: To optimize penetration and a bead shape of an arc start part in two-electrode arc welding. SOLUTION: In a method for controlling arc start for two-electrode arc welding performing arc welding using a welding torch WT equipped with a consumable electrode 1a and a non-consumable electrode 1b, a consumable electrode arc 3a is generated between the consumable electrode 1a and a base material 2. Then, the consumable electrode 1a is fed at a normal feeding speed, a non-consumable electrode arc 3b is generated between the non-consumable electrode 1b and the base material 2. Thereafter, during a preheating period, a preheating current having a larger value than a normal current value is made to flow to the non-consumable electrode arc 3b, a feeding speed is switched to a preheating feeding speed that is faster than the normal feeding speed in accordance with the preheating current value. Upon completion of the preheating period, the feeding speed is switched to the normal feeding speed and, simultaneously, the current value for energizing the non-consumable electrode arc 3b is switched to the normal current value and made to shift to the normal welding state.

Owner:DAIHEN CORP

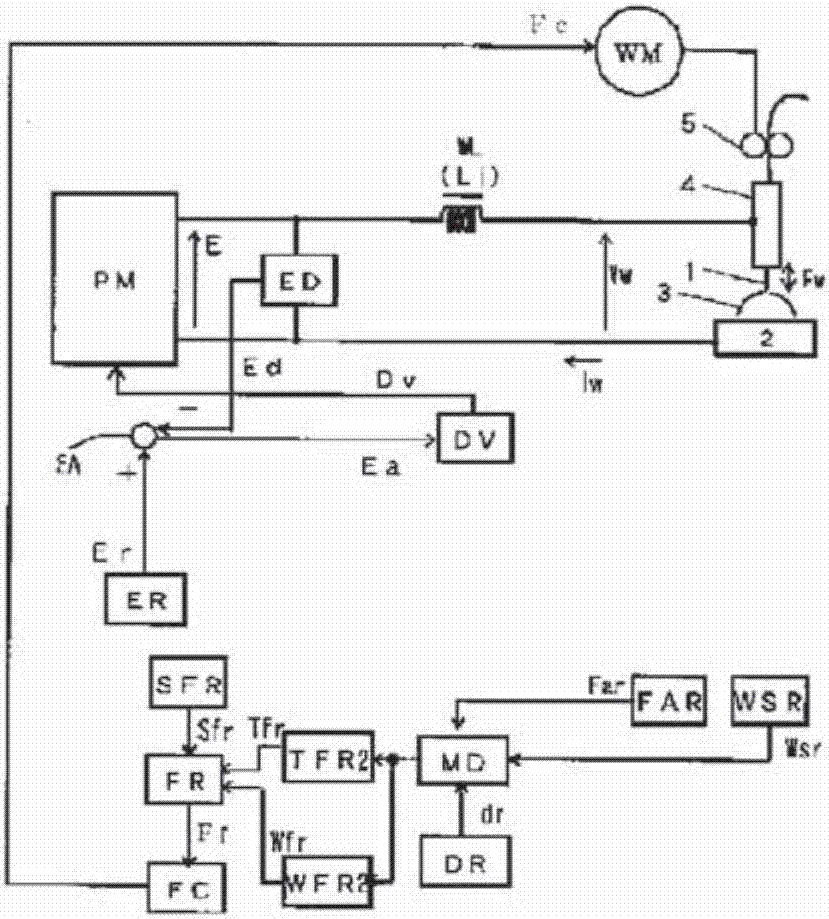

Arc welding control method

The stability of the arc welding in which forward feeding and reverse feeding of the welding wire (1) are periodically repeated is improved. Welding is performed by repeating the forward feed and reverse feed of the feed speed (Fw) of the welding wire (1) at a given cycle (Tf) and given amplitude (Wf) to generate a short circuit period and an arc period In the arc welding control method, the period (Tf) of the feed speed (Fw) is automatically set based on the average feed speed (Far) and the welding speed (Wsr), or the welding wire deposition amount (Md) per unit welding length and / or amplitude (Wf). Furthermore, when the amplitude (Wf) changes, feedback control is performed on the forward feed side shift amount (Sf) so that the average value of the feed speed (Fw) becomes constant. Thereby, since the period (Tf) and amplitude (Wf) of a feed rate (Fw) are always set to an appropriate value, a stable welding state can be maintained.

Owner:DAIHEN CORP

Necking detection and control method of melting electrode and electric arc welding

ActiveCN102233470BHigh sensitivityEnhanced inhibitory effectArc welding apparatusLower limitEngineering

Owner:DAIHEN CORP

Sucking pipe connection structure of rotary compressor

InactiveCN1782437BAdvantages of connection structureSimple connection structureRotary piston pumpsRotary piston liquid enginesWorking fluidClassical mechanics

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Squeezing detection control method for consumable electrode arc welding

ActiveUS9421631B2Increase currentWelding state is stableArc welding apparatusElectrical resistance and conductanceElectrical current

Owner:DAIHEN CORP

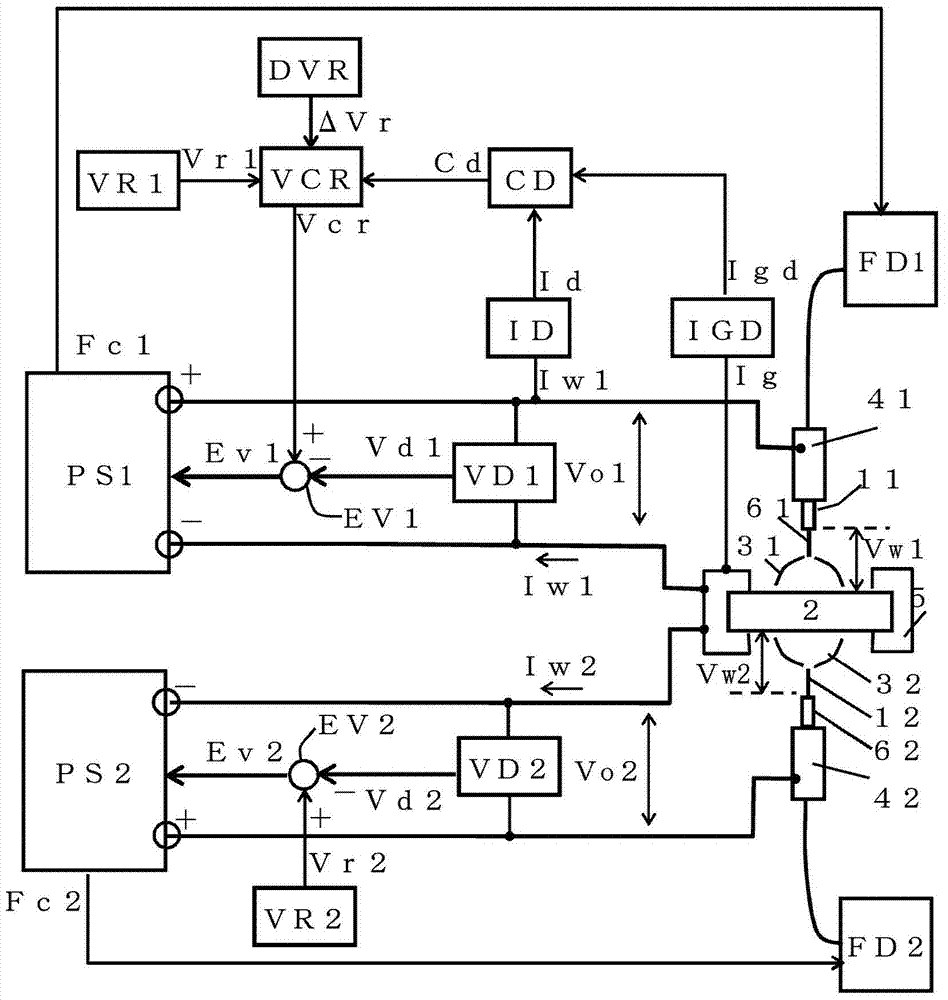

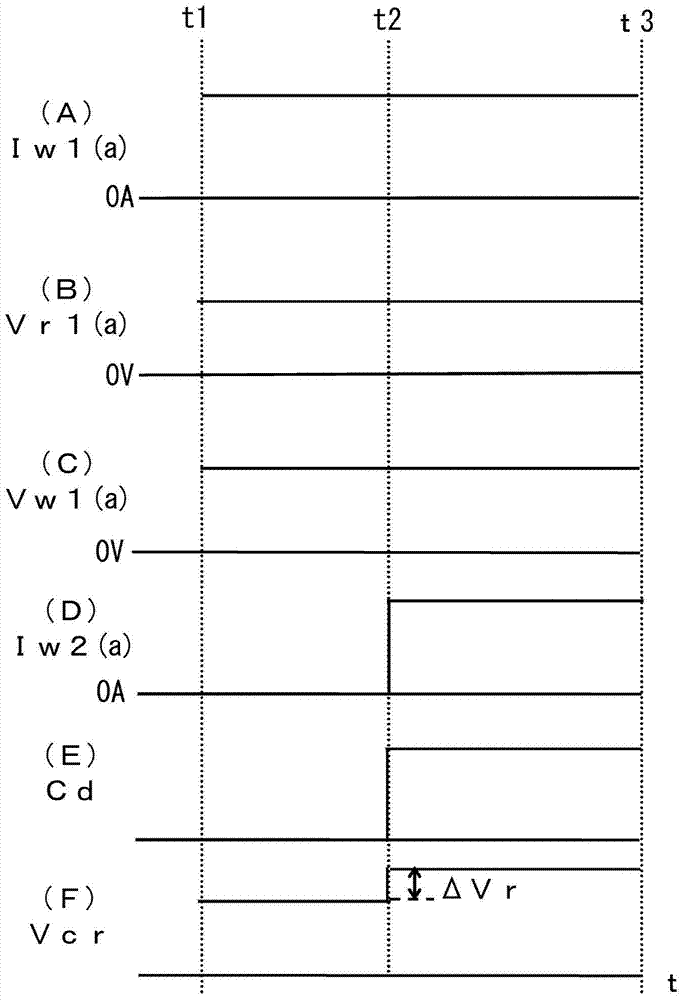

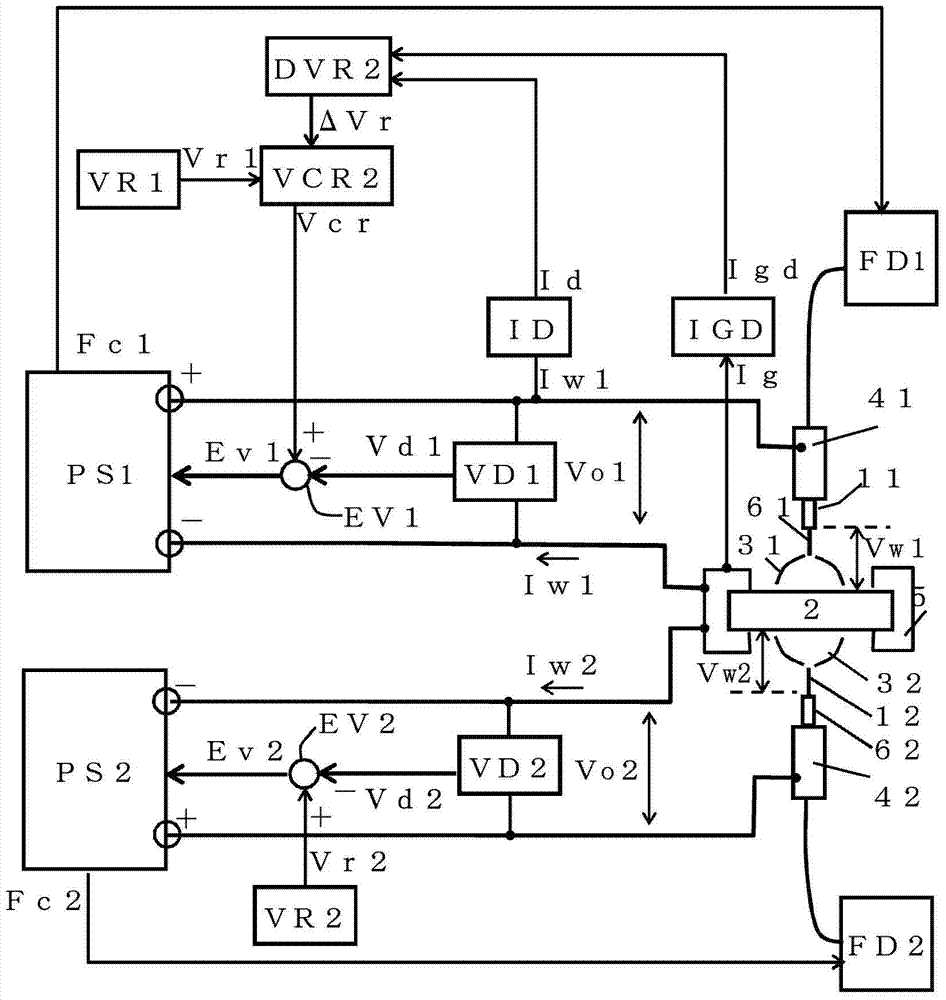

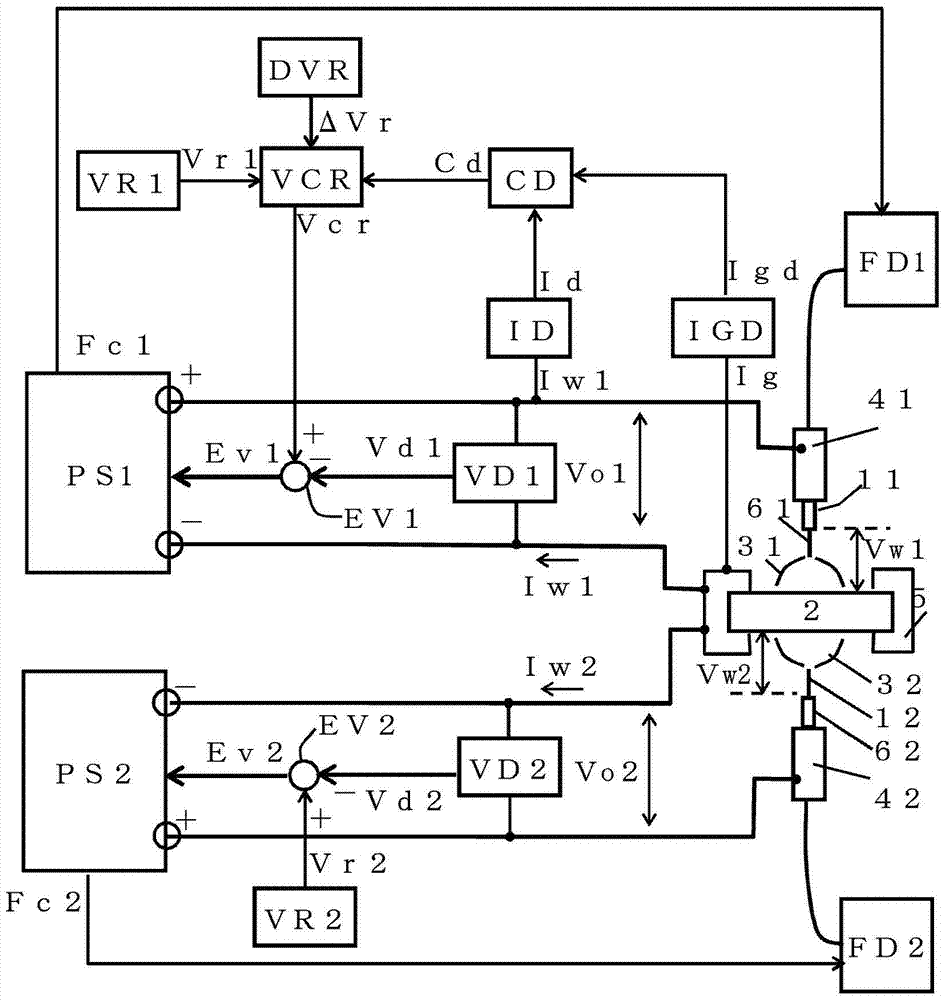

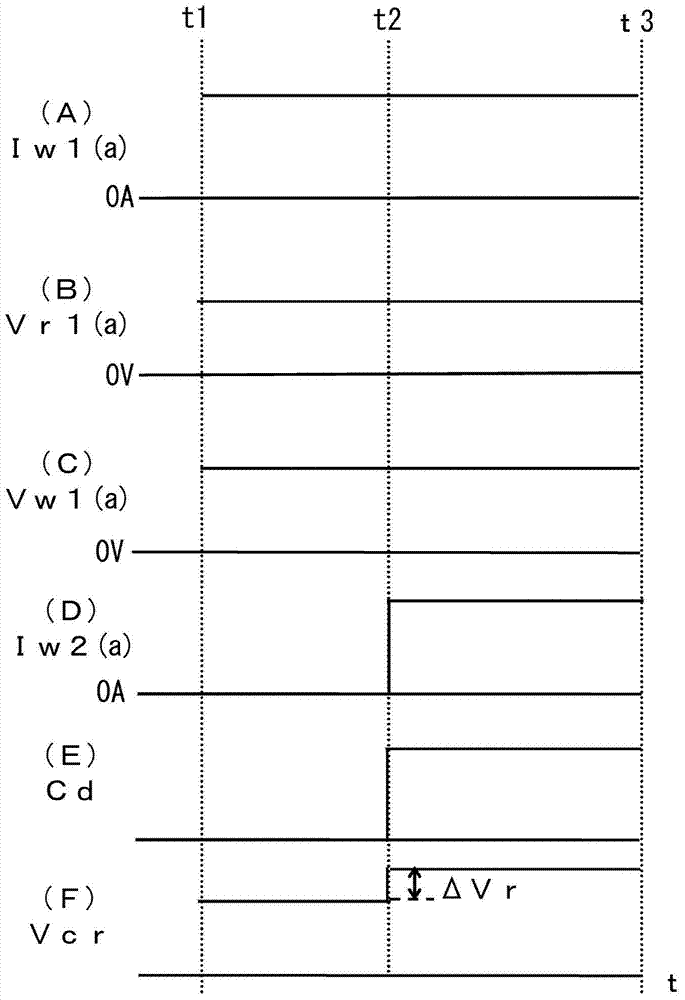

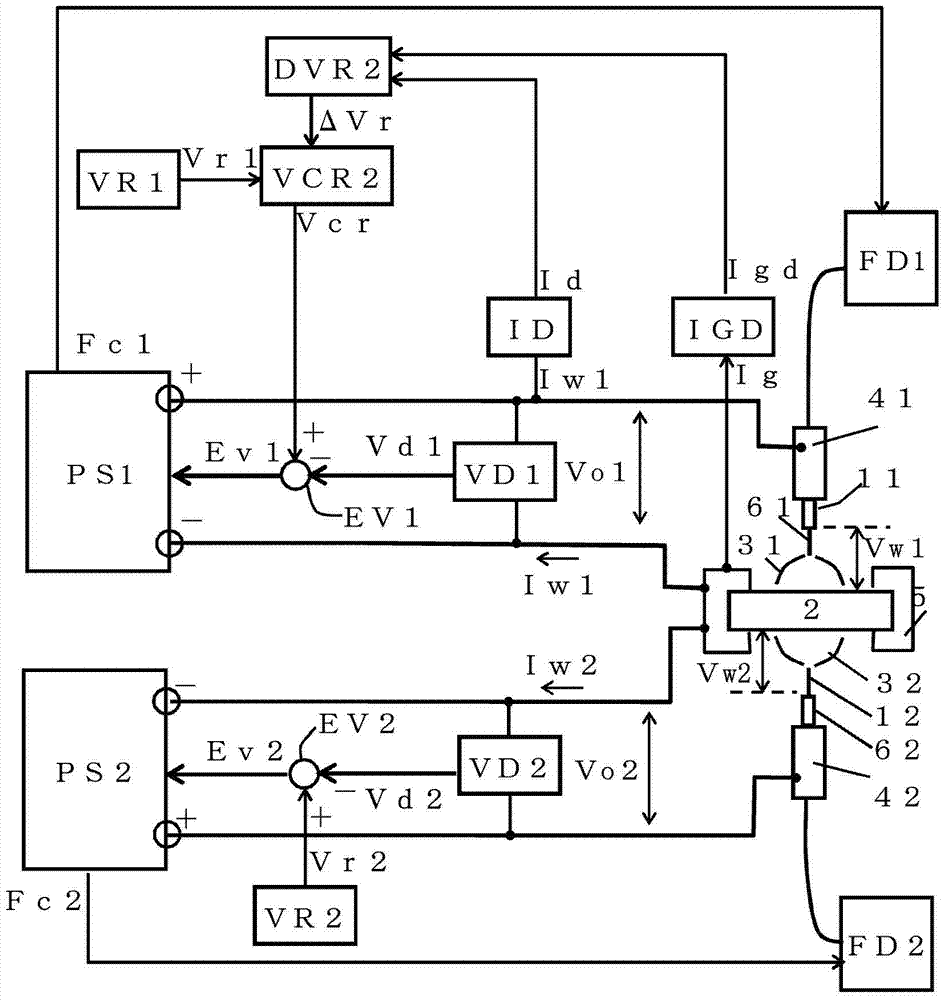

Output control method for welding power source

ActiveCN104275540AWelding state is stableArc welding apparatusElectrical resistance and conductancePower flow

The invention provides an output control method for a welding power source. When a plurality of welding power sources are used at the same time, the welding power sources are prevented from being influenced by the welding currents of other welding power sources. Therefore, the welding voltage is lowered and the welding state is made unstable. The output of a welding power source (PS1) is controlled, so that the voltage detection value is equal to a voltage preset value (Vr1). In voltage detection value (Vd), according to the through power from a welding power source of the total welding current (Ig) a common energizing the electric resistance value (Rg) path and the generated voltage (Vw1)-overlapping with the welding voltage. In a common electrical path, from the other of the energized the welding power supply with the welding current is not energized, the voltage compared to a set value (Vr1) is set to increase the voltage increase (delta Vr) detecting welding power supply is energized from the other of the welding current for a total of to the mean value of the (Igd-Id), a voltage increase the value according to the delta Vr=Rg*(Igd-Id) operation are automatically set. Therefore, it is possible to suppress the reduction of the welding voltage (Vw1).

Owner:DAIHEN CORP

Output control method of welding power supply

ActiveCN104275540BWelding state is stableArc welding apparatusElectrical resistance and conductancePower flow

The invention provides an output control method for a welding power source. When a plurality of welding power sources are used at the same time, the welding power sources are prevented from being influenced by the welding currents of other welding power sources. Therefore, the welding voltage is lowered and the welding state is made unstable. The output of a welding power source (PS1) is controlled, so that the voltage detection value is equal to a voltage preset value (Vr1). In voltage detection value (Vd), according to the through power from a welding power source of the total welding current (Ig) a common energizing the electric resistance value (Rg) path and the generated voltage (Vw1)-overlapping with the welding voltage. In a common electrical path, from the other of the energized the welding power supply with the welding current is not energized, the voltage compared to a set value (Vr1) is set to increase the voltage increase (delta Vr) detecting welding power supply is energized from the other of the welding current for a total of to the mean value of the (Igd-Id), a voltage increase the value according to the delta Vr=Rg*(Igd-Id) operation are automatically set. Therefore, it is possible to suppress the reduction of the welding voltage (Vw1).

Owner:DAIHEN CORP

Consumable electrode arc welding control method

ActiveCN103286419BSuppress changesWelding state is stableArc welding apparatusPower flowFeedback control

The invention provides a control method for consumable electrode arc welding. If constriction of molten droplet is detected, a welding current powered to a short circuit load is reduced so as to generate a constriction detection and control of the arc again. A feedback control (feed speed variable control) for the feed speed (Fw) is carried out according to a manner of a welding current smoothed value (Iav) equal to a predetermined current set value, so as to weld. The control method comprises an action mode for acting the constriction detection control and a forbidden mode for forbidding the constriction detection control. A transition response time (T1) of the feedback control in the action mode is longer than that in the forbidden mode. Therefore, the feed speed (Fw) changes slowly in relative to the change of a distance between a power chip and a base material, thereby keeping the welding state stably. The method can inhibit that the welding state becomes unstable when the constriction detection control acts together with the feed speed variable control at a constant welding current.

Owner:DAIHEN CORP

A double-station automatic tooth palm welding and process grinding equipment and welding method

ActiveCN110549050BImprove protectionDegree of automationEdge grinding machinesGrinding carriagesButt weldingIndustrial engineering

Owner:CANGZHOU GREAT DRILL

Forward and reverse feed AC arc welding method

Owner:DAIHEN CORP

Plasma metal inert gas arc welding method

InactiveCN102126077BWelding state is stableAccurate calculationArc welding apparatusPlasma welding apparatusPower flowReference Period

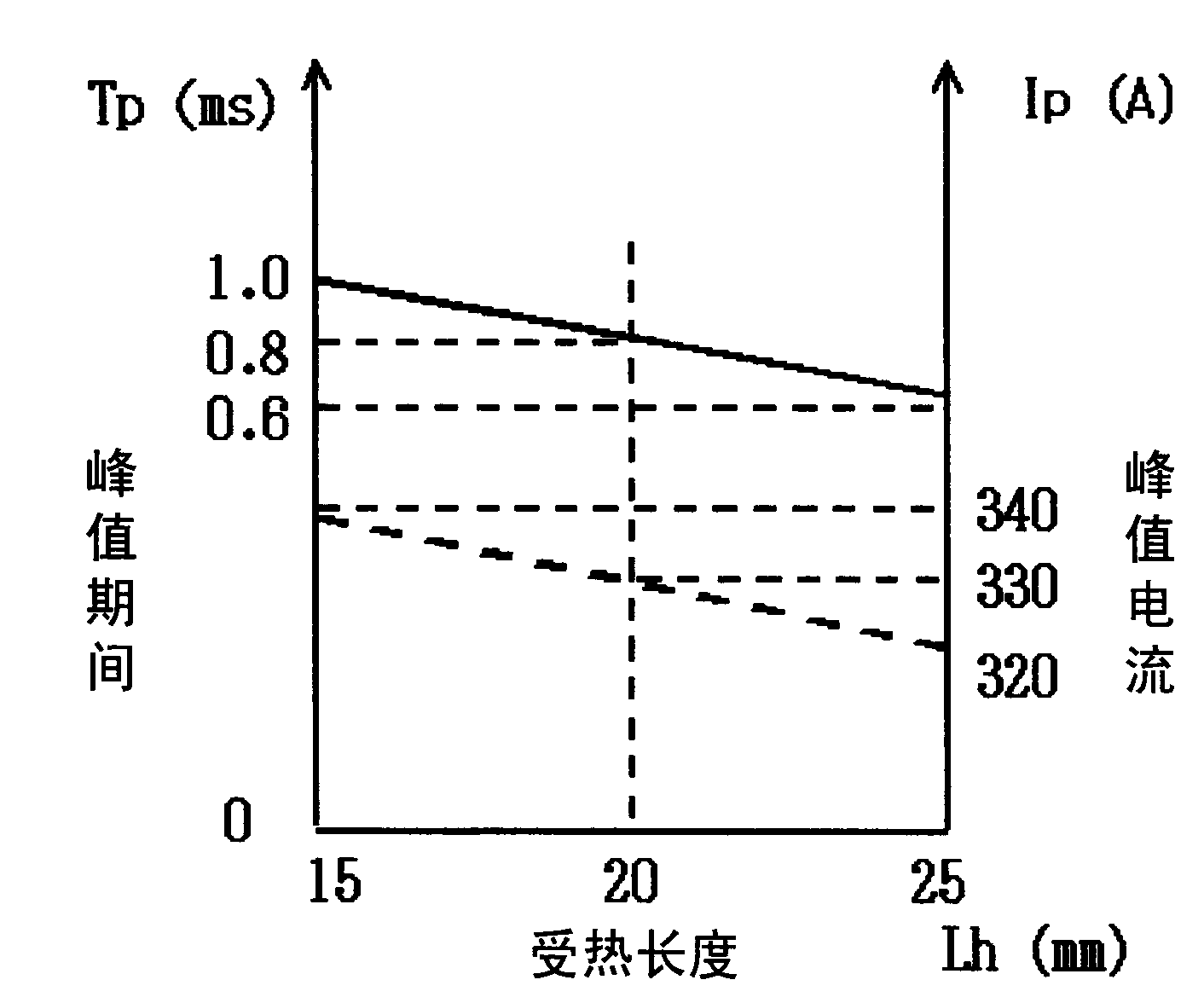

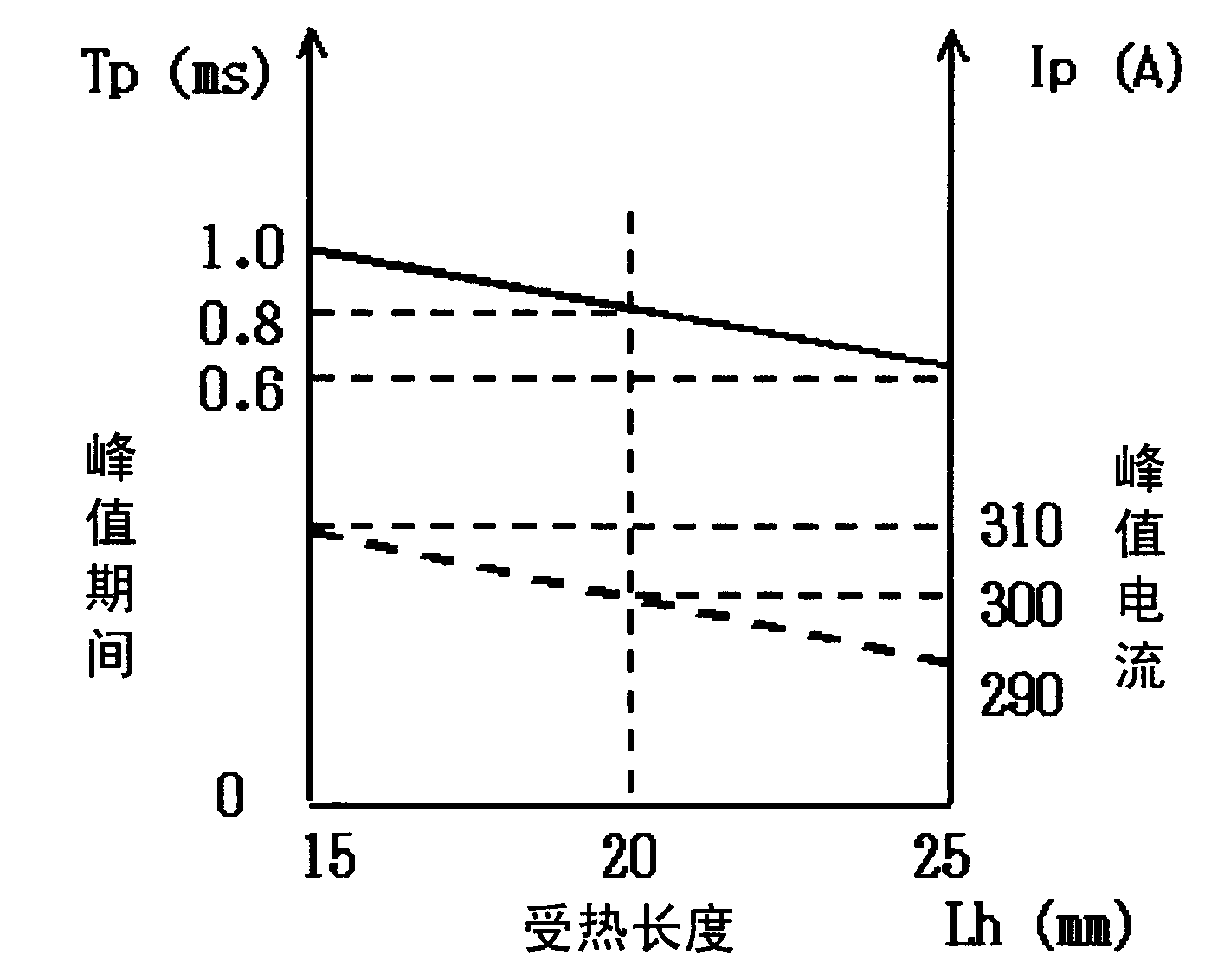

In a plasma metal insert gas arc welding method which causes a metal insert gas arc (3a) and a plasma arc (3b) to generate from a welding torch (WT), even a welding torch height (Lp) changes, a stable fused drop transition state of the metal insert gas arc can be kept. For this purpose, a plasma welding current (Iwp) is applied between a plasma electrode (1b) and a mother plate (2) for generating the plasma arc (3b). Additionally, a peak current in a peak period and a reference current in a reference period are applied between a welding wire (1a) and the mother plate (2). Furthermore, the peak period and / or the peak current is changed according to the heated length of the welding wire (1a), which is heated by the plasma arc (3b). Thus, even the welding torch height (=Lp) is changed, the unit pulse condition can be optimized correspondingly, and the stability of the fused drop transition state can be always kept.

Owner:DAIHEN CORP

Arc welding control method

ActiveCN106457445BWelding state is stableStable to maintain welded stateArc welding apparatusFeedback controlTransition state

The arc welding control method alternately switches the feeding speed (Fw) of the welding wire (1) to the forward feeding period and the reverse feeding period, controls the welding voltage (Vw) based on the voltage setting value, repeats the short circuit period and the arc period to Welding is performed, and in this arc welding control method, the smooth value of the welding voltage (Vw) is detected, and the cycle (Tf) of the feed speed (Fw) is feedback-controlled so that the smooth value of the welding voltage is equal to the voltage setting value Therefore, the period (Tf) of the feed speed (Fw) is adapted corresponding to the change of the droplet transfer state accompanying the change of the voltage setting value, so that the forward feed at the feed speed (Fw) can be suppressed. The period of feed and reverse feed is synchronously deviated from the period of short-circuit period and arc period, and the welding state can be maintained stably.

Owner:DAIHEN CORP

Output control method of welding power supply

Owner:DAIHEN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com